boot SUBARU LEGACY 1999 Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 825 of 1456

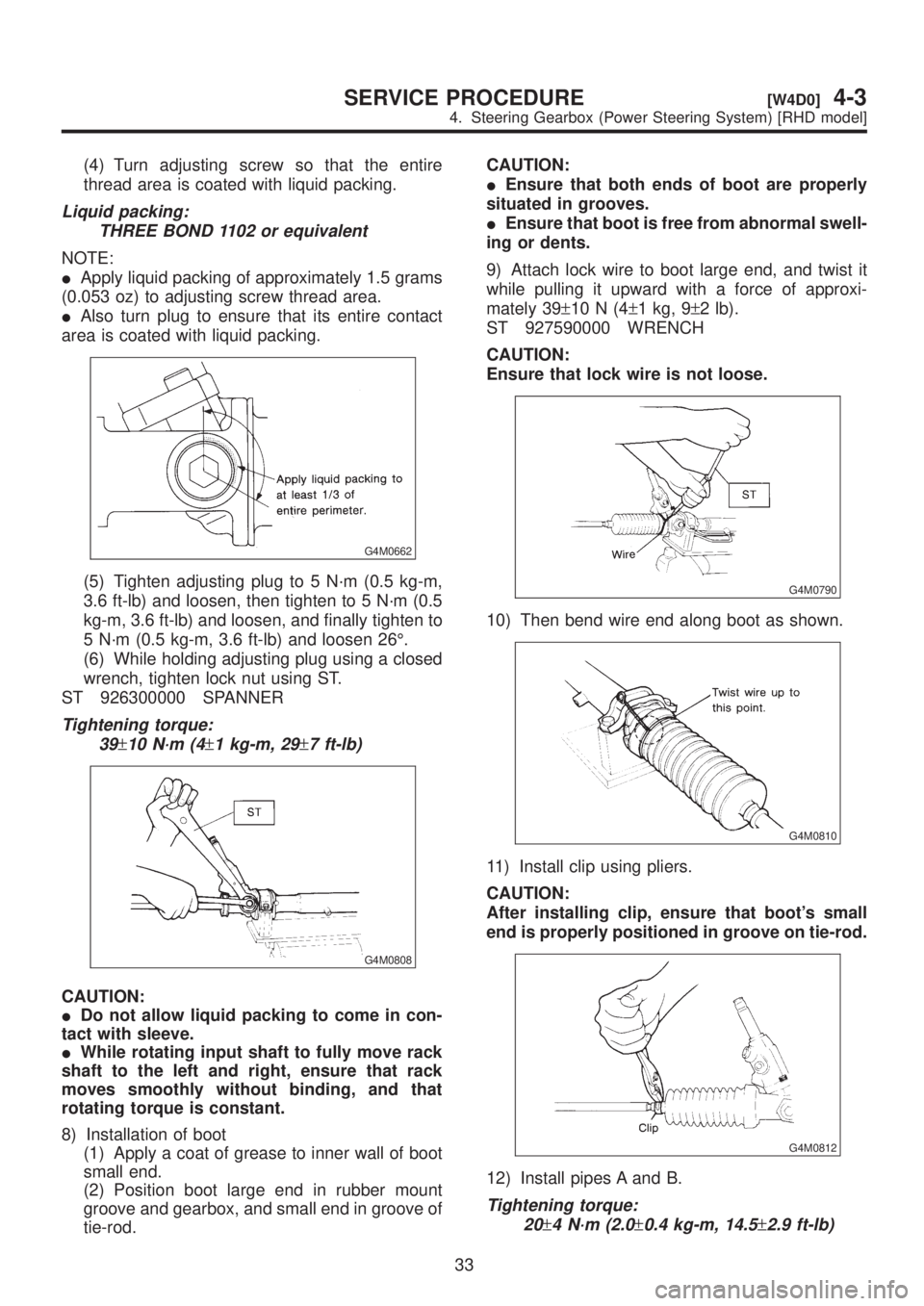

(4) Turn adjusting screw so that the entire

thread area is coated with liquid packing.

Liquid packing:

THREE BOND 1102 or equivalent

NOTE:

IApply liquid packing of approximately 1.5 grams

(0.053 oz) to adjusting screw thread area.

IAlso turn plug to ensure that its entire contact

area is coated with liquid packing.

G4M0662

(5) Tighten adjusting plug to 5 N´m (0.5 kg-m,

3.6 ft-lb) and loosen, then tighten to 5 N´m (0.5

kg-m, 3.6 ft-lb) and loosen, and finally tighten to

5 N´m (0.5 kg-m, 3.6 ft-lb) and loosen 26É.

(6) While holding adjusting plug using a closed

wrench, tighten lock nut using ST.

ST 926300000 SPANNER

Tightening torque:

39

±10 N´m (4±1 kg-m, 29±7 ft-lb)

G4M0808

CAUTION:

IDo not allow liquid packing to come in con-

tact with sleeve.

IWhile rotating input shaft to fully move rack

shaft to the left and right, ensure that rack

moves smoothly without binding, and that

rotating torque is constant.

8) Installation of boot

(1) Apply a coat of grease to inner wall of boot

small end.

(2) Position boot large end in rubber mount

groove and gearbox, and small end in groove of

tie-rod.CAUTION:

IEnsure that both ends of boot are properly

situated in grooves.

IEnsure that boot is free from abnormal swell-

ing or dents.

9) Attach lock wire to boot large end, and twist it

while pulling it upward with a force of approxi-

mately 39±10N(4±1 kg, 9±2 lb).

ST 927590000 WRENCH

CAUTION:

Ensure that lock wire is not loose.

G4M0790

10) Then bend wire end along boot as shown.

G4M0810

11) Install clip using pliers.

CAUTION:

After installing clip, ensure that boot's small

end is properly positioned in groove on tie-rod.

G4M0812

12) Install pipes A and B.

Tightening torque:

20

±4 N´m (2.0±0.4 kg-m, 14.5±2.9 ft-lb)

33

[W4D0]4-3SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 826 of 1456

E: INSTALLATION

Installation is in the reverse order of removal.

Do the following:

CAUTION:

When adjusting toe-in, hold boot as shown to

prevent it from being rotated or twisted. If

twisted, straighten it.

G4M0132

F: ADJUSTMENT

1) Adjust front toe.

Standard of front toe:

IN 3 Ð OUT 3 mm (IN 0.12 Ð OUT 0.12

in)

G4M0133

2) Adjust steering angle of wheels.

Standard of steering angle:

Inner wheel 37.6É

±1.5É

Outer wheel 32.6É

±1.5É

3) If steering wheel spokes are not horizontal

when wheels are set in the straight ahead position,

and error is more than 5É on the periphery of steer-

ing wheel, correctly re-install the steering wheel.

B4M0133A

4) If steering wheel spokes are not horizontal with

vehicle set in the straight ahead position after this

adjustment, correct it by turning the right and left

tie-rods in the same direction by the same amount.

G4M0135

34

4-3[W4E0]SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 827 of 1456

![SUBARU LEGACY 1999 Service Service Manual 5. Control Valve (Power Steering Gearbox) [LHD model]

A: CHECKING OIL LEAKING POINTS

B4M1132A

(1) Power cylinder

(2) Cylinder

(3) Rack piston

(4) Rack axle

(5) Input shaft(6) Torsion bar

(7) Valve hou SUBARU LEGACY 1999 Service Service Manual 5. Control Valve (Power Steering Gearbox) [LHD model]

A: CHECKING OIL LEAKING POINTS

B4M1132A

(1) Power cylinder

(2) Cylinder

(3) Rack piston

(4) Rack axle

(5) Input shaft(6) Torsion bar

(7) Valve hou](/img/17/57435/w960_57435-826.png)

5. Control Valve (Power Steering Gearbox) [LHD model]

A: CHECKING OIL LEAKING POINTS

B4M1132A

(1) Power cylinder

(2) Cylinder

(3) Rack piston

(4) Rack axle

(5) Input shaft(6) Torsion bar

(7) Valve housing

(8) Valve body

(9) Control valve

(10) Pipe B(11) Pipe A

(12) Pinion

(13) Pinion axle

1. OIL LEAKING POINTS

1) If leak point is other than a, b, c, or d, perform

check step 5) in ªOIL LEAK CHECK PROCEDURE

AND REPLACEMENT PARTSº before dismounting

gearbox from vehicle.

gearbox is dismounted without confirming where

the leak is, it must be mounted again to locate the

leak point.

2) Even if the location of the leak can be easily

found by observing the leaking condition, it is nec-

essary to thoroughly remove the oil from the sus-

pected portion and turn the steering wheel from

lock to lock about 30 to 40 times with engine

running, then make comparison of the suspected

portion between immediately after and several

hours after this operation.

3) Before starting oil leak repair work, be sure to

clean the gearbox, hoses, pipes, and surrounding

parts. After completing repair work, clean these

areas again.

2. OIL LEAK CHECK PROCEDURE AND

REPLACEMENT PARTS

NOTE:

Parts requiring replacement are described in the

smallest unit of spare parts including damaged

parts and spare parts damaged. In actual disas-sembly work, accidental damage as well as inevi-

table damage to some related parts must be taken

into account, and spare parts for them must also

be prepared. However, it is essential to pinpoint the

cause of trouble, and limit the number of replace-

ment parts as much as possible.

1) Leakage from ªaº

The oil seal is damaged. Replace valve assembly

with a new one.

2) Leakage from ªbº

The torsion bar O-ring is damaged. Replace valve

assembly with a new one.

3) Leakage from ªcº

The oil seal is damaged. Replace valve assembly

with a new one.

4) Leakage from ªdº

The pipe is damaged. Replace the faulty pipe or

O-ring.

5) If leak is other than a, b, c, or d, and if oil is

leaking from the gearbox, move the right and left

boots toward tie-rod end side, respectively, with the

gearbox mounted to the vehicle, and remove oil

from the surrounding portions. Then, turn the steer-

ing wheel from lock to lock 30 to 40 times with the

engine running, then make comparison of the

leaked portion immediately after and several hours

after this operation.

35

[W5A2]4-3SERVICE PROCEDURE

5. Control Valve (Power Steering Gearbox) [LHD model]

Page 835 of 1456

boots toward tie-rod end side, respectively, with the

gearbox mounted to the vehicle, and remove oil

from the surrounding portions. Then, turn the steer-

ing wheel from lock to lock 30 to 40 times with the

engine running, then make comparison of the

leaked portion immediately after and several hours

after this operation.

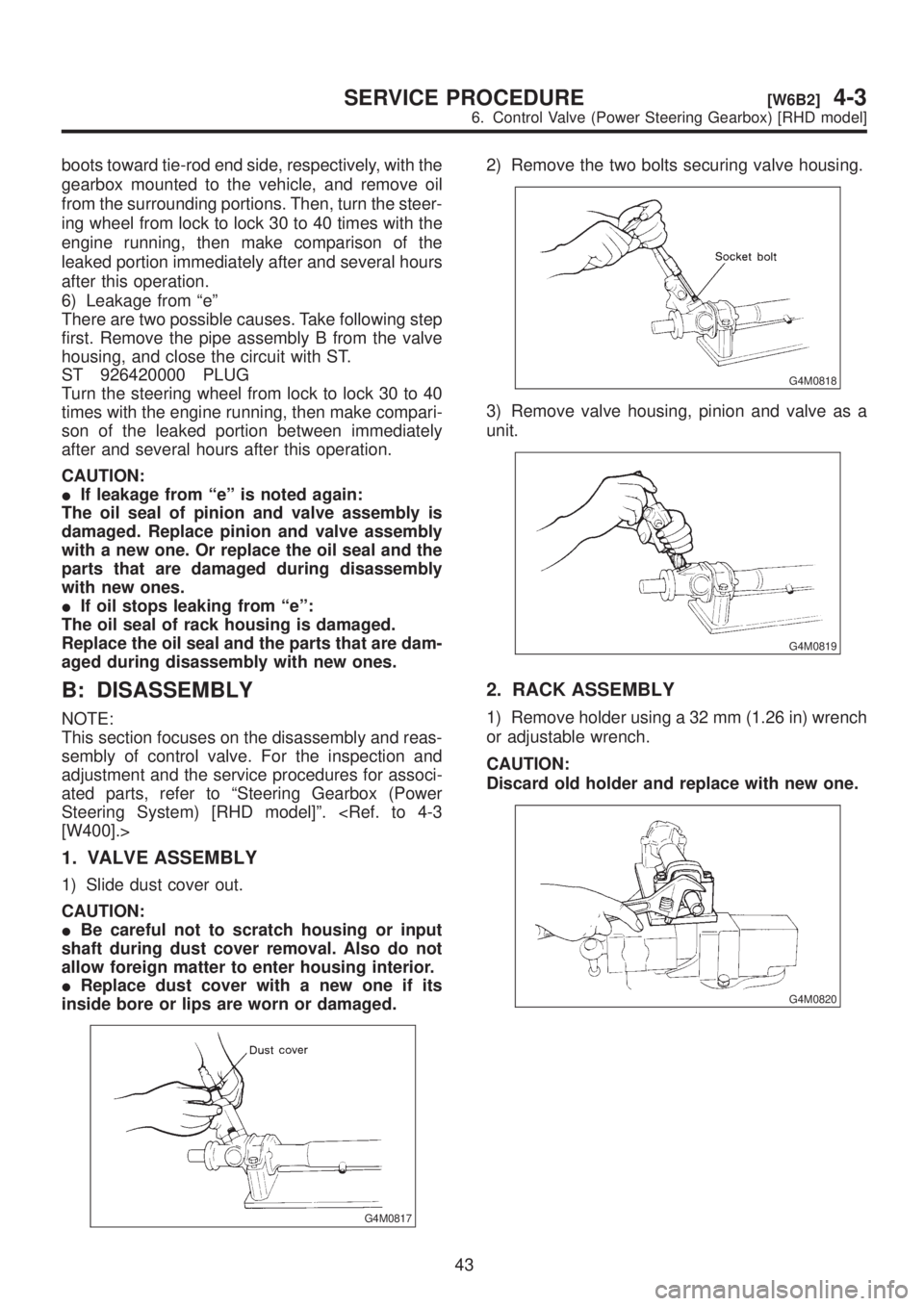

6) Leakage from ªeº

There are two possible causes. Take following step

first. Remove the pipe assembly B from the valve

housing, and close the circuit with ST.

ST 926420000 PLUG

Turn the steering wheel from lock to lock 30 to 40

times with the engine running, then make compari-

son of the leaked portion between immediately

after and several hours after this operation.

CAUTION:

IIf leakage from ªeº is noted again:

The oil seal of pinion and valve assembly is

damaged. Replace pinion and valve assembly

with a new one. Or replace the oil seal and the

parts that are damaged during disassembly

with new ones.

IIf oil stops leaking from ªeº:

The oil seal of rack housing is damaged.

Replace the oil seal and the parts that are dam-

aged during disassembly with new ones.

B: DISASSEMBLY

NOTE:

This section focuses on the disassembly and reas-

sembly of control valve. For the inspection and

adjustment and the service procedures for associ-

ated parts, refer to ªSteering Gearbox (Power

Steering System) [RHD model]º.

1. VALVE ASSEMBLY

1) Slide dust cover out.

CAUTION:

IBe careful not to scratch housing or input

shaft during dust cover removal. Also do not

allow foreign matter to enter housing interior.

IReplace dust cover with a new one if its

inside bore or lips are worn or damaged.

G4M0817

2) Remove the two bolts securing valve housing.

G4M0818

3) Remove valve housing, pinion and valve as a

unit.

G4M0819

2. RACK ASSEMBLY

1) Remove holder using a 32 mm (1.26 in) wrench

or adjustable wrench.

CAUTION:

Discard old holder and replace with new one.

G4M0820

43

[W6B2]4-3SERVICE PROCEDURE

6. Control Valve (Power Steering Gearbox) [RHD model]

Page 877 of 1456

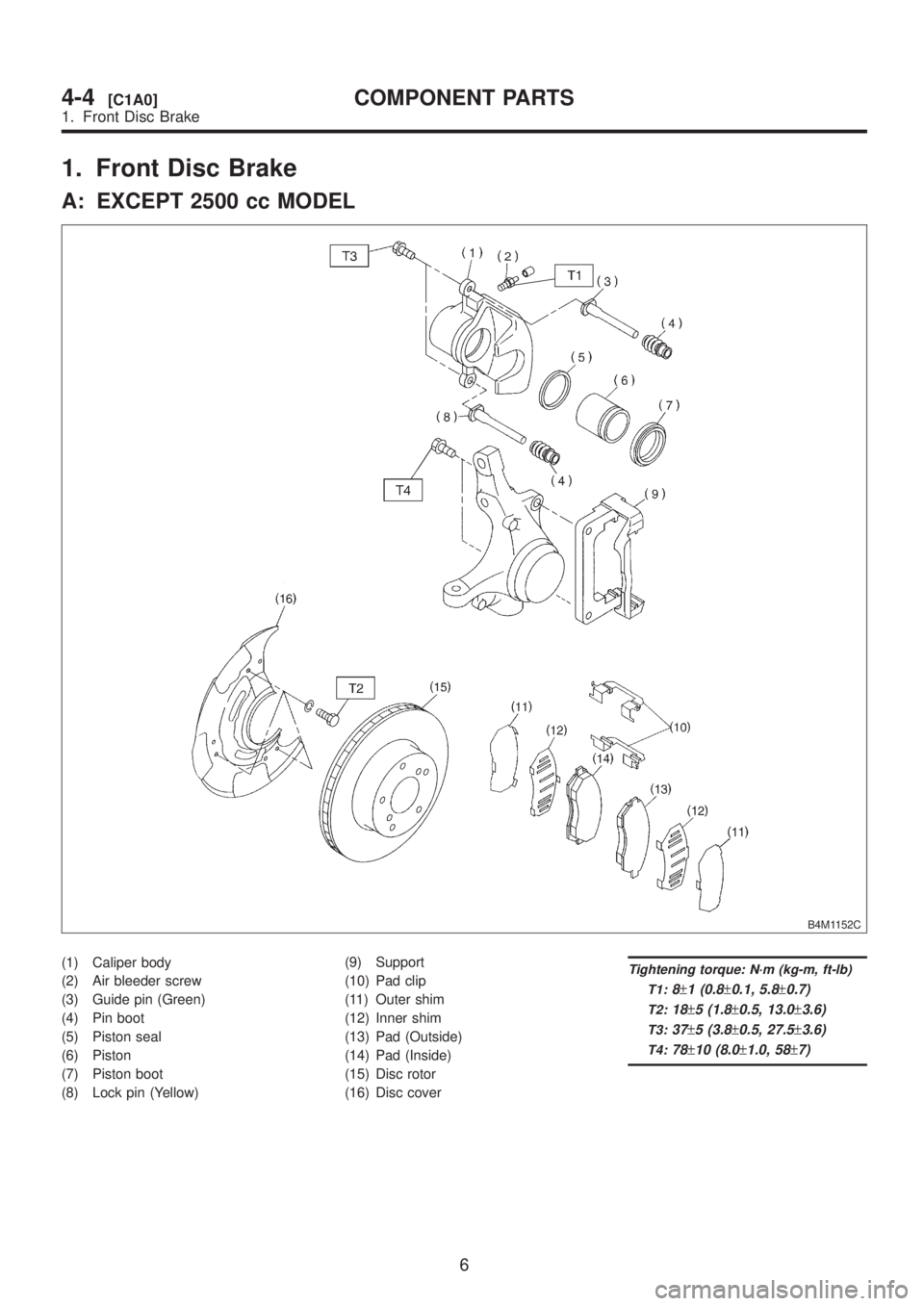

1. Front Disc Brake

A: EXCEPT 2500 cc MODEL

B4M1152C

(1) Caliper body

(2) Air bleeder screw

(3) Guide pin (Green)

(4) Pin boot

(5) Piston seal

(6) Piston

(7) Piston boot

(8) Lock pin (Yellow)(9) Support

(10) Pad clip

(11) Outer shim

(12) Inner shim

(13) Pad (Outside)

(14) Pad (Inside)

(15) Disc rotor

(16) Disc coverTightening torque: N´m (kg-m, ft-lb)

T1:

8±1 (0.8±0.1, 5.8±0.7)

T2:18±5 (1.8±0.5, 13.0±3.6)

T3:37±5 (3.8±0.5, 27.5±3.6)

T4:78±10 (8.0±1.0, 58±7)

6

4-4[C1A0]COMPONENT PARTS

1. Front Disc Brake

Page 878 of 1456

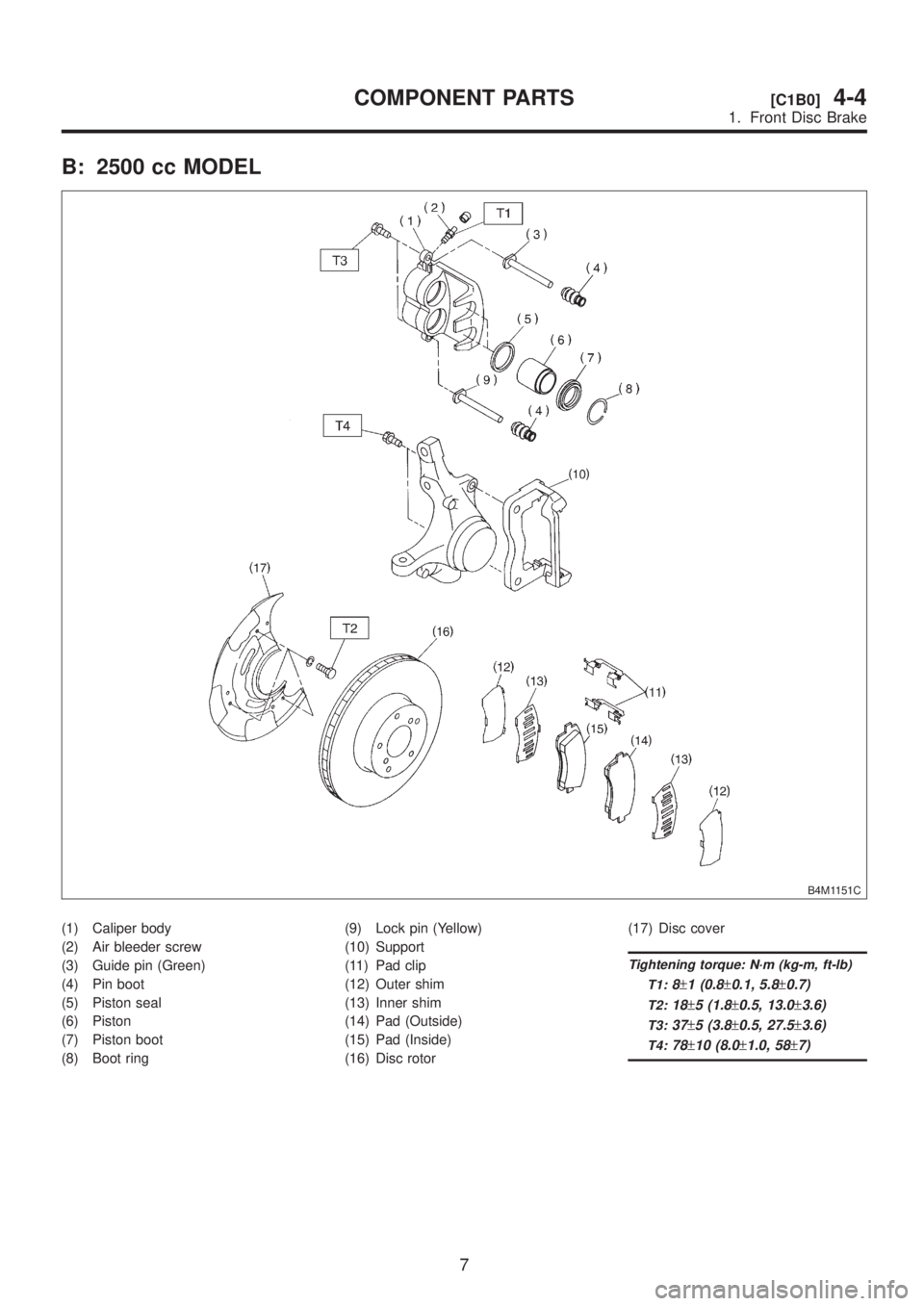

B: 2500 cc MODEL

B4M1151C

(1) Caliper body

(2) Air bleeder screw

(3) Guide pin (Green)

(4) Pin boot

(5) Piston seal

(6) Piston

(7) Piston boot

(8) Boot ring(9) Lock pin (Yellow)

(10) Support

(11) Pad clip

(12) Outer shim

(13) Inner shim

(14) Pad (Outside)

(15) Pad (Inside)

(16) Disc rotor(17) Disc cover

Tightening torque: N´m (kg-m, ft-lb)

T1:

8±1 (0.8±0.1, 5.8±0.7)

T2:18±5 (1.8±0.5, 13.0±3.6)

T3:37±5 (3.8±0.5, 27.5±3.6)

T4:78±10 (8.0±1.0, 58±7)

7

[C1B0]4-4COMPONENT PARTS

1. Front Disc Brake

Page 879 of 1456

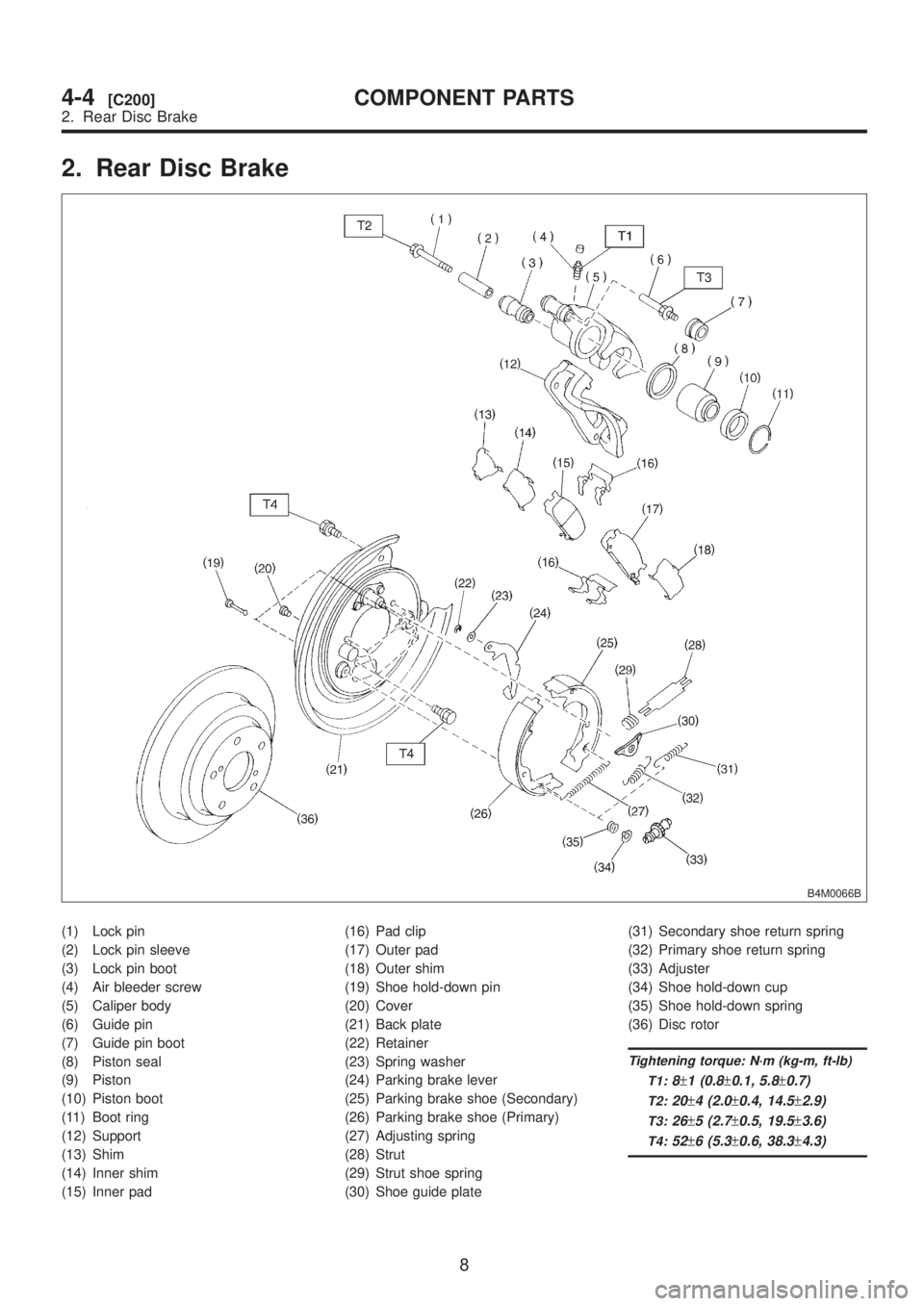

2. Rear Disc Brake

B4M0066B

(1) Lock pin

(2) Lock pin sleeve

(3) Lock pin boot

(4) Air bleeder screw

(5) Caliper body

(6) Guide pin

(7) Guide pin boot

(8) Piston seal

(9) Piston

(10) Piston boot

(11) Boot ring

(12) Support

(13) Shim

(14) Inner shim

(15) Inner pad(16) Pad clip

(17) Outer pad

(18) Outer shim

(19) Shoe hold-down pin

(20) Cover

(21) Back plate

(22) Retainer

(23) Spring washer

(24) Parking brake lever

(25) Parking brake shoe (Secondary)

(26) Parking brake shoe (Primary)

(27) Adjusting spring

(28) Strut

(29) Strut shoe spring

(30) Shoe guide plate(31) Secondary shoe return spring

(32) Primary shoe return spring

(33) Adjuster

(34) Shoe hold-down cup

(35) Shoe hold-down spring

(36) Disc rotor

Tightening torque: N´m (kg-m, ft-lb)

T1:

8±1 (0.8±0.1, 5.8±0.7)

T2:20±4 (2.0±0.4, 14.5±2.9)

T3:26±5 (2.7±0.5, 19.5±3.6)

T4:52±6 (5.3±0.6, 38.3±4.3)

8

4-4[C200]COMPONENT PARTS

2. Rear Disc Brake

Page 880 of 1456

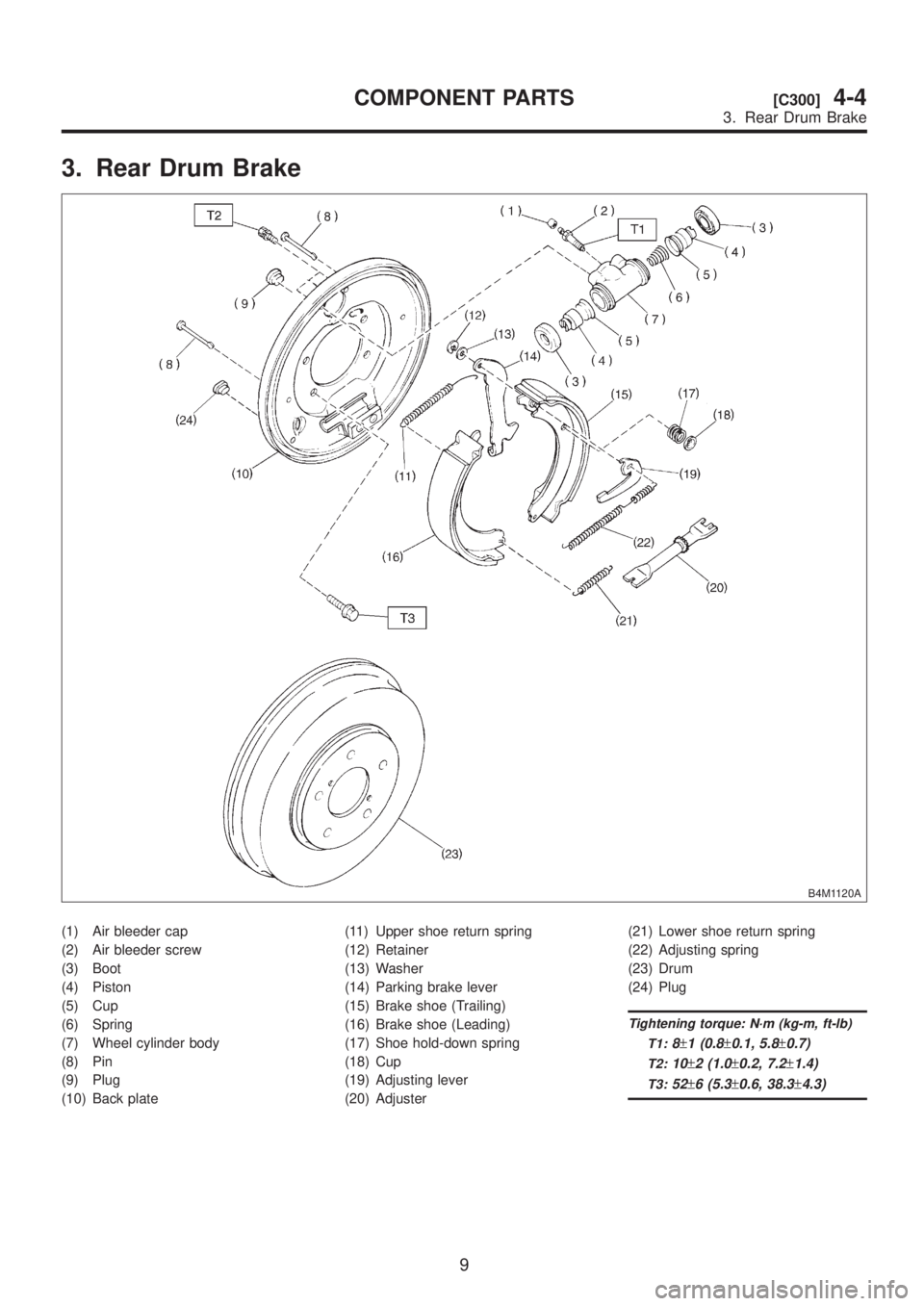

3. Rear Drum Brake

B4M1120A

(1) Air bleeder cap

(2) Air bleeder screw

(3) Boot

(4) Piston

(5) Cup

(6) Spring

(7) Wheel cylinder body

(8) Pin

(9) Plug

(10) Back plate(11) Upper shoe return spring

(12) Retainer

(13) Washer

(14) Parking brake lever

(15) Brake shoe (Trailing)

(16) Brake shoe (Leading)

(17) Shoe hold-down spring

(18) Cup

(19) Adjusting lever

(20) Adjuster(21) Lower shoe return spring

(22) Adjusting spring

(23) Drum

(24) Plug

Tightening torque: N´m (kg-m, ft-lb)

T1:

8±1 (0.8±0.1, 5.8±0.7)

T2:10±2 (1.0±0.2, 7.2±1.4)

T3:52±6 (5.3±0.6, 38.3±4.3)

9

[C300]4-4COMPONENT PARTS

3. Rear Drum Brake

Page 891 of 1456

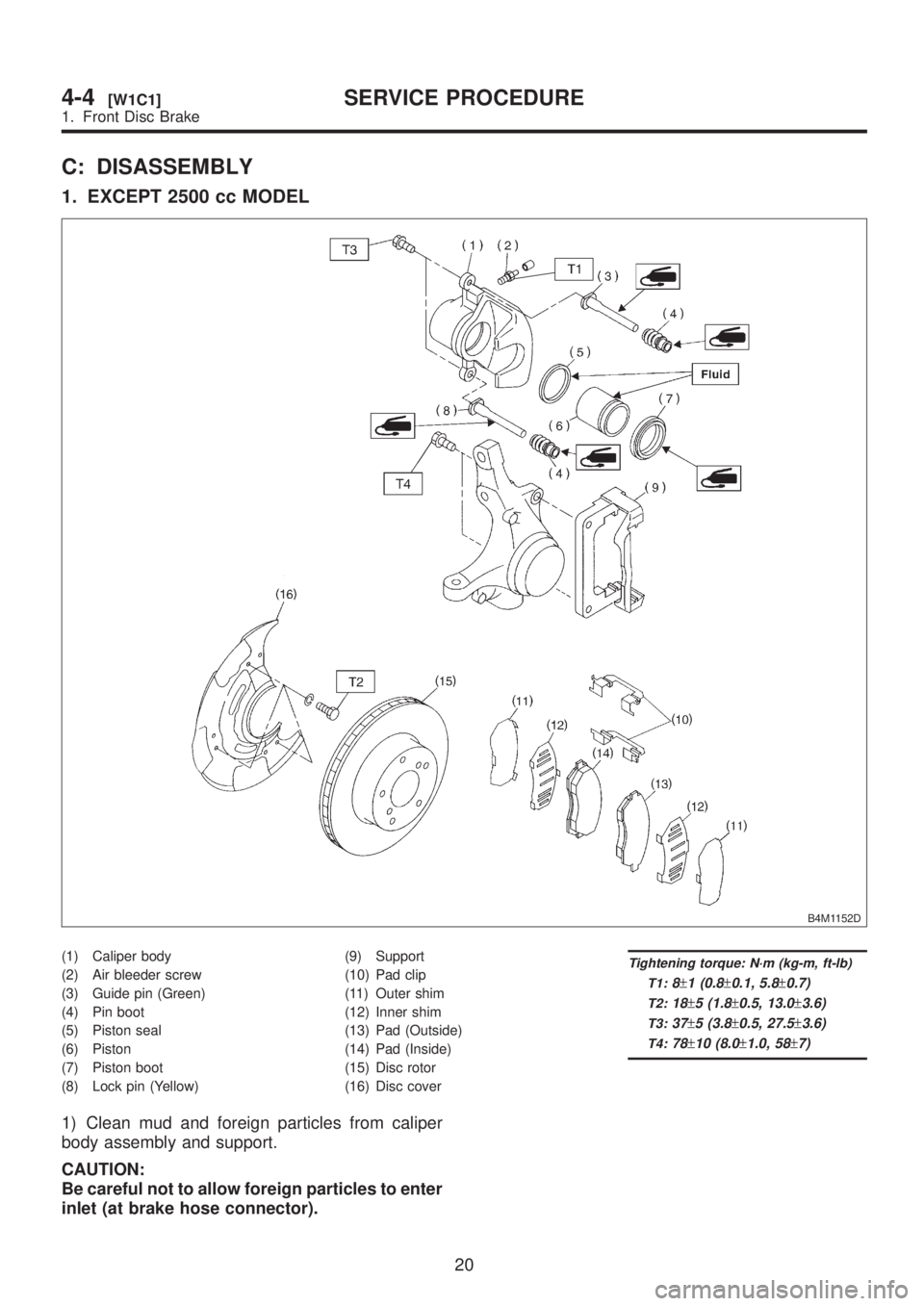

C: DISASSEMBLY

1. EXCEPT 2500 cc MODEL

B4M1152D

(1) Caliper body

(2) Air bleeder screw

(3) Guide pin (Green)

(4) Pin boot

(5) Piston seal

(6) Piston

(7) Piston boot

(8) Lock pin (Yellow)(9) Support

(10) Pad clip

(11) Outer shim

(12) Inner shim

(13) Pad (Outside)

(14) Pad (Inside)

(15) Disc rotor

(16) Disc coverTightening torque: N´m (kg-m, ft-lb)

T1:

8±1 (0.8±0.1, 5.8±0.7)

T2:18±5 (1.8±0.5, 13.0±3.6)

T3:37±5 (3.8±0.5, 27.5±3.6)

T4:78±10 (8.0±1.0, 58±7)

1) Clean mud and foreign particles from caliper

body assembly and support.

CAUTION:

Be careful not to allow foreign particles to enter

inlet (at brake hose connector).

20

4-4[W1C1]SERVICE PROCEDURE

1. Front Disc Brake

Page 892 of 1456

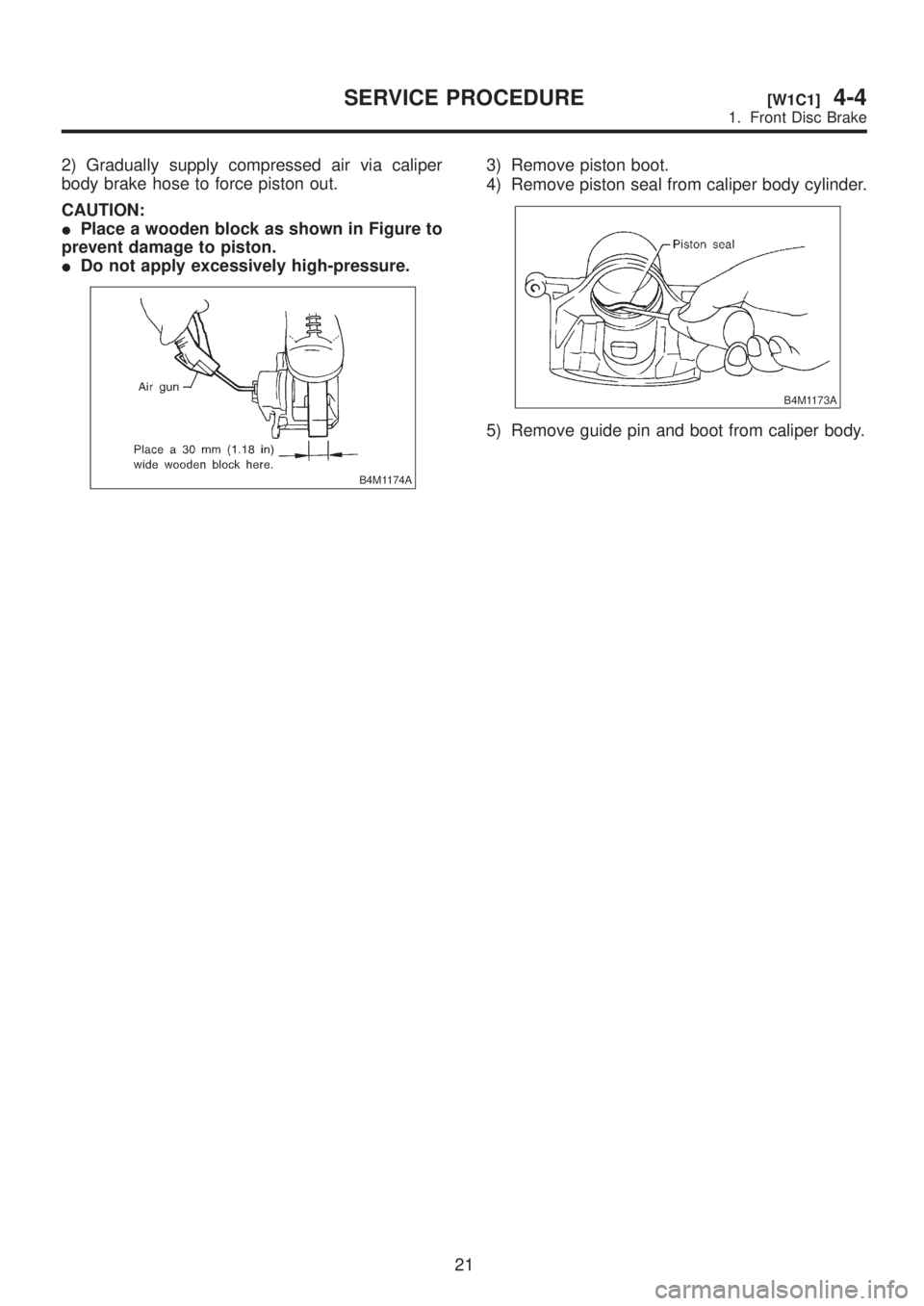

2) Gradually supply compressed air via caliper

body brake hose to force piston out.

CAUTION:

IPlace a wooden block as shown in Figure to

prevent damage to piston.

IDo not apply excessively high-pressure.

B4M1174A

3) Remove piston boot.

4) Remove piston seal from caliper body cylinder.

B4M1173A

5) Remove guide pin and boot from caliper body.

21

[W1C1]4-4SERVICE PROCEDURE

1. Front Disc Brake