automatic SUBARU LEGACY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 554 of 1456

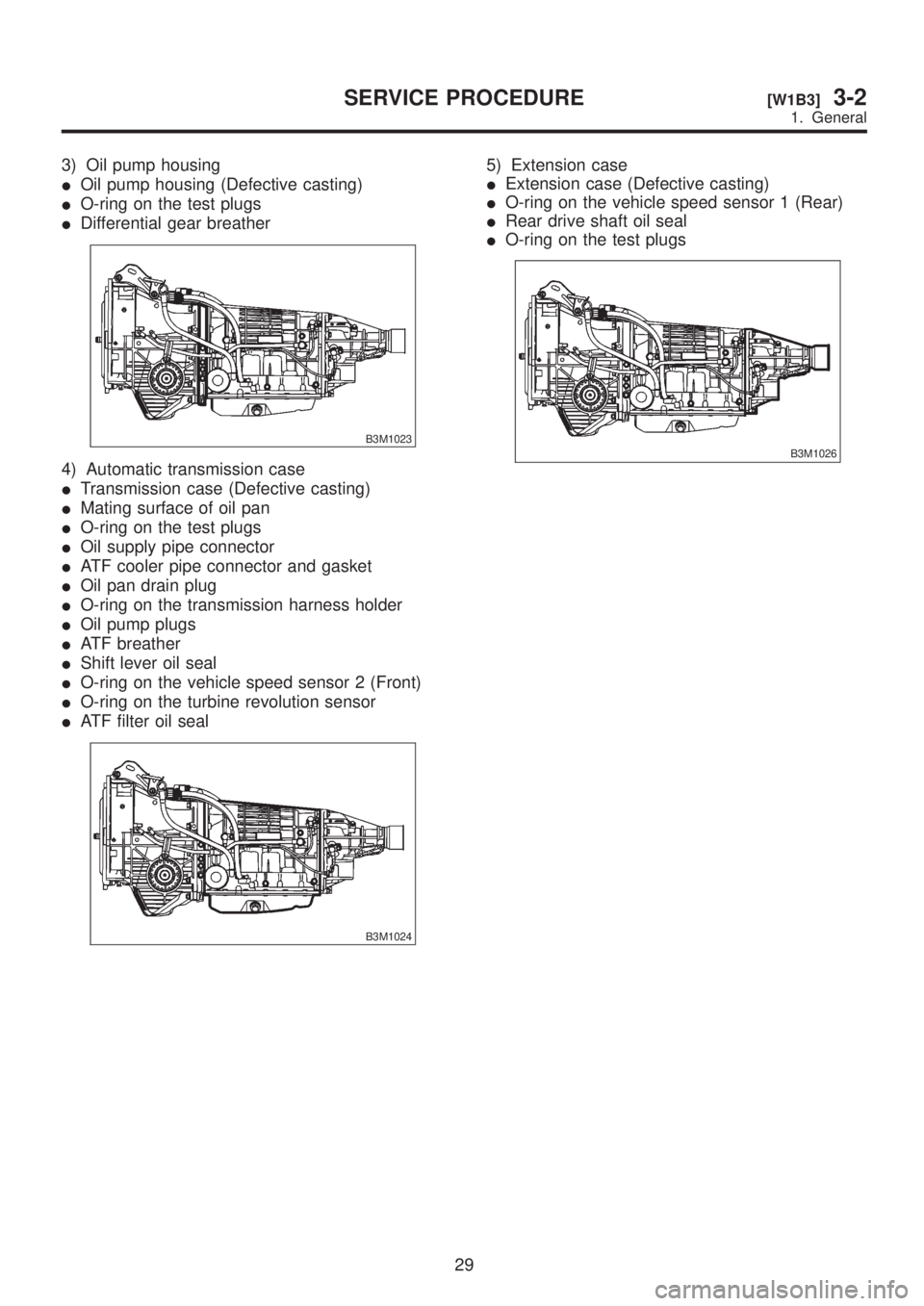

3) Oil pump housing

IOil pump housing (Defective casting)

IO-ring on the test plugs

IDifferential gear breather

B3M1023

4) Automatic transmission case

ITransmission case (Defective casting)

IMating surface of oil pan

IO-ring on the test plugs

IOil supply pipe connector

IATF cooler pipe connector and gasket

IOil pan drain plug

IO-ring on the transmission harness holder

IOil pump plugs

IATF breather

IShift lever oil seal

IO-ring on the vehicle speed sensor 2 (Front)

IO-ring on the turbine revolution sensor

IATF filter oil seal

B3M1024

5) Extension case

IExtension case (Defective casting)

IO-ring on the vehicle speed sensor 1 (Rear)

IRear drive shaft oil seal

IO-ring on the test plugs

B3M1026

29

[W1B3]3-2SERVICE PROCEDURE

1. General

Page 566 of 1456

9) Install pitching stopper.

Tightening torque:

T1: 49

±5 N´m (5.0±0.5 kg-m, 36.2±3.6 ft-lb)

T2: 57

±10 N´m (5.8±1.0 kg-m, 42±7 ft-lb)

B3M1042A

10) Replenish ATF and check oil level. Check for

leaks.

B3M1020A

6. Road Test

A: INSPECTION

1. GENERAL PRECAUTION

Road tests should be conducted to properly diag-

nose the condition of the automatic transmission.

CAUTION:

When performing test, do not exceed posted

speed limit.

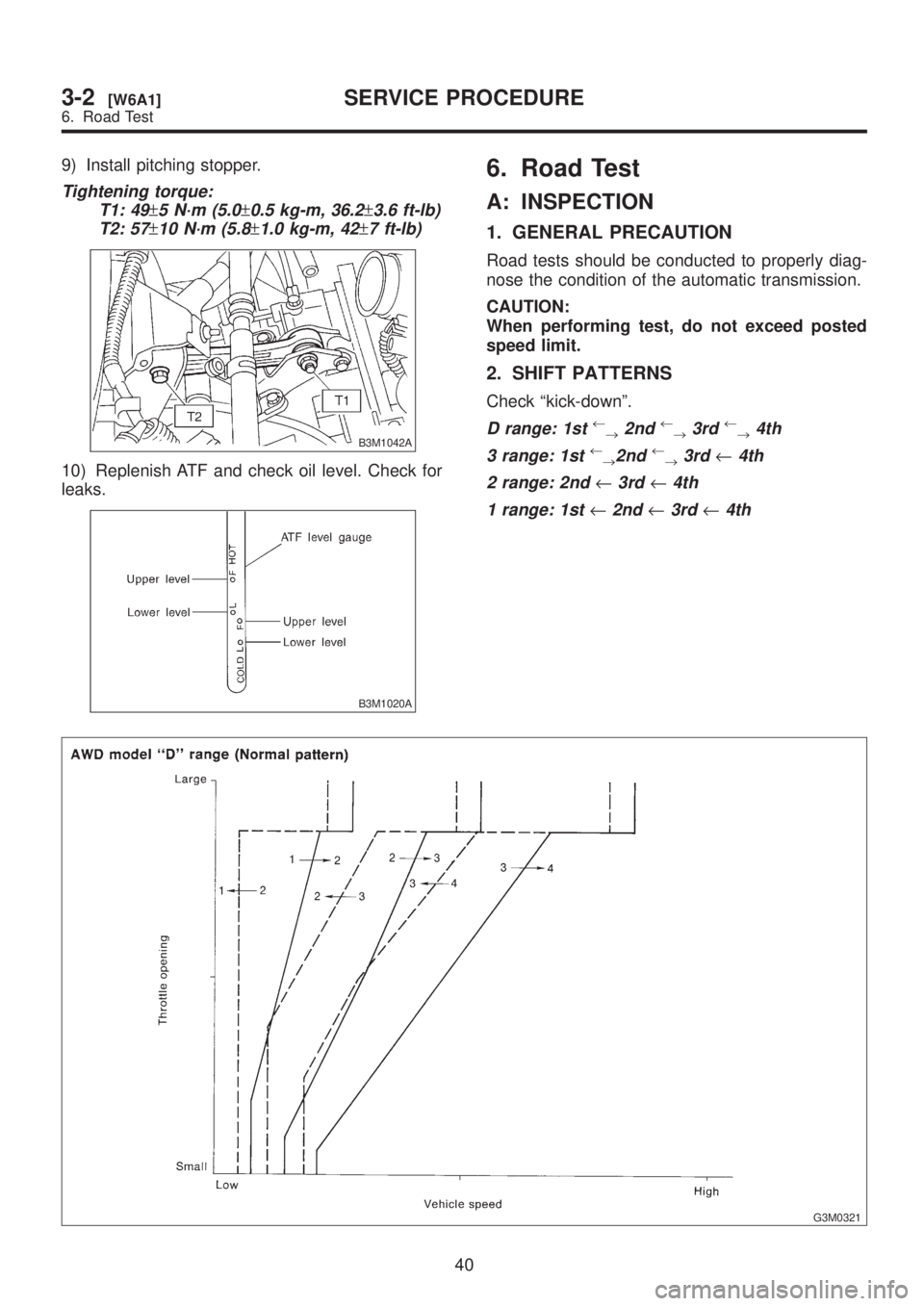

2. SHIFT PATTERNS

Check ªkick-downº.

D range: 1st¬

®2nd¬

®3rd¬

®4th

3 range: 1st

¬

®2nd¬

®3rd¬4th

2 range: 2nd

¬3rd¬4th

1 range: 1st

¬2nd¬3rd¬4th

G3M0321

40

3-2[W6A1]SERVICE PROCEDURE

6. Road Test

Page 567 of 1456

9) Install pitching stopper.

Tightening torque:

T1: 49

±5 N´m (5.0±0.5 kg-m, 36.2±3.6 ft-lb)

T2: 57

±10 N´m (5.8±1.0 kg-m, 42±7 ft-lb)

B3M1042A

10) Replenish ATF and check oil level. Check for

leaks.

B3M1020A

6. Road Test

A: INSPECTION

1. GENERAL PRECAUTION

Road tests should be conducted to properly diag-

nose the condition of the automatic transmission.

CAUTION:

When performing test, do not exceed posted

speed limit.

2. SHIFT PATTERNS

Check ªkick-downº.

D range: 1st¬

®2nd¬

®3rd¬

®4th

3 range: 1st

¬

®2nd¬

®3rd¬4th

2 range: 2nd

¬3rd¬4th

1 range: 1st

¬2nd¬3rd¬4th

G3M0321

40

3-2[W6A1]SERVICE PROCEDURE

6. Road Test

Page 568 of 1456

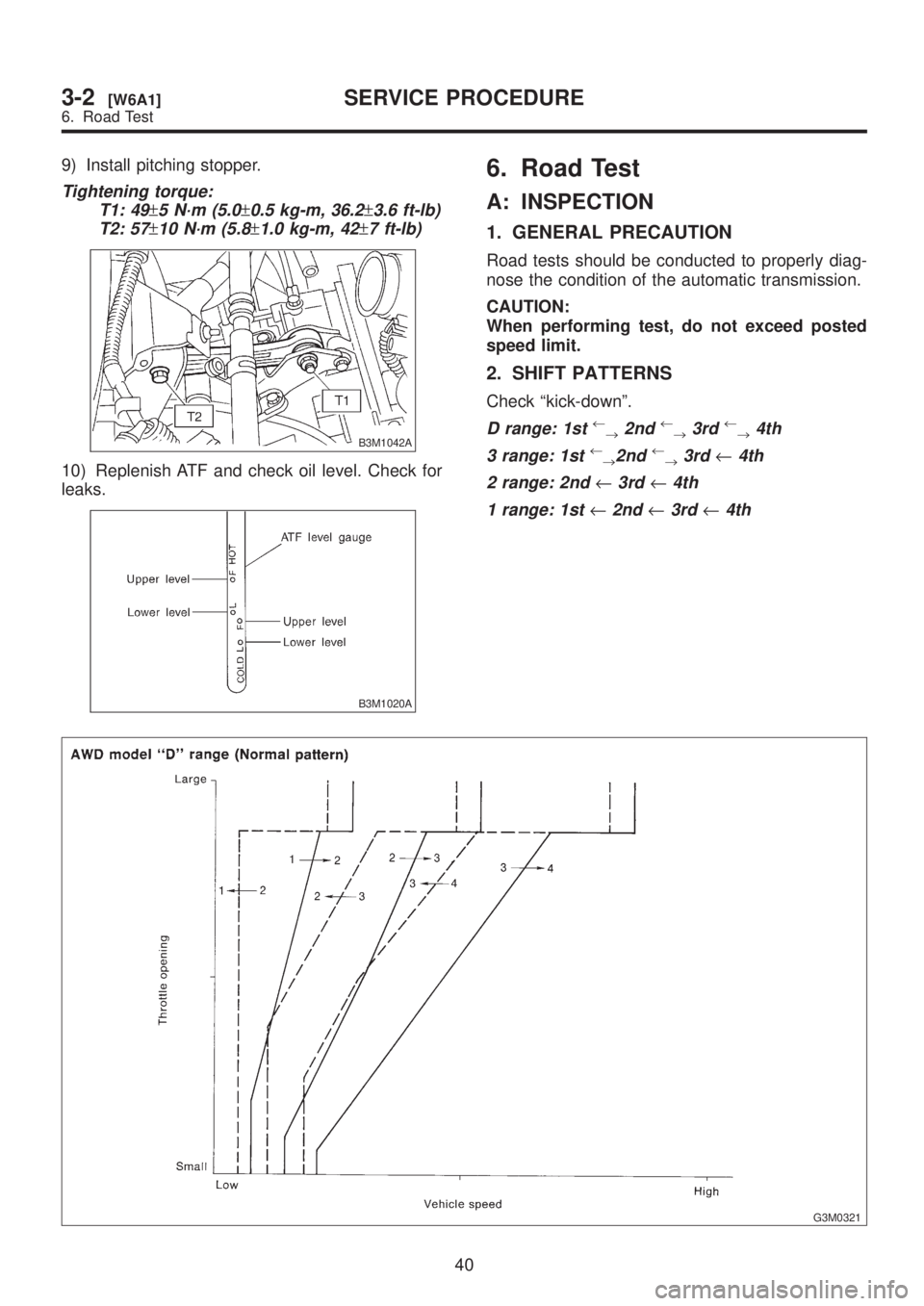

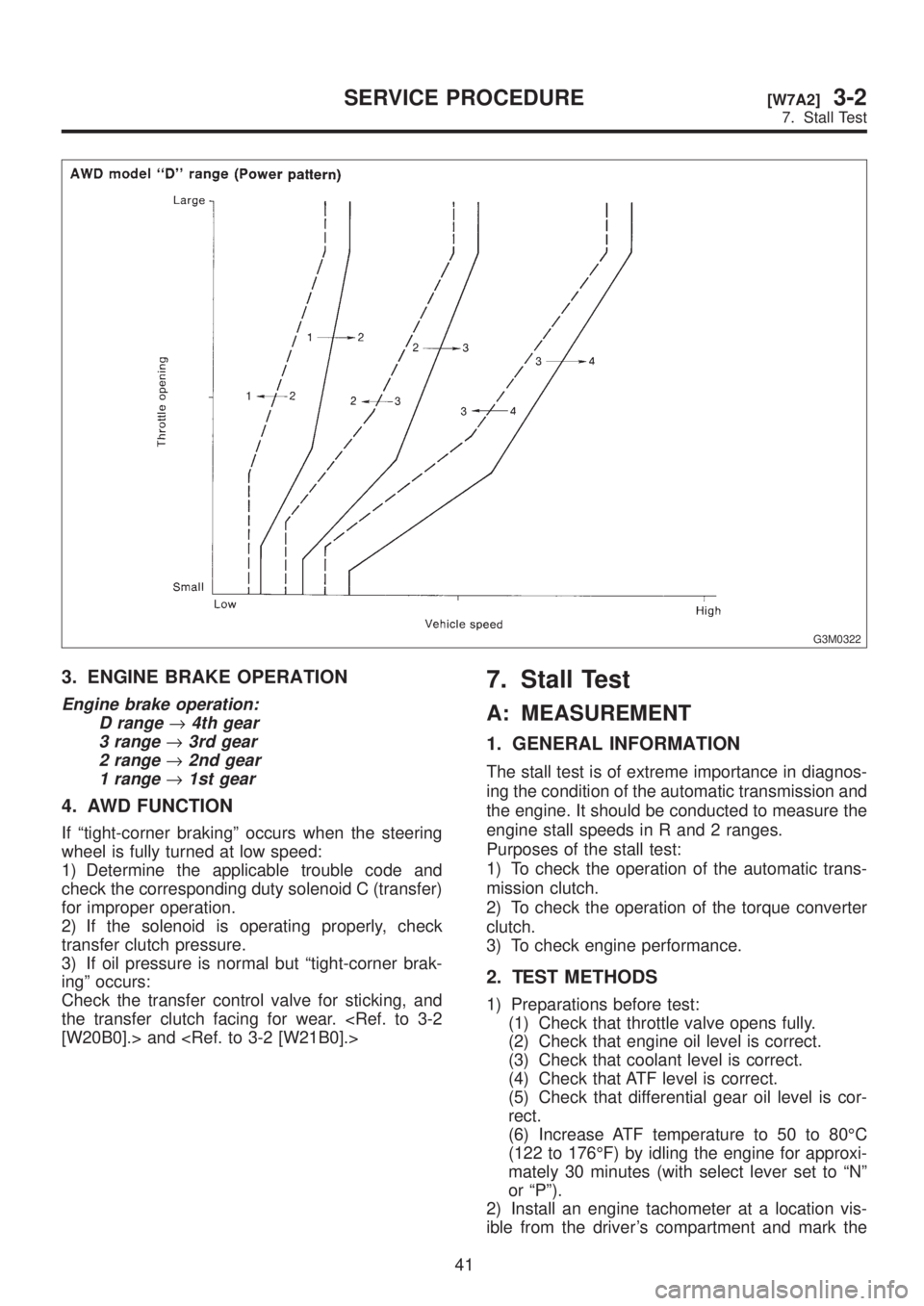

G3M0322

3. ENGINE BRAKE OPERATION

Engine brake operation:

D range

®4th gear

3 range

®3rd gear

2 range

®2nd gear

1 range

®1st gear

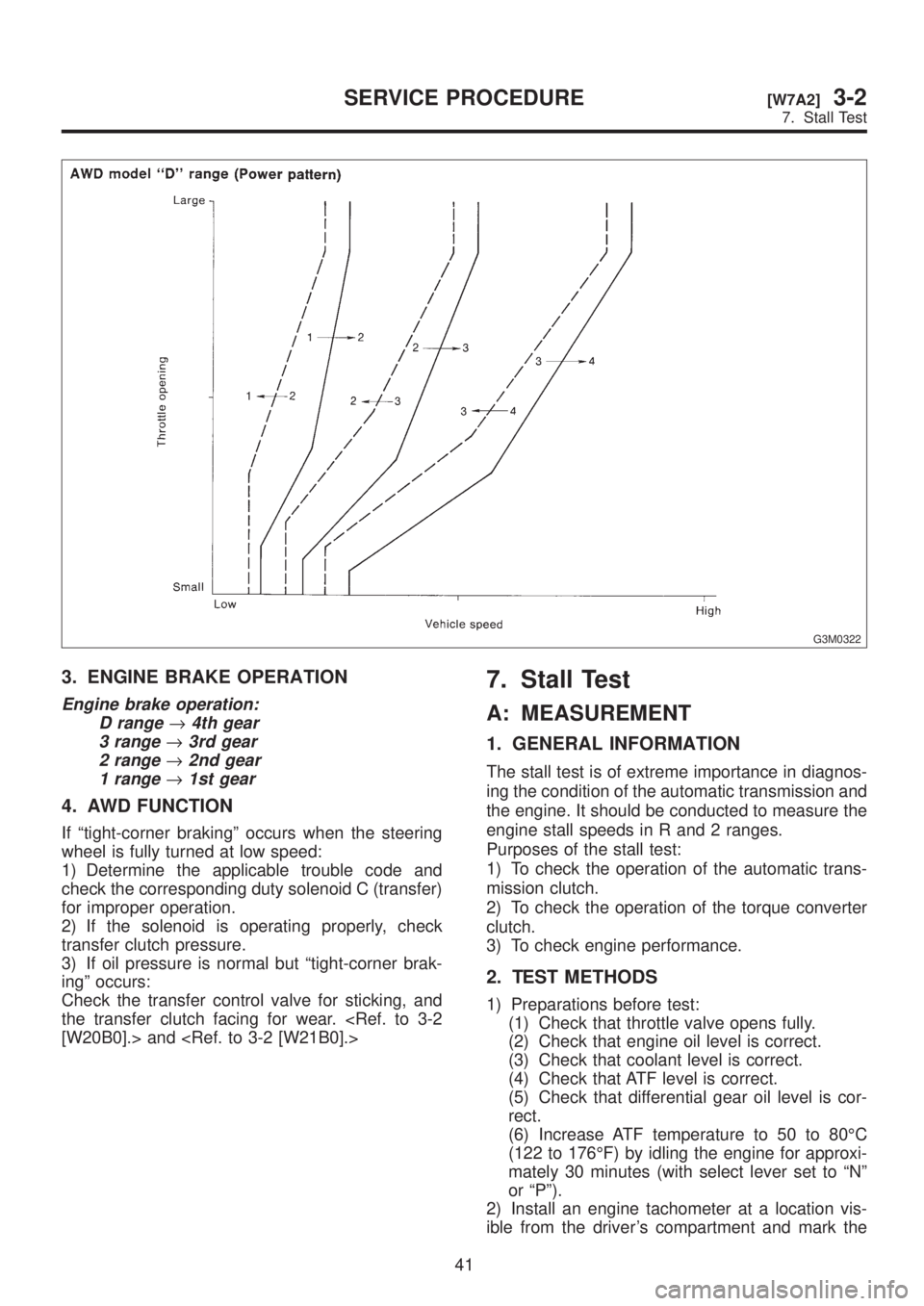

4. AWD FUNCTION

If ªtight-corner brakingº occurs when the steering

wheel is fully turned at low speed:

1) Determine the applicable trouble code and

check the corresponding duty solenoid C (transfer)

for improper operation.

2) If the solenoid is operating properly, check

transfer clutch pressure.

3) If oil pressure is normal but ªtight-corner brak-

ingº occurs:

Check the transfer control valve for sticking, and

the transfer clutch facing for wear.

7. Stall Test

A: MEASUREMENT

1. GENERAL INFORMATION

The stall test is of extreme importance in diagnos-

ing the condition of the automatic transmission and

the engine. It should be conducted to measure the

engine stall speeds in R and 2 ranges.

Purposes of the stall test:

1) To check the operation of the automatic trans-

mission clutch.

2) To check the operation of the torque converter

clutch.

3) To check engine performance.

2. TEST METHODS

1) Preparations before test:

(1) Check that throttle valve opens fully.

(2) Check that engine oil level is correct.

(3) Check that coolant level is correct.

(4) Check that ATF level is correct.

(5) Check that differential gear oil level is cor-

rect.

(6) Increase ATF temperature to 50 to 80ÉC

(122 to 176ÉF) by idling the engine for approxi-

mately 30 minutes (with select lever set to ªNº

or ªPº).

2) Install an engine tachometer at a location vis-

ible from the driver's compartment and mark the

41

[W7A2]3-2SERVICE PROCEDURE

7. Stall Test

Page 569 of 1456

G3M0322

3. ENGINE BRAKE OPERATION

Engine brake operation:

D range

®4th gear

3 range

®3rd gear

2 range

®2nd gear

1 range

®1st gear

4. AWD FUNCTION

If ªtight-corner brakingº occurs when the steering

wheel is fully turned at low speed:

1) Determine the applicable trouble code and

check the corresponding duty solenoid C (transfer)

for improper operation.

2) If the solenoid is operating properly, check

transfer clutch pressure.

3) If oil pressure is normal but ªtight-corner brak-

ingº occurs:

Check the transfer control valve for sticking, and

the transfer clutch facing for wear.

7. Stall Test

A: MEASUREMENT

1. GENERAL INFORMATION

The stall test is of extreme importance in diagnos-

ing the condition of the automatic transmission and

the engine. It should be conducted to measure the

engine stall speeds in R and 2 ranges.

Purposes of the stall test:

1) To check the operation of the automatic trans-

mission clutch.

2) To check the operation of the torque converter

clutch.

3) To check engine performance.

2. TEST METHODS

1) Preparations before test:

(1) Check that throttle valve opens fully.

(2) Check that engine oil level is correct.

(3) Check that coolant level is correct.

(4) Check that ATF level is correct.

(5) Check that differential gear oil level is cor-

rect.

(6) Increase ATF temperature to 50 to 80ÉC

(122 to 176ÉF) by idling the engine for approxi-

mately 30 minutes (with select lever set to ªNº

or ªPº).

2) Install an engine tachometer at a location vis-

ible from the driver's compartment and mark the

41

[W7A2]3-2SERVICE PROCEDURE

7. Stall Test

Page 570 of 1456

stall speed range on the tachometer scale.

3) Place the wheel chocks at the front and rear of

all wheels and engage the parking brake.

4) Move the manual linkage to ensure it operates

properly, and shift the select lever to the 2 range.

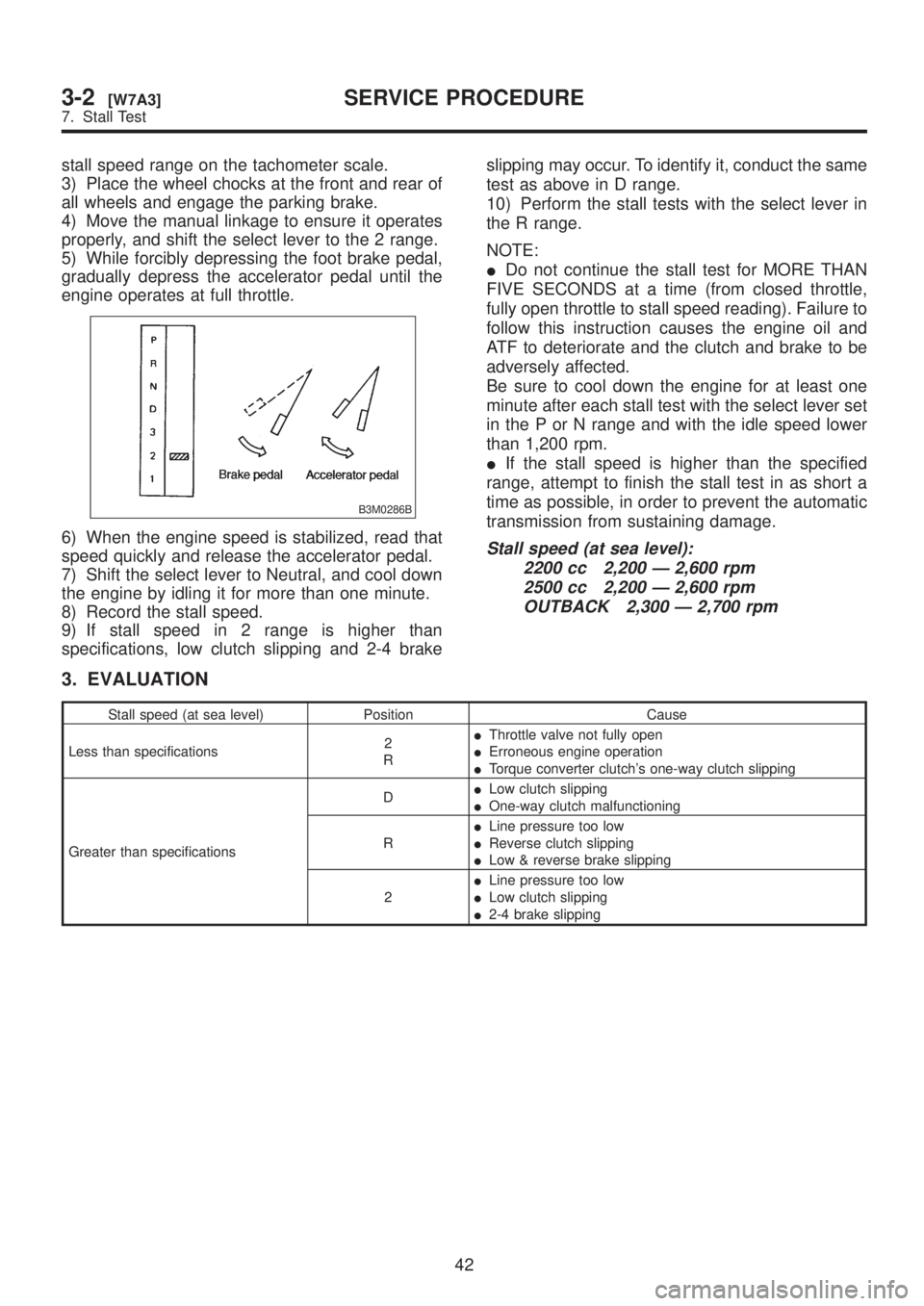

5) While forcibly depressing the foot brake pedal,

gradually depress the accelerator pedal until the

engine operates at full throttle.

B3M0286B

6) When the engine speed is stabilized, read that

speed quickly and release the accelerator pedal.

7) Shift the select lever to Neutral, and cool down

the engine by idling it for more than one minute.

8) Record the stall speed.

9) If stall speed in 2 range is higher than

specifications, low clutch slipping and 2-4 brakeslipping may occur. To identify it, conduct the same

test as above in D range.

10) Perform the stall tests with the select lever in

the R range.

NOTE:

IDo not continue the stall test for MORE THAN

FIVE SECONDS at a time (from closed throttle,

fully open throttle to stall speed reading). Failure to

follow this instruction causes the engine oil and

ATF to deteriorate and the clutch and brake to be

adversely affected.

Be sure to cool down the engine for at least one

minute after each stall test with the select lever set

in the P or N range and with the idle speed lower

than 1,200 rpm.

IIf the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.Stall speed (at sea level):

2200 cc 2,200 Ð 2,600 rpm

2500 cc 2,200 Ð 2,600 rpm

OUTBACK 2,300 Ð 2,700 rpm

3. EVALUATION

Stall speed (at sea level) Position Cause

Less than specifications2

RIThrottle valve not fully open

IErroneous engine operation

ITorque converter clutch's one-way clutch slipping

Greater than specificationsDILow clutch slipping

IOne-way clutch malfunctioning

RILine pressure too low

IReverse clutch slipping

ILow & reverse brake slipping

2ILine pressure too low

ILow clutch slipping

I2-4 brake slipping

42

3-2[W7A3]SERVICE PROCEDURE

7. Stall Test

Page 575 of 1456

11. Overall Transmission

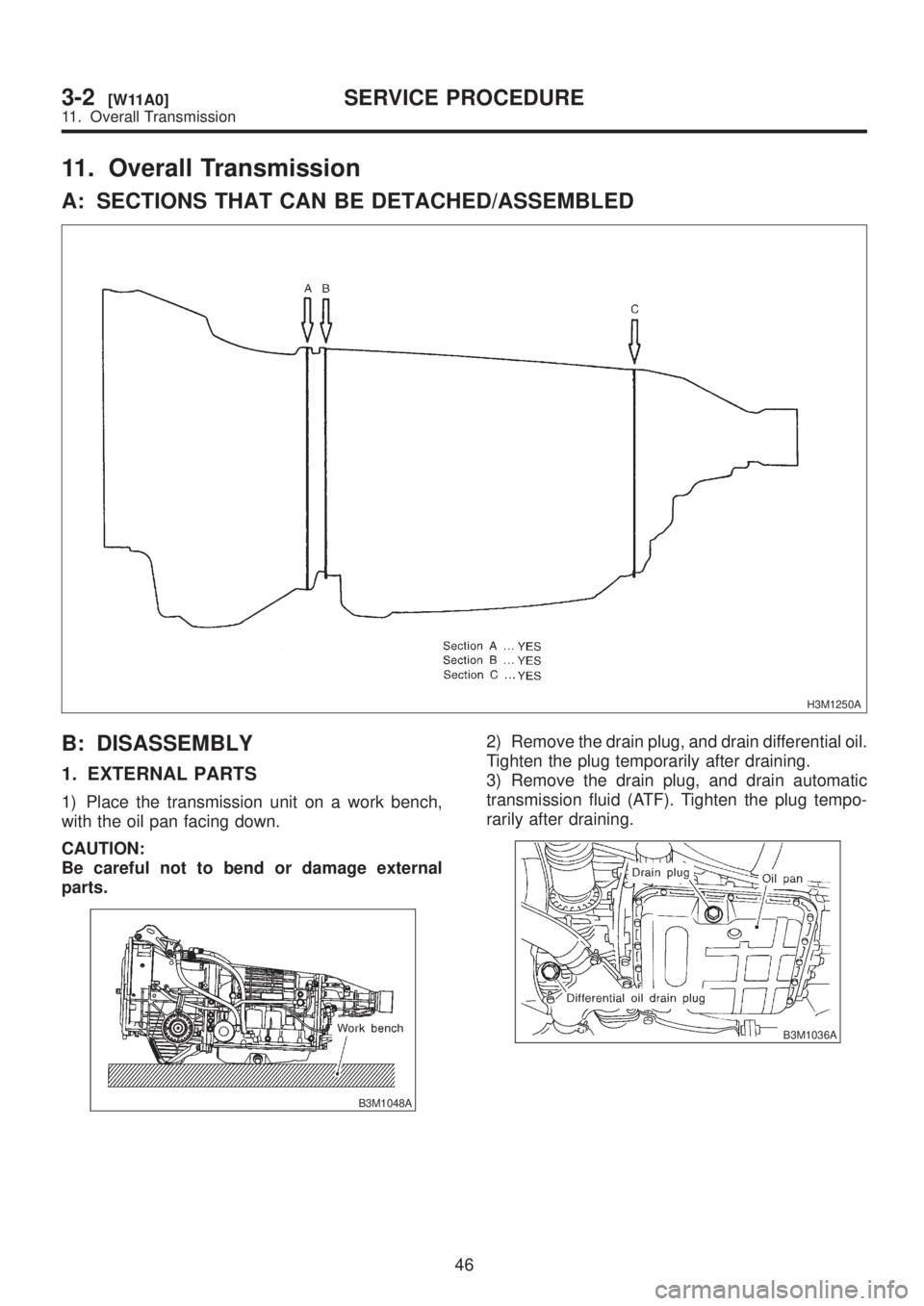

A: SECTIONS THAT CAN BE DETACHED/ASSEMBLED

H3M1250A

B: DISASSEMBLY

1. EXTERNAL PARTS

1) Place the transmission unit on a work bench,

with the oil pan facing down.

CAUTION:

Be careful not to bend or damage external

parts.

B3M1048A

2) Remove the drain plug, and drain differential oil.

Tighten the plug temporarily after draining.

3) Remove the drain plug, and drain automatic

transmission fluid (ATF). Tighten the plug tempo-

rarily after draining.

B3M1036A

46

3-2[W11A0]SERVICE PROCEDURE

11. Overall Transmission

Page 602 of 1456

12) Fill ATF and differential gear oil.

NOTE:

After filling oil, insert the oil level gauge into the oil

inlet.

Differential gear oil capacity:

1.1 Ð 1.3

(1.2 Ð 1.4 US qt, 1.0 Ð 1.1

Imp qt)

Automatic transmission fluid capacity:

2200 cc; 8.4 Ð 8.7

(8.9 Ð 9.2 US qt, 7.4

Ð 7.7 Imp qt)

2500 cc; 9.3 Ð 9.6

(9.8 Ð 10.1 US qt,

8.2 Ð 8.4 Imp qt)

Recommended fluid:

Dexron II or Dexron III type automatic

transmission

73

[W11C7]3-2SERVICE PROCEDURE

11. Overall Transmission

Page 641 of 1456

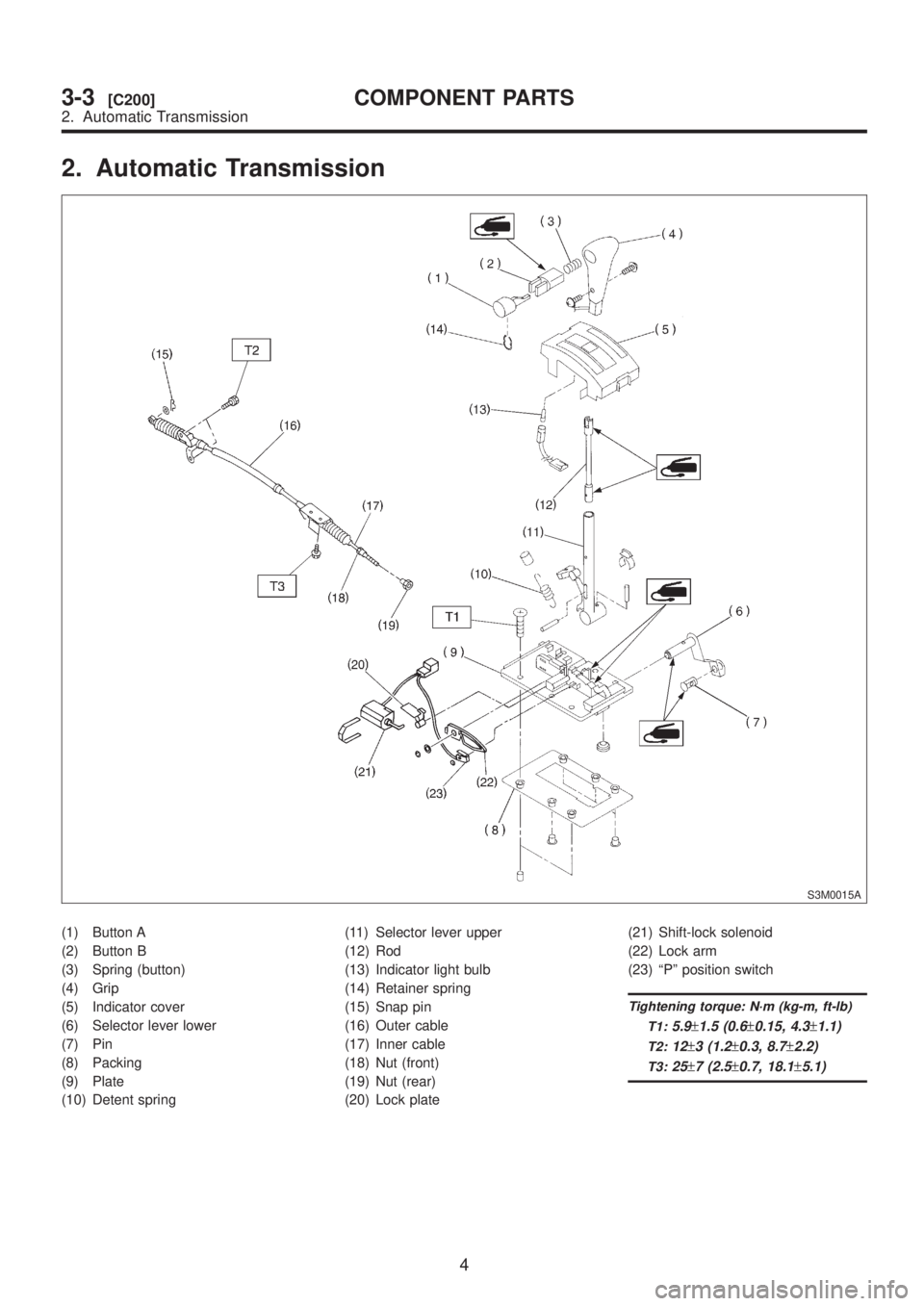

2. Automatic Transmission

S3M0015A

(1) Button A

(2) Button B

(3) Spring (button)

(4) Grip

(5) Indicator cover

(6) Selector lever lower

(7) Pin

(8) Packing

(9) Plate

(10) Detent spring(11) Selector lever upper

(12) Rod

(13) Indicator light bulb

(14) Retainer spring

(15) Snap pin

(16) Outer cable

(17) Inner cable

(18) Nut (front)

(19) Nut (rear)

(20) Lock plate(21) Shift-lock solenoid

(22) Lock arm

(23) ªPº position switch

Tightening torque: N´m (kg-m, ft-lb)

T1:

5.9±1.5 (0.6±0.15, 4.3±1.1)

T2:12±3 (1.2±0.3, 8.7±2.2)

T3:25±7 (2.5±0.7, 18.1±5.1)

4

3-3[C200]COMPONENT PARTS

2. Automatic Transmission

Page 645 of 1456

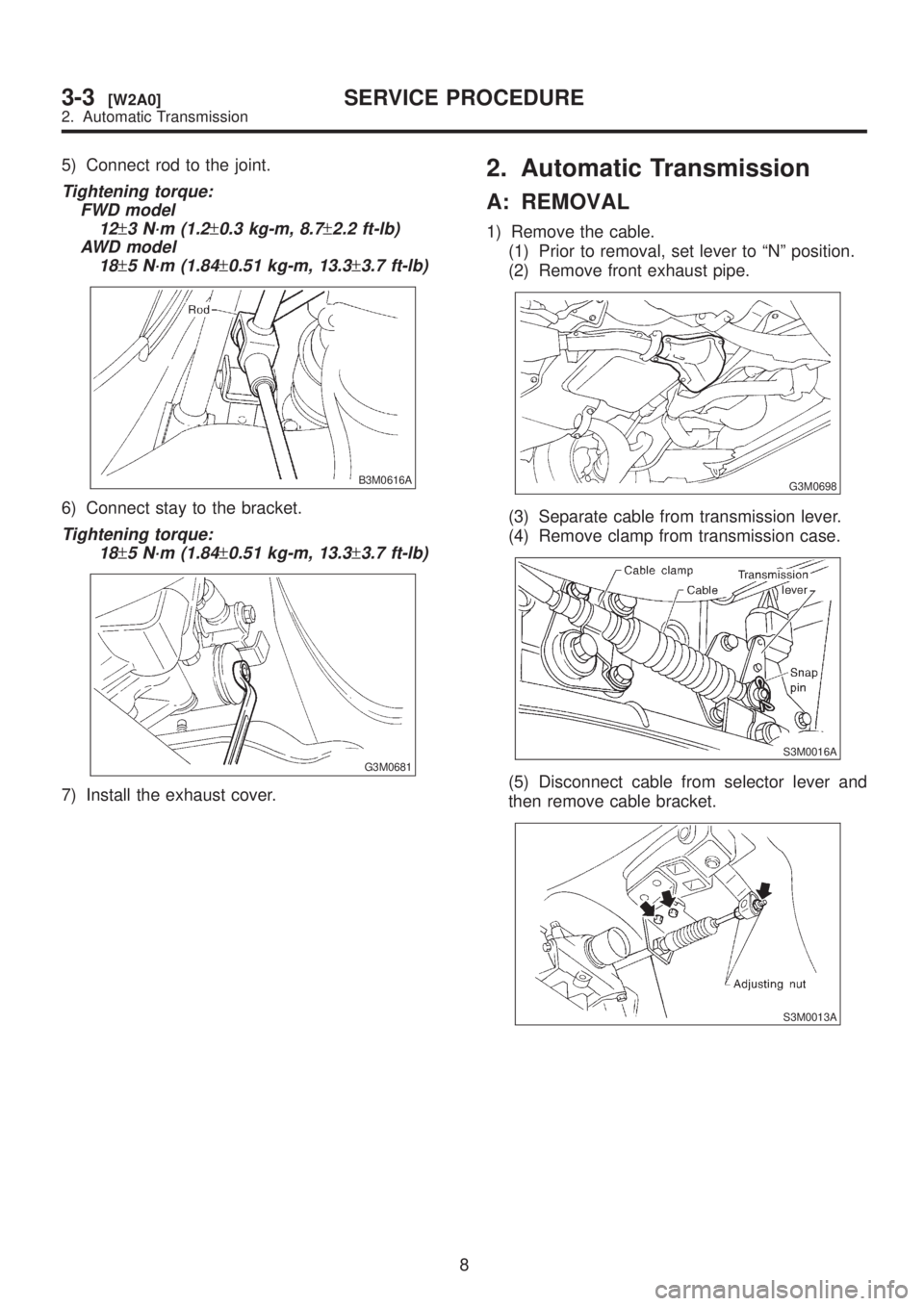

5) Connect rod to the joint.

Tightening torque:

FWD model

12

±3 N´m (1.2±0.3 kg-m, 8.7±2.2 ft-lb)

AWD model

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

B3M0616A

6) Connect stay to the bracket.

Tightening torque:

18

±5 N´m (1.84±0.51 kg-m, 13.3±3.7 ft-lb)

G3M0681

7) Install the exhaust cover.

2. Automatic Transmission

A: REMOVAL

1) Remove the cable.

(1) Prior to removal, set lever to ªNº position.

(2) Remove front exhaust pipe.

G3M0698

(3) Separate cable from transmission lever.

(4) Remove clamp from transmission case.

S3M0016A

(5) Disconnect cable from selector lever and

then remove cable bracket.

S3M0013A

8

3-3[W2A0]SERVICE PROCEDURE

2. Automatic Transmission