automatic SUBARU LEGACY 1999 Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 151 of 1456

(1) Slowly press the adjuster rod down to the

end surface of the cylinder. Repeat this motion

2 or 3 times.

(2) With the adjuster rod moved all the way up,

apply a pressure of 294 N (30 kg, 66 lb) to it.

Check adjuster rod stiffness.

(3) If the adjuster rod is not stiff and moves

down, replace the automatic belt tension

adjuster assembly with a new one.

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

4) Measure the extension of rod beyond the body.

If it is not within specifications, replace with a new

one.

Rod extension: H

5.7

±0.5 mm (0.224±0.020 in)

H2M2381A

3. BELT TENSION PULLEY

1) Check mating surfaces of timing belt and con-

tact point of adjuster rod for abnormal wear or

scratches. Replace belt tension pulley if faulty.

2) Check belt tension pulley for smooth rotation.

Replace if noise or excessive play is noted.

3) Check belt tension pulley for grease leakage.

4. BELT IDLER

1) Check idler for smooth rotation. Replace if

noise or excessive play is noted.

2) Check outer contacting surfaces of idler pulley

for abnormal wear and scratches.

3) Check idler for grease leakage.

5. SPROCKET

1) Check sprocket teeth for abnormal wear and

scratches.

2) Make sure there is no free play between

sprocket and key.

3) Check crankshaft sprocket notch for sensor for

damage and contamination of foreign matter.

20

2-3b[W2B3]SERVICE PROCEDURE

2. Timing Belt

Page 153 of 1456

5) Install right-hand exhaust camshaft sprocket.

To lock camshaft, use ST.

6) Install right-hand intake camshaft sprocket

using ST.

7) Install left-hand exhaust camshaft sprocket

using ST.

8) Install left-hand intake camshaft sprocket using

ST.

ST 499207300 CAMSHAFT SPROCKET

WRENCH

S2M0413A

2. AUTOMATIC BELT TENSION ADJUSTER ASSEMBLY AND BELT IDLER

H2M2400D

(1) Automatic belt tension adjuster

ASSY

(2) Belt idler No. 2(3) Belt idlerTightening torque: N´m (kg-m, ft-lb)

T1:

39±4 (4.0±0.4, 28.9±2.9)

22

2-3b[W2C2]SERVICE PROCEDURE

2. Timing Belt

Page 154 of 1456

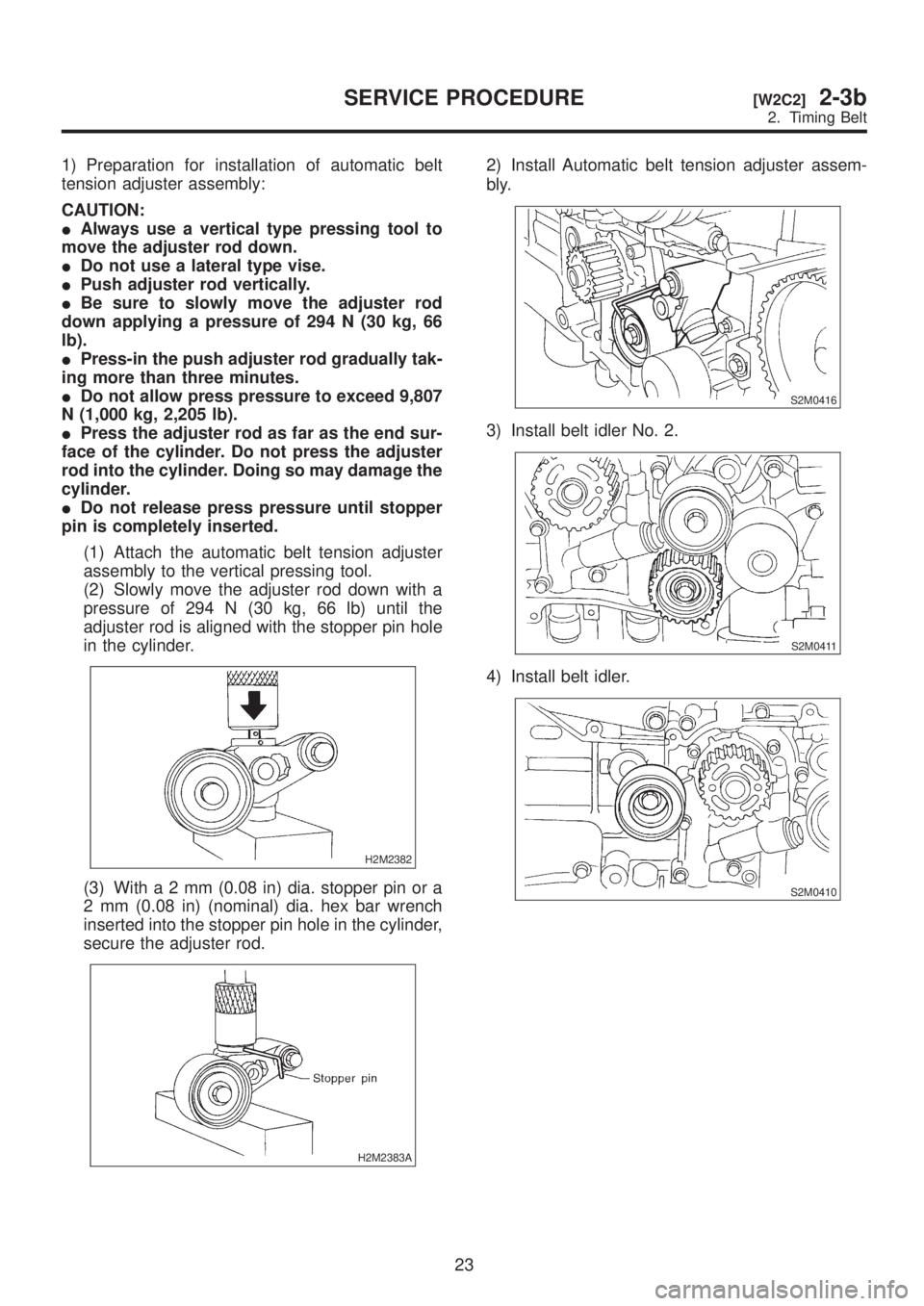

1) Preparation for installation of automatic belt

tension adjuster assembly:

CAUTION:

IAlways use a vertical type pressing tool to

move the adjuster rod down.

IDo not use a lateral type vise.

IPush adjuster rod vertically.

IBe sure to slowly move the adjuster rod

down applying a pressure of 294 N (30 kg, 66

lb).

IPress-in the push adjuster rod gradually tak-

ing more than three minutes.

IDo not allow press pressure to exceed 9,807

N (1,000 kg, 2,205 lb).

IPress the adjuster rod as far as the end sur-

face of the cylinder. Do not press the adjuster

rod into the cylinder. Doing so may damage the

cylinder.

IDo not release press pressure until stopper

pin is completely inserted.

(1) Attach the automatic belt tension adjuster

assembly to the vertical pressing tool.

(2) Slowly move the adjuster rod down with a

pressure of 294 N (30 kg, 66 lb) until the

adjuster rod is aligned with the stopper pin hole

in the cylinder.

H2M2382

(3) Witha2mm(0.08 in) dia. stopper pin or a

2 mm (0.08 in) (nominal) dia. hex bar wrench

inserted into the stopper pin hole in the cylinder,

secure the adjuster rod.

H2M2383A

2) Install Automatic belt tension adjuster assem-

bly.

S2M0416

3) Install belt idler No. 2.

S2M0411

4) Install belt idler.

S2M0410

23

[W2C2]2-3bSERVICE PROCEDURE

2. Timing Belt

Page 238 of 1456

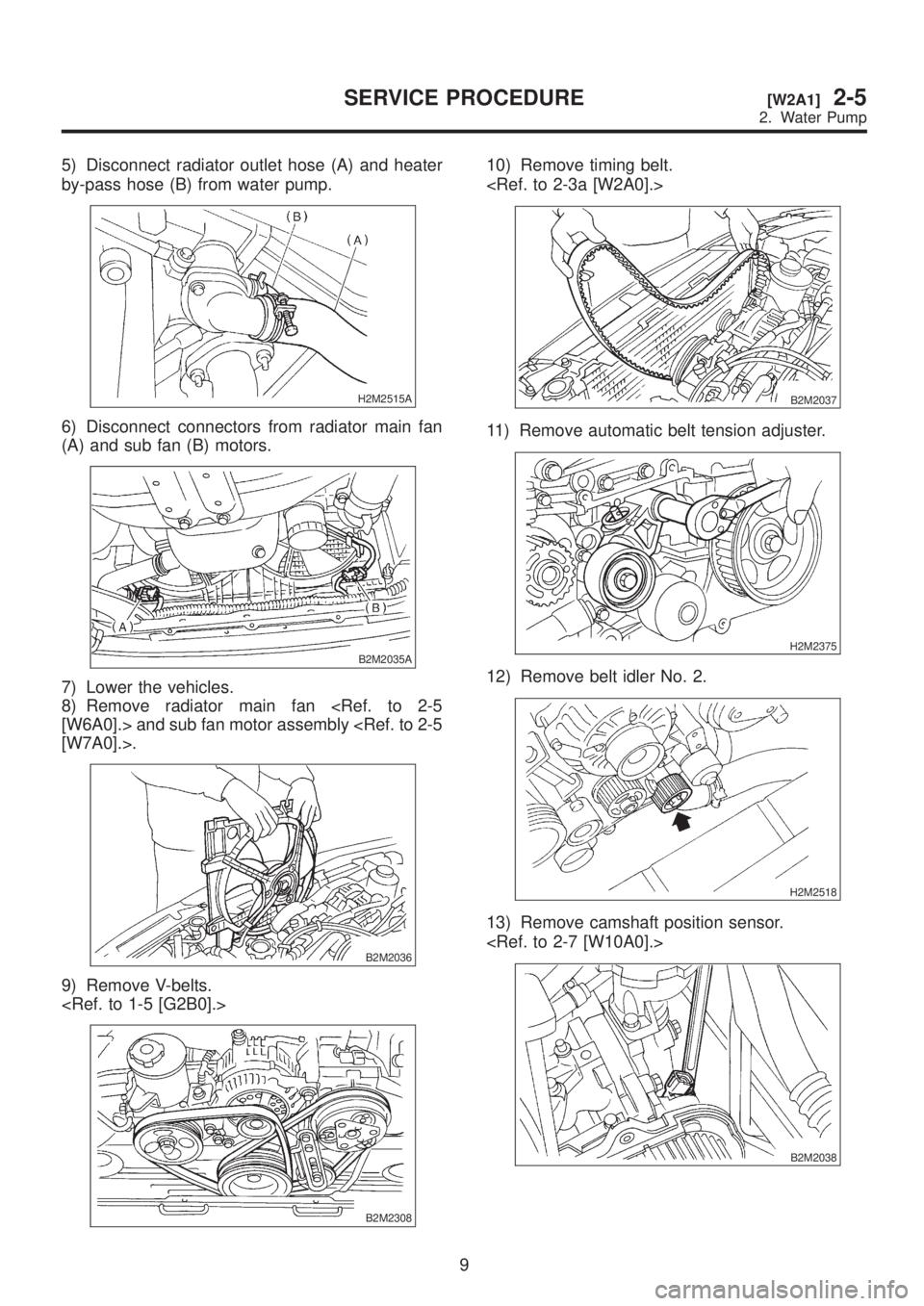

5) Disconnect radiator outlet hose (A) and heater

by-pass hose (B) from water pump.

H2M2515A

6) Disconnect connectors from radiator main fan

(A) and sub fan (B) motors.

B2M2035A

7) Lower the vehicles.

8) Remove radiator main fan

B2M2036

9) Remove V-belts.

B2M2308

10) Remove timing belt.

B2M2037

11) Remove automatic belt tension adjuster.

H2M2375

12) Remove belt idler No. 2.

H2M2518

13) Remove camshaft position sensor.

B2M2038

9

[W2A1]2-5SERVICE PROCEDURE

2. Water Pump

Page 240 of 1456

![SUBARU LEGACY 1999 Service User Guide 4) Drain engine coolant completely.

<Ref. to 2-5 [W1A0].>

B2M0015A

5) Disconnect connectors from radiator main fan

(A) and sub fan (B) motors.

B2M2035A

6) Loosen bolts which hold lower side of radiato SUBARU LEGACY 1999 Service User Guide 4) Drain engine coolant completely.

<Ref. to 2-5 [W1A0].>

B2M0015A

5) Disconnect connectors from radiator main fan

(A) and sub fan (B) motors.

B2M2035A

6) Loosen bolts which hold lower side of radiato](/img/17/57435/w960_57435-239.png)

4) Drain engine coolant completely.

B2M0015A

5) Disconnect connectors from radiator main fan

(A) and sub fan (B) motors.

B2M2035A

6) Loosen bolts which hold lower side of radiator

main fan and sub fan shrouds.

B2M2041

7) Disconnect radiator outlet hose (A) and heater

by-pass hose (B) from water pump.

H2M2515A

8) Lower the vehicle.

9) Remove radiator main fan

B2M2036

10) Remove V-belts.

B2M2308

11) Remove timing belt.

S2M0017

12) Remove automatic belt tension adjuster.

H2M2403

11

[W2A2]2-5SERVICE PROCEDURE

2. Water Pump

Page 527 of 1456

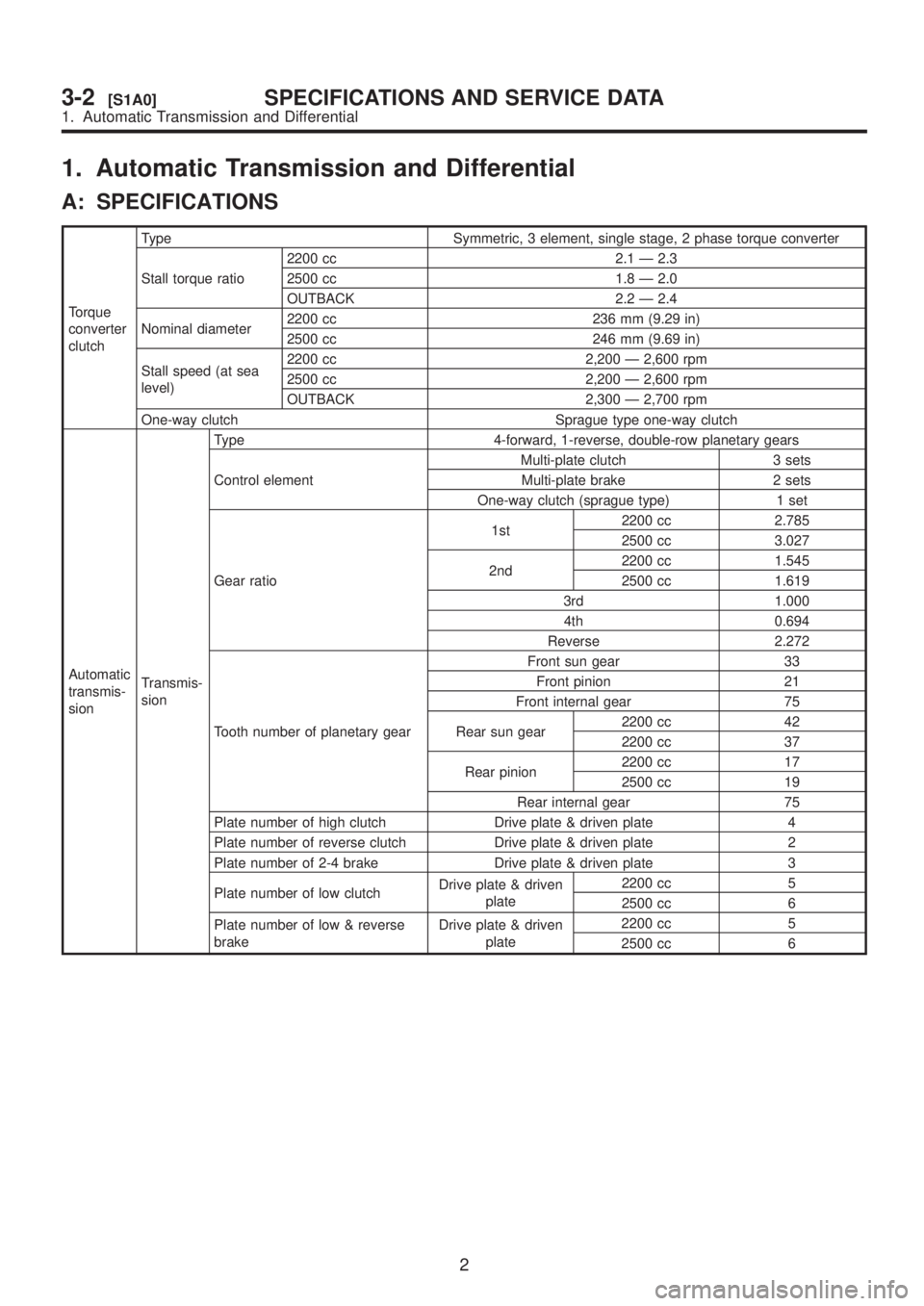

1. Automatic Transmission and Differential

A: SPECIFICATIONS

Torque

converter

clutchType Symmetric, 3 element, single stage, 2 phase torque converter

Stall torque ratio2200 cc 2.1 Ð 2.3

2500 cc 1.8 Ð 2.0

OUTBACK 2.2 Ð 2.4

Nominal diameter2200 cc 236 mm (9.29 in)

2500 cc 246 mm (9.69 in)

Stall speed (at sea

level)2200 cc 2,200 Ð 2,600 rpm

2500 cc 2,200 Ð 2,600 rpm

OUTBACK 2,300 Ð 2,700 rpm

One-way clutch Sprague type one-way clutch

Automatic

transmis-

sionTransmis-

sionType 4-forward, 1-reverse, double-row planetary gears

Control elementMulti-plate clutch 3 sets

Multi-plate brake 2 sets

One-way clutch (sprague type) 1 set

Gear ratio1st2200 cc 2.785

2500 cc 3.027

2nd2200 cc 1.545

2500 cc 1.619

3rd 1.000

4th 0.694

Reverse 2.272

Tooth number of planetary gearFront sun gear 33

Front pinion 21

Front internal gear 75

Rear sun gear2200 cc 42

2200 cc 37

Rear pinion2200 cc 17

2500 cc 19

Rear internal gear 75

Plate number of high clutch Drive plate & driven plate 4

Plate number of reverse clutch Drive plate & driven plate 2

Plate number of 2-4 brake Drive plate & driven plate 3

Plate number of low clutchDrive plate & driven

plate2200 cc 5

2500 cc 6

Plate number of low & reverse

brakeDrive plate & driven

plate2200 cc 5

2500 cc 6

2

3-2[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 528 of 1456

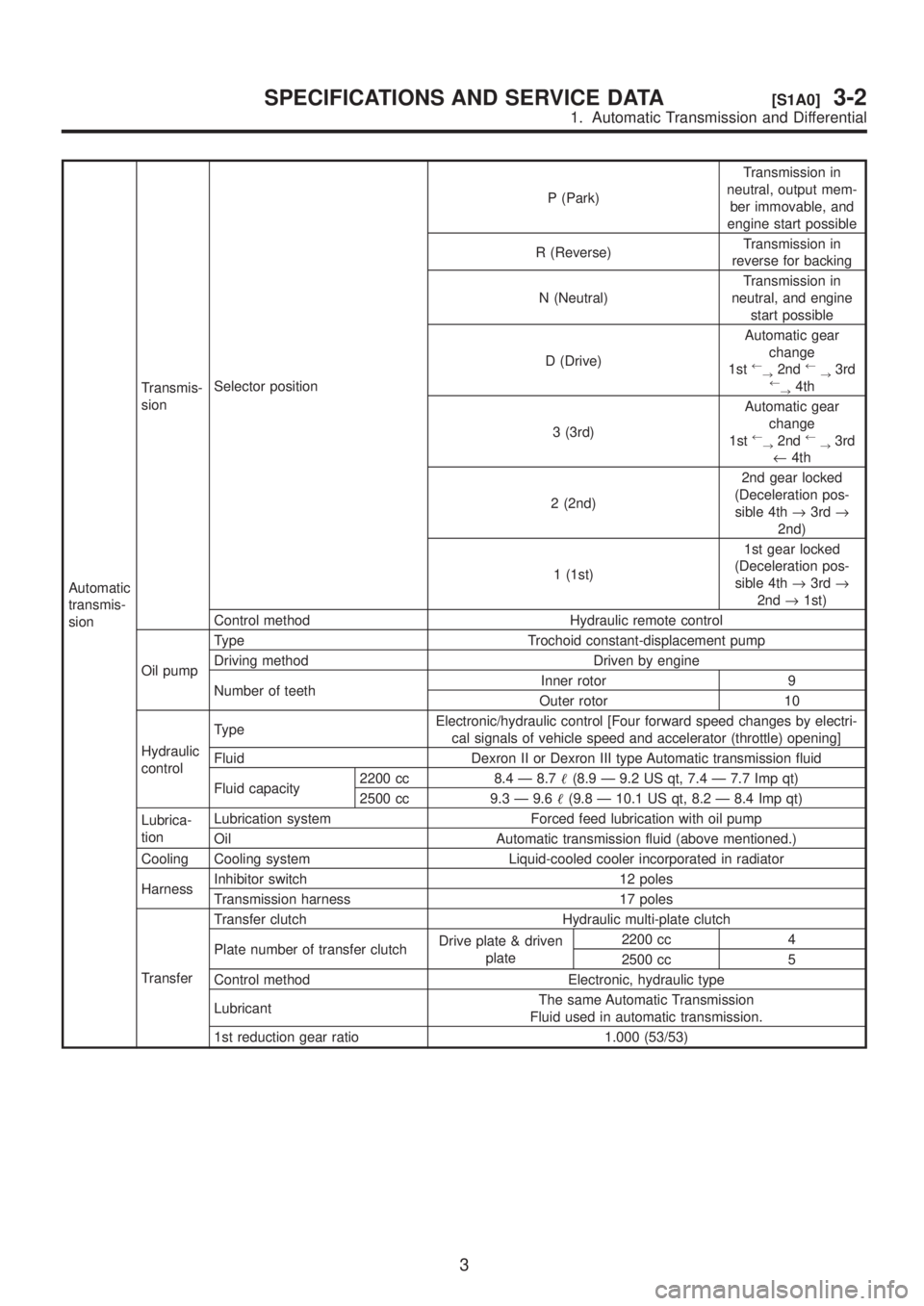

Automatic

transmis-

sionTransmis-

sionSelector positionP (Park)Transmission in

neutral, output mem-

ber immovable, and

engine start possible

R (Reverse)Transmission in

reverse for backing

N (Neutral)Transmission in

neutral, and engine

start possible

D (Drive)Automatic gear

change

1st

¬

®2nd¬

®3rd¬

®4th

3 (3rd)Automatic gear

change

1st

¬

®2nd¬

®3rd

¬4th

2 (2nd)2nd gear locked

(Deceleration pos-

sible 4th®3rd®

2nd)

1 (1st)1st gear locked

(Deceleration pos-

sible 4th®3rd®

2nd®1st)

Control method Hydraulic remote control

Oil pumpType Trochoid constant-displacement pump

Driving method Driven by engine

Number of teethInner rotor 9

Outer rotor 10

Hydraulic

controlTypeElectronic/hydraulic control [Four forward speed changes by electri-

cal signals of vehicle speed and accelerator (throttle) opening]

Fluid Dexron II or Dexron III type Automatic transmission fluid

Fluid capacity2200 cc 8.4 Ð 8.7(8.9 Ð 9.2 US qt, 7.4 Ð 7.7 Imp qt)

2500 cc 9.3 Ð 9.6(9.8 Ð 10.1 US qt, 8.2 Ð 8.4 Imp qt)

Lubrica-

tionLubrication system Forced feed lubrication with oil pump

Oil Automatic transmission fluid (above mentioned.)

Cooling Cooling system Liquid-cooled cooler incorporated in radiator

HarnessInhibitor switch 12 poles

Transmission harness 17 poles

TransferTransfer clutch Hydraulic multi-plate clutch

Plate number of transfer clutchDrive plate & driven

plate2200 cc 4

2500 cc 5

Control method Electronic, hydraulic type

LubricantThe same Automatic Transmission

Fluid used in automatic transmission.

1st reduction gear ratio 1.000 (53/53)

3

[S1A0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 529 of 1456

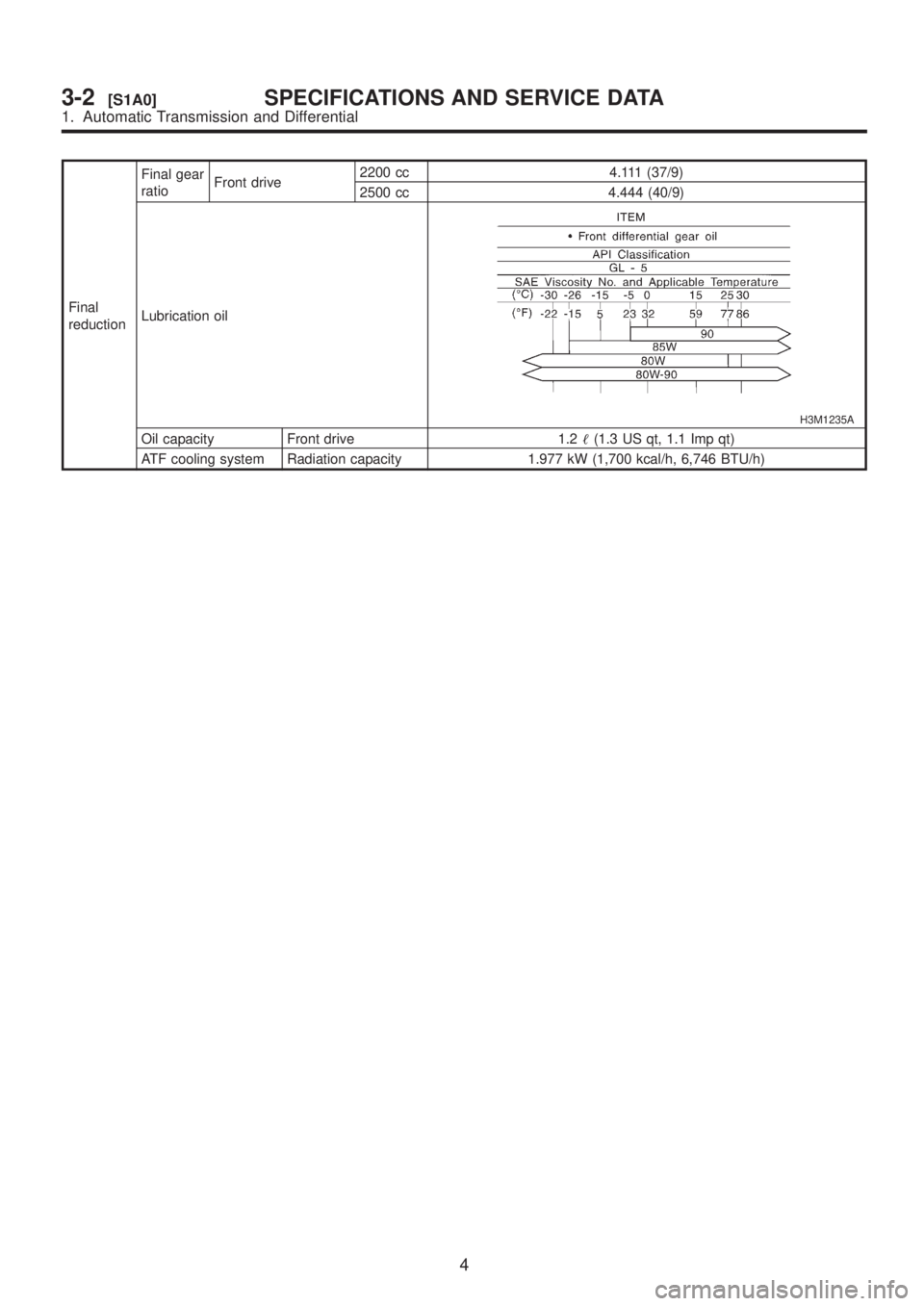

Final

reductionFinal gear

ratioFront drive2200 cc 4.111 (37/9)

2500 cc 4.444 (40/9)

Lubrication oil

H3M1235A

Oil capacity Front drive 1.2(1.3 US qt, 1.1 Imp qt)

ATF cooling system Radiation capacity 1.977 kW (1,700 kcal/h, 6,746 BTU/h)

4

3-2[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 530 of 1456

![SUBARU LEGACY 1999 Service User Guide MEMO:

5

[S1A0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential SUBARU LEGACY 1999 Service User Guide MEMO:

5

[S1A0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential](/img/17/57435/w960_57435-529.png)

MEMO:

5

[S1A0]3-2SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential

Page 531 of 1456

![SUBARU LEGACY 1999 Service User Guide B: ADJUSTING PARTS

B3M1015A

6

3-2[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential SUBARU LEGACY 1999 Service User Guide B: ADJUSTING PARTS

B3M1015A

6

3-2[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential](/img/17/57435/w960_57435-530.png)

B: ADJUSTING PARTS

B3M1015A

6

3-2[S1B0]SPECIFICATIONS AND SERVICE DATA

1. Automatic Transmission and Differential