automatic SUBARU LEGACY 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 532 of 1456

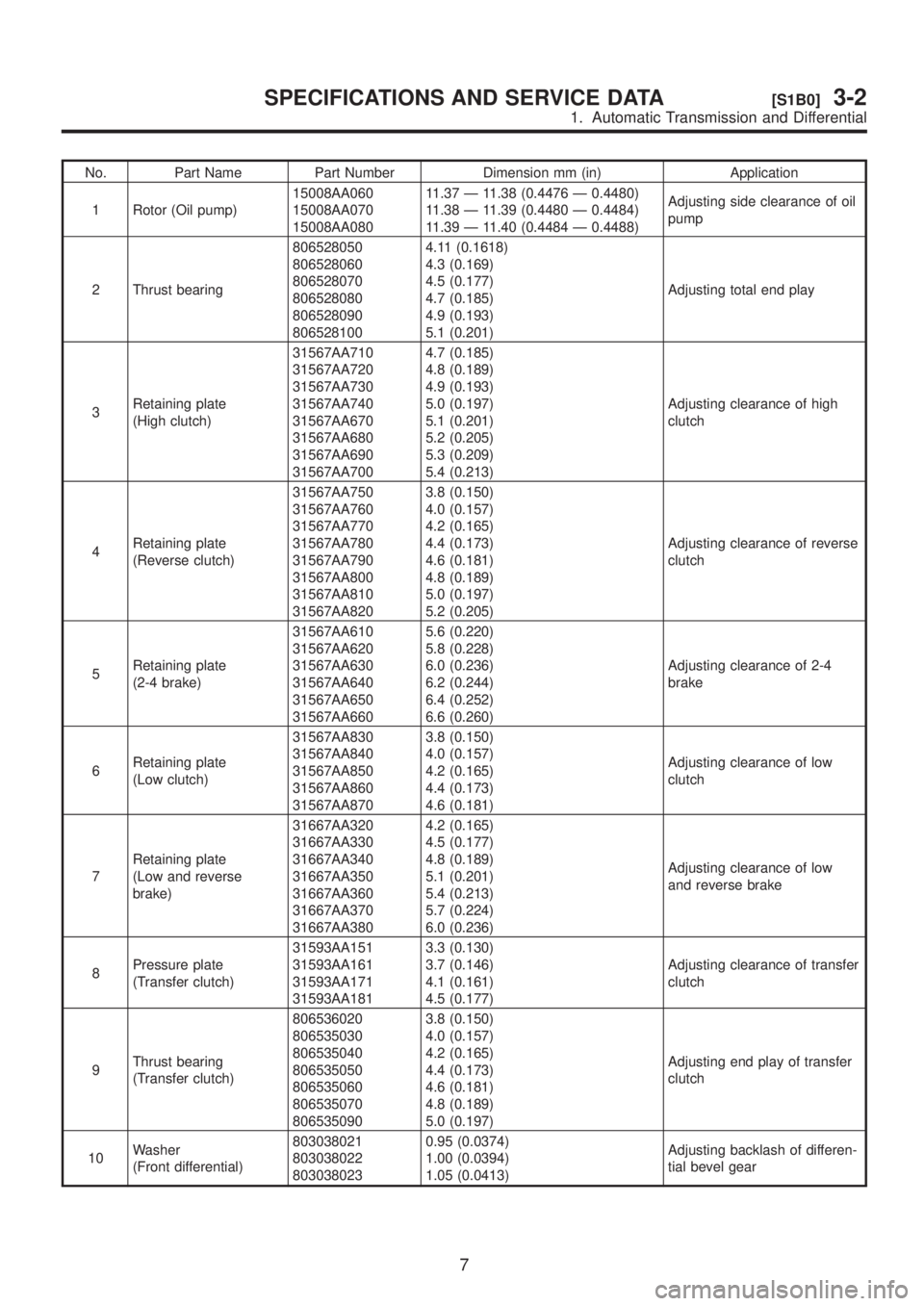

No. Part Name Part Number Dimension mm (in) Application

1 Rotor (Oil pump)15008AA060

15008AA070

15008AA08011.37 Ð 11.38 (0.4476 Ð 0.4480)

11.38 Ð 11.39 (0.4480 Ð 0.4484)

11.39 Ð 11.40 (0.4484 Ð 0.4488)Adjusting side clearance of oil

pump

2 Thrust bearing806528050

806528060

806528070

806528080

806528090

8065281004.11 (0.1618)

4.3 (0.169)

4.5 (0.177)

4.7 (0.185)

4.9 (0.193)

5.1 (0.201)Adjusting total end play

3Retaining plate

(High clutch)31567AA710

31567AA720

31567AA730

31567AA740

31567AA670

31567AA680

31567AA690

31567AA7004.7 (0.185)

4.8 (0.189)

4.9 (0.193)

5.0 (0.197)

5.1 (0.201)

5.2 (0.205)

5.3 (0.209)

5.4 (0.213)Adjusting clearance of high

clutch

4Retaining plate

(Reverse clutch)31567AA750

31567AA760

31567AA770

31567AA780

31567AA790

31567AA800

31567AA810

31567AA8203.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205)Adjusting clearance of reverse

clutch

5Retaining plate

(2-4 brake)31567AA610

31567AA620

31567AA630

31567AA640

31567AA650

31567AA6605.6 (0.220)

5.8 (0.228)

6.0 (0.236)

6.2 (0.244)

6.4 (0.252)

6.6 (0.260)Adjusting clearance of 2-4

brake

6Retaining plate

(Low clutch)31567AA830

31567AA840

31567AA850

31567AA860

31567AA8703.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)Adjusting clearance of low

clutch

7Retaining plate

(Low and reverse

brake)31667AA320

31667AA330

31667AA340

31667AA350

31667AA360

31667AA370

31667AA3804.2 (0.165)

4.5 (0.177)

4.8 (0.189)

5.1 (0.201)

5.4 (0.213)

5.7 (0.224)

6.0 (0.236)Adjusting clearance of low

and reverse brake

8Pressure plate

(Transfer clutch)31593AA151

31593AA161

31593AA171

31593AA1813.3 (0.130)

3.7 (0.146)

4.1 (0.161)

4.5 (0.177)Adjusting clearance of transfer

clutch

9Thrust bearing

(Transfer clutch)806536020

806535030

806535040

806535050

806535060

806535070

8065350903.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)Adjusting end play of transfer

clutch

10Washer

(Front differential)803038021

803038022

8030380230.95 (0.0374)

1.00 (0.0394)

1.05 (0.0413)Adjusting backlash of differen-

tial bevel gear

7

[S1B0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 533 of 1456

No. Part Name Part Number Dimension mm (in) Application

11 Drive pinion shim31451AA050

31451AA060

31451AA070

31451AA080

31451AA090

31451AA1000.150 (0.0059)

0.175 (0.0069)

0.200 (0.0079)

0.225 (0.0089)

0.250 (0.0098)

0.275 (0.0108)Adjusting drive pinion shim

8

3-2[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 534 of 1456

![SUBARU LEGACY 1999 Service Owners Manual MEMO:

9

[S1B0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential SUBARU LEGACY 1999 Service Owners Manual MEMO:

9

[S1B0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential](/img/17/57435/w960_57435-533.png)

MEMO:

9

[S1B0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 535 of 1456

![SUBARU LEGACY 1999 Service Owners Manual C: LOCATION AND INSTALLING DIRECTION OF THRUST NEEDLE BEARING

B3M1016A

10

3-2[S1C0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential SUBARU LEGACY 1999 Service Owners Manual C: LOCATION AND INSTALLING DIRECTION OF THRUST NEEDLE BEARING

B3M1016A

10

3-2[S1C0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential](/img/17/57435/w960_57435-534.png)

C: LOCATION AND INSTALLING DIRECTION OF THRUST NEEDLE BEARING

B3M1016A

10

3-2[S1C0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 536 of 1456

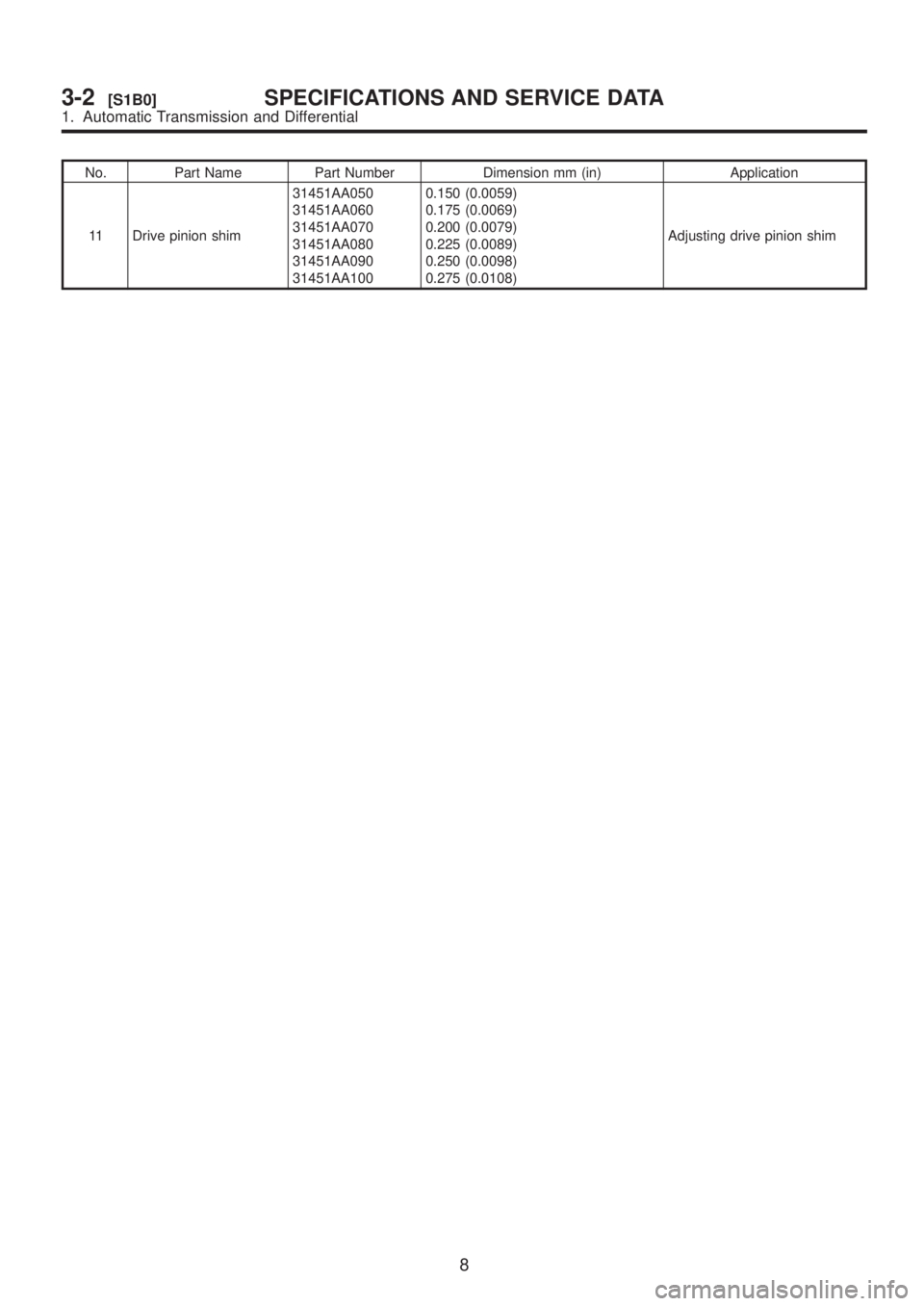

No. Part Name Part NumberInside diameter

mm (in)Outside diameter

mm (in)Dimension

mm (in)Application

(1)Thrust needle

bearing806528050

806528060

806528070

806528080

806528090

80652810028.5 (1.122) 48 (1.89)4.1 (0.161)

4.3 (0.169)

4.5 (0.177)

4.7 (0.185)

4.9 (0.193)

5.1 (0.201)Adjusting total

end play

(2)Thrust needle

bearing806530040 30 (1.18) 47 (1.85) 3.8 (0.150)Place of high

clutch

(3)Thrust needle

bearing806551020 51 (2.01) 71 (2.80) 3.3 (0.130)Place of front sun

gear

(4)Thrust needle

bearing806535120 35 (1.38) 53 (2.09) 4.8 (0.189)Place of rear sun

gear

(5)Thrust needle

bearing806534060 35 (1.38) 53 (2.09) 3.3 (0.130)Place of rear sun

gear

(6)Thrust needle

bearing806558030 58 (2.28) 78 (3.07) 2.8 (0.110)Place of rear

internal gear

(7)Thrust needle

bearing806541020 39.7 (1.563) 54 (2.13) 3.6 (0.142)Place of one-way

clutch

(8)Thrust needle

bearing806536020

806535030

806535040

806535050

806535060

806535070

80653509036 (1.42) 53 (2.09)3.8 (0.150)

4.0 (0.157)

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)Adjusting end play

of transfer clutch

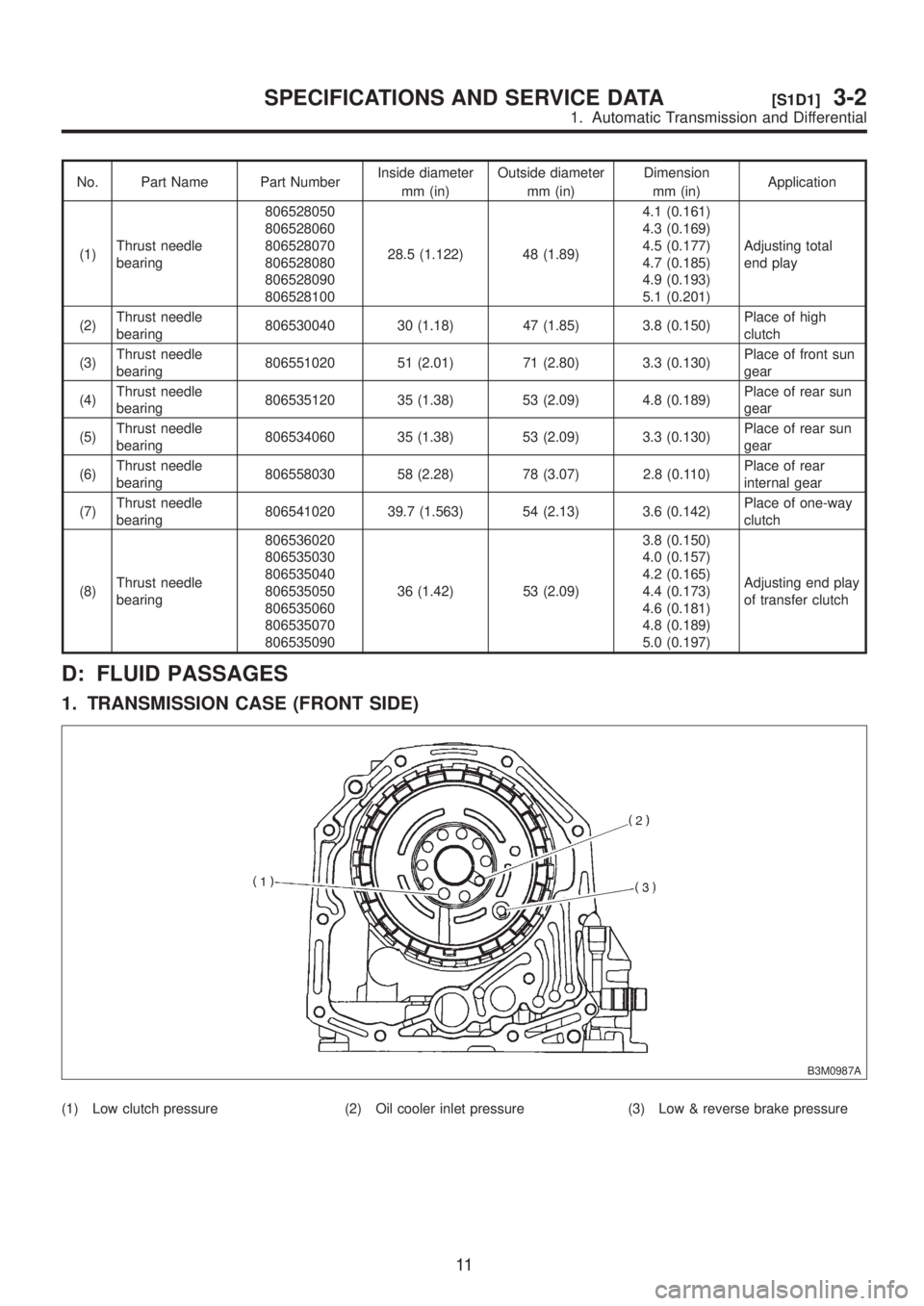

D: FLUID PASSAGES

1. TRANSMISSION CASE (FRONT SIDE)

B3M0987A

(1) Low clutch pressure (2) Oil cooler inlet pressure (3) Low & reverse brake pressure

11

[S1D1]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 537 of 1456

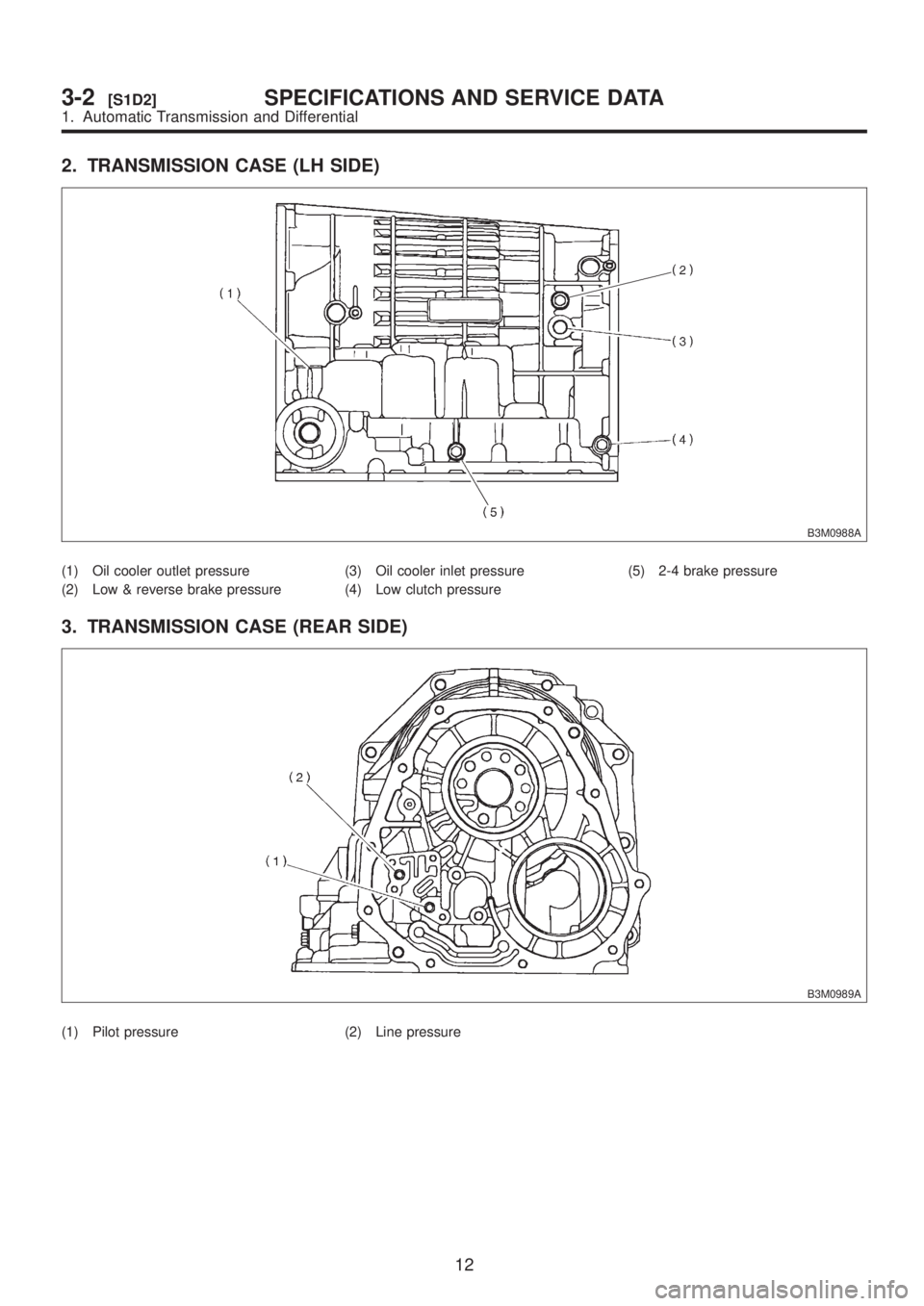

2. TRANSMISSION CASE (LH SIDE)

B3M0988A

(1) Oil cooler outlet pressure

(2) Low & reverse brake pressure(3) Oil cooler inlet pressure

(4) Low clutch pressure(5) 2-4 brake pressure

3. TRANSMISSION CASE (REAR SIDE)

B3M0989A

(1) Pilot pressure (2) Line pressure

12

3-2[S1D2]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 538 of 1456

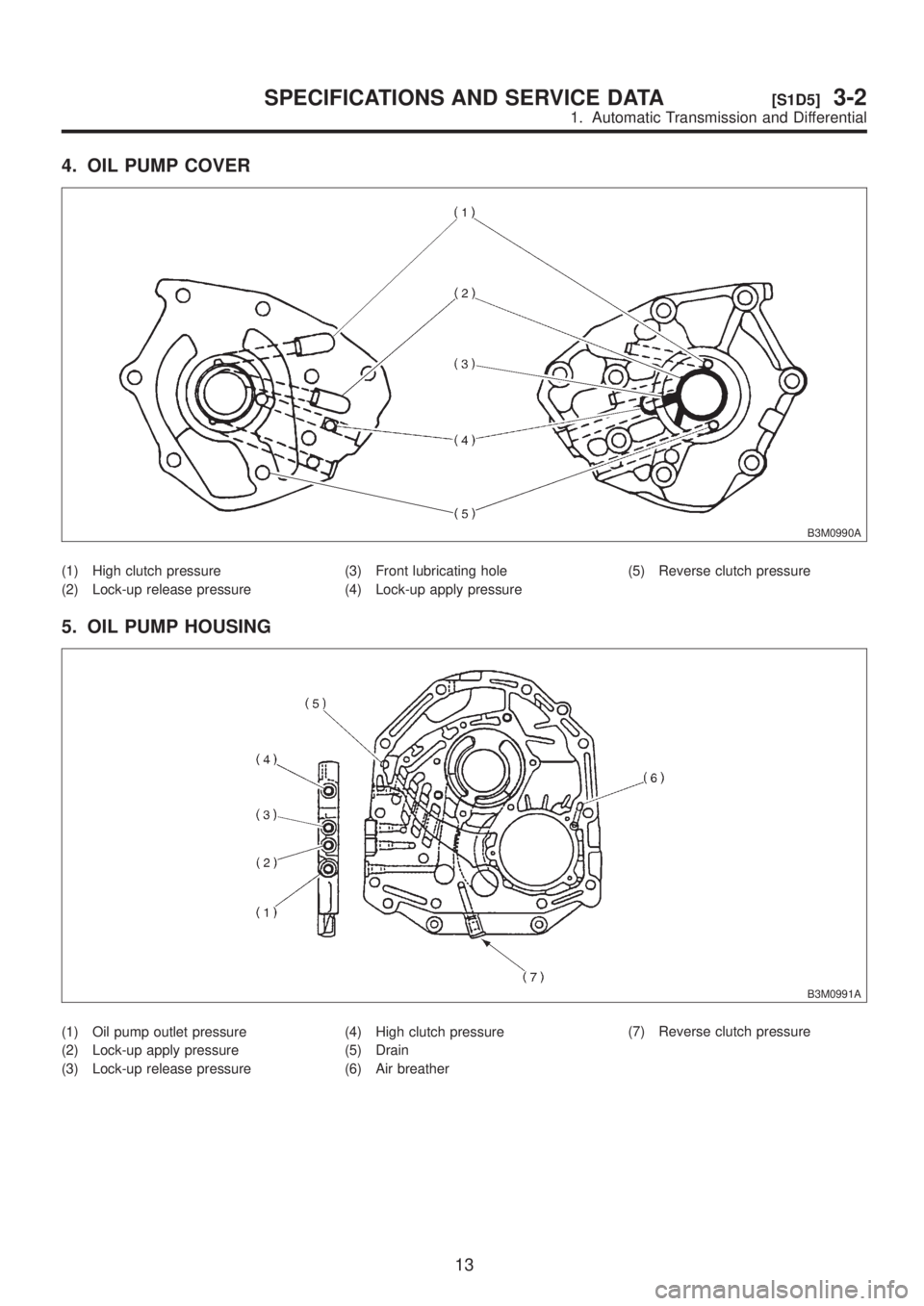

4. OIL PUMP COVER

B3M0990A

(1) High clutch pressure

(2) Lock-up release pressure(3) Front lubricating hole

(4) Lock-up apply pressure(5) Reverse clutch pressure

5. OIL PUMP HOUSING

B3M0991A

(1) Oil pump outlet pressure

(2) Lock-up apply pressure

(3) Lock-up release pressure(4) High clutch pressure

(5) Drain

(6) Air breather(7) Reverse clutch pressure

13

[S1D5]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 539 of 1456

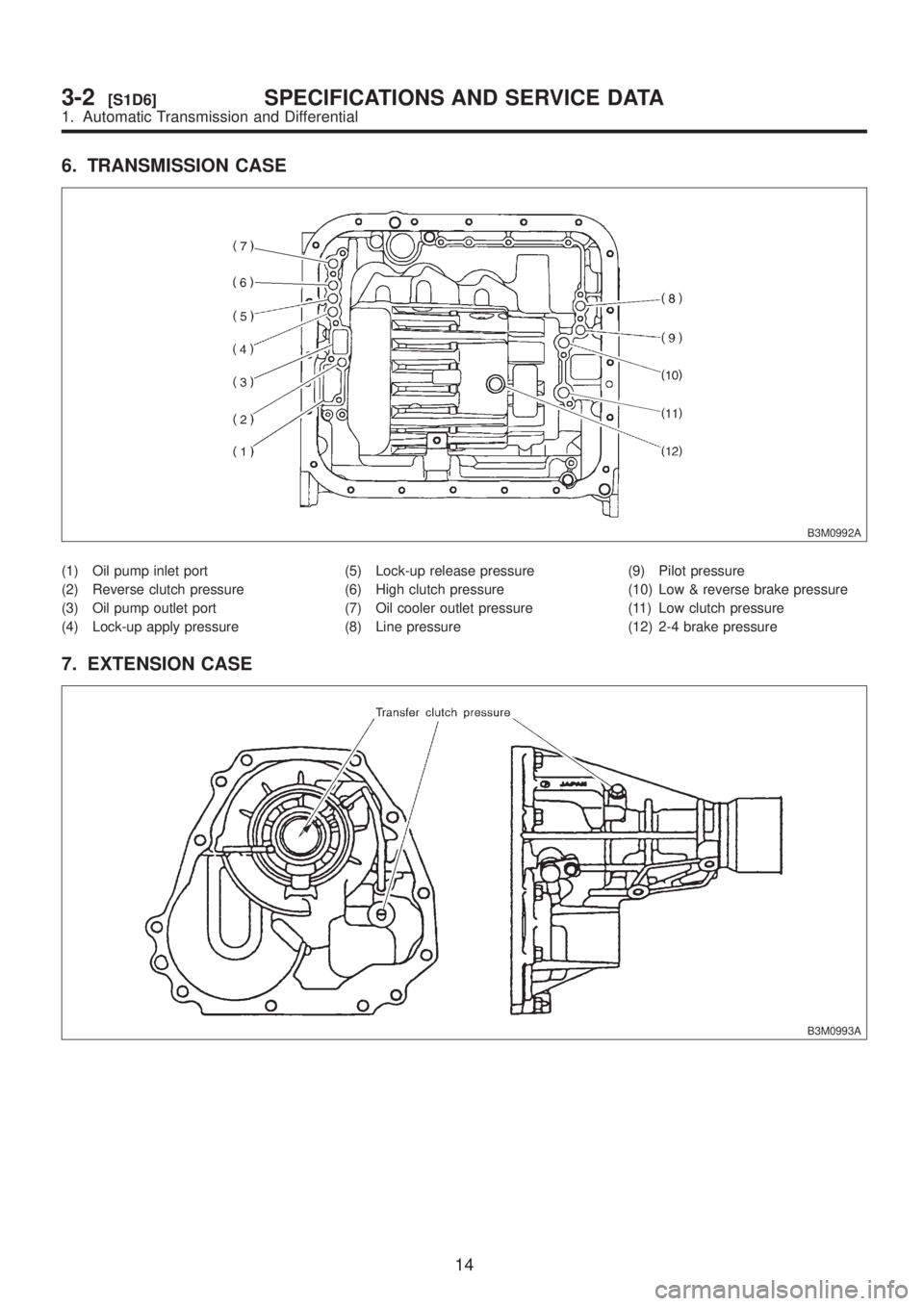

6. TRANSMISSION CASE

B3M0992A

(1) Oil pump inlet port

(2) Reverse clutch pressure

(3) Oil pump outlet port

(4) Lock-up apply pressure(5) Lock-up release pressure

(6) High clutch pressure

(7) Oil cooler outlet pressure

(8) Line pressure(9) Pilot pressure

(10) Low & reverse brake pressure

(11) Low clutch pressure

(12) 2-4 brake pressure

7. EXTENSION CASE

B3M0993A

14

3-2[S1D6]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 552 of 1456

1. General

A: PRECAUTION

When disassembling or assembling the automatic

transmission, observe the following instructions.

1) Workshop

Provide a place that is clean and free from dust.

Principally the conventional workshop is suitable

except for a dusty place. In a workshop where

grinding work, etc. which produces fine particles is

done, make independent place divided by the vinyl

curtain or the equivalent.

2) Work table

The size of 1 x 1.5 m (40 x 60 in) is large enough

to work, and it is more desirable that its surface be

covered with flat plate like iron plate which is not

rusted too much.

3) Cleaning of exterior

(1) Clean the exterior surface of transmission

with steam and/or kerosene prior to

disassembly, however it should be noted that

vinyl tape be placed on the air breather or oil

level gauge to prevent infiltration of the steam

into the transmission and also the cleaning job

be done away from the place of disassembly

and assembly.

(2) Partial cleaning will do, depending on the

extent of disassembly (such as when disassem-

bly is limited to some certain parts).

4) Disassembly, assembly and cleaning

(1) Disassemble and assemble the transmis-

sion while inspecting the parts in accordance

with the Diagnostics.

(2) During job, do not use gloves. Do not clean

the parts with rags: Use chamois or nylon cloth.

(3) Pay special attention to the air to be used

for cleaning. Get the moisture and the dust rid

of the air as much as possible. Be careful not to

scratch or dent any part while checking for

proper operation with an air gun.

(4) Complete the job from cleaning to comple-

tion of assembly as continuously and speedily

as possible in order to avoid occurrence of sec-

ondary troubles caused by dust. When stopping

the job unavoidably cover the parts with clean

chamois or nylon cloth to keep them away from

any dust.

(5) Use kerosene, white gasoline or the equiva-

lent as washing fluid. Use always new fluid for

cleaning the automatic transmission parts and

never reuse. The used fluid is usable in disas-

semble and assemble work of engine and

manual transmission.

(6) Although the cleaning should be done by

dipping into the washing fluid or blowing of the

pressurized washing fluid, the dipping is more

desirable. (Do not rub with a brush.) Assemblethe parts immediately after the cleaning without

exposure to the air for a while. Besides in case

of washing rubber parts, perform the job quickly

not to dip them into the washing fluid for long

time.

(7) Apply the automatic transmission fluid

(ATF) onto the parts immediately prior to

assembly, and the specified tightening torque

should be observed carefully.

(8) Use vaseline if it is necessary to hold parts

in the position when assembling.

(9) Drain ATF and differential gear oil into a

saucer so that the conditions of fluid and oil can

be inspected.

(10) Do not support axle drive shaft, stator

shaft, input shaft or various pipes when moving

transmission from one place to another.

(11) Always discard old oil seals and O-ring,

and install new ones.

(12) Always discard old oil seals and O-ring,

and install new ones.

(13) Be sure to replace parts which are

damaged, worn, scratched, discolored, etc.

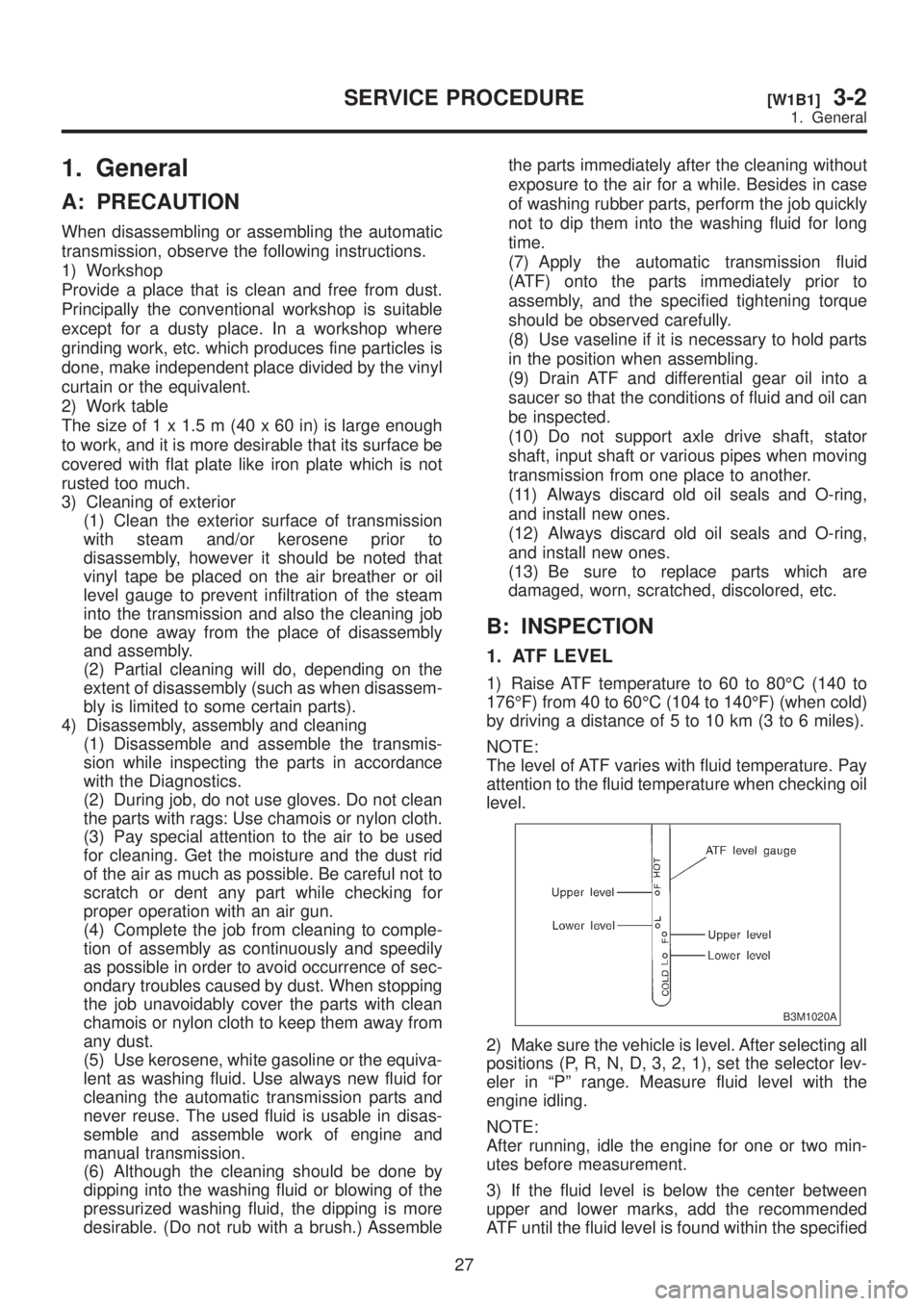

B: INSPECTION

1. ATF LEVEL

1) Raise ATF temperature to 60 to 80ÉC (140 to

176ÉF) from 40 to 60ÉC (104 to 140ÉF) (when cold)

by driving a distance of 5 to 10 km (3 to 6 miles).

NOTE:

The level of ATF varies with fluid temperature. Pay

attention to the fluid temperature when checking oil

level.

B3M1020A

2) Make sure the vehicle is level. After selecting all

positions (P, R, N, D, 3, 2, 1), set the selector lev-

eler in ªPº range. Measure fluid level with the

engine idling.

NOTE:

After running, idle the engine for one or two min-

utes before measurement.

3) If the fluid level is below the center between

upper and lower marks, add the recommended

ATF until the fluid level is found within the specified

27

[W1B1]3-2SERVICE PROCEDURE

1. General

Page 553 of 1456

range (above the center between upper and lower

marks). When the transmission is hot, the level

should be above the center of upper and lower

marks, and when it is cold, the level should be

found below the center of these two marks.

CAUTION:

IUse care not to exceed the upper limit level.

IATF level varies with temperature. Remem-

ber that the addition of fluid to the upper limit

mark when the transmission is cold will result

in the overfilling of fluid.

4) Fluid temperature rising speed

IBy idling the engine

Time for temperature rise to 60ÉC (140ÉF) with

atmospheric temperature of 0ÉC (32ÉF): More than

25 minutes

Time for temperature rise to 30ÉC (86ÉF) with

atmospheric temperature of 0ÉC (32ÉF): Approx. 8

minutes

IBy running the vehicle

Time for temperature rise to 60ÉC (140ÉF) with

atmospheric temperature of 0ÉC (32ÉF): More than

10 minutes

5) Method for checking fluid level upon delivery or

at periodic inspection

Check fluid level after a warm-up run of approx. 10

minutes. During the warm-up period, the automatic

transmission functions can also be checked.

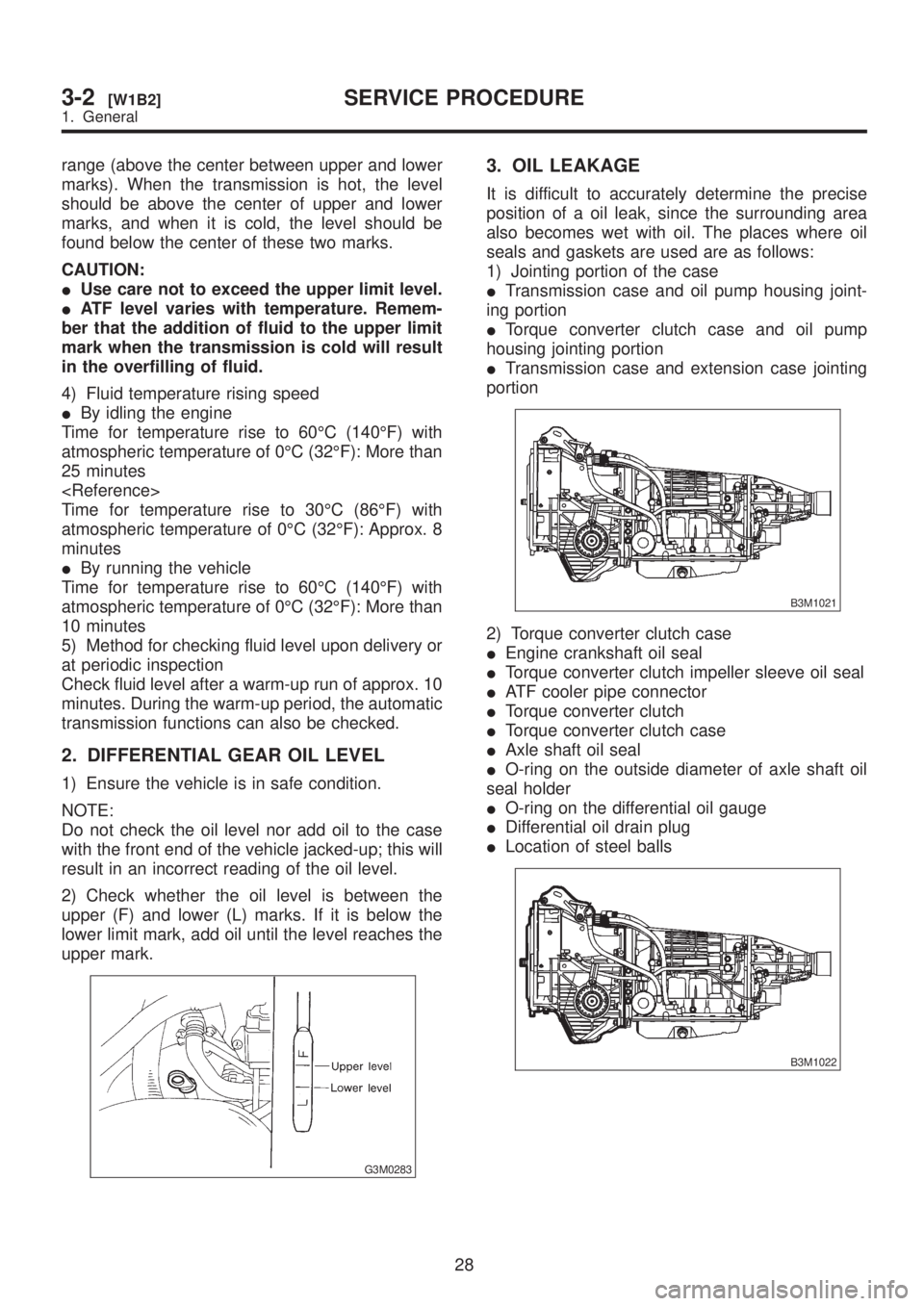

2. DIFFERENTIAL GEAR OIL LEVEL

1) Ensure the vehicle is in safe condition.

NOTE:

Do not check the oil level nor add oil to the case

with the front end of the vehicle jacked-up; this will

result in an incorrect reading of the oil level.

2) Check whether the oil level is between the

upper (F) and lower (L) marks. If it is below the

lower limit mark, add oil until the level reaches the

upper mark.

G3M0283

3. OIL LEAKAGE

It is difficult to accurately determine the precise

position of a oil leak, since the surrounding area

also becomes wet with oil. The places where oil

seals and gaskets are used are as follows:

1) Jointing portion of the case

ITransmission case and oil pump housing joint-

ing portion

ITorque converter clutch case and oil pump

housing jointing portion

ITransmission case and extension case jointing

portion

B3M1021

2) Torque converter clutch case

IEngine crankshaft oil seal

ITorque converter clutch impeller sleeve oil seal

IATF cooler pipe connector

ITorque converter clutch

ITorque converter clutch case

IAxle shaft oil seal

IO-ring on the outside diameter of axle shaft oil

seal holder

IO-ring on the differential oil gauge

IDifferential oil drain plug

ILocation of steel balls

B3M1022

28

3-2[W1B2]SERVICE PROCEDURE

1. General