specifications SUBARU LEGACY 1999 Service Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 945 of 1456

Trouble and possible cause Corrective action

In the case of the disc brake:

(1) Excessively worn pad or the support Replace the pad or the support.

In the case of the drum brake:

(1) Excessively worn shoe ridge Replace the back plate.

(2) Lack of oil on the shoe ridge surface and anchor Add more grease.

2. Hill Holder

CAUTION:

IDescription in parentheses is a characteris-

tic of hill holder and does not indicate abnor-

mality.

Depressing force required for clutch pedal

equipped to hill holder specifications is 20 to

29 N (2 to 3 kg, 4 to 7 lb) larger than the con-

ventional specifications, which does not con-

stitute abnormality.IWhen vehicle cannot travel (brake cannot be

released) because return spring is broken,

remove adjusting nut, disconnect clutch and

PHV, and then return PHV lever to release the

brake. (Be sure to apply the parking brake

before starting this operation.)

IThe hill holder may not be activated on a

slope of an extremely small inclination.

Trouble and possible cause Corrective action

1. Counterforce of clutch pedal is too strong.

(1) PHV cable is damaged or does not operate properly. Repair or replace.

(2) Lever of PHV is defective. Replace entire PHV assembly.

(3) Clutch system is anomalous. Refer to ªClutch and pedal cable systemº.

2. Vehicle does not stop on uphill road of 3É or higher inclination.

(1) Front side of vehicle is lowered. Refer to ªSuspensionº.

(2) PHV cable is broken. Replace.

(3) Play of clutch is excessive. Adjust.

(4) PHV cable is elongated. Adjust.

(5) Sealing of PHV is poor. Replace entire PHV assembly.

3. Shock is felt when starting.

(1) Poor adjustment of starting performance: Adjust.

(2) When depressing the brake pedal strongly:(The stronger brake pedal depressing force, the later hill

holder releases.)

(3) When starting on flat road after stopping reverse move-

ment:(Because hill holder is activated.)

4. Vehicle slips down when starting.

(1) PHV cable is elongated. Adjust.

(2) Clutch facing is worn out. Adjust or replace.

(3) Bracket (cable) or stay (PHV) is deformed. Repair or replace.

5. Vehicle cannot start after stoppage.

(1) Return spring is fatigued or broken. Replace.

(2) PHV lever won't return. Replace entire PHV assembly.

(3) When intentionally depressing brake pedal strongly:[When the brake pedal is depressed by a force of 1,177 N

(120 kg, 265 lb) or more.]

6. Abnormal sound is generated upon releasing brake pedal when stopping.

(1) Rotor and pad matched with each other due to inadequate

depressing force to brake pedal.(Abnormal sound is not generated when depressing brake

pedal a little stronger.)

7. Abnormal sound is generated when operating clutch pedal.

(1) Grease is inadequate for the hook of return spring and

sliding portion of PHV cable end.Apply grease.

(2) When releasing after maintaining high fluid pressure: (Flowing sound of fluid when releasing high fluid pressure.)

(3) Clutch system is anomalous. Refer to ªClutch and pedal cable systemº.

65

[K200]4-4DIAGNOSTICS

2. Hill Holder

Page 947 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 1. Pedal System

Brake pedal Free play1Ð3mm(0.04 Ð 0.12 in) [Depress brake pedal pad

with a force of less than 10 N (1 kg, 2 lb).]

Clutch pedalFree play At clutch pedal padExcept 2500 cc model: 10 Ð SUBARU LEGACY 1999 Service Owners Manual 1. Pedal System

Brake pedal Free play1Ð3mm(0.04 Ð 0.12 in) [Depress brake pedal pad

with a force of less than 10 N (1 kg, 2 lb).]

Clutch pedalFree play At clutch pedal padExcept 2500 cc model: 10 Ð](/img/17/57435/w960_57435-946.png)

1. Pedal System

Brake pedal Free play1Ð3mm(0.04 Ð 0.12 in) [Depress brake pedal pad

with a force of less than 10 N (1 kg, 2 lb).]

Clutch pedalFree play At clutch pedal padExcept 2500 cc model: 10 Ð 20 mm (0.39 Ð 0.79 in)

2500 cc model:4Ð13mm(0.16 Ð 0.51 in)

Full stroke At clutch pedal padExcept 2500 cc model: 140 Ð 145 mm (5.51 Ð 5.71 in)

2500 cc model: 130 Ð 135 mm (5.12 Ð 5.31 in)

Accelerator pedalFree play At pedal pad1Ð4mm(0.04 Ð 0.16 in)

Stroke At pedal pad 50 Ð 55 mm (1.97 Ð 2.17 in)

2

4-5[S100]SPECIFICATIONS AND SERVICE DATA

1. Pedal System

Page 956 of 1456

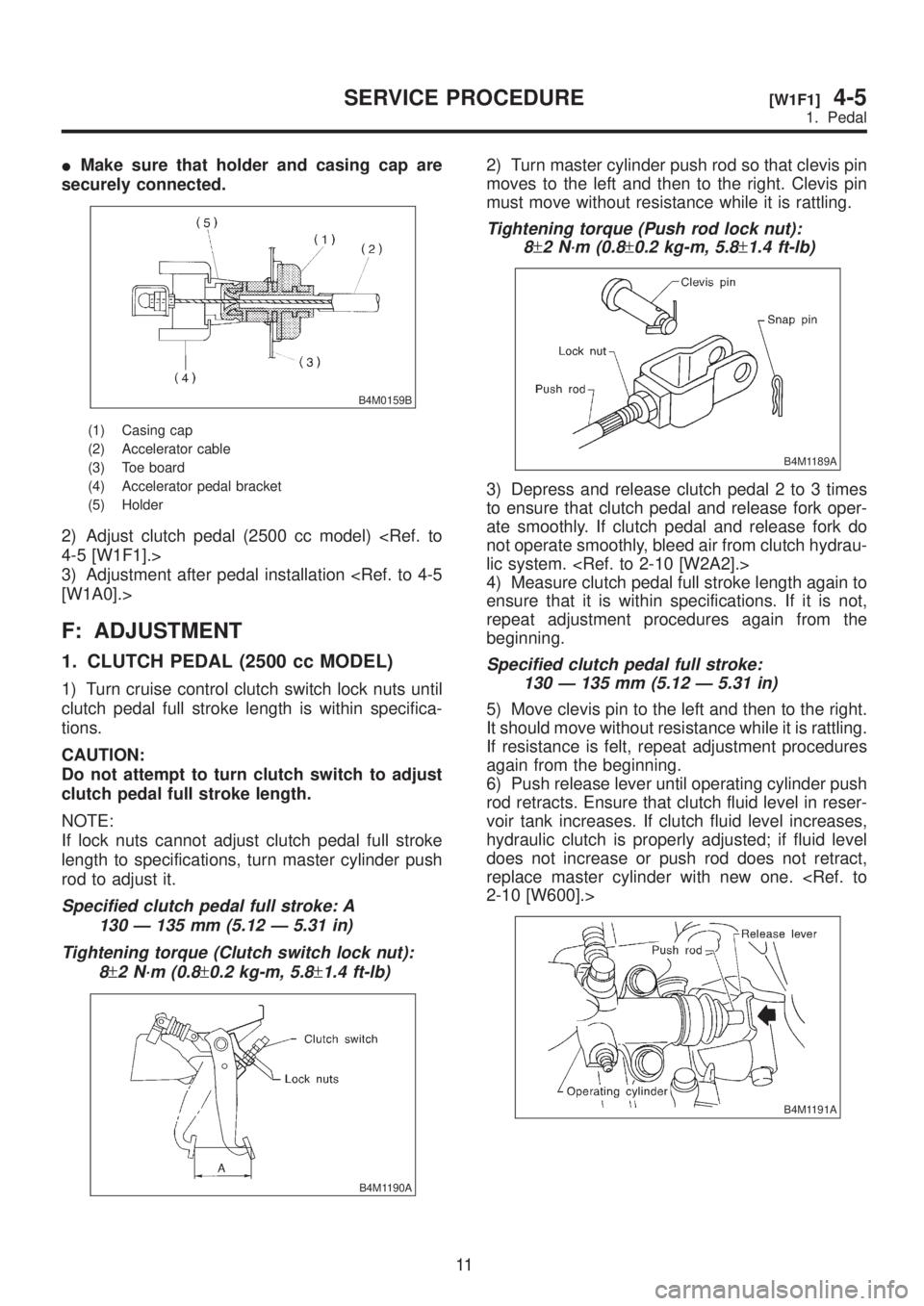

IMake sure that holder and casing cap are

securely connected.

B4M0159B

(1) Casing cap

(2) Accelerator cable

(3) Toe board

(4) Accelerator pedal bracket

(5) Holder

2) Adjust clutch pedal (2500 cc model)

3) Adjustment after pedal installation

F: ADJUSTMENT

1. CLUTCH PEDAL (2500 cc MODEL)

1) Turn cruise control clutch switch lock nuts until

clutch pedal full stroke length is within specifica-

tions.

CAUTION:

Do not attempt to turn clutch switch to adjust

clutch pedal full stroke length.

NOTE:

If lock nuts cannot adjust clutch pedal full stroke

length to specifications, turn master cylinder push

rod to adjust it.

Specified clutch pedal full stroke: A

130 Ð 135 mm (5.12 Ð 5.31 in)

Tightening torque (Clutch switch lock nut):

8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

B4M1190A

2) Turn master cylinder push rod so that clevis pin

moves to the left and then to the right. Clevis pin

must move without resistance while it is rattling.

Tightening torque (Push rod lock nut):

8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

B4M1189A

3) Depress and release clutch pedal 2 to 3 times

to ensure that clutch pedal and release fork oper-

ate smoothly. If clutch pedal and release fork do

not operate smoothly, bleed air from clutch hydrau-

lic system.

4) Measure clutch pedal full stroke length again to

ensure that it is within specifications. If it is not,

repeat adjustment procedures again from the

beginning.

Specified clutch pedal full stroke:

130 Ð 135 mm (5.12 Ð 5.31 in)

5) Move clevis pin to the left and then to the right.

It should move without resistance while it is rattling.

If resistance is felt, repeat adjustment procedures

again from the beginning.

6) Push release lever until operating cylinder push

rod retracts. Ensure that clutch fluid level in reser-

voir tank increases. If clutch fluid level increases,

hydraulic clutch is properly adjusted; if fluid level

does not increase or push rod does not retract,

replace master cylinder with new one.

B4M1191A

11

[W1F1]4-5SERVICE PROCEDURE

1. Pedal

Page 962 of 1456

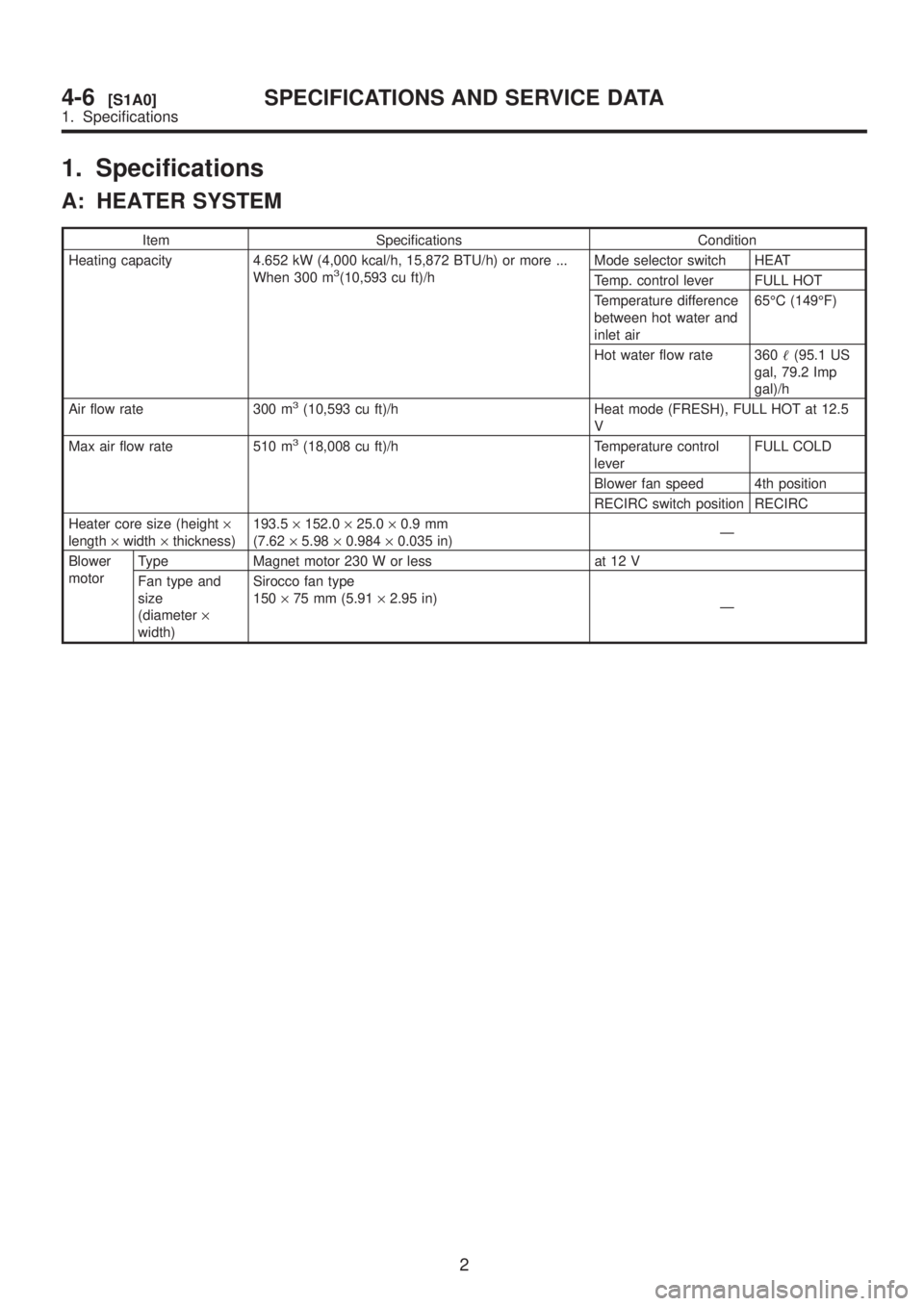

1. Specifications

A: HEATER SYSTEM

Item Specifications Condition

Heating capacity 4.652 kW (4,000 kcal/h, 15,872 BTU/h) or more ...

When 300 m

3(10,593 cu ft)/hMode selector switch HEAT

Temp. control lever FULL HOT

Temperature difference

between hot water and

inlet air65ÉC (149ÉF)

Hot water flow rate 360(95.1 US

gal, 79.2 Imp

gal)/h

Air flow rate 300 m

3(10,593 cu ft)/h Heat mode (FRESH), FULL HOT at 12.5

V

Max air flow rate 510 m

3(18,008 cu ft)/h Temperature control

leverFULL COLD

Blower fan speed 4th position

RECIRC switch position RECIRC

Heater core size (height´

length´width´thickness)193.5´152.0´25.0´0.9 mm

(7.62´5.98´0.984´0.035 in)Ð

Blower

motorType Magnet motor 230 W or less at 12 V

Fan type and

size

(diameter´

width)Sirocco fan type

150´75 mm (5.91´2.95 in)

Ð

2

4-6[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Specifications

Page 976 of 1456

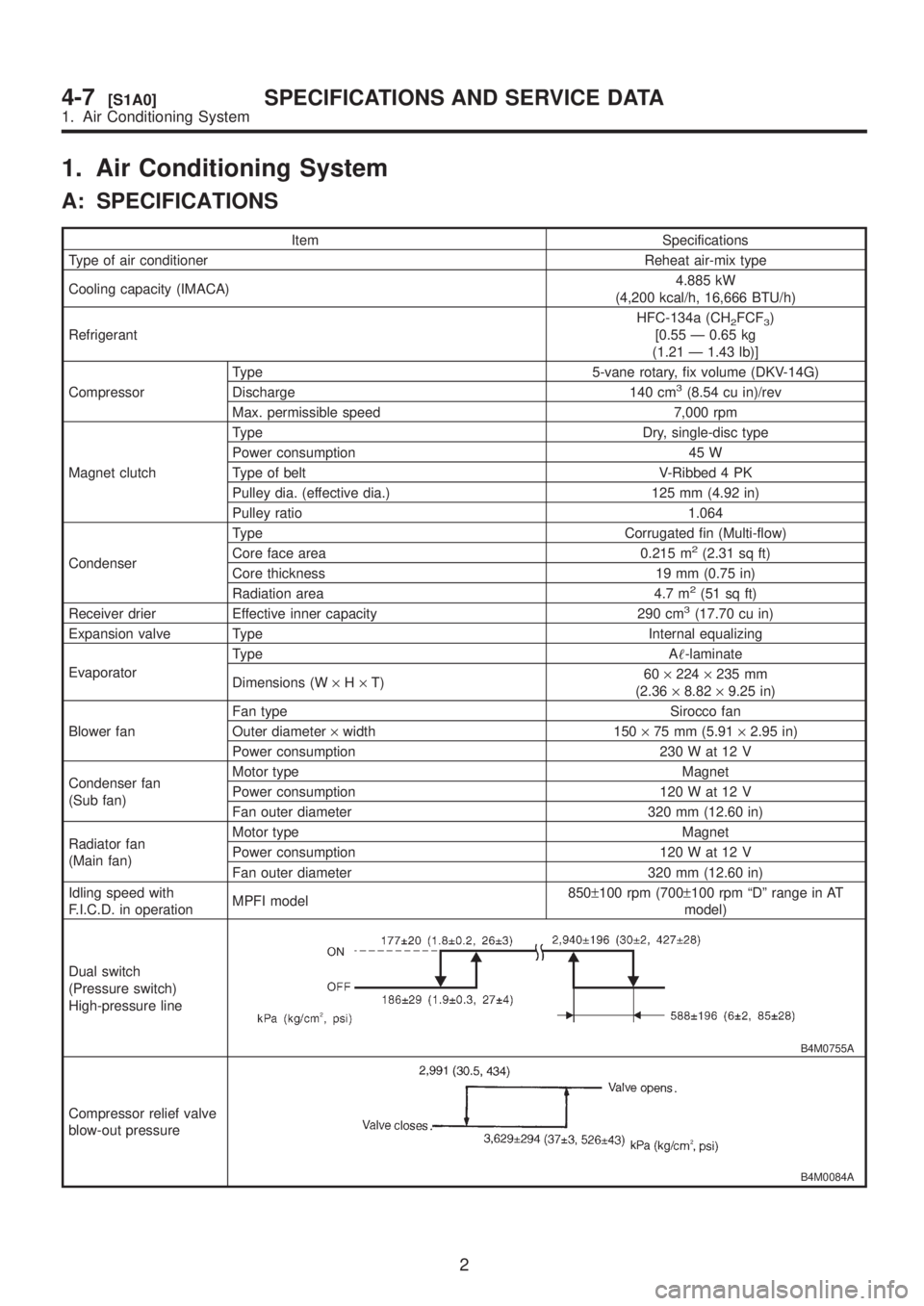

1. Air Conditioning System

A: SPECIFICATIONS

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity (IMACA)4.885 kW

(4,200 kcal/h, 16,666 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.55 Ð 0.65 kg

(1.21 Ð 1.43 lb)]

CompressorType 5-vane rotary, fix volume (DKV-14G)

Discharge 140 cm

3(8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 45 W

Type of belt V-Ribbed 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Multi-flow)

Core face area 0.215 m

2(2.31 sq ft)

Core thickness 19 mm (0.75 in)

Radiation area 4.7 m

2(51 sq ft)

Receiver drier Effective inner capacity 290 cm3(17.70 cu in)

Expansion valve Type Internal equalizing

EvaporatorType A-laminate

Dimensions (W´H´T)60´224´235 mm

(2.36´8.82´9.25 in)

Blower fanFan type Sirocco fan

Outer diameter´width 150´75 mm (5.91´2.95 in)

Power consumption 230 W at 12 V

Condenser fan

(Sub fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Radiator fan

(Main fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Idling speed with

F.I.C.D. in operationMPFI model850±100 rpm (700±100 rpm ªDº range in AT

model)

Dual switch

(Pressure switch)

High-pressure line

B4M0755A

Compressor relief valve

blow-out pressure

B4M0084A

2

4-7[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System

Page 977 of 1456

![SUBARU LEGACY 1999 Service Owners Manual Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System SUBARU LEGACY 1999 Service Owners Manual Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System](/img/17/57435/w960_57435-976.png)

Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System

Page 993 of 1456

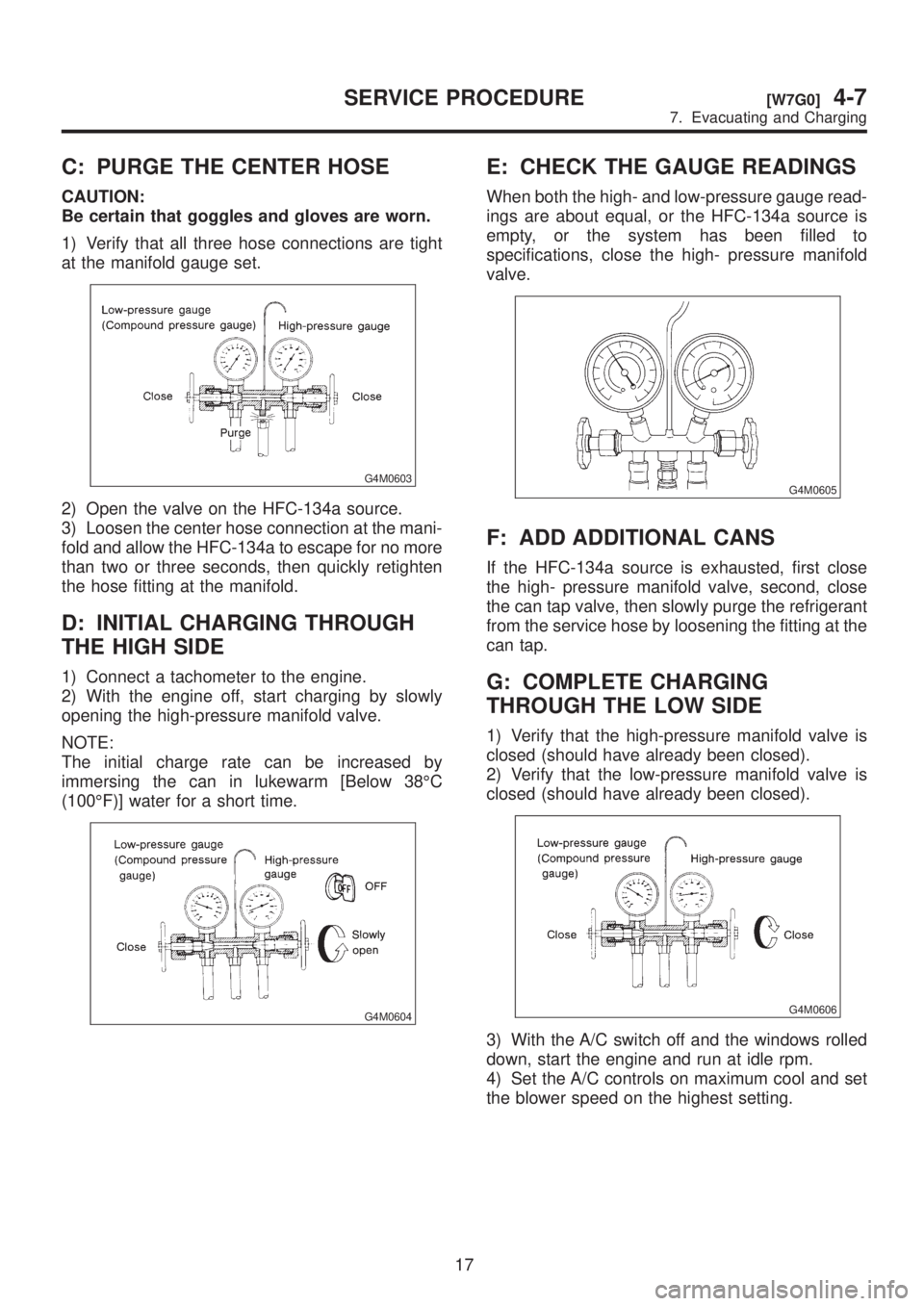

C: PURGE THE CENTER HOSE

CAUTION:

Be certain that goggles and gloves are worn.

1) Verify that all three hose connections are tight

at the manifold gauge set.

G4M0603

2) Open the valve on the HFC-134a source.

3) Loosen the center hose connection at the mani-

fold and allow the HFC-134a to escape for no more

than two or three seconds, then quickly retighten

the hose fitting at the manifold.

D: INITIAL CHARGING THROUGH

THE HIGH SIDE

1) Connect a tachometer to the engine.

2) With the engine off, start charging by slowly

opening the high-pressure manifold valve.

NOTE:

The initial charge rate can be increased by

immersing the can in lukewarm [Below 38ÉC

(100ÉF)] water for a short time.

G4M0604

E: CHECK THE GAUGE READINGS

When both the high- and low-pressure gauge read-

ings are about equal, or the HFC-134a source is

empty, or the system has been filled to

specifications, close the high- pressure manifold

valve.

G4M0605

F: ADD ADDITIONAL CANS

If the HFC-134a source is exhausted, first close

the high- pressure manifold valve, second, close

the can tap valve, then slowly purge the refrigerant

from the service hose by loosening the fitting at the

can tap.

G: COMPLETE CHARGING

THROUGH THE LOW SIDE

1) Verify that the high-pressure manifold valve is

closed (should have already been closed).

2) Verify that the low-pressure manifold valve is

closed (should have already been closed).

G4M0606

3) With the A/C switch off and the windows rolled

down, start the engine and run at idle rpm.

4) Set the A/C controls on maximum cool and set

the blower speed on the highest setting.

17

[W7G0]4-7SERVICE PROCEDURE

7. Evacuating and Charging

Page 1025 of 1456

1. Precaution

A: SUPPLEMENTAL RESTRAINT

SYSTEM ªAIRBAGº

Airbag system wiring harness is routed on and

along body panels.

CAUTION:

IAll Airbag system wiring harness and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

IBe careful not to damage Airbag system wir-

ing harness when repairing the body panel.

2

5-1[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Precaution

Page 1026 of 1456

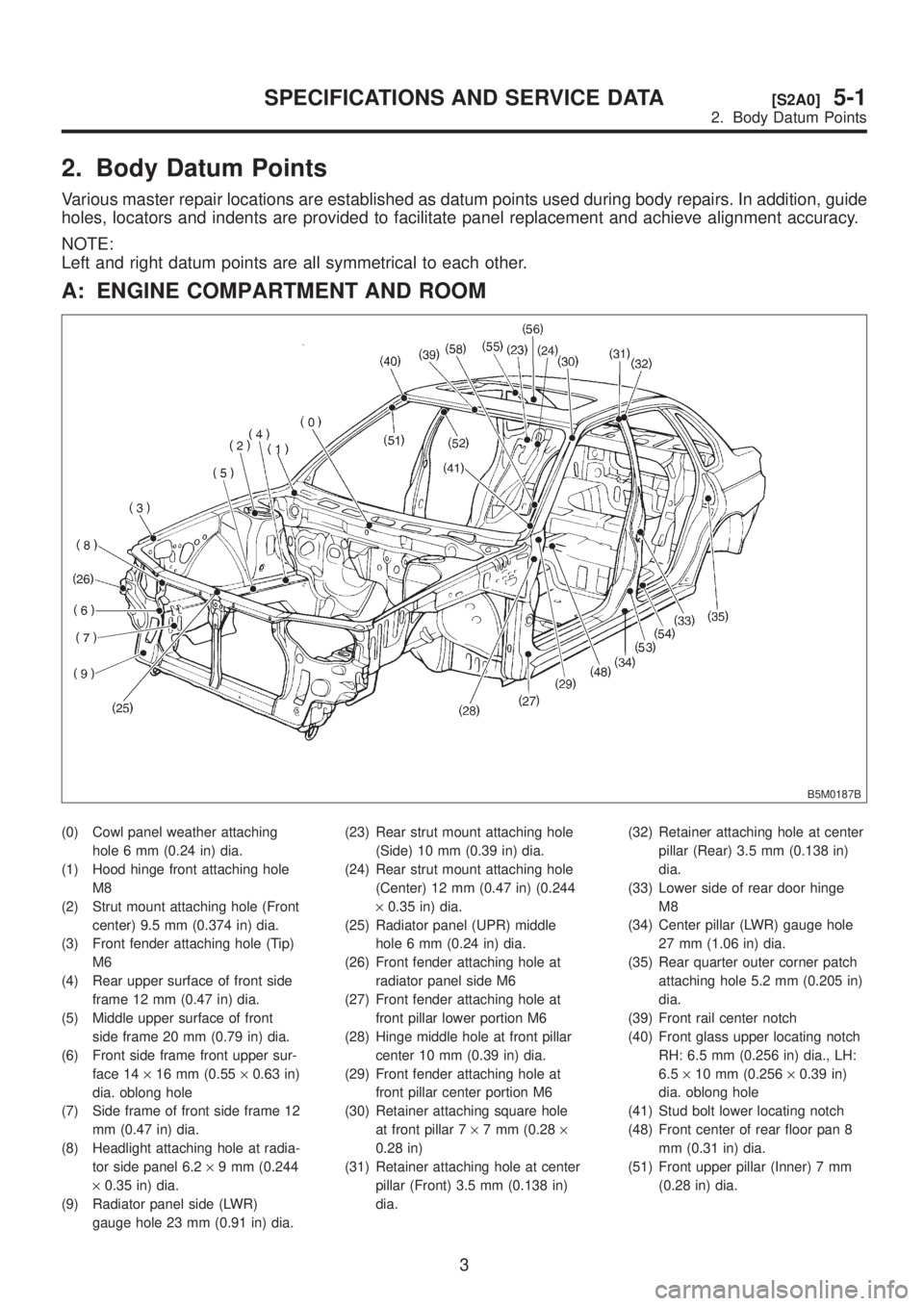

2. Body Datum Points

Various master repair locations are established as datum points used during body repairs. In addition, guide

holes, locators and indents are provided to facilitate panel replacement and achieve alignment accuracy.

NOTE:

Left and right datum points are all symmetrical to each other.

A: ENGINE COMPARTMENT AND ROOM

B5M0187B

(0) Cowl panel weather attaching

hole 6 mm (0.24 in) dia.

(1) Hood hinge front attaching hole

M8

(2) Strut mount attaching hole (Front

center) 9.5 mm (0.374 in) dia.

(3) Front fender attaching hole (Tip)

M6

(4) Rear upper surface of front side

frame 12 mm (0.47 in) dia.

(5) Middle upper surface of front

side frame 20 mm (0.79 in) dia.

(6) Front side frame front upper sur-

face 14´16 mm (0.55´0.63 in)

dia. oblong hole

(7) Side frame of front side frame 12

mm (0.47 in) dia.

(8) Headlight attaching hole at radia-

tor side panel 6.2´9 mm (0.244

´0.35 in) dia.

(9) Radiator panel side (LWR)

gauge hole 23 mm (0.91 in) dia.(23) Rear strut mount attaching hole

(Side) 10 mm (0.39 in) dia.

(24) Rear strut mount attaching hole

(Center) 12 mm (0.47 in) (0.244

´0.35 in) dia.

(25) Radiator panel (UPR) middle

hole 6 mm (0.24 in) dia.

(26) Front fender attaching hole at

radiator panel side M6

(27) Front fender attaching hole at

front pillar lower portion M6

(28) Hinge middle hole at front pillar

center 10 mm (0.39 in) dia.

(29) Front fender attaching hole at

front pillar center portion M6

(30) Retainer attaching square hole

at front pillar 7´7 mm (0.28´

0.28 in)

(31) Retainer attaching hole at center

pillar (Front) 3.5 mm (0.138 in)

dia.(32) Retainer attaching hole at center

pillar (Rear) 3.5 mm (0.138 in)

dia.

(33) Lower side of rear door hinge

M8

(34) Center pillar (LWR) gauge hole

27 mm (1.06 in) dia.

(35) Rear quarter outer corner patch

attaching hole 5.2 mm (0.205 in)

dia.

(39) Front rail center notch

(40) Front glass upper locating notch

RH: 6.5 mm (0.256 in) dia., LH:

6.5´10 mm (0.256´0.39 in)

dia. oblong hole

(41) Stud bolt lower locating notch

(48) Front center of rear floor pan 8

mm (0.31 in) dia.

(51) Front upper pillar (Inner) 7 mm

(0.28 in) dia.

3

[S2A0]5-1SPECIFICATIONS AND SERVICE DATA

2. Body Datum Points

Page 1027 of 1456

(52) Front seat belt adjust plate

attaching hole 12 mm (0.47 in)

dia.

(53) Rear door hinge middle hole 10

mm (0.39 in) dia.(54) Rear floor, near door 8 mm (0.31

in) dia.

(55) Trim upper attaching hole at 6

light 8 mm (0.31 in) dia.(56) Trim lower attaching hole at 6

light 8 mm (0.31 in) dia.

(58) Rear floor, near floor strut 15´

20 mm (0.59´0.79 in) dia.

oblong hole

4

5-1[S2A0]SPECIFICATIONS AND SERVICE DATA

2. Body Datum Points