boot SUBARU LEGACY 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 775 of 1456

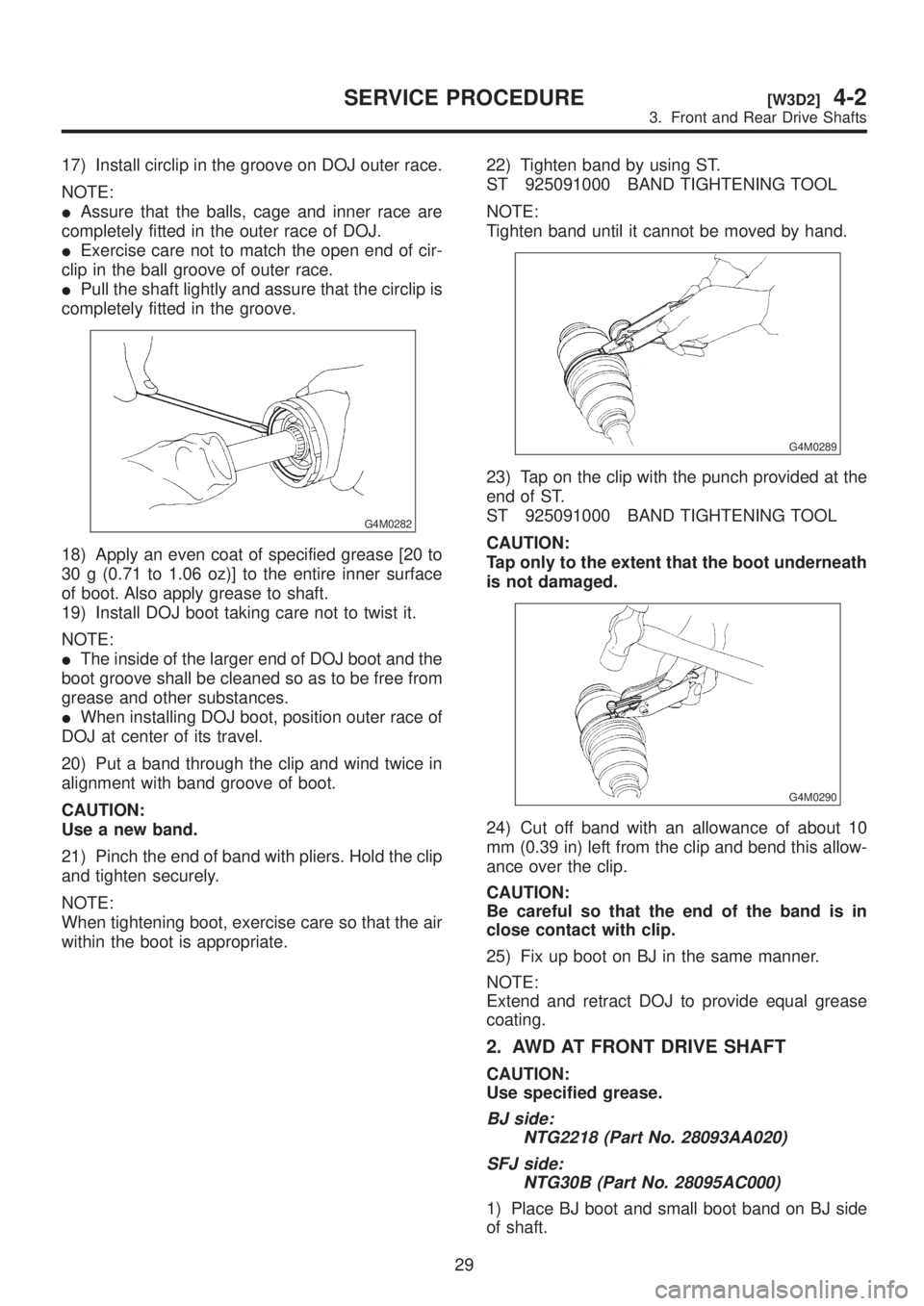

17) Install circlip in the groove on DOJ outer race.

NOTE:

IAssure that the balls, cage and inner race are

completely fitted in the outer race of DOJ.

IExercise care not to match the open end of cir-

clip in the ball groove of outer race.

IPull the shaft lightly and assure that the circlip is

completely fitted in the groove.

G4M0282

18) Apply an even coat of specified grease [20 to

30 g (0.71 to 1.06 oz)] to the entire inner surface

of boot. Also apply grease to shaft.

19) Install DOJ boot taking care not to twist it.

NOTE:

IThe inside of the larger end of DOJ boot and the

boot groove shall be cleaned so as to be free from

grease and other substances.

IWhen installing DOJ boot, position outer race of

DOJ at center of its travel.

20) Put a band through the clip and wind twice in

alignment with band groove of boot.

CAUTION:

Use a new band.

21) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, exercise care so that the air

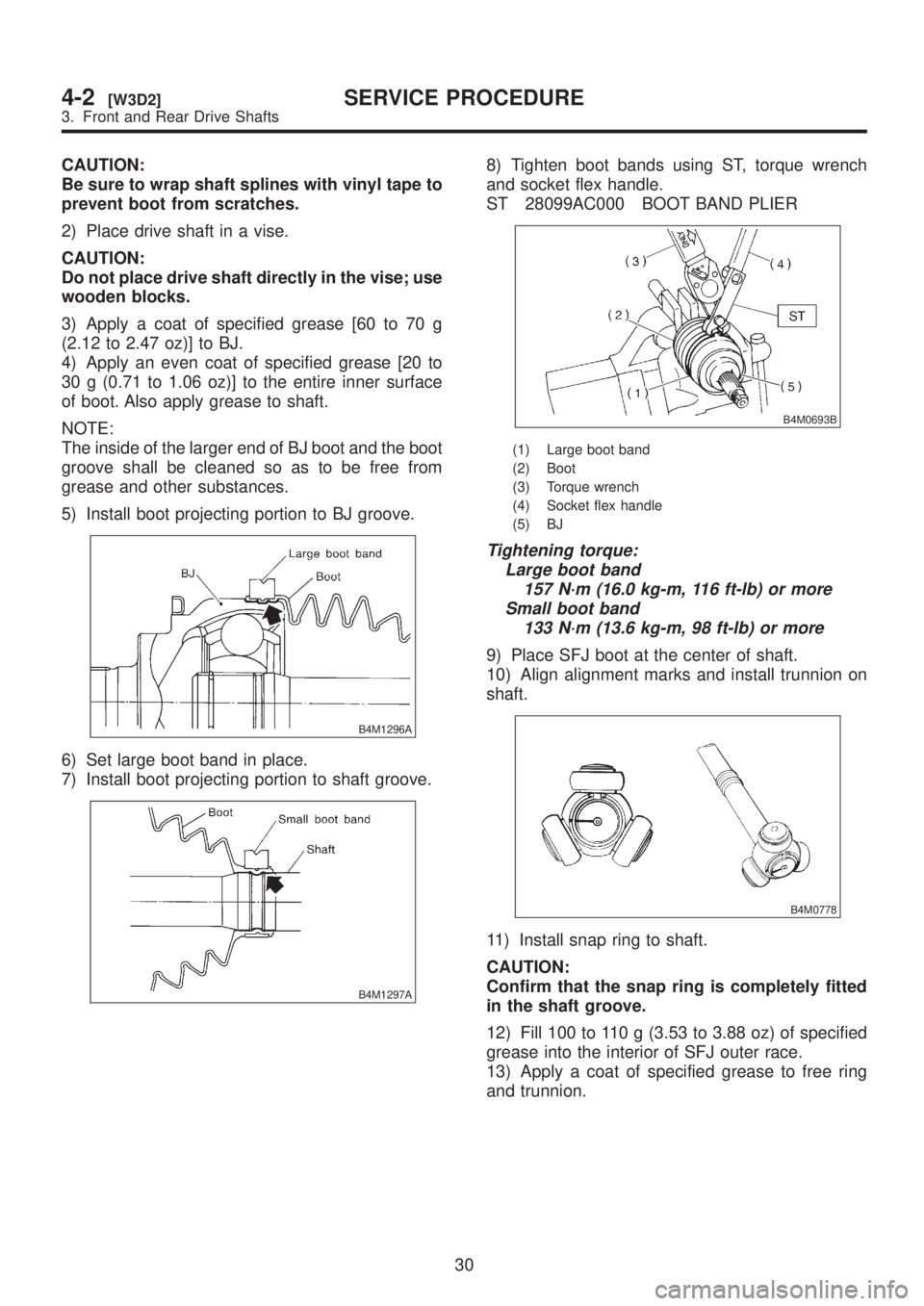

within the boot is appropriate.22) Tighten band by using ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tighten band until it cannot be moved by hand.

G4M0289

23) Tap on the clip with the punch provided at the

end of ST.

ST 925091000 BAND TIGHTENING TOOL

CAUTION:

Tap only to the extent that the boot underneath

is not damaged.

G4M0290

24) Cut off band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

CAUTION:

Be careful so that the end of the band is in

close contact with clip.

25) Fix up boot on BJ in the same manner.

NOTE:

Extend and retract DOJ to provide equal grease

coating.

2. AWD AT FRONT DRIVE SHAFT

CAUTION:

Use specified grease.

BJ side:

NTG2218 (Part No. 28093AA020)

SFJ side:

NTG30B (Part No. 28095AC000)

1) Place BJ boot and small boot band on BJ side

of shaft.

29

[W3D2]4-2SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 776 of 1456

CAUTION:

Be sure to wrap shaft splines with vinyl tape to

prevent boot from scratches.

2) Place drive shaft in a vise.

CAUTION:

Do not place drive shaft directly in the vise; use

wooden blocks.

3) Apply a coat of specified grease [60 to 70 g

(2.12 to 2.47 oz)] to BJ.

4) Apply an even coat of specified grease [20 to

30 g (0.71 to 1.06 oz)] to the entire inner surface

of boot. Also apply grease to shaft.

NOTE:

The inside of the larger end of BJ boot and the boot

groove shall be cleaned so as to be free from

grease and other substances.

5) Install boot projecting portion to BJ groove.

B4M1296A

6) Set large boot band in place.

7) Install boot projecting portion to shaft groove.

B4M1297A

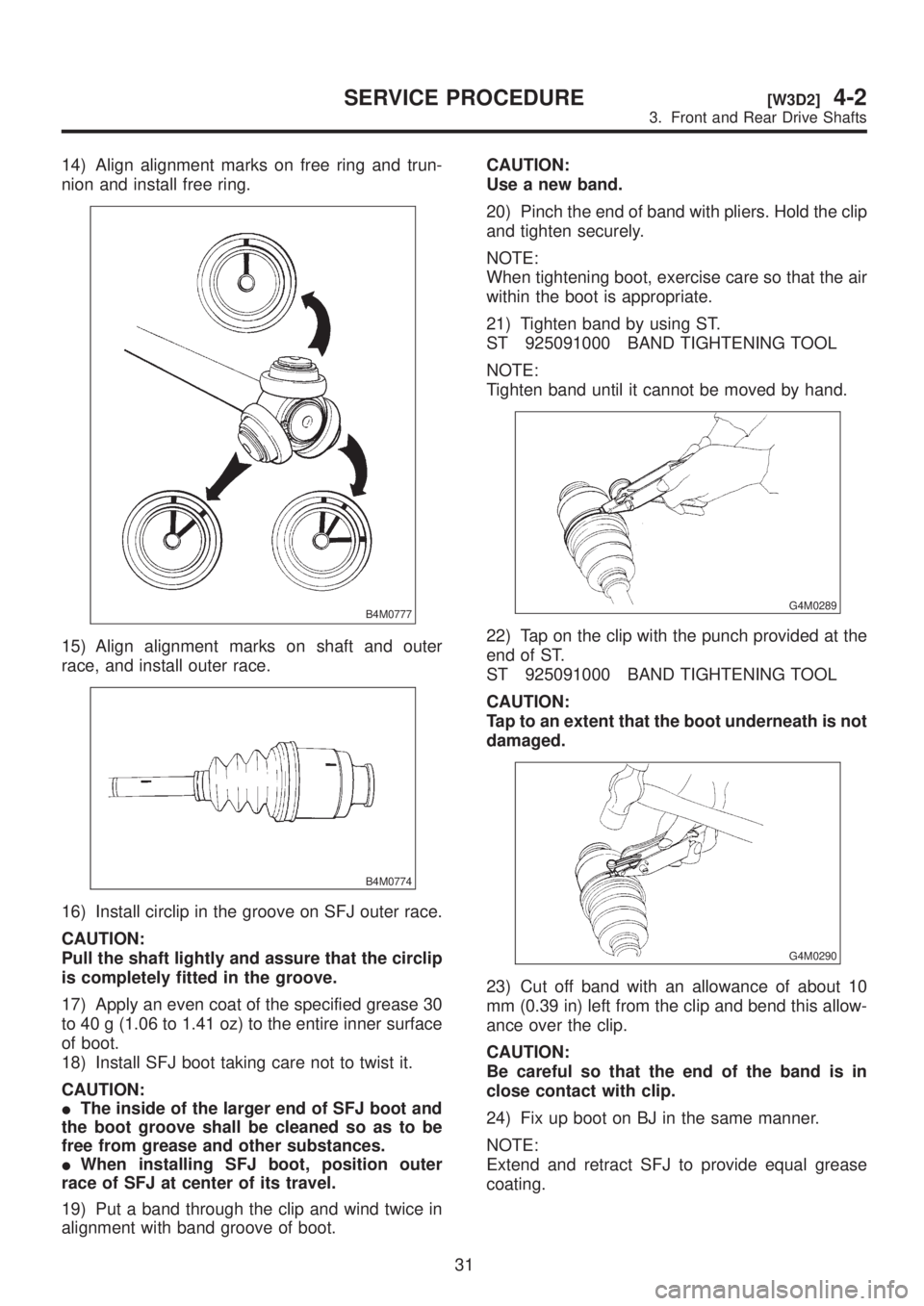

8) Tighten boot bands using ST, torque wrench

and socket flex handle.

ST 28099AC000 BOOT BAND PLIER

B4M0693B

(1) Large boot band

(2) Boot

(3) Torque wrench

(4) Socket flex handle

(5) BJ

Tightening torque:

Large boot band

157 N´m (16.0 kg-m, 116 ft-lb) or more

Small boot band

133 N´m (13.6 kg-m, 98 ft-lb) or more

9) Place SFJ boot at the center of shaft.

10) Align alignment marks and install trunnion on

shaft.

B4M0778

11) Install snap ring to shaft.

CAUTION:

Confirm that the snap ring is completely fitted

in the shaft groove.

12) Fill 100 to 110 g (3.53 to 3.88 oz) of specified

grease into the interior of SFJ outer race.

13) Apply a coat of specified grease to free ring

and trunnion.

30

4-2[W3D2]SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 777 of 1456

14) Align alignment marks on free ring and trun-

nion and install free ring.

B4M0777

15) Align alignment marks on shaft and outer

race, and install outer race.

B4M0774

16) Install circlip in the groove on SFJ outer race.

CAUTION:

Pull the shaft lightly and assure that the circlip

is completely fitted in the groove.

17) Apply an even coat of the specified grease 30

to 40 g (1.06 to 1.41 oz) to the entire inner surface

of boot.

18) Install SFJ boot taking care not to twist it.

CAUTION:

IThe inside of the larger end of SFJ boot and

the boot groove shall be cleaned so as to be

free from grease and other substances.

IWhen installing SFJ boot, position outer

race of SFJ at center of its travel.

19) Put a band through the clip and wind twice in

alignment with band groove of boot.CAUTION:

Use a new band.

20) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, exercise care so that the air

within the boot is appropriate.

21) Tighten band by using ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tighten band until it cannot be moved by hand.

G4M0289

22) Tap on the clip with the punch provided at the

end of ST.

ST 925091000 BAND TIGHTENING TOOL

CAUTION:

Tap to an extent that the boot underneath is not

damaged.

G4M0290

23) Cut off band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

CAUTION:

Be careful so that the end of the band is in

close contact with clip.

24) Fix up boot on BJ in the same manner.

NOTE:

Extend and retract SFJ to provide equal grease

coating.

31

[W3D2]4-2SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 778 of 1456

3. REAR DRIVE SHAFT

CAUTION:

Use specified grease.

BJ side:

Molylex No. 2 (Part No. 723223010) or

Sunlight TB2-A

DOJ side:

VU-3A702 (Yellow) (Part No. 23223GA050)

1) Install BJ boot in specified position, and fill it

with 60 to 70 g (2.12 to 2.47 oz) of specified

grease.

2) Place DOJ boot at the center of shaft.

CAUTION:

Be sure to wrap shaft splines with vinyl tape to

prevent boot from scratches.

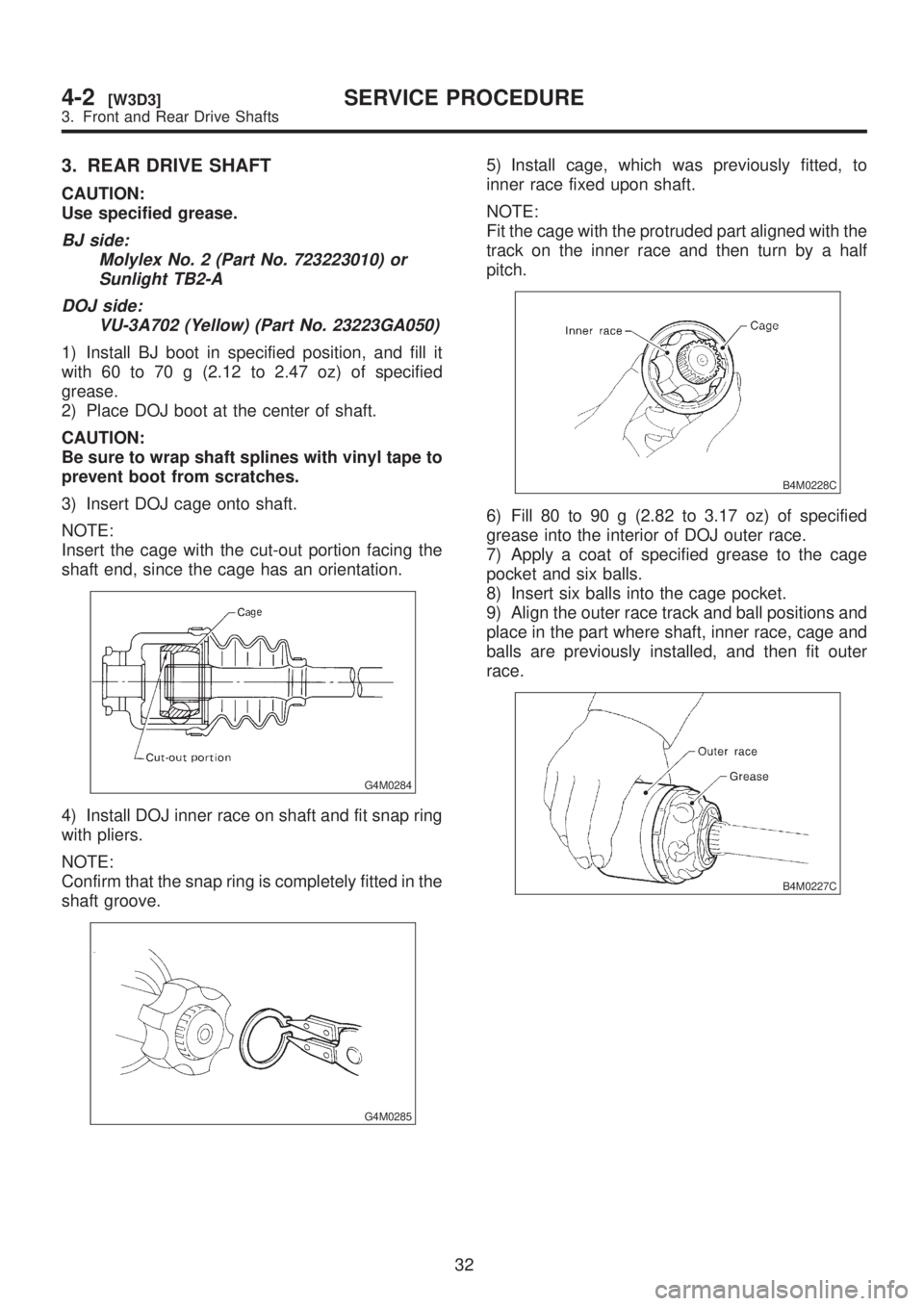

3) Insert DOJ cage onto shaft.

NOTE:

Insert the cage with the cut-out portion facing the

shaft end, since the cage has an orientation.

G4M0284

4) Install DOJ inner race on shaft and fit snap ring

with pliers.

NOTE:

Confirm that the snap ring is completely fitted in the

shaft groove.

G4M0285

5) Install cage, which was previously fitted, to

inner race fixed upon shaft.

NOTE:

Fit the cage with the protruded part aligned with the

track on the inner race and then turn by a half

pitch.

B4M0228C

6) Fill 80 to 90 g (2.82 to 3.17 oz) of specified

grease into the interior of DOJ outer race.

7) Apply a coat of specified grease to the cage

pocket and six balls.

8) Insert six balls into the cage pocket.

9) Align the outer race track and ball positions and

place in the part where shaft, inner race, cage and

balls are previously installed, and then fit outer

race.

B4M0227C

32

4-2[W3D3]SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 779 of 1456

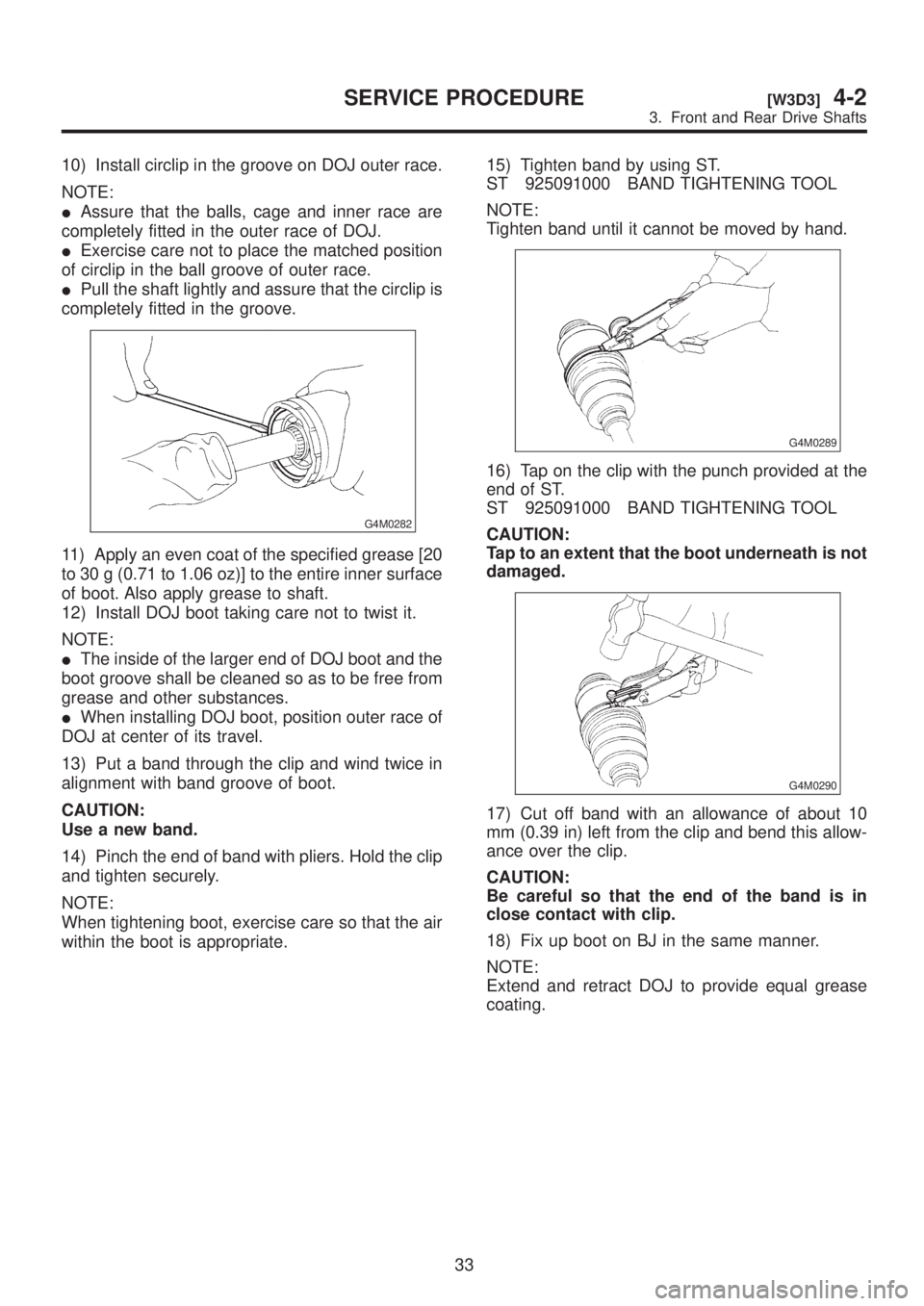

10) Install circlip in the groove on DOJ outer race.

NOTE:

IAssure that the balls, cage and inner race are

completely fitted in the outer race of DOJ.

IExercise care not to place the matched position

of circlip in the ball groove of outer race.

IPull the shaft lightly and assure that the circlip is

completely fitted in the groove.

G4M0282

11) Apply an even coat of the specified grease [20

to 30 g (0.71 to 1.06 oz)] to the entire inner surface

of boot. Also apply grease to shaft.

12) Install DOJ boot taking care not to twist it.

NOTE:

IThe inside of the larger end of DOJ boot and the

boot groove shall be cleaned so as to be free from

grease and other substances.

IWhen installing DOJ boot, position outer race of

DOJ at center of its travel.

13) Put a band through the clip and wind twice in

alignment with band groove of boot.

CAUTION:

Use a new band.

14) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, exercise care so that the air

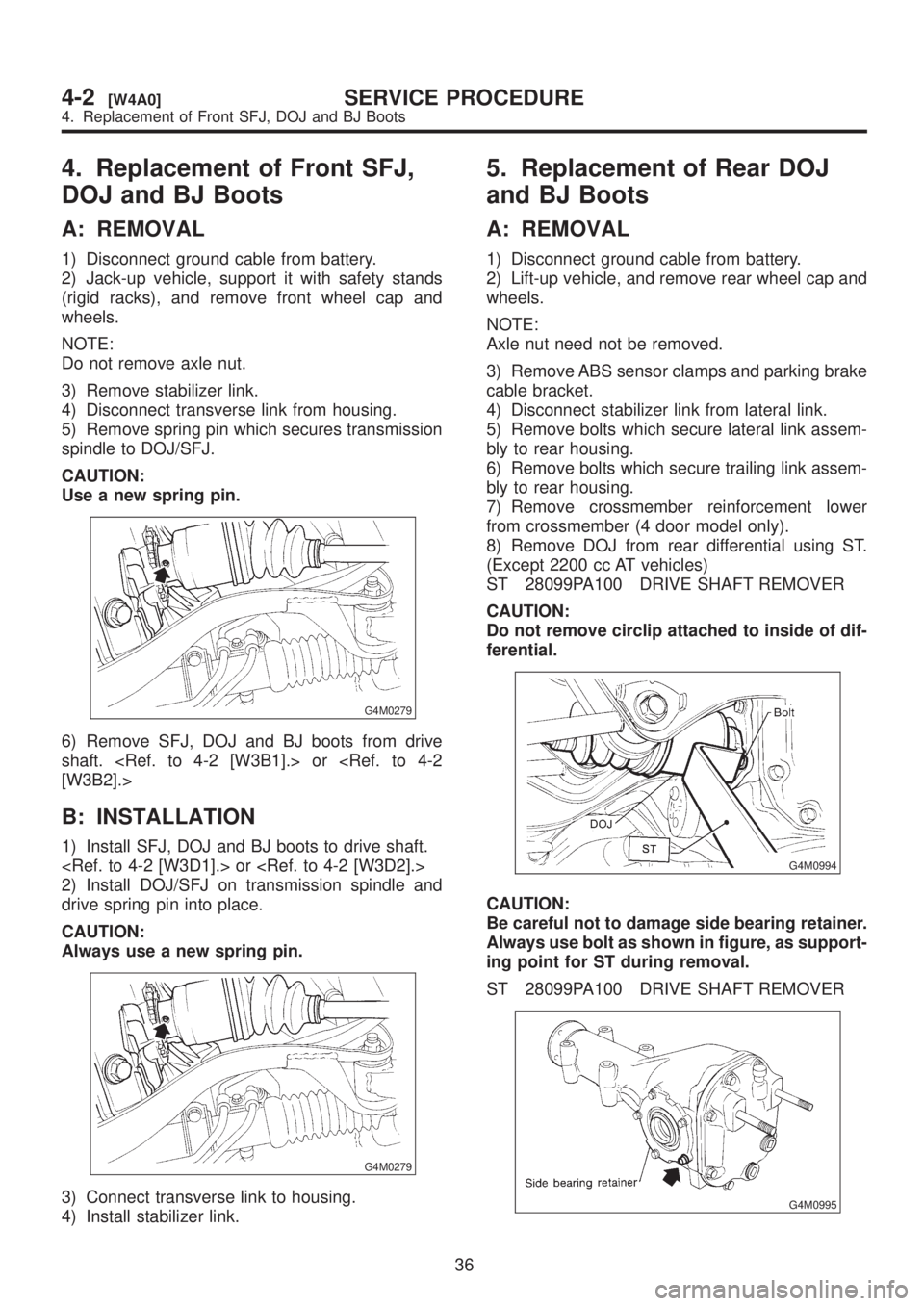

within the boot is appropriate.15) Tighten band by using ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tighten band until it cannot be moved by hand.

G4M0289

16) Tap on the clip with the punch provided at the

end of ST.

ST 925091000 BAND TIGHTENING TOOL

CAUTION:

Tap to an extent that the boot underneath is not

damaged.

G4M0290

17) Cut off band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

CAUTION:

Be careful so that the end of the band is in

close contact with clip.

18) Fix up boot on BJ in the same manner.

NOTE:

Extend and retract DOJ to provide equal grease

coating.

33

[W3D3]4-2SERVICE PROCEDURE

3. Front and Rear Drive Shafts

Page 782 of 1456

4. Replacement of Front SFJ,

DOJ and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Jack-up vehicle, support it with safety stands

(rigid racks), and remove front wheel cap and

wheels.

NOTE:

Do not remove axle nut.

3) Remove stabilizer link.

4) Disconnect transverse link from housing.

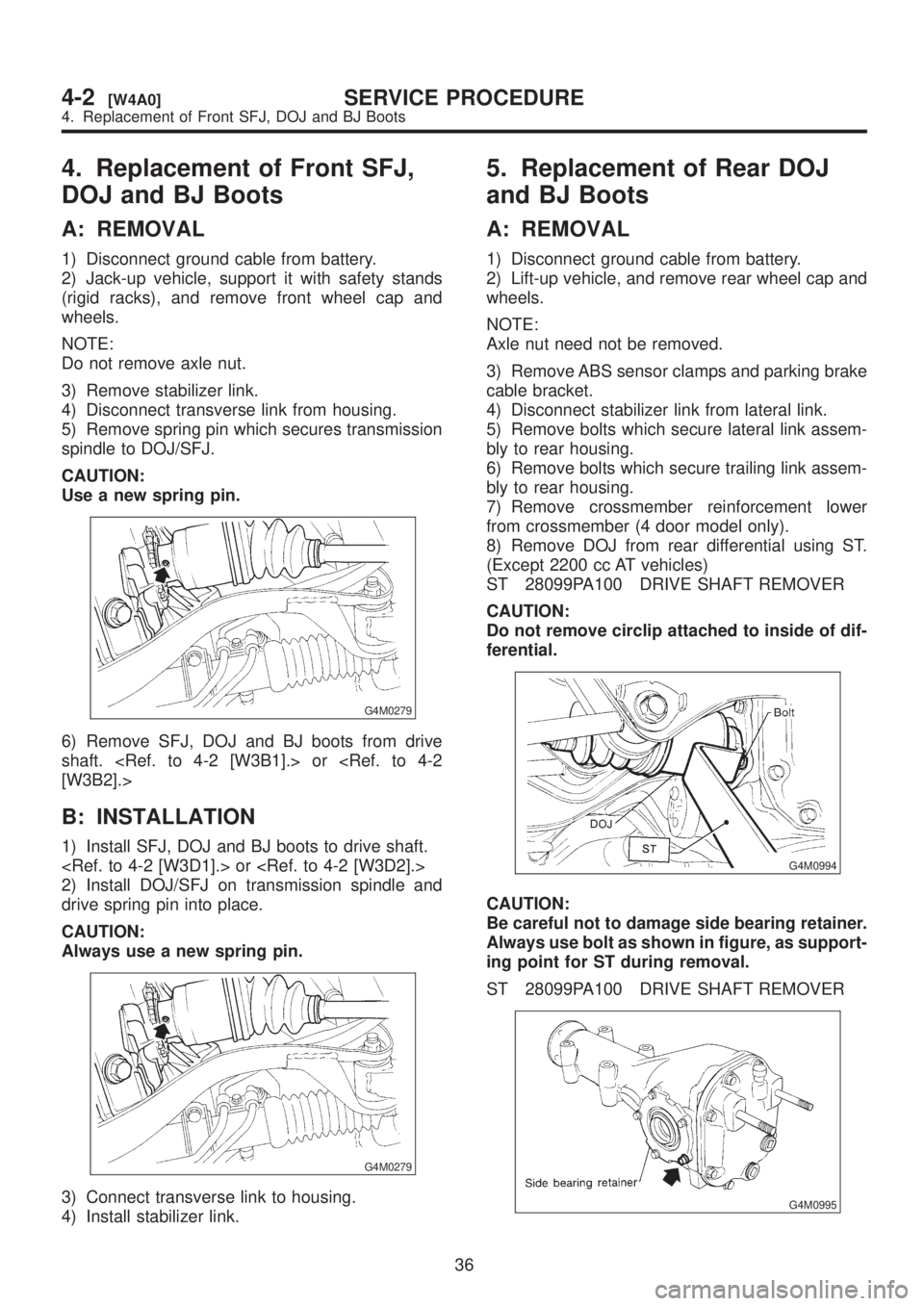

5) Remove spring pin which secures transmission

spindle to DOJ/SFJ.

CAUTION:

Use a new spring pin.

G4M0279

6) Remove SFJ, DOJ and BJ boots from drive

shaft.

B: INSTALLATION

1) Install SFJ, DOJ and BJ boots to drive shaft.

2) Install DOJ/SFJ on transmission spindle and

drive spring pin into place.

CAUTION:

Always use a new spring pin.

G4M0279

3) Connect transverse link to housing.

4) Install stabilizer link.

5. Replacement of Rear DOJ

and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Lift-up vehicle, and remove rear wheel cap and

wheels.

NOTE:

Axle nut need not be removed.

3) Remove ABS sensor clamps and parking brake

cable bracket.

4) Disconnect stabilizer link from lateral link.

5) Remove bolts which secure lateral link assem-

bly to rear housing.

6) Remove bolts which secure trailing link assem-

bly to rear housing.

7) Remove crossmember reinforcement lower

from crossmember (4 door model only).

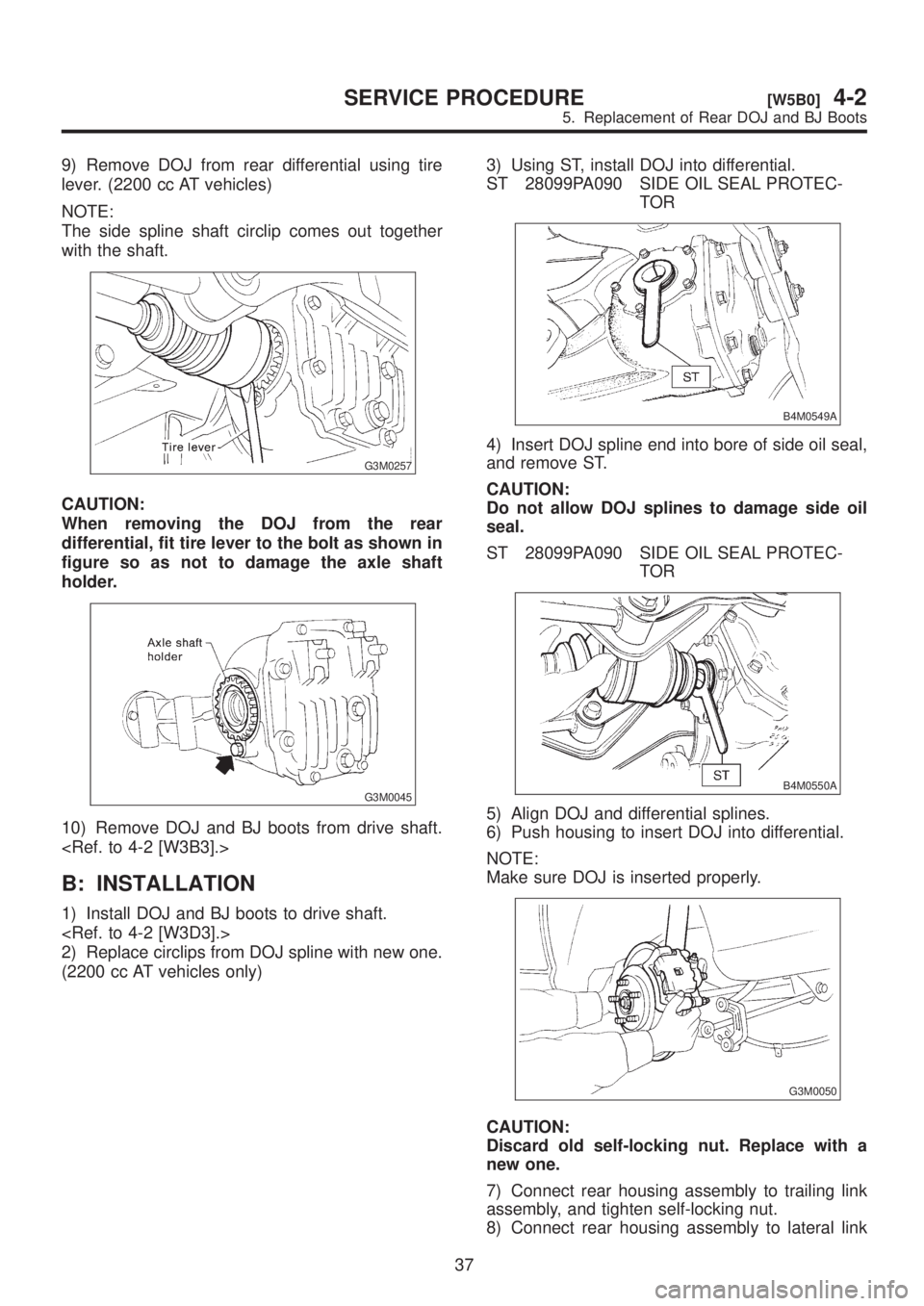

8) Remove DOJ from rear differential using ST.

(Except 2200 cc AT vehicles)

ST 28099PA100 DRIVE SHAFT REMOVER

CAUTION:

Do not remove circlip attached to inside of dif-

ferential.

G4M0994

CAUTION:

Be careful not to damage side bearing retainer.

Always use bolt as shown in figure, as support-

ing point for ST during removal.

ST 28099PA100 DRIVE SHAFT REMOVER

G4M0995

36

4-2[W4A0]SERVICE PROCEDURE

4. Replacement of Front SFJ, DOJ and BJ Boots

Page 783 of 1456

4. Replacement of Front SFJ,

DOJ and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Jack-up vehicle, support it with safety stands

(rigid racks), and remove front wheel cap and

wheels.

NOTE:

Do not remove axle nut.

3) Remove stabilizer link.

4) Disconnect transverse link from housing.

5) Remove spring pin which secures transmission

spindle to DOJ/SFJ.

CAUTION:

Use a new spring pin.

G4M0279

6) Remove SFJ, DOJ and BJ boots from drive

shaft.

B: INSTALLATION

1) Install SFJ, DOJ and BJ boots to drive shaft.

2) Install DOJ/SFJ on transmission spindle and

drive spring pin into place.

CAUTION:

Always use a new spring pin.

G4M0279

3) Connect transverse link to housing.

4) Install stabilizer link.

5. Replacement of Rear DOJ

and BJ Boots

A: REMOVAL

1) Disconnect ground cable from battery.

2) Lift-up vehicle, and remove rear wheel cap and

wheels.

NOTE:

Axle nut need not be removed.

3) Remove ABS sensor clamps and parking brake

cable bracket.

4) Disconnect stabilizer link from lateral link.

5) Remove bolts which secure lateral link assem-

bly to rear housing.

6) Remove bolts which secure trailing link assem-

bly to rear housing.

7) Remove crossmember reinforcement lower

from crossmember (4 door model only).

8) Remove DOJ from rear differential using ST.

(Except 2200 cc AT vehicles)

ST 28099PA100 DRIVE SHAFT REMOVER

CAUTION:

Do not remove circlip attached to inside of dif-

ferential.

G4M0994

CAUTION:

Be careful not to damage side bearing retainer.

Always use bolt as shown in figure, as support-

ing point for ST during removal.

ST 28099PA100 DRIVE SHAFT REMOVER

G4M0995

36

4-2[W4A0]SERVICE PROCEDURE

4. Replacement of Front SFJ, DOJ and BJ Boots

Page 784 of 1456

9) Remove DOJ from rear differential using tire

lever. (2200 cc AT vehicles)

NOTE:

The side spline shaft circlip comes out together

with the shaft.

G3M0257

CAUTION:

When removing the DOJ from the rear

differential, fit tire lever to the bolt as shown in

figure so as not to damage the axle shaft

holder.

G3M0045

10) Remove DOJ and BJ boots from drive shaft.

B: INSTALLATION

1) Install DOJ and BJ boots to drive shaft.

2) Replace circlips from DOJ spline with new one.

(2200 cc AT vehicles only)3) Using ST, install DOJ into differential.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0549A

4) Insert DOJ spline end into bore of side oil seal,

and remove ST.

CAUTION:

Do not allow DOJ splines to damage side oil

seal.

ST 28099PA090 SIDE OIL SEAL PROTEC-

TOR

B4M0550A

5) Align DOJ and differential splines.

6) Push housing to insert DOJ into differential.

NOTE:

Make sure DOJ is inserted properly.

G3M0050

CAUTION:

Discard old self-locking nut. Replace with a

new one.

7) Connect rear housing assembly to trailing link

assembly, and tighten self-locking nut.

8) Connect rear housing assembly to lateral link

37

[W5B0]4-2SERVICE PROCEDURE

5. Replacement of Rear DOJ and BJ Boots

Page 796 of 1456

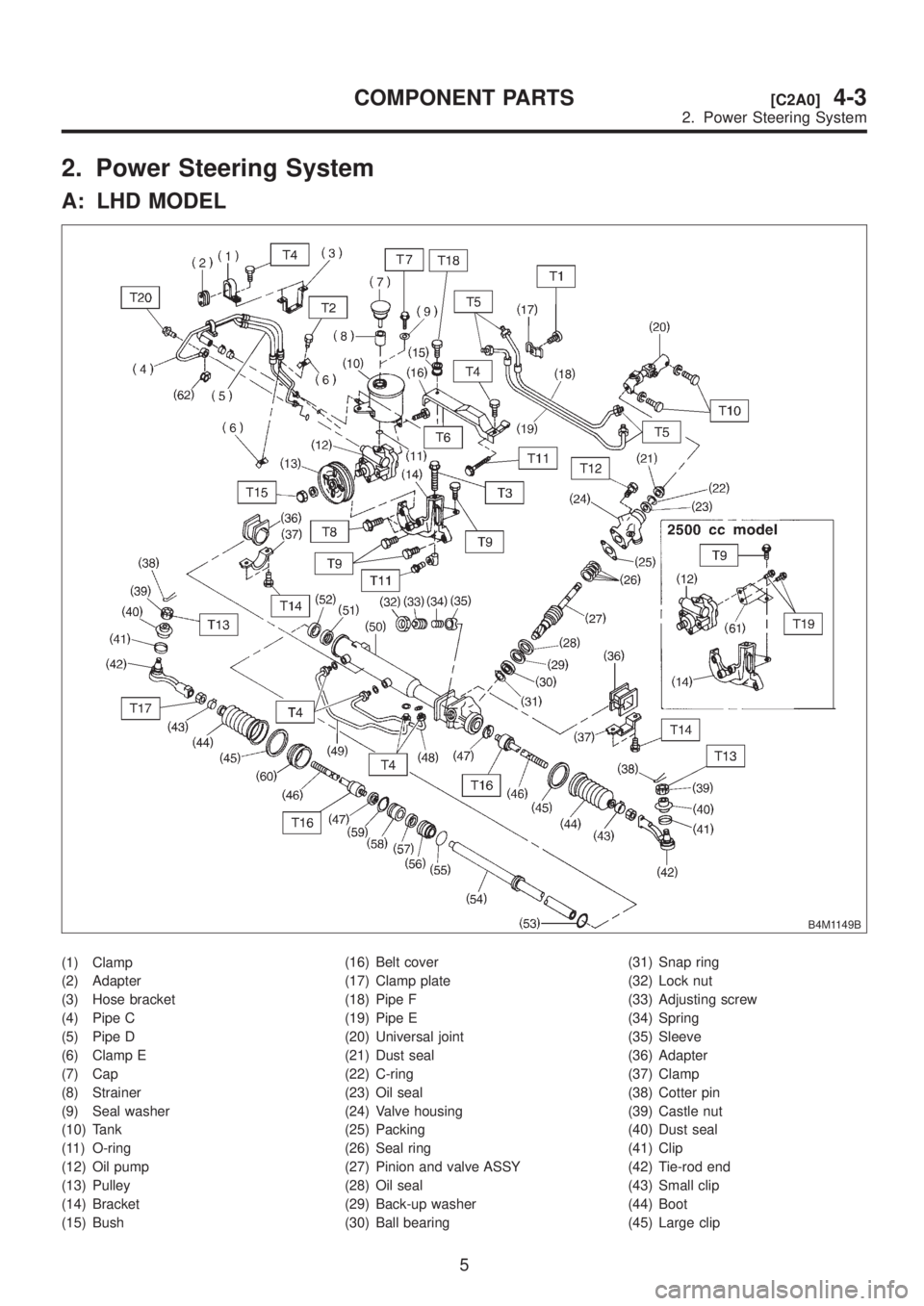

2. Power Steering System

A: LHD MODEL

B4M1149B

(1) Clamp

(2) Adapter

(3) Hose bracket

(4) Pipe C

(5) Pipe D

(6) Clamp E

(7) Cap

(8) Strainer

(9) Seal washer

(10) Tank

(11) O-ring

(12) Oil pump

(13) Pulley

(14) Bracket

(15) Bush(16) Belt cover

(17) Clamp plate

(18) Pipe F

(19) Pipe E

(20) Universal joint

(21) Dust seal

(22) C-ring

(23) Oil seal

(24) Valve housing

(25) Packing

(26) Seal ring

(27) Pinion and valve ASSY

(28) Oil seal

(29) Back-up washer

(30) Ball bearing(31) Snap ring

(32) Lock nut

(33) Adjusting screw

(34) Spring

(35) Sleeve

(36) Adapter

(37) Clamp

(38) Cotter pin

(39) Castle nut

(40) Dust seal

(41) Clip

(42) Tie-rod end

(43) Small clip

(44) Boot

(45) Large clip

5

[C2A0]4-3COMPONENT PARTS

2. Power Steering System

Page 798 of 1456

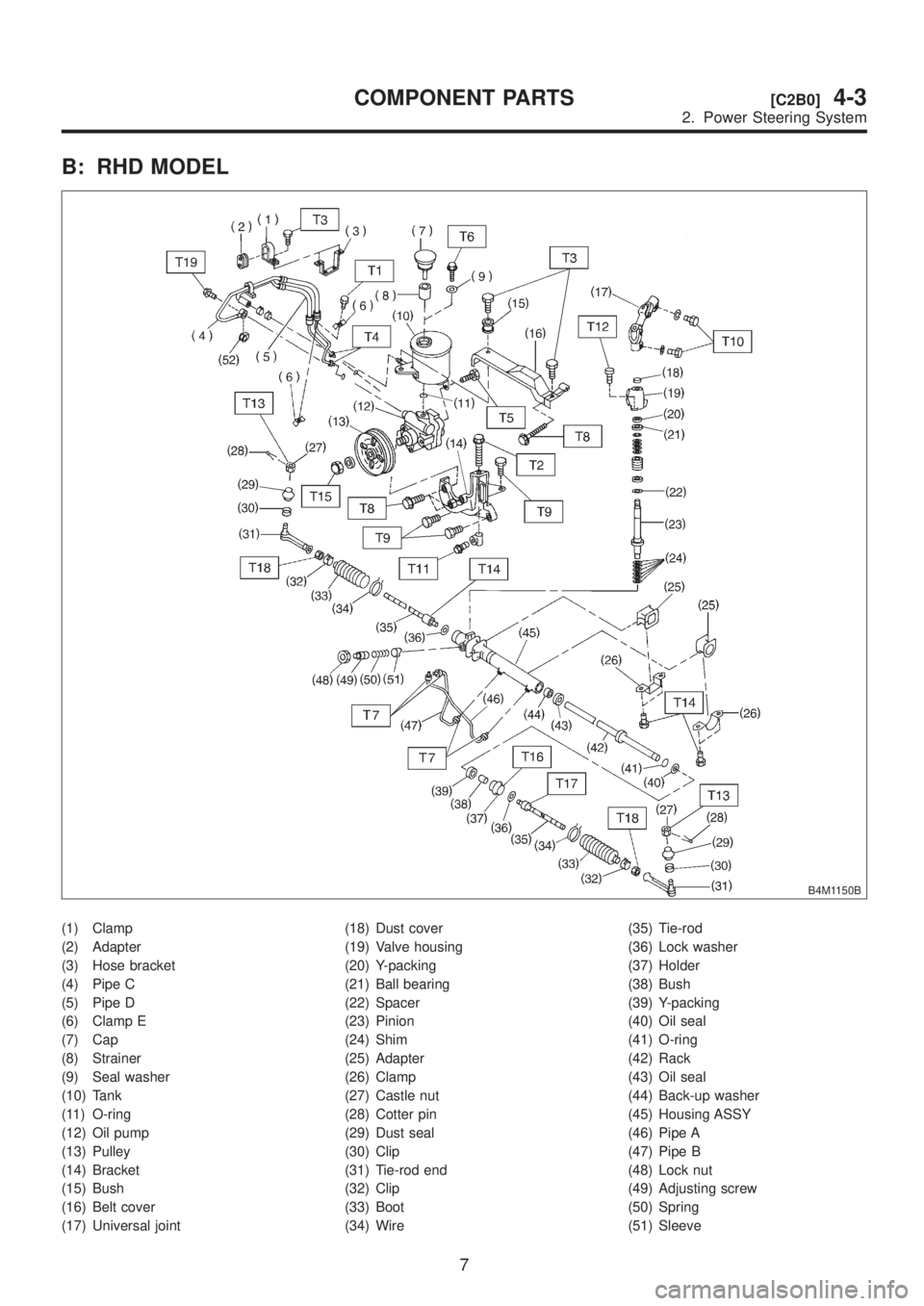

B: RHD MODEL

B4M1150B

(1) Clamp

(2) Adapter

(3) Hose bracket

(4) Pipe C

(5) Pipe D

(6) Clamp E

(7) Cap

(8) Strainer

(9) Seal washer

(10) Tank

(11) O-ring

(12) Oil pump

(13) Pulley

(14) Bracket

(15) Bush

(16) Belt cover

(17) Universal joint(18) Dust cover

(19) Valve housing

(20) Y-packing

(21) Ball bearing

(22) Spacer

(23) Pinion

(24) Shim

(25) Adapter

(26) Clamp

(27) Castle nut

(28) Cotter pin

(29) Dust seal

(30) Clip

(31) Tie-rod end

(32) Clip

(33) Boot

(34) Wire(35) Tie-rod

(36) Lock washer

(37) Holder

(38) Bush

(39) Y-packing

(40) Oil seal

(41) O-ring

(42) Rack

(43) Oil seal

(44) Back-up washer

(45) Housing ASSY

(46) Pipe A

(47) Pipe B

(48) Lock nut

(49) Adjusting screw

(50) Spring

(51) Sleeve

7

[C2B0]4-3COMPONENT PARTS

2. Power Steering System