check engine SUBARU FORESTER 2004 Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2004, Model line: FORESTER, Model: SUBARU FORESTER 2004Pages: 2870, PDF Size: 38.67 MB

Page 767 of 2870

PM-30

PERIODIC MAINTENANCE SERVICE

Brake Line

18.Brake Line

A: INSPECTION

1. BRAKE LINE

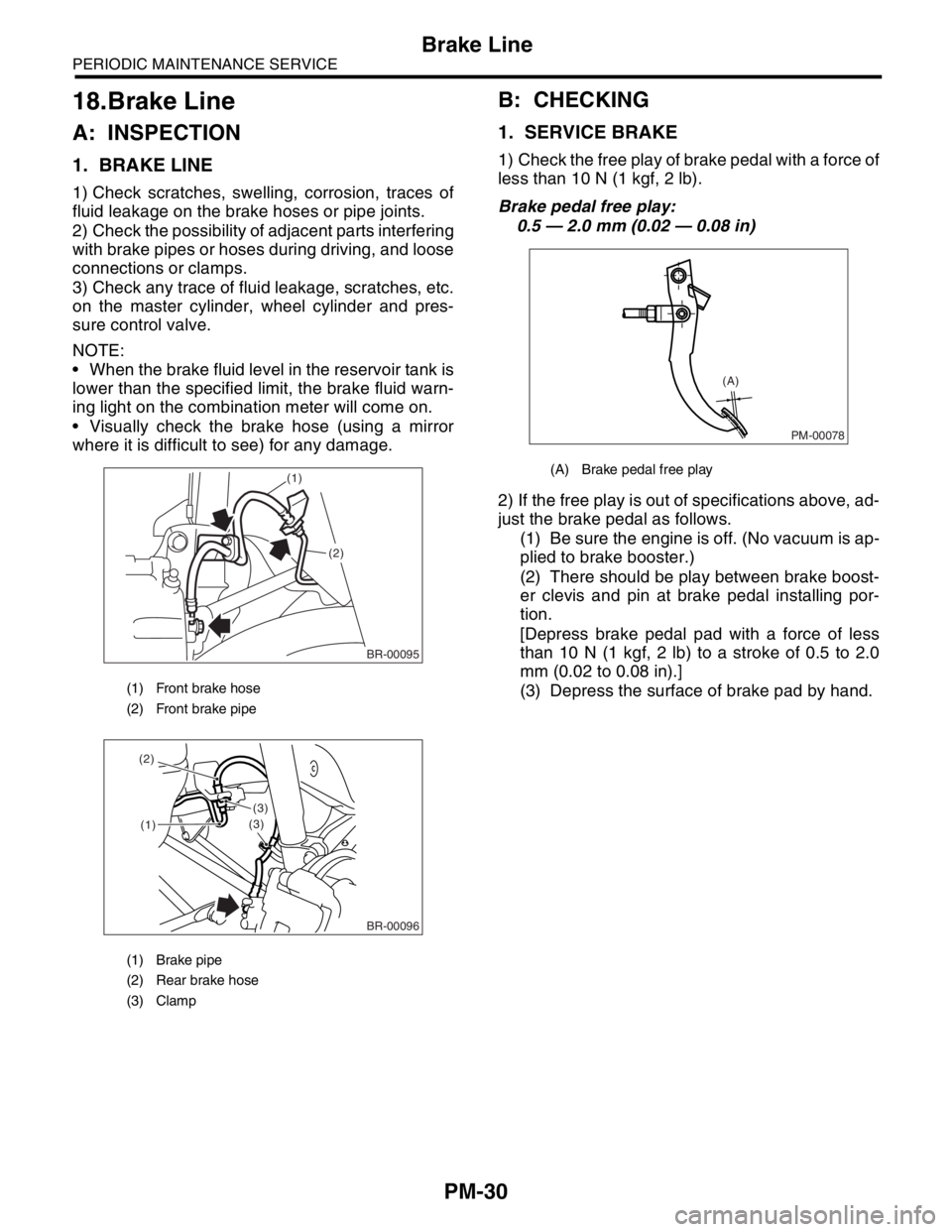

1) Check scratches, swelling, corrosion, traces of

fluid leakage on the brake hoses or pipe joints.

2) Check the possibility of adjacent parts interfering

with brake pipes or hoses during driving, and loose

connections or clamps.

3) Check any trace of fluid leakage, scratches, etc.

on the master cylinder, wheel cylinder and pres-

sure control valve.

NOTE:

When the brake fluid level in the reservoir tank is

lower than the specified limit, the brake fluid warn-

ing light on the combination meter will come on.

Visually check the brake hose (using a mirror

where it is difficult to see) for any damage.

B: CHECKING

1. SERVICE BRAKE

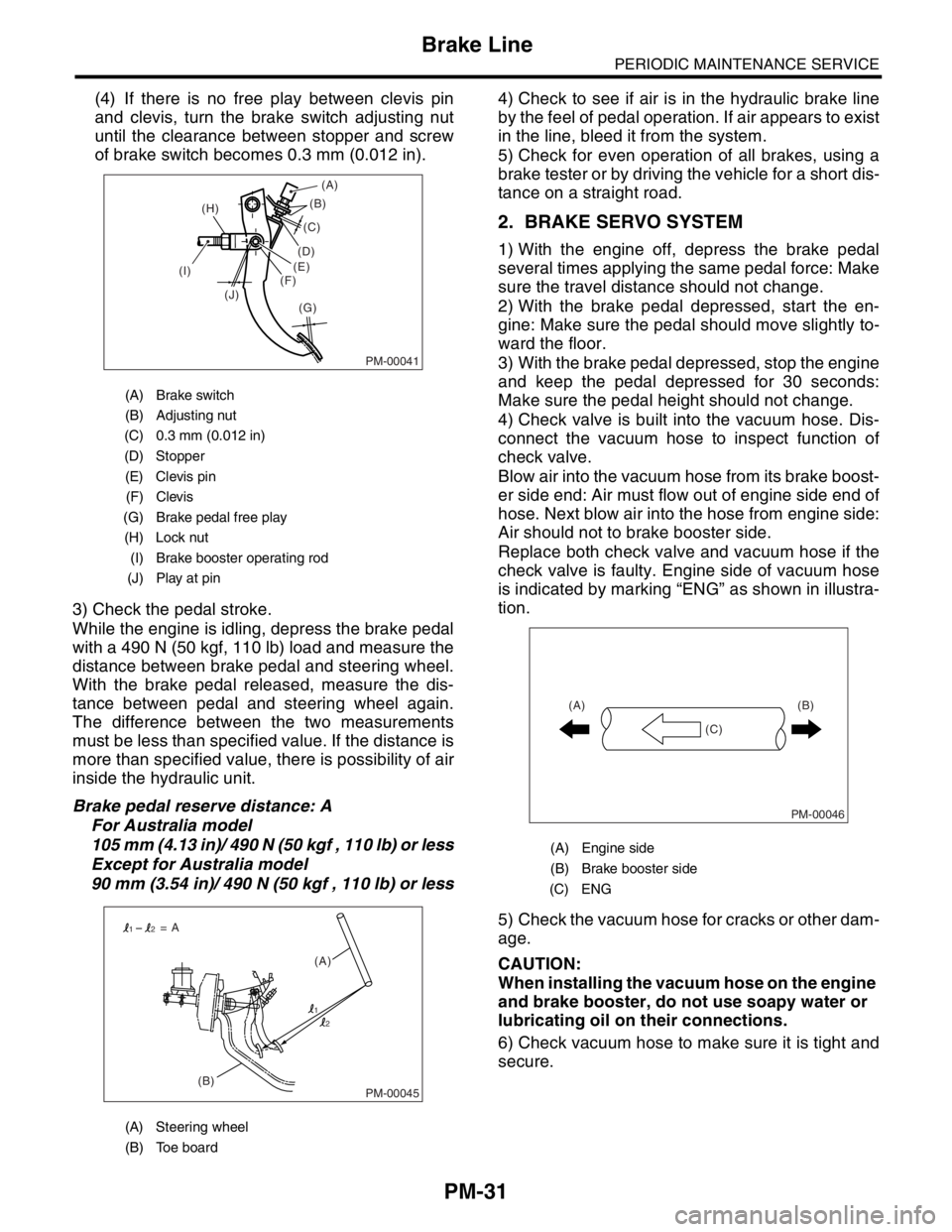

1) Check the free play of brake pedal with a force of

less than 10 N (1 kgf, 2 lb).

Brake pedal free play:

0.5 — 2.0 mm (0.02 — 0.08 in)

2) If the free play is out of specifications above, ad-

just the brake pedal as follows.

(1) Be sure the engine is off. (No vacuum is ap-

plied to brake booster.)

(2) There should be play between brake boost-

er clevis and pin at brake pedal installing por-

tion.

[Depress brake pedal pad with a force of less

than 10 N (1 kgf, 2 lb) to a stroke of 0.5 to 2.0

mm (0.02 to 0.08 in).]

(3) Depress the surface of brake pad by hand.

(1) Front brake hose

(2) Front brake pipe

(1) Brake pipe

(2) Rear brake hose

(3) Clamp

BR-00095

(1)

(2)

(1)

(3)

(3) (2)

BR-00096

(A) Brake pedal free play

PM-00078

(A)

Page 768 of 2870

PM-31

PERIODIC MAINTENANCE SERVICE

Brake Line

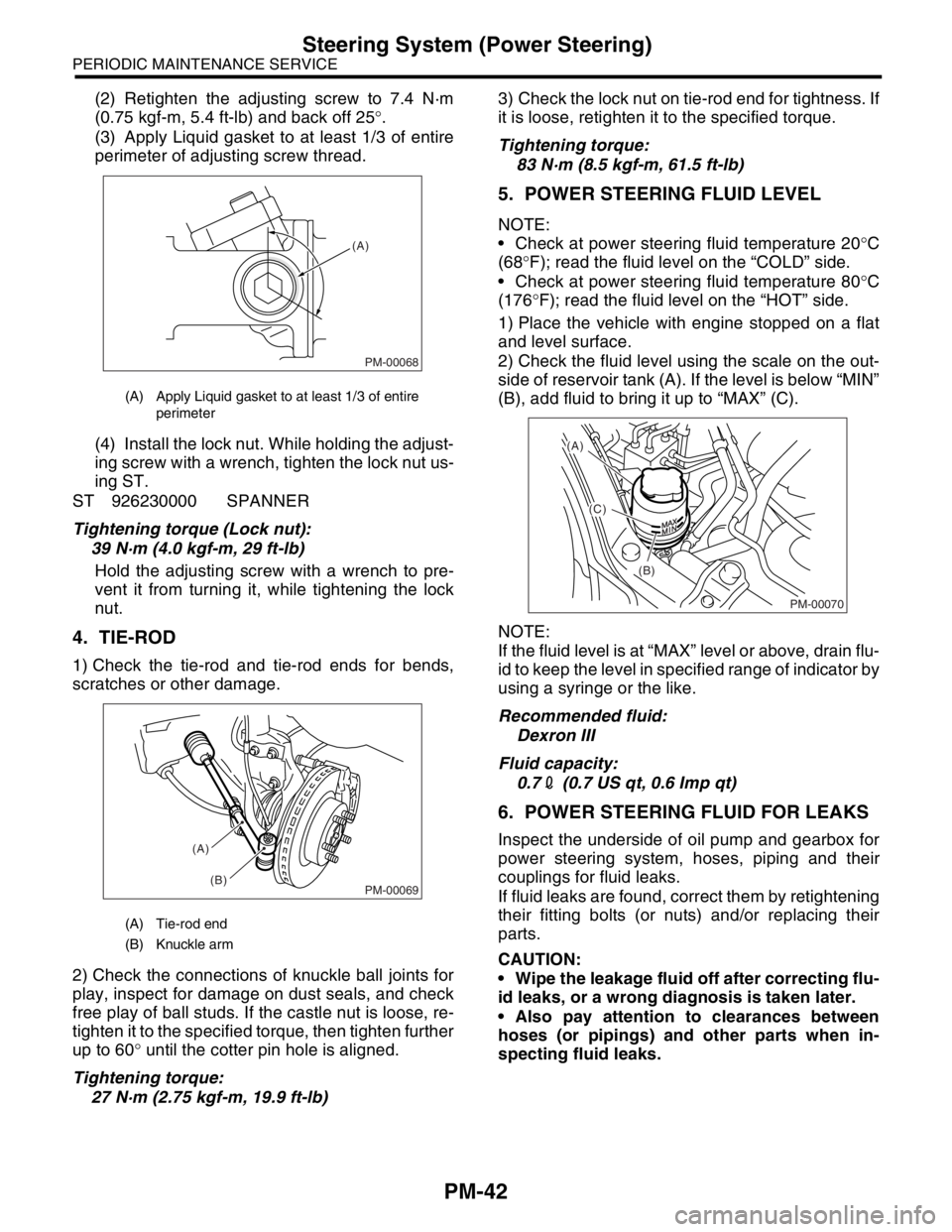

(4) If there is no free play between clevis pin

and clevis, turn the brake switch adjusting nut

until the clearance between stopper and screw

of brake switch becomes 0.3 mm (0.012 in).

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 490 N (50 kgf, 110 lb) load and measure the

distance between brake pedal and steering wheel.

With the brake pedal released, measure the dis-

tance between pedal and steering wheel again.

The difference between the two measurements

must be less than specified value. If the distance is

more than specified value, there is possibility of air

inside the hydraulic unit.

Brake pedal reserve distance: A

For Australia model

105 mm (4.13 in)/ 490 N (50 kgf , 110 lb) or less

Except for Australia model

90 mm (3.54 in)/ 490 N (50 kgf , 110 lb) or less4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

2. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force: Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine: Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds:

Make sure the pedal height should not change.

4) Check valve is built into the vacuum hose. Dis-

connect the vacuum hose to inspect function of

check valve.

Blow air into the vacuum hose from its brake boost-

er side end: Air must flow out of engine side end of

hose. Next blow air into the hose from engine side:

Air should not to brake booster side.

Replace both check valve and vacuum hose if the

check valve is faulty. Engine side of vacuum hose

is indicated by marking “ENG” as shown in illustra-

tion.

5) Check the vacuum hose for cracks or other dam-

age.

CAUTION:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or

lubricating oil on their connections.

6) Check vacuum hose to make sure it is tight and

secure.

(A) Brake switch

(B) Adjusting nut

(C) 0.3 mm (0.012 in)

(D) Stopper

(E) Clevis pin

(F) Clevis

(G) Brake pedal free play

(H) Lock nut

(I) Brake booster operating rod

(J) Play at pin

(A) Steering wheel

(B) Toe board

PM-00041

(B)

(G) (H)

(I)

(J)(C)

(D)

(E)

(F)(A)

PM-00045(B)(A) = A

1

12

2

(A) Engine side

(B) Brake booster side

(C) ENG

PM-00046

(B)

(C) (A)

Page 779 of 2870

PM-42

PERIODIC MAINTENANCE SERVICE

Steering System (Power Steering)

(2) Retighten the adjusting screw to 7.4 N·m

(0.75 kgf-m, 5.4 ft-lb) and back off 25°.

(3) Apply Liquid gasket to at least 1/3 of entire

perimeter of adjusting screw thread.

(4) Install the lock nut. While holding the adjust-

ing screw with a wrench, tighten the lock nut us-

ing ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39 N·m (4.0 kgf-m, 29 ft-lb)

Hold the adjusting screw with a wrench to pre-

vent it from turning it, while tightening the lock

nut.

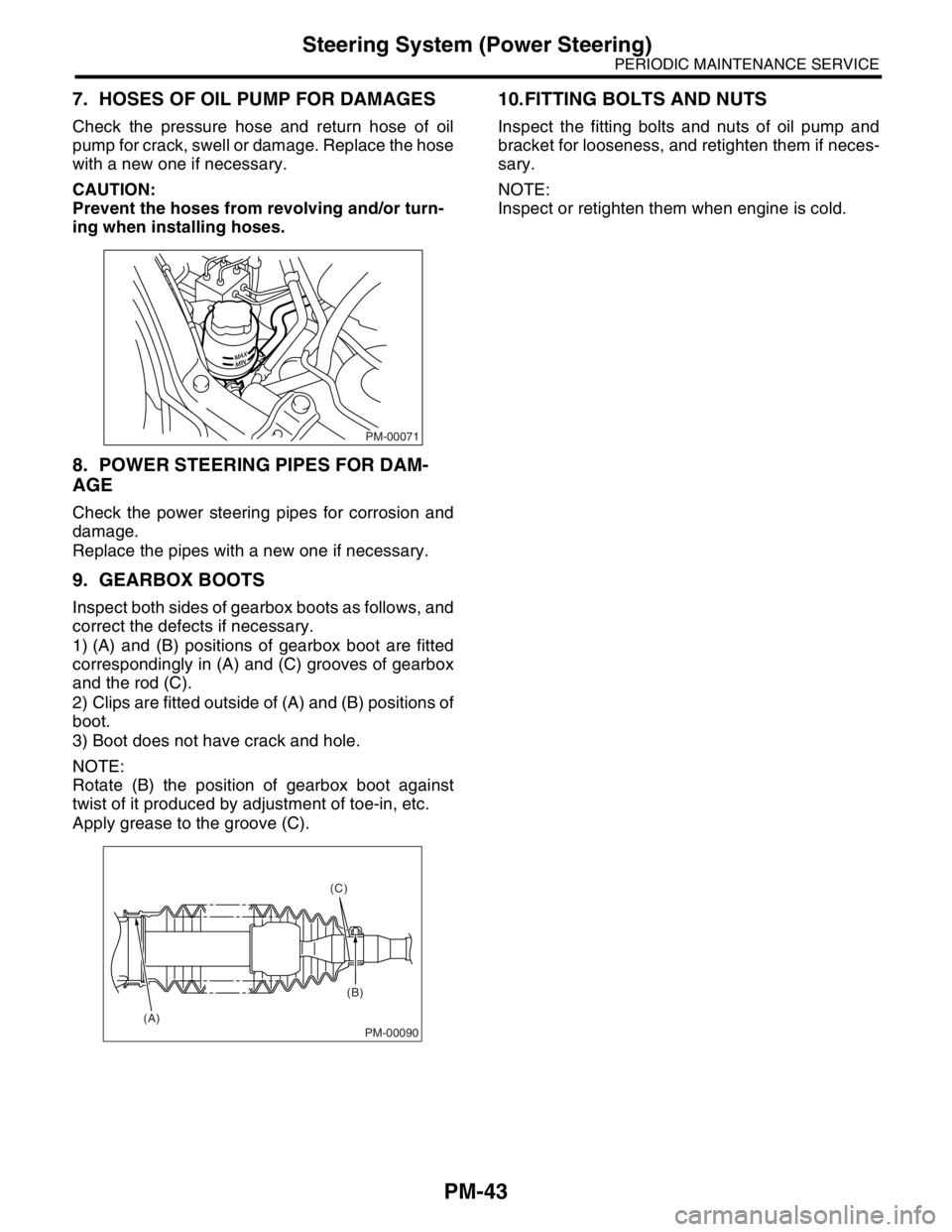

4. TIE-ROD

1) Check the tie-rod and tie-rod ends for bends,

scratches or other damage.

2) Check the connections of knuckle ball joints for

play, inspect for damage on dust seals, and check

free play of ball studs. If the castle nut is loose, re-

tighten it to the specified torque, then tighten further

up to 60° until the cotter pin hole is aligned.

Tightening torque:

27 N·m (2.75 kgf-m, 19.9 ft-lb)3) Check the lock nut on tie-rod end for tightness. If

it is loose, retighten it to the specified torque.

Tightening torque:

83 N·m (8.5 kgf-m, 61.5 ft-lb)

5. POWER STEERING FLUID LEVEL

NOTE:

Check at power steering fluid temperature 20°C

(68°F); read the fluid level on the “COLD” side.

Check at power steering fluid temperature 80°C

(176°F); read the fluid level on the “HOT” side.

1) Place the vehicle with engine stopped on a flat

and level surface.

2) Check the fluid level using the scale on the out-

side of reservoir tank (A). If the level is below “MIN”

(B), add fluid to bring it up to “MAX” (C).

NOTE:

If the fluid level is at “MAX” level or above, drain flu-

id to keep the level in specified range of indicator by

using a syringe or the like.

Recommended fluid:

Dexron III

Fluid capacity:

0.72 (0.7 US qt, 0.6 Imp qt)

6. POWER STEERING FLUID FOR LEAKS

Inspect the underside of oil pump and gearbox for

power steering system, hoses, piping and their

couplings for fluid leaks.

If fluid leaks are found, correct them by retightening

their fitting bolts (or nuts) and/or replacing their

parts.

CAUTION:

Wipe the leakage fluid off after correcting flu-

id leaks, or a wrong diagnosis is taken later.

Also pay attention to clearances between

hoses (or pipings) and other parts when in-

specting fluid leaks.

(A) Apply Liquid gasket to at least 1/3 of entire

perimeter

(A) Tie-rod end

(B) Knuckle arm

PM-00068

(A)

PM-00069

(A)

(B)

PM-00070

(A)

(C)

(B)

Page 780 of 2870

PM-43

PERIODIC MAINTENANCE SERVICE

Steering System (Power Steering)

7. HOSES OF OIL PUMP FOR DAMAGES

Check the pressure hose and return hose of oil

pump for crack, swell or damage. Replace the hose

with a new one if necessary.

CAUTION:

Prevent the hoses from revolving and/or turn-

ing when installing hoses.

8. POWER STEERING PIPES FOR DAM-

AGE

Check the power steering pipes for corrosion and

damage.

Replace the pipes with a new one if necessary.

9. GEARBOX BOOTS

Inspect both sides of gearbox boots as follows, and

correct the defects if necessary.

1) (A) and (B) positions of gearbox boot are fitted

correspondingly in (A) and (C) grooves of gearbox

and the rod (C).

2) Clips are fitted outside of (A) and (B) positions of

boot.

3) Boot does not have crack and hole.

NOTE:

Rotate (B) the position of gearbox boot against

twist of it produced by adjustment of toe-in, etc.

Apply grease to the groove (C).

10.FITTING BOLTS AND NUTS

Inspect the fitting bolts and nuts of oil pump and

bracket for looseness, and retighten them if neces-

sary.

NOTE:

Inspect or retighten them when engine is cold.

PM-00071

PM-00090

(C)

(B)

(A)

Page 812 of 2870

FU(H4SO)-30

FUEL INJECTION (FUEL SYSTEM)

Throttle Position Sensor

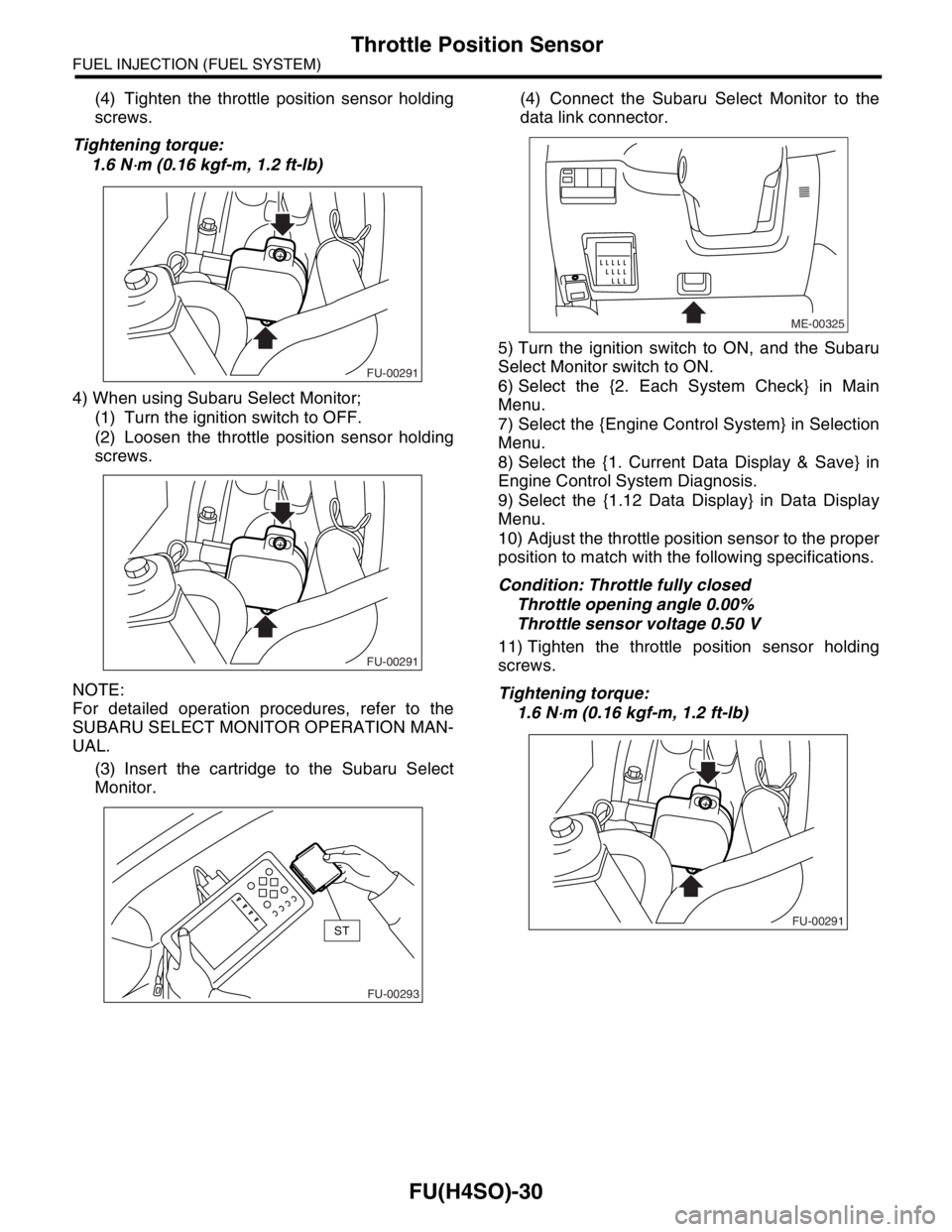

(4) Tighten the throttle position sensor holding

screws.

Tightening torque:

1.6 N

⋅m (0.16 kgf-m, 1.2 ft-lb)

4) When using Subaru Select Monitor;

(1) Turn the ignition switch to OFF.

(2) Loosen the throttle position sensor holding

screws.

NOTE:

For detailed operation procedures, refer to the

SUBARU SELECT MONITOR OPERATION MAN-

UAL.

(3) Insert the cartridge to the Subaru Select

Monitor.(4) Connect the Subaru Select Monitor to the

data link connector.

5) Turn the ignition switch to ON, and the Subaru

Select Monitor switch to ON.

6) Select the {2. Each System Check} in Main

Menu.

7) Select the {Engine Control System} in Selection

Menu.

8) Select the {1. Current Data Display & Save} in

Engine Control System Diagnosis.

9) Select the {1.12 Data Display} in Data Display

Menu.

10) Adjust the throttle position sensor to the proper

position to match with the following specifications.

Condition: Throttle fully closed

Throttle opening angle 0.00%

Throttle sensor voltage 0.50 V

11) Tighten the throttle position sensor holding

screws.

Tightening torque:

1.6 N

⋅m (0.16 kgf-m, 1.2 ft-lb)

FU-00291

FU-00291

FU-00293

ST

ME-00325

FU-00291

Page 884 of 2870

ME(H4SO)-15

MECHANICAL

General Description

C: CAUTION

Wear working clothing, including a cap, protec-

tive goggles and protective shoes during operation.

Remove contamination including dirt and corro-

sion before removal, installation or disassembly.

Keep the disassembled parts in order and pro-

tect them from dust or dirt.

Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

Be careful not to burn yourself, because each

part in the vehicle is hot after running.

Be sure to tighten bolts and nuts to the specified

torque.

Place shop jacks or rigid racks at the specified

points.

Before disconnecting electrical connectors of

sensors or units, be sure to disconnect the ground

cable from battery.

All parts should be thoroughly cleaned, paying

special attention to the engine oil passages, pis-

tons and bearings. Rotating parts and sliding parts such as piston,

bearing and gear should be coated with oil prior to

assembly.

Be careful not to let oil, grease or coolant contact

the timing belt, clutch disc and flywheel.

All removed parts, if to be reused, should be re-

installed in the original positions and directions.

Bolts, nuts and washers should be replaced with

new ones as required.

Even if necessary inspections have been made

in advance, proceed with assembly work while

making rechecks.

Remove or install engine in an area where chain

hoists, lifting devices, etc. are available for ready

use.

Be sure not to damage coated surfaces of body

panels with tools, or not to stain seats and windows

with coolant or oil. Place a cover over fenders, as

required, for protection.

Prior to starting work, prepare the following:

Service tools, clean cloth, containers to catch cool-

ant and oil, wire ropes, chain hoist, transmission

jacks, etc.

Lift-up or lower the vehicle when necessary.

Make sure to support the correct positions.

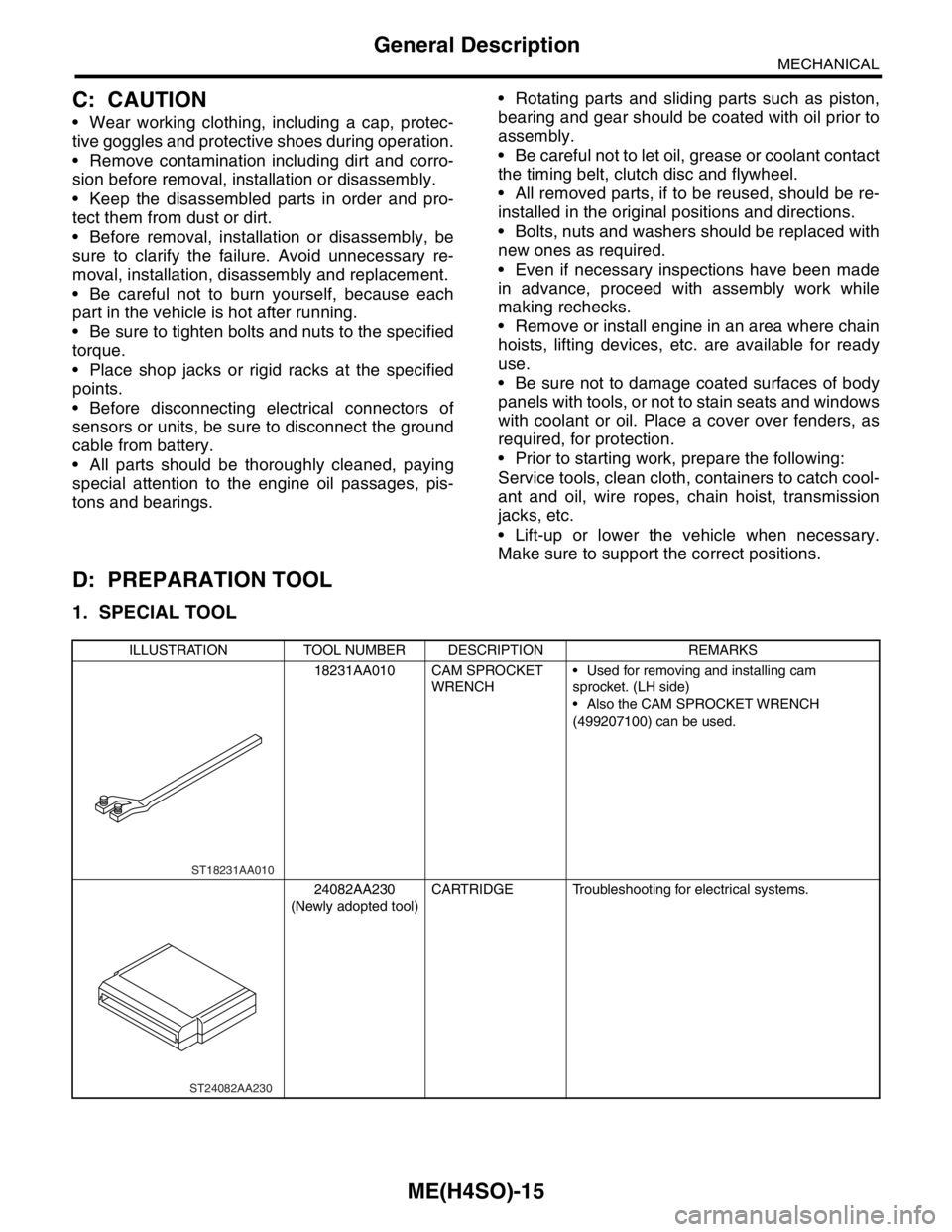

D: PREPARATION TOOL

1. SPECIAL TOOL

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

18231AA010 CAM SPROCKET

WRENCH Used for removing and installing cam

sprocket. (LH side)

Also the CAM SPROCKET WRENCH

(499207100) can be used.

24082AA230

(Newly adopted tool)CARTRIDGE Troubleshooting for electrical systems.

ST18231AA010

ST24082AA230

Page 894 of 2870

ME(H4SO)-25

MECHANICAL

Compression

2. Compression

A: INSPECTION

CAUTION:

After warming-up, engine becomes very hot. Be

careful not to burn yourself during measure-

ment.

1) After warming-up the engine, turn the ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Release the fuel pressure.

TION, Fuel.>

4) Remove all the spark plugs.

5) Fully open the throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against spark

plug hole.

NOTE:

When using a screw-in type compression gauge,

the screw (put into cylinder head spark plug hole)

should be less than 18 mm (0.71 in) long.

8) Crank the engine by means of starter motor, and

then read the maximum value on the gauge when

the pointer is steady.

9) Perform at least two measurements per cylinder,

and make sure that the values are correct.

Compression (350 rpm and fully open throttle):

Standard;

1,275 kPa (13.0 kgf/cm

2, 185 psi)

Limit;

1,020 kPa (10.4 kgf/cm

2, 148 psi)

Difference between cylinders;

49 kPa (0.5 kgf/cm

2, 7 psi), or less

ME-00192

Page 895 of 2870

ME(H4SO)-26

MECHANICAL

Idle Speed

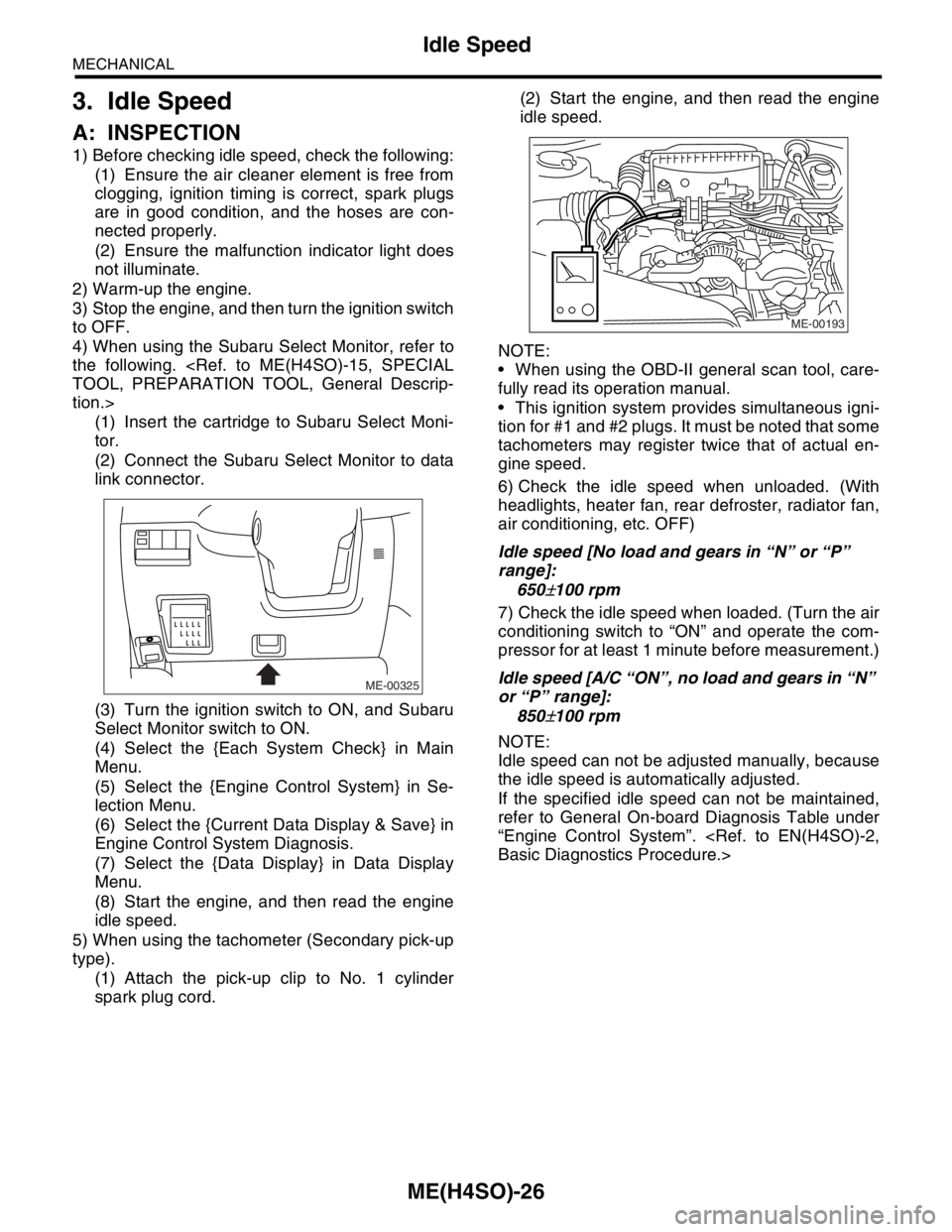

3. Idle Speed

A: INSPECTION

1) Before checking idle speed, check the following:

(1) Ensure the air cleaner element is free from

clogging, ignition timing is correct, spark plugs

are in good condition, and the hoses are con-

nected properly.

(2) Ensure the malfunction indicator light does

not illuminate.

2) Warm-up the engine.

3) Stop the engine, and then turn the ignition switch

to OFF.

4) When using the Subaru Select Monitor, refer to

the following.

tion.>

(1) Insert the cartridge to Subaru Select Moni-

tor.

(2) Connect the Subaru Select Monitor to data

link connector.

(3) Turn the ignition switch to ON, and Subaru

Select Monitor switch to ON.

(4) Select the {Each System Check} in Main

Menu.

(5) Select the {Engine Control System} in Se-

lection Menu.

(6) Select the {Current Data Display & Save} in

Engine Control System Diagnosis.

(7) Select the {Data Display} in Data Display

Menu.

(8) Start the engine, and then read the engine

idle speed.

5) When using the tachometer (Secondary pick-up

type).

(1) Attach the pick-up clip to No. 1 cylinder

spark plug cord.(2) Start the engine, and then read the engine

idle speed.

NOTE:

When using the OBD-II general scan tool, care-

fully read its operation manual.

This ignition system provides simultaneous igni-

tion for #1 and #2 plugs. It must be noted that some

tachometers may register twice that of actual en-

gine speed.

6) Check the idle speed when unloaded. (With

headlights, heater fan, rear defroster, radiator fan,

air conditioning, etc. OFF)

Idle speed [No load and gears in “N” or “P”

range]:

650

±100 rpm

7) Check the idle speed when loaded. (Turn the air

conditioning switch to “ON” and operate the com-

pressor for at least 1 minute before measurement.)

Idle speed [A/C “ON”, no load and gears in “N”

or “P” range]:

850

±100 rpm

NOTE:

Idle speed can not be adjusted manually, because

the idle speed is automatically adjusted.

If the specified idle speed can not be maintained,

refer to General On-board Diagnosis Table under

“Engine Control System”.

ME-00325

ME-00193

Page 896 of 2870

ME(H4SO)-27

MECHANICAL

Ignition Timing

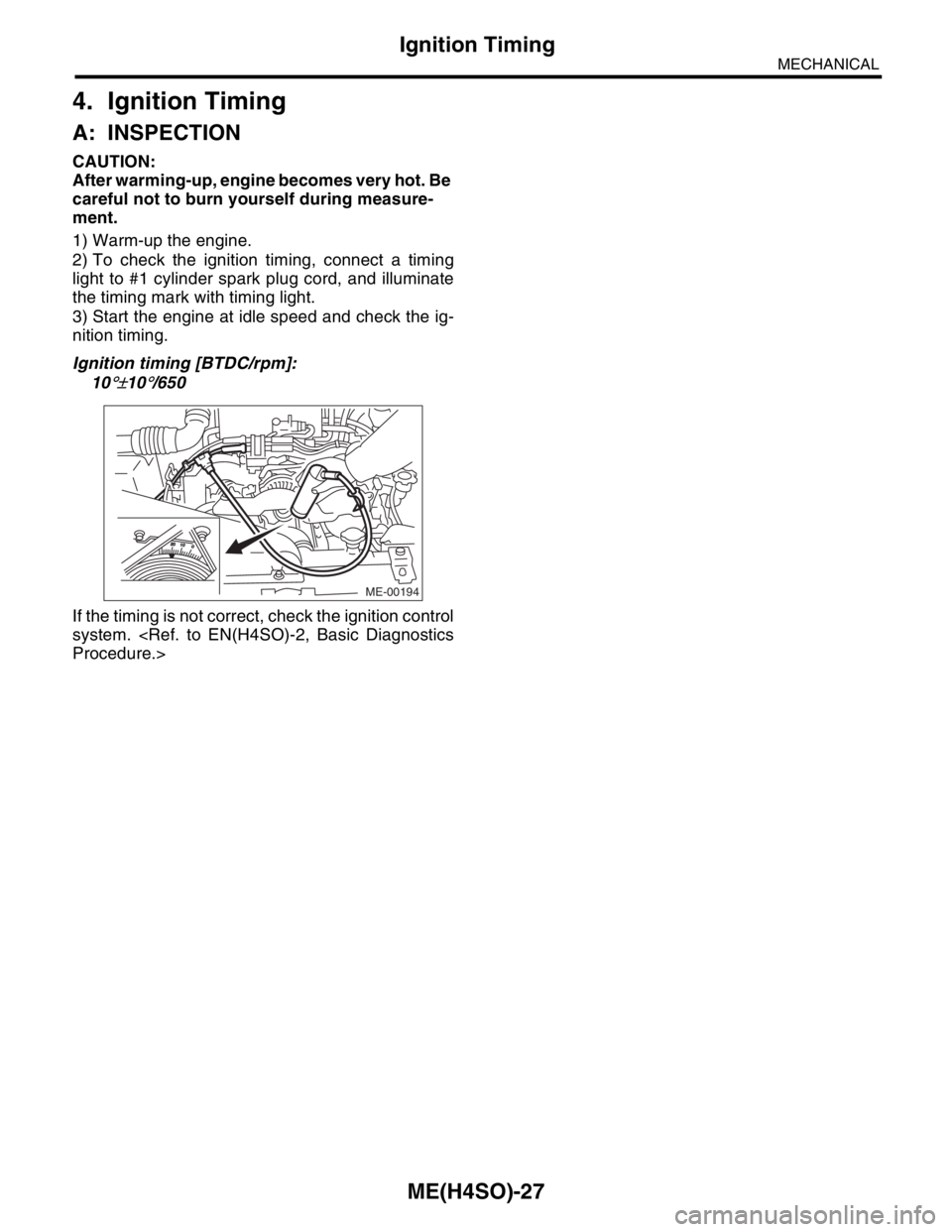

4. Ignition Timing

A: INSPECTION

CAUTION:

After warming-up, engine becomes very hot. Be

careful not to burn yourself during measure-

ment.

1) Warm-up the engine.

2) To check the ignition timing, connect a timing

light to #1 cylinder spark plug cord, and illuminate

the timing mark with timing light.

3) Start the engine at idle speed and check the ig-

nition timing.

Ignition timing [BTDC/rpm]:

10

°±10°/650

If the timing is not correct, check the ignition control

system.

ME-00194

Page 898 of 2870

ME(H4SO)-29

MECHANICAL

Engine Oil Pressure

6. Engine Oil Pressure

A: INSPECTION

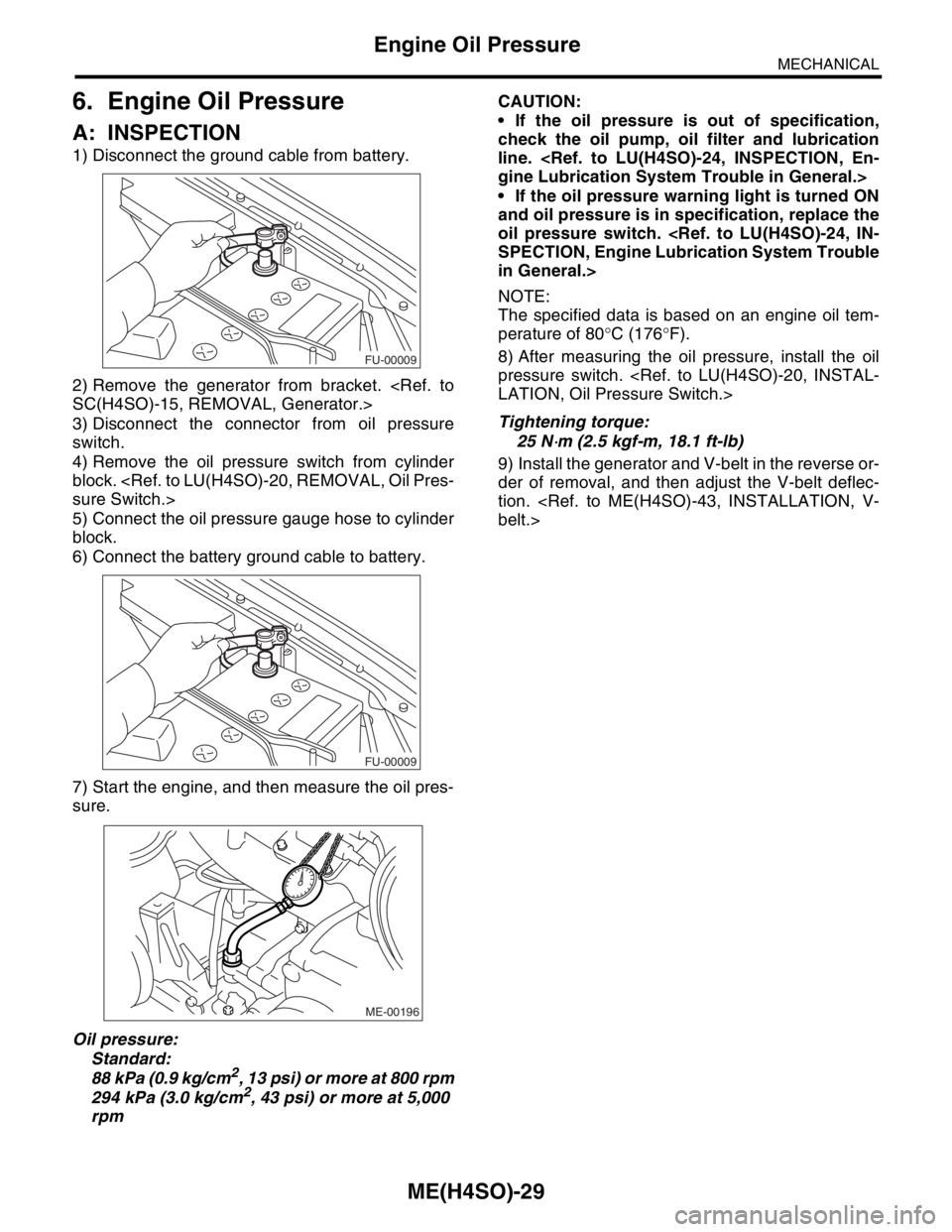

1) Disconnect the ground cable from battery.

2) Remove the generator from bracket.

3) Disconnect the connector from oil pressure

switch.

4) Remove the oil pressure switch from cylinder

block.

5) Connect the oil pressure gauge hose to cylinder

block.

6) Connect the battery ground cable to battery.

7) Start the engine, and then measure the oil pres-

sure.

Oil pressure:

Standard:

88 kPa (0.9 kg/cm

2, 13 psi) or more at 800 rpm

294 kPa (3.0 kg/cm2, 43 psi) or more at 5,000

rpmCAUTION:

If the oil pressure is out of specification,

check the oil pump, oil filter and lubrication

line.

If the oil pressure warning light is turned ON

and oil pressure is in specification, replace the

oil pressure switch.

in General.>

NOTE:

The specified data is based on an engine oil tem-

perature of 80°C (176°F).

8) After measuring the oil pressure, install the oil

pressure switch.

Tightening torque:

25 N

⋅m (2.5 kgf-m, 18.1 ft-lb)

9) Install the generator and V-belt in the reverse or-

der of removal, and then adjust the V-belt deflec-

tion.

FU-00009

FU-00009

ME-00196