compressor SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 592 of 1456

Available retaining plates

Part No. Thickness mm (in)

31667AA320

31667AA330

31667AA340

31667AA350

31667AA360

31667AA370

31667AA3804.2 (0.165)

4.5 (0.177)

4.8 (0.189)

5.1 (0.201)

5.4 (0.213)

5.7 (0.224)

6.0 (0.236)

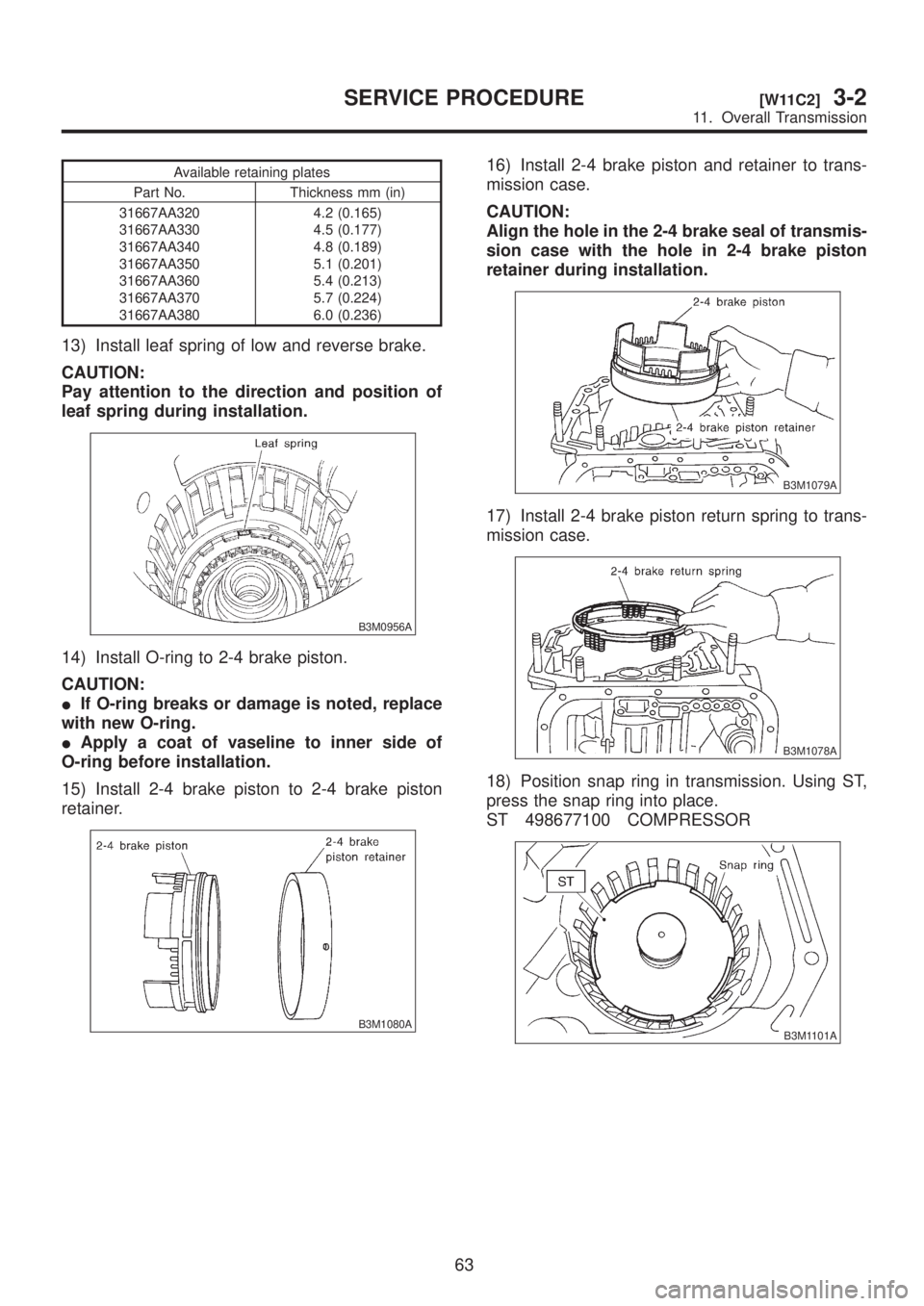

13) Install leaf spring of low and reverse brake.

CAUTION:

Pay attention to the direction and position of

leaf spring during installation.

B3M0956A

14) Install O-ring to 2-4 brake piston.

CAUTION:

IIf O-ring breaks or damage is noted, replace

with new O-ring.

IApply a coat of vaseline to inner side of

O-ring before installation.

15) Install 2-4 brake piston to 2-4 brake piston

retainer.

B3M1080A

16) Install 2-4 brake piston and retainer to trans-

mission case.

CAUTION:

Align the hole in the 2-4 brake seal of transmis-

sion case with the hole in 2-4 brake piston

retainer during installation.

B3M1079A

17) Install 2-4 brake piston return spring to trans-

mission case.

B3M1078A

18) Position snap ring in transmission. Using ST,

press the snap ring into place.

ST 498677100 COMPRESSOR

B3M1101A

63

[W11C2]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 607 of 1456

B: DISASSEMBLY

1) Remove oil strainer from lower control valve

body.

B3M1038A

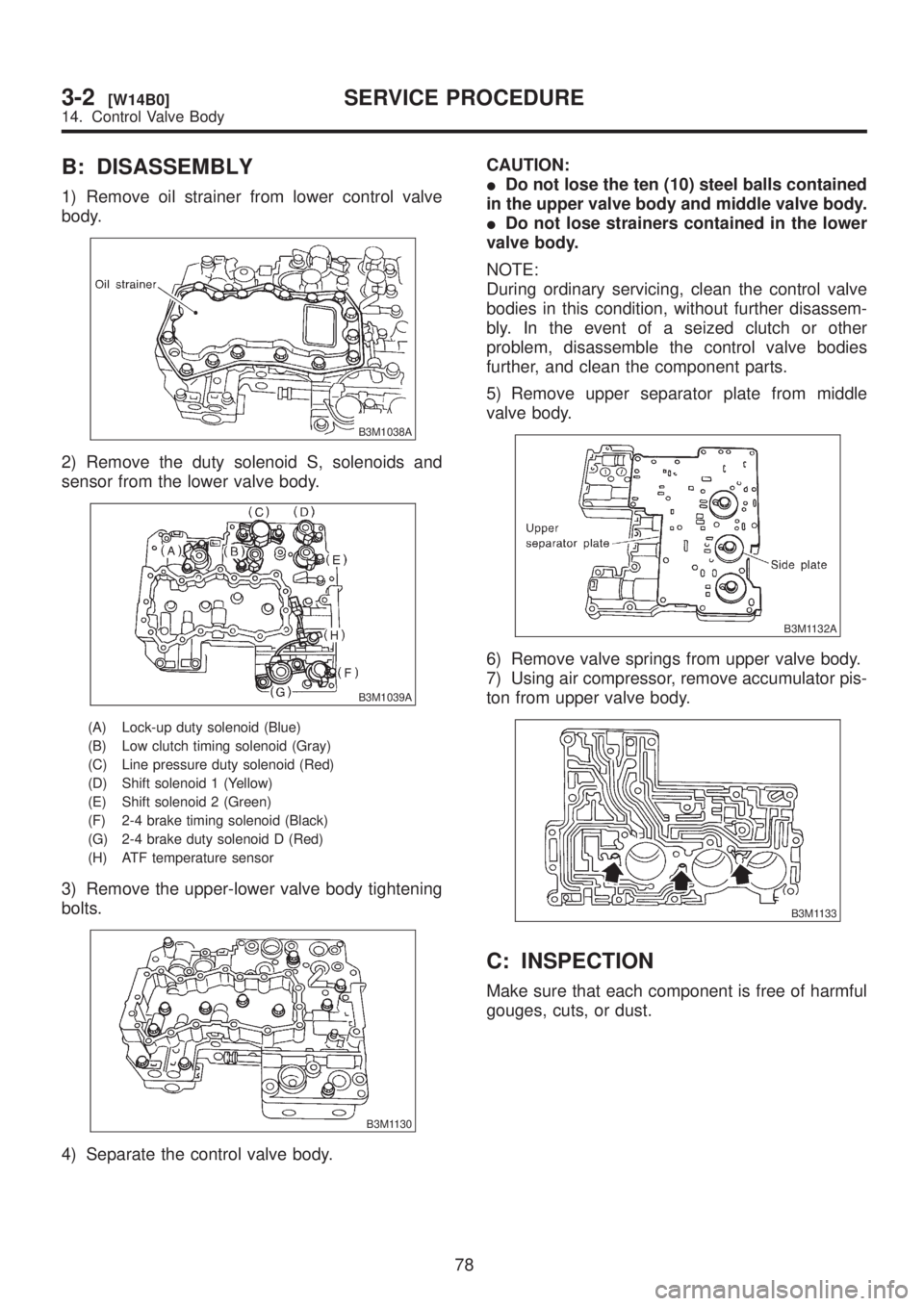

2) Remove the duty solenoid S, solenoids and

sensor from the lower valve body.

B3M1039A

(A) Lock-up duty solenoid (Blue)

(B) Low clutch timing solenoid (Gray)

(C) Line pressure duty solenoid (Red)

(D) Shift solenoid 1 (Yellow)

(E) Shift solenoid 2 (Green)

(F) 2-4 brake timing solenoid (Black)

(G) 2-4 brake duty solenoid D (Red)

(H) ATF temperature sensor

3) Remove the upper-lower valve body tightening

bolts.

B3M1130

4) Separate the control valve body.CAUTION:

IDo not lose the ten (10) steel balls contained

in the upper valve body and middle valve body.

IDo not lose strainers contained in the lower

valve body.

NOTE:

During ordinary servicing, clean the control valve

bodies in this condition, without further disassem-

bly. In the event of a seized clutch or other

problem, disassemble the control valve bodies

further, and clean the component parts.

5) Remove upper separator plate from middle

valve body.

B3M1132A

6) Remove valve springs from upper valve body.

7) Using air compressor, remove accumulator pis-

ton from upper valve body.

B3M1133

C: INSPECTION

Make sure that each component is free of harmful

gouges, cuts, or dust.

78

3-2[W14B0]SERVICE PROCEDURE

14. Control Valve Body

Page 617 of 1456

1) Remove the snap ring, and take out the retain-

ing plate, drive plates, driven plates.

B3M1142A

2) Remove snap ring, and take out the retaining

plate, drive plates and driven plates.

B3M1143A

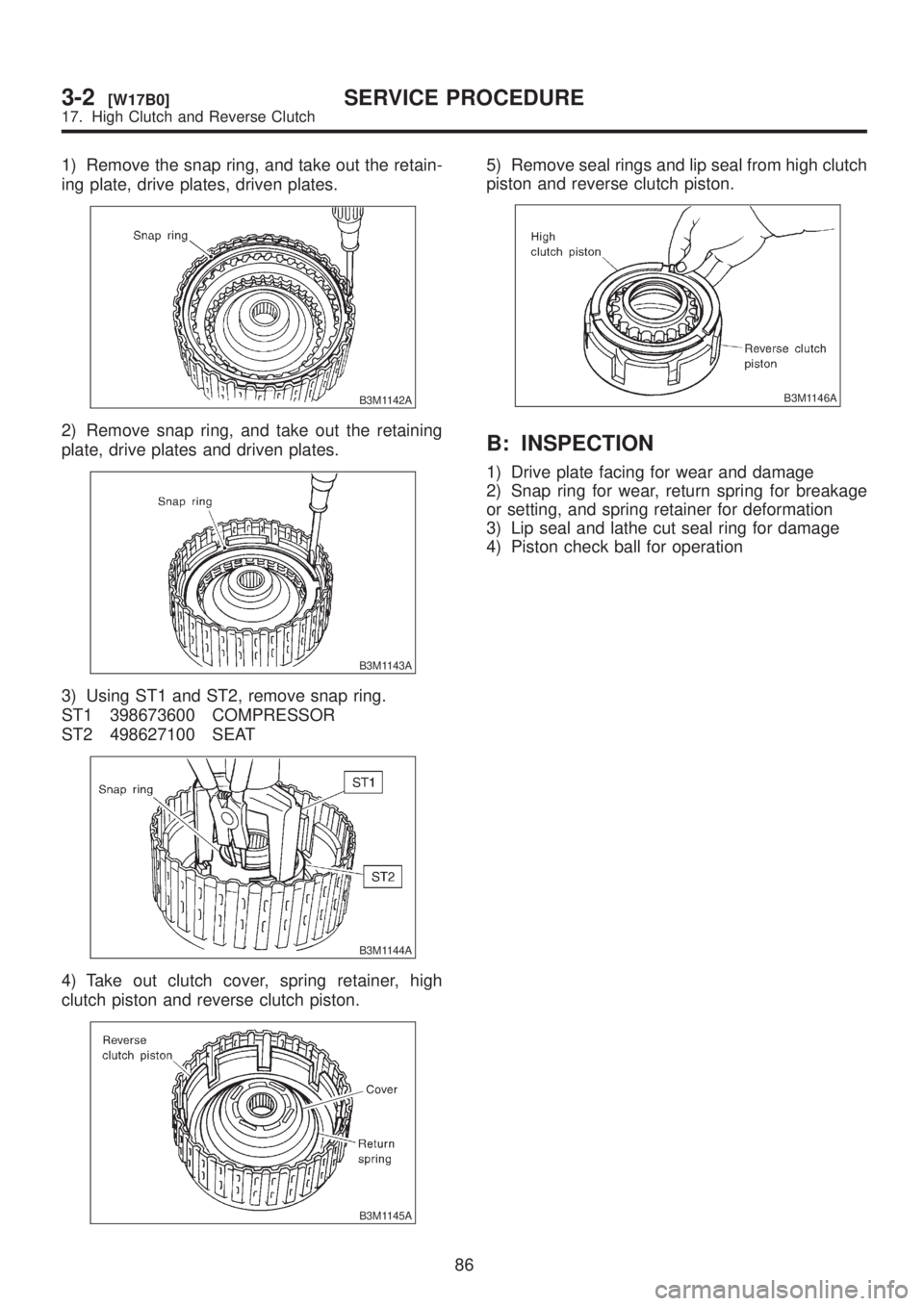

3) Using ST1 and ST2, remove snap ring.

ST1 398673600 COMPRESSOR

ST2 498627100 SEAT

B3M1144A

4) Take out clutch cover, spring retainer, high

clutch piston and reverse clutch piston.

B3M1145A

5) Remove seal rings and lip seal from high clutch

piston and reverse clutch piston.

B3M1146A

B: INSPECTION

1) Drive plate facing for wear and damage

2) Snap ring for wear, return spring for breakage

or setting, and spring retainer for deformation

3) Lip seal and lathe cut seal ring for damage

4) Piston check ball for operation

86

3-2[W17B0]SERVICE PROCEDURE

17. High Clutch and Reverse Clutch

Page 619 of 1456

1) Install seal rings and lip seal to high clutch pis-

ton and reverse clutch piston.

2) Install high clutch piston to reverse clutch pis-

ton.

B3M1146A

3) Install reverse clutch to high clutch drum.

NOTE:

Align the groove on the reverse clutch piston with

the groove on the high clutch drum during installa-

tion.

B3M1148A

4) Install spring retainer to high clutch piston.

B3M1149A

5) Install ST to high clutch piston.

ST 498437000 HIGH CLUTCH PISTON

GAUGE

B3M1150A

6) Install cover to high clutch piston.

CAUTION:

Be careful not to fold over the high clutch pis-

ton seal during installation.

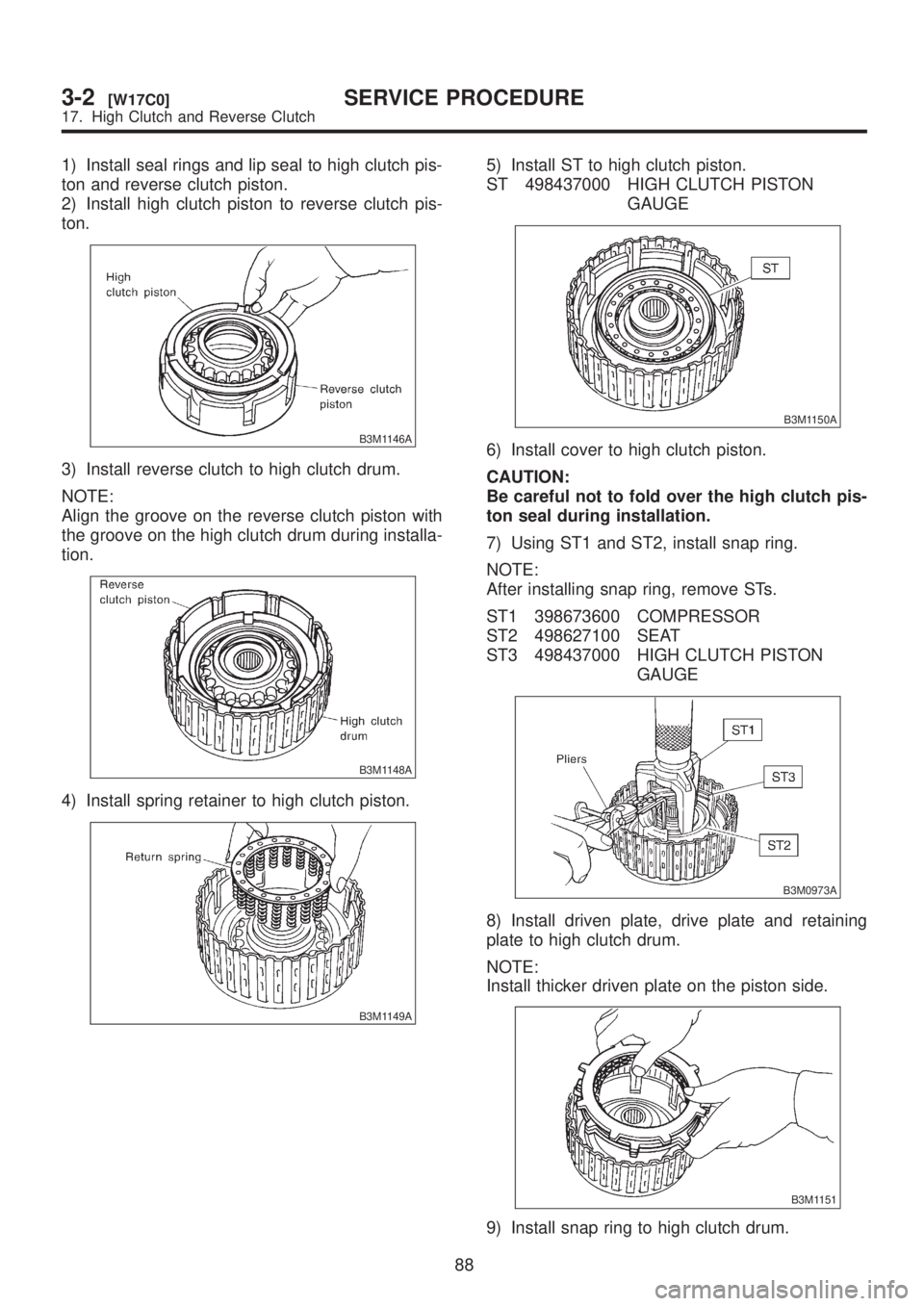

7) Using ST1 and ST2, install snap ring.

NOTE:

After installing snap ring, remove STs.

ST1 398673600 COMPRESSOR

ST2 498627100 SEAT

ST3 498437000 HIGH CLUTCH PISTON

GAUGE

B3M0973A

8) Install driven plate, drive plate and retaining

plate to high clutch drum.

NOTE:

Install thicker driven plate on the piston side.

B3M1151

9) Install snap ring to high clutch drum.

88

3-2[W17C0]SERVICE PROCEDURE

17. High Clutch and Reverse Clutch

Page 623 of 1456

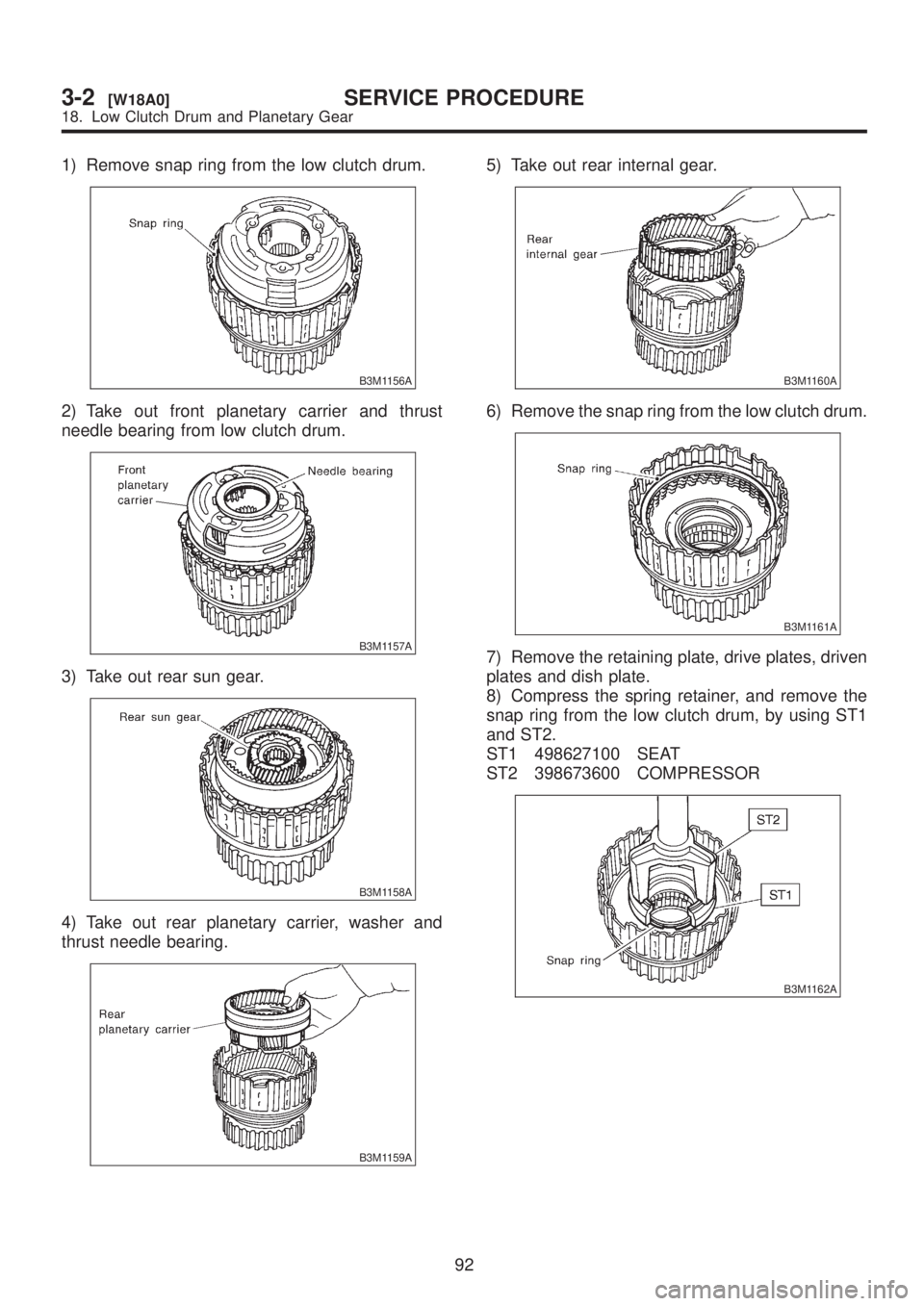

1) Remove snap ring from the low clutch drum.

B3M1156A

2) Take out front planetary carrier and thrust

needle bearing from low clutch drum.

B3M1157A

3) Take out rear sun gear.

B3M1158A

4) Take out rear planetary carrier, washer and

thrust needle bearing.

B3M1159A

5) Take out rear internal gear.

B3M1160A

6) Remove the snap ring from the low clutch drum.

B3M1161A

7) Remove the retaining plate, drive plates, driven

plates and dish plate.

8) Compress the spring retainer, and remove the

snap ring from the low clutch drum, by using ST1

and ST2.

ST1 498627100 SEAT

ST2 398673600 COMPRESSOR

B3M1162A

92

3-2[W18A0]SERVICE PROCEDURE

18. Low Clutch Drum and Planetary Gear

Page 626 of 1456

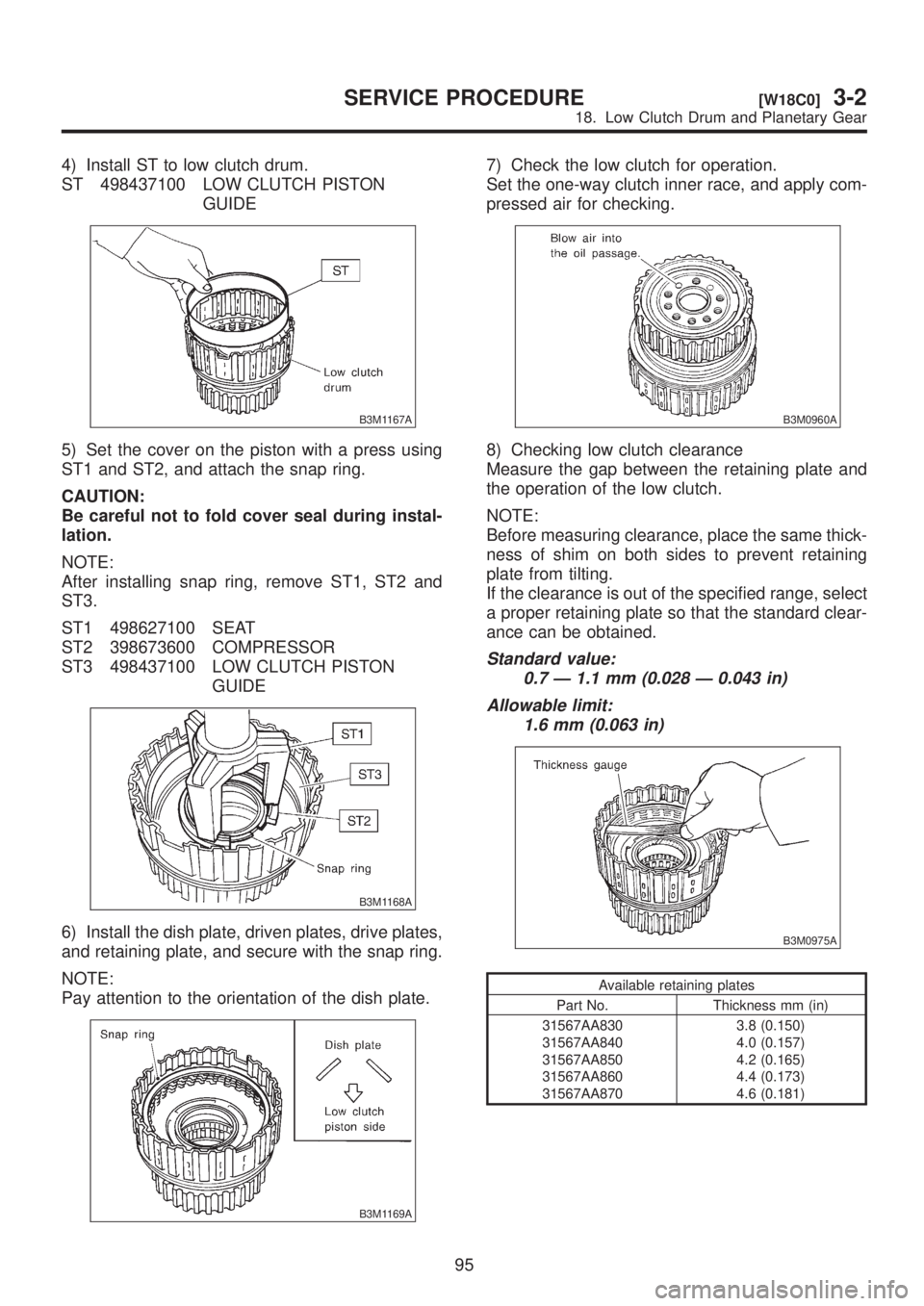

4) Install ST to low clutch drum.

ST 498437100 LOW CLUTCH PISTON

GUIDE

B3M1167A

5) Set the cover on the piston with a press using

ST1 and ST2, and attach the snap ring.

CAUTION:

Be careful not to fold cover seal during instal-

lation.

NOTE:

After installing snap ring, remove ST1, ST2 and

ST3.

ST1 498627100 SEAT

ST2 398673600 COMPRESSOR

ST3 498437100 LOW CLUTCH PISTON

GUIDE

B3M1168A

6) Install the dish plate, driven plates, drive plates,

and retaining plate, and secure with the snap ring.

NOTE:

Pay attention to the orientation of the dish plate.

B3M1169A

7) Check the low clutch for operation.

Set the one-way clutch inner race, and apply com-

pressed air for checking.

B3M0960A

8) Checking low clutch clearance

Measure the gap between the retaining plate and

the operation of the low clutch.

NOTE:

Before measuring clearance, place the same thick-

ness of shim on both sides to prevent retaining

plate from tilting.

If the clearance is out of the specified range, select

a proper retaining plate so that the standard clear-

ance can be obtained.

Standard value:

0.7 Ð 1.1 mm (0.028 Ð 0.043 in)

Allowable limit:

1.6 mm (0.063 in)

B3M0975A

Available retaining plates

Part No. Thickness mm (in)

31567AA830

31567AA840

31567AA850

31567AA860

31567AA8703.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

95

[W18C0]3-2SERVICE PROCEDURE

18. Low Clutch Drum and Planetary Gear

Page 632 of 1456

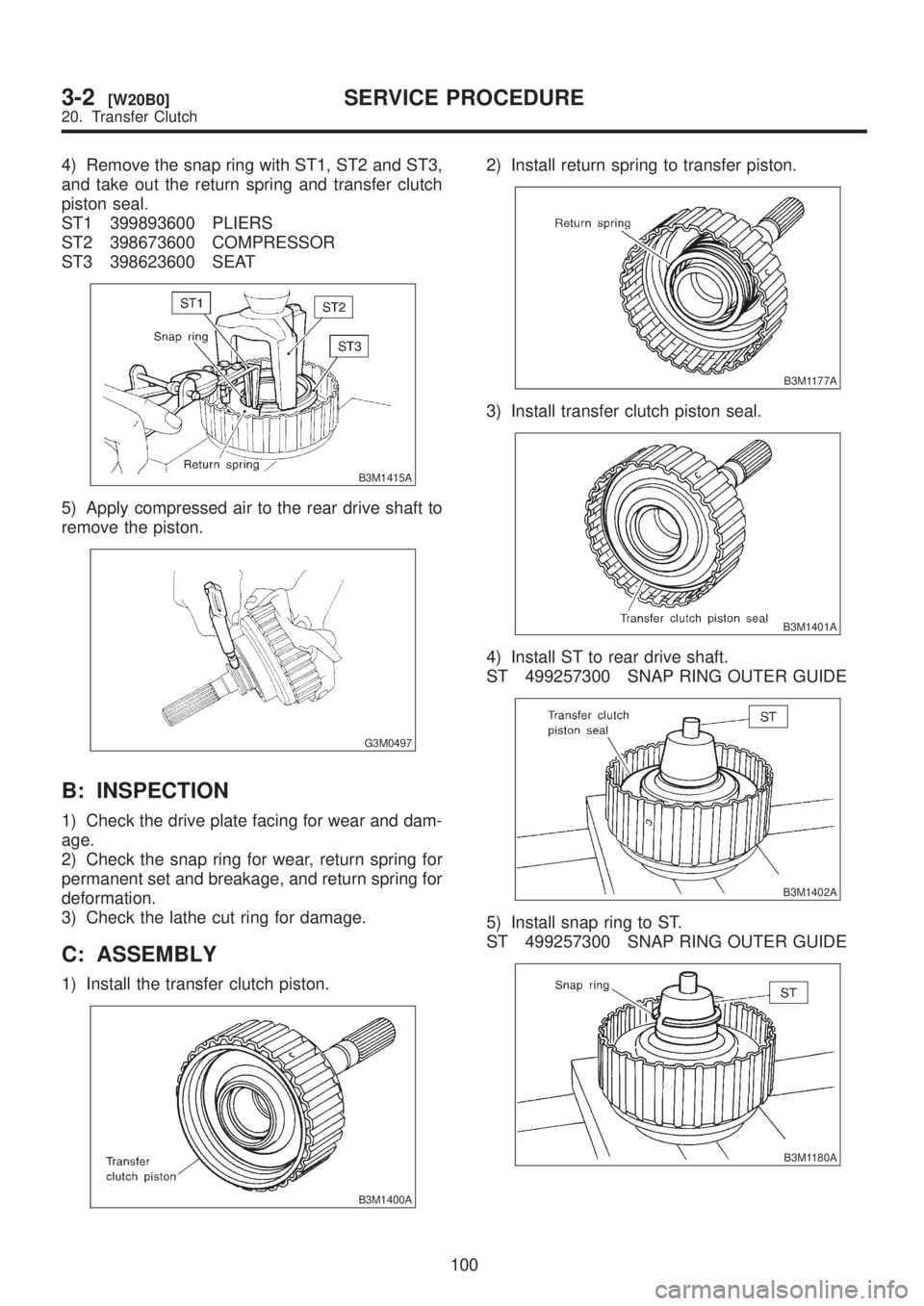

4) Remove the snap ring with ST1, ST2 and ST3,

and take out the return spring and transfer clutch

piston seal.

ST1 399893600 PLIERS

ST2 398673600 COMPRESSOR

ST3 398623600 SEAT

B3M1415A

5) Apply compressed air to the rear drive shaft to

remove the piston.

G3M0497

B: INSPECTION

1) Check the drive plate facing for wear and dam-

age.

2) Check the snap ring for wear, return spring for

permanent set and breakage, and return spring for

deformation.

3) Check the lathe cut ring for damage.

C: ASSEMBLY

1) Install the transfer clutch piston.

B3M1400A

2) Install return spring to transfer piston.

B3M1177A

3) Install transfer clutch piston seal.

B3M1401A

4) Install ST to rear drive shaft.

ST 499257300 SNAP RING OUTER GUIDE

B3M1402A

5) Install snap ring to ST.

ST 499257300 SNAP RING OUTER GUIDE

B3M1180A

100

3-2[W20B0]SERVICE PROCEDURE

20. Transfer Clutch

Page 722 of 1456

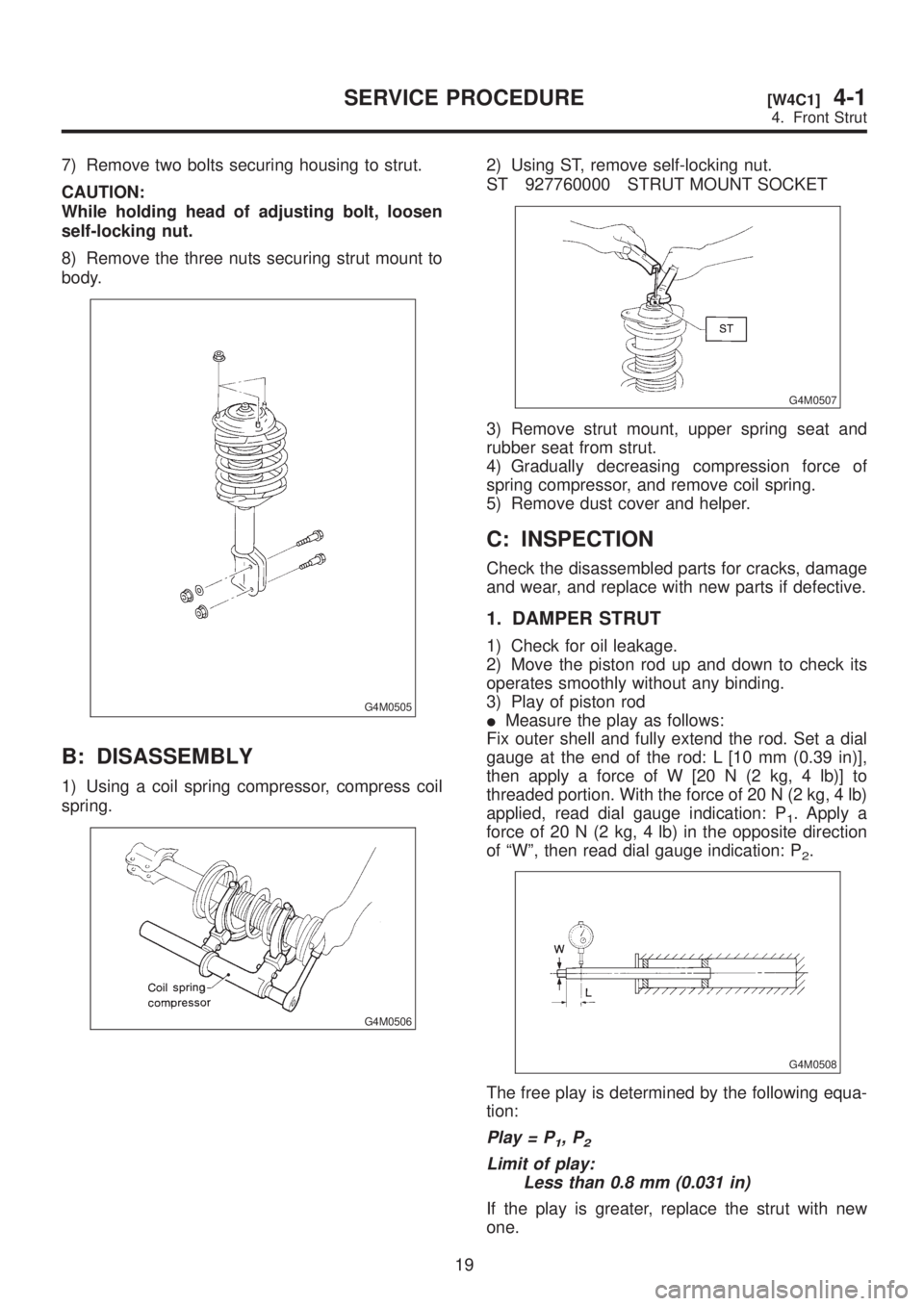

7) Remove two bolts securing housing to strut.

CAUTION:

While holding head of adjusting bolt, loosen

self-locking nut.

8) Remove the three nuts securing strut mount to

body.

G4M0505

B: DISASSEMBLY

1) Using a coil spring compressor, compress coil

spring.

G4M0506

2) Using ST, remove self-locking nut.

ST 927760000 STRUT MOUNT SOCKET

G4M0507

3) Remove strut mount, upper spring seat and

rubber seat from strut.

4) Gradually decreasing compression force of

spring compressor, and remove coil spring.

5) Remove dust cover and helper.

C: INSPECTION

Check the disassembled parts for cracks, damage

and wear, and replace with new parts if defective.

1. DAMPER STRUT

1) Check for oil leakage.

2) Move the piston rod up and down to check its

operates smoothly without any binding.

3) Play of piston rod

IMeasure the play as follows:

Fix outer shell and fully extend the rod. Set a dial

gauge at the end of the rod: L [10 mm (0.39 in)],

then apply a force of W [20 N (2 kg, 4 lb)] to

threaded portion. With the force of 20 N (2 kg, 4 lb)

applied, read dial gauge indication: P

1. Apply a

force of 20 N (2 kg, 4 lb) in the opposite direction

of ªWº, then read dial gauge indication: P

2.

G4M0508

The free play is determined by the following equa-

tion:

Play = P1,P2

Limit of play:

Less than 0.8 mm (0.031 in)

If the play is greater, replace the strut with new

one.

19

[W4C1]4-1SERVICE PROCEDURE

4. Front Strut

Page 723 of 1456

2. STRUT MOUNT

Check rubber part for wear, cracks and

deterioration, and replace it with new one if defec-

tive.

3. DUST COVER

If any cracks or damage are found, replace it with

new one.

4. COIL SPRING

When vehicle posture is uneven, although there

are no considerable reasons like tire puncture,

uneven loading, etc., check coil spring and spring

seats for cracks, deformation, etc., and replace it

with a new one if defective.

5. HELPER

Replace it with new one if cracked or damaged.

D: ASSEMBLY

1) Before installing coil spring, strut mount, etc.,

on the strut, check for the presence of air in the

dampening force generating mechanism of the

strut since air prevents proper dampening force

from being produced.

2) Checking for the presence of air

(1) Place the strut vertically with the piston rod

facing upward.

(2) Move the piston rod to the center of its

entire stroke.

(3) While holding the piston rod end with finger-

tips, move the rod up and down.

(4) If the piston rod moves at least 10 mm (0.39

in) in former step, purge air from the strut.

3) Air purging procedure

(1) Place the strut vertically with the piston rod

facing upward.

(2) Fully extend the piston rod.

(3) With the piston rod fully extended, place the

piston rod side down. The strut must stand ver-

tically.

(4) Fully contract the piston rod.

(5) Repeat 3 or 4 times from first step.

NOTE:

After completely purging air from the strut, be sure

to place the strut with the piston rod facing upward.

If it is laid down, check for entry of air in the strut

as outlined under ªChecking for the presence of

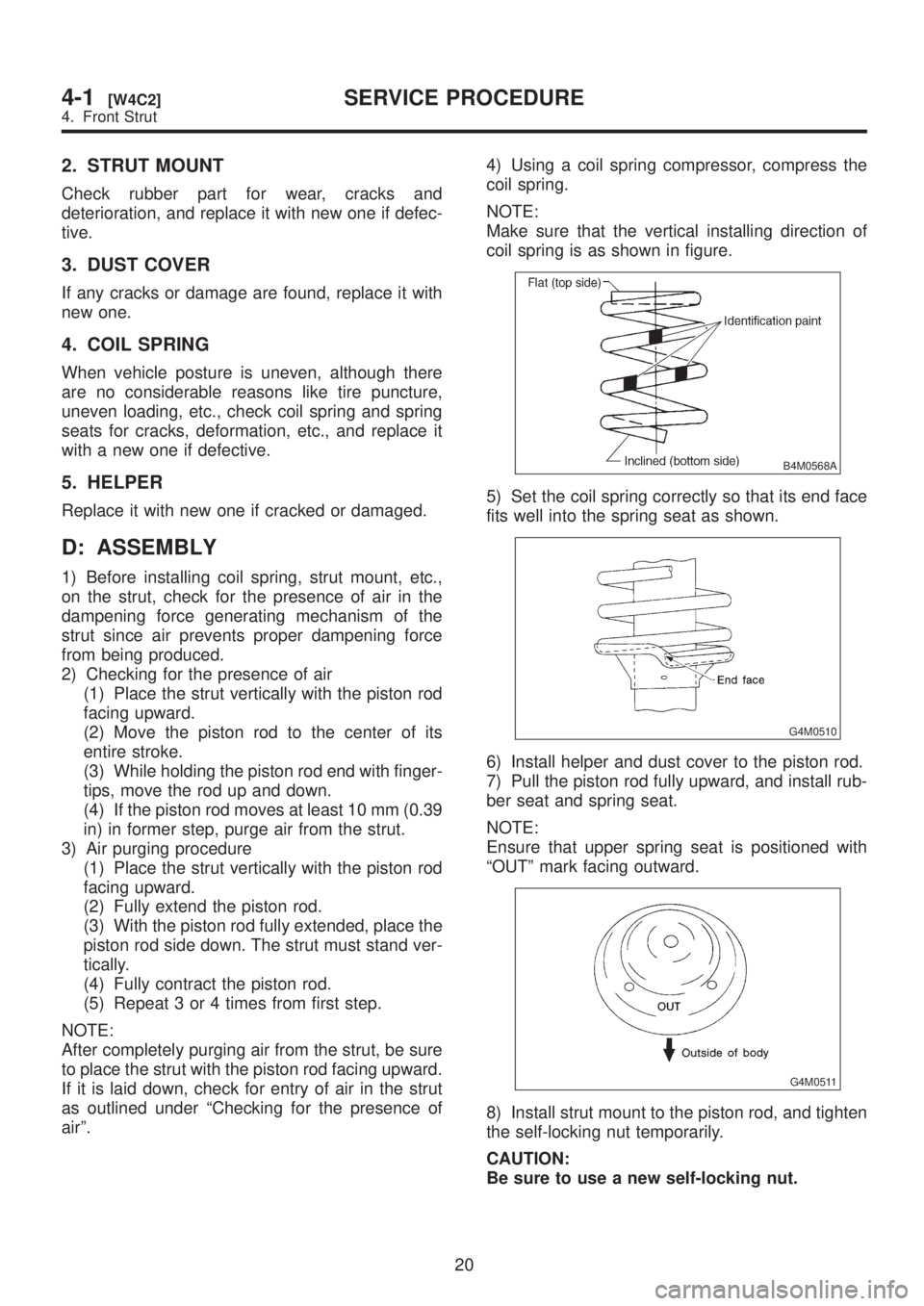

airº.4) Using a coil spring compressor, compress the

coil spring.

NOTE:

Make sure that the vertical installing direction of

coil spring is as shown in figure.

B4M0568A

5) Set the coil spring correctly so that its end face

fits well into the spring seat as shown.

G4M0510

6) Install helper and dust cover to the piston rod.

7) Pull the piston rod fully upward, and install rub-

ber seat and spring seat.

NOTE:

Ensure that upper spring seat is positioned with

ªOUTº mark facing outward.

G4M0511

8) Install strut mount to the piston rod, and tighten

the self-locking nut temporarily.

CAUTION:

Be sure to use a new self-locking nut.

20

4-1[W4C2]SERVICE PROCEDURE

4. Front Strut

Page 976 of 1456

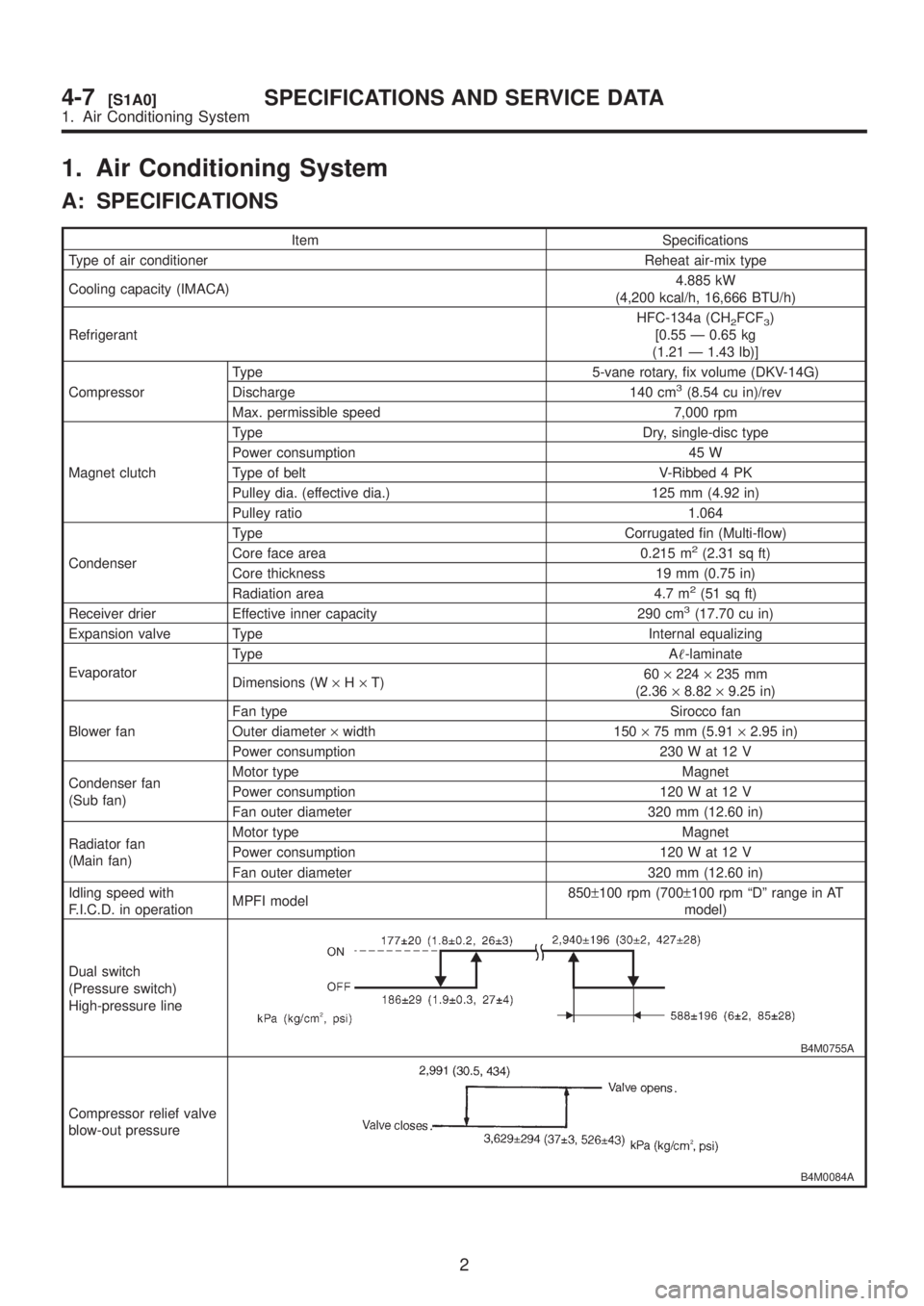

1. Air Conditioning System

A: SPECIFICATIONS

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity (IMACA)4.885 kW

(4,200 kcal/h, 16,666 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.55 Ð 0.65 kg

(1.21 Ð 1.43 lb)]

CompressorType 5-vane rotary, fix volume (DKV-14G)

Discharge 140 cm

3(8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 45 W

Type of belt V-Ribbed 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Multi-flow)

Core face area 0.215 m

2(2.31 sq ft)

Core thickness 19 mm (0.75 in)

Radiation area 4.7 m

2(51 sq ft)

Receiver drier Effective inner capacity 290 cm3(17.70 cu in)

Expansion valve Type Internal equalizing

EvaporatorType A-laminate

Dimensions (W´H´T)60´224´235 mm

(2.36´8.82´9.25 in)

Blower fanFan type Sirocco fan

Outer diameter´width 150´75 mm (5.91´2.95 in)

Power consumption 230 W at 12 V

Condenser fan

(Sub fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Radiator fan

(Main fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Idling speed with

F.I.C.D. in operationMPFI model850±100 rpm (700±100 rpm ªDº range in AT

model)

Dual switch

(Pressure switch)

High-pressure line

B4M0755A

Compressor relief valve

blow-out pressure

B4M0084A

2

4-7[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System