torque SUBARU FORESTER 2004 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 1530 of 2870

ME(H4DOTC)-72

MECHANICAL

Camshaft

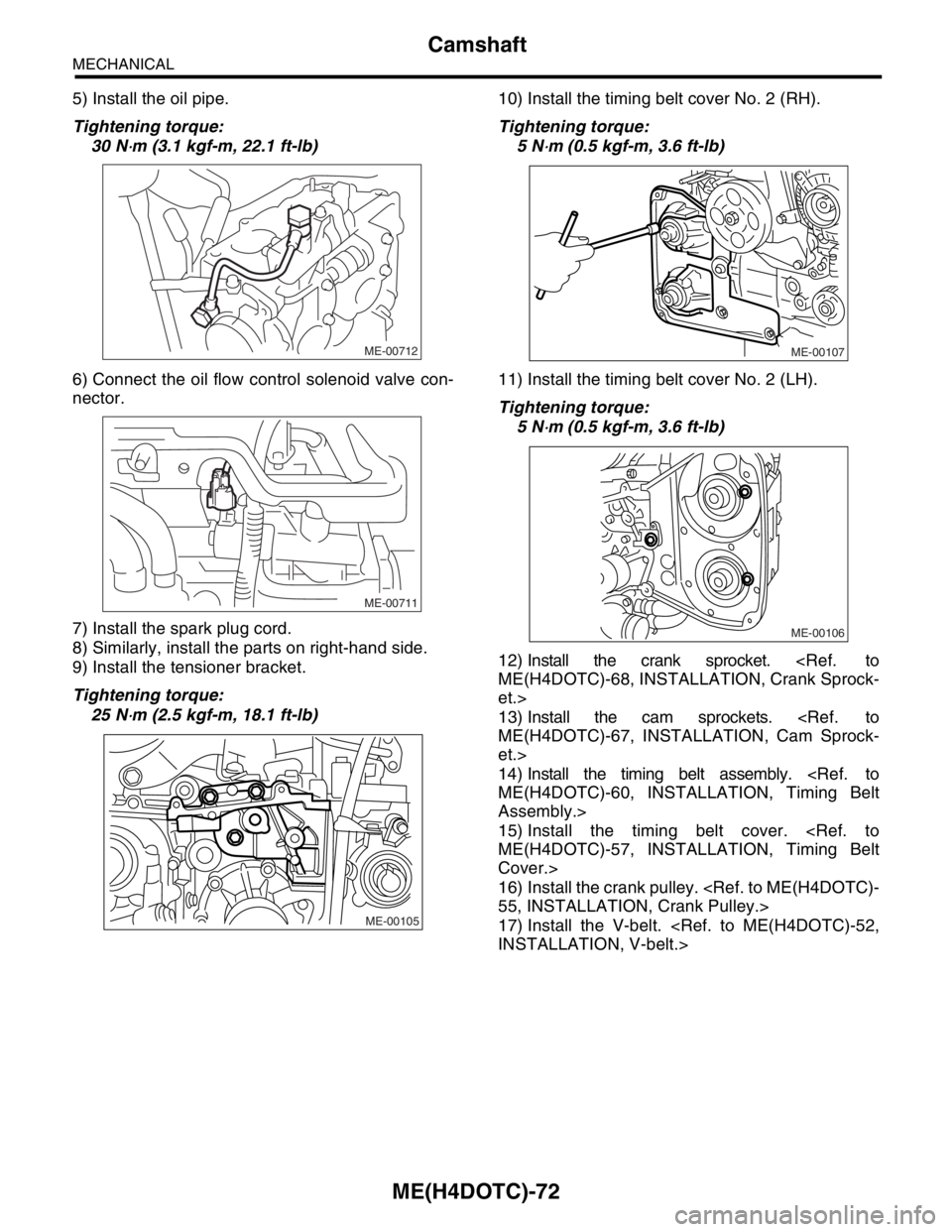

5) Install the oil pipe.

Tightening torque:

30 N

⋅m (3.1 kgf-m, 22.1 ft-lb)

6) Connect the oil flow control solenoid valve con-

nector.

7) Install the spark plug cord.

8) Similarly, install the parts on right-hand side.

9) Install the tensioner bracket.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)10) Install the timing belt cover No. 2 (RH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

11) Install the timing belt cover No. 2 (LH).

Tightening torque:

5 N

⋅m (0.5 kgf-m, 3.6 ft-lb)

12) Install the crank sprocket.

et.>

13) Install the cam sprockets.

et.>

14) Install the timing belt assembly.

Assembly.>

15) Install the timing belt cover.

Cover.>

16) Install the crank pulley.

17) Install the V-belt.

ME-00712

ME-00711

ME-00105

ME-00107

ME-00106

Page 1531 of 2870

ME(H4DOTC)-73

MECHANICAL

Camshaft

C: INSPECTION

1) Measure the bend, and repair or replace if nec-

essary.

Limit:

0.020 mm (0.0008 in)

2) Check the journal for damage and wear. Re-

place if faulty.

3) Measure the outside diameter of camshaft jour-

nal. If the journal diameter is not as specified,

check the oil clearance.

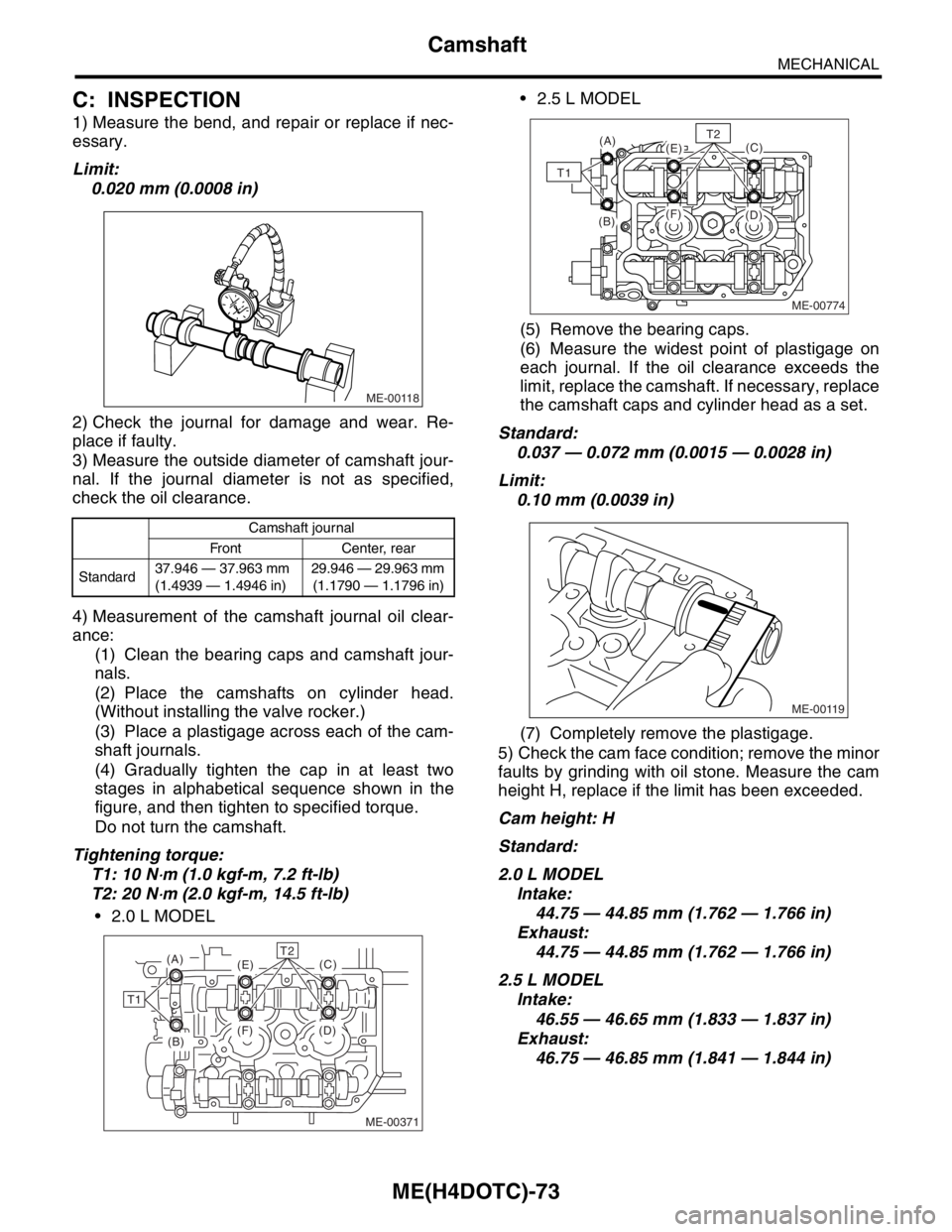

4) Measurement of the camshaft journal oil clear-

ance:

(1) Clean the bearing caps and camshaft jour-

nals.

(2) Place the camshafts on cylinder head.

(Without installing the valve rocker.)

(3) Place a plastigage across each of the cam-

shaft journals.

(4) Gradually tighten the cap in at least two

stages in alphabetical sequence shown in the

figure, and then tighten to specified torque.

Do not turn the camshaft.

Tightening torque:

T1: 10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

T2: 20 N

⋅m (2.0 kgf-m, 14.5 ft-lb)

2.0 L MODEL 2.5 L MODEL

(5) Remove the bearing caps.

(6) Measure the widest point of plastigage on

each journal. If the oil clearance exceeds the

limit, replace the camshaft. If necessary, replace

the camshaft caps and cylinder head as a set.

Standard:

0.037 — 0.072 mm (0.0015 — 0.0028 in)

Limit:

0.10 mm (0.0039 in)

(7) Completely remove the plastigage.

5) Check the cam face condition; remove the minor

faults by grinding with oil stone. Measure the cam

height H, replace if the limit has been exceeded.

Cam height: H

Standard:

2.0 L MODEL

Intake:

44.75 — 44.85 mm (1.762 — 1.766 in)

Exhaust:

44.75 — 44.85 mm (1.762 — 1.766 in)

2.5 L MODEL

Intake:

46.55 — 46.65 mm (1.833 — 1.837 in)

Exhaust:

46.75 — 46.85 mm (1.841 — 1.844 in)

Camshaft journal

Front Center, rear

Standard37.946 — 37.963 mm

(1.4939 — 1.4946 in)29.946 — 29.963 mm

(1.1790 — 1.1796 in)

ME-00118

ME-00371

(F) (D)(C)

T1

T2(A)(E)

(B)

ME-00774

(A)(E)

(F)(B)(D)

(C)T2

T1

ME-00119

Page 1536 of 2870

ME(H4DOTC)-78

MECHANICAL

Cylinder Head Assembly

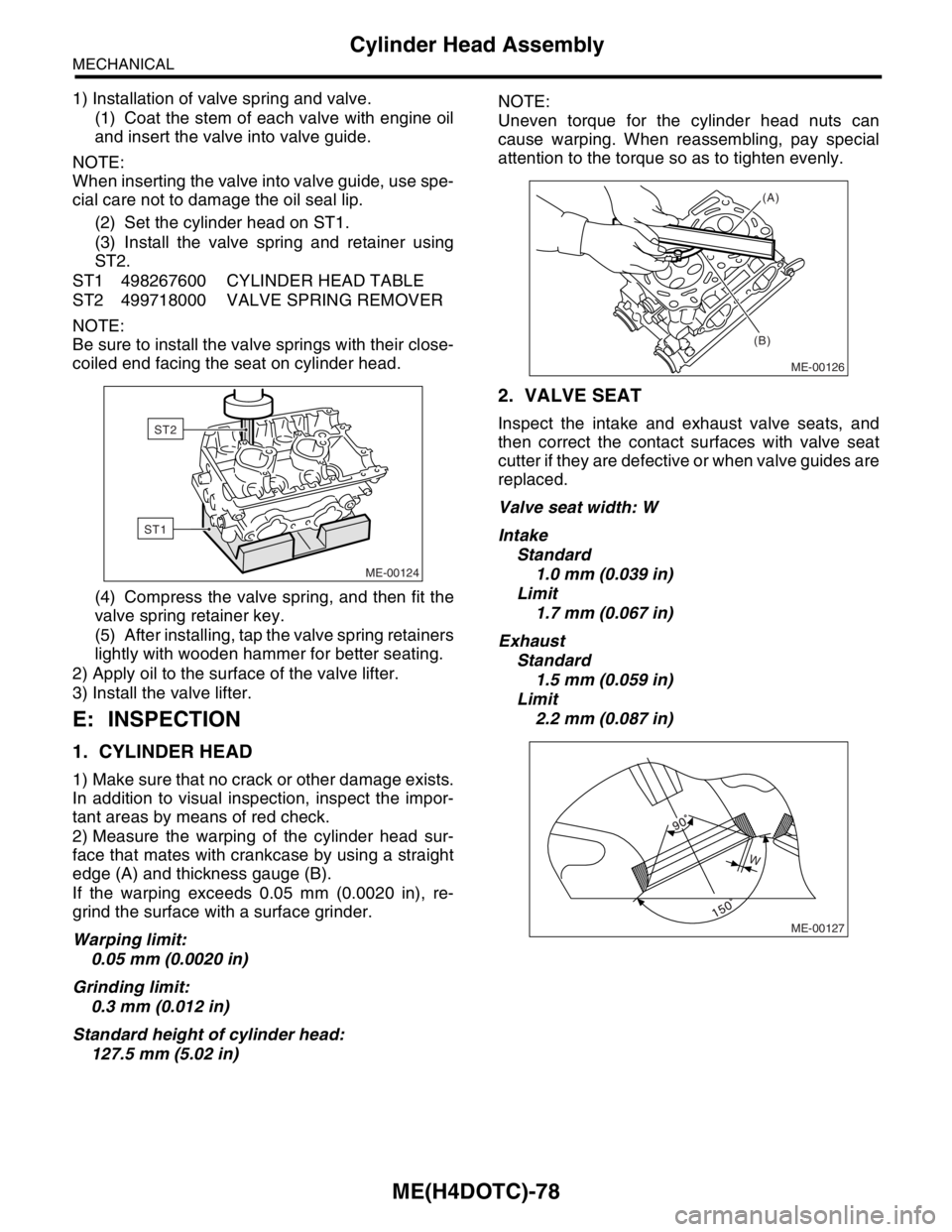

1) Installation of valve spring and valve.

(1) Coat the stem of each valve with engine oil

and insert the valve into valve guide.

NOTE:

When inserting the valve into valve guide, use spe-

cial care not to damage the oil seal lip.

(2) Set the cylinder head on ST1.

(3) Install the valve spring and retainer using

ST2.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499718000 VALVE SPRING REMOVER

NOTE:

Be sure to install the valve springs with their close-

coiled end facing the seat on cylinder head.

(4) Compress the valve spring, and then fit the

valve spring retainer key.

(5) After installing, tap the valve spring retainers

lightly with wooden hammer for better seating.

2) Apply oil to the surface of the valve lifter.

3) Install the valve lifter.

E: INSPECTION

1. CYLINDER HEAD

1) Make sure that no crack or other damage exists.

In addition to visual inspection, inspect the impor-

tant areas by means of red check.

2) Measure the warping of the cylinder head sur-

face that mates with crankcase by using a straight

edge (A) and thickness gauge (B).

If the warping exceeds 0.05 mm (0.0020 in), re-

grind the surface with a surface grinder.

Warping limit:

0.05 mm (0.0020 in)

Grinding limit:

0.3 mm (0.012 in)

Standard height of cylinder head:

127.5 mm (5.02 in)NOTE:

Uneven torque for the cylinder head nuts can

cause warping. When reassembling, pay special

attention to the torque so as to tighten evenly.

2. VALVE SEAT

Inspect the intake and exhaust valve seats, and

then correct the contact surfaces with valve seat

cutter if they are defective or when valve guides are

replaced.

Valve seat width: W

Intake

Standard

1.0 mm (0.039 in)

Limit

1.7 mm (0.067 in)

Exhaust

Standard

1.5 mm (0.059 in)

Limit

2.2 mm (0.087 in)

ME-00124

ST1

ST2

ME-00126

(A)

(B)

ME-00127

W

Page 1548 of 2870

ME(H4DOTC)-88

MECHANICAL

Cylinder Block

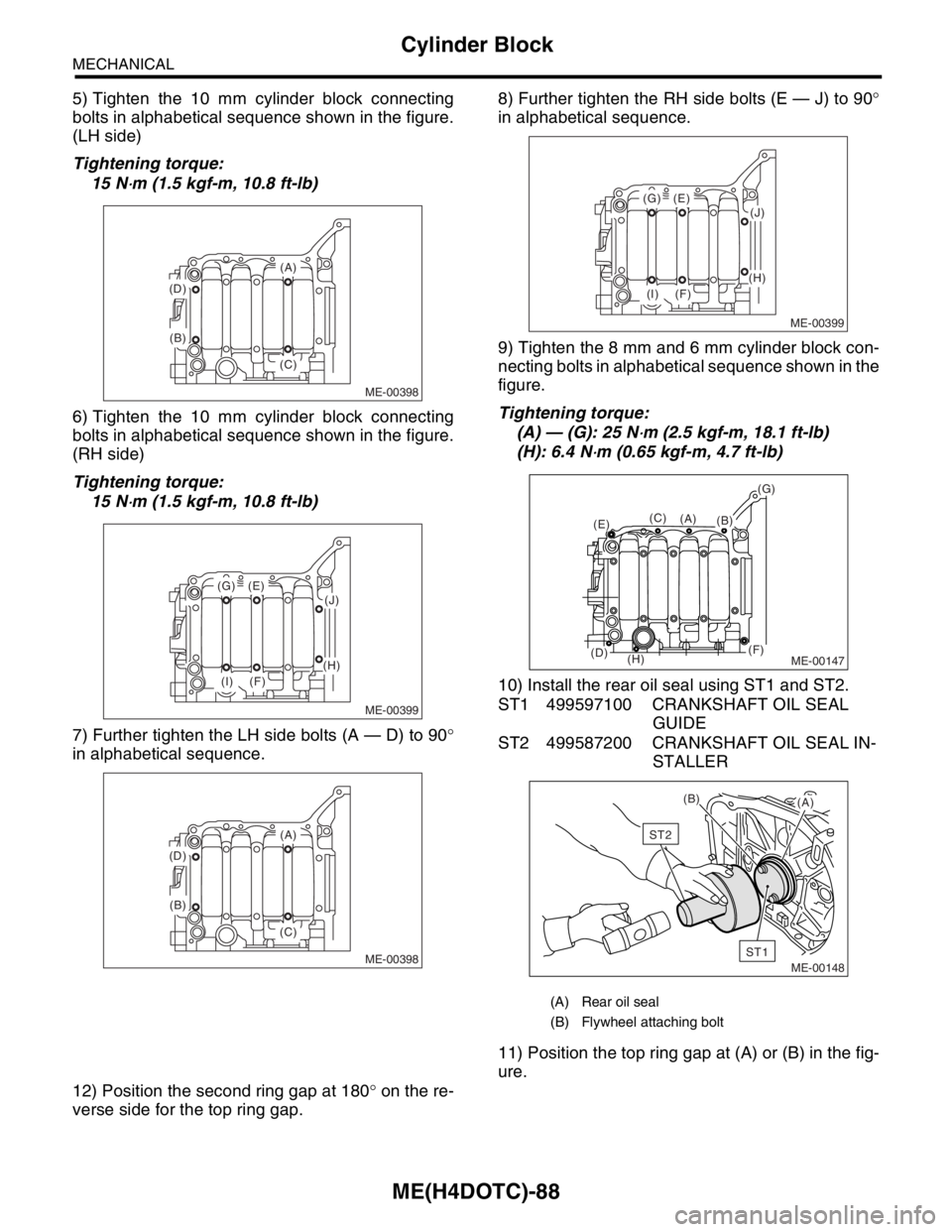

5) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(LH side)

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

6) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(RH side)

Tightening torque:

15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

7) Further tighten the LH side bolts (A — D) to 90°

in alphabetical sequence.8) Further tighten the RH side bolts (E — J) to 90°

in alphabetical sequence.

9) Tighten the 8 mm and 6 mm cylinder block con-

necting bolts in alphabetical sequence shown in the

figure.

Tightening torque:

(A) — (G): 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

10) Install the rear oil seal using ST1 and ST2.

ST1 499597100 CRANKSHAFT OIL SEAL

GUIDE

ST2 499587200 CRANKSHAFT OIL SEAL IN-

STALLER

11) Position the top ring gap at (A) or (B) in the fig-

ure.

12) Position the second ring gap at 180° on the re-

verse side for the top ring gap.

ME-00398

(A)

(B)

(C) (D)

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00398

(A)

(B)

(C) (D)

(A) Rear oil seal

(B) Flywheel attaching bolt

ME-00399

(E)(G)

(F)(I)

(J)

(H)

ME-00147

(B)(C)

(D)

(E)

(F)

(G)

(H)

(A)

ME-00148

ST1

ST2

(B)

(A)

Page 1550 of 2870

ME(H4DOTC)-90

MECHANICAL

Cylinder Block

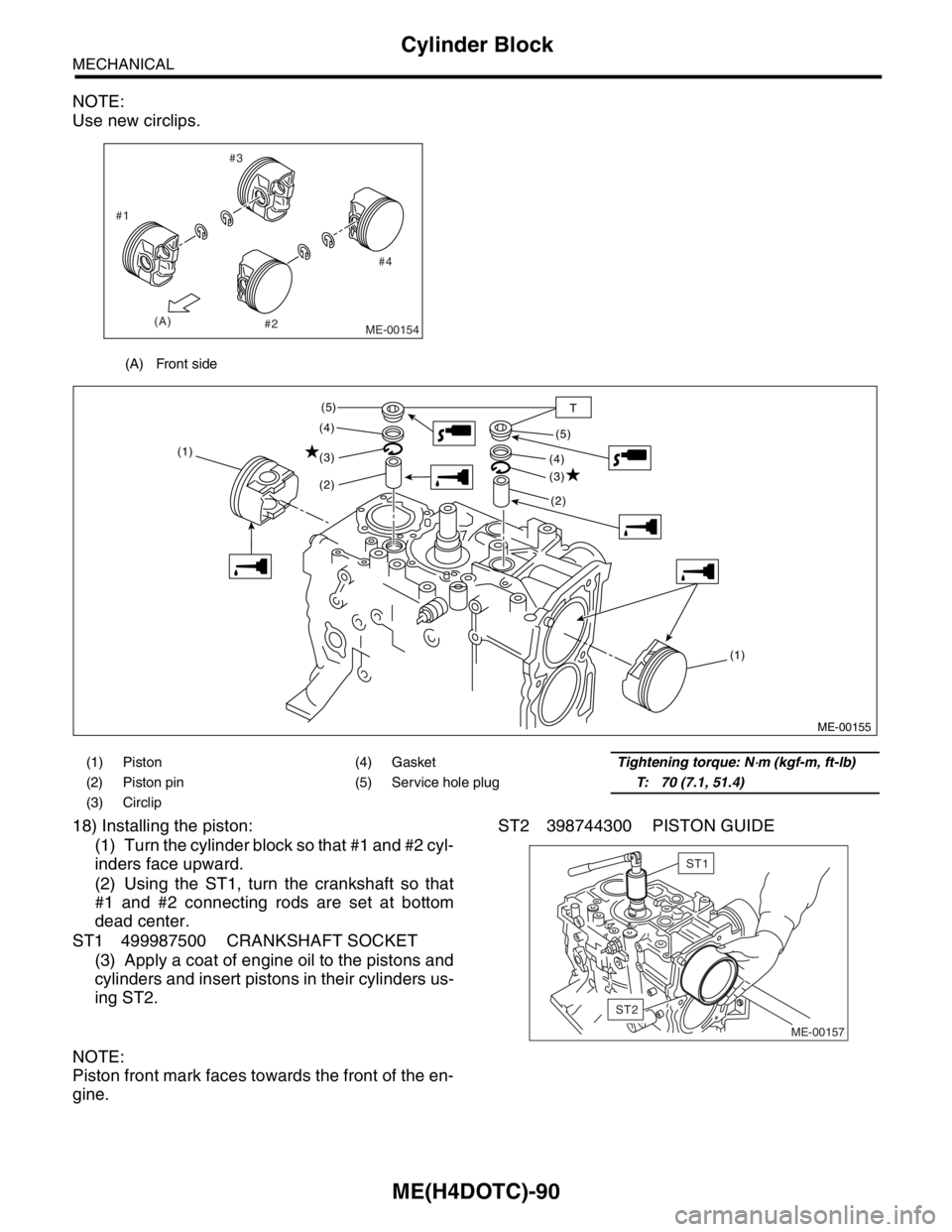

NOTE:

Use new circlips.

18) Installing the piston:

(1) Turn the cylinder block so that #1 and #2 cyl-

inders face upward.

(2) Using the ST1, turn the crankshaft so that

#1 and #2 connecting rods are set at bottom

dead center.

ST1 499987500 CRANKSHAFT SOCKET

(3) Apply a coat of engine oil to the pistons and

cylinders and insert pistons in their cylinders us-

ing ST2.ST2 398744300 PISTON GUIDE

NOTE:

Piston front mark faces towards the front of the en-

gine.

(A) Front side

ME-00154

#4 #3

#2 #1

(A)

(1) Piston (4) GasketTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (5) Service hole plugT: 70 (7.1, 51.4)

(3) Circlip

ME-00155

(1) (1)

(2)

(2) (3)

(3) (4)

(4) (5)

(5)

T

ME-00157

ST2

ST1

Page 1552 of 2870

ME(H4DOTC)-92

MECHANICAL

Cylinder Block

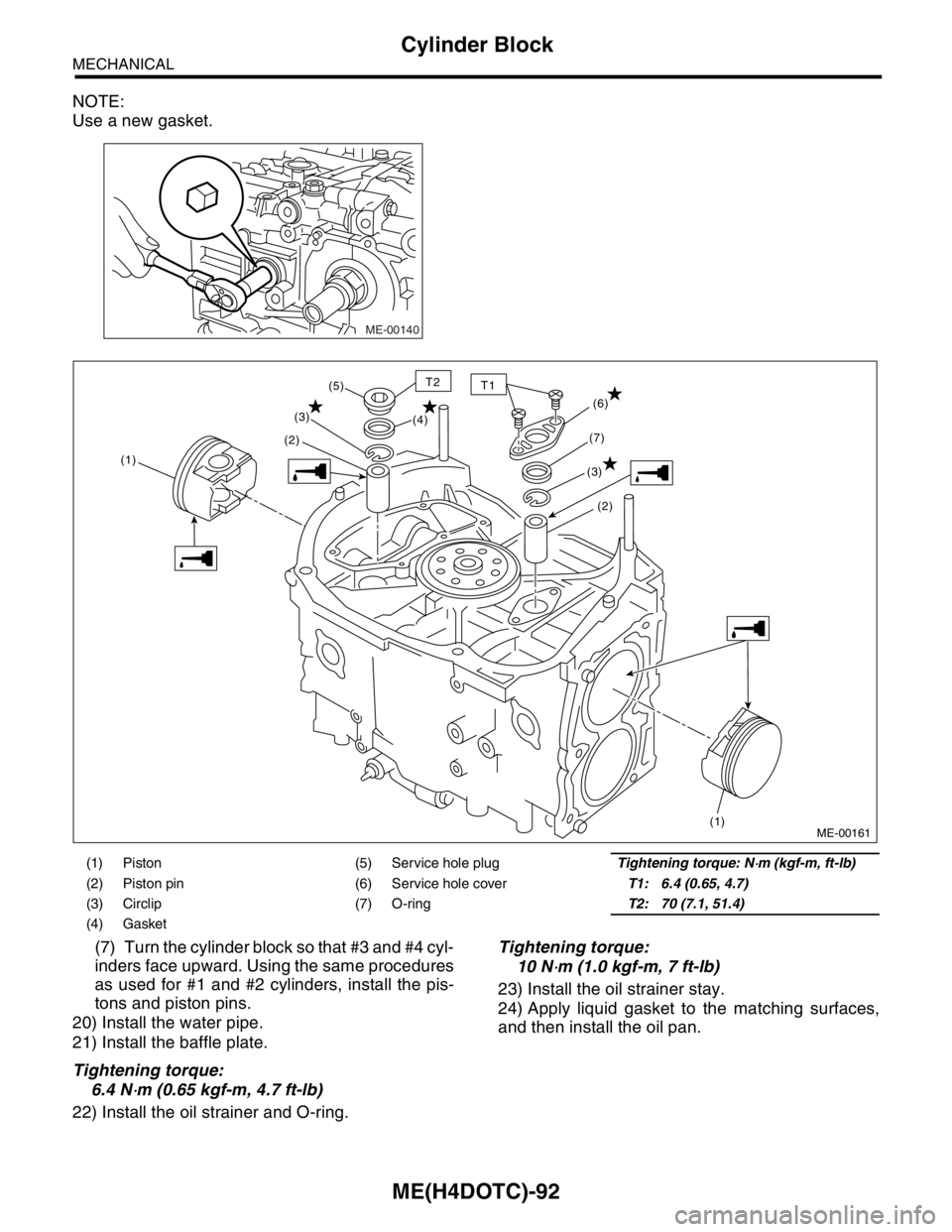

NOTE:

Use a new gasket.

(7) Turn the cylinder block so that #3 and #4 cyl-

inders face upward. Using the same procedures

as used for #1 and #2 cylinders, install the pis-

tons and piston pins.

20) Install the water pipe.

21) Install the baffle plate.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

22) Install the oil strainer and O-ring.Tightening torque:

10 N

⋅m (1.0 kgf-m, 7 ft-lb)

23) Install the oil strainer stay.

24) Apply liquid gasket to the matching surfaces,

and then install the oil pan.

ME-00140

(1) Piston (5) Service hole plugTightening torque: N⋅m (kgf-m, ft-lb)

(2) Piston pin (6) Service hole coverT1: 6.4 (0.65, 4.7)

(3) Circlip (7) O-ringT2: 70 (7.1, 51.4)

(4) Gasket

(1)(2)(3)

(1)

(2) (6)

(3)(7) (4) (5)

ME-00161

T2T1

Page 1553 of 2870

ME(H4DOTC)-93

MECHANICAL

Cylinder Block

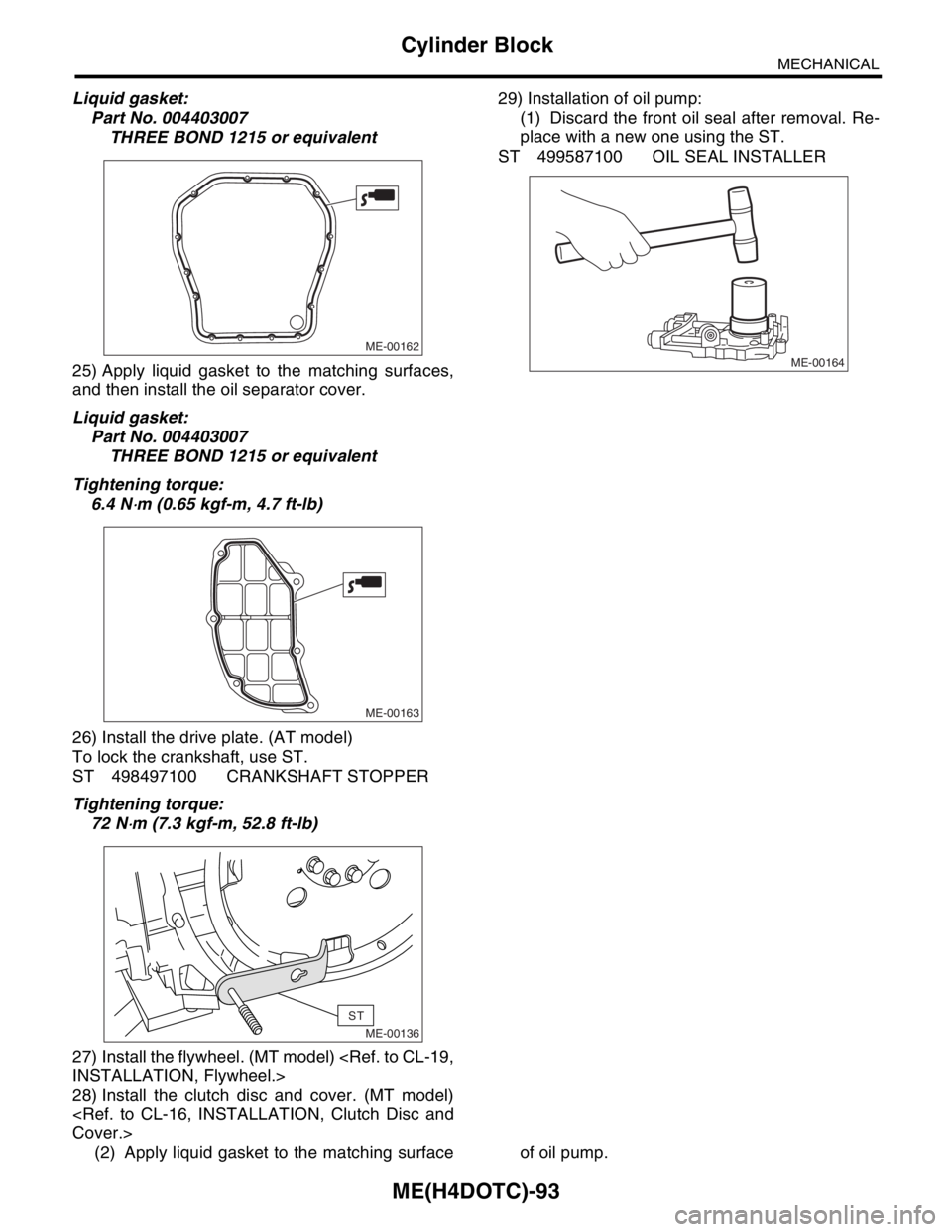

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

25) Apply liquid gasket to the matching surfaces,

and then install the oil separator cover.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

26) Install the drive plate. (AT model)

To lock the crankshaft, use ST.

ST 498497100 CRANKSHAFT STOPPER

Tightening torque:

72 N

⋅m (7.3 kgf-m, 52.8 ft-lb)

27) Install the flywheel. (MT model)

28) Install the clutch disc and cover. (MT model)

(1) Discard the front oil seal after removal. Re-

place with a new one using the ST.

ST 499587100 OIL SEAL INSTALLER

(2) Apply liquid gasket to the matching surface of oil pump.

ME-00162

ME-00163

ME-00136

ST

ME-00164

Page 1554 of 2870

ME(H4DOTC)-94

MECHANICAL

Cylinder Block

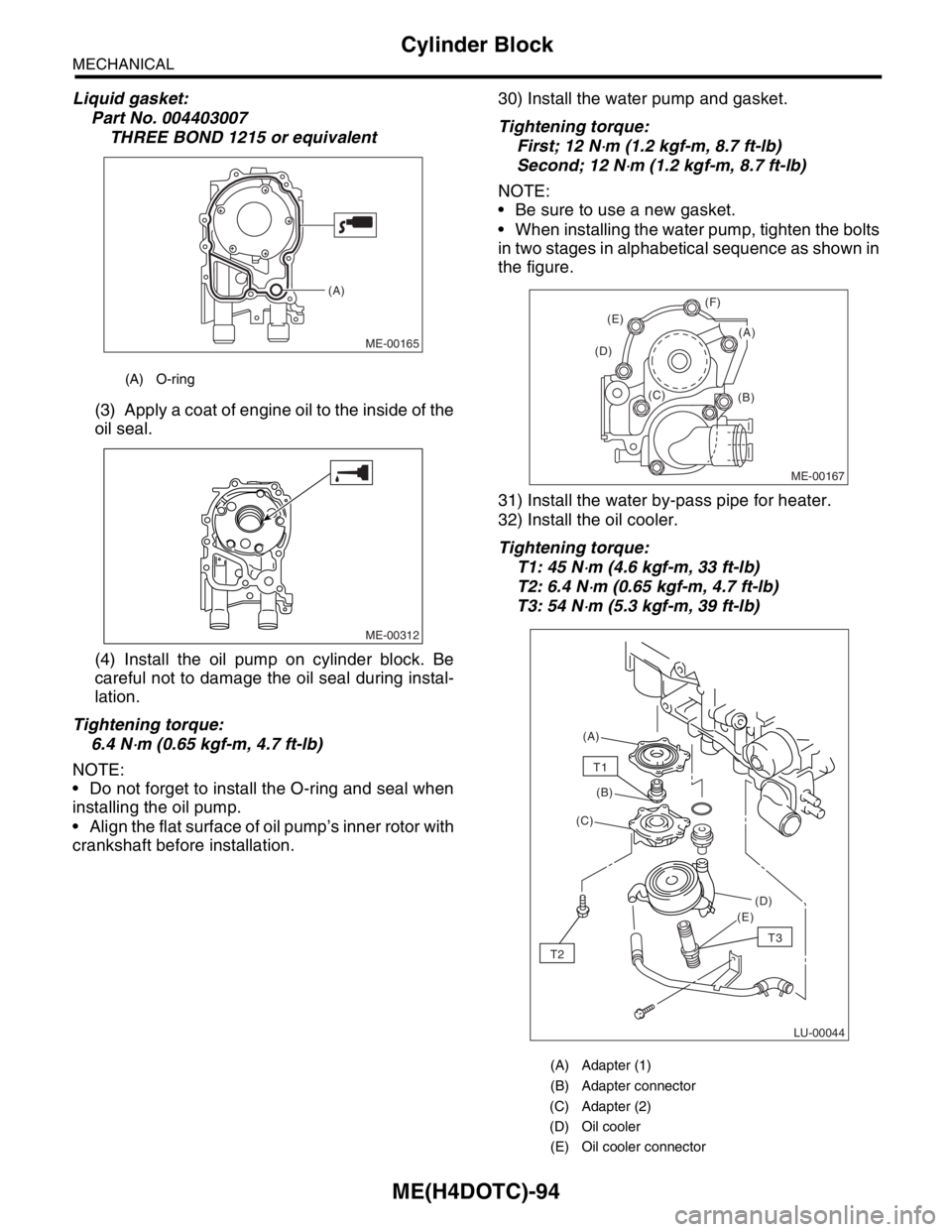

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

(3) Apply a coat of engine oil to the inside of the

oil seal.

(4) Install the oil pump on cylinder block. Be

careful not to damage the oil seal during instal-

lation.

Tightening torque:

6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

Do not forget to install the O-ring and seal when

installing the oil pump.

Align the flat surface of oil pump’s inner rotor with

crankshaft before installation.30) Install the water pump and gasket.

Tightening torque:

First; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

Second; 12 N

⋅m (1.2 kgf-m, 8.7 ft-lb)

NOTE:

Be sure to use a new gasket.

When installing the water pump, tighten the bolts

in two stages in alphabetical sequence as shown in

the figure.

31) Install the water by-pass pipe for heater.

32) Install the oil cooler.

Tightening torque:

T1: 45 N

⋅m (4.6 kgf-m, 33 ft-lb)

T2: 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

T3: 54 N

⋅m (5.3 kgf-m, 39 ft-lb)

(A) O-ring

ME-00165

(A)

ME-00312

(A) Adapter (1)

(B) Adapter connector

(C) Adapter (2)

(D) Oil cooler

(E) Oil cooler connector

ME-00167

(B) (C) (D)(E)(F)

(A)

LU-00044

(A)

(B)

(C)

(D)

(E)

T1

T2

T3

Page 1556 of 2870

ME(H4DOTC)-96

MECHANICAL

Cylinder Block

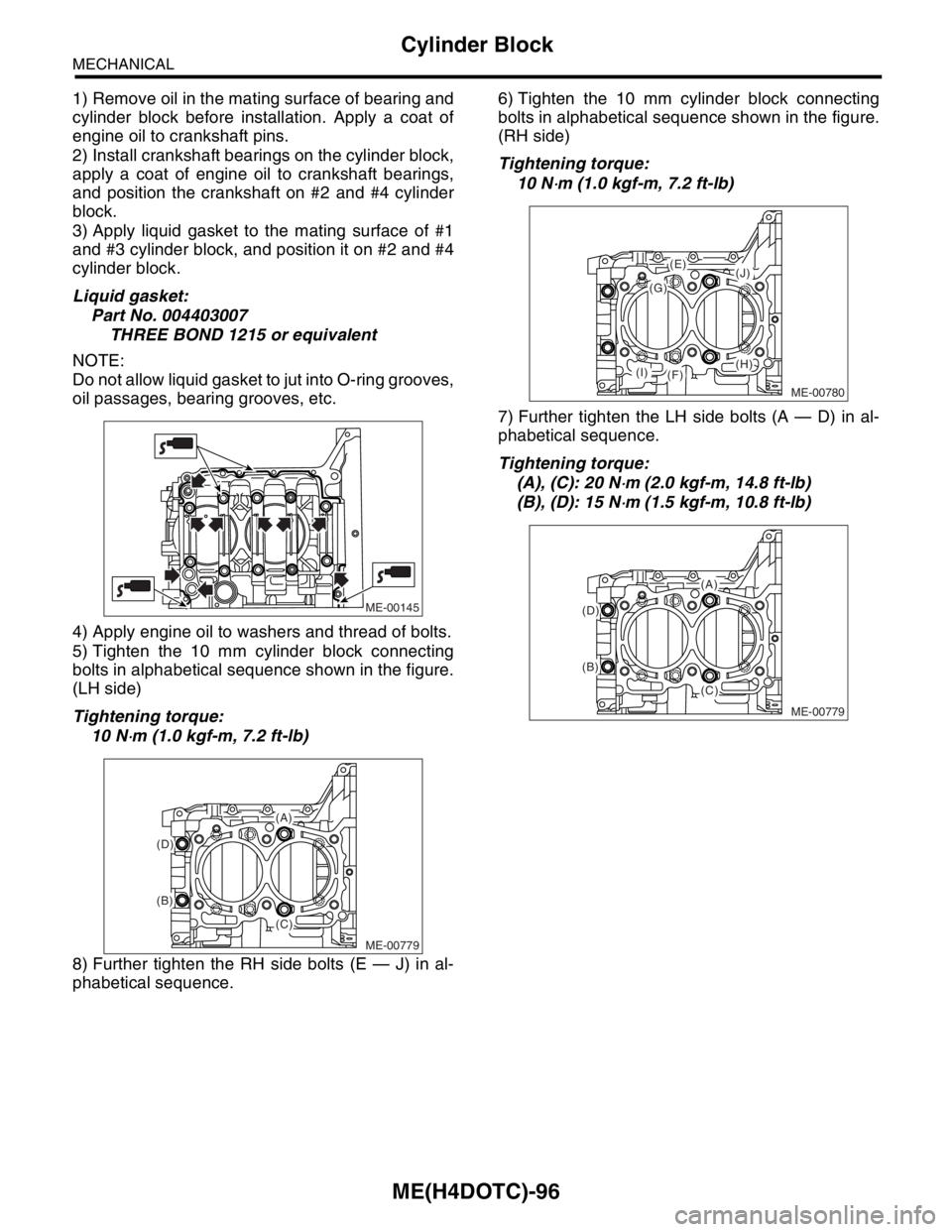

1) Remove oil in the mating surface of bearing and

cylinder block before installation. Apply a coat of

engine oil to crankshaft pins.

2) Install crankshaft bearings on the cylinder block,

apply a coat of engine oil to crankshaft bearings,

and position the crankshaft on #2 and #4 cylinder

block.

3) Apply liquid gasket to the mating surface of #1

and #3 cylinder block, and position it on #2 and #4

cylinder block.

Liquid gasket:

Part No. 004403007

THREE BOND 1215 or equivalent

NOTE:

Do not allow liquid gasket to jut into O-ring grooves,

oil passages, bearing grooves, etc.

4) Apply engine oil to washers and thread of bolts.

5) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(LH side)

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)6) Tighten the 10 mm cylinder block connecting

bolts in alphabetical sequence shown in the figure.

(RH side)

Tightening torque:

10 N

⋅m (1.0 kgf-m, 7.2 ft-lb)

7) Further tighten the LH side bolts (A — D) in al-

phabetical sequence.

Tightening torque:

(A), (C): 20 N

⋅m (2.0 kgf-m, 14.8 ft-lb)

(B), (D): 15 N

⋅m (1.5 kgf-m, 10.8 ft-lb)

8) Further tighten the RH side bolts (E — J) in al-

phabetical sequence.

ME-00145

ME-00779

(A)

(B)

(D)

(C)

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

ME-00779

(A)

(B)

(D)

(C)

Page 1557 of 2870

ME(H4DOTC)-97

MECHANICAL

Cylinder Block

Tightening torque:

(E), (F), (G), (I): 20 N

⋅m (2.0 kgf-m, 14.8 ft-lb)

(H), (J): 18 N

⋅m (1.8 kgf-m, 13.3 ft-lb)

9) Further tighten the LH side bolts (A — D) by 90°

in alphabetical sequence.

10) Further tighten the RH side bolts (E — J) by 90°

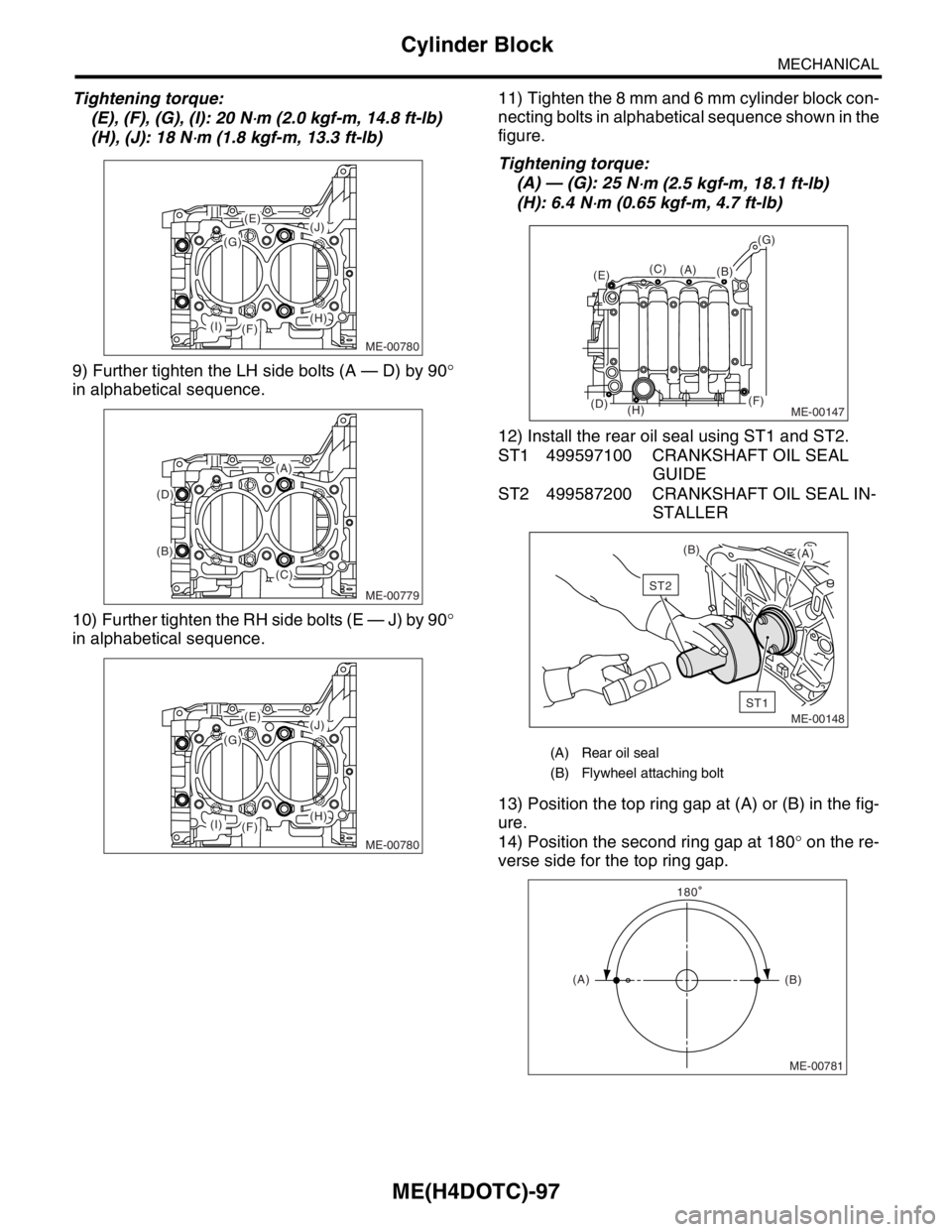

in alphabetical sequence.11) Tighten the 8 mm and 6 mm cylinder block con-

necting bolts in alphabetical sequence shown in the

figure.

Tightening torque:

(A) — (G): 25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

(H): 6.4 N

⋅m (0.65 kgf-m, 4.7 ft-lb)

12) Install the rear oil seal using ST1 and ST2.

ST1 499597100 CRANKSHAFT OIL SEAL

GUIDE

ST2 499587200 CRANKSHAFT OIL SEAL IN-

STALLER

13) Position the top ring gap at (A) or (B) in the fig-

ure.

14) Position the second ring gap at 180° on the re-

verse side for the top ring gap.

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

ME-00779

(A)

(B)

(D)

(C)

ME-00780

(J)

(H)

(G)

(E)

(F)(I)

(A) Rear oil seal

(B) Flywheel attaching bolt

ME-00147

(B)(C)

(D)

(E)

(F)

(G)

(H)

(A)

ME-00148

ST1

ST2

(B)

(A)

ME-00781

(A)(B) 180