automatic SUBARU LEGACY 1999 Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 646 of 1456

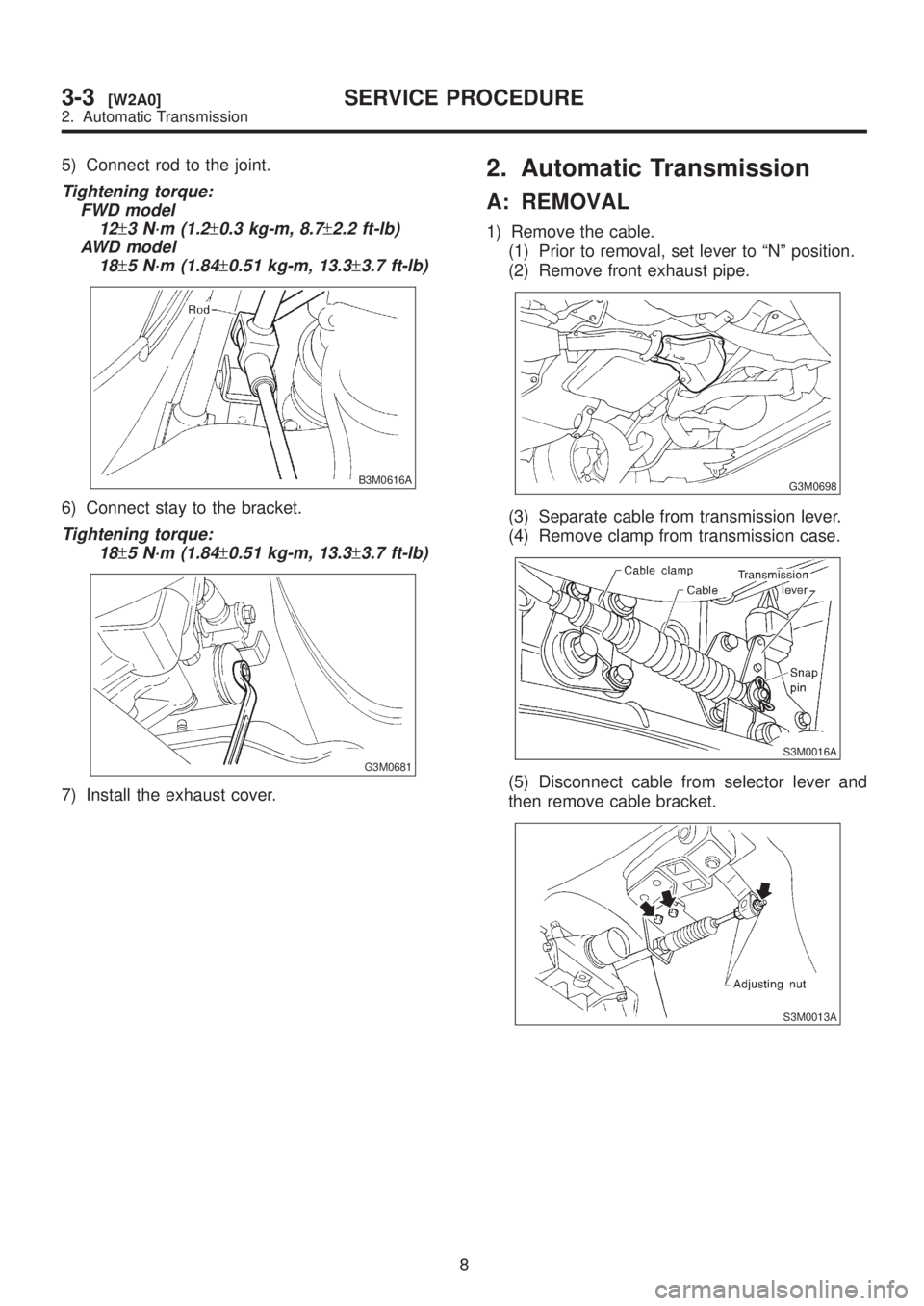

5) Connect rod to the joint.

Tightening torque:

FWD model

12

±3 N´m (1.2±0.3 kg-m, 8.7±2.2 ft-lb)

AWD model

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

B3M0616A

6) Connect stay to the bracket.

Tightening torque:

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

G3M0681

7) Install the exhaust cover.

2. Automatic Transmission

A: REMOVAL

1) Remove the cable.

(1) Prior to removal, set lever to ªNº position.

(2) Remove front exhaust pipe.

G3M0698

(3) Separate cable from transmission lever.

(4) Remove clamp from transmission case.

S3M0016A

(5) Disconnect cable from selector lever and

then remove cable bracket.

S3M0013A

8

3-3[W2A0]SERVICE PROCEDURE

2. Automatic Transmission

Page 647 of 1456

![SUBARU LEGACY 1999 Service Service Manual 2) Remove console box. <Ref. to 5-4 [W1A0].>

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector SUBARU LEGACY 1999 Service Service Manual 2) Remove console box. <Ref. to 5-4 [W1A0].>

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector](/img/17/57435/w960_57435-646.png)

2) Remove console box.

3) Disconnect the connectors, then remove the six

screws to take out the selector lever assembly

from the body.

S3M0017A

B: DISASSEMBLY

1) Remove connector from plate.

B3M0645

2) Remove indicator light and two screws.

3) Remove retainer spring, then pull up selector

lever grip with indicator cover for holding selector

lever button.

CAUTION:

Pull the selector lever grip carefully so that the

selector lever button may not jump out.

B3M0646A

4) Remove shift-lock solenoid and ªPº position

switch.

S3M0018A

5) Remove cap and clip, then extract pin.

6) Remove selector lever lower then take away

selector lever upper from plate.

B3M0647A

C: INSPECTION

1) Inspect removed parts by comparing with new

ones for deformation, damage and wear. Correct

or replace if defective.

2) Confirm the following parts for operating condi-

tion before assembly.

(1) Sliding condition of the button in the grip ...

it should move smoothly.

(2) Insertion of the grip on the selector lever ...

when pushing the grip on the selector lever by

hand, screw holes should be aligned.

(3) Operation of selector lever and rod ... they

should move smoothly.

D: ASSEMBLY

1) Clean all parts before assembly.

2) Apply grease [NIGTIGHT LYW No. 2 or equiva-

lent] to each parts.

3) Assembly is in the reverse order of disassem-

bly.

4) After completion of fitting, transfer selector

lever to range ªPº Ð ª1º, pressing the button of the

grip; then check whether the indicator and selector

lever agree, whether the pointer and position mark

agree and what the operating force is.

9

[W2D0]3-3SERVICE PROCEDURE

2. Automatic Transmission

Page 648 of 1456

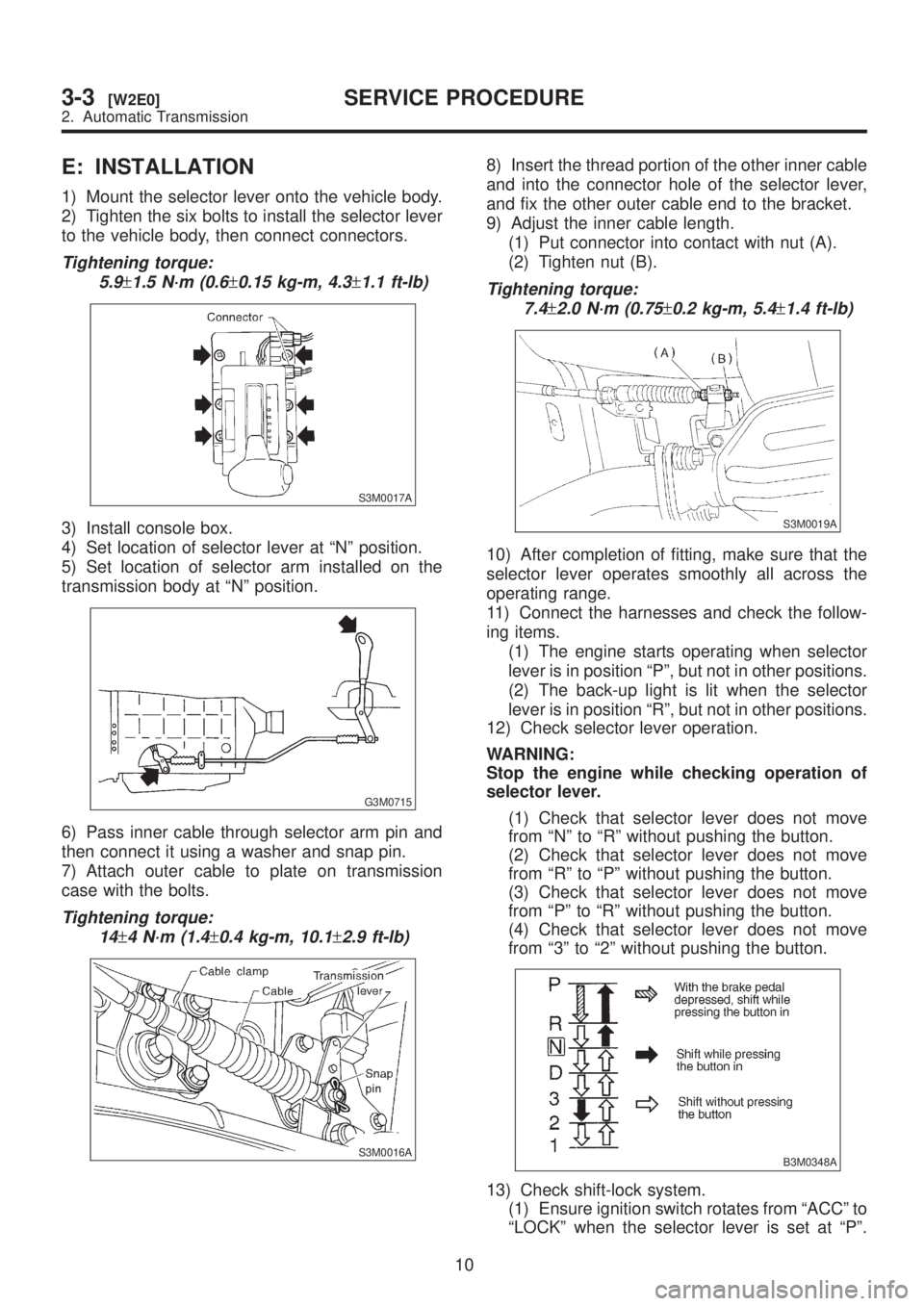

E: INSTALLATION

1) Mount the selector lever onto the vehicle body.

2) Tighten the six bolts to install the selector lever

to the vehicle body, then connect connectors.

Tightening torque:

5.9

±1.5 N´m (0.6±0.15 kg-m, 4.3±1.1 ft-lb)

S3M0017A

3) Install console box.

4) Set location of selector lever at ªNº position.

5) Set location of selector arm installed on the

transmission body at ªNº position.

G3M0715

6) Pass inner cable through selector arm pin and

then connect it using a washer and snap pin.

7) Attach outer cable to plate on transmission

case with the bolts.

Tightening torque:

14

±4 N´m (1.4±0.4 kg-m, 10.1±2.9 ft-lb)

S3M0016A

8) Insert the thread portion of the other inner cable

and into the connector hole of the selector lever,

and fix the other outer cable end to the bracket.

9) Adjust the inner cable length.

(1) Put connector into contact with nut (A).

(2) Tighten nut (B).

Tightening torque:

7.4

±2.0 N´m (0.75±0.2 kg-m, 5.4±1.4 ft-lb)

S3M0019A

10) After completion of fitting, make sure that the

selector lever operates smoothly all across the

operating range.

11) Connect the harnesses and check the follow-

ing items.

(1) The engine starts operating when selector

lever is in position ªPº, but not in other positions.

(2) The back-up light is lit when the selector

lever is in position ªRº, but not in other positions.

12) Check selector lever operation.

WARNING:

Stop the engine while checking operation of

selector lever.

(1) Check that selector lever does not move

from ªNº to ªRº without pushing the button.

(2) Check that selector lever does not move

from ªRº to ªPº without pushing the button.

(3) Check that selector lever does not move

from ªPº to ªRº without pushing the button.

(4) Check that selector lever does not move

from ª3º to ª2º without pushing the button.

B3M0348A

13) Check shift-lock system.

(1) Ensure ignition switch rotates from ªACCº to

ªLOCKº when the selector lever is set at ªPº.

10

3-3[W2E0]SERVICE PROCEDURE

2. Automatic Transmission

Page 649 of 1456

Also check that ignition key can be removed

only from the ªLOCKº position.

(2) Ensure selector lever moves from ªPº to any

other position when the brake pedal isdepressed with ignition key set at ªONº or

ªSTARTº.

11

[W2E0]3-3SERVICE PROCEDURE

2. Automatic Transmission

Page 788 of 1456

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

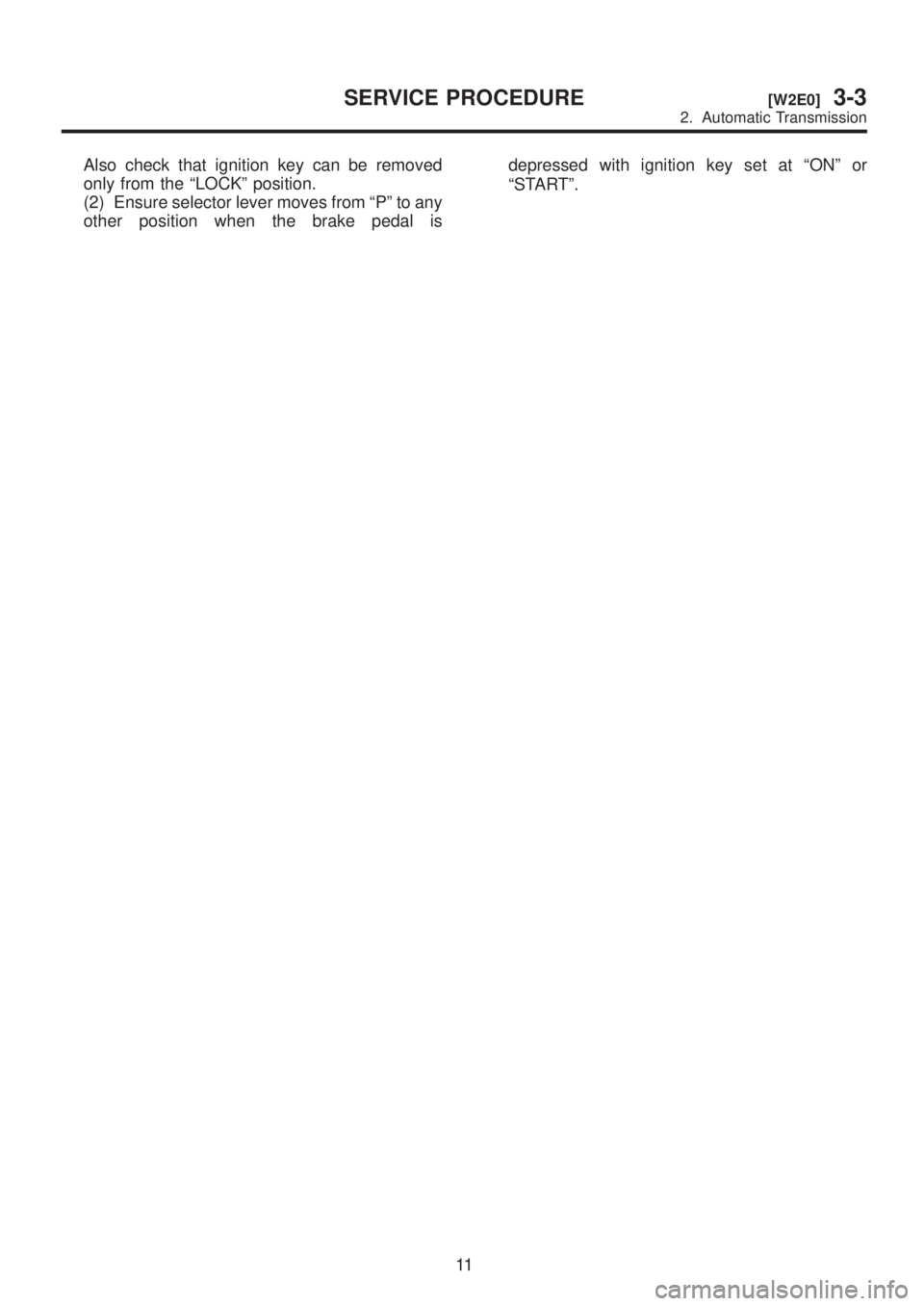

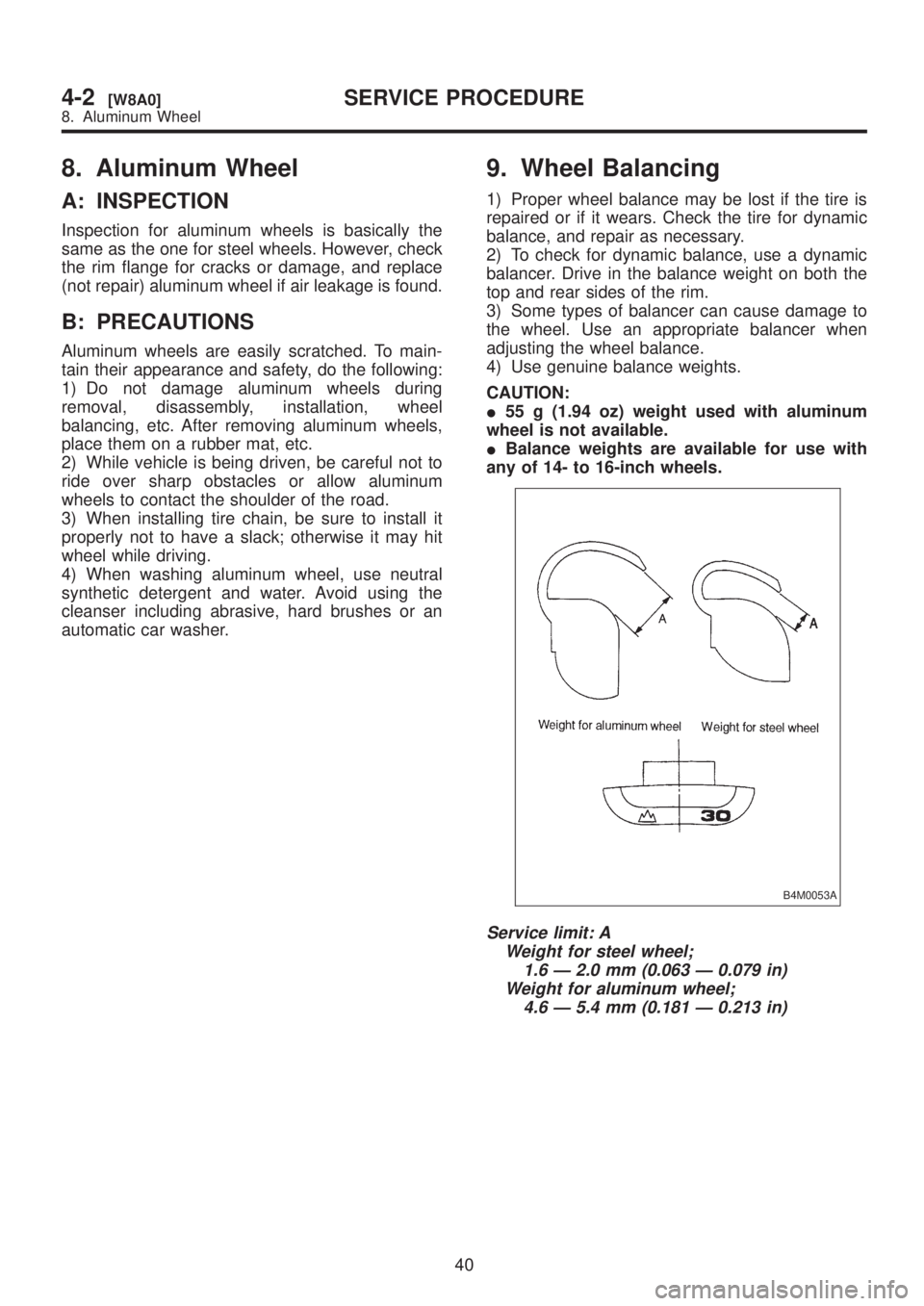

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 789 of 1456

8. Aluminum Wheel

A: INSPECTION

Inspection for aluminum wheels is basically the

same as the one for steel wheels. However, check

the rim flange for cracks or damage, and replace

(not repair) aluminum wheel if air leakage is found.

B: PRECAUTIONS

Aluminum wheels are easily scratched. To main-

tain their appearance and safety, do the following:

1) Do not damage aluminum wheels during

removal, disassembly, installation, wheel

balancing, etc. After removing aluminum wheels,

place them on a rubber mat, etc.

2) While vehicle is being driven, be careful not to

ride over sharp obstacles or allow aluminum

wheels to contact the shoulder of the road.

3) When installing tire chain, be sure to install it

properly not to have a slack; otherwise it may hit

wheel while driving.

4) When washing aluminum wheel, use neutral

synthetic detergent and water. Avoid using the

cleanser including abrasive, hard brushes or an

automatic car washer.

9. Wheel Balancing

1) Proper wheel balance may be lost if the tire is

repaired or if it wears. Check the tire for dynamic

balance, and repair as necessary.

2) To check for dynamic balance, use a dynamic

balancer. Drive in the balance weight on both the

top and rear sides of the rim.

3) Some types of balancer can cause damage to

the wheel. Use an appropriate balancer when

adjusting the wheel balance.

4) Use genuine balance weights.

CAUTION:

I55 g (1.94 oz) weight used with aluminum

wheel is not available.

IBalance weights are available for use with

any of 14- to 16-inch wheels.

B4M0053A

Service limit: A

Weight for steel wheel;

1.6 Ð 2.0 mm (0.063 Ð 0.079 in)

Weight for aluminum wheel;

4.6 Ð 5.4 mm (0.181 Ð 0.213 in)

40

4-2[W8A0]SERVICE PROCEDURE

8. Aluminum Wheel

Page 793 of 1456

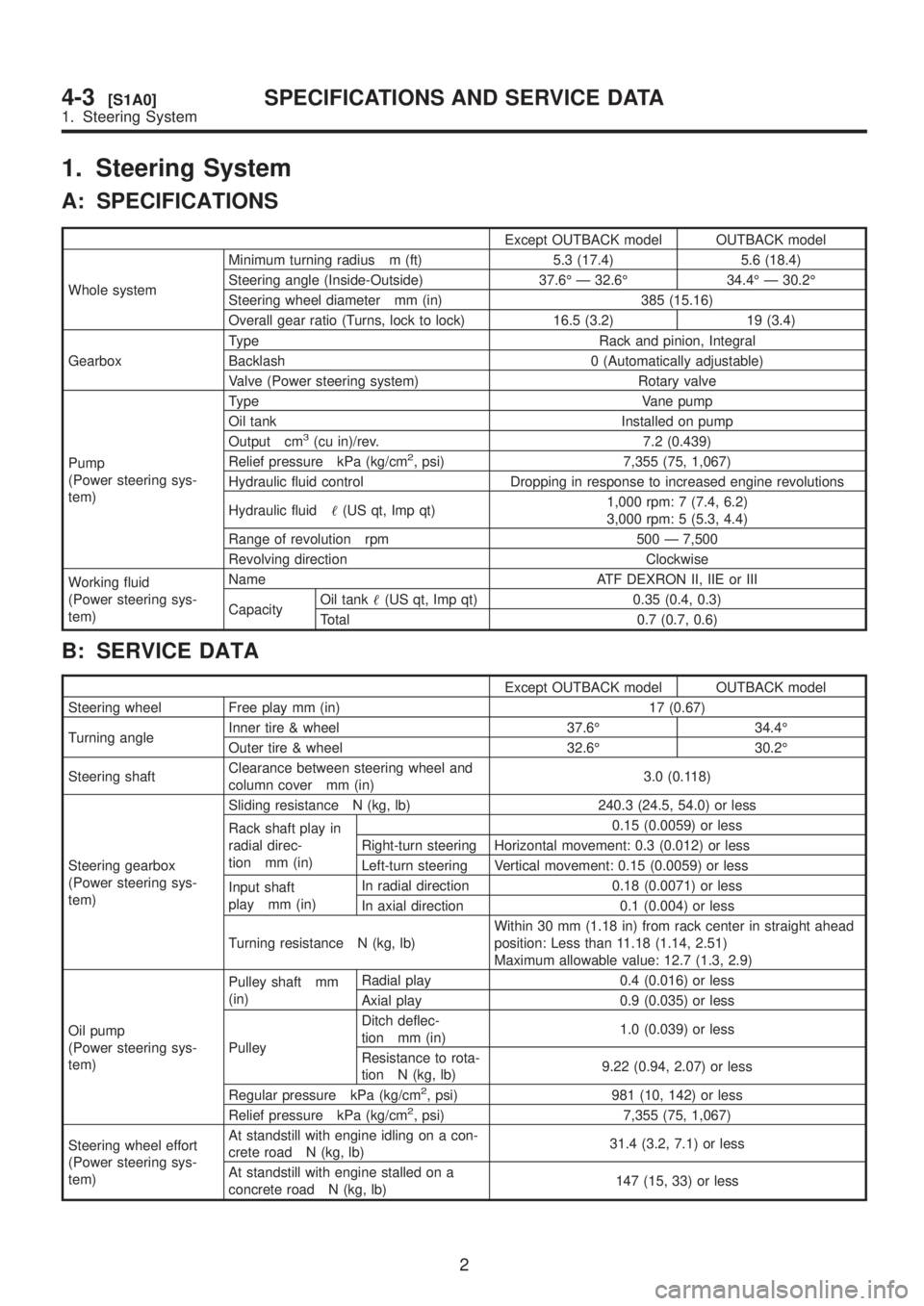

1. Steering System

A: SPECIFICATIONS

Except OUTBACK model OUTBACK model

Whole systemMinimum turning radius m (ft) 5.3 (17.4) 5.6 (18.4)

Steering angle (Inside-Outside) 37.6É Ð 32.6É 34.4É Ð 30.2É

Steering wheel diameter mm (in) 385 (15.16)

Overall gear ratio (Turns, lock to lock) 16.5 (3.2) 19 (3.4)

GearboxType Rack and pinion, Integral

Backlash 0 (Automatically adjustable)

Valve (Power steering system) Rotary valve

Pump

(Power steering sys-

tem)Type Vane pump

Oil tank Installed on pump

Output cm

3(cu in)/rev. 7.2 (0.439)

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Hydraulic fluid control Dropping in response to increased engine revolutions

Hydraulic fluid(US qt, Imp qt)1,000 rpm: 7 (7.4, 6.2)

3,000 rpm: 5 (5.3, 4.4)

Range of revolution rpm 500 Ð 7,500

Revolving direction Clockwise

Working fluid

(Power steering sys-

tem)Name ATF DEXRON II, IIE or III

CapacityOil tank(US qt, Imp qt) 0.35 (0.4, 0.3)

Total 0.7 (0.7, 0.6)

B: SERVICE DATA

Except OUTBACK model OUTBACK model

Steering wheel Free play mm (in) 17 (0.67)

Turning angleInner tire & wheel 37.6É 34.4É

Outer tire & wheel 32.6É 30.2É

Steering shaftClearance between steering wheel and

column cover mm (in)3.0 (0.118)

Steering gearbox

(Power steering sys-

tem)Sliding resistance N (kg, lb) 240.3 (24.5, 54.0) or less

Rack shaft play in

radial direc-

tion mm (in)0.15 (0.0059) or less

Right-turn steering Horizontal movement: 0.3 (0.012) or less

Left-turn steering Vertical movement: 0.15 (0.0059) or less

Input shaft

play mm (in)In radial direction 0.18 (0.0071) or less

In axial direction 0.1 (0.004) or less

Turning resistance N (kg, lb)Within 30 mm (1.18 in) from rack center in straight ahead

position: Less than 11.18 (1.14, 2.51)

Maximum allowable value: 12.7 (1.3, 2.9)

Oil pump

(Power steering sys-

tem)Pulley shaft mm

(in)Radial play 0.4 (0.016) or less

Axial play 0.9 (0.035) or less

PulleyDitch deflec-

tion mm (in)1.0 (0.039) or less

Resistance to rota-

tion N (kg, lb)9.22 (0.94, 2.07) or less

Regular pressure kPa (kg/cm

2, psi) 981 (10, 142) or less

Relief pressure kPa (kg/cm2, psi) 7,355 (75, 1,067)

Steering wheel effort

(Power steering sys-

tem)At standstill with engine idling on a con-

crete road N (kg, lb)31.4 (3.2, 7.1) or less

At standstill with engine stalled on a

concrete road N (kg, lb)147 (15, 33) or less

2

4-3[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Steering System

Page 868 of 1456

Fluid leaking area Possible cause Corrective action

Leakage from connecting portions of

pipes and hoses, numbered with (1) thru

(9) in figureInsufficient tightening of flare nut, catch-

ing dirt or the like, damage to flare or

flare nutLoosen and retighten, if ineffective,

replace.

Poor insertion of hose, poor clamping Retighten or replace clamp.

Damaged O-ring Replace O-ring pipe or hose with new

one, if ineffective, replace gearbox also.

Leakage from hose (10) and (11) in fig-

ureCrack or damage in hose Replace with a new one.

Crack or damage in hose hardware Replace with a new one.

Leakage from surrounding of cast iron

portion of oil pump (12) and (13) in fig-

ureDamaged O-ring Replace O-ring.

Damaged gasket Replace gasket.

Leakage from oil tank, (14) and (15) in

figureCrack in oil tank, (14) Replace oil tank.

Damaged O-ring, (15) Replace O-ring.

Leakage from filler neck (16) Damaged cap packing Replace cap.

Crack in root of filler neck Replace oil tank.

High fluid level *1 Adjust fluid level.

Leakage from surrounding of power cyl-

inder of gearbox, (17) in figureDamaged oil seal Replace oil seal.

Leakage from control valve of gearbox,

(18) and (19) in figureDamaged packing or oil seal Replace problem parts.

Damage in control valve Replace control valve.

*1 Fluid level is specified at optimum position (range) for ordinary use. Accordingly, if the vehicle is used often under hard

conditions such as on very rough roads or in mountainous areas, fluid may bleed out from cap air vent hole. This is not

a problem. If a customer complains strongly and is not likely to be satisfied with the leakage, lower the fluid level to the

extent that fluid will not bleed out under the conditions described, and have the customer check the fluid level and its

quality more frequency than usual.

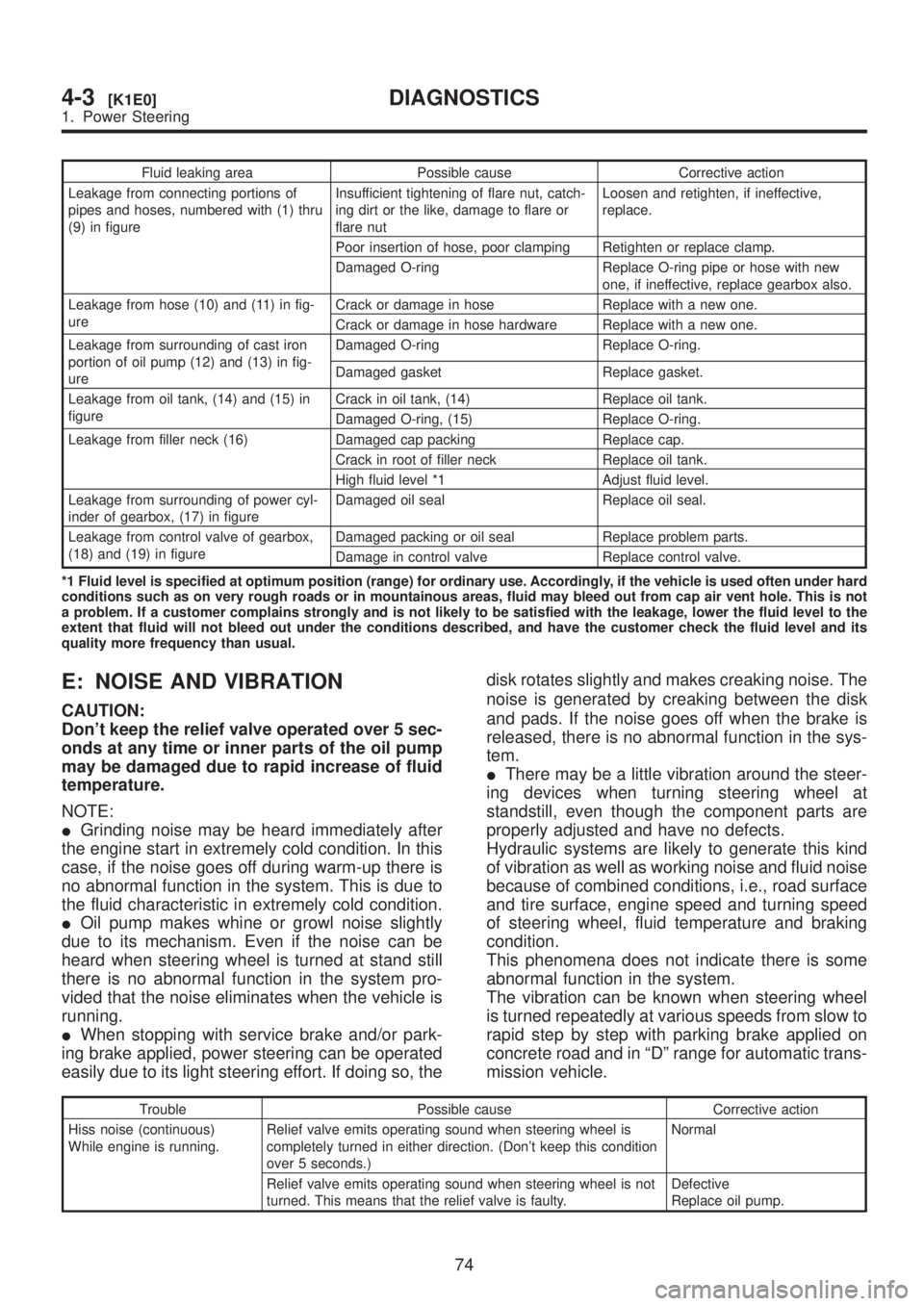

E: NOISE AND VIBRATION

CAUTION:

Don't keep the relief valve operated over 5 sec-

onds at any time or inner parts of the oil pump

may be damaged due to rapid increase of fluid

temperature.

NOTE:

IGrinding noise may be heard immediately after

the engine start in extremely cold condition. In this

case, if the noise goes off during warm-up there is

no abnormal function in the system. This is due to

the fluid characteristic in extremely cold condition.

IOil pump makes whine or growl noise slightly

due to its mechanism. Even if the noise can be

heard when steering wheel is turned at stand still

there is no abnormal function in the system pro-

vided that the noise eliminates when the vehicle is

running.

IWhen stopping with service brake and/or park-

ing brake applied, power steering can be operated

easily due to its light steering effort. If doing so, thedisk rotates slightly and makes creaking noise. The

noise is generated by creaking between the disk

and pads. If the noise goes off when the brake is

released, there is no abnormal function in the sys-

tem.

IThere may be a little vibration around the steer-

ing devices when turning steering wheel at

standstill, even though the component parts are

properly adjusted and have no defects.

Hydraulic systems are likely to generate this kind

of vibration as well as working noise and fluid noise

because of combined conditions, i.e., road surface

and tire surface, engine speed and turning speed

of steering wheel, fluid temperature and braking

condition.

This phenomena does not indicate there is some

abnormal function in the system.

The vibration can be known when steering wheel

is turned repeatedly at various speeds from slow to

rapid step by step with parking brake applied on

concrete road and in ªDº range for automatic trans-

mission vehicle.

Trouble Possible cause Corrective action

Hiss noise (continuous)

While engine is running.Relief valve emits operating sound when steering wheel is

completely turned in either direction. (Don't keep this condition

over 5 seconds.)Normal

Relief valve emits operating sound when steering wheel is not

turned. This means that the relief valve is faulty.Defective

Replace oil pump.

74

4-3[K1E0]DIAGNOSTICS

1. Power Steering

Page 870 of 1456

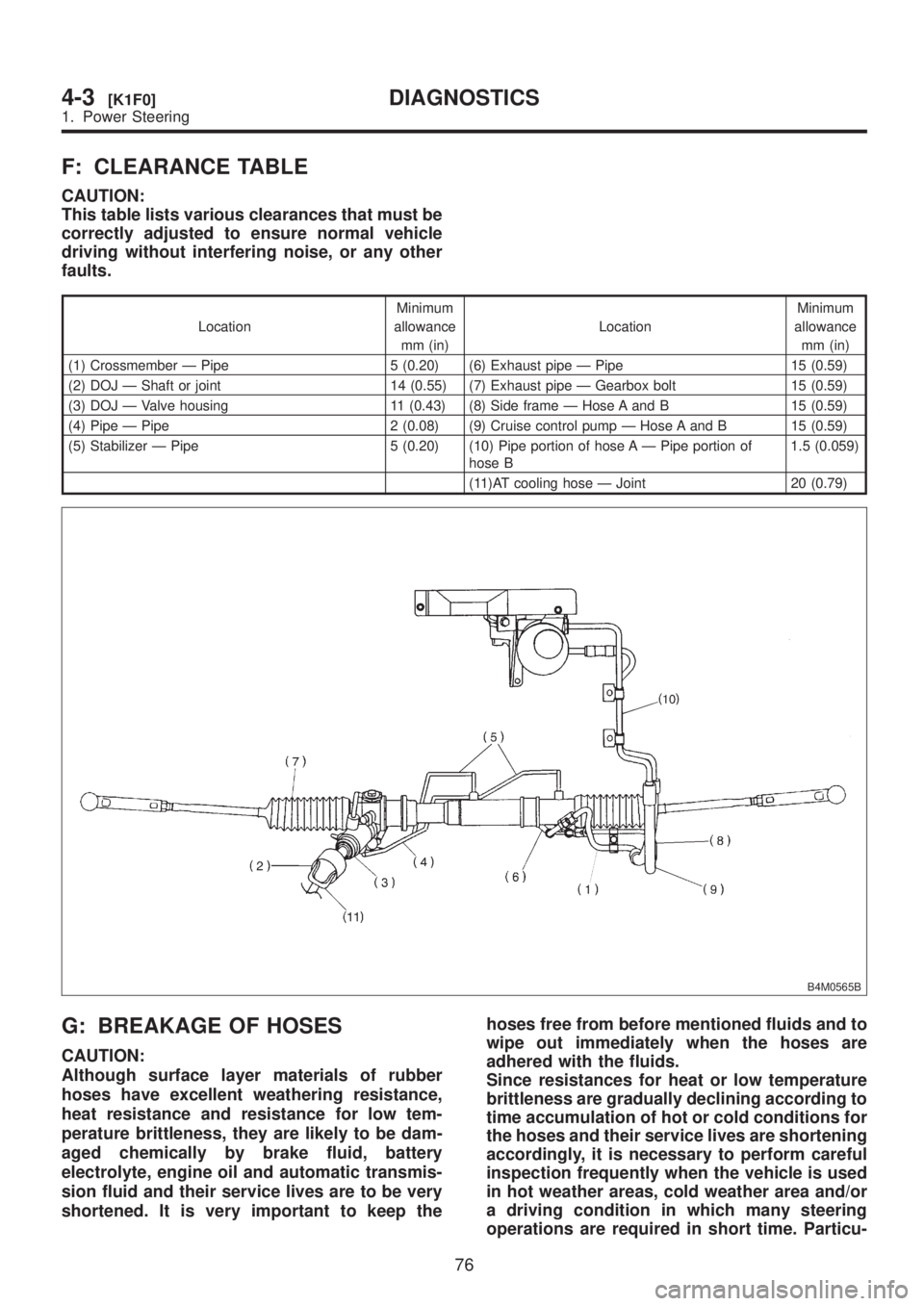

F: CLEARANCE TABLE

CAUTION:

This table lists various clearances that must be

correctly adjusted to ensure normal vehicle

driving without interfering noise, or any other

faults.

LocationMinimum

allowance

mm (in)LocationMinimum

allowance

mm (in)

(1) Crossmember Ð Pipe 5 (0.20) (6) Exhaust pipe Ð Pipe 15 (0.59)

(2) DOJ Ð Shaft or joint 14 (0.55) (7) Exhaust pipe Ð Gearbox bolt 15 (0.59)

(3) DOJ Ð Valve housing 11 (0.43) (8) Side frame Ð Hose A and B 15 (0.59)

(4) Pipe Ð Pipe 2 (0.08) (9) Cruise control pump Ð Hose A and B 15 (0.59)

(5) Stabilizer Ð Pipe 5 (0.20) (10) Pipe portion of hose A Ð Pipe portion of

hose B1.5 (0.059)

(11)AT cooling hose Ð Joint 20 (0.79)

B4M0565B

G: BREAKAGE OF HOSES

CAUTION:

Although surface layer materials of rubber

hoses have excellent weathering resistance,

heat resistance and resistance for low tem-

perature brittleness, they are likely to be dam-

aged chemically by brake fluid, battery

electrolyte, engine oil and automatic transmis-

sion fluid and their service lives are to be very

shortened. It is very important to keep thehoses free from before mentioned fluids and to

wipe out immediately when the hoses are

adhered with the fluids.

Since resistances for heat or low temperature

brittleness are gradually declining according to

time accumulation of hot or cold conditions for

the hoses and their service lives are shortening

accordingly, it is necessary to perform careful

inspection frequently when the vehicle is used

in hot weather areas, cold weather area and/or

a driving condition in which many steering

operations are required in short time. Particu-

76

4-3[K1F0]DIAGNOSTICS

1. Power Steering

Page 873 of 1456

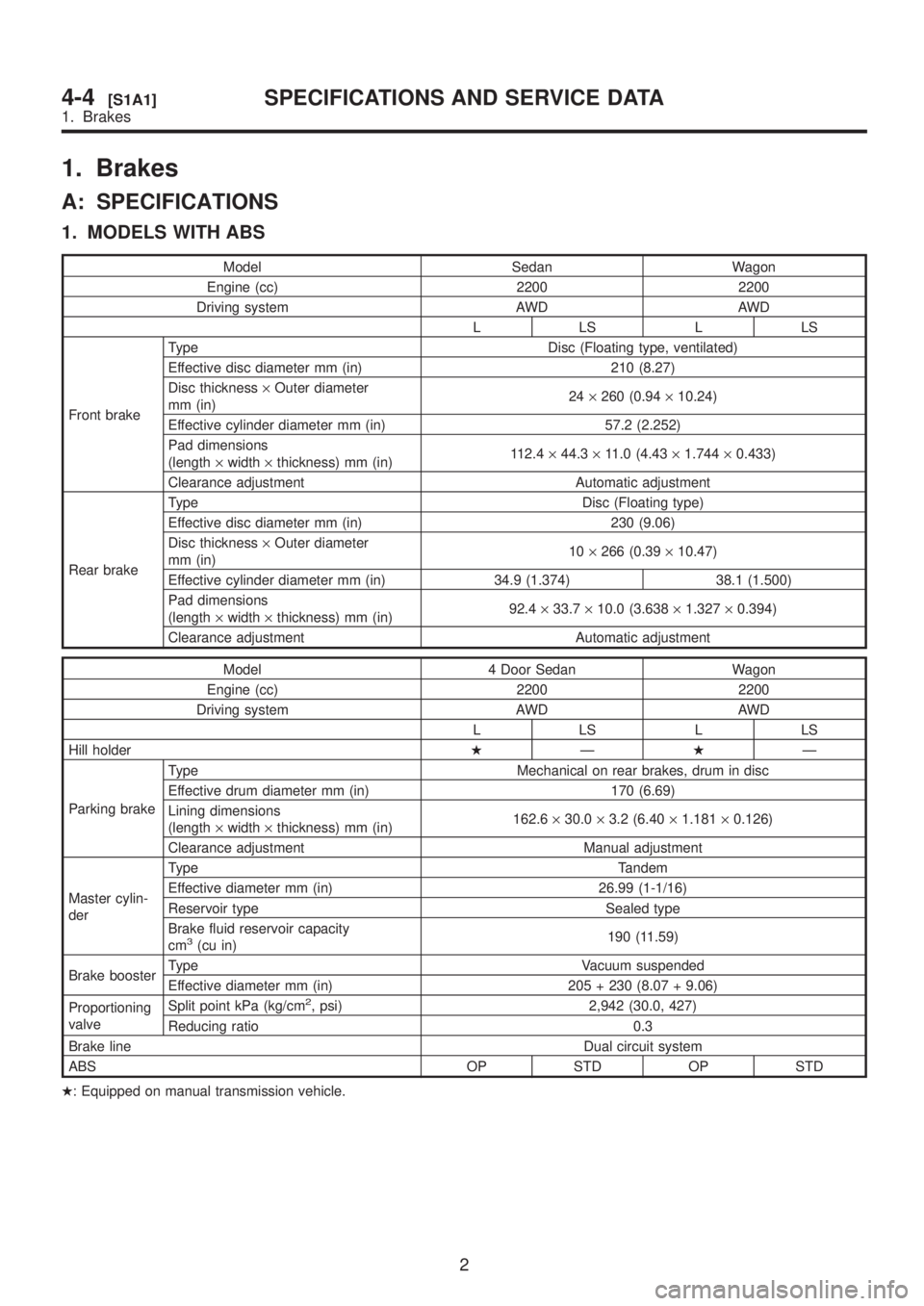

1. Brakes

A: SPECIFICATIONS

1. MODELS WITH ABS

Model Sedan Wagon

Engine (cc) 2200 2200

Driving system AWD AWD

LLSLLS

Front brakeType Disc (Floating type, ventilated)

Effective disc diameter mm (in) 210 (8.27)

Disc thickness´Outer diameter

mm (in)24´260 (0.94´10.24)

Effective cylinder diameter mm (in) 57.2 (2.252)

Pad dimensions

(length´width´thickness) mm (in)112.4´44.3´11.0 (4.43´1.744´0.433)

Clearance adjustment Automatic adjustment

Rear brakeType Disc (Floating type)

Effective disc diameter mm (in) 230 (9.06)

Disc thickness´Outer diameter

mm (in)10´266 (0.39´10.47)

Effective cylinder diameter mm (in) 34.9 (1.374) 38.1 (1.500)

Pad dimensions

(length´width´thickness) mm (in)92.4´33.7´10.0 (3.638´1.327´0.394)

Clearance adjustment Automatic adjustment

Model 4 Door Sedan Wagon

Engine (cc) 2200 2200

Driving system AWD AWD

LLSLLS

Hill holderHÐHÐ

Parking brakeType Mechanical on rear brakes, drum in disc

Effective drum diameter mm (in) 170 (6.69)

Lining dimensions

(length´width´thickness) mm (in)162.6´30.0´3.2 (6.40´1.181´0.126)

Clearance adjustment Manual adjustment

Master cylin-

derType Tandem

Effective diameter mm (in) 26.99 (1-1/16)

Reservoir type Sealed type

Brake fluid reservoir capacity

cm

3(cu in)190 (11.59)

Brake boosterType Vacuum suspended

Effective diameter mm (in) 205 + 230 (8.07 + 9.06)

Proportioning

valveSplit point kPa (kg/cm

2, psi) 2,942 (30.0, 427)

Reducing ratio 0.3

Brake lineDual circuit system

ABS OP STD OP STD

H: Equipped on manual transmission vehicle.

2

4-4[S1A1]SPECIFICATIONS AND SERVICE DATA

1. Brakes