automatic transmission SUBARU LEGACY 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 570 of 1456

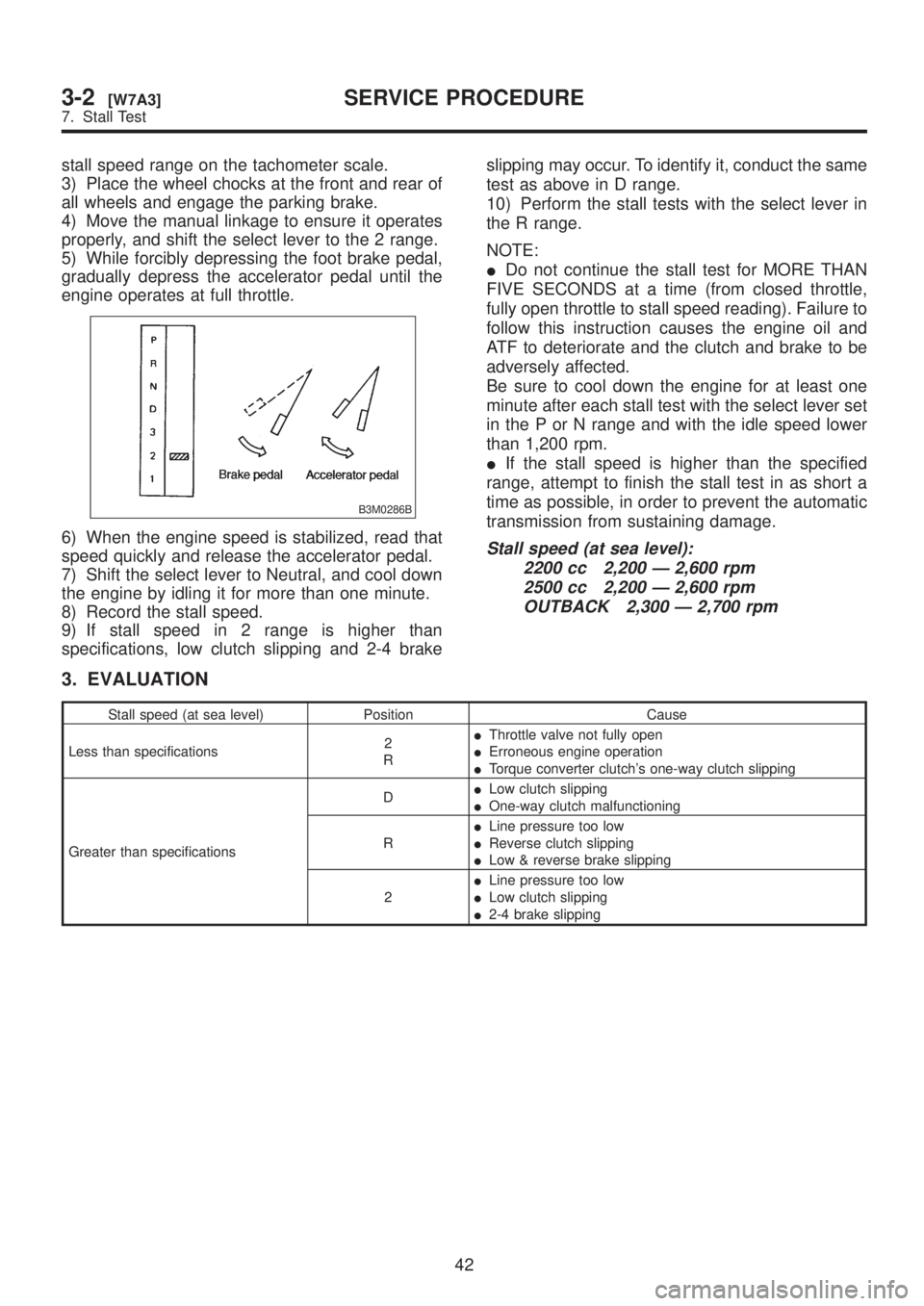

stall speed range on the tachometer scale.

3) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

4) Move the manual linkage to ensure it operates

properly, and shift the select lever to the 2 range.

5) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

B3M0286B

6) When the engine speed is stabilized, read that

speed quickly and release the accelerator pedal.

7) Shift the select lever to Neutral, and cool down

the engine by idling it for more than one minute.

8) Record the stall speed.

9) If stall speed in 2 range is higher than

specifications, low clutch slipping and 2-4 brakeslipping may occur. To identify it, conduct the same

test as above in D range.

10) Perform the stall tests with the select lever in

the R range.

NOTE:

IDo not continue the stall test for MORE THAN

FIVE SECONDS at a time (from closed throttle,

fully open throttle to stall speed reading). Failure to

follow this instruction causes the engine oil and

ATF to deteriorate and the clutch and brake to be

adversely affected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the P or N range and with the idle speed lower

than 1,200 rpm.

IIf the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.Stall speed (at sea level):

2200 cc 2,200 Ð 2,600 rpm

2500 cc 2,200 Ð 2,600 rpm

OUTBACK 2,300 Ð 2,700 rpm

3. EVALUATION

Stall speed (at sea level) Position Cause

Less than specifications2

RIThrottle valve not fully open

IErroneous engine operation

ITorque converter clutch's one-way clutch slipping

Greater than specificationsDILow clutch slipping

IOne-way clutch malfunctioning

RILine pressure too low

IReverse clutch slipping

ILow & reverse brake slipping

2ILine pressure too low

ILow clutch slipping

I2-4 brake slipping

42

3-2[W7A3]SERVICE PROCEDURE

7. Stall Test

Page 575 of 1456

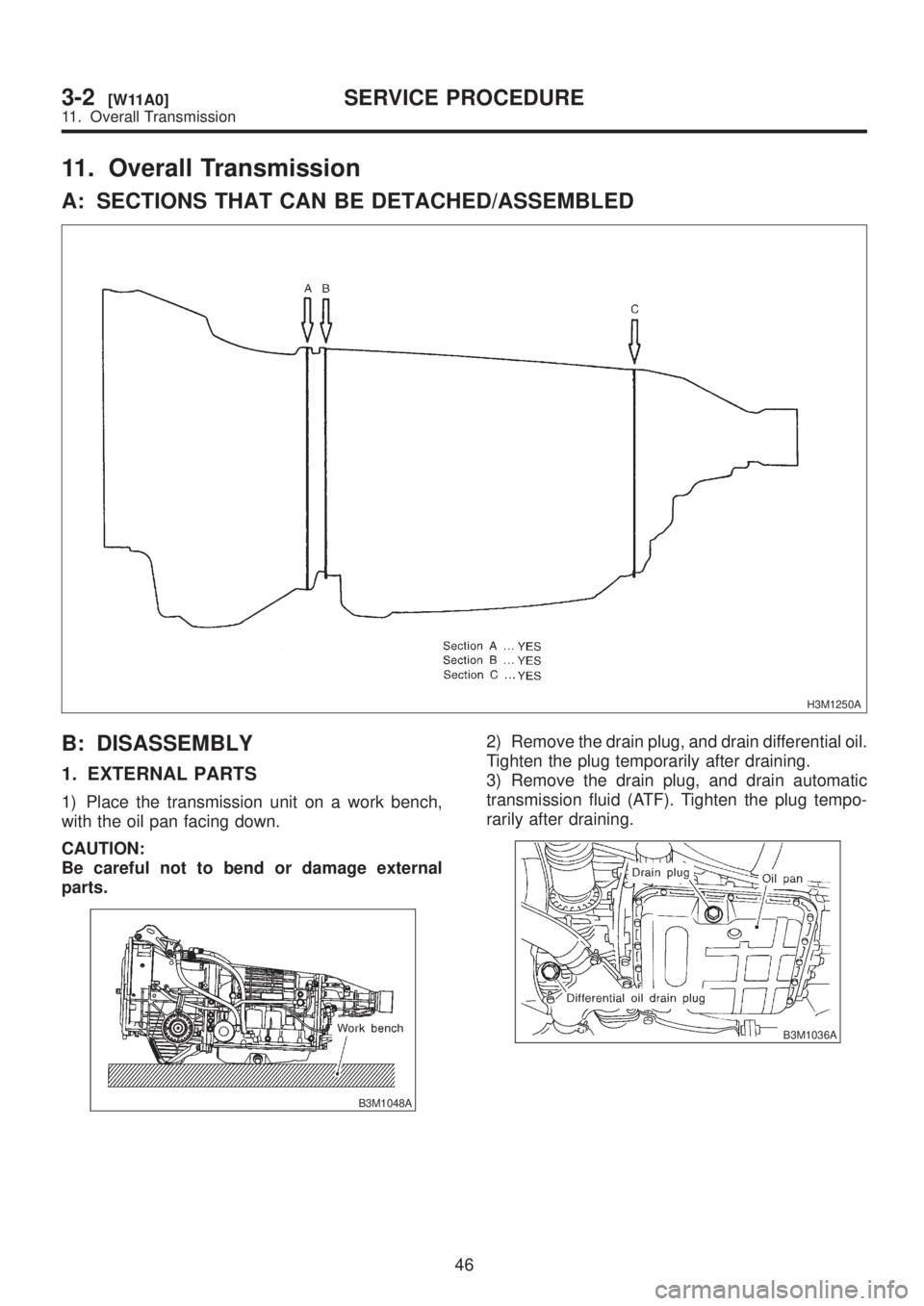

11. Overall Transmission

A: SECTIONS THAT CAN BE DETACHED/ASSEMBLED

H3M1250A

B: DISASSEMBLY

1. EXTERNAL PARTS

1) Place the transmission unit on a work bench,

with the oil pan facing down.

CAUTION:

Be careful not to bend or damage external

parts.

B3M1048A

2) Remove the drain plug, and drain differential oil.

Tighten the plug temporarily after draining.

3) Remove the drain plug, and drain automatic

transmission fluid (ATF). Tighten the plug tempo-

rarily after draining.

B3M1036A

46

3-2[W11A0]SERVICE PROCEDURE

11. Overall Transmission

Page 602 of 1456

12) Fill ATF and differential gear oil.

NOTE:

After filling oil, insert the oil level gauge into the oil

inlet.

Differential gear oil capacity:

1.1 Ð 1.3

(1.2 Ð 1.4 US qt, 1.0 Ð 1.1

Imp qt)

Automatic transmission fluid capacity:

2200 cc; 8.4 Ð 8.7

(8.9 Ð 9.2 US qt, 7.4

Ð 7.7 Imp qt)

2500 cc; 9.3 Ð 9.6

(9.8 Ð 10.1 US qt,

8.2 Ð 8.4 Imp qt)

Recommended fluid:

Dexron II or Dexron III type automatic

transmission

73

[W11C7]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 641 of 1456

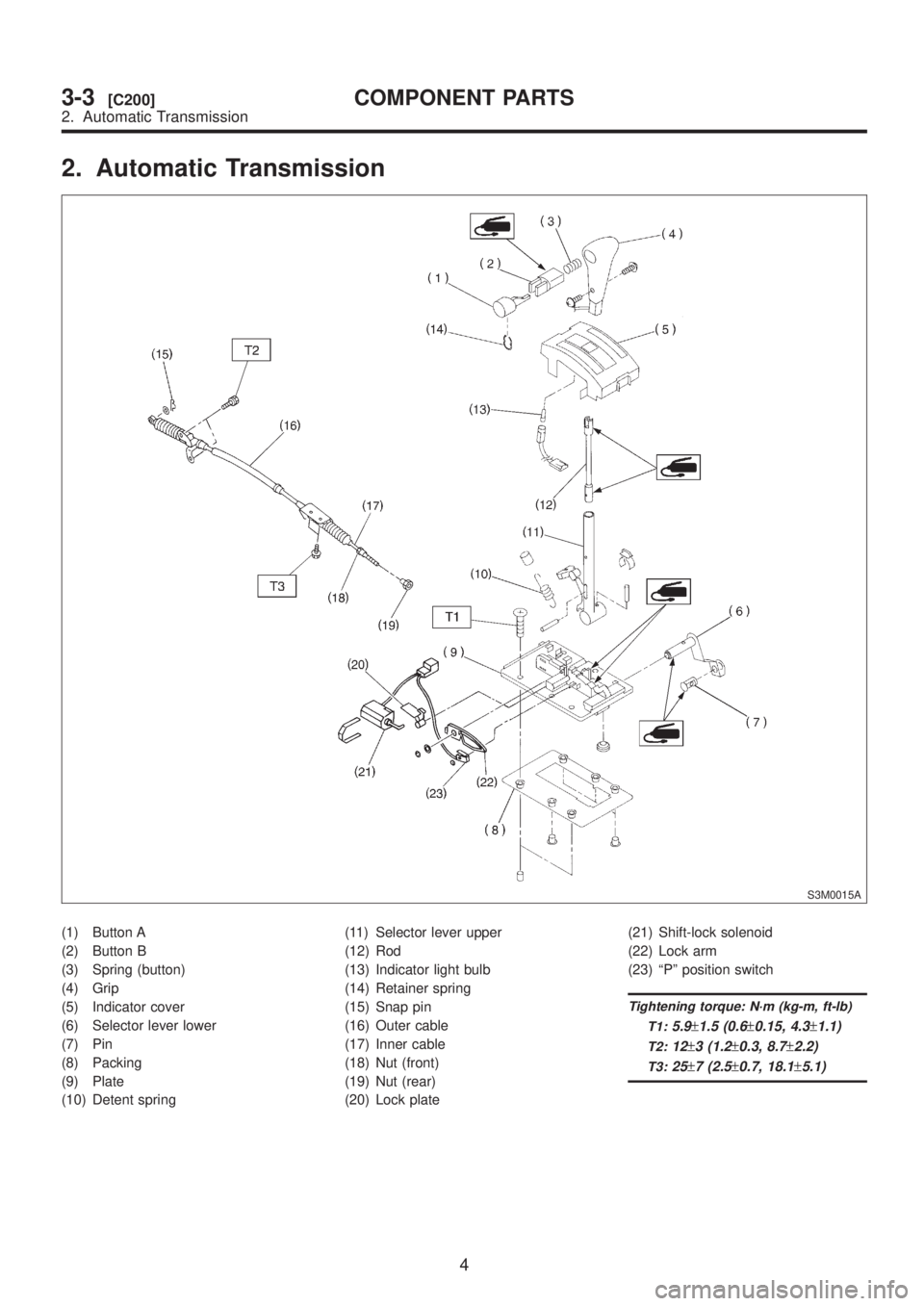

2. Automatic Transmission

S3M0015A

(1) Button A

(2) Button B

(3) Spring (button)

(4) Grip

(5) Indicator cover

(6) Selector lever lower

(7) Pin

(8) Packing

(9) Plate

(10) Detent spring(11) Selector lever upper

(12) Rod

(13) Indicator light bulb

(14) Retainer spring

(15) Snap pin

(16) Outer cable

(17) Inner cable

(18) Nut (front)

(19) Nut (rear)

(20) Lock plate(21) Shift-lock solenoid

(22) Lock arm

(23) ªPº position switch

Tightening torque: N´m (kg-m, ft-lb)

T1:

5.9±1.5 (0.6±0.15, 4.3±1.1)

T2:12±3 (1.2±0.3, 8.7±2.2)

T3:25±7 (2.5±0.7, 18.1±5.1)

4

3-3[C200]COMPONENT PARTS

2. Automatic Transmission

Page 645 of 1456

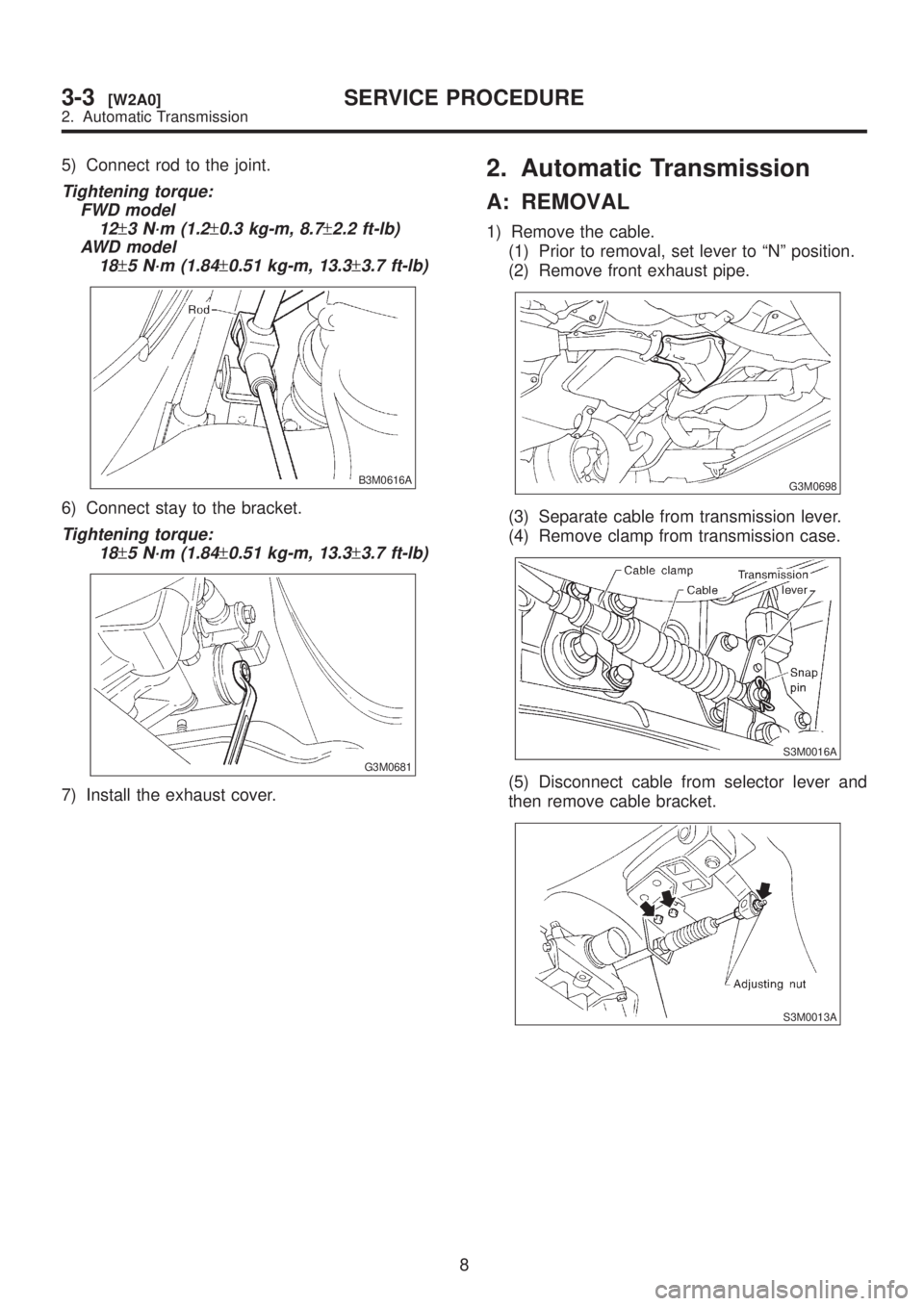

5) Connect rod to the joint.

Tightening torque:

FWD model

12

±3 N´m (1.2±0.3 kg-m, 8.7±2.2 ft-lb)

AWD model

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

B3M0616A

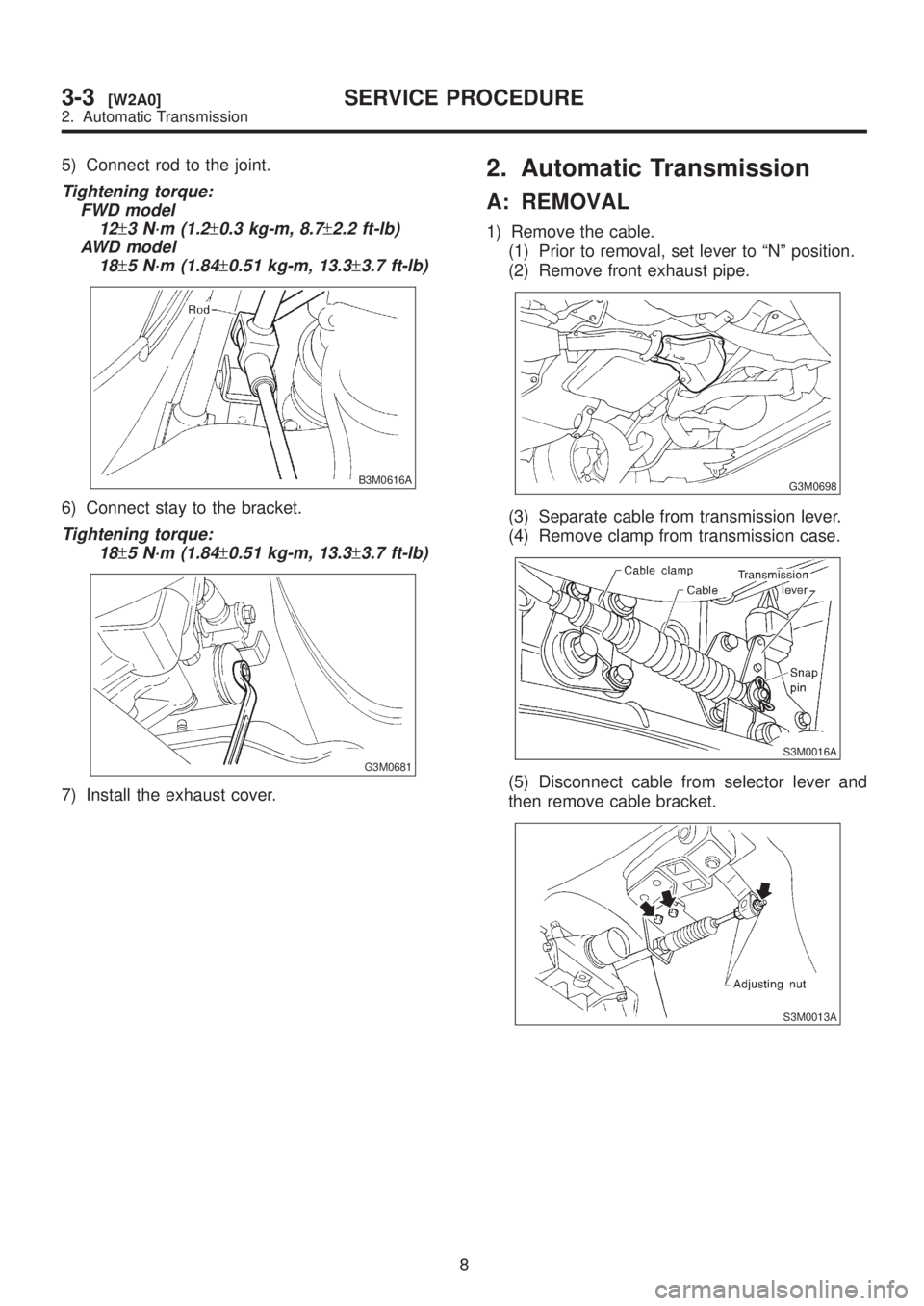

6) Connect stay to the bracket.

Tightening torque:

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

G3M0681

7) Install the exhaust cover.

2. Automatic Transmission

A: REMOVAL

1) Remove the cable.

(1) Prior to removal, set lever to ªNº position.

(2) Remove front exhaust pipe.

G3M0698

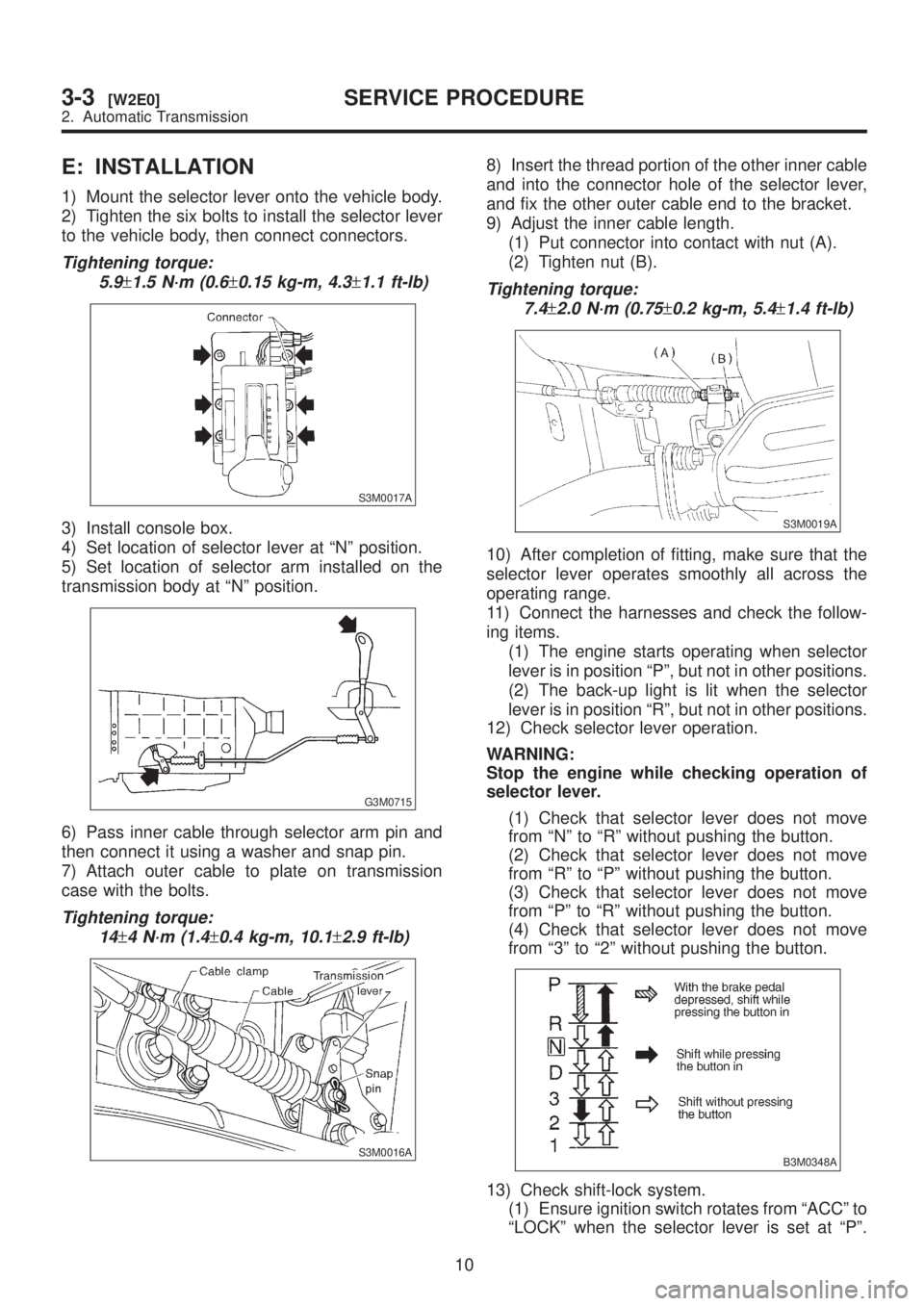

(3) Separate cable from transmission lever.

(4) Remove clamp from transmission case.

S3M0016A

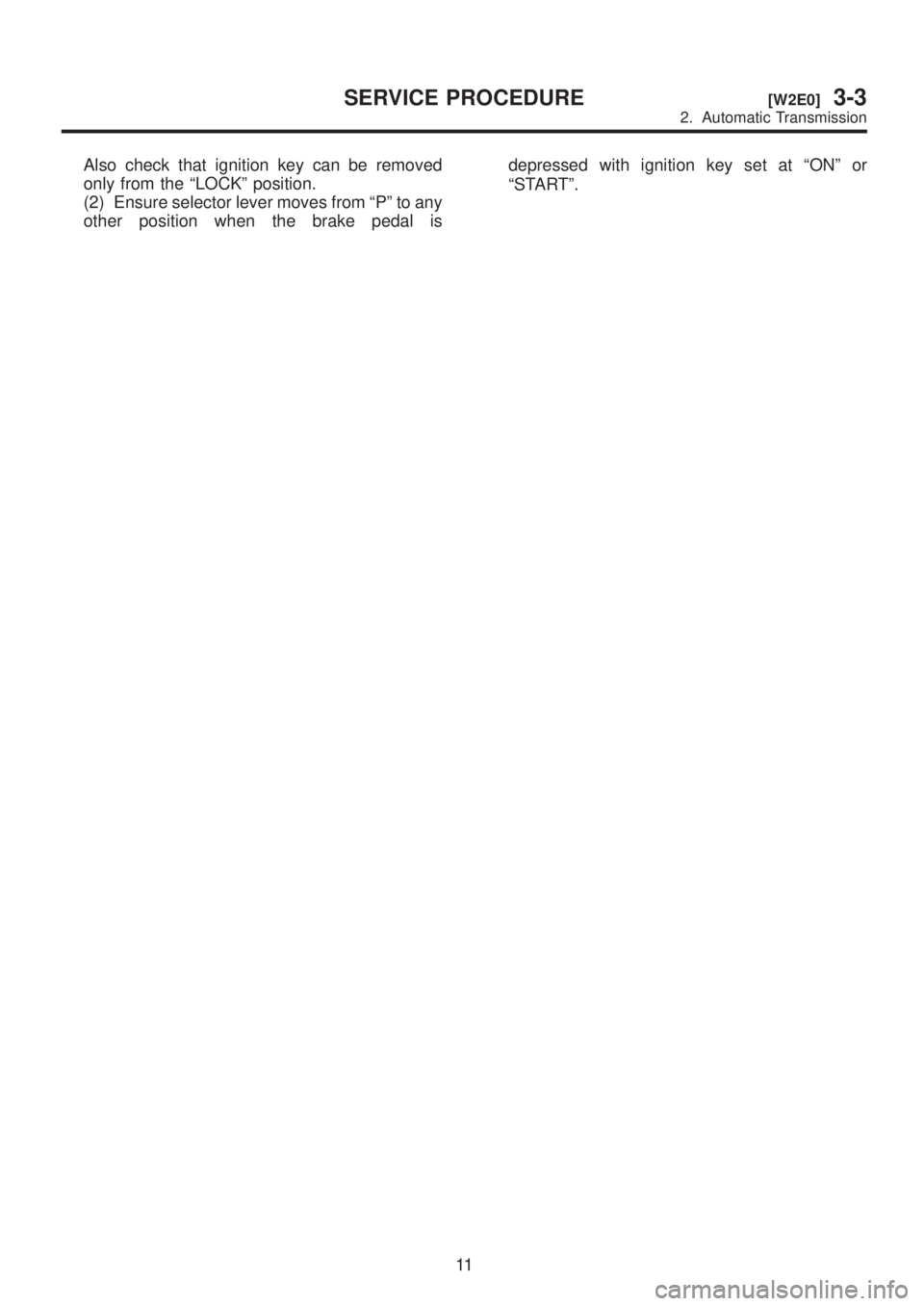

(5) Disconnect cable from selector lever and

then remove cable bracket.

S3M0013A

8

3-3[W2A0]SERVICE PROCEDURE

2. Automatic Transmission

Page 646 of 1456

5) Connect rod to the joint.

Tightening torque:

FWD model

12

±3 N´m (1.2±0.3 kg-m, 8.7±2.2 ft-lb)

AWD model

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

B3M0616A

6) Connect stay to the bracket.

Tightening torque:

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

G3M0681

7) Install the exhaust cover.

2. Automatic Transmission

A: REMOVAL

1) Remove the cable.

(1) Prior to removal, set lever to ªNº position.

(2) Remove front exhaust pipe.

G3M0698

(3) Separate cable from transmission lever.

(4) Remove clamp from transmission case.

S3M0016A

(5) Disconnect cable from selector lever and

then remove cable bracket.

S3M0013A

8

3-3[W2A0]SERVICE PROCEDURE

2. Automatic Transmission

Page 647 of 1456

![SUBARU LEGACY 1999 Service Owners Manual 2) Remove console box. <Ref. to 5-4 [W1A0].>

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector SUBARU LEGACY 1999 Service Owners Manual 2) Remove console box. <Ref. to 5-4 [W1A0].>

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector](/img/17/57435/w960_57435-646.png)

2) Remove console box.

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector from plate.

B3M0645

2) Remove indicator light and two screws.

3) Remove retainer spring, then pull up selector

lever grip with indicator cover for holding selector

lever button.

CAUTION:

Pull the selector lever grip carefully so that the

selector lever button may not jump out.

B3M0646A

4) Remove shift-lock solenoid and ªPº position

switch.

S3M0018A

5) Remove cap and clip, then extract pin.

6) Remove selector lever lower then take away

selector lever upper from plate.

B3M0647A

C: INSPECTION

1) Inspect removed parts by comparing with new

ones for deformation, damage and wear. Correct

or replace if defective.

2) Confirm the following parts for operating condi-

tion before assembly.

(1) Sliding condition of the button in the grip ...

it should move smoothly.

(2) Insertion of the grip on the selector lever ...

when pushing the grip on the selector lever by

hand, screw holes should be aligned.

(3) Operation of selector lever and rod ... they

should move smoothly.

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [NIGTIGHT LYW No. 2 or equiva-

lent] to each parts.

3) Assembly is in the reverse order of disassem-

bly.

4) After completion of fitting, transfer selector

lever to range ªPº Ð ª1º, pressing the button of the

grip; then check whether the indicator and selector

lever agree, whether the pointer and position mark

agree and what the operating force is.

9

[W2D0]3-3SERVICE PROCEDURE

2. Automatic Transmission

Page 648 of 1456

E: INSTALLATION

1) Mount the selector lever onto the vehicle body.

2) Tighten the six bolts to install the selector lever

to the vehicle body, then connect connectors.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

S3M0017A

3) Install console box.

4) Set location of selector lever at ªNº position.

5) Set location of selector arm installed on the

transmission body at ªNº position.

G3M0715

6) Pass inner cable through selector arm pin and

then connect it using a washer and snap pin.

7) Attach outer cable to plate on transmission

case with the bolts.

Tightening torque:

14

±4 N´m (1.4±0.4 kg-m, 10.1±2.9 ft-lb)

S3M0016A

8) Insert the thread portion of the other inner cable

and into the connector hole of the selector lever,

and fix the other outer cable end to the bracket.

9) Adjust the inner cable length.

(1) Put connector into contact with nut (A).

(2) Tighten nut (B).

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S3M0019A

10) After completion of fitting, make sure that the

selector lever operates smoothly all across the

operating range.

11) Connect the harnesses and check the follow-

ing items.

(1) The engine starts operating when selector

lever is in position ªPº, but not in other positions.

(2) The back-up light is lit when the selector

lever is in position ªRº, but not in other positions.

12) Check selector lever operation.

WARNING:

Stop the engine while checking operation of

selector lever.

(1) Check that selector lever does not move

from ªNº to ªRº without pushing the button.

(2) Check that selector lever does not move

from ªRº to ªPº without pushing the button.

(3) Check that selector lever does not move

from ªPº to ªRº without pushing the button.

(4) Check that selector lever does not move

from ª3º to ª2º without pushing the button.

B3M0348A

13) Check shift-lock system.

(1) Ensure ignition switch rotates from ªACCº to

ªLOCKº when the selector lever is set at ªPº.

10

3-3[W2E0]SERVICE PROCEDURE

2. Automatic Transmission

Page 649 of 1456

Also check that ignition key can be removed

only from the ªLOCKº position.

(2) Ensure selector lever moves from ªPº to any

other position when the brake pedal isdepressed with ignition key set at ªONº or

ªSTARTº.

11

[W2E0]3-3SERVICE PROCEDURE

2. Automatic Transmission

Page 873 of 1456

1. Brakes

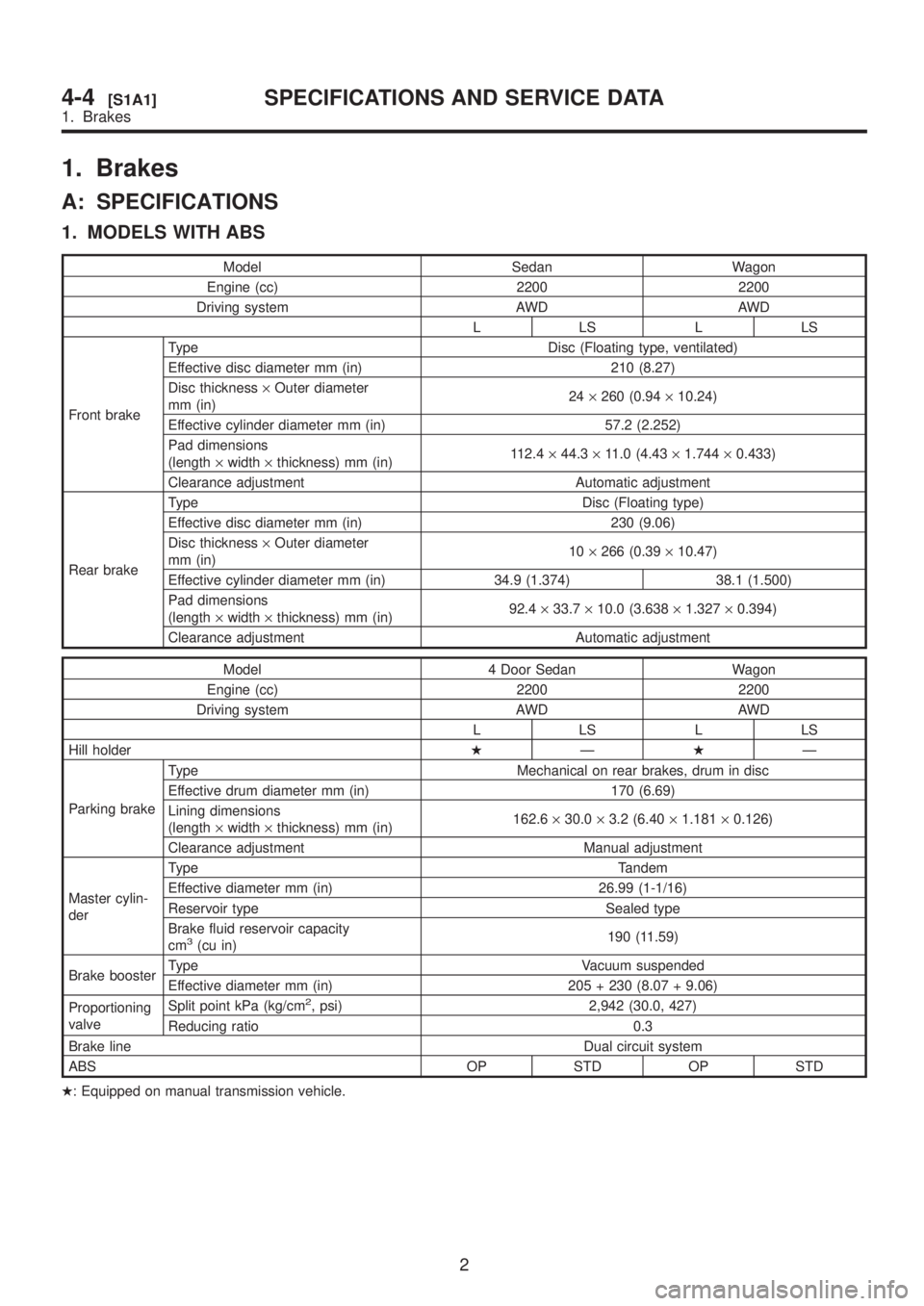

A: SPECIFICATIONS

1. MODELS WITH ABS

Model Sedan Wagon

Engine (cc) 2200 2200

Driving system AWD AWD

LLSLLS

Front brakeType Disc (Floating type, ventilated)

Effective disc diameter mm (in) 210 (8.27)

Disc thickness´Outer diameter

mm (in)24´260 (0.94´10.24)

Effective cylinder diameter mm (in) 57.2 (2.252)

Pad dimensions

(length´width´thickness) mm (in)112.4´44.3´11.0 (4.43´1.744´0.433)

Clearance adjustment Automatic adjustment

Rear brakeType Disc (Floating type)

Effective disc diameter mm (in) 230 (9.06)

Disc thickness´Outer diameter

mm (in)10´266 (0.39´10.47)

Effective cylinder diameter mm (in) 34.9 (1.374) 38.1 (1.500)

Pad dimensions

(length´width´thickness) mm (in)92.4´33.7´10.0 (3.638´1.327´0.394)

Clearance adjustment Automatic adjustment

Model 4 Door Sedan Wagon

Engine (cc) 2200 2200

Driving system AWD AWD

LLSLLS

Hill holderHÐHÐ

Parking brakeType Mechanical on rear brakes, drum in disc

Effective drum diameter mm (in) 170 (6.69)

Lining dimensions

(length´width´thickness) mm (in)162.6´30.0´3.2 (6.40´1.181´0.126)

Clearance adjustment Manual adjustment

Master cylin-

derType Tandem

Effective diameter mm (in) 26.99 (1-1/16)

Reservoir type Sealed type

Brake fluid reservoir capacity

cm

3(cu in)190 (11.59)

Brake boosterType Vacuum suspended

Effective diameter mm (in) 205 + 230 (8.07 + 9.06)

Proportioning

valveSplit point kPa (kg/cm

2, psi) 2,942 (30.0, 427)

Reducing ratio 0.3

Brake lineDual circuit system

ABS OP STD OP STD

H: Equipped on manual transmission vehicle.

2

4-4[S1A1]SPECIFICATIONS AND SERVICE DATA

1. Brakes