specifications SUBARU LEGACY 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 537 of 1456

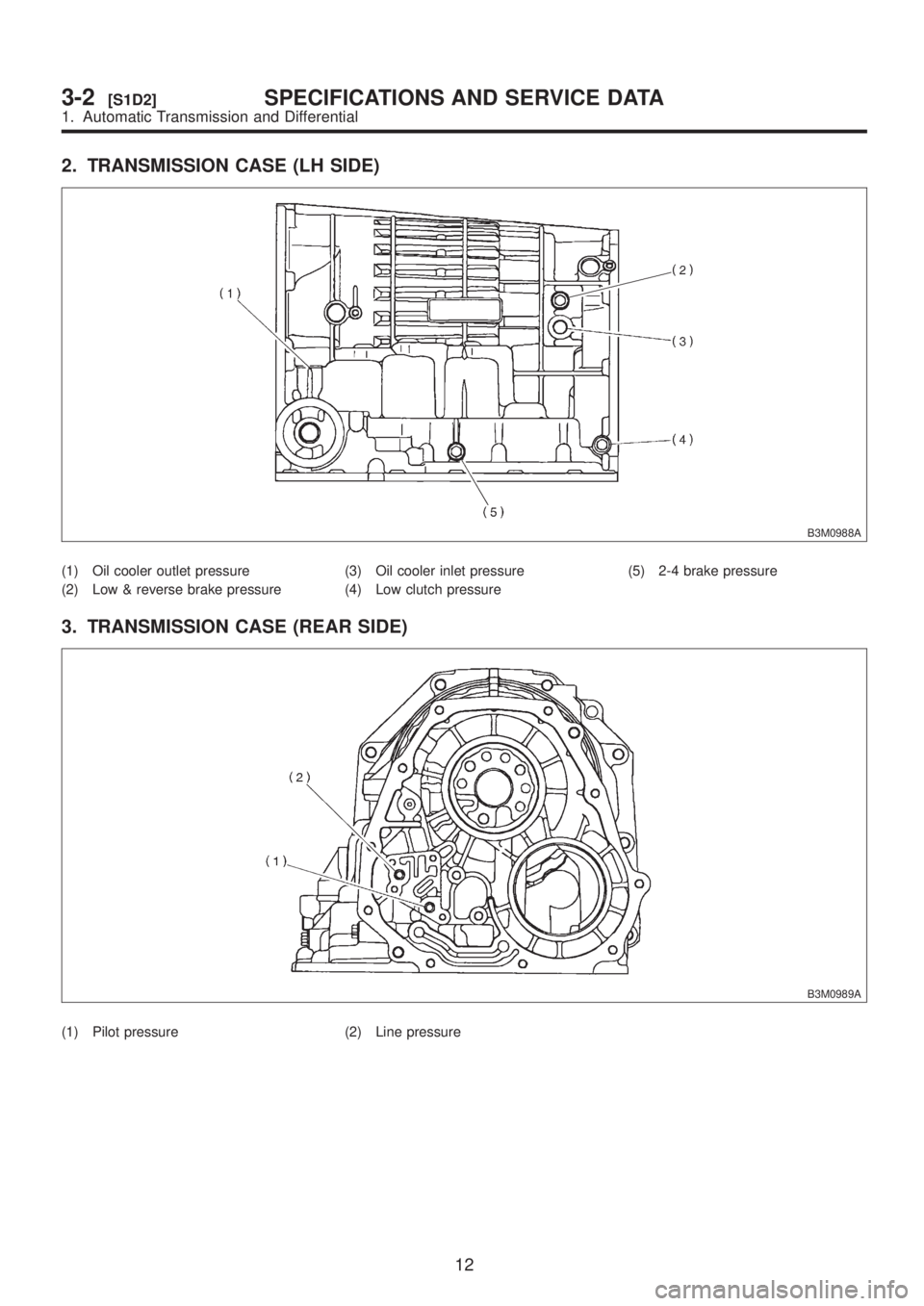

2. TRANSMISSION CASE (LH SIDE)

B3M0988A

(1) Oil cooler outlet pressure

(2) Low & reverse brake pressure(3) Oil cooler inlet pressure

(4) Low clutch pressure(5) 2-4 brake pressure

3. TRANSMISSION CASE (REAR SIDE)

B3M0989A

(1) Pilot pressure (2) Line pressure

12

3-2[S1D2]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 538 of 1456

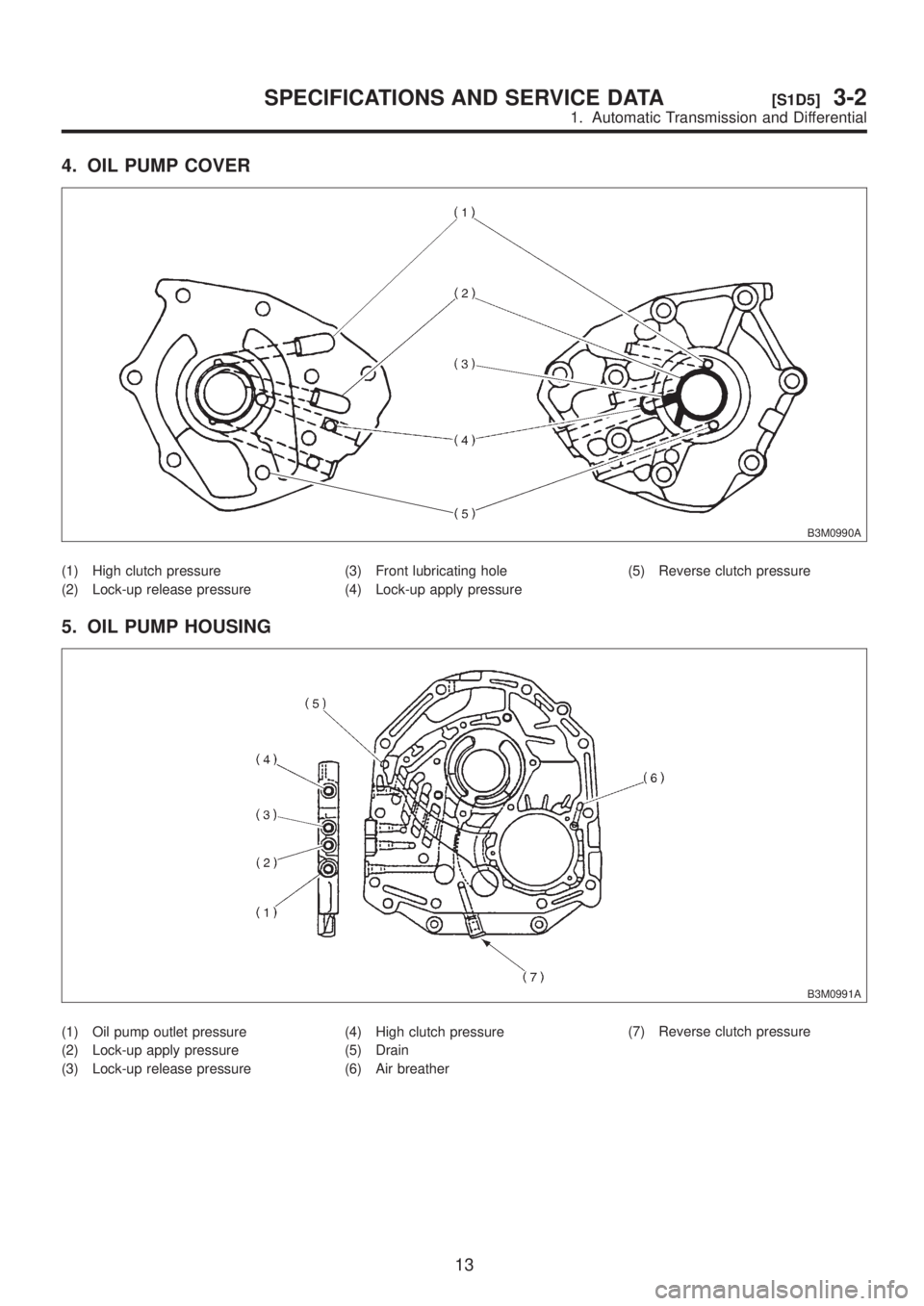

4. OIL PUMP COVER

B3M0990A

(1) High clutch pressure

(2) Lock-up release pressure(3) Front lubricating hole

(4) Lock-up apply pressure(5) Reverse clutch pressure

5. OIL PUMP HOUSING

B3M0991A

(1) Oil pump outlet pressure

(2) Lock-up apply pressure

(3) Lock-up release pressure(4) High clutch pressure

(5) Drain

(6) Air breather(7) Reverse clutch pressure

13

[S1D5]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 539 of 1456

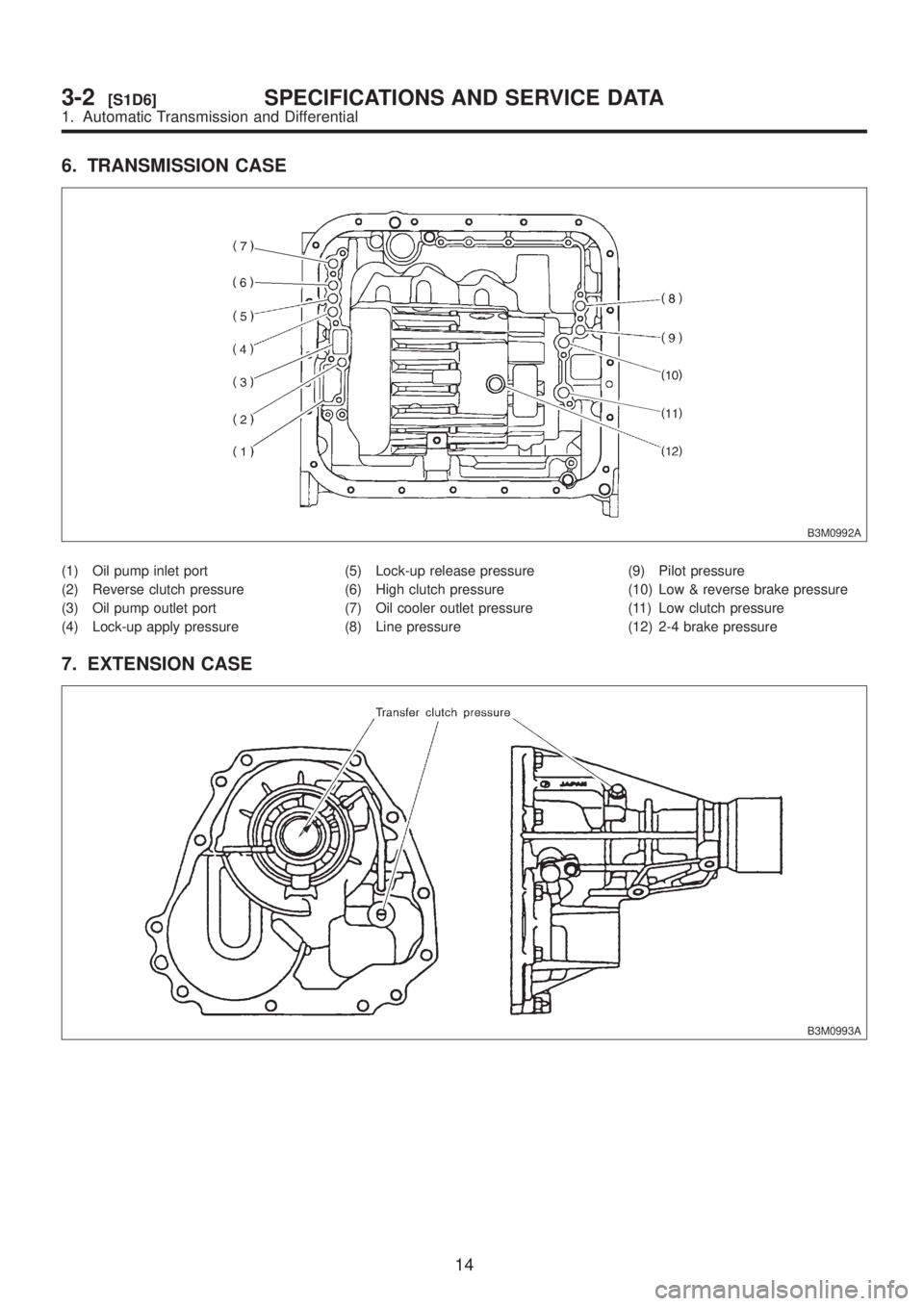

6. TRANSMISSION CASE

B3M0992A

(1) Oil pump inlet port

(2) Reverse clutch pressure

(3) Oil pump outlet port

(4) Lock-up apply pressure(5) Lock-up release pressure

(6) High clutch pressure

(7) Oil cooler outlet pressure

(8) Line pressure(9) Pilot pressure

(10) Low & reverse brake pressure

(11) Low clutch pressure

(12) 2-4 brake pressure

7. EXTENSION CASE

B3M0993A

14

3-2[S1D6]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 570 of 1456

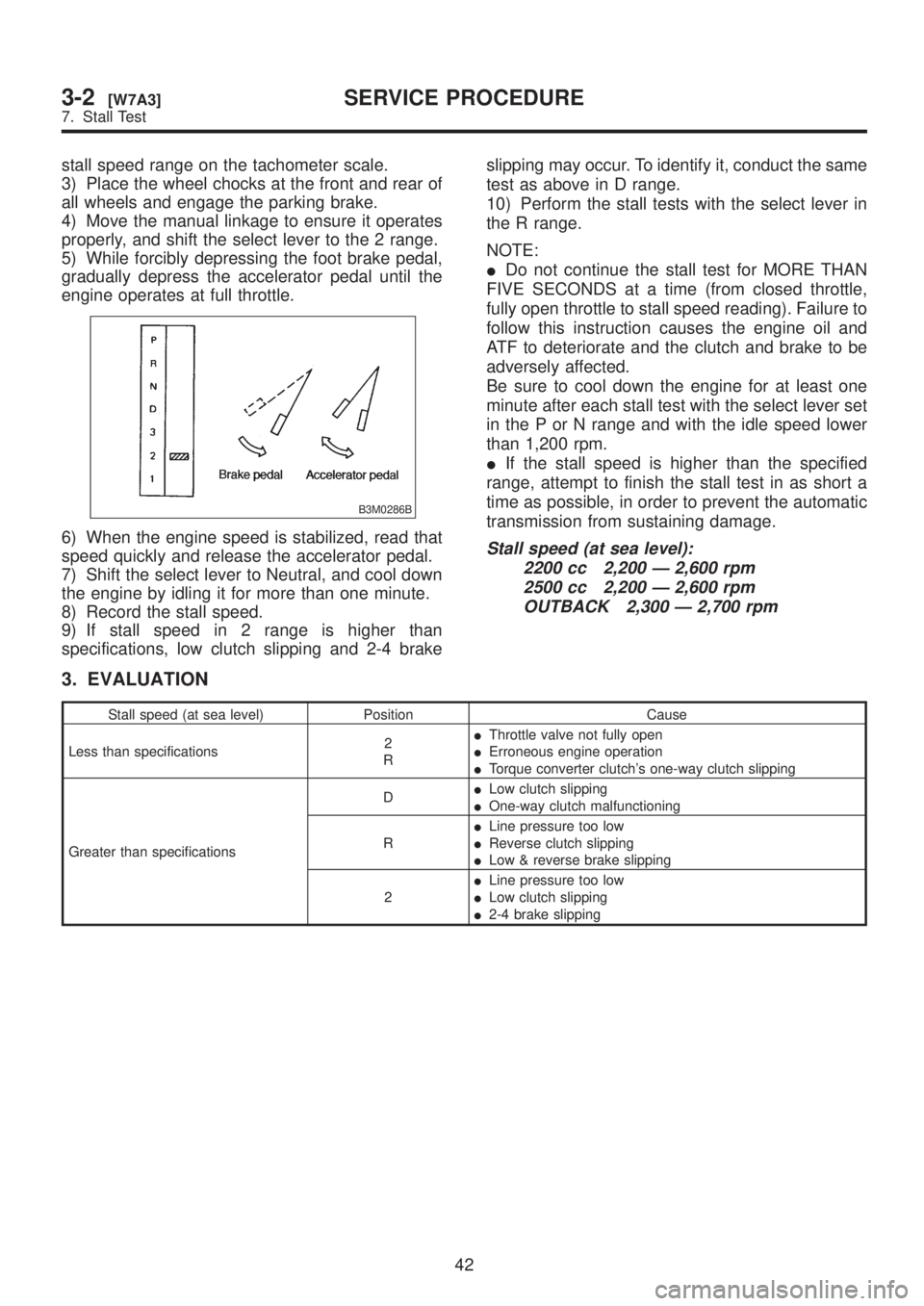

stall speed range on the tachometer scale.

3) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

4) Move the manual linkage to ensure it operates

properly, and shift the select lever to the 2 range.

5) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

B3M0286B

6) When the engine speed is stabilized, read that

speed quickly and release the accelerator pedal.

7) Shift the select lever to Neutral, and cool down

the engine by idling it for more than one minute.

8) Record the stall speed.

9) If stall speed in 2 range is higher than

specifications, low clutch slipping and 2-4 brakeslipping may occur. To identify it, conduct the same

test as above in D range.

10) Perform the stall tests with the select lever in

the R range.

NOTE:

IDo not continue the stall test for MORE THAN

FIVE SECONDS at a time (from closed throttle,

fully open throttle to stall speed reading). Failure to

follow this instruction causes the engine oil and

ATF to deteriorate and the clutch and brake to be

adversely affected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the P or N range and with the idle speed lower

than 1,200 rpm.

IIf the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.Stall speed (at sea level):

2200 cc 2,200 Ð 2,600 rpm

2500 cc 2,200 Ð 2,600 rpm

OUTBACK 2,300 Ð 2,700 rpm

3. EVALUATION

Stall speed (at sea level) Position Cause

Less than specifications2

RIThrottle valve not fully open

IErroneous engine operation

ITorque converter clutch's one-way clutch slipping

Greater than specificationsDILow clutch slipping

IOne-way clutch malfunctioning

RILine pressure too low

IReverse clutch slipping

ILow & reverse brake slipping

2ILine pressure too low

ILow clutch slipping

I2-4 brake slipping

42

3-2[W7A3]SERVICE PROCEDURE

7. Stall Test

Page 600 of 1456

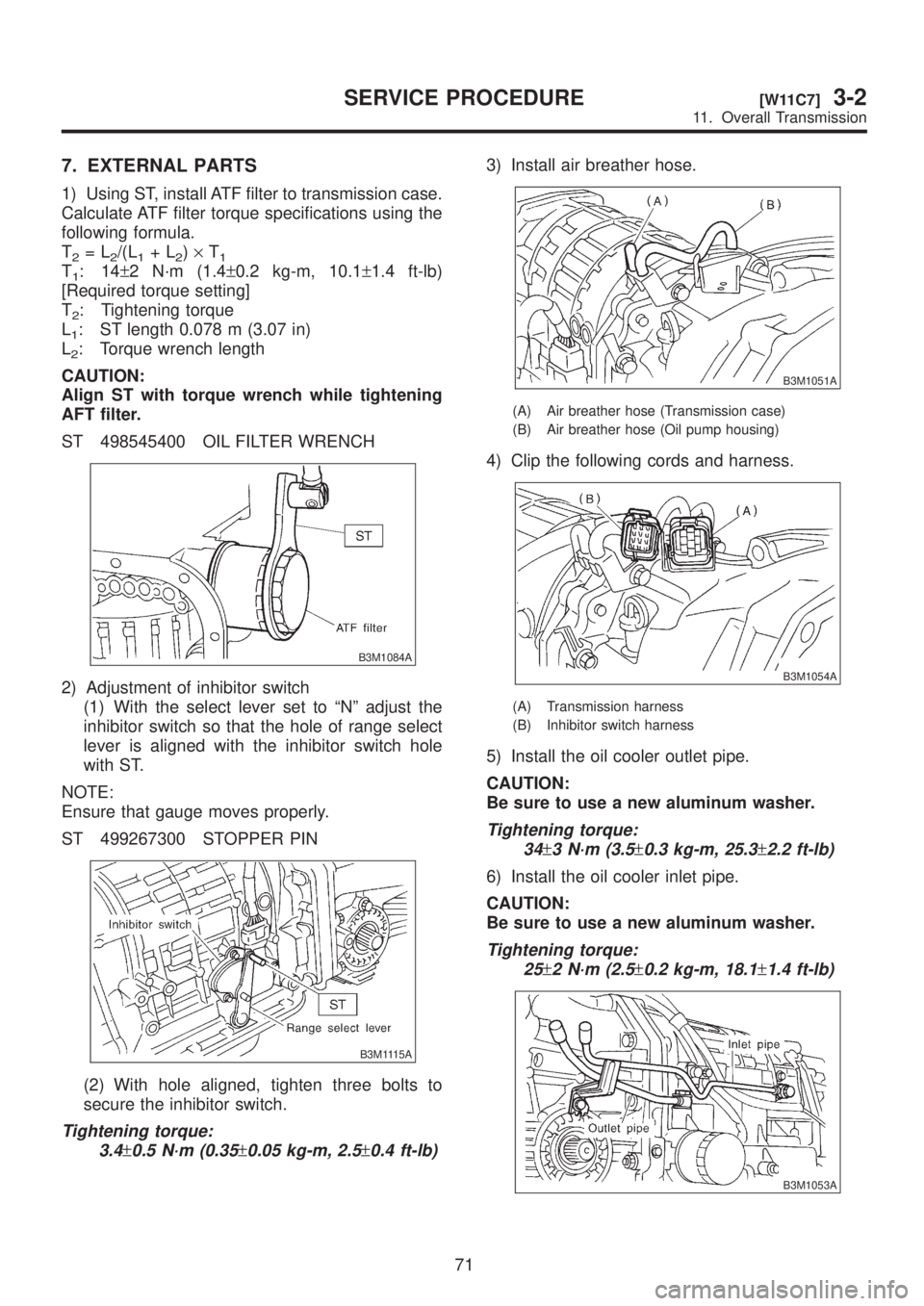

7. EXTERNAL PARTS

1) Using ST, install ATF filter to transmission case.

Calculate ATF filter torque specifications using the

following formula.

T

2=L2/(L1+L2)´T1T1:14±2 N´m (1.4±0.2 kg-m, 10.1±1.4 ft-lb)

[Required torque setting]

T

2: Tightening torque

L

1: ST length 0.078 m (3.07 in)

L

2: Torque wrench length

CAUTION:

Align ST with torque wrench while tightening

AFT filter.

ST 498545400 OIL FILTER WRENCH

B3M1084A

2) Adjustment of inhibitor switch

(1) With the select lever set to ªNº adjust the

inhibitor switch so that the hole of range select

lever is aligned with the inhibitor switch hole

with ST.

NOTE:

Ensure that gauge moves properly.

ST 499267300 STOPPER PIN

B3M1115A

(2) With hole aligned, tighten three bolts to

secure the inhibitor switch.

Tightening torque:

3.4

±0.5 N´m (0.35±0.05 kg-m, 2.5±0.4 ft-lb)

3) Install air breather hose.

B3M1051A

(A) Air breather hose (Transmission case)

(B) Air breather hose (Oil pump housing)

4) Clip the following cords and harness.

B3M1054A

(A) Transmission harness

(B) Inhibitor switch harness

5) Install the oil cooler outlet pipe.

CAUTION:

Be sure to use a new aluminum washer.

Tightening torque:

34

±3 N´m (3.5±0.3 kg-m, 25.3±2.2 ft-lb)

6) Install the oil cooler inlet pipe.

CAUTION:

Be sure to use a new aluminum washer.

Tightening torque:

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

B3M1053A

71

[W11C7]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 605 of 1456

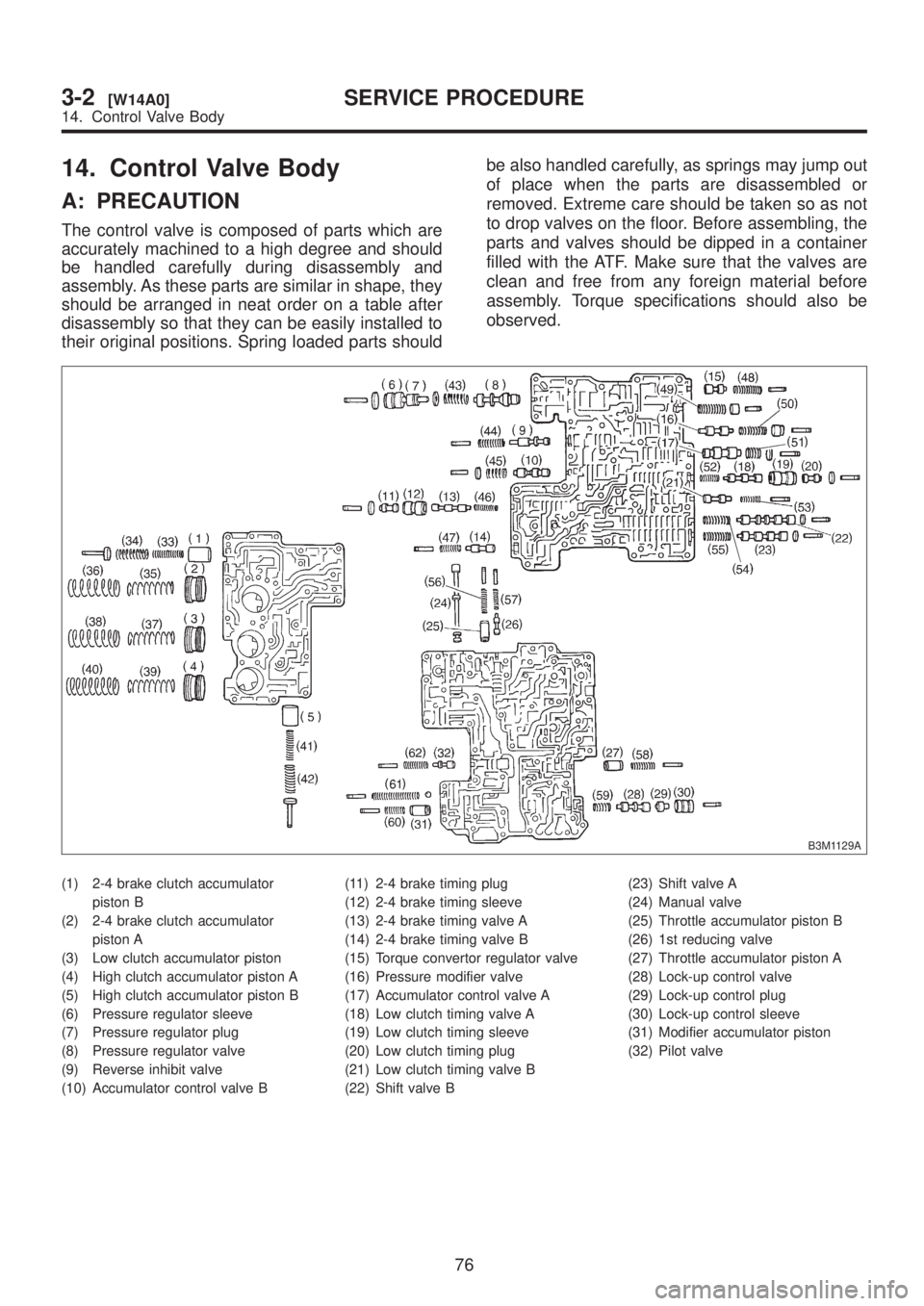

14. Control Valve Body

A: PRECAUTION

The control valve is composed of parts which are

accurately machined to a high degree and should

be handled carefully during disassembly and

assembly. As these parts are similar in shape, they

should be arranged in neat order on a table after

disassembly so that they can be easily installed to

their original positions. Spring loaded parts shouldbe also handled carefully, as springs may jump out

of place when the parts are disassembled or

removed. Extreme care should be taken so as not

to drop valves on the floor. Before assembling, the

parts and valves should be dipped in a container

filled with the ATF. Make sure that the valves are

clean and free from any foreign material before

assembly. Torque specifications should also be

observed.

B3M1129A

(1) 2-4 brake clutch accumulator

piston B

(2) 2-4 brake clutch accumulator

piston A

(3) Low clutch accumulator piston

(4) High clutch accumulator piston A

(5) High clutch accumulator piston B

(6) Pressure regulator sleeve

(7) Pressure regulator plug

(8) Pressure regulator valve

(9) Reverse inhibit valve

(10) Accumulator control valve B(11) 2-4 brake timing plug

(12) 2-4 brake timing sleeve

(13) 2-4 brake timing valve A

(14) 2-4 brake timing valve B

(15) Torque convertor regulator valve

(16) Pressure modifier valve

(17) Accumulator control valve A

(18) Low clutch timing valve A

(19) Low clutch timing sleeve

(20) Low clutch timing plug

(21) Low clutch timing valve B

(22) Shift valve B(23) Shift valve A

(24) Manual valve

(25) Throttle accumulator piston B

(26) 1st reducing valve

(27) Throttle accumulator piston A

(28) Lock-up control valve

(29) Lock-up control plug

(30) Lock-up control sleeve

(31) Modifier accumulator piston

(32) Pilot valve

76

3-2[W14A0]SERVICE PROCEDURE

14. Control Valve Body

Page 611 of 1456

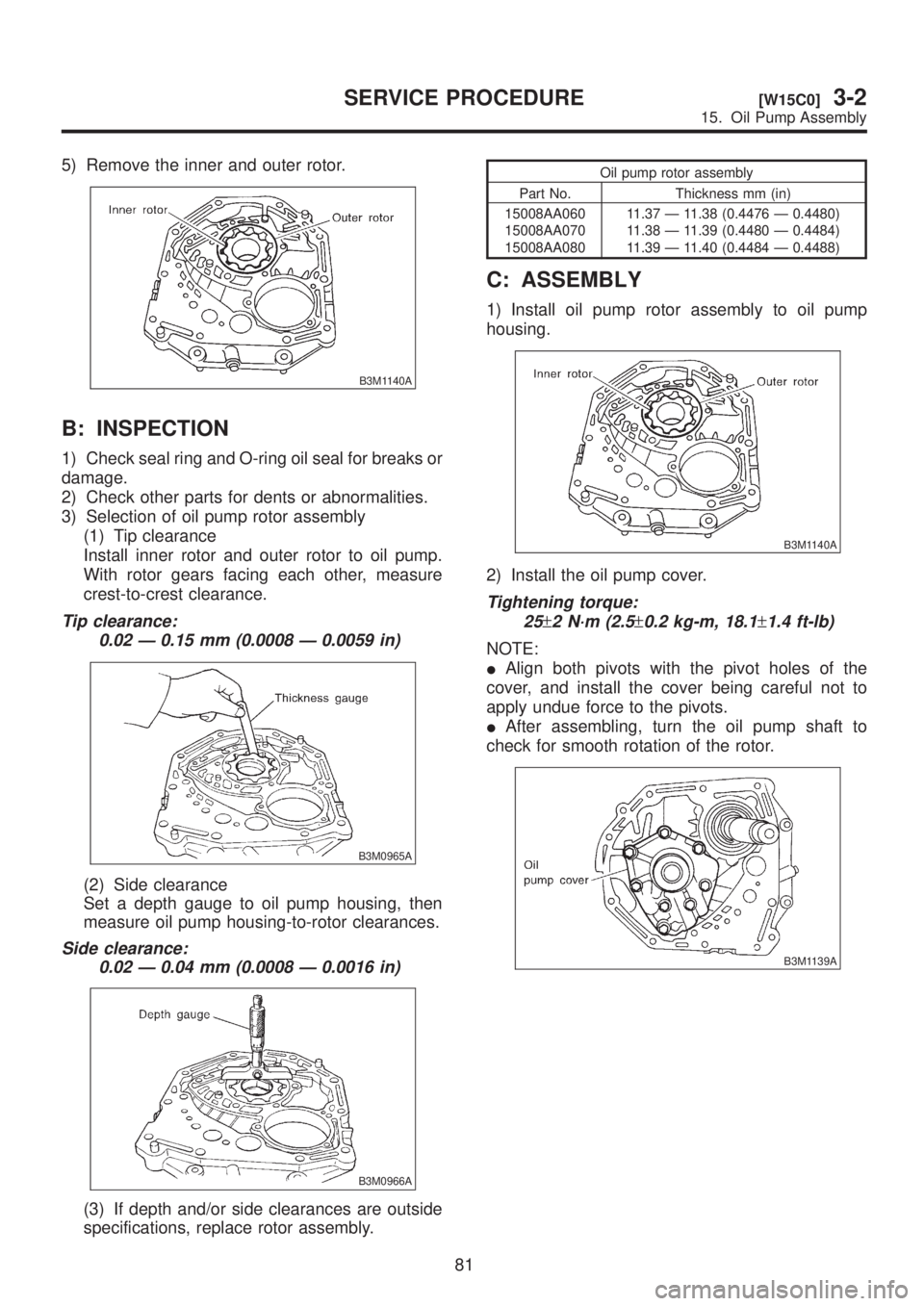

5) Remove the inner and outer rotor.

B3M1140A

B: INSPECTION

1) Check seal ring and O-ring oil seal for breaks or

damage.

2) Check other parts for dents or abnormalities.

3) Selection of oil pump rotor assembly

(1) Tip clearance

Install inner rotor and outer rotor to oil pump.

With rotor gears facing each other, measure

crest-to-crest clearance.

Tip clearance:

0.02 Ð 0.15 mm (0.0008 Ð 0.0059 in)

B3M0965A

(2) Side clearance

Set a depth gauge to oil pump housing, then

measure oil pump housing-to-rotor clearances.

Side clearance:

0.02 Ð 0.04 mm (0.0008 Ð 0.0016 in)

B3M0966A

(3) If depth and/or side clearances are outside

specifications, replace rotor assembly.

Oil pump rotor assembly

Part No. Thickness mm (in)

15008AA060

15008AA070

15008AA08011.37 Ð 11.38 (0.4476 Ð 0.4480)

11.38 Ð 11.39 (0.4480 Ð 0.4484)

11.39 Ð 11.40 (0.4484 Ð 0.4488)

C: ASSEMBLY

1) Install oil pump rotor assembly to oil pump

housing.

B3M1140A

2) Install the oil pump cover.

Tightening torque:

25

±2 N´m (2.5±0.2 kg-m, 18.1±1.4 ft-lb)

NOTE:

IAlign both pivots with the pivot holes of the

cover, and install the cover being careful not to

apply undue force to the pivots.

IAfter assembling, turn the oil pump shaft to

check for smooth rotation of the rotor.

B3M1139A

81

[W15C0]3-2SERVICE PROCEDURE

15. Oil Pump Assembly

Page 651 of 1456

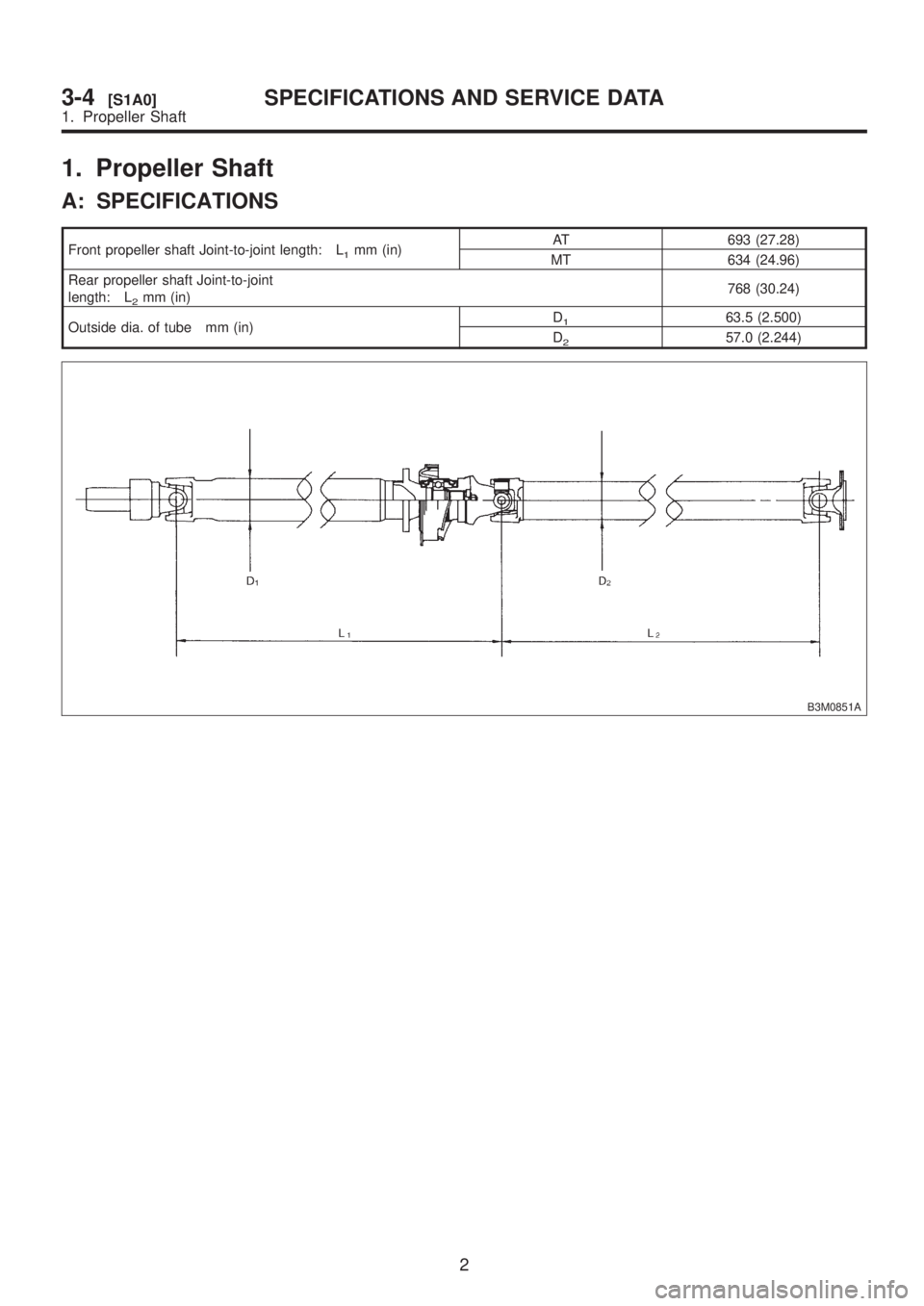

1. Propeller Shaft

A: SPECIFICATIONS

Front propeller shaft Joint-to-joint length: L1mm (in)AT 693 (27.28)

MT 634 (24.96)

Rear propeller shaft Joint-to-joint

length: L

2mm (in)768 (30.24)

Outside dia. of tube mm (in)D

163.5 (2.500)

D

257.0 (2.244)

B3M0851A

2

3-4[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Propeller Shaft

Page 652 of 1456

2. Rear Differential

A: SPECIFICATIONS

Type of gearHypoid

MT AT

2200 cc 2500 cc 2200 cc 2500 cc

Gear ratio (Number of gear teeth) 3.900 (39/10) 4.111 (37/9) 4.111 (37/9) 4.444 (40/9)

Oil capacity 0.8(0.8 US qt, 0.7 Imp qt)

Rear differential gear oil GL-5

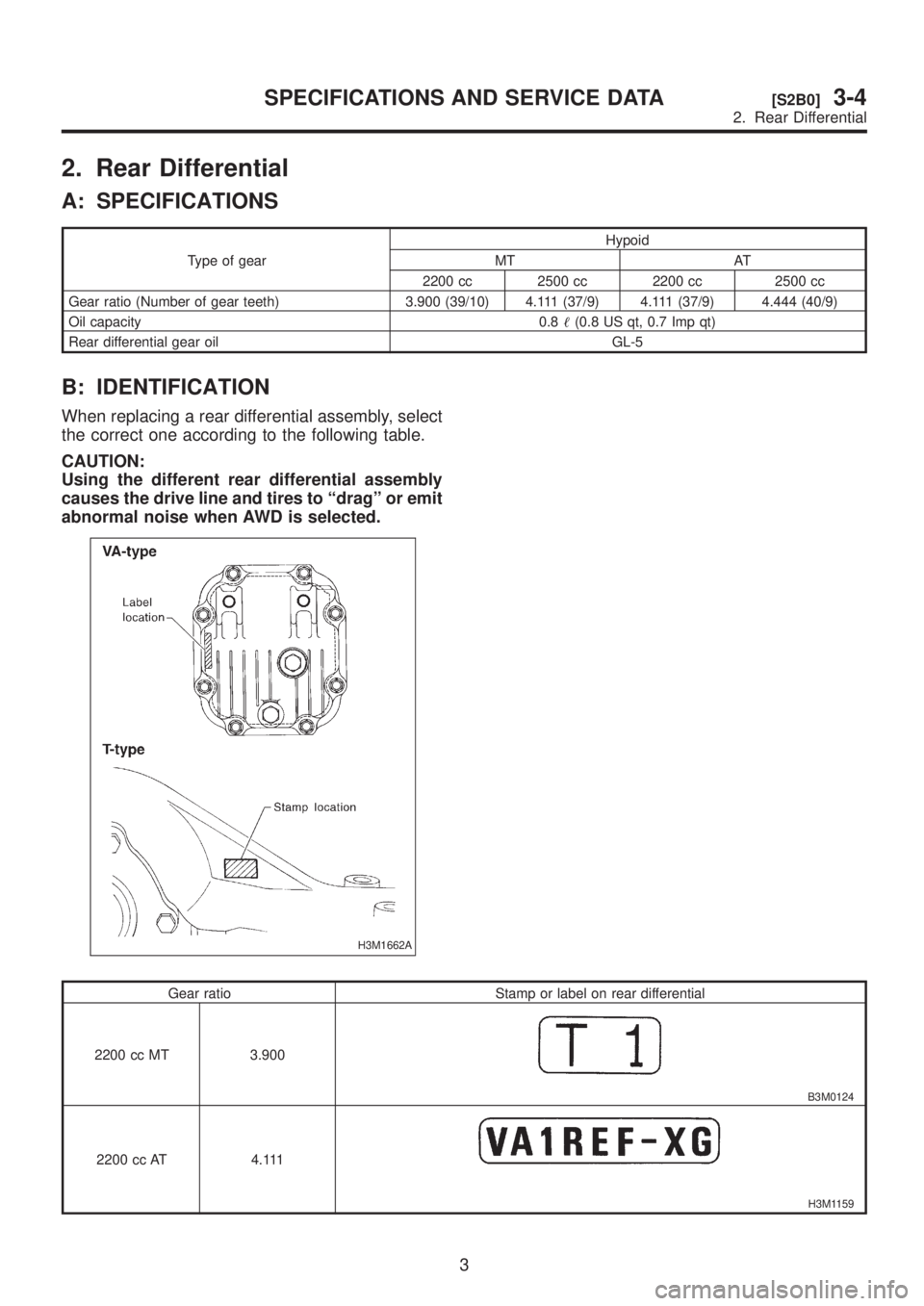

B: IDENTIFICATION

When replacing a rear differential assembly, select

the correct one according to the following table.

CAUTION:

Using the different rear differential assembly

causes the drive line and tires to ªdragº or emit

abnormal noise when AWD is selected.

H3M1662A

Gear ratio Stamp or label on rear differential

2200 cc MT 3.900

B3M0124

2200 cc AT 4.111

H3M1159

3

[S2B0]3-4SPECIFICATIONS AND SERVICE DATA

2. Rear Differential

Page 653 of 1456

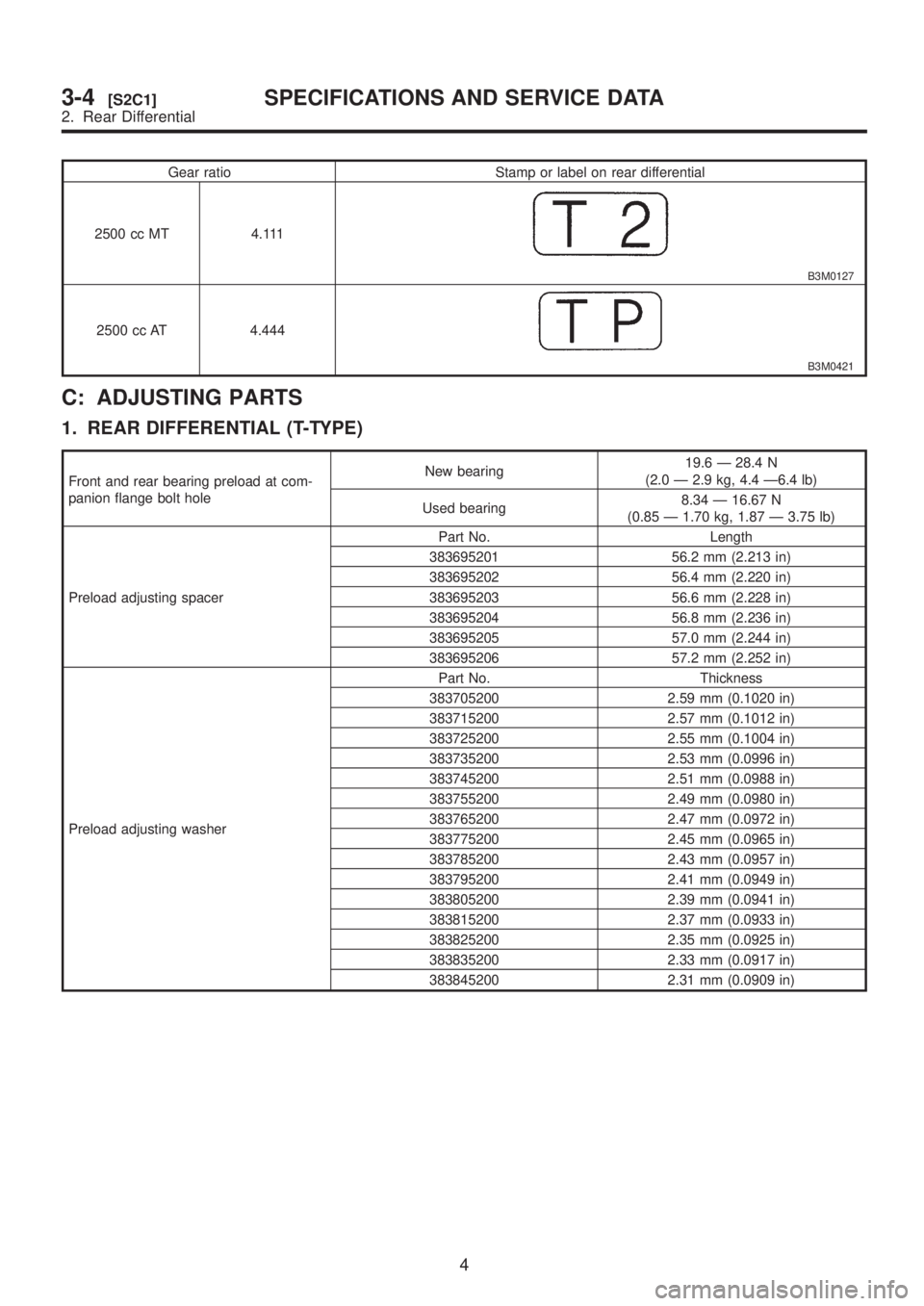

Gear ratio Stamp or label on rear differential

2500 cc MT 4.111

B3M0127

2500 cc AT 4.444

B3M0421

C: ADJUSTING PARTS

1. REAR DIFFERENTIAL (T-TYPE)

Front and rear bearing preload at com-

panion flange bolt holeNew bearing19.6 Ð 28.4 N

(2.0 Ð 2.9 kg, 4.4 Ð6.4 lb)

Used bearing8.34 Ð 16.67 N

(0.85 Ð 1.70 kg, 1.87 Ð 3.75 lb)

Preload adjusting spacerPart No. Length

383695201 56.2 mm (2.213 in)

383695202 56.4 mm (2.220 in)

383695203 56.6 mm (2.228 in)

383695204 56.8 mm (2.236 in)

383695205 57.0 mm (2.244 in)

383695206 57.2 mm (2.252 in)

Preload adjusting washerPart No. Thickness

383705200 2.59 mm (0.1020 in)

383715200 2.57 mm (0.1012 in)

383725200 2.55 mm (0.1004 in)

383735200 2.53 mm (0.0996 in)

383745200 2.51 mm (0.0988 in)

383755200 2.49 mm (0.0980 in)

383765200 2.47 mm (0.0972 in)

383775200 2.45 mm (0.0965 in)

383785200 2.43 mm (0.0957 in)

383795200 2.41 mm (0.0949 in)

383805200 2.39 mm (0.0941 in)

383815200 2.37 mm (0.0933 in)

383825200 2.35 mm (0.0925 in)

383835200 2.33 mm (0.0917 in)

383845200 2.31 mm (0.0909 in)

4

3-4[S2C1]SPECIFICATIONS AND SERVICE DATA

2. Rear Differential