light SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 150 of 1456

1) Remove left-hand intake camshaft sprocket.

2) Remove left-hand exhaust camshaft sprocket.

3) Remove right-hand intake camshaft sprocket.

4) Remove right-hand exhaust camshaft sprocket.

ST 499207300 CAMSHAFT SPROCKET

WRENCH

S2M0413A

5) Remove crankshaft sprocket.

S2M0414

6) Remove tensioner bracket.

H2M2407

7) Remove left-hand belt cover No. 2.

S2M0415

8) Remove right-hand belt cover No. 2.

B2M0738

B: INSPECTION

1. TIMING BELT

1) Check timing belt teeth for breaks, cracks and

wear. If any fault is found, replace belt.

2) Check the condition of back side of belt; if any

crack is found, replace belt.

CAUTION:

IBe careful not to let oil, grease or coolant

contact the belt. Remove quickly and thor-

oughly if this happens.

IDo not bend the belt sharply.

Bending radius: h

60 mm (2.36 in) or more

G2M0115

2. AUTOMATIC BELT TENSION

ADJUSTER

1) Visually check oil seals for leaks, and rod ends

for abnormal wear or scratches. If necessary,

replace automatic belt tension adjuster assembly.

CAUTION:

Slight traces of oil at rod's oil seal does not

indicate a problem.

2) Check that the adjuster rod does not move

when a pressure of 294 N (30 kg, 66 lb) is applied

to it. This is to check adjuster rod stiffness.

3) If the adjuster rod is not stiff and moves freely

when applying 294 N (30 kg, 66 lb), check it using

the following procedures:

19

[W2B2]2-3bSERVICE PROCEDURE

2. Timing Belt

Page 165 of 1456

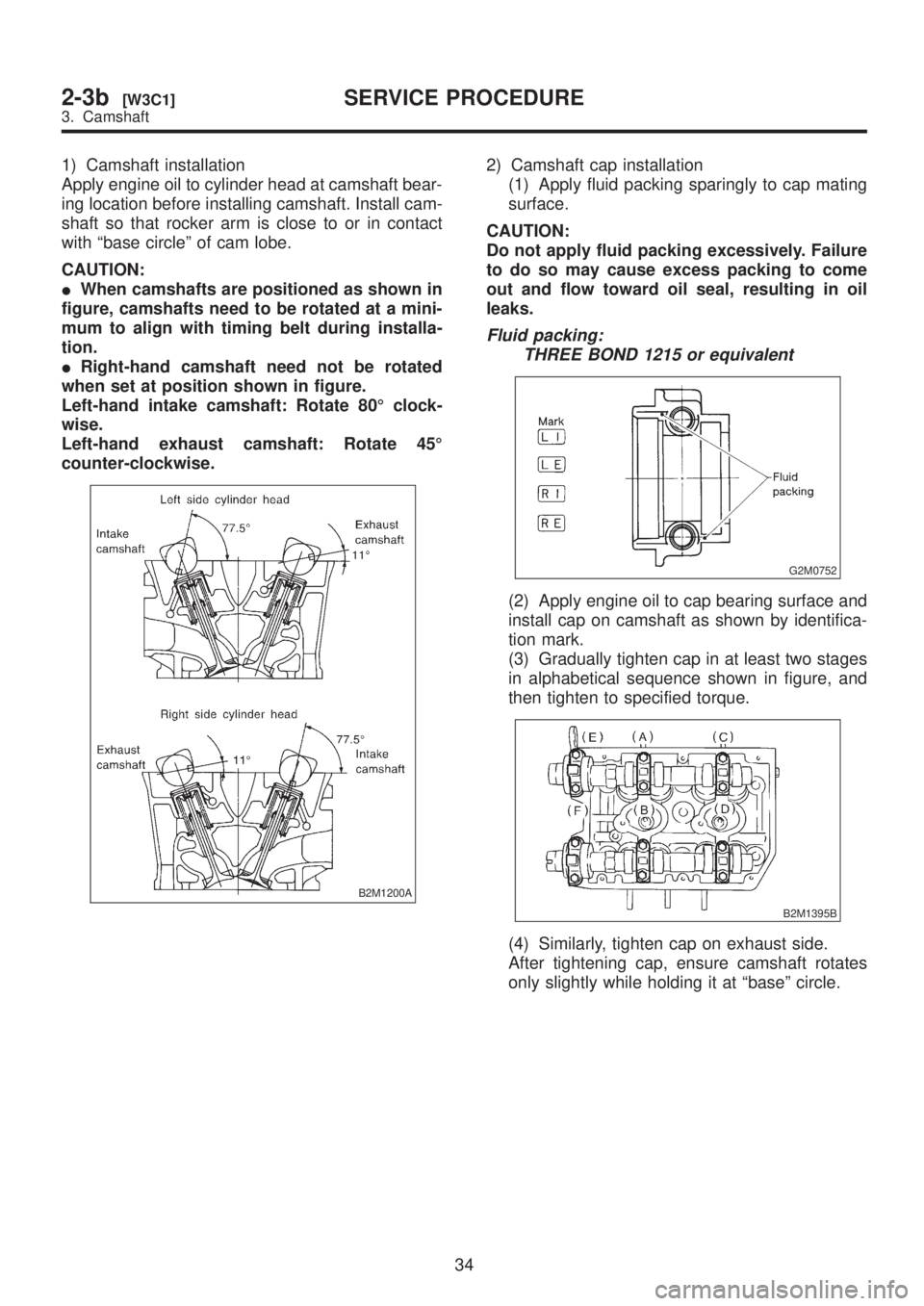

1) Camshaft installation

Apply engine oil to cylinder head at camshaft bear-

ing location before installing camshaft. Install cam-

shaft so that rocker arm is close to or in contact

with ªbase circleº of cam lobe.

CAUTION:

IWhen camshafts are positioned as shown in

figure, camshafts need to be rotated at a mini-

mum to align with timing belt during installa-

tion.

IRight-hand camshaft need not be rotated

when set at position shown in figure.

Left-hand intake camshaft: Rotate 80É clock-

wise.

Left-hand exhaust camshaft: Rotate 45É

counter-clockwise.

B2M1200A

2) Camshaft cap installation

(1) Apply fluid packing sparingly to cap mating

surface.

CAUTION:

Do not apply fluid packing excessively. Failure

to do so may cause excess packing to come

out and flow toward oil seal, resulting in oil

leaks.

Fluid packing:

THREE BOND 1215 or equivalent

G2M0752

(2) Apply engine oil to cap bearing surface and

install cap on camshaft as shown by identifica-

tion mark.

(3) Gradually tighten cap in at least two stages

in alphabetical sequence shown in figure, and

then tighten to specified torque.

B2M1395B

(4) Similarly, tighten cap on exhaust side.

After tightening cap, ensure camshaft rotates

only slightly while holding it at ªbaseº circle.

34

2-3b[W3C1]SERVICE PROCEDURE

3. Camshaft

Page 171 of 1456

(5) Put new valve guide, coated with sufficient

oil, in cylinder, and insert ST1 into valve guide.

Press in until the valve guide upper end is flush

with the upper surface of ST2.

ST1 499767200 VALVE GUIDE REMOVER

ST2 498267700 VALVE GUIDE ADJUSTER

B2M1398A

(6) Check the valve guide protrusion.

Valve guide protrusion: L

12.0 Ð 12.4 mm (0.472 Ð 0.488 in)

(7) Ream the inside of valve guide with ST.

Gently rotate the reamer clockwise while press-

ing it lightly into valve guide, and return it also

rotating clockwise. After reaming, clean valve

guide to remove chips.

ST 499767400 VALVE GUIDE REAMER

CAUTION:

IApply engine oil to the reamer when ream-

ing.

IIf the inner surface of the valve guide is torn,

the edge of the reamer should be slightly

ground with an oil stone.

IIf the inner surface of the valve guide

becomes lustrous and the reamer does not

chips, use a new reamer or remedy the reamer.

(8) Recheck the contact condition between

valve and valve seat after replacing valve guide.

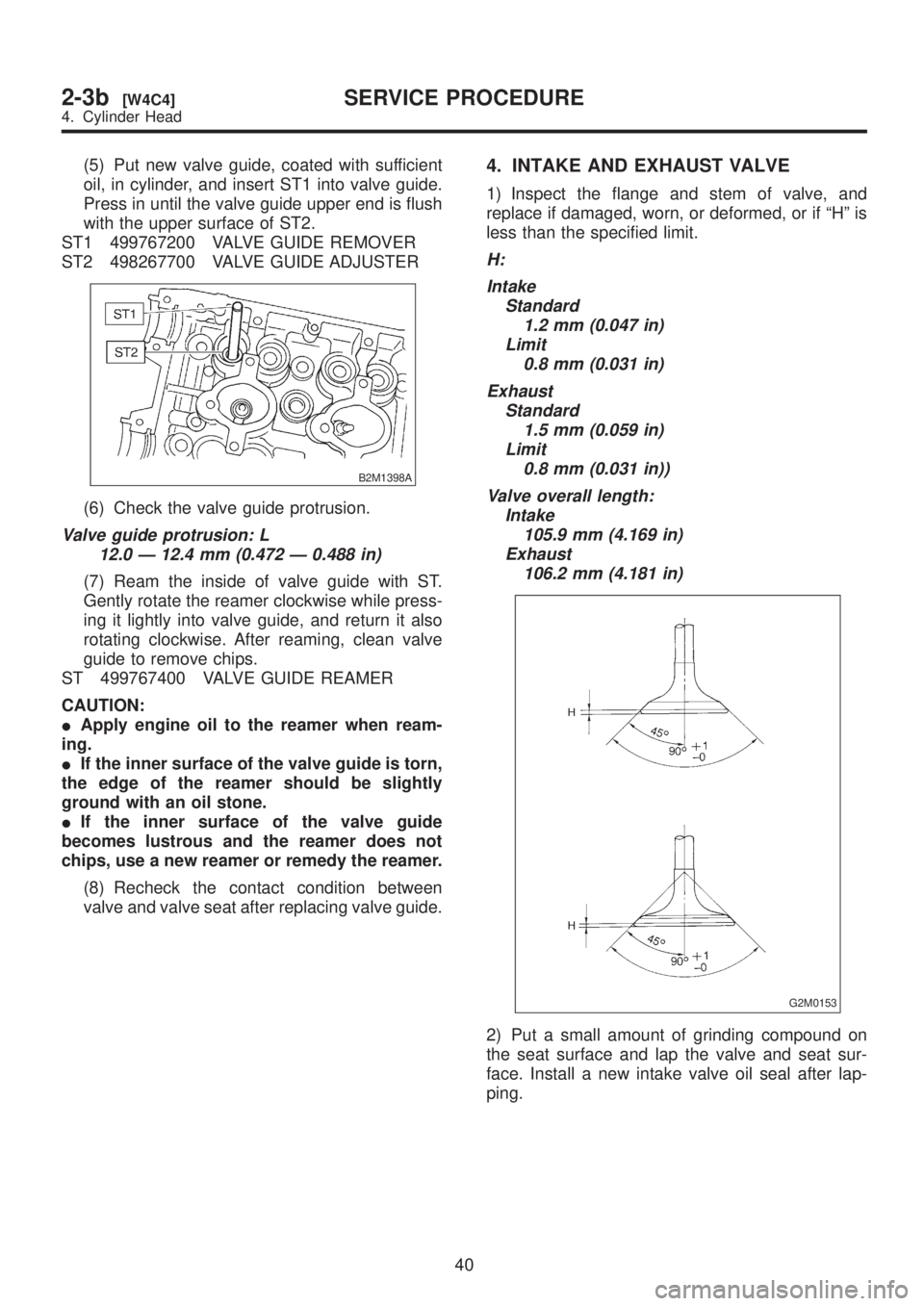

4. INTAKE AND EXHAUST VALVE

1) Inspect the flange and stem of valve, and

replace if damaged, worn, or deformed, or if ªHº is

less than the specified limit.

H:

Intake

Standard

1.2 mm (0.047 in)

Limit

0.8 mm (0.031 in)

Exhaust

Standard

1.5 mm (0.059 in)

Limit

0.8 mm (0.031 in))

Valve overall length:

Intake

105.9 mm (4.169 in)

Exhaust

106.2 mm (4.181 in)

G2M0153

2) Put a small amount of grinding compound on

the seat surface and lap the valve and seat sur-

face. Install a new intake valve oil seal after lap-

ping.

40

2-3b[W4C4]SERVICE PROCEDURE

4. Cylinder Head

Page 174 of 1456

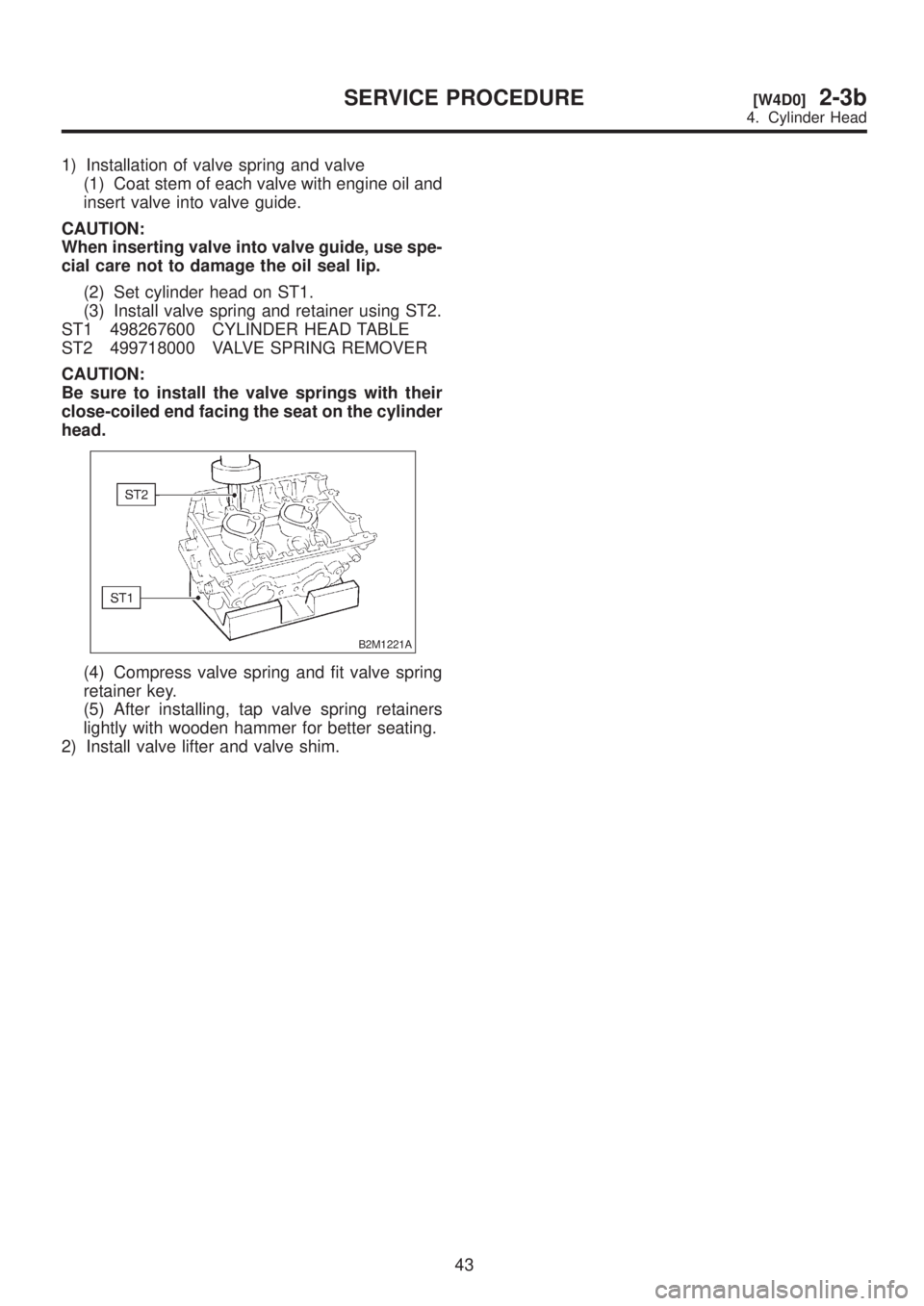

1) Installation of valve spring and valve

(1) Coat stem of each valve with engine oil and

insert valve into valve guide.

CAUTION:

When inserting valve into valve guide, use spe-

cial care not to damage the oil seal lip.

(2) Set cylinder head on ST1.

(3) Install valve spring and retainer using ST2.

ST1 498267600 CYLINDER HEAD TABLE

ST2 499718000 VALVE SPRING REMOVER

CAUTION:

Be sure to install the valve springs with their

close-coiled end facing the seat on the cylinder

head.

B2M1221A

(4) Compress valve spring and fit valve spring

retainer key.

(5) After installing, tap valve spring retainers

lightly with wooden hammer for better seating.

2) Install valve lifter and valve shim.

43

[W4D0]2-3bSERVICE PROCEDURE

4. Cylinder Head

Page 189 of 1456

4) Check circlip installation groove on the piston

for burr. If necessary, remove burr from the groove

so that piston pin can lightly move.

B2M0420A

5) Check piston pin circlip for distortion, cracks

and wear.

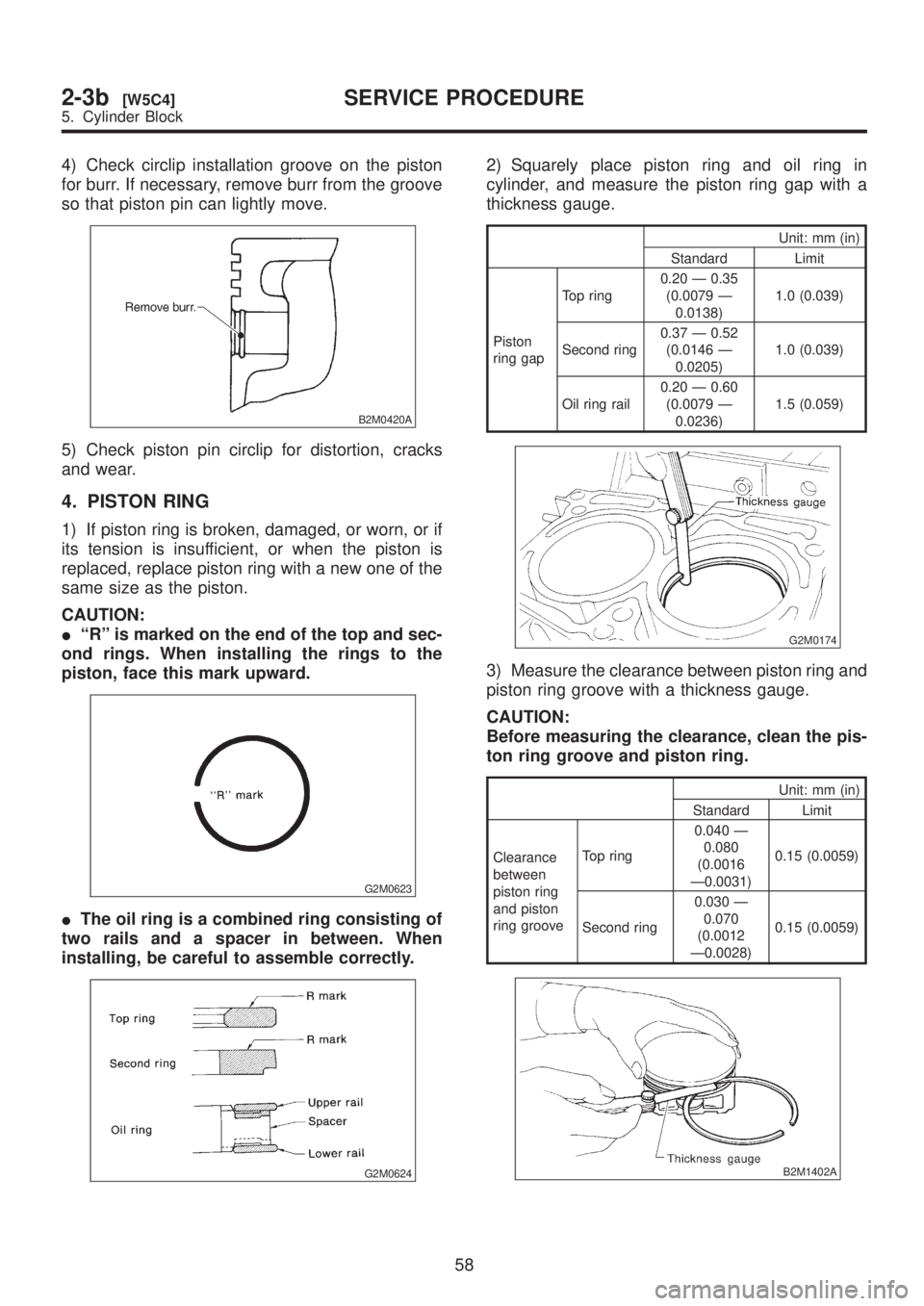

4. PISTON RING

1) If piston ring is broken, damaged, or worn, or if

its tension is insufficient, or when the piston is

replaced, replace piston ring with a new one of the

same size as the piston.

CAUTION:

IªRº is marked on the end of the top and sec-

ond rings. When installing the rings to the

piston, face this mark upward.

G2M0623

IThe oil ring is a combined ring consisting of

two rails and a spacer in between. When

installing, be careful to assemble correctly.

G2M0624

2) Squarely place piston ring and oil ring in

cylinder, and measure the piston ring gap with a

thickness gauge.

Unit: mm (in)

Standard Limit

Piston

ring gapTop ring0.20 Ð 0.35

(0.0079 Ð

0.0138)1.0 (0.039)

Second ring0.37 Ð 0.52

(0.0146 Ð

0.0205)1.0 (0.039)

Oil ring rail0.20 Ð 0.60

(0.0079 Ð

0.0236)1.5 (0.059)

G2M0174

3) Measure the clearance between piston ring and

piston ring groove with a thickness gauge.

CAUTION:

Before measuring the clearance, clean the pis-

ton ring groove and piston ring.

Unit: mm (in)

Standard Limit

Clearance

between

piston ring

and piston

ring grooveTop ring0.040 Ð

0.080

(0.0016

Ð0.0031)0.15 (0.0059)

Second ring0.030 Ð

0.070

(0.0012

Ð0.0028)0.15 (0.0059)

B2M1402A

58

2-3b[W5C4]SERVICE PROCEDURE

5. Cylinder Block

Page 207 of 1456

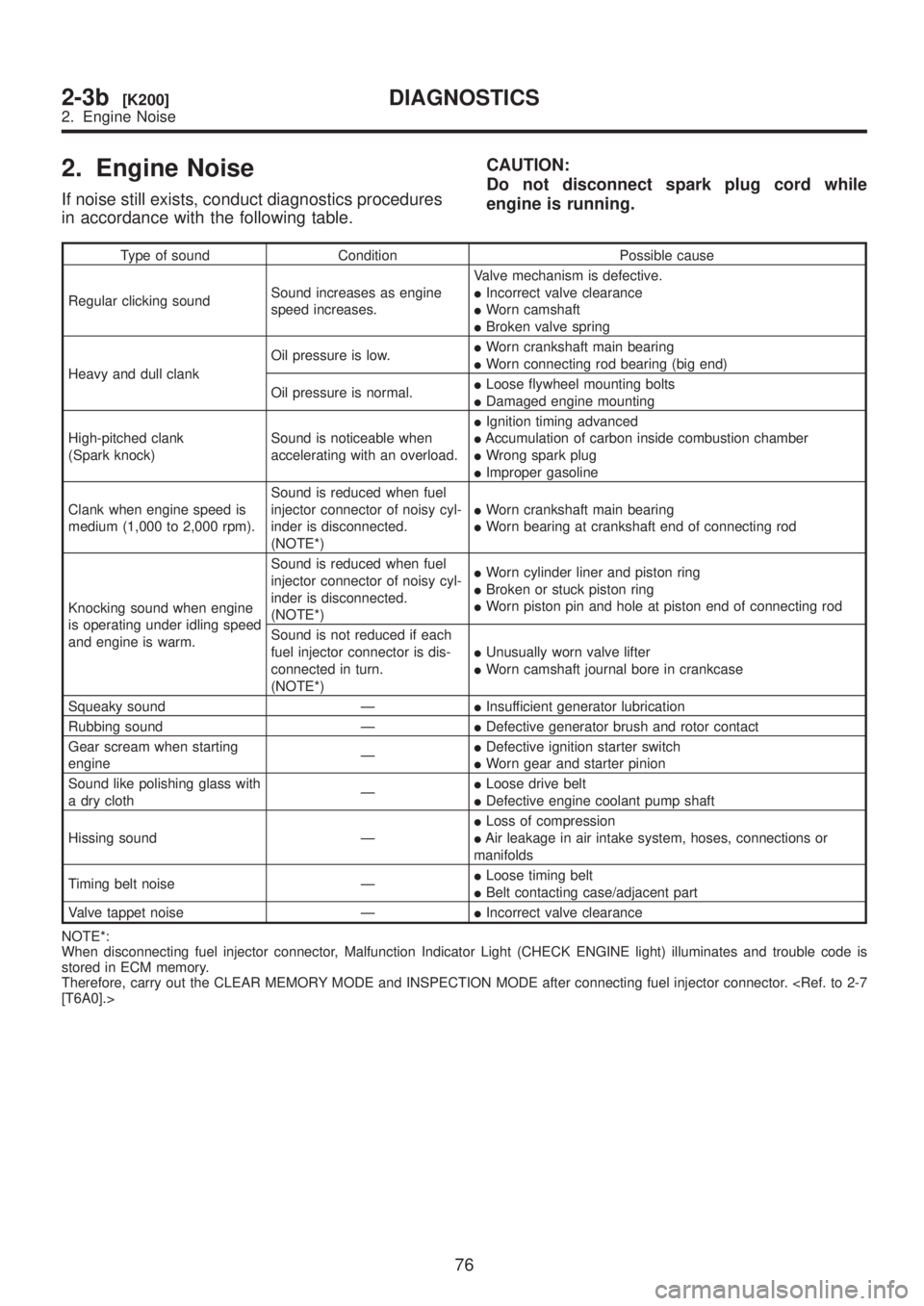

2. Engine Noise

If noise still exists, conduct diagnostics procedures

in accordance with the following table.CAUTION:

Do not disconnect spark plug cord while

engine is running.

Type of sound Condition Possible cause

Regular clicking soundSound increases as engine

speed increases.Valve mechanism is defective.

IIncorrect valve clearance

IWorn camshaft

IBroken valve spring

Heavy and dull clankOil pressure is low.IWorn crankshaft main bearing

IWorn connecting rod bearing (big end)

Oil pressure is normal.ILoose flywheel mounting bolts

IDamaged engine mounting

High-pitched clank

(Spark knock)Sound is noticeable when

accelerating with an overload.IIgnition timing advanced

IAccumulation of carbon inside combustion chamber

IWrong spark plug

IImproper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm).Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn crankshaft main bearing

IWorn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warm.Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn cylinder liner and piston ring

IBroken or stuck piston ring

IWorn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn.

(NOTE*)IUnusually worn valve lifter

IWorn camshaft journal bore in crankcase

Squeaky sound ÐIInsufficient generator lubrication

Rubbing sound ÐIDefective generator brush and rotor contact

Gear scream when starting

engineÐIDefective ignition starter switch

IWorn gear and starter pinion

Sound like polishing glass with

a dry clothÐILoose drive belt

IDefective engine coolant pump shaft

Hissing sound ÐILoss of compression

IAir leakage in air intake system, hoses, connections or

manifolds

Timing belt noise ÐILoose timing belt

IBelt contacting case/adjacent part

Valve tappet noise ÐIIncorrect valve clearance

NOTE*:

When disconnecting fuel injector connector, Malfunction Indicator Light (CHECK ENGINE light) illuminates and trouble code is

stored in ECM memory.

Therefore, carry out the CLEAR MEMORY MODE and INSPECTION MODE after connecting fuel injector connector.

76

2-3b[K200]DIAGNOSTICS

2. Engine Noise

Page 208 of 1456

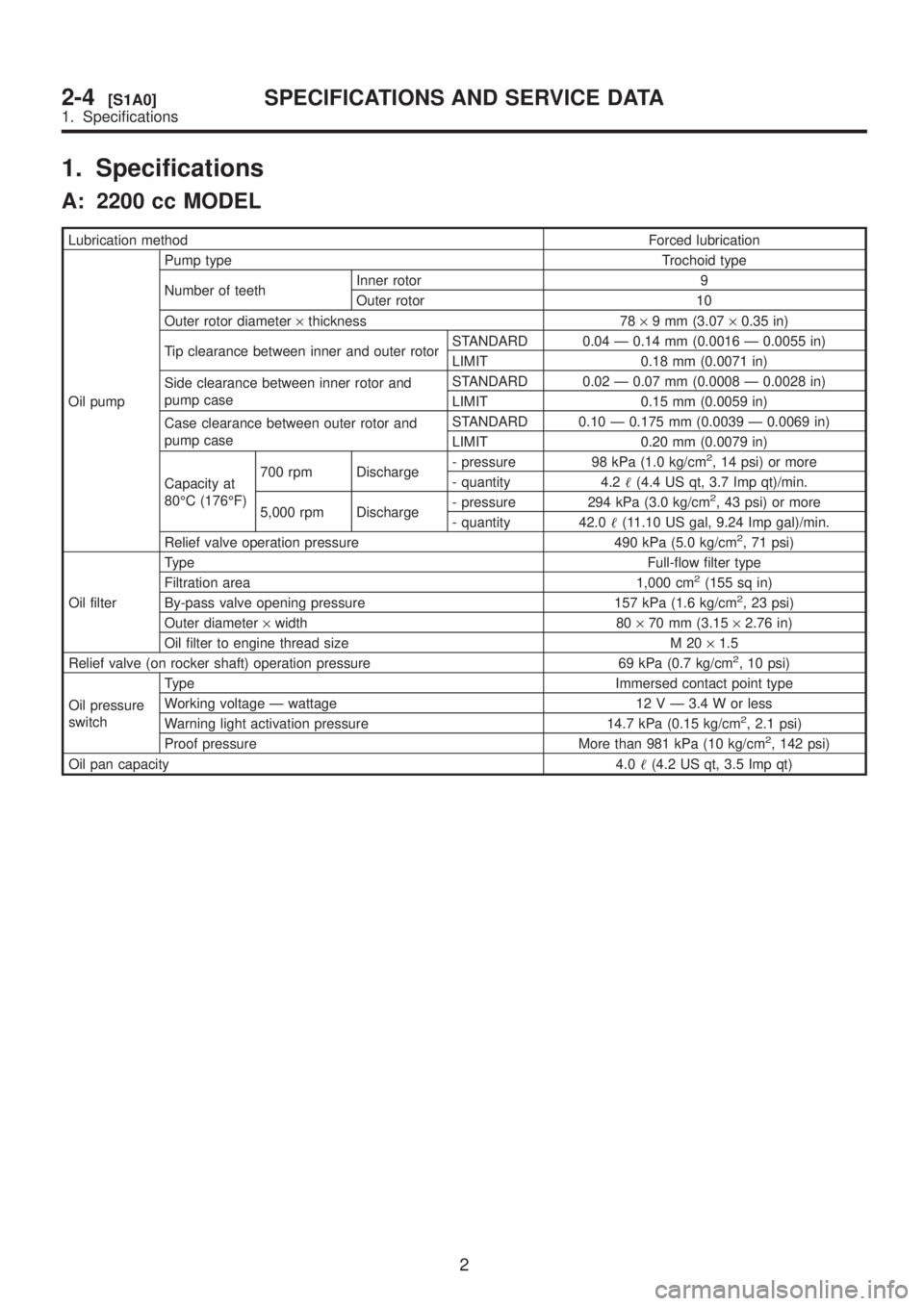

1. Specifications

A: 2200 cc MODEL

Lubrication methodForced lubrication

Oil pumpPump type Trochoid type

Number of teethInner rotor 9

Outer rotor 10

Outer rotor diameter´thickness 78´9 mm (3.07´0.35 in)

Tip clearance between inner and outer rotorSTANDARD 0.04 Ð 0.14 mm (0.0016 Ð 0.0055 in)

LIMIT 0.18 mm (0.0071 in)

Side clearance between inner rotor and

pump caseSTANDARD 0.02 Ð 0.07 mm (0.0008 Ð 0.0028 in)

LIMIT 0.15 mm (0.0059 in)

Case clearance between outer rotor and

pump caseSTANDARD 0.10 Ð 0.175 mm (0.0039 Ð 0.0069 in)

LIMIT 0.20 mm (0.0079 in)

Capacity at

80ÉC (176ÉF)700 rpm Discharge- pressure 98 kPa (1.0 kg/cm

2, 14 psi) or more

- quantity 4.2(4.4 US qt, 3.7 Imp qt)/min.

5,000 rpm Discharge- pressure 294 kPa (3.0 kg/cm

2, 43 psi) or more

- quantity 42.0(11.10 US gal, 9.24 Imp gal)/min.

Relief valve operation pressure 490 kPa (5.0 kg/cm

2, 71 psi)

Oil filterTypeFull-flow filter type

Filtration area 1,000 cm

2(155 sq in)

By-pass valve opening pressure 157 kPa (1.6 kg/cm2, 23 psi)

Outer diameter´width 80´70 mm (3.15´2.76 in)

Oil filter to engine thread size M 20´1.5

Relief valve (on rocker shaft) operation pressure 69 kPa (0.7 kg/cm

2, 10 psi)

Oil pressure

switchType Immersed contact point type

Working voltage Ð wattage 12 V Ð 3.4 W or less

Warning light activation pressure 14.7 kPa (0.15 kg/cm

2, 2.1 psi)

Proof pressure More than 981 kPa (10 kg/cm2, 142 psi)

Oil pan capacity4.0(4.2 US qt, 3.5 Imp qt)

2

2-4[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Specifications

Page 209 of 1456

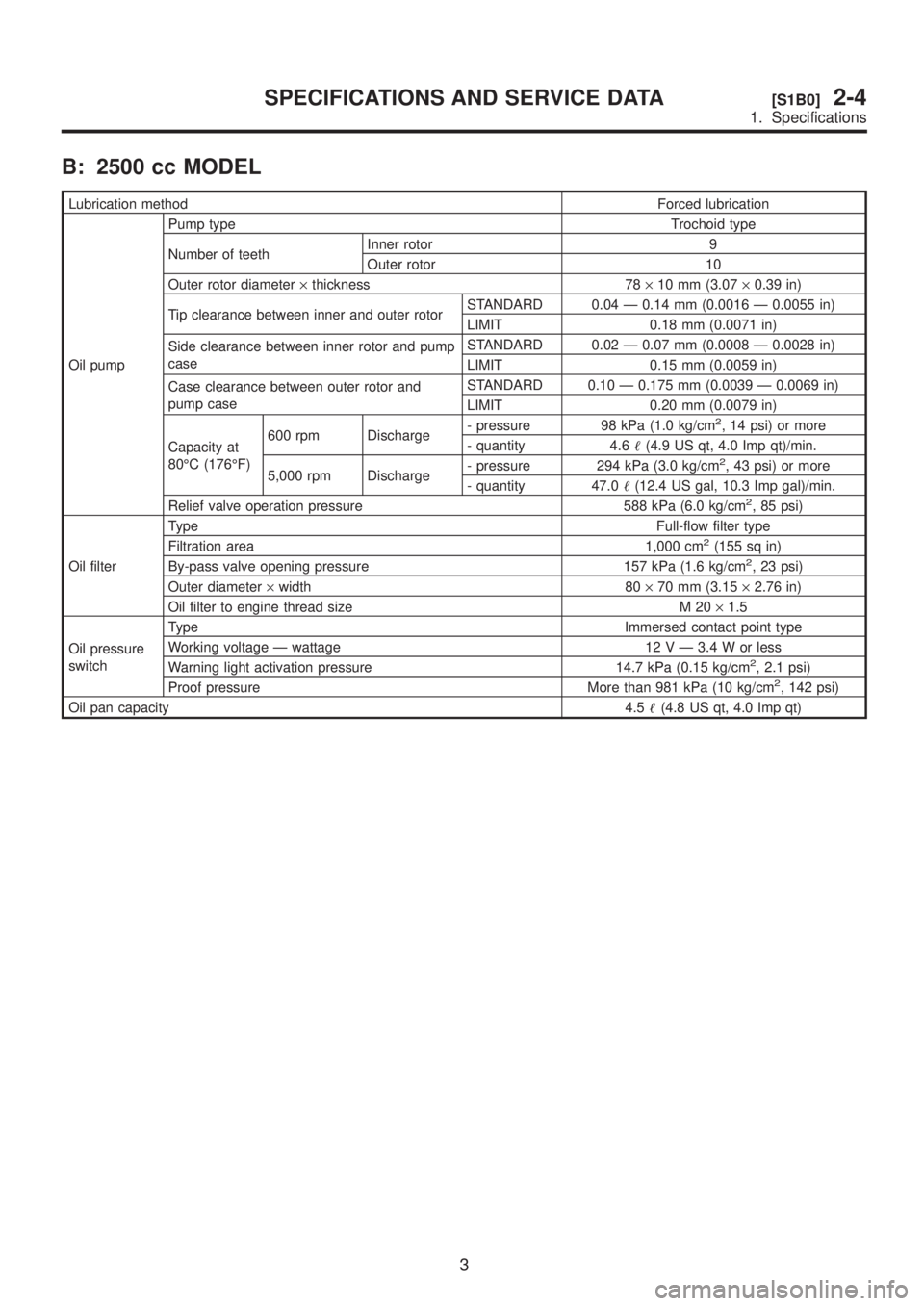

B: 2500 cc MODEL

Lubrication methodForced lubrication

Oil pumpPump type Trochoid type

Number of teethInner rotor 9

Outer rotor 10

Outer rotor diameter´thickness 78´10 mm (3.07´0.39 in)

Tip clearance between inner and outer rotorSTANDARD 0.04 Ð 0.14 mm (0.0016 Ð 0.0055 in)

LIMIT 0.18 mm (0.0071 in)

Side clearance between inner rotor and pump

caseSTANDARD 0.02 Ð 0.07 mm (0.0008 Ð 0.0028 in)

LIMIT 0.15 mm (0.0059 in)

Case clearance between outer rotor and

pump caseSTANDARD 0.10 Ð 0.175 mm (0.0039 Ð 0.0069 in)

LIMIT 0.20 mm (0.0079 in)

Capacity at

80ÉC (176ÉF)600 rpm Discharge- pressure 98 kPa (1.0 kg/cm

2, 14 psi) or more

- quantity 4.6(4.9 US qt, 4.0 Imp qt)/min.

5,000 rpm Discharge- pressure 294 kPa (3.0 kg/cm

2, 43 psi) or more

- quantity 47.0(12.4 US gal, 10.3 Imp gal)/min.

Relief valve operation pressure 588 kPa (6.0 kg/cm

2, 85 psi)

Oil filterTypeFull-flow filter type

Filtration area 1,000 cm

2(155 sq in)

By-pass valve opening pressure 157 kPa (1.6 kg/cm2, 23 psi)

Outer diameter´width 80´70 mm (3.15´2.76 in)

Oil filter to engine thread size M 20´1.5

Oil pressure

switchType Immersed contact point type

Working voltage Ð wattage 12 V Ð 3.4 W or less

Warning light activation pressure 14.7 kPa (0.15 kg/cm

2, 2.1 psi)

Proof pressure More than 981 kPa (10 kg/cm2, 142 psi)

Oil pan capacity4.5(4.8 US qt, 4.0 Imp qt)

3

[S1B0]2-4SPECIFICATIONS AND SERVICE DATA

1. Specifications

Page 227 of 1456

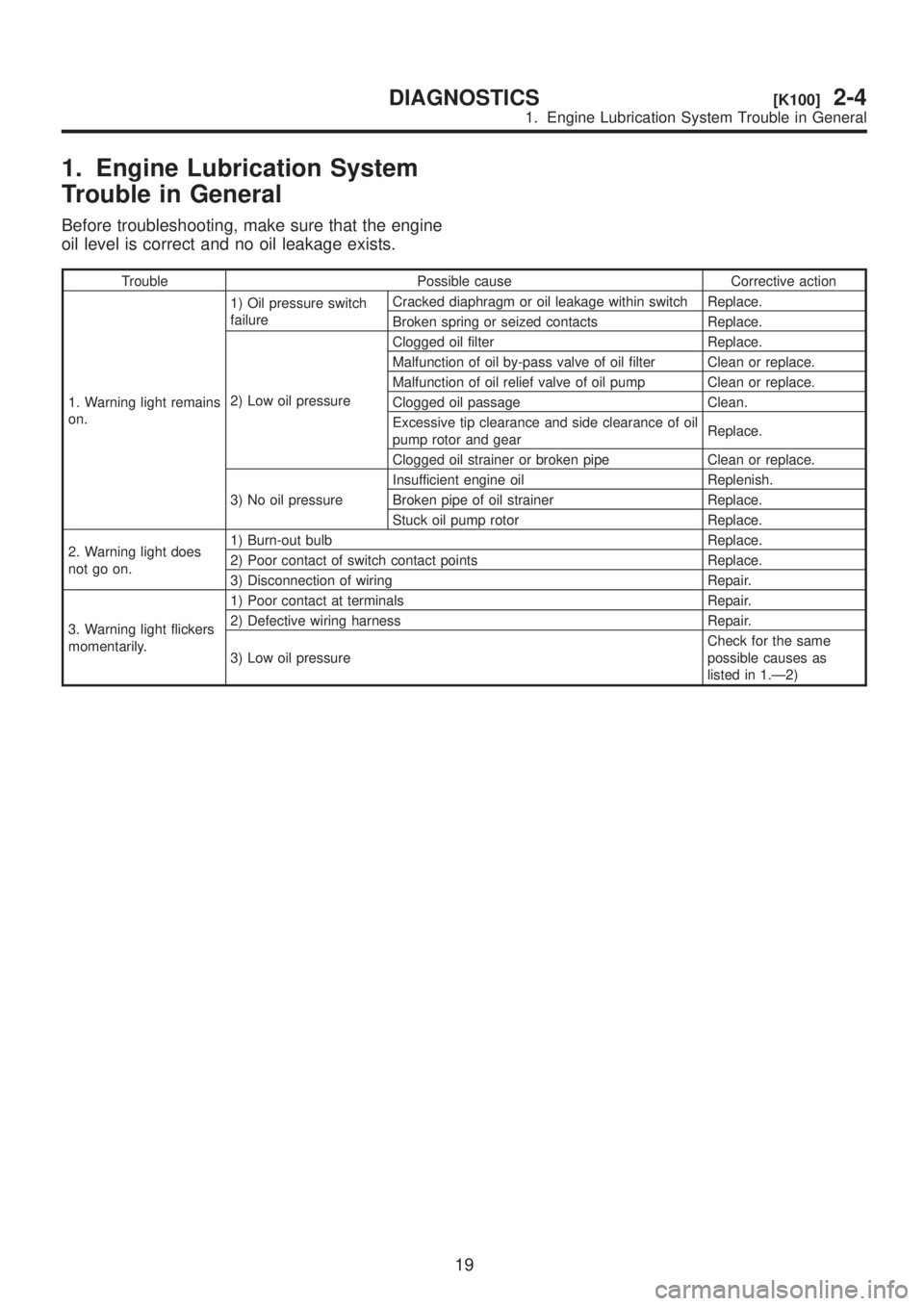

1. Engine Lubrication System

Trouble in General

Before troubleshooting, make sure that the engine

oil level is correct and no oil leakage exists.

Trouble Possible cause Corrective action

1. Warning light remains

on.1) Oil pressure switch

failureCracked diaphragm or oil leakage within switch Replace.

Broken spring or seized contacts Replace.

2) Low oil pressureClogged oil filter Replace.

Malfunction of oil by-pass valve of oil filter Clean or replace.

Malfunction of oil relief valve of oil pump Clean or replace.

Clogged oil passage Clean.

Excessive tip clearance and side clearance of oil

pump rotor and gearReplace.

Clogged oil strainer or broken pipe Clean or replace.

3) No oil pressureInsufficient engine oil Replenish.

Broken pipe of oil strainer Replace.

Stuck oil pump rotor Replace.

2. Warning light does

not go on.1) Burn-out bulb Replace.

2) Poor contact of switch contact points Replace.

3) Disconnection of wiring Repair.

3. Warning light flickers

momentarily.1) Poor contact at terminals Repair.

2) Defective wiring harness Repair.

3) Low oil pressureCheck for the same

possible causes as

listed in 1.Ð2)

19

[K100]2-4DIAGNOSTICS

1. Engine Lubrication System Trouble in General

Page 246 of 1456

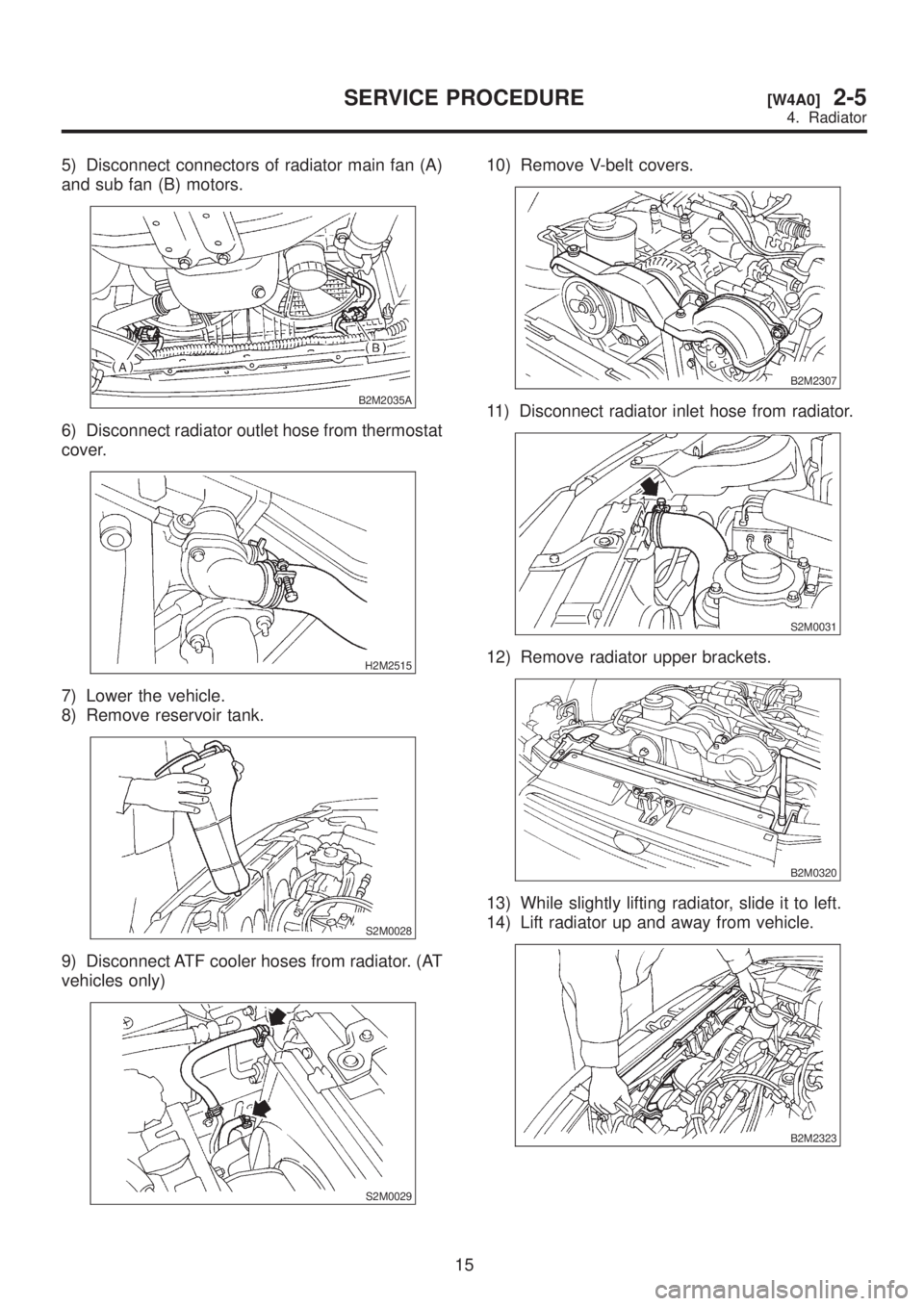

5) Disconnect connectors of radiator main fan (A)

and sub fan (B) motors.

B2M2035A

6) Disconnect radiator outlet hose from thermostat

cover.

H2M2515

7) Lower the vehicle.

8) Remove reservoir tank.

S2M0028

9) Disconnect ATF cooler hoses from radiator. (AT

vehicles only)

S2M0029

10) Remove V-belt covers.

B2M2307

11) Disconnect radiator inlet hose from radiator.

S2M0031

12) Remove radiator upper brackets.

B2M0320

13) While slightly lifting radiator, slide it to left.

14) Lift radiator up and away from vehicle.

B2M2323

15

[W4A0]2-5SERVICE PROCEDURE

4. Radiator