diff SUBARU LEGACY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 484 of 1456

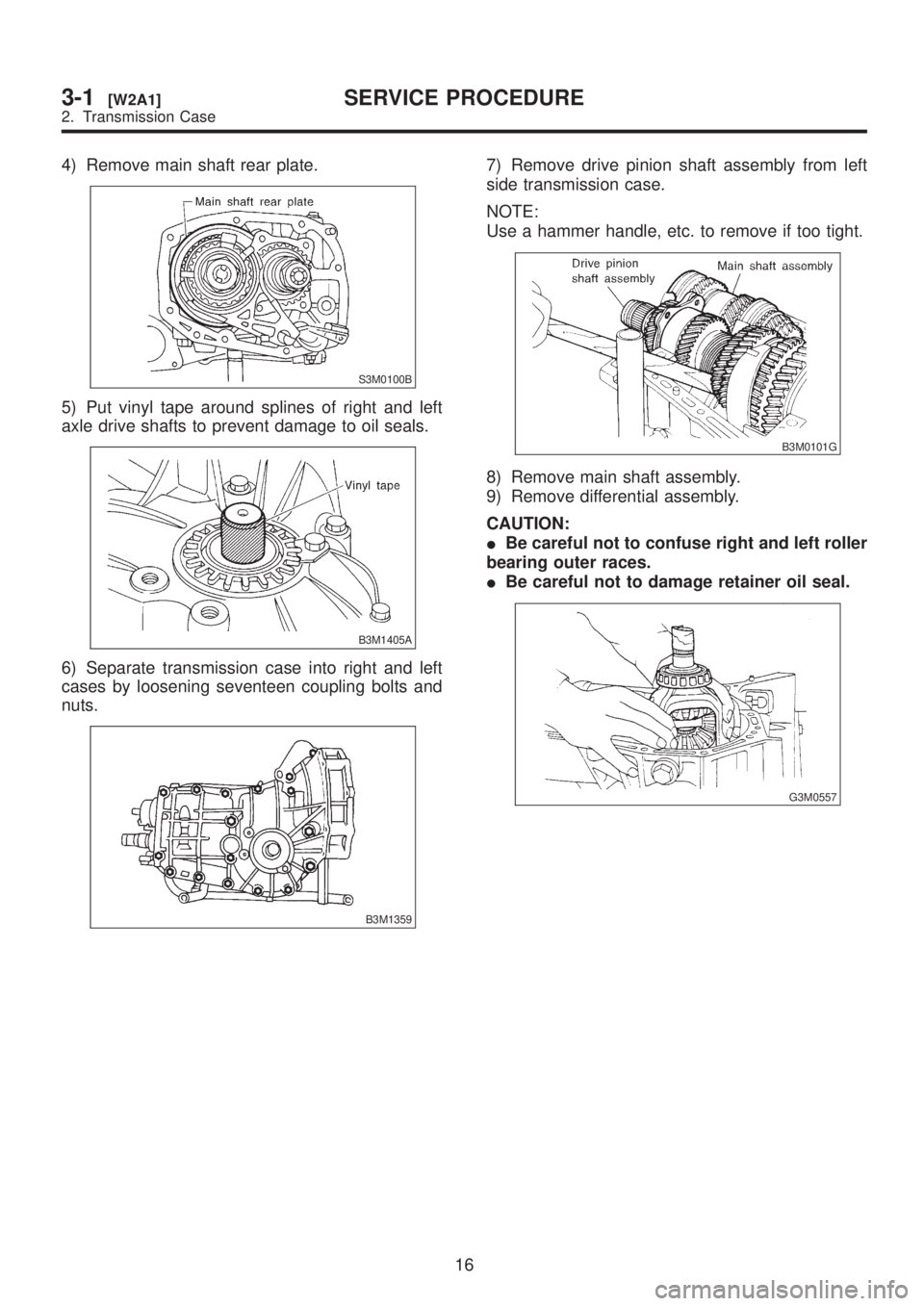

4) Remove main shaft rear plate.

S3M0100B

5) Put vinyl tape around splines of right and left

axle drive shafts to prevent damage to oil seals.

B3M1405A

6) Separate transmission case into right and left

cases by loosening seventeen coupling bolts and

nuts.

B3M1359

7) Remove drive pinion shaft assembly from left

side transmission case.

NOTE:

Use a hammer handle, etc. to remove if too tight.

B3M0101G

8) Remove main shaft assembly.

9) Remove differential assembly.

CAUTION:

IBe careful not to confuse right and left roller

bearing outer races.

IBe careful not to damage retainer oil seal.

G3M0557

16

3-1[W2A1]SERVICE PROCEDURE

2. Transmission Case

Page 486 of 1456

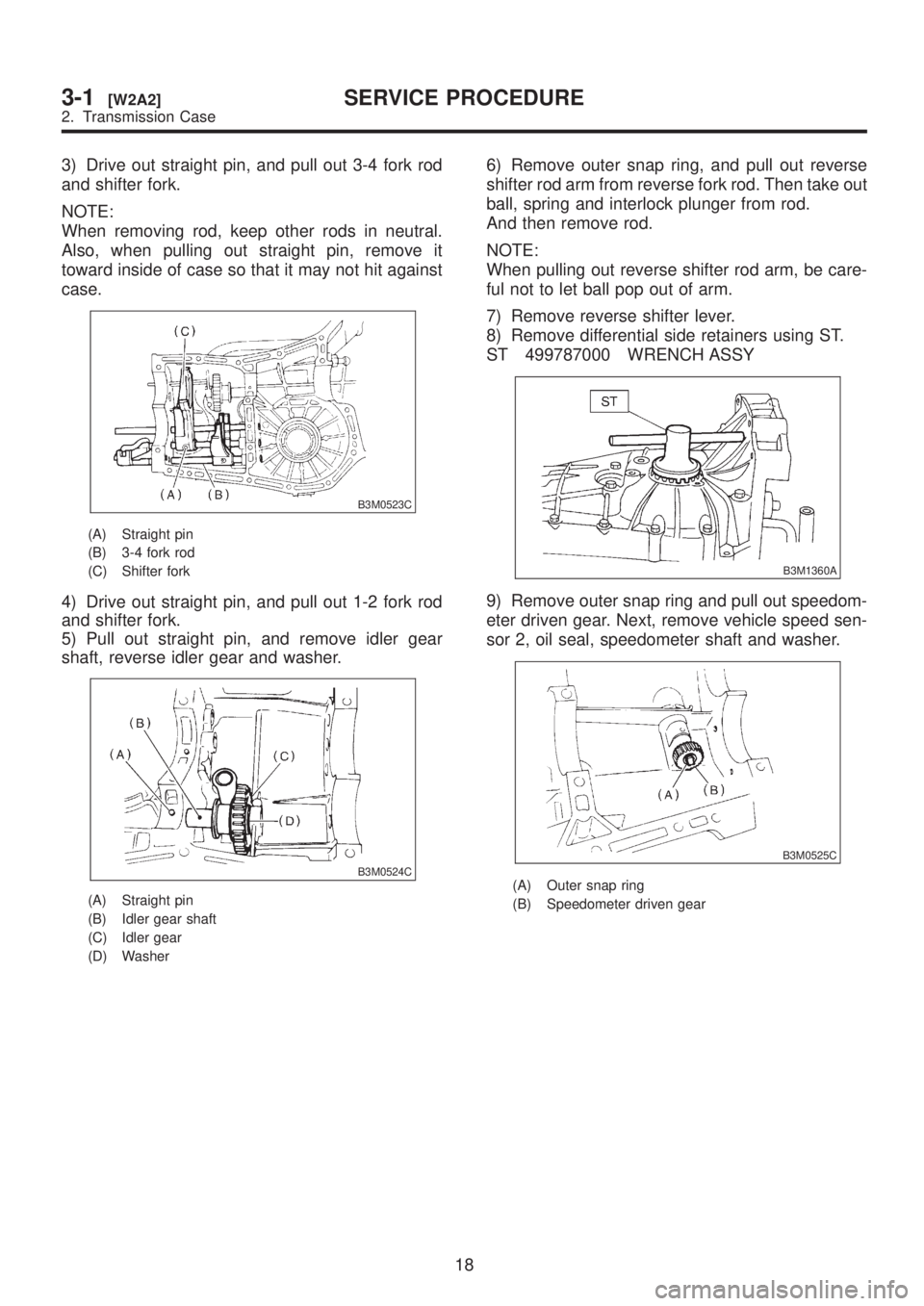

3) Drive out straight pin, and pull out 3-4 fork rod

and shifter fork.

NOTE:

When removing rod, keep other rods in neutral.

Also, when pulling out straight pin, remove it

toward inside of case so that it may not hit against

case.

B3M0523C

(A) Straight pin

(B) 3-4 fork rod

(C) Shifter fork

4) Drive out straight pin, and pull out 1-2 fork rod

and shifter fork.

5) Pull out straight pin, and remove idler gear

shaft, reverse idler gear and washer.

B3M0524C

(A) Straight pin

(B) Idler gear shaft

(C) Idler gear

(D) Washer

6) Remove outer snap ring, and pull out reverse

shifter rod arm from reverse fork rod. Then take out

ball, spring and interlock plunger from rod.

And then remove rod.

NOTE:

When pulling out reverse shifter rod arm, be care-

ful not to let ball pop out of arm.

7) Remove reverse shifter lever.

8) Remove differential side retainers using ST.

ST 499787000 WRENCH ASSY

B3M1360A

9) Remove outer snap ring and pull out speedom-

eter driven gear. Next, remove vehicle speed sen-

sor 2, oil seal, speedometer shaft and washer.

B3M0525C

(A) Outer snap ring

(B) Speedometer driven gear

18

3-1[W2A2]SERVICE PROCEDURE

2. Transmission Case

Page 490 of 1456

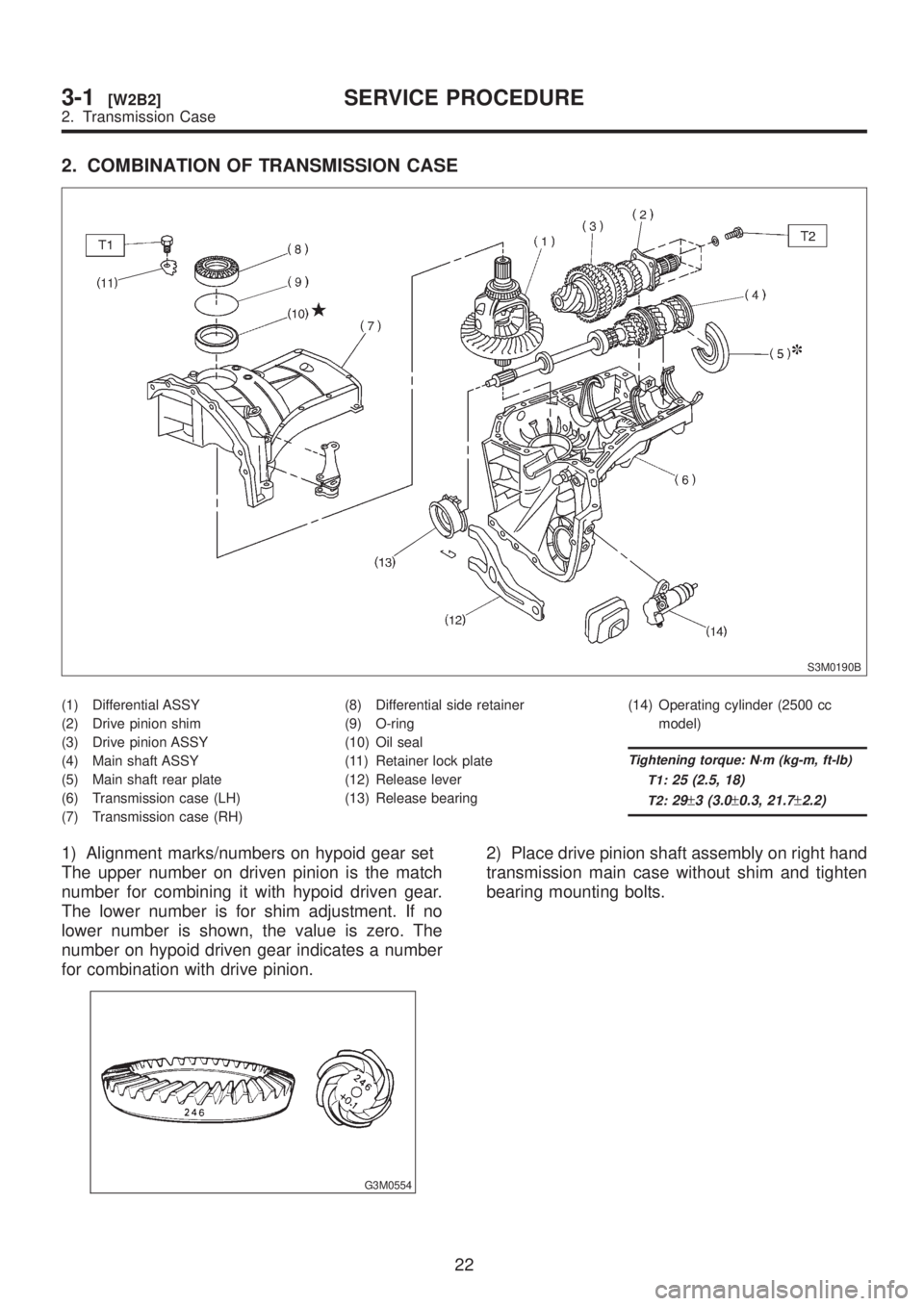

2. COMBINATION OF TRANSMISSION CASE

S3M0190B

(1) Differential ASSY

(2) Drive pinion shim

(3) Drive pinion ASSY

(4) Main shaft ASSY

(5) Main shaft rear plate

(6) Transmission case (LH)

(7) Transmission case (RH)(8) Differential side retainer

(9) O-ring

(10) Oil seal

(11) Retainer lock plate

(12) Release lever

(13) Release bearing(14) Operating cylinder (2500 cc

model)

Tightening torque: N´m (kg-m, ft-lb)

T1:

25 (2.5, 18)

T2:29±3 (3.0±0.3, 21.7±2.2)

1) Alignment marks/numbers on hypoid gear set

The upper number on driven pinion is the match

number for combining it with hypoid driven gear.

The lower number is for shim adjustment. If no

lower number is shown, the value is zero. The

number on hypoid driven gear indicates a number

for combination with drive pinion.

G3M0554

2) Place drive pinion shaft assembly on right hand

transmission main case without shim and tighten

bearing mounting bolts.

22

3-1[W2B2]SERVICE PROCEDURE

2. Transmission Case

Page 491 of 1456

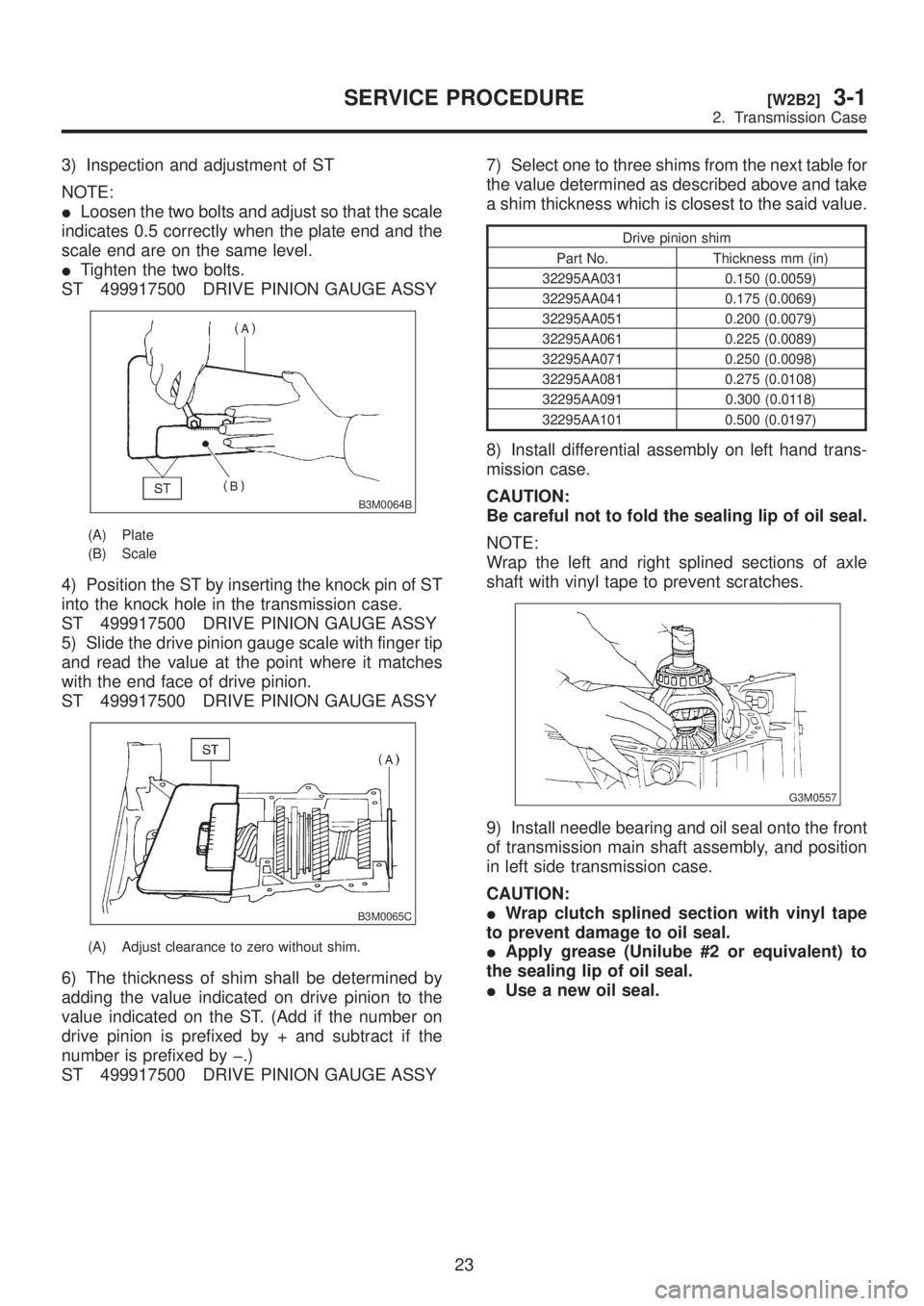

3) Inspection and adjustment of ST

NOTE:

ILoosen the two bolts and adjust so that the scale

indicates 0.5 correctly when the plate end and the

scale end are on the same level.

ITighten the two bolts.

ST 499917500 DRIVE PINION GAUGE ASSY

B3M0064B

(A) Plate

(B) Scale

4) Position the ST by inserting the knock pin of ST

into the knock hole in the transmission case.

ST 499917500 DRIVE PINION GAUGE ASSY

5) Slide the drive pinion gauge scale with finger tip

and read the value at the point where it matches

with the end face of drive pinion.

ST 499917500 DRIVE PINION GAUGE ASSY

B3M0065C

(A) Adjust clearance to zero without shim.

6) The thickness of shim shall be determined by

adding the value indicated on drive pinion to the

value indicated on the ST. (Add if the number on

drive pinion is prefixed by + and subtract if the

number is prefixed by þ.)

ST 499917500 DRIVE PINION GAUGE ASSY7) Select one to three shims from the next table for

the value determined as described above and take

a shim thickness which is closest to the said value.

Drive pinion shim

Part No. Thickness mm (in)

32295AA031 0.150 (0.0059)

32295AA041 0.175 (0.0069)

32295AA051 0.200 (0.0079)

32295AA061 0.225 (0.0089)

32295AA071 0.250 (0.0098)

32295AA081 0.275 (0.0108)

32295AA091 0.300 (0.0118)

32295AA101 0.500 (0.0197)

8) Install differential assembly on left hand trans-

mission case.

CAUTION:

Be careful not to fold the sealing lip of oil seal.

NOTE:

Wrap the left and right splined sections of axle

shaft with vinyl tape to prevent scratches.

G3M0557

9) Install needle bearing and oil seal onto the front

of transmission main shaft assembly, and position

in left side transmission case.

CAUTION:

IWrap clutch splined section with vinyl tape

to prevent damage to oil seal.

IApply grease (Unilube #2 or equivalent) to

the sealing lip of oil seal.

IUse a new oil seal.

23

[W2B2]3-1SERVICE PROCEDURE

2. Transmission Case

Page 497 of 1456

3. Drive Pinion Assembly

A: DISASSEMBLY

1. DRIVE PINION SHAFT

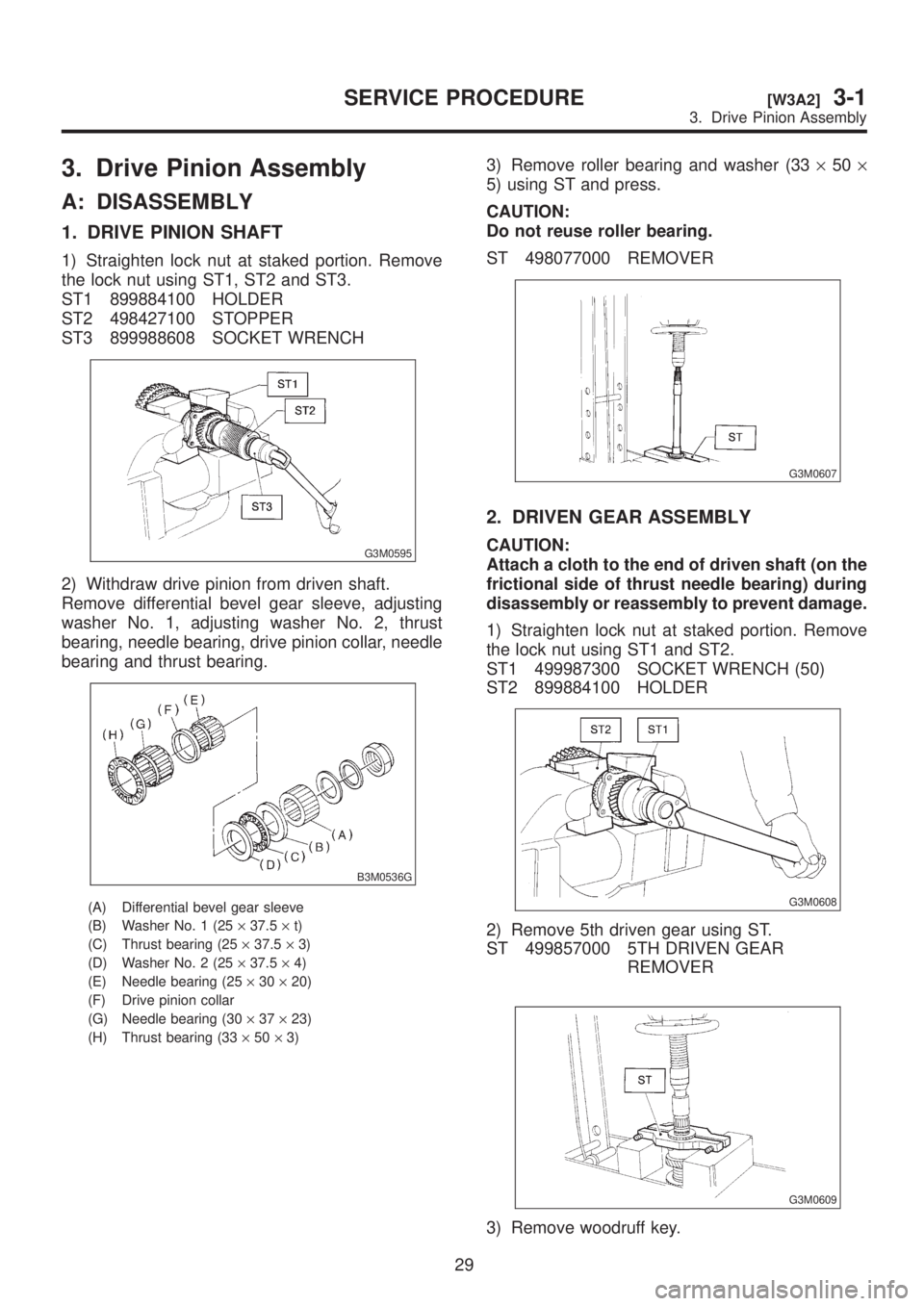

1) Straighten lock nut at staked portion. Remove

the lock nut using ST1, ST2 and ST3.

ST1 899884100 HOLDER

ST2 498427100 STOPPER

ST3 899988608 SOCKET WRENCH

G3M0595

2) Withdraw drive pinion from driven shaft.

Remove differential bevel gear sleeve, adjusting

washer No. 1, adjusting washer No. 2, thrust

bearing, needle bearing, drive pinion collar, needle

bearing and thrust bearing.

B3M0536G

(A) Differential bevel gear sleeve

(B) Washer No. 1 (25´37.5´t)

(C) Thrust bearing (25´37.5´3)

(D) Washer No. 2 (25´37.5´4)

(E) Needle bearing (25´30´20)

(F) Drive pinion collar

(G) Needle bearing (30´37´23)

(H) Thrust bearing (33´50´3)

3) Remove roller bearing and washer (33´50´

5) using ST and press.

CAUTION:

Do not reuse roller bearing.

ST 498077000 REMOVER

G3M0607

2. DRIVEN GEAR ASSEMBLY

CAUTION:

Attach a cloth to the end of driven shaft (on the

frictional side of thrust needle bearing) during

disassembly or reassembly to prevent damage.

1) Straighten lock nut at staked portion. Remove

the lock nut using ST1 and ST2.

ST1 499987300 SOCKET WRENCH (50)

ST2 899884100 HOLDER

G3M0608

2) Remove 5th driven gear using ST.

ST 499857000 5TH DRIVEN GEAR

REMOVER

G3M0609

3) Remove woodruff key.

29

[W3A2]3-1SERVICE PROCEDURE

3. Drive Pinion Assembly

Page 501 of 1456

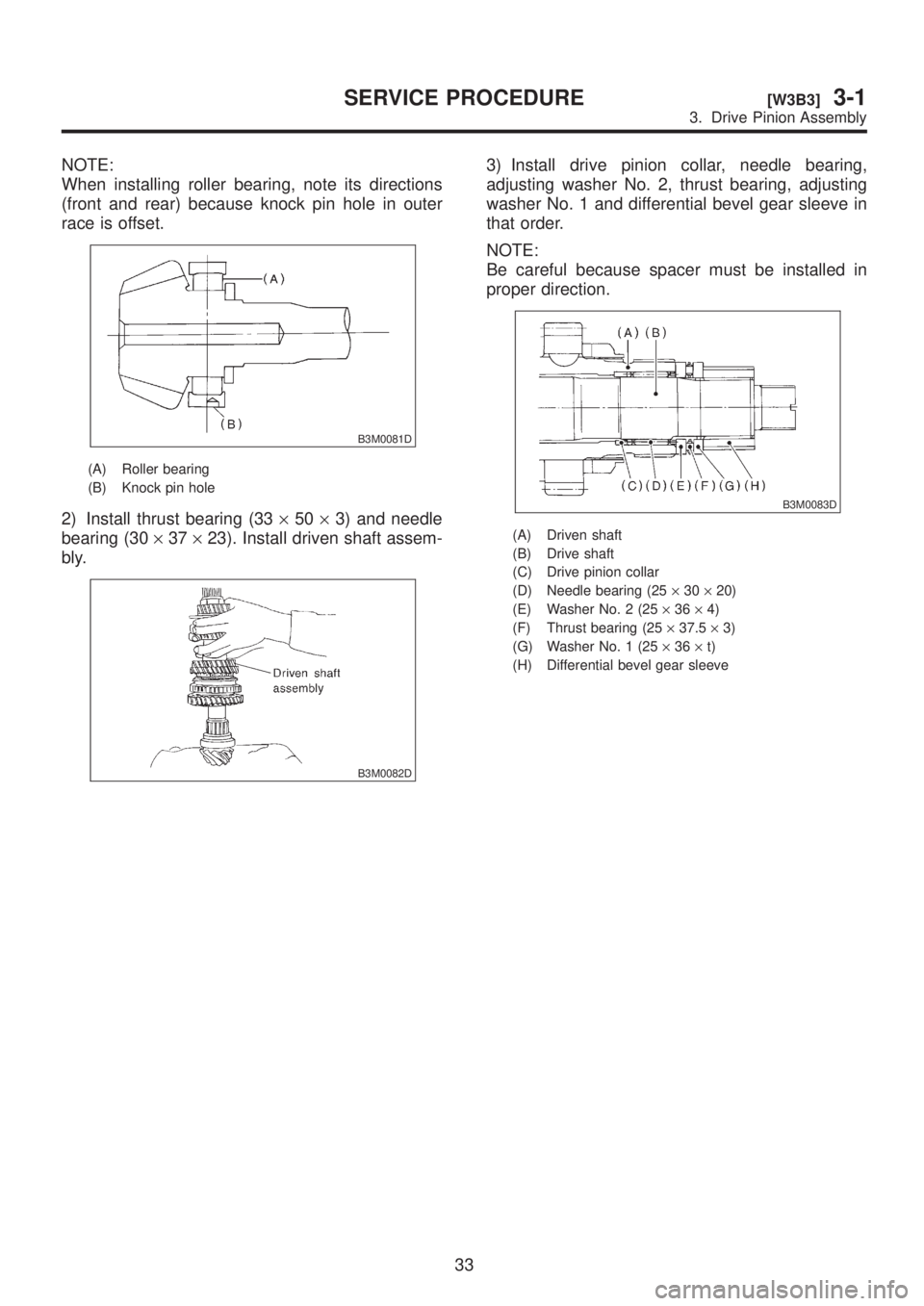

NOTE:

When installing roller bearing, note its directions

(front and rear) because knock pin hole in outer

race is offset.

B3M0081D

(A) Roller bearing

(B) Knock pin hole

2) Install thrust bearing (33´50´3) and needle

bearing (30´37´23). Install driven shaft assem-

bly.

B3M0082D

3) Install drive pinion collar, needle bearing,

adjusting washer No. 2, thrust bearing, adjusting

washer No. 1 and differential bevel gear sleeve in

that order.

NOTE:

Be careful because spacer must be installed in

proper direction.

B3M0083D

(A) Driven shaft

(B) Drive shaft

(C) Drive pinion collar

(D) Needle bearing (25´30´20)

(E) Washer No. 2 (25´36´4)

(F) Thrust bearing (25´37.5´3)

(G) Washer No. 1 (25´36´t)

(H) Differential bevel gear sleeve

33

[W3B3]3-1SERVICE PROCEDURE

3. Drive Pinion Assembly

Page 513 of 1456

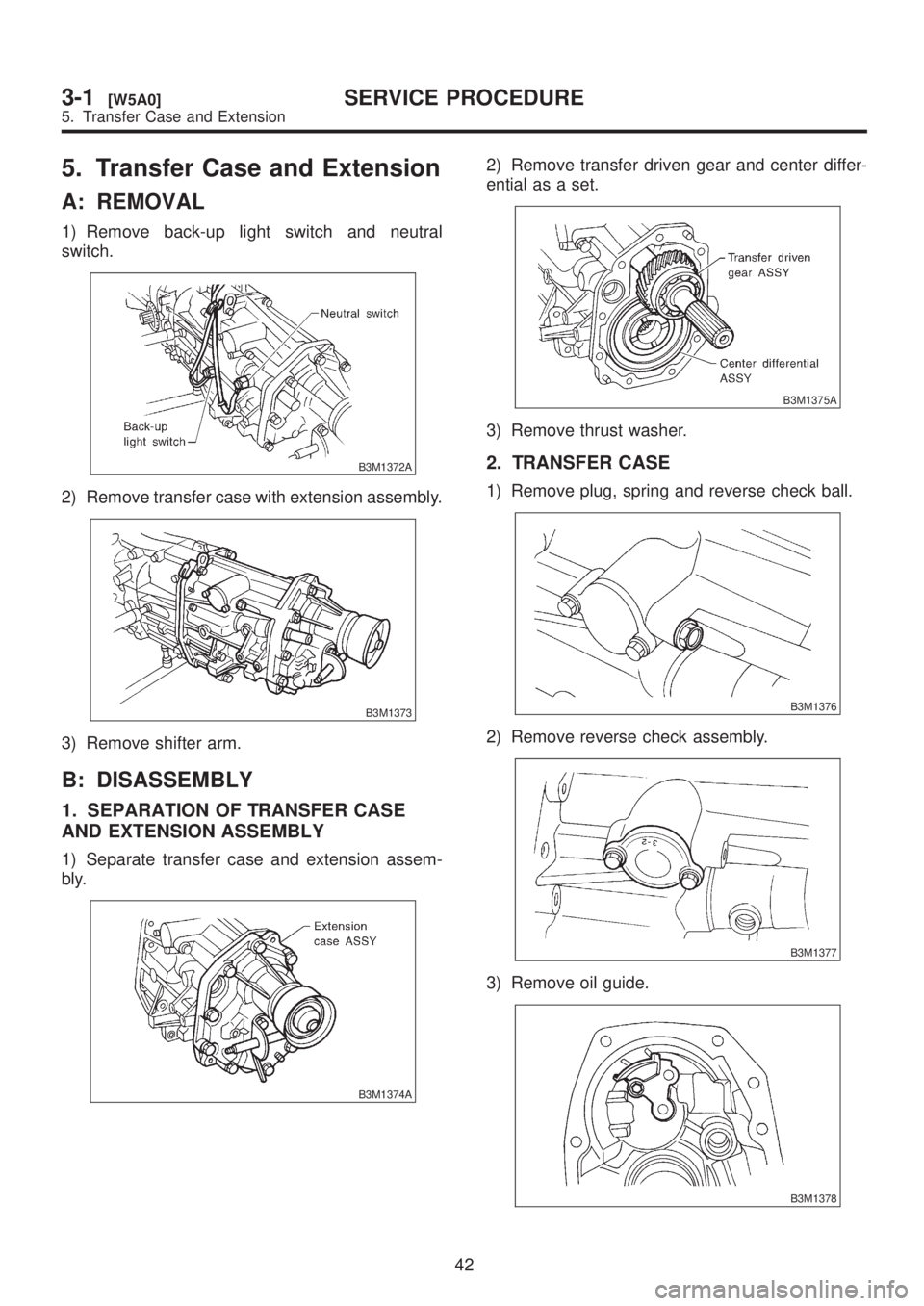

5. Transfer Case and Extension

A: REMOVAL

1) Remove back-up light switch and neutral

switch.

B3M1372A

2) Remove transfer case with extension assembly.

B3M1373

3) Remove shifter arm.

B: DISASSEMBLY

1. SEPARATION OF TRANSFER CASE

AND EXTENSION ASSEMBLY

1) Separate transfer case and extension assem-

bly.

B3M1374A

2) Remove transfer driven gear and center differ-

ential as a set.

B3M1375A

3) Remove thrust washer.

2. TRANSFER CASE

1) Remove plug, spring and reverse check ball.

B3M1376

2) Remove reverse check assembly.

B3M1377

3) Remove oil guide.

B3M1378

42

3-1[W5A0]SERVICE PROCEDURE

5. Transfer Case and Extension

Page 517 of 1456

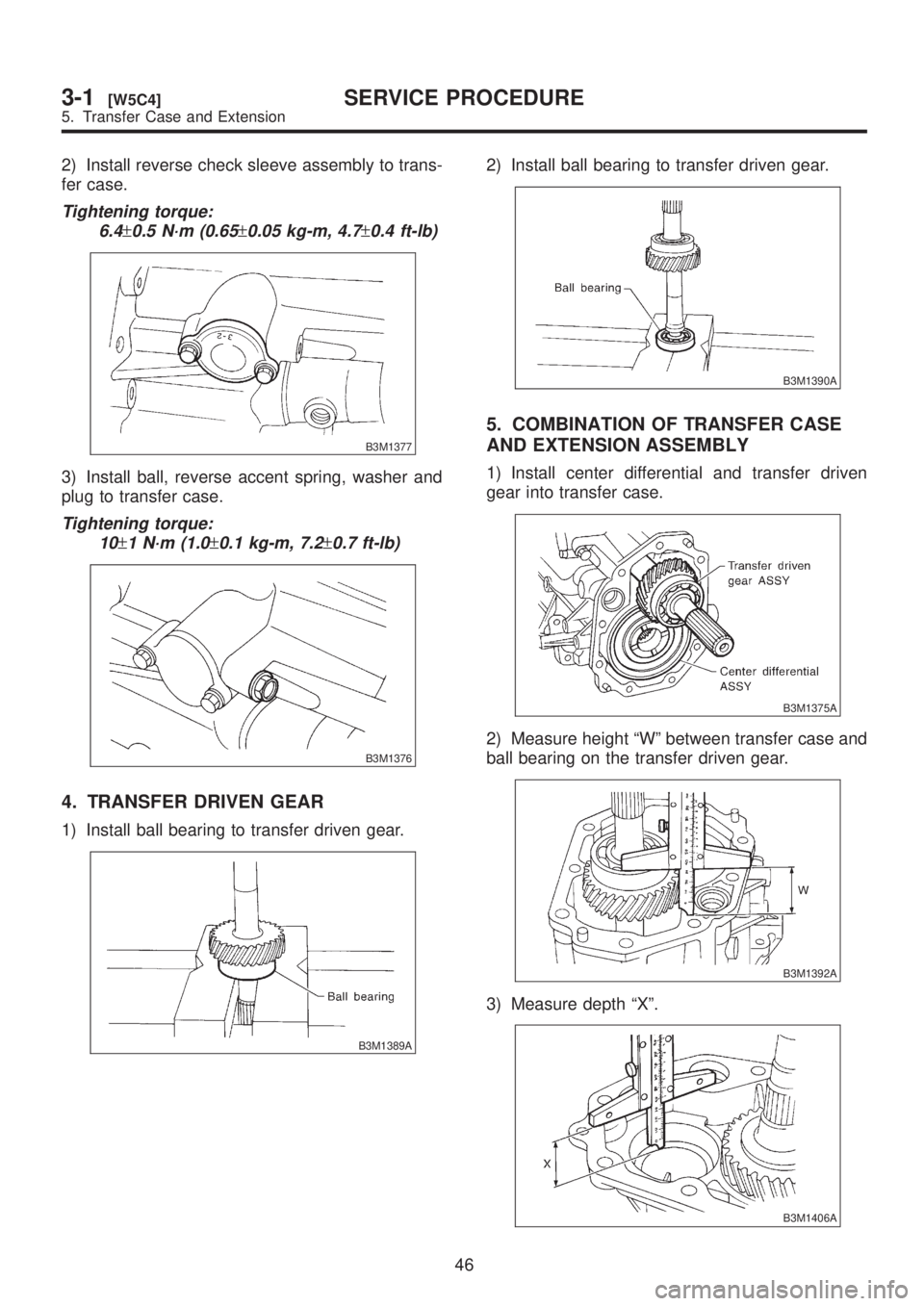

2) Install reverse check sleeve assembly to trans-

fer case.

Tightening torque:

6.4

±0.5 N´m (0.65±0.05 kg-m, 4.7±0.4 ft-lb)

B3M1377

3) Install ball, reverse accent spring, washer and

plug to transfer case.

Tightening torque:

10

±1 N´m (1.0±0.1 kg-m, 7.2±0.7 ft-lb)

B3M1376

4. TRANSFER DRIVEN GEAR

1) Install ball bearing to transfer driven gear.

B3M1389A

2) Install ball bearing to transfer driven gear.

B3M1390A

5. COMBINATION OF TRANSFER CASE

AND EXTENSION ASSEMBLY

1) Install center differential and transfer driven

gear into transfer case.

B3M1375A

2) Measure height ªWº between transfer case and

ball bearing on the transfer driven gear.

B3M1392A

3) Measure depth ªXº.

B3M1406A

46

3-1[W5C4]SERVICE PROCEDURE

5. Transfer Case and Extension

Page 518 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 4) Calculate space ªYº using the following equa-

tion: Y=XþW+0.24 mm (0.0094 in) [Thickness

of gasket]

5) Select suitable washer in the following table:

Standard clearance between thrust washer

and SUBARU LEGACY 1999 Service Owners Guide 4) Calculate space ªYº using the following equa-

tion: Y=XþW+0.24 mm (0.0094 in) [Thickness

of gasket]

5) Select suitable washer in the following table:

Standard clearance between thrust washer

and](/img/17/57435/w960_57435-517.png)

4) Calculate space ªYº using the following equa-

tion: Y=XþW+0.24 mm (0.0094 in) [Thickness

of gasket]

5) Select suitable washer in the following table:

Standard clearance between thrust washer

and ball bearing:

0.05 Ð 0.30 mm (0.0020 Ð 0.0118 in)

Space ªYº mm (in)Thrust washer (52´61´t)

Part No.Thickness

mm (in)

0.55 Ð 0.79

(0.0217 Ð 0.0311)803052021 0.50 (0.0197)

0.80 Ð 1.04

(0.0315 Ð 0.0409)803052022 0.75 (0.0295)

1.05 Ð 1.30

(0.0413 Ð 0.0512)803052023 1.00 (0.0394)

6) Fit thrust washers on transfer drive shaft.

7) Measure depth ªSº between transfer case and

center differential.

ST 398643600 GAUGE

B3M1407A

8) Measure depth ªTº between extension case

and transfer drive grar.

ST 398643600 GAUGE

B3M1395A

9) Calculate space ªUº using the following equa-

tion:U=S+T-0.24 mm (0.0094 in) [Thickness

of gasket]

10) Select suitable washer inthe following table:

Standard clearance:

0.15 Ð 0.35 mm (0.0059 Ð 0.0138 in)

Thrust washer

Part No. Thickness mm (in)

803036050 0.9 (0.035)

803036054 1.0 (0.039)

803036051 1.1 (0.043)

803036055 1.2 (0.047)

803036052 1.3 (0.051)

803036056 1.4 (0.055)

803036053 1.5 (0.059)

803036057 1.6 (0.063)

803036058 1.7 (0.067)

11) Fit thrust washer on center differential.

12) Install extension assembly into transfer case.

Tightening torque:

37

±3 N´m (3.8±0.3 kg-m, 27.5±2.2 ft-lb)

B3M0052A

D: INSTALLATION

1) Install shifter arm to transfer case.

B3M1396

2) Hang the shifter arm on the 3rd-4th fork rod.

B3M1397A

47

[W5D0]3-1SERVICE PROCEDURE

5. Transfer Case and Extension

Page 520 of 1456

6. Front Differential

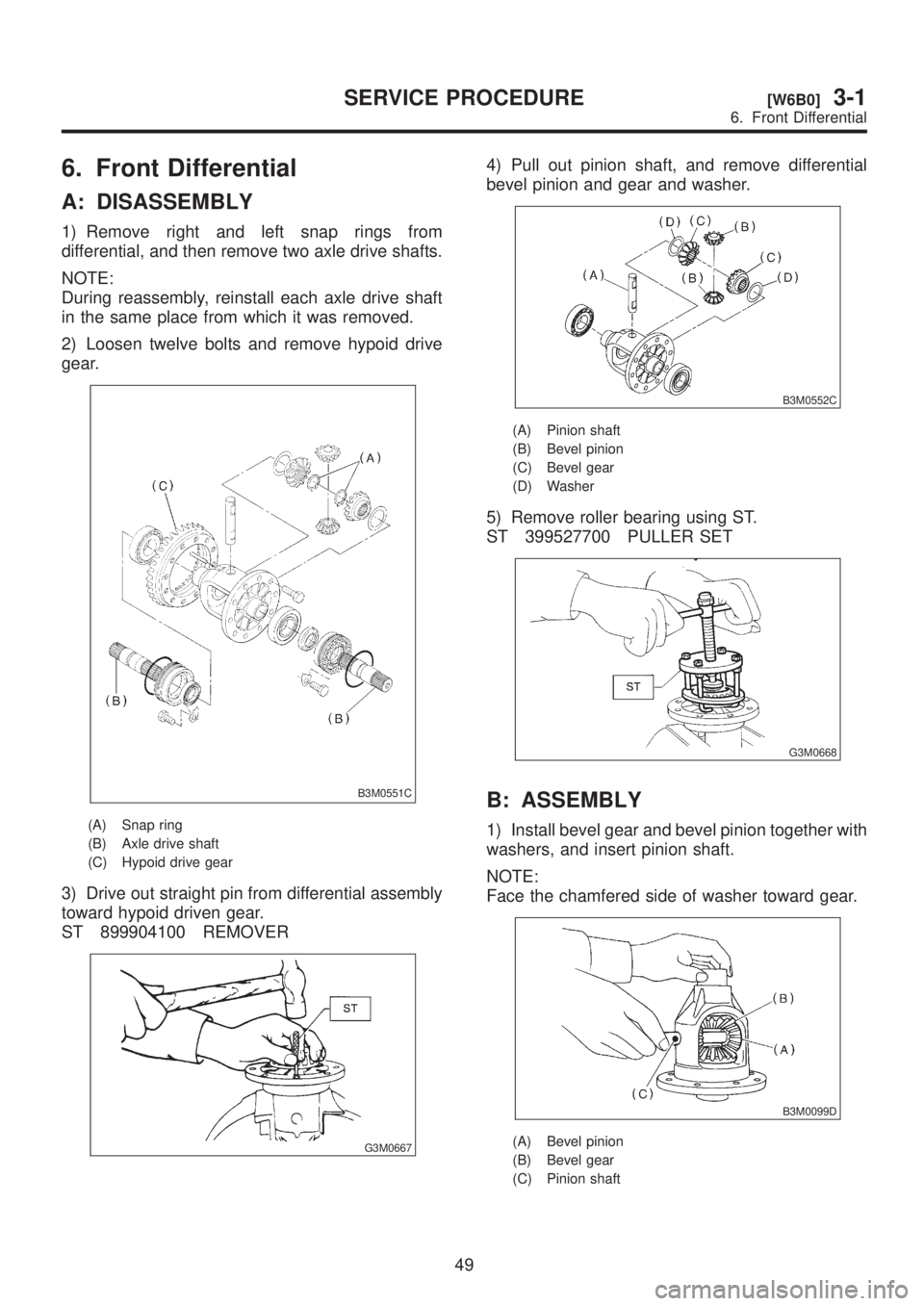

A: DISASSEMBLY

1) Remove right and left snap rings from

differential, and then remove two axle drive shafts.

NOTE:

During reassembly, reinstall each axle drive shaft

in the same place from which it was removed.

2) Loosen twelve bolts and remove hypoid drive

gear.

B3M0551C

(A) Snap ring

(B) Axle drive shaft

(C) Hypoid drive gear

3) Drive out straight pin from differential assembly

toward hypoid driven gear.

ST 899904100 REMOVER

G3M0667

4) Pull out pinion shaft, and remove differential

bevel pinion and gear and washer.

B3M0552C

(A) Pinion shaft

(B) Bevel pinion

(C) Bevel gear

(D) Washer

5) Remove roller bearing using ST.

ST 399527700 PULLER SET

G3M0668

B: ASSEMBLY

1) Install bevel gear and bevel pinion together with

washers, and insert pinion shaft.

NOTE:

Face the chamfered side of washer toward gear.

B3M0099D

(A) Bevel pinion

(B) Bevel gear

(C) Pinion shaft

49

[W6B0]3-1SERVICE PROCEDURE

6. Front Differential