compressor SUBARU LEGACY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 1003 of 1456

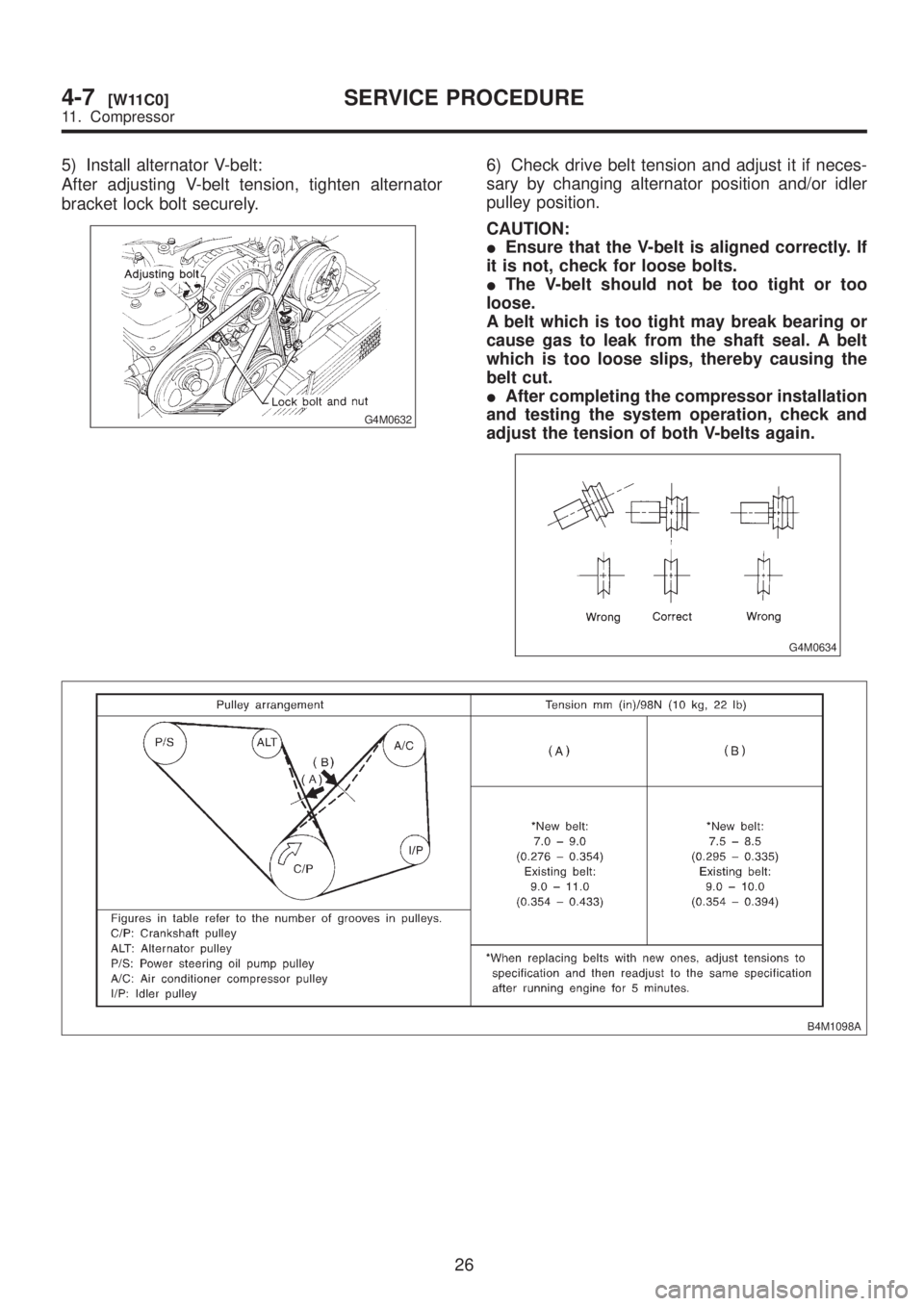

5) Install alternator V-belt:

After adjusting V-belt tension, tighten alternator

bracket lock bolt securely.

G4M0632

6) Check drive belt tension and adjust it if neces-

sary by changing alternator position and/or idler

pulley position.

CAUTION:

IEnsure that the V-belt is aligned correctly. If

it is not, check for loose bolts.

IThe V-belt should not be too tight or too

loose.

A belt which is too tight may break bearing or

cause gas to leak from the shaft seal. A belt

which is too loose slips, thereby causing the

belt cut.

IAfter completing the compressor installation

and testing the system operation, check and

adjust the tension of both V-belts again.

G4M0634

B4M1098A

26

4-7[W11C0]SERVICE PROCEDURE

11. Compressor

Page 1004 of 1456

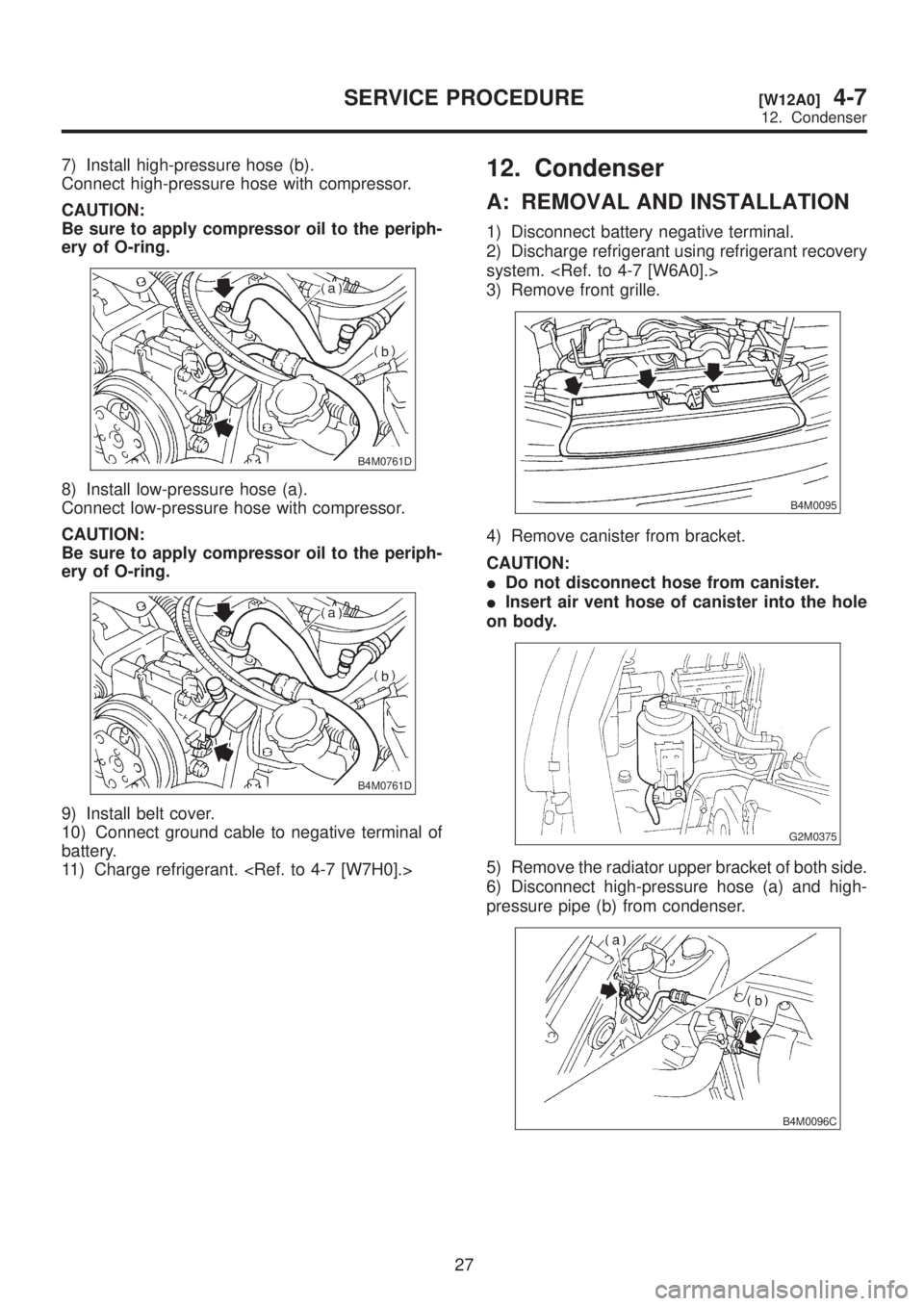

7) Install high-pressure hose (b).

Connect high-pressure hose with compressor.

CAUTION:

Be sure to apply compressor oil to the periph-

ery of O-ring.

B4M0761D

8) Install low-pressure hose (a).

Connect low-pressure hose with compressor.

CAUTION:

Be sure to apply compressor oil to the periph-

ery of O-ring.

B4M0761D

9) Install belt cover.

10) Connect ground cable to negative terminal of

battery.

11) Charge refrigerant.

12. Condenser

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system.

3) Remove front grille.

B4M0095

4) Remove canister from bracket.

CAUTION:

IDo not disconnect hose from canister.

IInsert air vent hose of canister into the hole

on body.

G2M0375

5) Remove the radiator upper bracket of both side.

6) Disconnect high-pressure hose (a) and high-

pressure pipe (b) from condenser.

B4M0096C

27

[W12A0]4-7SERVICE PROCEDURE

12. Condenser

Page 1005 of 1456

7) Install high-pressure hose (b).

Connect high-pressure hose with compressor.

CAUTION:

Be sure to apply compressor oil to the periph-

ery of O-ring.

B4M0761D

8) Install low-pressure hose (a).

Connect low-pressure hose with compressor.

CAUTION:

Be sure to apply compressor oil to the periph-

ery of O-ring.

B4M0761D

9) Install belt cover.

10) Connect ground cable to negative terminal of

battery.

11) Charge refrigerant.

12. Condenser

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system.

3) Remove front grille.

B4M0095

4) Remove canister from bracket.

CAUTION:

IDo not disconnect hose from canister.

IInsert air vent hose of canister into the hole

on body.

G2M0375

5) Remove the radiator upper bracket of both side.

6) Disconnect high-pressure hose (a) and high-

pressure pipe (b) from condenser.

B4M0096C

27

[W12A0]4-7SERVICE PROCEDURE

12. Condenser

Page 1011 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA SUBARU LEGACY 1999 Service Owners Guide 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA](/img/17/57435/w960_57435-1010.png)

16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system.

3) Remove low-pressure hose:

CAUTION:

With the following cautions, replace flexible

hoses with new ones if they are damaged or

swollen.

IThe flexible hoses should be free from twists

and tension after they have been connected.

IThe flexible hoses must not be bent or

twisted forcibly.

(1) Remove hose attaching bolts.

CAUTION:

Plug the opening to prevent foreign matter

from getting in.

(2) Disconnect the connector at evaporator

unit.

B4M0103

4) Remove high-pressure hose:

CAUTION:

With the following cautions, replace flexible

hoses with new ones if they are damaged or

swollen.

IThe flexible hoses should be free from twists

and tension after they have been connected.

IThe flexible hoses must not be bent or

twisted forcibly.

(1) Disconnect hose attaching bolt (compressor

side).

(2) Disconnect hose attaching bolt (condenser

side).

CAUTION:

Plug the opening to prevent foreign matter

from getting in.

B4M0764

5) Installation is in the reverse order of removal.

6) Charge refrigerant.

31

[W16A0]4-7SERVICE PROCEDURE

16. Flexible Hose

Page 1015 of 1456

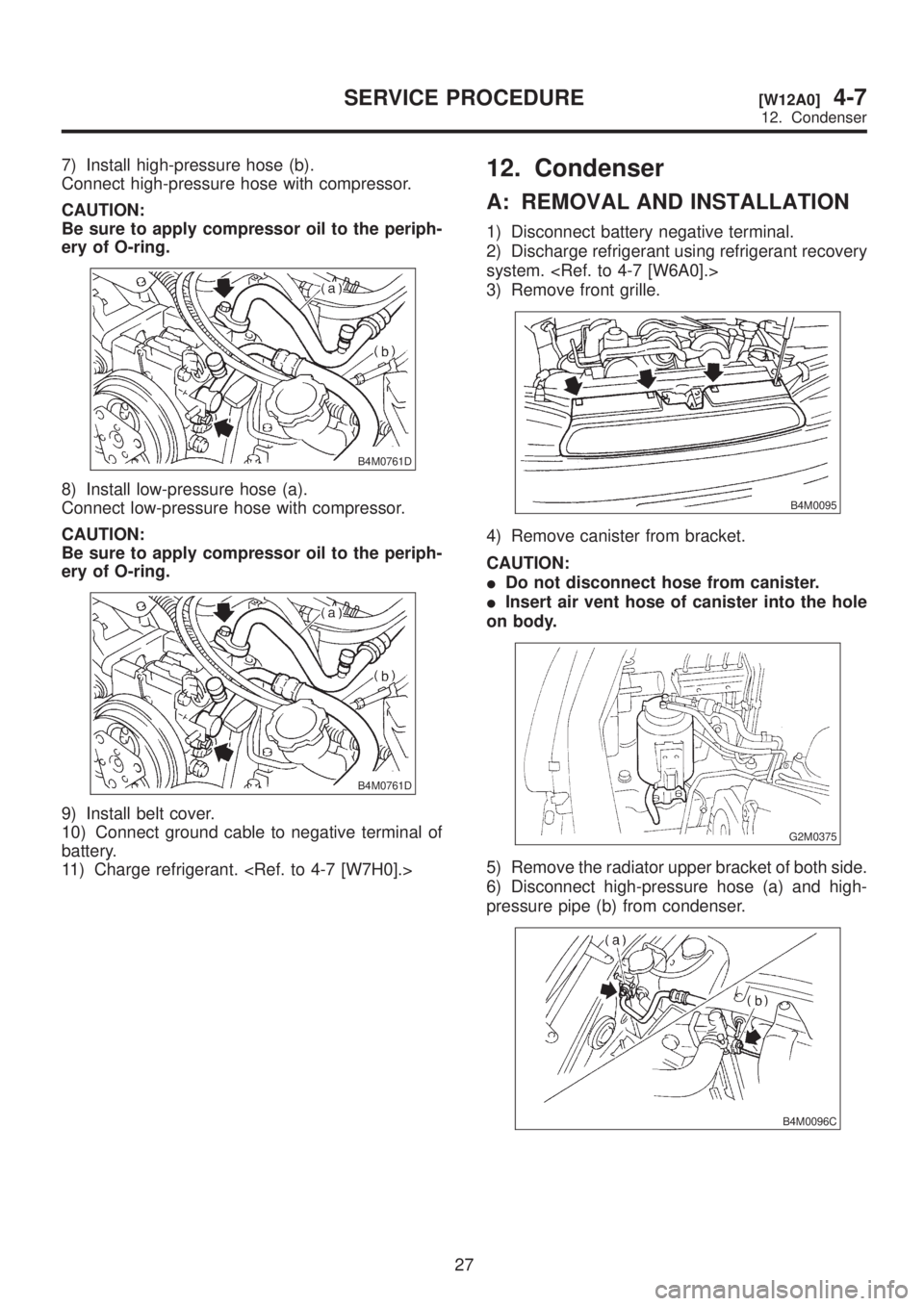

2. Performance Test Diagnosis

If various conditions caused to other air conditioning system, the characteristics revealed on manifold gauge

reading are shown in the following:

As to the method of a performance test, refer to the item of ªPerformance Testº.

Each shaded area on the following tables indicates a reading of the normal system when the temperature

of outside air is 32.5ÉC (91ÉF).

Condition Probable cause Corrective action

INSUFFICIENT REFRIGERANT CHARGE

G4M0673

Insufficient cooling Refrigerant is small, or

leaking a little.(1) Perform leak test.

(2) Repair leak.

(3) Charge system.

Evacuate, as

necessary, and

recharge system.

ALMOST NO REFRIGERANT

G4M0674

No cooling action Serious refrigerant leak.Stop compressor

immediately.

(1) Perform leak test.

(2) Discharge system.

(3) Repair leak(s).

(4) Replace receiver

drier if necessary.

(5) Check oil level.

(6) Evacuate and

recharge system.

FAULTY EXPANSION VALVE

G4M0675

Slight cooling;

Sweating or frosted

expansion valve inlet.Expansion valve

restricts refrigerant flow.

IExpansion valve is

clogged.

IExpansion valve is

inoperative.

IValve stuck closed.

IThermal bulb has lost

charge.If valve inlet reveals

sweat or frost:

(1) Discharge system

(2) Remove valve and

clean it. Replace it if

necessary.

(3) Evacuate system

(4) Charge system.

If valve does not oper-

ate:

(1) Discharge system.

(2) Replace valve.

(3) Evacuate and

charge system.

35

[K200]4-7DIAGNOSTICS

2. Performance Test Diagnosis

Page 1017 of 1456

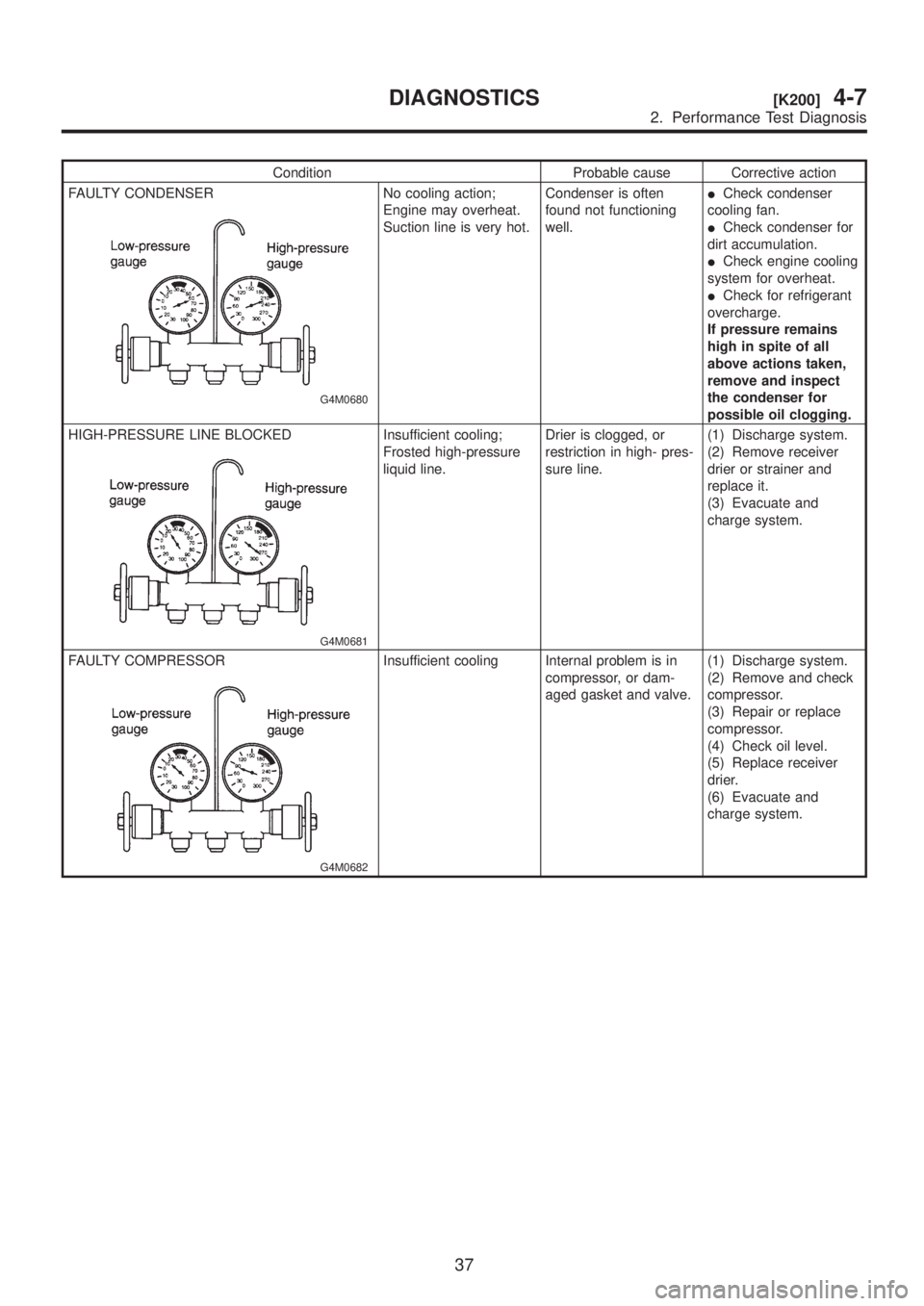

Condition Probable cause Corrective action

FAULTY CONDENSER

G4M0680

No cooling action;

Engine may overheat.

Suction line is very hot.Condenser is often

found not functioning

well.ICheck condenser

cooling fan.

ICheck condenser for

dirt accumulation.

ICheck engine cooling

system for overheat.

ICheck for refrigerant

overcharge.

If pressure remains

high in spite of all

above actions taken,

remove and inspect

the condenser for

possible oil clogging.

HIGH-PRESSURE LINE BLOCKED

G4M0681

Insufficient cooling;

Frosted high-pressure

liquid line.Drier is clogged, or

restriction in high- pres-

sure line.(1) Discharge system.

(2) Remove receiver

drier or strainer and

replace it.

(3) Evacuate and

charge system.

FAULTY COMPRESSOR

G4M0682

Insufficient cooling Internal problem is in

compressor, or dam-

aged gasket and valve.(1) Discharge system.

(2) Remove and check

compressor.

(3) Repair or replace

compressor.

(4) Check oil level.

(5) Replace receiver

drier.

(6) Evacuate and

charge system.

37

[K200]4-7DIAGNOSTICS

2. Performance Test Diagnosis

Page 1019 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis SUBARU LEGACY 1999 Service Owners Guide 4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis](/img/17/57435/w960_57435-1018.png)

4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis

Page 1020 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis SUBARU LEGACY 1999 Service Owners Guide 5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis](/img/17/57435/w960_57435-1019.png)

5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis

Page 1021 of 1456

![SUBARU LEGACY 1999 Service Owners Guide B4M1106A

41

[K500]4-7DIAGNOSTICS

5. Compressor Clutch Diagnosis SUBARU LEGACY 1999 Service Owners Guide B4M1106A

41

[K500]4-7DIAGNOSTICS

5. Compressor Clutch Diagnosis](/img/17/57435/w960_57435-1020.png)

B4M1106A

41

[K500]4-7DIAGNOSTICS

5. Compressor Clutch Diagnosis

Page 1413 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 7. Electrical Unit Location

A: LIST

Electrical unit Index No.

ABS control module <Ref. to 4-4 [T300].>

ABS G sensor (MT) <Ref. to 4-4 [T300].>

A/C compressor relay <Ref. to 6-3 [D7B1].>

A/C fuse <Ref. SUBARU LEGACY 1999 Service Owners Guide 7. Electrical Unit Location

A: LIST

Electrical unit Index No.

ABS control module <Ref. to 4-4 [T300].>

ABS G sensor (MT) <Ref. to 4-4 [T300].>

A/C compressor relay <Ref. to 6-3 [D7B1].>

A/C fuse <Ref.](/img/17/57435/w960_57435-1412.png)

7. Electrical Unit Location

A: LIST

Electrical unit Index No.

ABS control module

ABS G sensor (MT)

A/C compressor relay

A/C fuse

A/C main fan relay 1

A/C main fan relay 2

A/C pressure switch

A/C sub fan relay 2

ATF temperature sensor

Blower motor resistor

Blower relay

Camshaft position sensor

Check connector

Clutch switch (MT)

Crankshaft position sensor

Cruise control module

Cruise control pump

Data link connector (for

OBD-II G.S.T.)

Data link connector (for

S.S.M.)

Diagnosis connector

Diagnosis terminal (Ground)

Door lock timer

Engine control module

Engine coolant temperature

sensor

Engine hood switch (Secu-

rity)

Evaporator thermoswitch

F/B

FRESH/RECIRC actuator

Fuel pump relay

Fuel gauge module

Fuel gauge sub module

(AWD)

FWD switch (AT)

Headlight alarm relay

(Security)

Headlight relay LH

Electrical unit Index No.

Headlight relay RH

Horn relay

Hydraulic unit (ABS)

Ignition coil

Ignitor

Idle air control solenoid

valve

Illumination control module

Inhibitor switch

Knock sensor

Main fan relay

Main relay

Mass air flow sensor

Mode actuator

M/B

Oil pressure switch

Oxygen sensor

Pedal stroke sensor (TCS)

Power window and sunroof

relay

Power window circuit

breaker

Purge control solenoid valve

Rear defogger relay

Seat belt timer

Security control module

Shift lock control module

Starter interrupt relay (Secu-

rity)

Stop & brake switch (With

cruise control)

Sunroof control module

Tail and illumination relay

TCS control module

TCS motor relay

TCS valve relay

Throttle position sensor

Test mode connector

Transmission control mod-

ule

Turn & hazard module

Vehicle speed sensor 1

Vehicle speed sensor 2

133

[D7A0]6-3WIRING DIAGRAM

7. Electrical Unit Location