boot SUBARU LEGACY 1999 Service Manual PDF

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 919 of 1456

7) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

8) Bleed air from the brake system.

2. REAR BRAKE HOSE

1) Pass brake hose through the hole of bracket,

and lightly tighten flare nut to connect brake pipe.

2) Insert clamp upward to fix brake hose.

3) While holding hexagonal part of brake hose fit-

ting with a wrench, tighten flare nut to the specified

torque.

Tightening torque (Brake pipe flare nut):

15+3/þ2N´m (1.5+0.3/þ0.2kg-m, 10.8+2.2/þ1.4ft-lb)

4) Bleed air from the brake system.

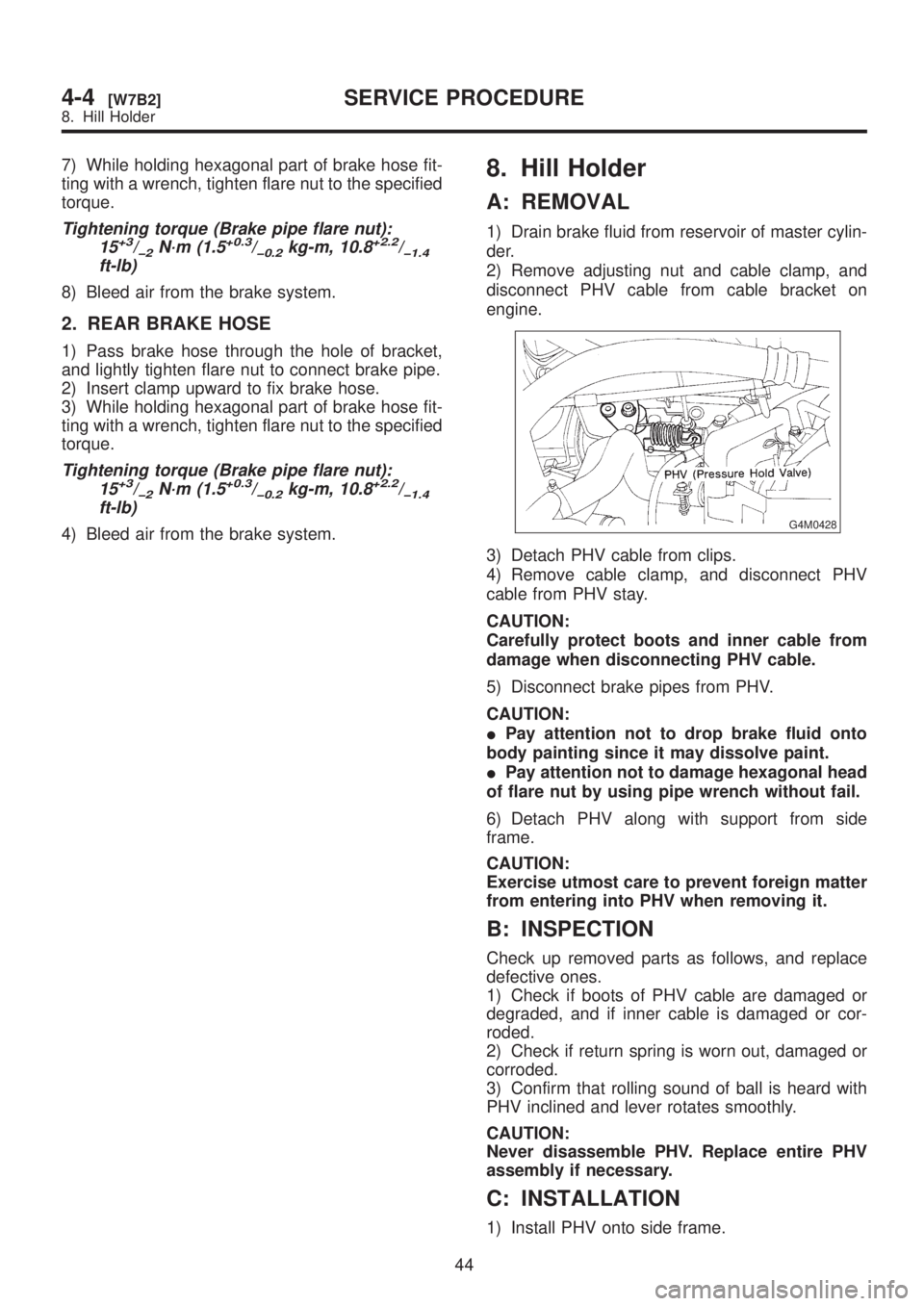

8. Hill Holder

A: REMOVAL

1) Drain brake fluid from reservoir of master cylin-

der.

2) Remove adjusting nut and cable clamp, and

disconnect PHV cable from cable bracket on

engine.

G4M0428

3) Detach PHV cable from clips.

4) Remove cable clamp, and disconnect PHV

cable from PHV stay.

CAUTION:

Carefully protect boots and inner cable from

damage when disconnecting PHV cable.

5) Disconnect brake pipes from PHV.

CAUTION:

IPay attention not to drop brake fluid onto

body painting since it may dissolve paint.

IPay attention not to damage hexagonal head

of flare nut by using pipe wrench without fail.

6) Detach PHV along with support from side

frame.

CAUTION:

Exercise utmost care to prevent foreign matter

from entering into PHV when removing it.

B: INSPECTION

Check up removed parts as follows, and replace

defective ones.

1) Check if boots of PHV cable are damaged or

degraded, and if inner cable is damaged or cor-

roded.

2) Check if return spring is worn out, damaged or

corroded.

3) Confirm that rolling sound of ball is heard with

PHV inclined and lever rotates smoothly.

CAUTION:

Never disassemble PHV. Replace entire PHV

assembly if necessary.

C: INSTALLATION

1) Install PHV onto side frame.

44

4-4[W7B2]SERVICE PROCEDURE

8. Hill Holder

Page 943 of 1456

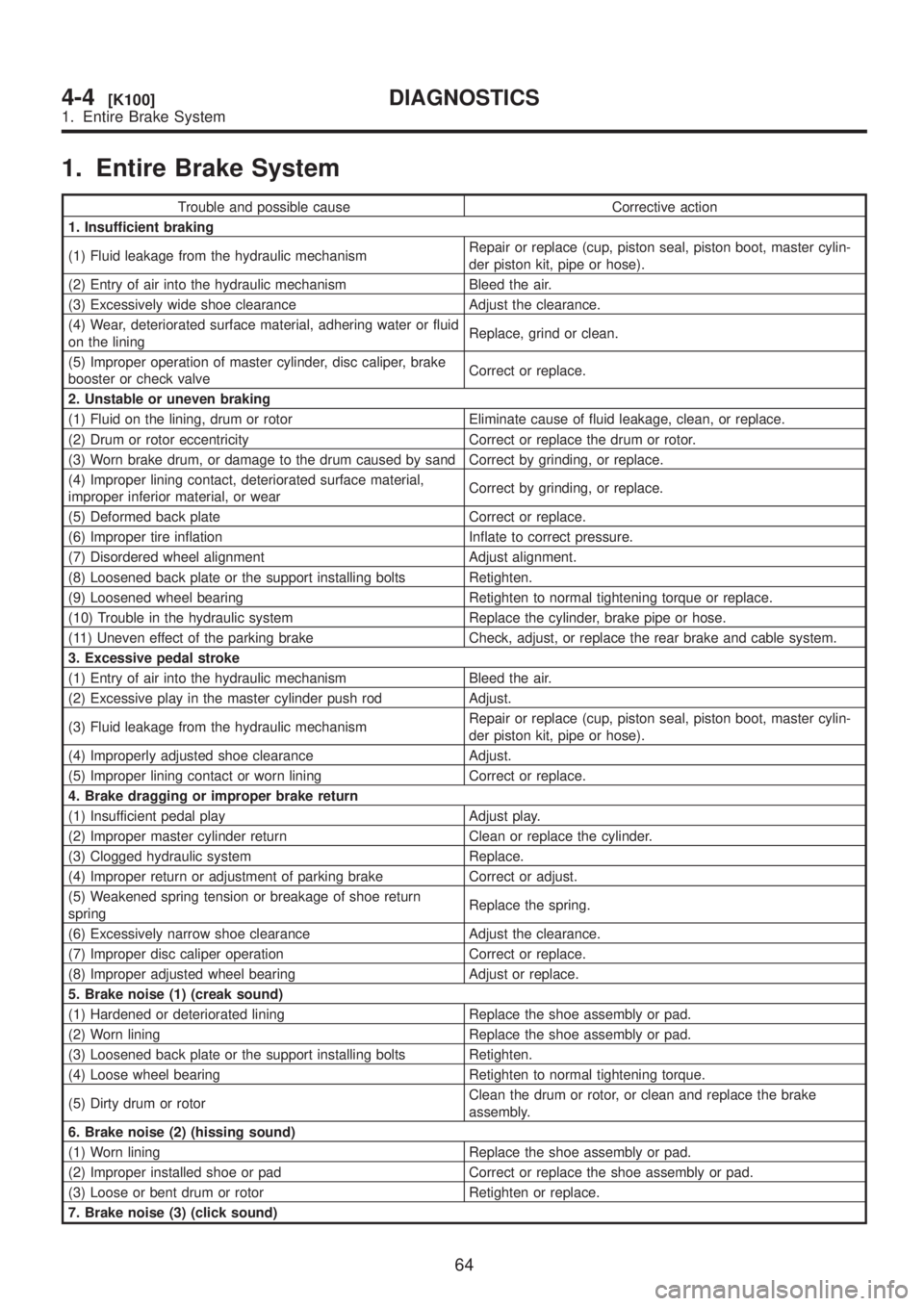

1. Entire Brake System

Trouble and possible cause Corrective action

1. Insufficient braking

(1) Fluid leakage from the hydraulic mechanismRepair or replace (cup, piston seal, piston boot, master cylin-

der piston kit, pipe or hose).

(2) Entry of air into the hydraulic mechanism Bleed the air.

(3) Excessively wide shoe clearance Adjust the clearance.

(4) Wear, deteriorated surface material, adhering water or fluid

on the liningReplace, grind or clean.

(5) Improper operation of master cylinder, disc caliper, brake

booster or check valveCorrect or replace.

2. Unstable or uneven braking

(1) Fluid on the lining, drum or rotor Eliminate cause of fluid leakage, clean, or replace.

(2) Drum or rotor eccentricity Correct or replace the drum or rotor.

(3) Worn brake drum, or damage to the drum caused by sand Correct by grinding, or replace.

(4) Improper lining contact, deteriorated surface material,

improper inferior material, or wearCorrect by grinding, or replace.

(5) Deformed back plate Correct or replace.

(6) Improper tire inflation Inflate to correct pressure.

(7) Disordered wheel alignment Adjust alignment.

(8) Loosened back plate or the support installing bolts Retighten.

(9) Loosened wheel bearing Retighten to normal tightening torque or replace.

(10) Trouble in the hydraulic system Replace the cylinder, brake pipe or hose.

(11) Uneven effect of the parking brake Check, adjust, or replace the rear brake and cable system.

3. Excessive pedal stroke

(1) Entry of air into the hydraulic mechanism Bleed the air.

(2) Excessive play in the master cylinder push rod Adjust.

(3) Fluid leakage from the hydraulic mechanismRepair or replace (cup, piston seal, piston boot, master cylin-

der piston kit, pipe or hose).

(4) Improperly adjusted shoe clearance Adjust.

(5) Improper lining contact or worn lining Correct or replace.

4. Brake dragging or improper brake return

(1) Insufficient pedal play Adjust play.

(2) Improper master cylinder return Clean or replace the cylinder.

(3) Clogged hydraulic system Replace.

(4) Improper return or adjustment of parking brake Correct or adjust.

(5) Weakened spring tension or breakage of shoe return

springReplace the spring.

(6) Excessively narrow shoe clearance Adjust the clearance.

(7) Improper disc caliper operation Correct or replace.

(8) Improper adjusted wheel bearing Adjust or replace.

5. Brake noise (1) (creak sound)

(1) Hardened or deteriorated lining Replace the shoe assembly or pad.

(2) Worn lining Replace the shoe assembly or pad.

(3) Loosened back plate or the support installing bolts Retighten.

(4) Loose wheel bearing Retighten to normal tightening torque.

(5) Dirty drum or rotorClean the drum or rotor, or clean and replace the brake

assembly.

6. Brake noise (2) (hissing sound)

(1) Worn lining Replace the shoe assembly or pad.

(2) Improper installed shoe or pad Correct or replace the shoe assembly or pad.

(3) Loose or bent drum or rotor Retighten or replace.

7. Brake noise (3) (click sound)

64

4-4[K100]DIAGNOSTICS

1. Entire Brake System

Page 955 of 1456

2. ACCELERATOR PEDAL

Lightly move pedal pad in lateral the direction to

ensure pedal deflection is in specified range.

Deflection of accelerator pedal:

Service limit

5.0 mm (0.197 in) or less

CAUTION:

If excessive deflection is noted, replace bush-

ing and clip with new ones.

G4M0333

3. STOP LIGHT SWITCH

If stop light switch does not operate properly (or if

it does not stop at the specified position), replace

with a new one.

Specified position: L

2.8+1.5/0mm (0.110+0.059/0in)

G4M0327

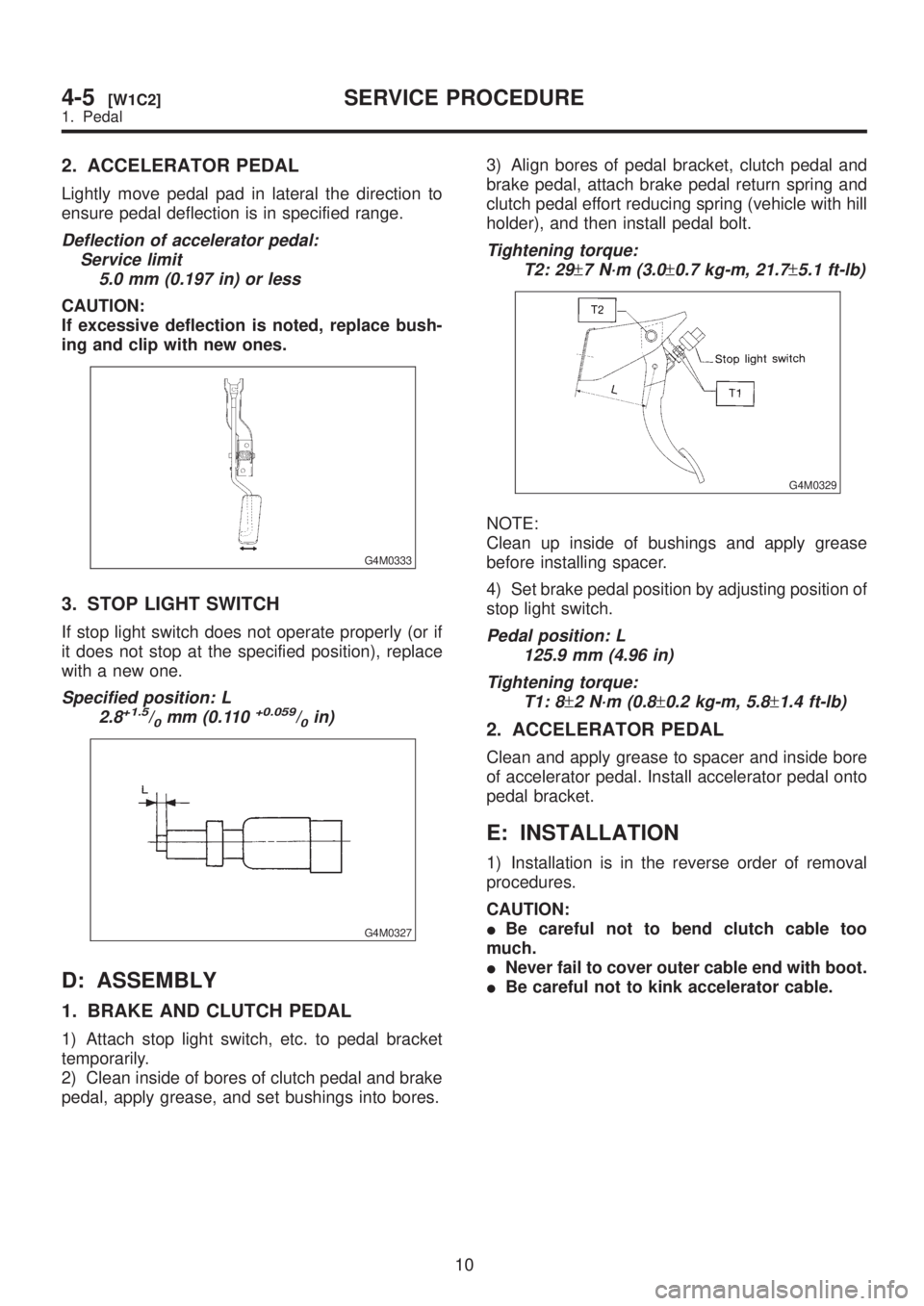

D: ASSEMBLY

1. BRAKE AND CLUTCH PEDAL

1) Attach stop light switch, etc. to pedal bracket

temporarily.

2) Clean inside of bores of clutch pedal and brake

pedal, apply grease, and set bushings into bores.3) Align bores of pedal bracket, clutch pedal and

brake pedal, attach brake pedal return spring and

clutch pedal effort reducing spring (vehicle with hill

holder), and then install pedal bolt.

Tightening torque:

T2: 29

±7 N´m (3.0±0.7 kg-m, 21.7±5.1 ft-lb)

G4M0329

NOTE:

Clean up inside of bushings and apply grease

before installing spacer.

4) Set brake pedal position by adjusting position of

stop light switch.

Pedal position: L

125.9 mm (4.96 in)

Tightening torque:

T1: 8

±2 N´m (0.8±0.2 kg-m, 5.8±1.4 ft-lb)

2. ACCELERATOR PEDAL

Clean and apply grease to spacer and inside bore

of accelerator pedal. Install accelerator pedal onto

pedal bracket.

E: INSTALLATION

1) Installation is in the reverse order of removal

procedures.

CAUTION:

IBe careful not to bend clutch cable too

much.

INever fail to cover outer cable end with boot.

IBe careful not to kink accelerator cable.

10

4-5[W1C2]SERVICE PROCEDURE

1. Pedal

Page 1160 of 1456

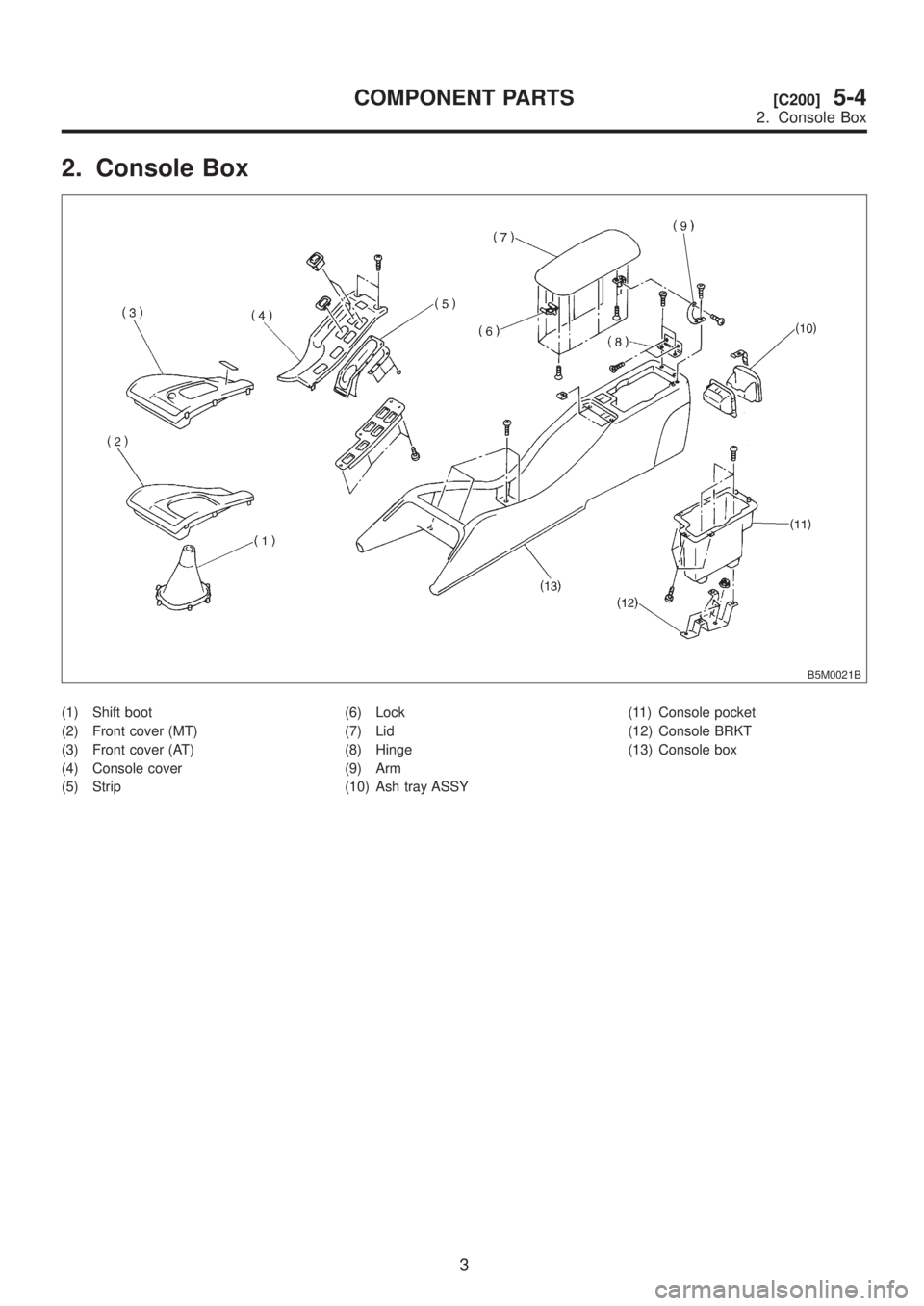

2. Console Box

B5M0021B

(1) Shift boot

(2) Front cover (MT)

(3) Front cover (AT)

(4) Console cover

(5) Strip(6) Lock

(7) Lid

(8) Hinge

(9) Arm

(10) Ash tray ASSY(11) Console pocket

(12) Console BRKT

(13) Console box

3

[C200]5-4COMPONENT PARTS

2. Console Box

Page 1203 of 1456

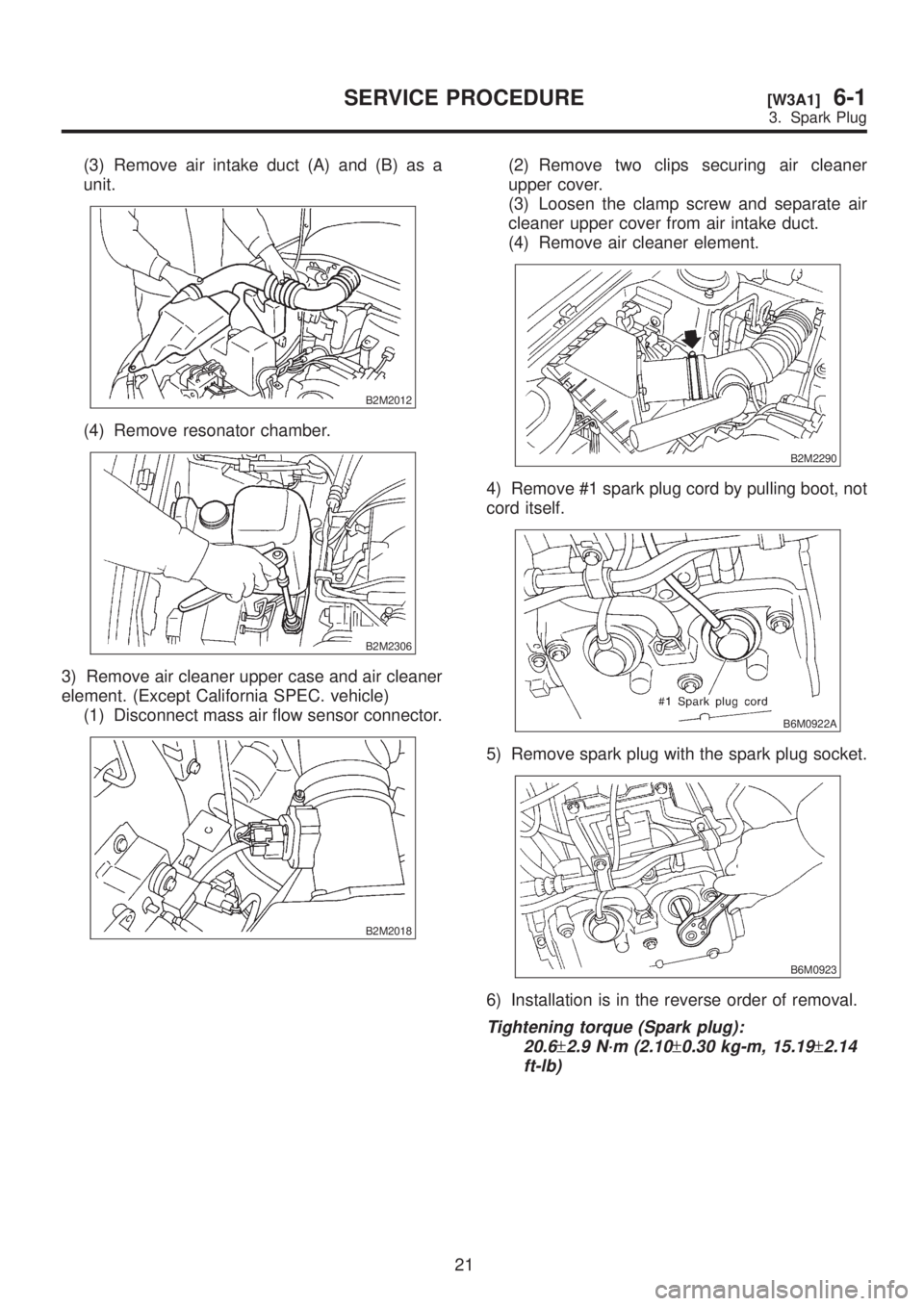

(3) Remove air intake duct (A) and (B) as a

unit.

B2M2012

(4) Remove resonator chamber.

B2M2306

3) Remove air cleaner upper case and air cleaner

element. (Except California SPEC. vehicle)

(1) Disconnect mass air flow sensor connector.

B2M2018

(2) Remove two clips securing air cleaner

upper cover.

(3) Loosen the clamp screw and separate air

cleaner upper cover from air intake duct.

(4) Remove air cleaner element.

B2M2290

4) Remove #1 spark plug cord by pulling boot, not

cord itself.

B6M0922A

5) Remove spark plug with the spark plug socket.

B6M0923

6) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

21

[W3A1]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1204 of 1456

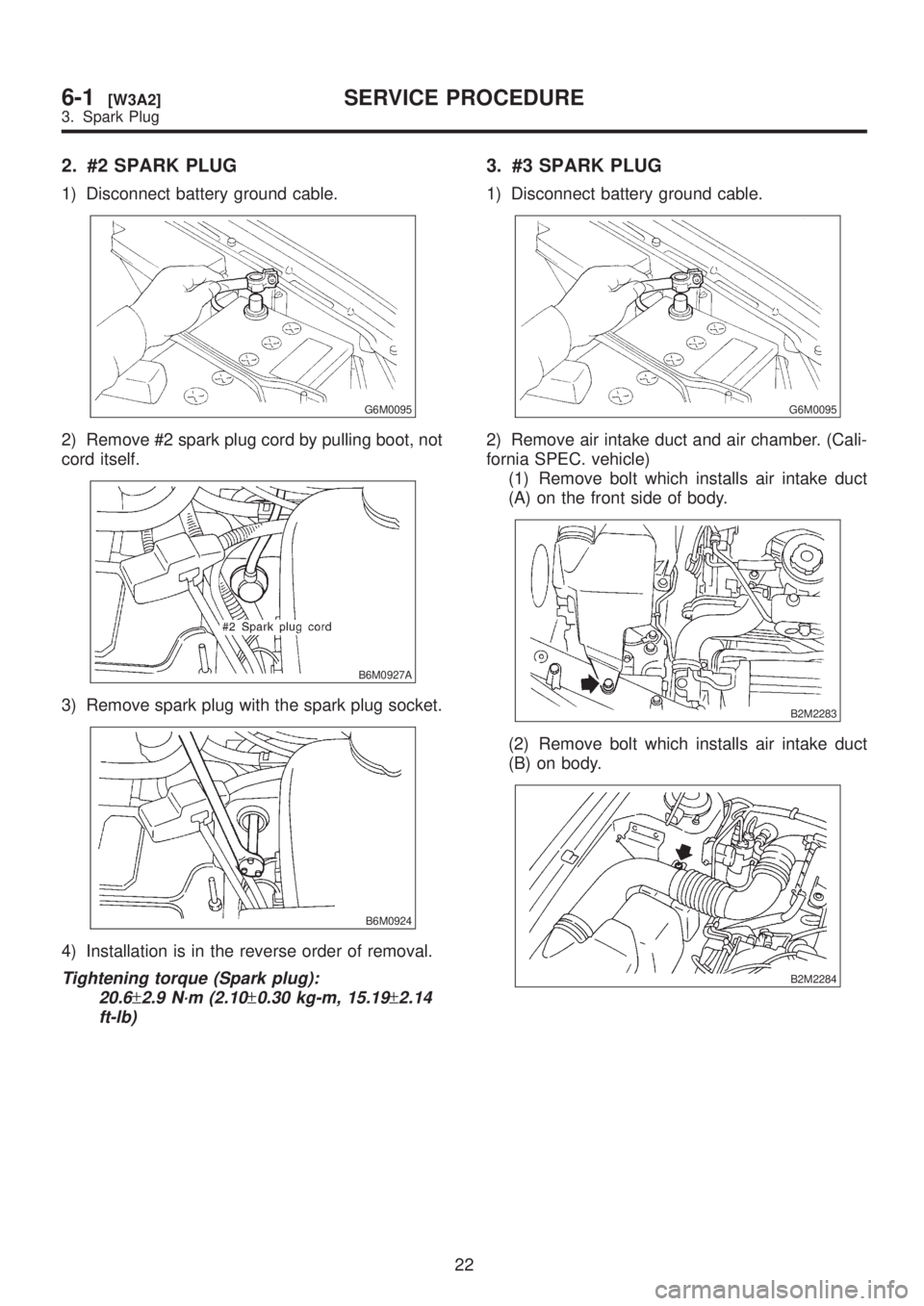

2. #2 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove #2 spark plug cord by pulling boot, not

cord itself.

B6M0927A

3) Remove spark plug with the spark plug socket.

B6M0924

4) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

3. #3 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove air intake duct and air chamber. (Cali-

fornia SPEC. vehicle)

(1) Remove bolt which installs air intake duct

(A) on the front side of body.

B2M2283

(2) Remove bolt which installs air intake duct

(B) on body.

B2M2284

22

6-1[W3A2]SERVICE PROCEDURE

3. Spark Plug

Page 1205 of 1456

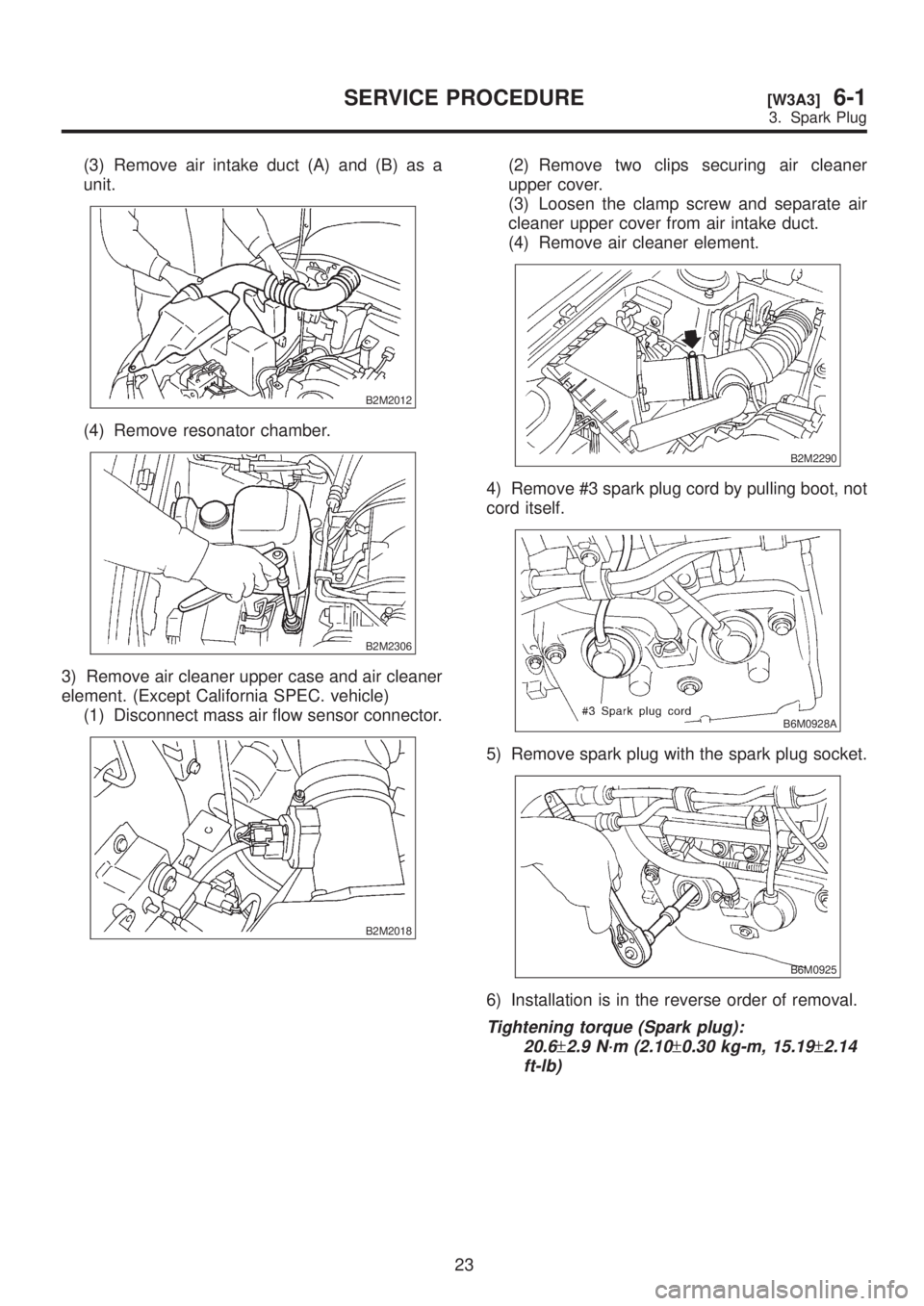

(3) Remove air intake duct (A) and (B) as a

unit.

B2M2012

(4) Remove resonator chamber.

B2M2306

3) Remove air cleaner upper case and air cleaner

element. (Except California SPEC. vehicle)

(1) Disconnect mass air flow sensor connector.

B2M2018

(2) Remove two clips securing air cleaner

upper cover.

(3) Loosen the clamp screw and separate air

cleaner upper cover from air intake duct.

(4) Remove air cleaner element.

B2M2290

4) Remove #3 spark plug cord by pulling boot, not

cord itself.

B6M0928A

5) Remove spark plug with the spark plug socket.

B6M0925

6) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

23

[W3A3]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1206 of 1456

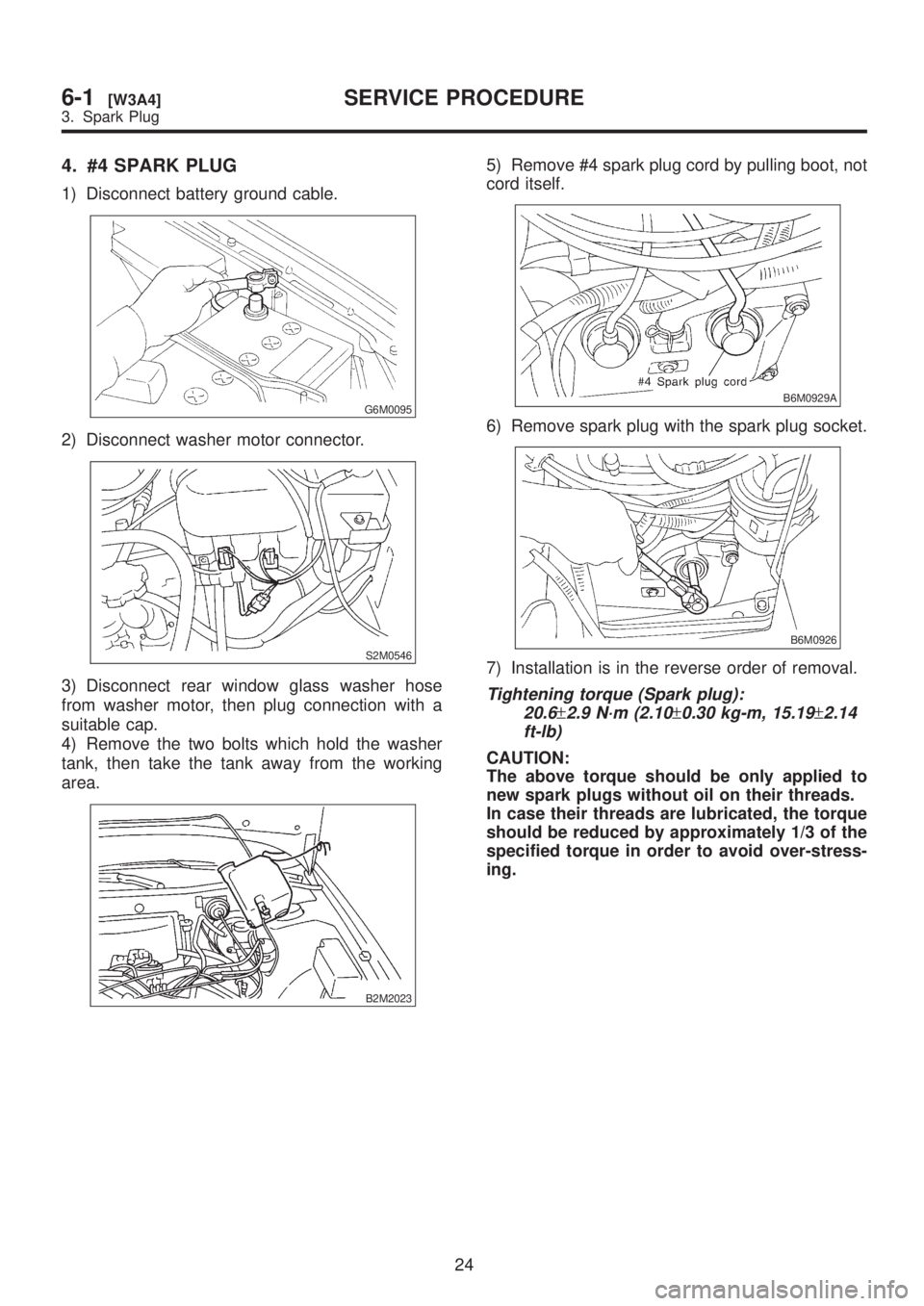

4. #4 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Disconnect washer motor connector.

S2M0546

3) Disconnect rear window glass washer hose

from washer motor, then plug connection with a

suitable cap.

4) Remove the two bolts which hold the washer

tank, then take the tank away from the working

area.

B2M2023

5) Remove #4 spark plug cord by pulling boot, not

cord itself.

B6M0929A

6) Remove spark plug with the spark plug socket.

B6M0926

7) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

CAUTION:

The above torque should be only applied to

new spark plugs without oil on their threads.

In case their threads are lubricated, the torque

should be reduced by approximately 1/3 of the

specified torque in order to avoid over-stress-

ing.

24

6-1[W3A4]SERVICE PROCEDURE

3. Spark Plug

Page 1207 of 1456

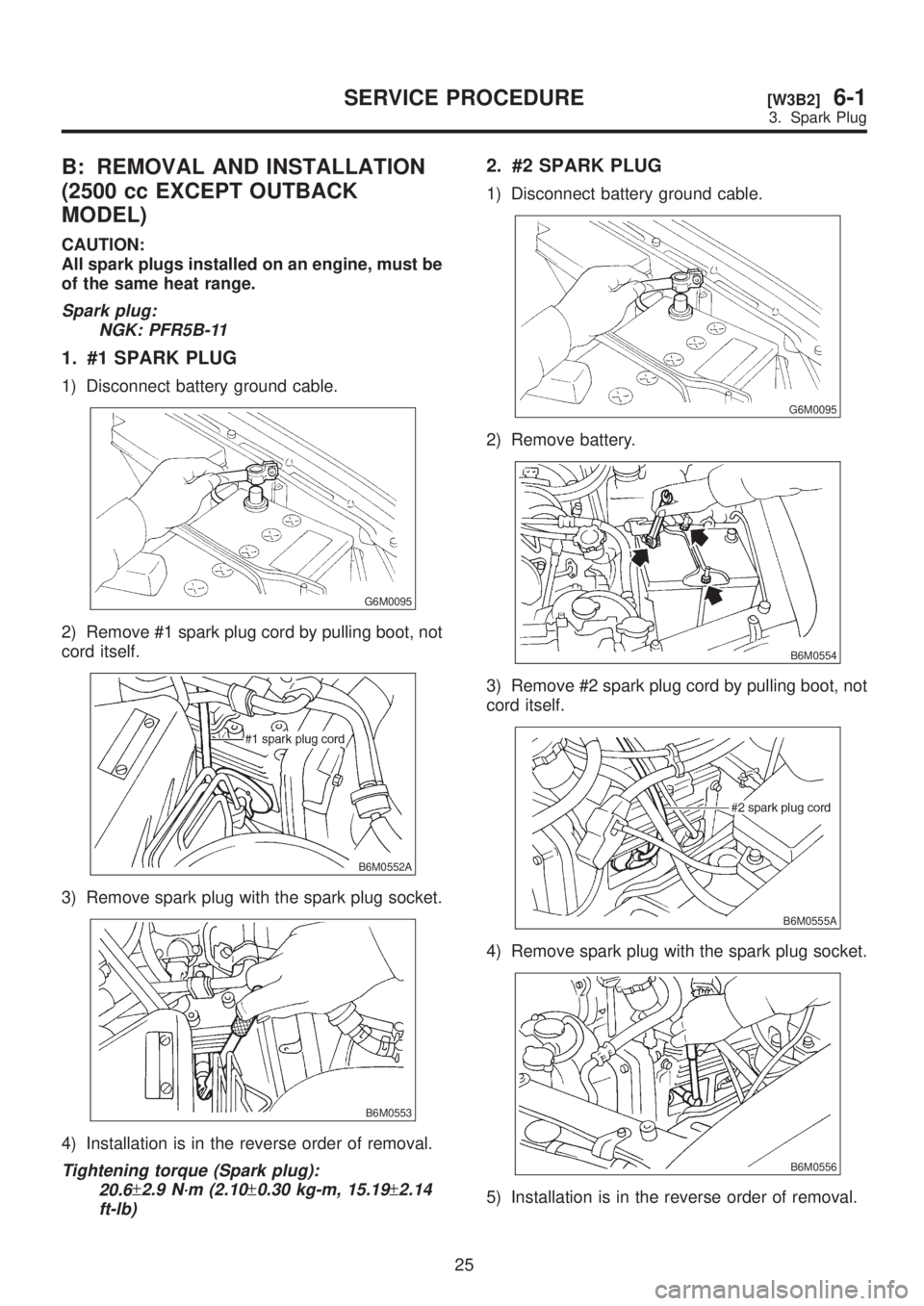

B: REMOVAL AND INSTALLATION

(2500 cc EXCEPT OUTBACK

MODEL)

CAUTION:

All spark plugs installed on an engine, must be

of the same heat range.

Spark plug:

NGK: PFR5B-11

1. #1 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove #1 spark plug cord by pulling boot, not

cord itself.

B6M0552A

3) Remove spark plug with the spark plug socket.

B6M0553

4) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

2. #2 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Remove battery.

B6M0554

3) Remove #2 spark plug cord by pulling boot, not

cord itself.

B6M0555A

4) Remove spark plug with the spark plug socket.

B6M0556

5) Installation is in the reverse order of removal.

25

[W3B2]6-1SERVICE PROCEDURE

3. Spark Plug

Page 1208 of 1456

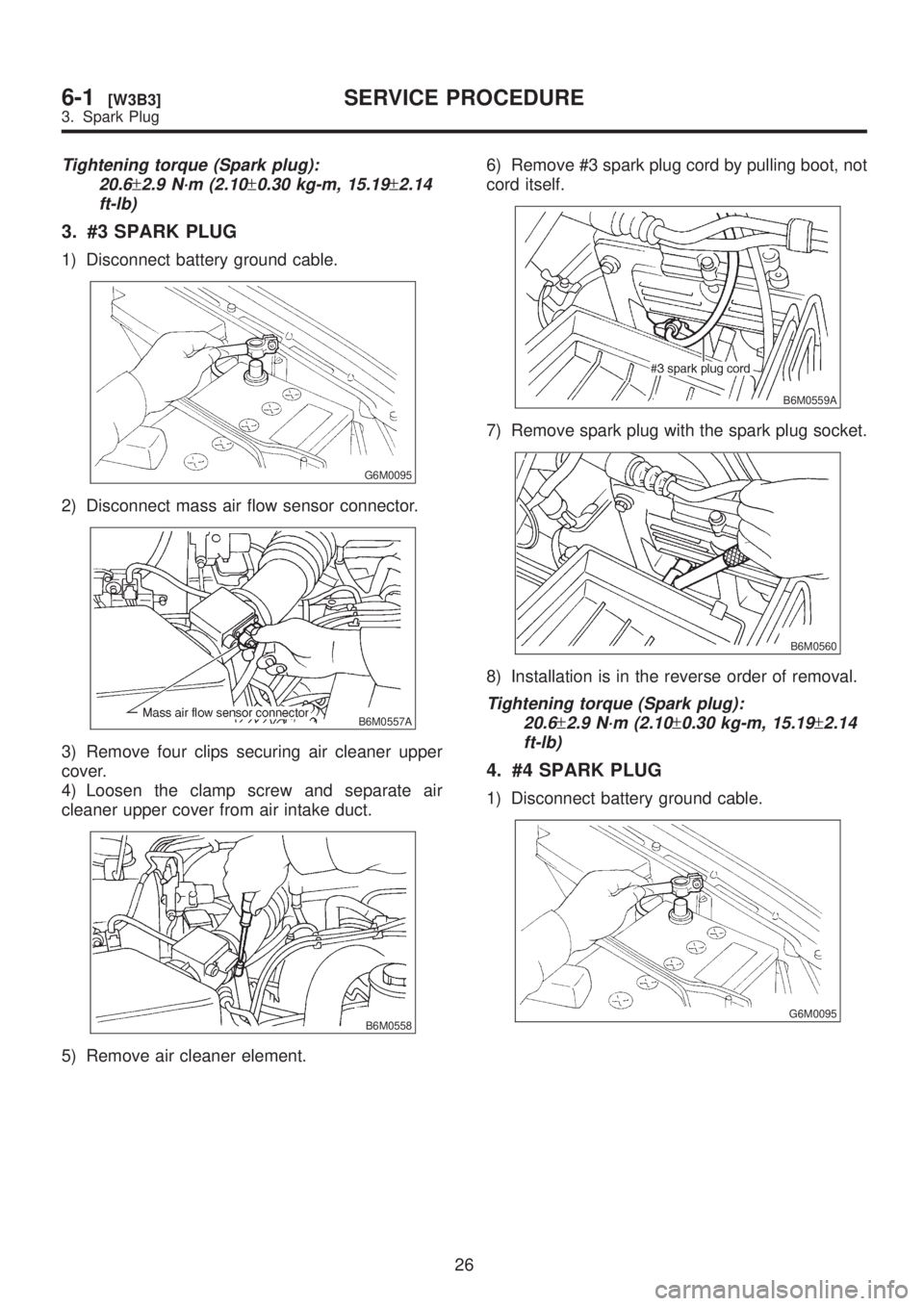

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

3. #3 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

2) Disconnect mass air flow sensor connector.

B6M0557A

3) Remove four clips securing air cleaner upper

cover.

4) Loosen the clamp screw and separate air

cleaner upper cover from air intake duct.

B6M0558

5) Remove air cleaner element.6) Remove #3 spark plug cord by pulling boot, not

cord itself.

B6M0559A

7) Remove spark plug with the spark plug socket.

B6M0560

8) Installation is in the reverse order of removal.

Tightening torque (Spark plug):

20.6

±2.9 N´m (2.10±0.30 kg-m, 15.19±2.14

ft-lb)

4. #4 SPARK PLUG

1) Disconnect battery ground cable.

G6M0095

26

6-1[W3B3]SERVICE PROCEDURE

3. Spark Plug