boot SUBARU LEGACY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 805 of 1456

CAUTION:

Insert roll connector guide pin into guide hole

on lower end of surface of steering wheel to

prevent damage.

Draw out airbag system connector, horn con-

nector and cruise control connectors from

guide hole of steering wheel lower end. (with

airbag model)

8) Install airbag module to steering wheel. (with

airbag model)

WARNING:

Always refer to 5-5 Supplemental Restraint

System before performing the service opera-

tion.

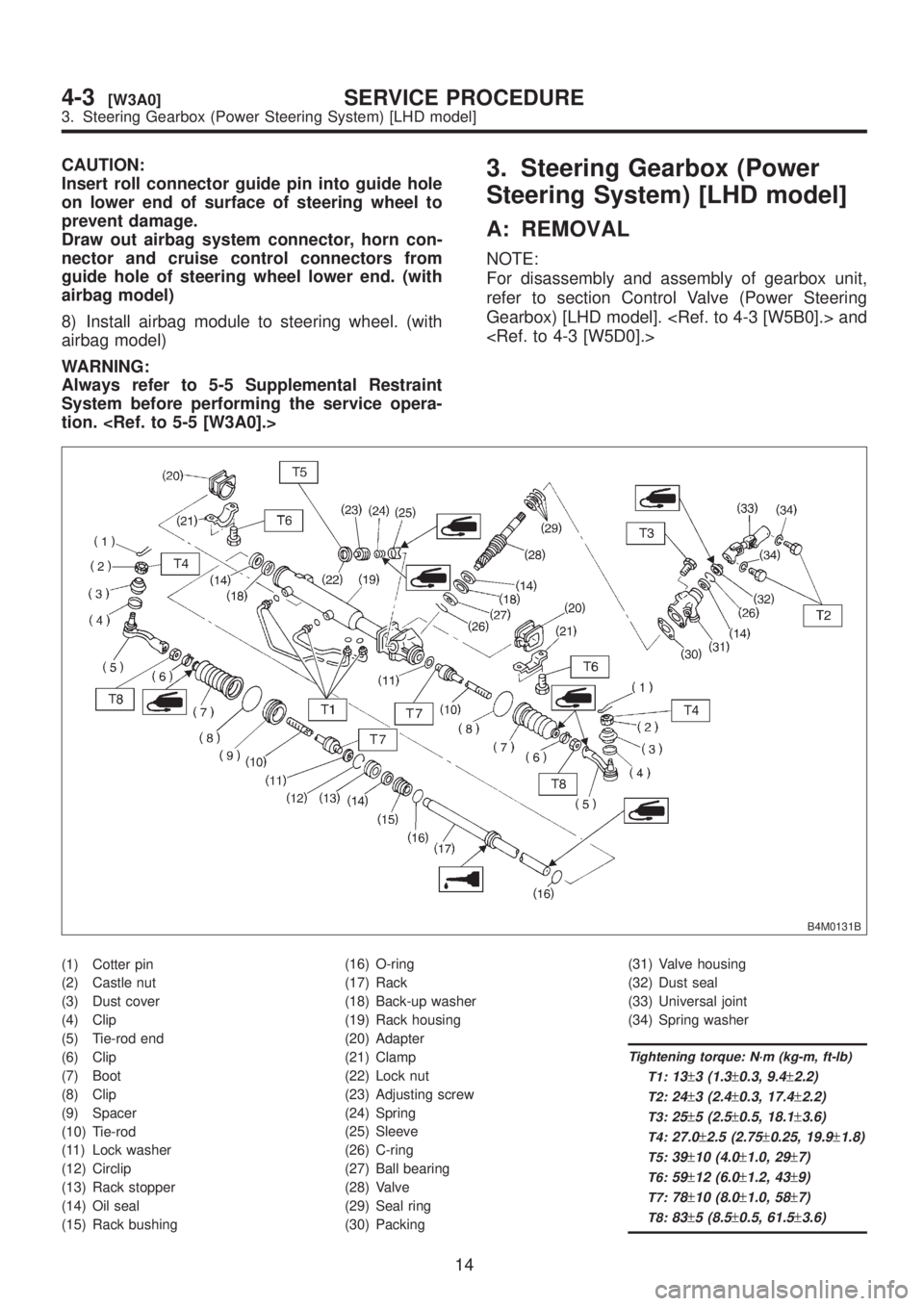

Steering System) [LHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [LHD model].

B4M0131B

(1) Cotter pin

(2) Castle nut

(3) Dust cover

(4) Clip

(5) Tie-rod end

(6) Clip

(7) Boot

(8) Clip

(9) Spacer

(10) Tie-rod

(11) Lock washer

(12) Circlip

(13) Rack stopper

(14) Oil seal

(15) Rack bushing(16) O-ring

(17) Rack

(18) Back-up washer

(19) Rack housing

(20) Adapter

(21) Clamp

(22) Lock nut

(23) Adjusting screw

(24) Spring

(25) Sleeve

(26) C-ring

(27) Ball bearing

(28) Valve

(29) Seal ring

(30) Packing(31) Valve housing

(32) Dust seal

(33) Universal joint

(34) Spring washer

Tightening torque: N´m (kg-m, ft-lb)

T1:

13±3 (1.3±0.3, 9.4±2.2)

T2:24±3 (2.4±0.3, 17.4±2.2)

T3:25±5 (2.5±0.5, 18.1±3.6)

T4:27.0±2.5 (2.75±0.25, 19.9±1.8)

T5:39±10 (4.0±1.0, 29±7)

T6:59±12 (6.0±1.2, 43±9)

T7:78±10 (8.0±1.0, 58±7)

T8:83±5 (8.5±0.5, 61.5±3.6)

14

4-3[W3A0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 806 of 1456

CAUTION:

Insert roll connector guide pin into guide hole

on lower end of surface of steering wheel to

prevent damage.

Draw out airbag system connector, horn con-

nector and cruise control connectors from

guide hole of steering wheel lower end. (with

airbag model)

8) Install airbag module to steering wheel. (with

airbag model)

WARNING:

Always refer to 5-5 Supplemental Restraint

System before performing the service opera-

tion.

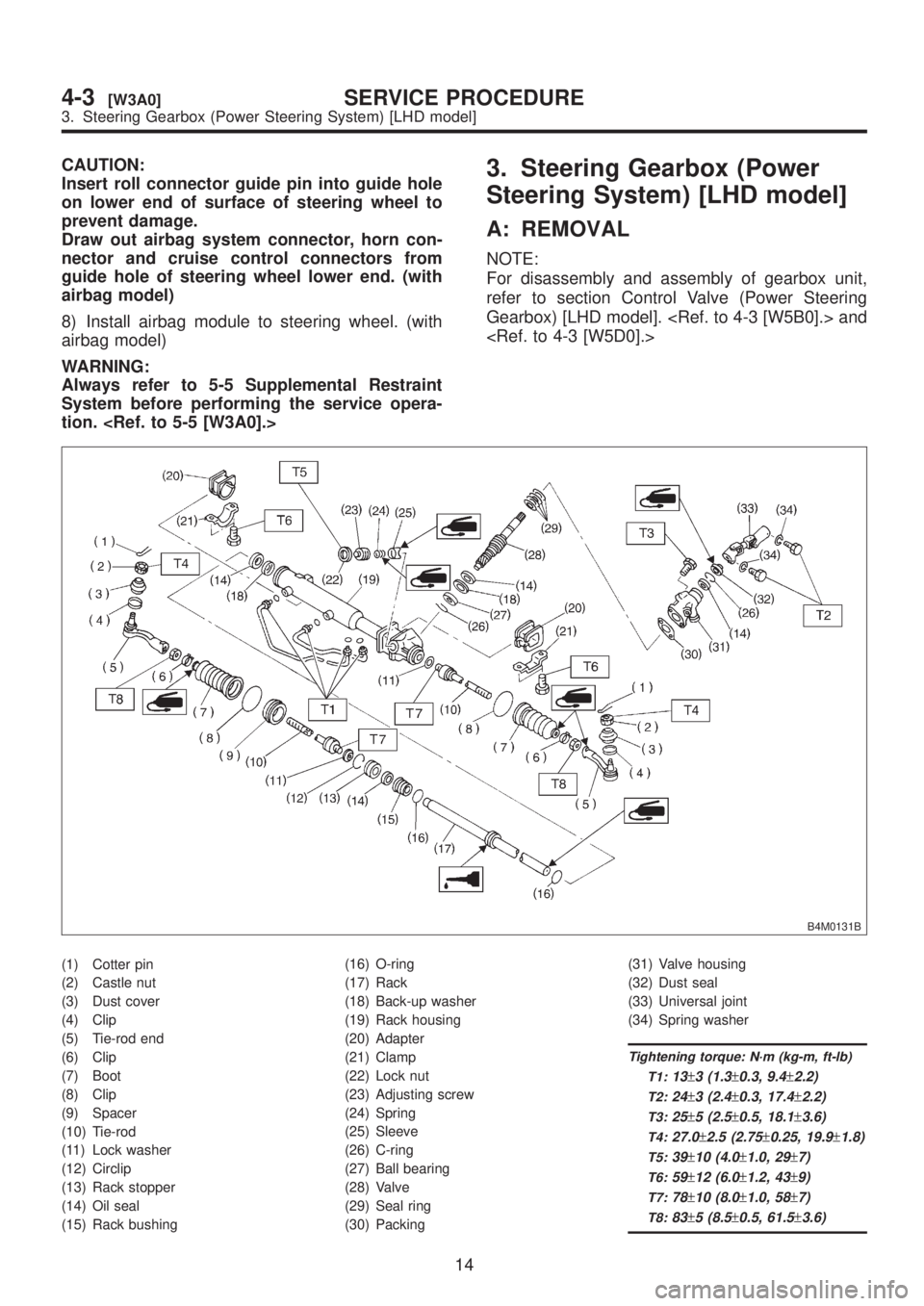

Steering System) [LHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [LHD model].

B4M0131B

(1) Cotter pin

(2) Castle nut

(3) Dust cover

(4) Clip

(5) Tie-rod end

(6) Clip

(7) Boot

(8) Clip

(9) Spacer

(10) Tie-rod

(11) Lock washer

(12) Circlip

(13) Rack stopper

(14) Oil seal

(15) Rack bushing(16) O-ring

(17) Rack

(18) Back-up washer

(19) Rack housing

(20) Adapter

(21) Clamp

(22) Lock nut

(23) Adjusting screw

(24) Spring

(25) Sleeve

(26) C-ring

(27) Ball bearing

(28) Valve

(29) Seal ring

(30) Packing(31) Valve housing

(32) Dust seal

(33) Universal joint

(34) Spring washer

Tightening torque: N´m (kg-m, ft-lb)

T1:

13±3 (1.3±0.3, 9.4±2.2)

T2:24±3 (2.4±0.3, 17.4±2.2)

T3:25±5 (2.5±0.5, 18.1±3.6)

T4:27.0±2.5 (2.75±0.25, 19.9±1.8)

T5:39±10 (4.0±1.0, 29±7)

T6:59±12 (6.0±1.2, 43±9)

T7:78±10 (8.0±1.0, 58±7)

T8:83±5 (8.5±0.5, 61.5±3.6)

14

4-3[W3A0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 808 of 1456

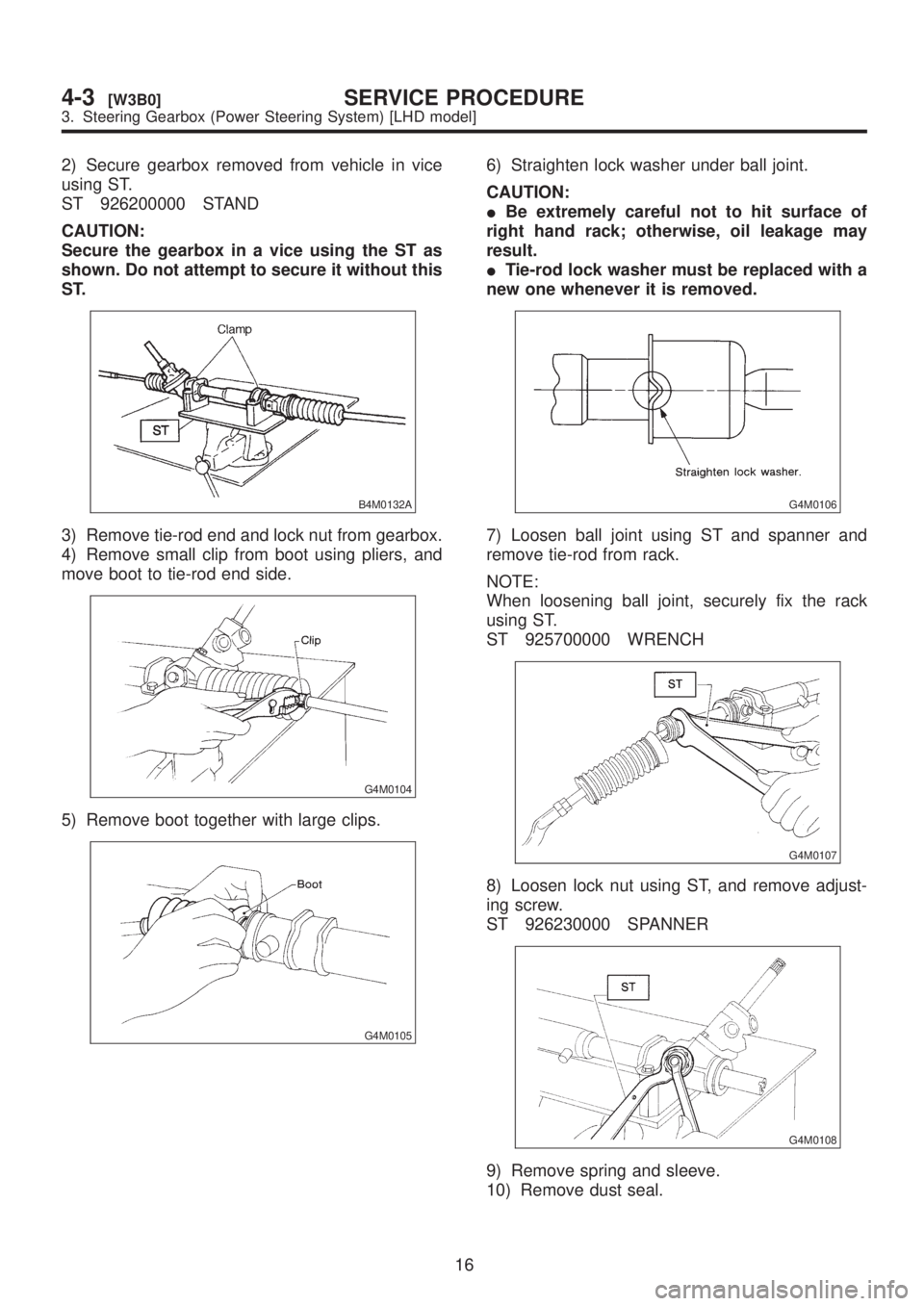

2) Secure gearbox removed from vehicle in vice

using ST.

ST 926200000 STAND

CAUTION:

Secure the gearbox in a vice using the ST as

shown. Do not attempt to secure it without this

ST.

B4M0132A

3) Remove tie-rod end and lock nut from gearbox.

4) Remove small clip from boot using pliers, and

move boot to tie-rod end side.

G4M0104

5) Remove boot together with large clips.

G4M0105

6) Straighten lock washer under ball joint.

CAUTION:

IBe extremely careful not to hit surface of

right hand rack; otherwise, oil leakage may

result.

ITie-rod lock washer must be replaced with a

new one whenever it is removed.

G4M0106

7) Loosen ball joint using ST and spanner and

remove tie-rod from rack.

NOTE:

When loosening ball joint, securely fix the rack

using ST.

ST 925700000 WRENCH

G4M0107

8) Loosen lock nut using ST, and remove adjust-

ing screw.

ST 926230000 SPANNER

G4M0108

9) Remove spring and sleeve.

10) Remove dust seal.

16

4-3[W3B0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 809 of 1456

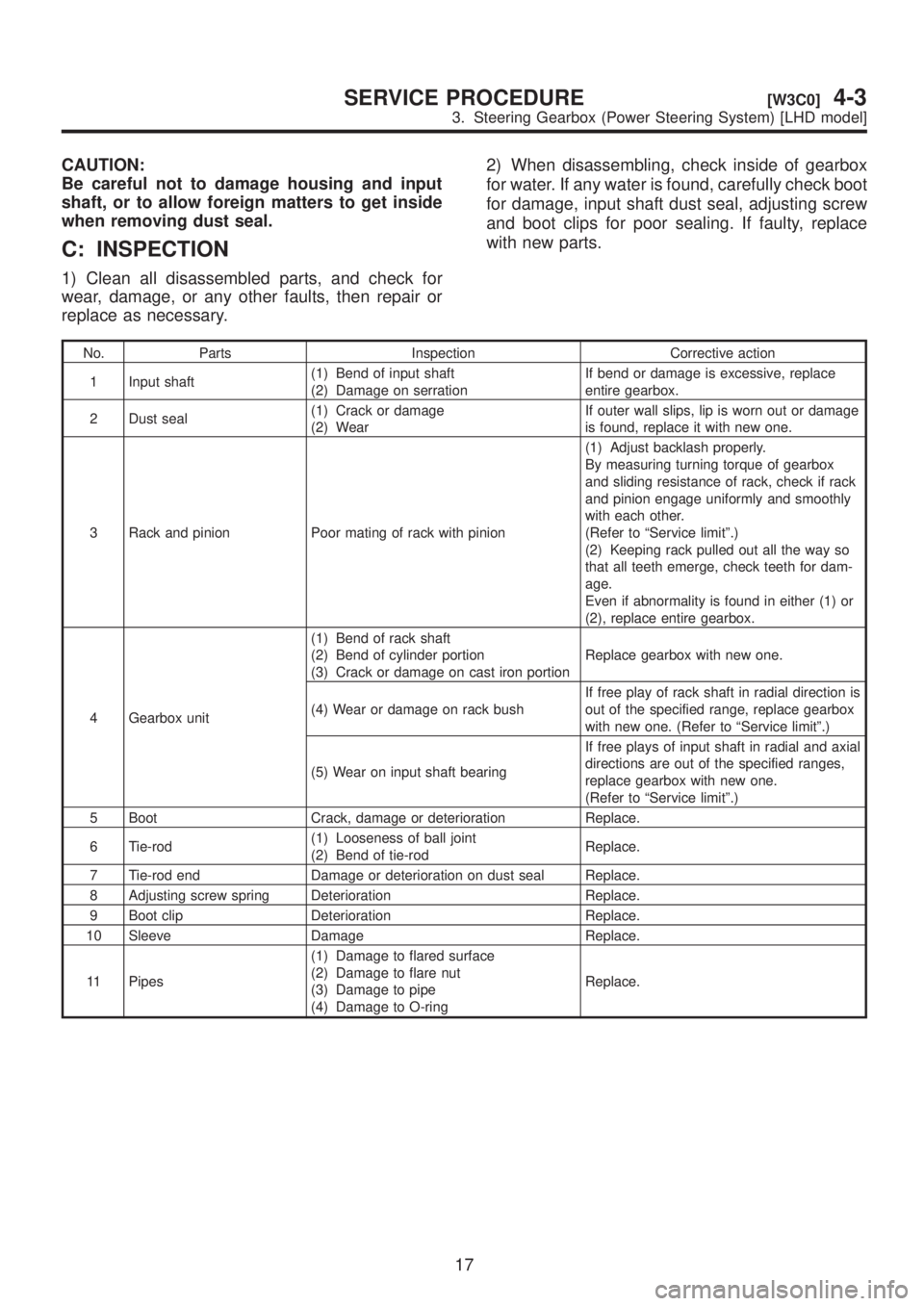

CAUTION:

Be careful not to damage housing and input

shaft, or to allow foreign matters to get inside

when removing dust seal.

C: INSPECTION

1) Clean all disassembled parts, and check for

wear, damage, or any other faults, then repair or

replace as necessary.2) When disassembling, check inside of gearbox

for water. If any water is found, carefully check boot

for damage, input shaft dust seal, adjusting screw

and boot clips for poor sealing. If faulty, replace

with new parts.

No. Parts Inspection Corrective action

1 Input shaft(1) Bend of input shaft

(2) Damage on serrationIf bend or damage is excessive, replace

entire gearbox.

2 Dust seal(1) Crack or damage

(2) WearIf outer wall slips, lip is worn out or damage

is found, replace it with new one.

3 Rack and pinion Poor mating of rack with pinion(1) Adjust backlash properly.

By measuring turning torque of gearbox

and sliding resistance of rack, check if rack

and pinion engage uniformly and smoothly

with each other.

(Refer to ªService limitº.)

(2) Keeping rack pulled out all the way so

that all teeth emerge, check teeth for dam-

age.

Even if abnormality is found in either (1) or

(2), replace entire gearbox.

4 Gearbox unit(1) Bend of rack shaft

(2) Bend of cylinder portion

(3) Crack or damage on cast iron portionReplace gearbox with new one.

(4) Wear or damage on rack bushIf free play of rack shaft in radial direction is

out of the specified range, replace gearbox

with new one. (Refer to ªService limitº.)

(5) Wear on input shaft bearingIf free plays of input shaft in radial and axial

directions are out of the specified ranges,

replace gearbox with new one.

(Refer to ªService limitº.)

5 Boot Crack, damage or deterioration Replace.

6 Tie-rod(1) Looseness of ball joint

(2) Bend of tie-rodReplace.

7 Tie-rod end Damage or deterioration on dust seal Replace.

8 Adjusting screw spring Deterioration Replace.

9 Boot clip Deterioration Replace.

10 Sleeve Damage Replace.

11 Pipes(1) Damage to flared surface

(2) Damage to flare nut

(3) Damage to pipe

(4) Damage to O-ringReplace.

17

[W3C0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 813 of 1456

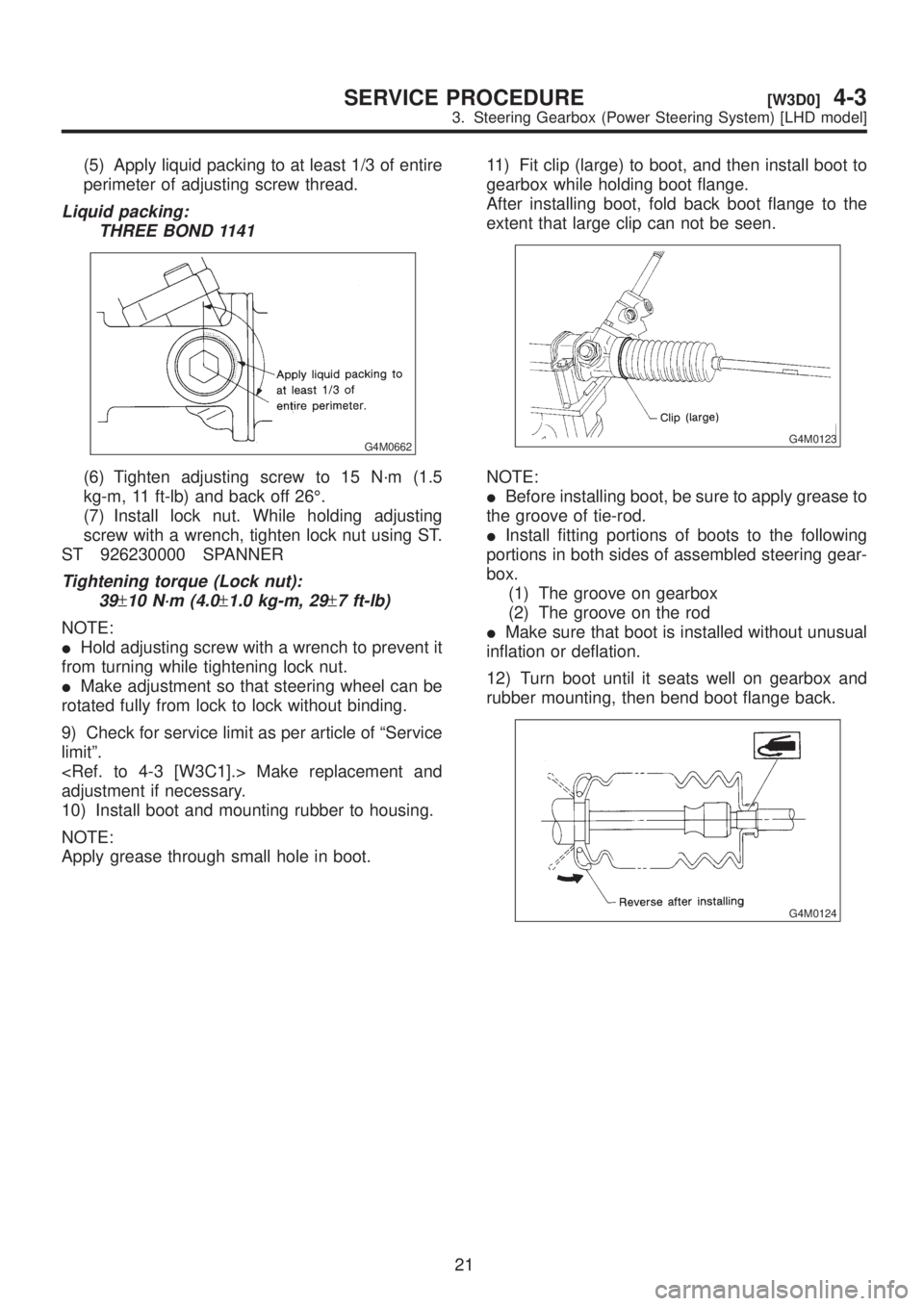

(5) Apply liquid packing to at least 1/3 of entire

perimeter of adjusting screw thread.

Liquid packing:

THREE BOND 1141

G4M0662

(6) Tighten adjusting screw to 15 N´m (1.5

kg-m, 11 ft-lb) and back off 26É.

(7) Install lock nut. While holding adjusting

screw with a wrench, tighten lock nut using ST.

ST 926230000 SPANNER

Tightening torque (Lock nut):

39

±10 N´m (4.0±1.0 kg-m, 29±7 ft-lb)

NOTE:

IHold adjusting screw with a wrench to prevent it

from turning while tightening lock nut.

IMake adjustment so that steering wheel can be

rotated fully from lock to lock without binding.

9) Check for service limit as per article of ªService

limitº.

adjustment if necessary.

10) Install boot and mounting rubber to housing.

NOTE:

Apply grease through small hole in boot.11) Fit clip (large) to boot, and then install boot to

gearbox while holding boot flange.

After installing boot, fold back boot flange to the

extent that large clip can not be seen.

G4M0123

NOTE:

IBefore installing boot, be sure to apply grease to

the groove of tie-rod.

IInstall fitting portions of boots to the following

portions in both sides of assembled steering gear-

box.

(1) The groove on gearbox

(2) The groove on the rod

IMake sure that boot is installed without unusual

inflation or deflation.

12) Turn boot until it seats well on gearbox and

rubber mounting, then bend boot flange back.

G4M0124

21

[W3D0]4-3SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 814 of 1456

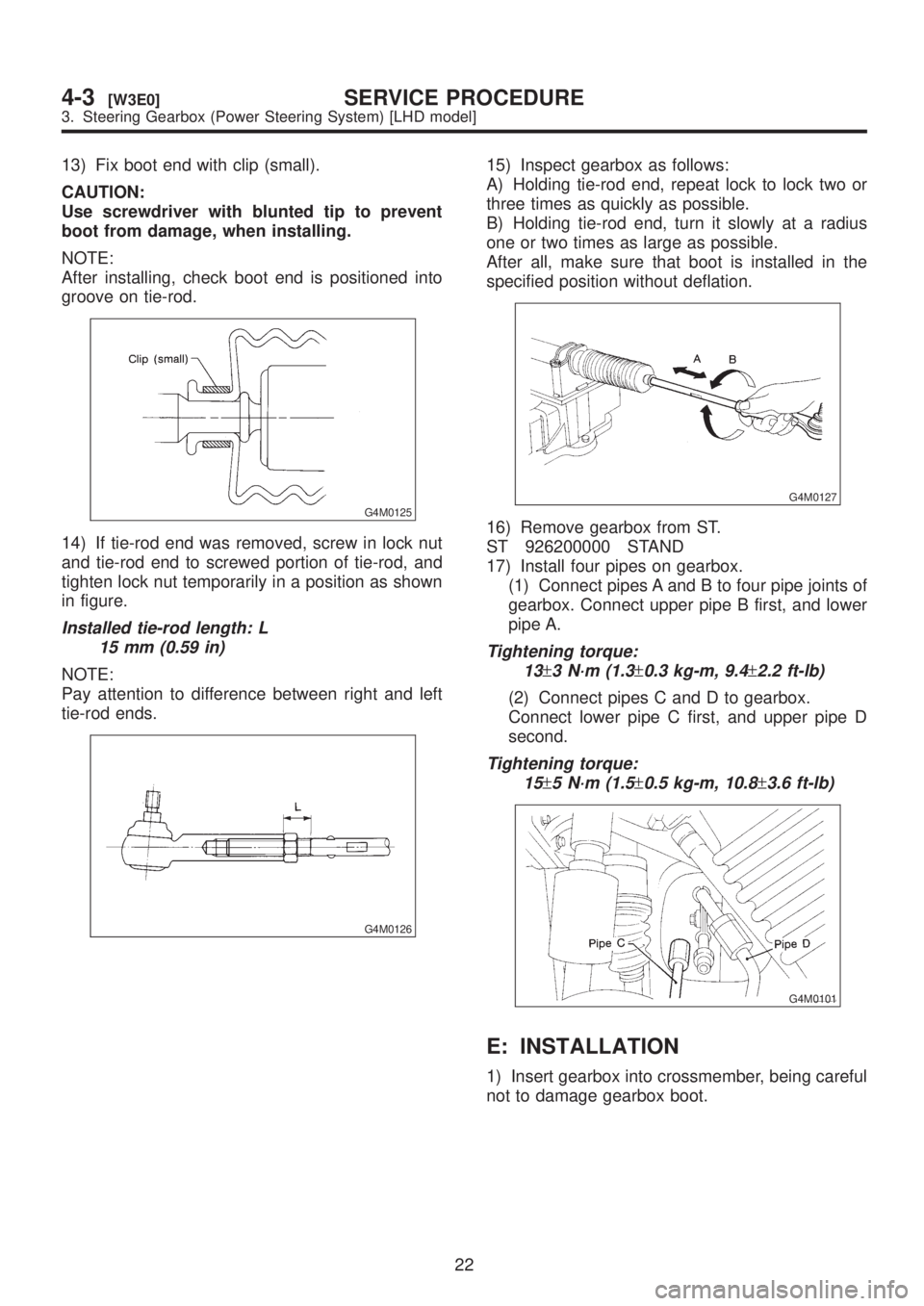

13) Fix boot end with clip (small).

CAUTION:

Use screwdriver with blunted tip to prevent

boot from damage, when installing.

NOTE:

After installing, check boot end is positioned into

groove on tie-rod.

G4M0125

14) If tie-rod end was removed, screw in lock nut

and tie-rod end to screwed portion of tie-rod, and

tighten lock nut temporarily in a position as shown

in figure.

Installed tie-rod length: L

15 mm (0.59 in)

NOTE:

Pay attention to difference between right and left

tie-rod ends.

G4M0126

15) Inspect gearbox as follows:

A) Holding tie-rod end, repeat lock to lock two or

three times as quickly as possible.

B) Holding tie-rod end, turn it slowly at a radius

one or two times as large as possible.

After all, make sure that boot is installed in the

specified position without deflation.

G4M0127

16) Remove gearbox from ST.

ST 926200000 STAND

17) Install four pipes on gearbox.

(1) Connect pipes A and B to four pipe joints of

gearbox. Connect upper pipe B first, and lower

pipe A.

Tightening torque:

13

±3 N´m (1.3±0.3 kg-m, 9.4±2.2 ft-lb)

(2) Connect pipes C and D to gearbox.

Connect lower pipe C first, and upper pipe D

second.

Tightening torque:

15

±5 N´m (1.5±0.5 kg-m, 10.8±3.6 ft-lb)

G4M0101

E: INSTALLATION

1) Insert gearbox into crossmember, being careful

not to damage gearbox boot.

22

4-3[W3E0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 816 of 1456

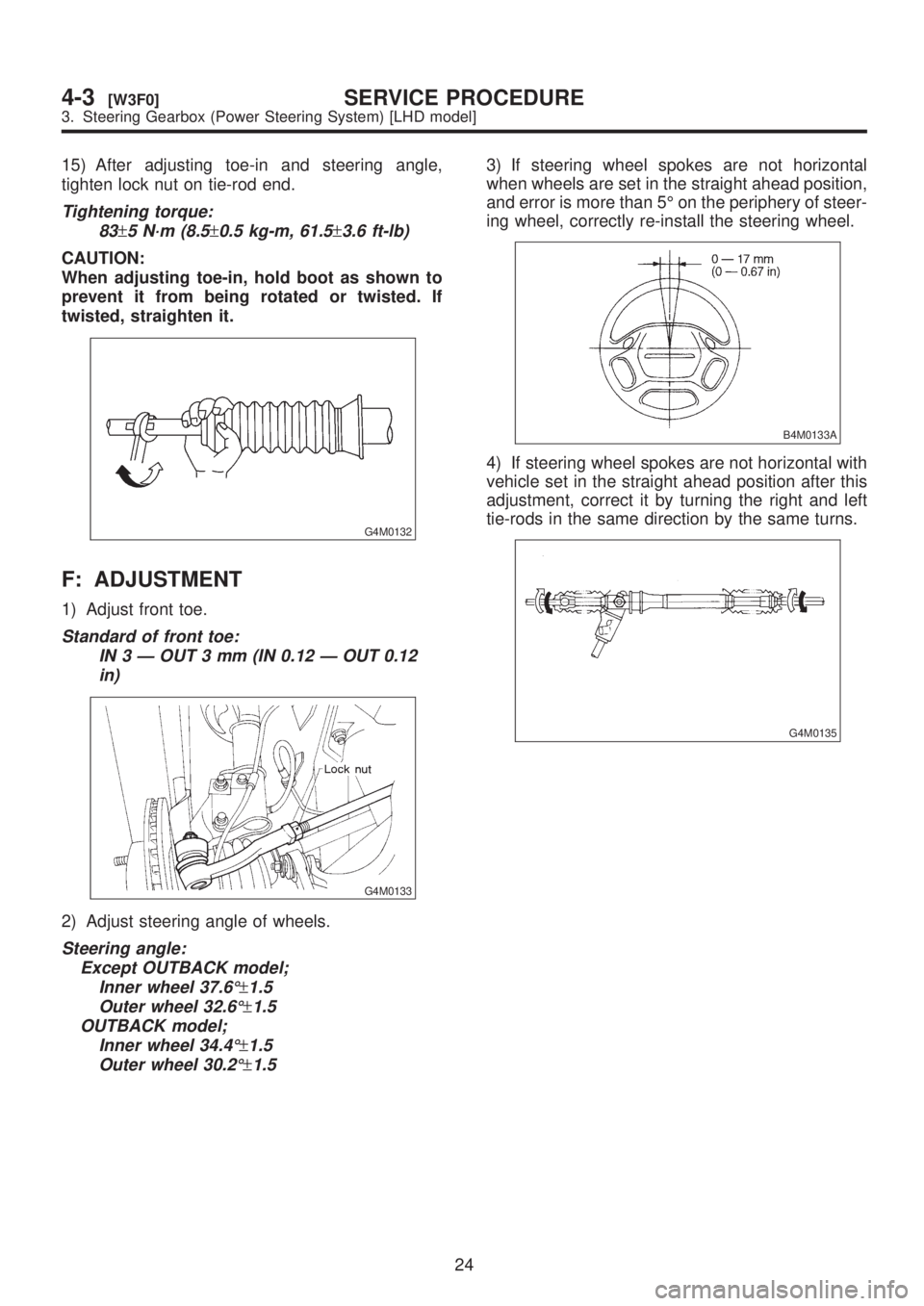

15) After adjusting toe-in and steering angle,

tighten lock nut on tie-rod end.

Tightening torque:

83

±5 N´m (8.5±0.5 kg-m, 61.5±3.6 ft-lb)

CAUTION:

When adjusting toe-in, hold boot as shown to

prevent it from being rotated or twisted. If

twisted, straighten it.

G4M0132

F: ADJUSTMENT

1) Adjust front toe.

Standard of front toe:

IN 3 Ð OUT 3 mm (IN 0.12 Ð OUT 0.12

in)

G4M0133

2) Adjust steering angle of wheels.

Steering angle:

Except OUTBACK model;

Inner wheel 37.6É

±1.5

Outer wheel 32.6É

±1.5

OUTBACK model;

Inner wheel 34.4É

±1.5

Outer wheel 30.2É

±1.5

3) If steering wheel spokes are not horizontal

when wheels are set in the straight ahead position,

and error is more than 5É on the periphery of steer-

ing wheel, correctly re-install the steering wheel.

B4M0133A

4) If steering wheel spokes are not horizontal with

vehicle set in the straight ahead position after this

adjustment, correct it by turning the right and left

tie-rods in the same direction by the same turns.

G4M0135

24

4-3[W3F0]SERVICE PROCEDURE

3. Steering Gearbox (Power Steering System) [LHD model]

Page 817 of 1456

![SUBARU LEGACY 1999 Service Owners Guide 4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model]. <Ref. to 4-3 SUBARU LEGACY 1999 Service Owners Guide 4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model]. <Ref. to 4-3](/img/17/57435/w960_57435-816.png)

4. Steering Gearbox (Power

Steering System) [RHD model]

A: REMOVAL

NOTE:

For disassembly and assembly of gearbox unit,

refer to section Control Valve (Power Steering

Gearbox) [RHD model].

B4M0666B

(1) Dust cover

(2) Valve housing

(3) Y-packing

(4) Ball-bearing

(5) Spacer

(6) Pinion

(7) Shim

(8) Dust seal(9) Clip

(10) Tie-rod end

(11) Clip

(12) Boot

(13) Wire

(14) Tie-rod RH

(15) Lock washer

(16) Sleeve(17) Spring

(18) Adjusting screw

(19) Lock nut

(20) Pipe A

(21) Pipe B

(22) Adapter

(23) Housing ASSY

(24) Back-up washer

25

[W4A0]4-3SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 820 of 1456

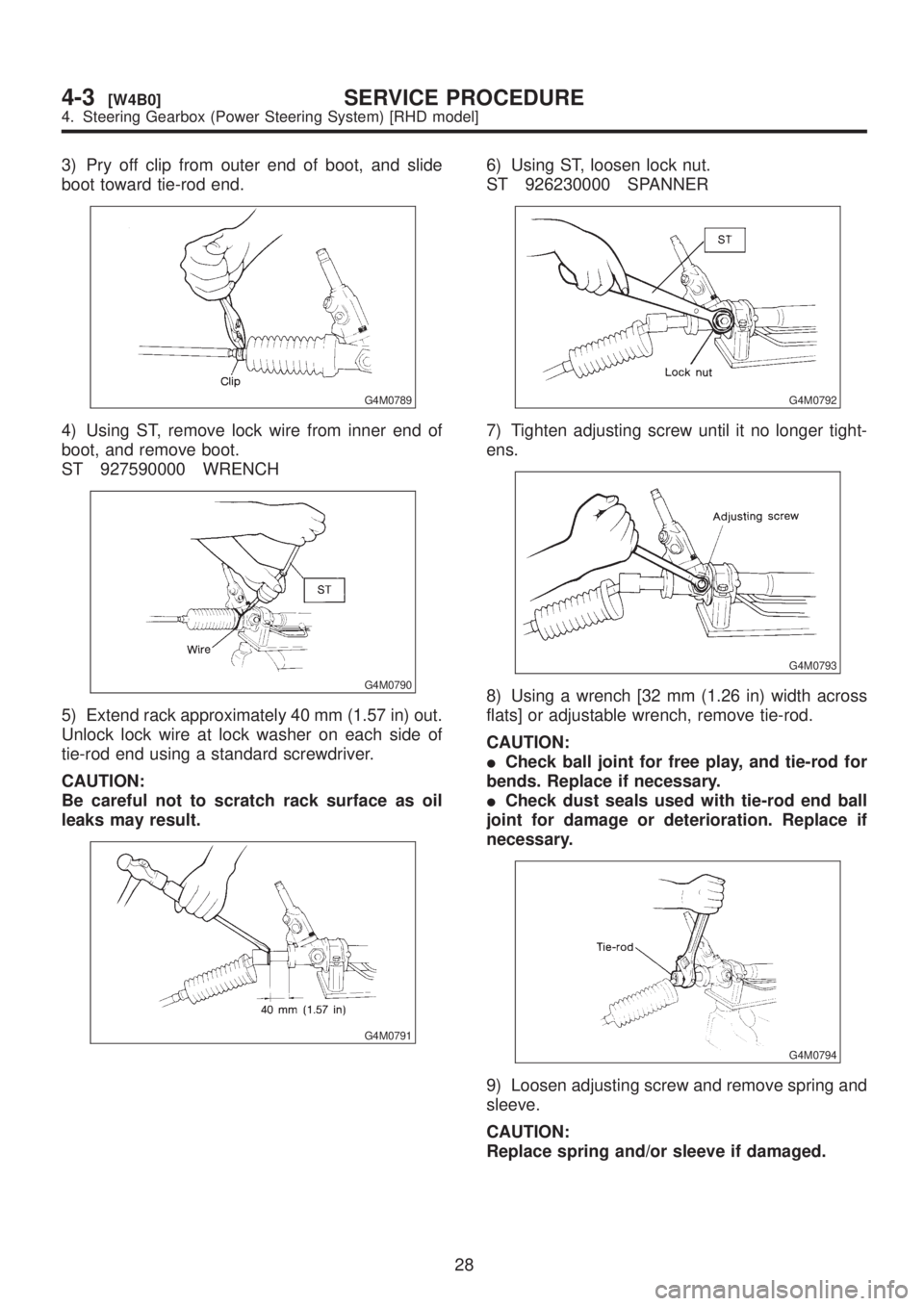

3) Pry off clip from outer end of boot, and slide

boot toward tie-rod end.

G4M0789

4) Using ST, remove lock wire from inner end of

boot, and remove boot.

ST 927590000 WRENCH

G4M0790

5) Extend rack approximately 40 mm (1.57 in) out.

Unlock lock wire at lock washer on each side of

tie-rod end using a standard screwdriver.

CAUTION:

Be careful not to scratch rack surface as oil

leaks may result.

G4M0791

6) Using ST, loosen lock nut.

ST 926230000 SPANNER

G4M0792

7) Tighten adjusting screw until it no longer tight-

ens.

G4M0793

8) Using a wrench [32 mm (1.26 in) width across

flats] or adjustable wrench, remove tie-rod.

CAUTION:

ICheck ball joint for free play, and tie-rod for

bends. Replace if necessary.

ICheck dust seals used with tie-rod end ball

joint for damage or deterioration. Replace if

necessary.

G4M0794

9) Loosen adjusting screw and remove spring and

sleeve.

CAUTION:

Replace spring and/or sleeve if damaged.

28

4-3[W4B0]SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]

Page 821 of 1456

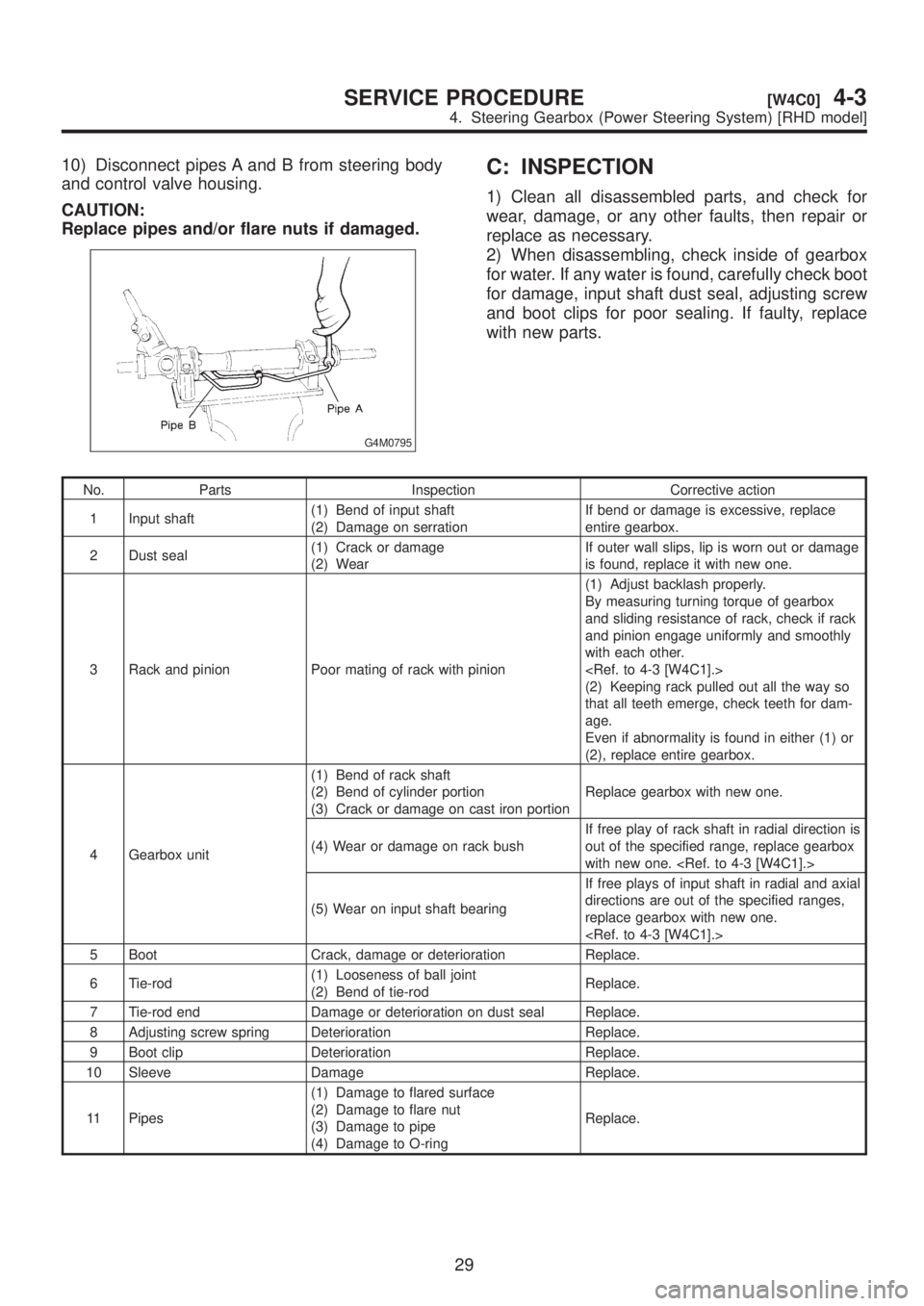

10) Disconnect pipes A and B from steering body

and control valve housing.

CAUTION:

Replace pipes and/or flare nuts if damaged.

G4M0795

C: INSPECTION

1) Clean all disassembled parts, and check for

wear, damage, or any other faults, then repair or

replace as necessary.

2) When disassembling, check inside of gearbox

for water. If any water is found, carefully check boot

for damage, input shaft dust seal, adjusting screw

and boot clips for poor sealing. If faulty, replace

with new parts.

No. Parts Inspection Corrective action

1 Input shaft(1) Bend of input shaft

(2) Damage on serrationIf bend or damage is excessive, replace

entire gearbox.

2 Dust seal(1) Crack or damage

(2) WearIf outer wall slips, lip is worn out or damage

is found, replace it with new one.

3 Rack and pinion Poor mating of rack with pinion(1) Adjust backlash properly.

By measuring turning torque of gearbox

and sliding resistance of rack, check if rack

and pinion engage uniformly and smoothly

with each other.

(2) Keeping rack pulled out all the way so

that all teeth emerge, check teeth for dam-

age.

Even if abnormality is found in either (1) or

(2), replace entire gearbox.

4 Gearbox unit(1) Bend of rack shaft

(2) Bend of cylinder portion

(3) Crack or damage on cast iron portionReplace gearbox with new one.

(4) Wear or damage on rack bushIf free play of rack shaft in radial direction is

out of the specified range, replace gearbox

with new one.

(5) Wear on input shaft bearingIf free plays of input shaft in radial and axial

directions are out of the specified ranges,

replace gearbox with new one.

5 Boot Crack, damage or deterioration Replace.

6 Tie-rod(1) Looseness of ball joint

(2) Bend of tie-rodReplace.

7 Tie-rod end Damage or deterioration on dust seal Replace.

8 Adjusting screw spring Deterioration Replace.

9 Boot clip Deterioration Replace.

10 Sleeve Damage Replace.

11 Pipes(1) Damage to flared surface

(2) Damage to flare nut

(3) Damage to pipe

(4) Damage to O-ringReplace.

29

[W4C0]4-3SERVICE PROCEDURE

4. Steering Gearbox (Power Steering System) [RHD model]