SUBARU LEGACY 1999 Service Repair Manual

LEGACY 1999

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57435/w960_57435-0.png

SUBARU LEGACY 1999 Service Repair Manual

Trending: checking oil, clock, oil level, headrest, boot, jump cable, window

Page 971 of 1456

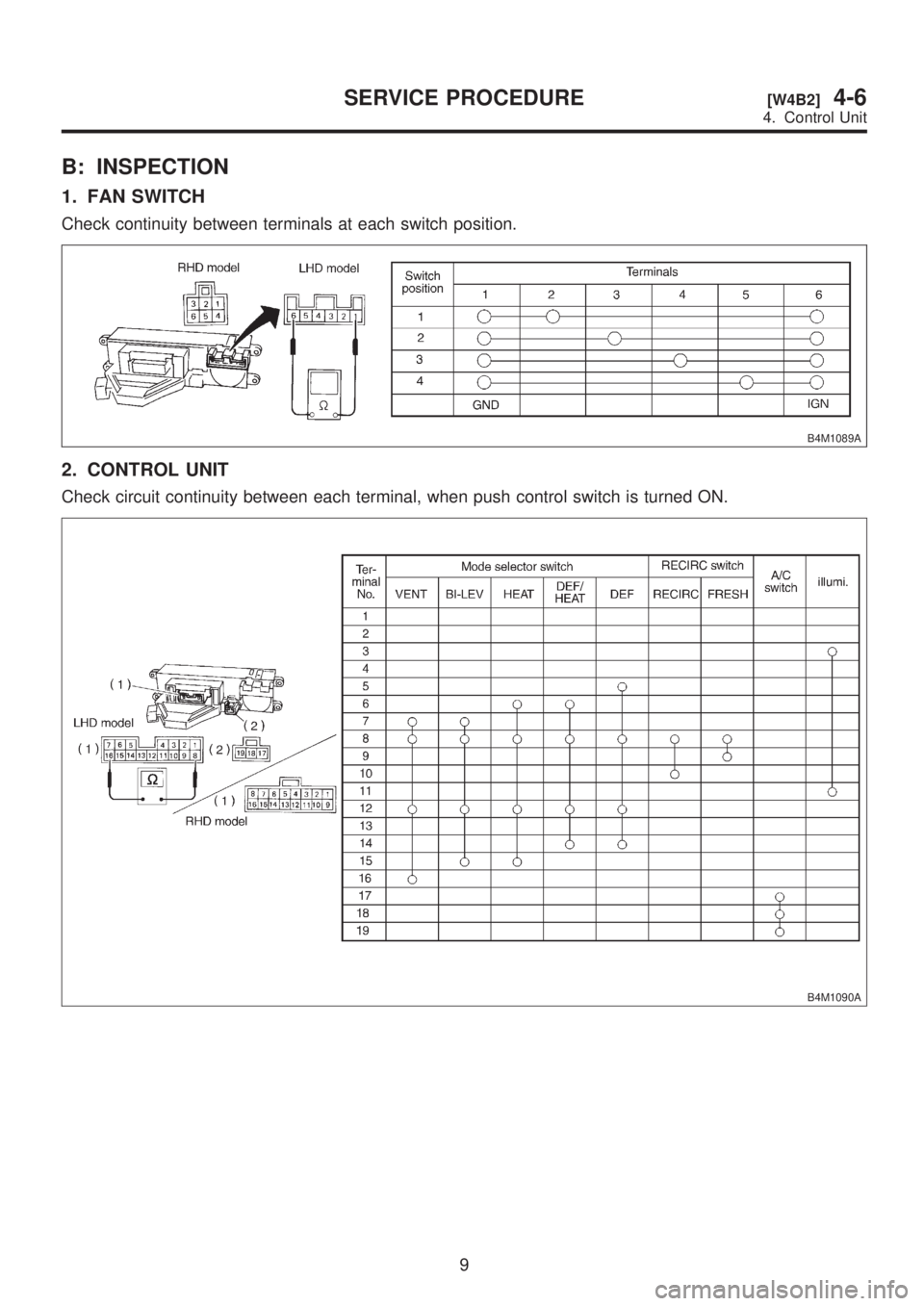

B: INSPECTION

1. FAN SWITCH

Check continuity between terminals at each switch position.

B4M1089A

2. CONTROL UNIT

Check circuit continuity between each terminal, when push control switch is turned ON.

B4M1090A

9

[W4B2]4-6SERVICE PROCEDURE

4. Control Unit

Page 972 of 1456

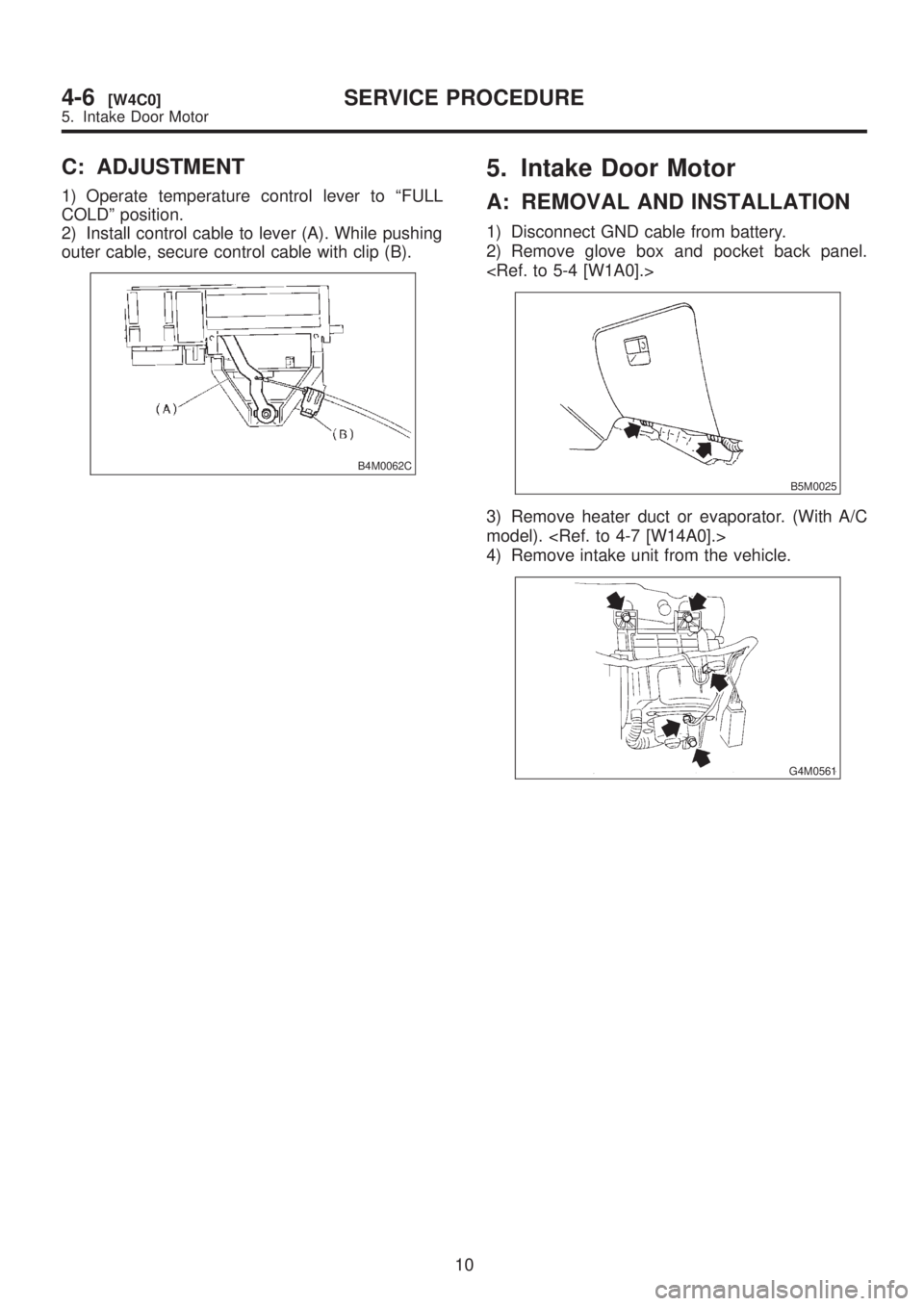

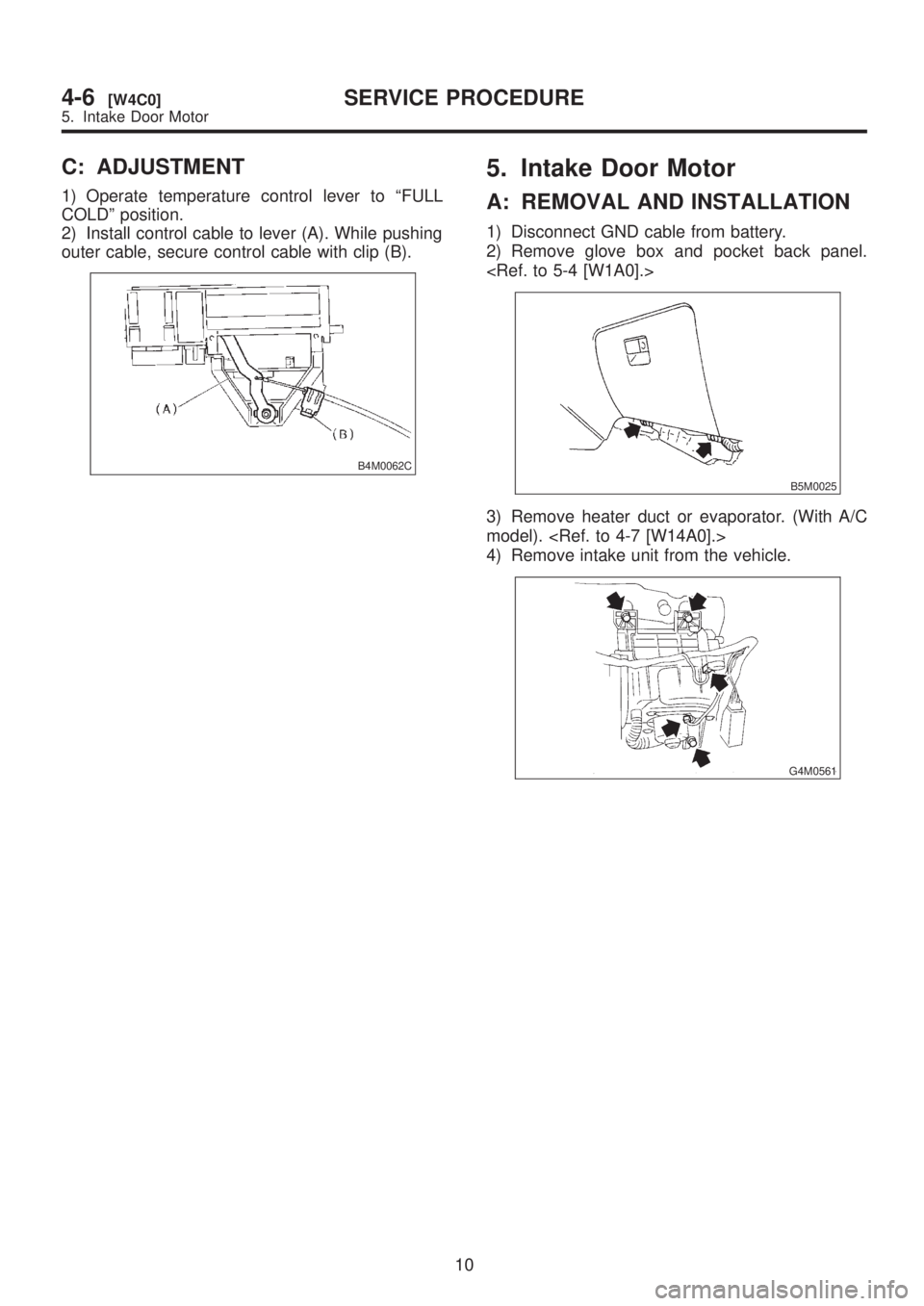

C: ADJUSTMENT

1) Operate temperature control lever to ªFULL

COLDº position.

2) Install control cable to lever (A). While pushing

outer cable, secure control cable with clip (B).

B4M0062C

5. Intake Door Motor

A: REMOVAL AND INSTALLATION

1) Disconnect GND cable from battery.

2) Remove glove box and pocket back panel.

B5M0025

3) Remove heater duct or evaporator. (With A/C

model).

4) Remove intake unit from the vehicle.

G4M0561

10

4-6[W4C0]SERVICE PROCEDURE

5. Intake Door Motor

Page 973 of 1456

C: ADJUSTMENT

1) Operate temperature control lever to ªFULL

COLDº position.

2) Install control cable to lever (A). While pushing

outer cable, secure control cable with clip (B).

B4M0062C

5. Intake Door Motor

A: REMOVAL AND INSTALLATION

1) Disconnect GND cable from battery.

2) Remove glove box and pocket back panel.

B5M0025

3) Remove heater duct or evaporator. (With A/C

model).

4) Remove intake unit from the vehicle.

G4M0561

10

4-6[W4C0]SERVICE PROCEDURE

5. Intake Door Motor

Page 974 of 1456

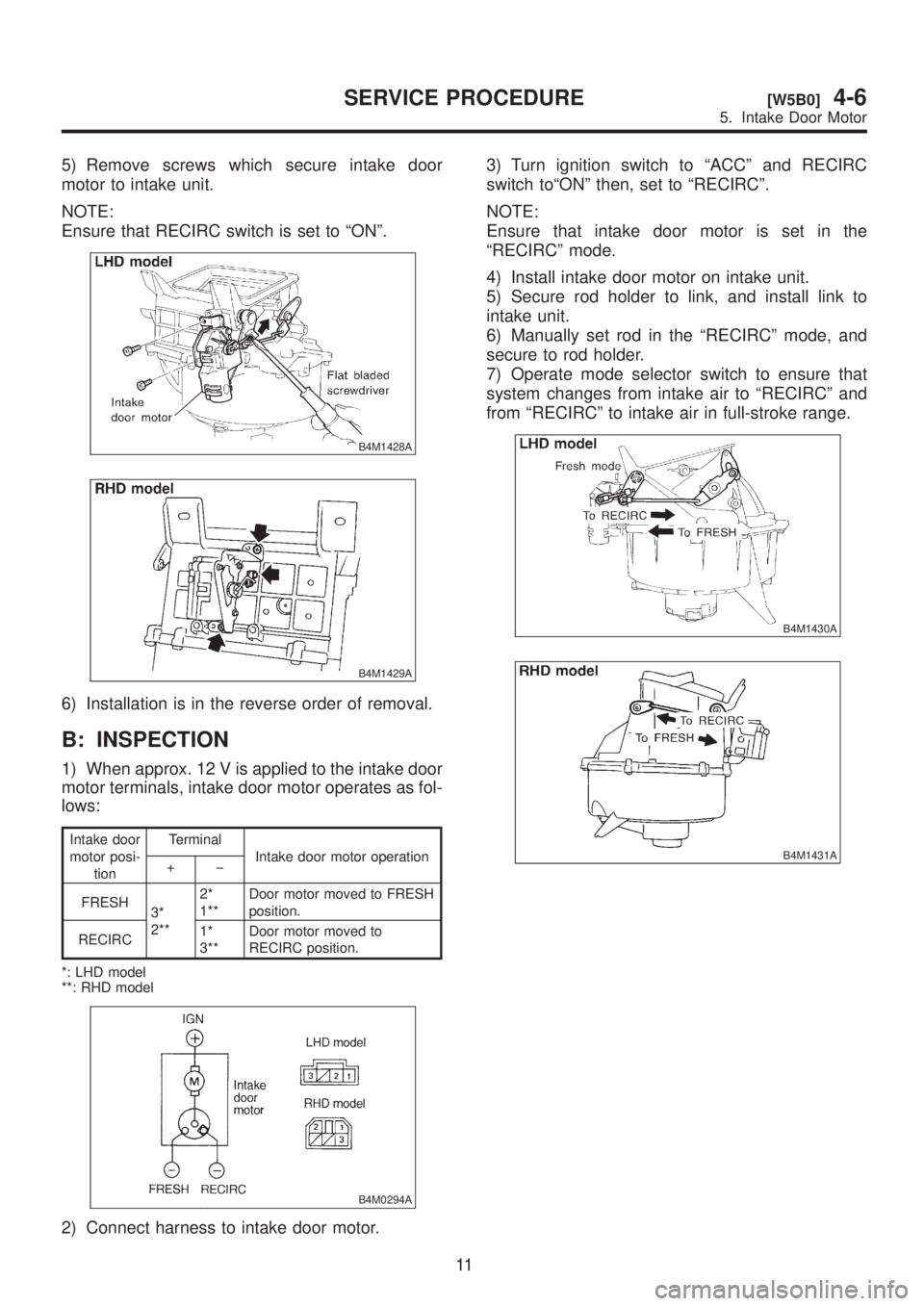

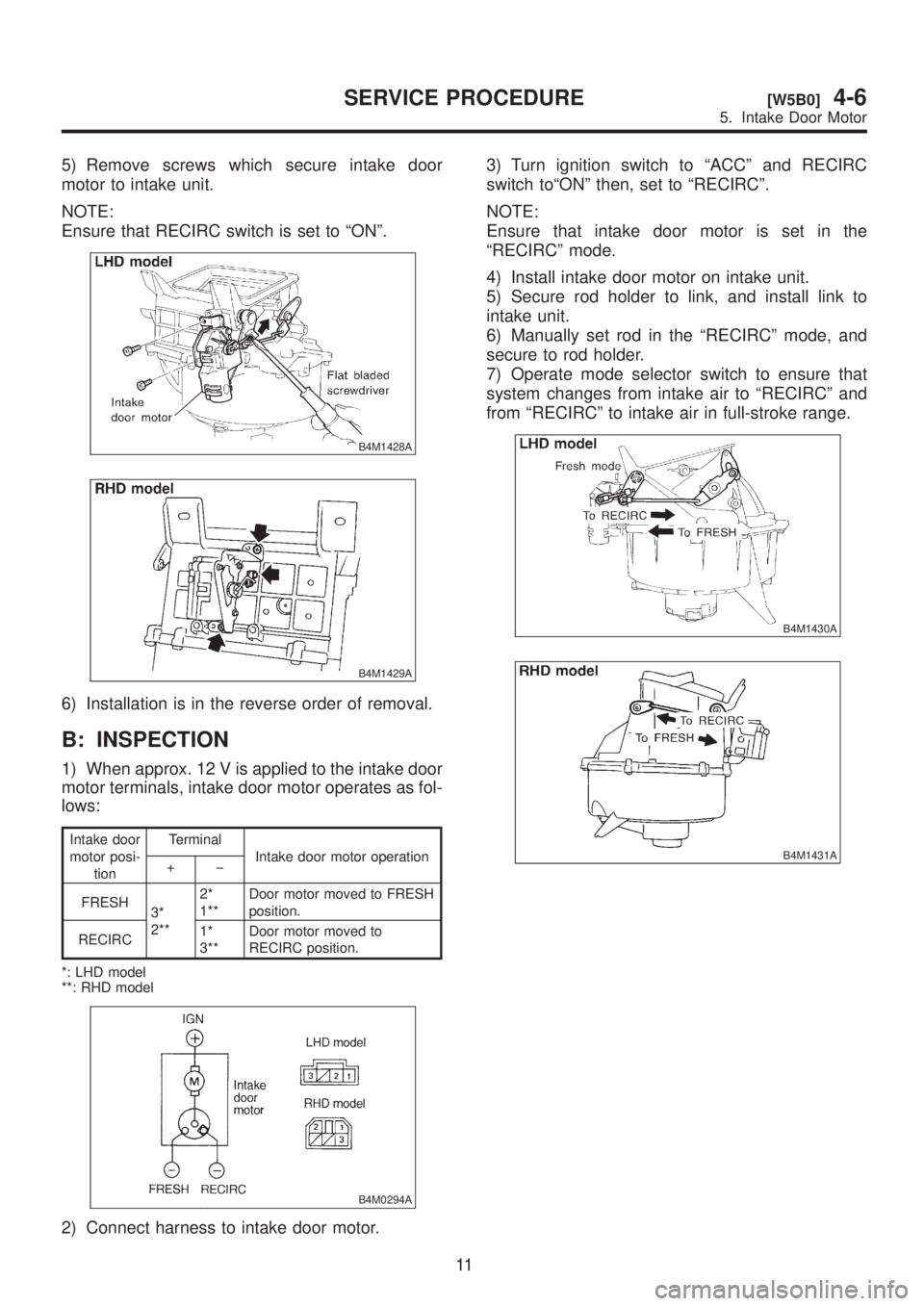

5) Remove screws which secure intake door

motor to intake unit.

NOTE:

Ensure that RECIRC switch is set to ªONº.

B4M1428A

B4M1429A

6) Installation is in the reverse order of removal.

B: INSPECTION

1) When approx. 12 V is applied to the intake door

motor terminals, intake door motor operates as fol-

lows:

Intake door

motor posi-

tionTerminal

Intake door motor operation

+þ

FRESH

3*

2**2*

1**Door motor moved to FRESH

position.

RECIRC1*

3**Door motor moved to

RECIRC position.

*: LHD model

**: RHD model

B4M0294A

2) Connect harness to intake door motor.3) Turn ignition switch to ªACCº and RECIRC

switch toªONº then, set to ªRECIRCº.

NOTE:

Ensure that intake door motor is set in the

ªRECIRCº mode.

4) Install intake door motor on intake unit.

5) Secure rod holder to link, and install link to

intake unit.

6) Manually set rod in the ªRECIRCº mode, and

secure to rod holder.

7) Operate mode selector switch to ensure that

system changes from intake air to ªRECIRCº and

from ªRECIRCº to intake air in full-stroke range.

B4M1430A

B4M1431A

11

[W5B0]4-6SERVICE PROCEDURE

5. Intake Door Motor

Page 975 of 1456

6. Mode Door Motor

A: REMOVAL AND INSTALLATION

1) Remove instrument panel.

2) Remove mode door motor.

B4M0063

3) Installation is in the reverse order of removal.

B: INSPECTION

1) When approx. 12 V is applied to the mode door motor terminals, mode door motor operates as follows:

B4M1092A

2) Check mode door motor position switch.

When the mode door motor is moved to each mode position by using the mode selector switch, check if

continuity exists between each terminal as follows:

Mode selector switch positions Terminal No.

VENT 8 or 7

9 (GND) BI-LEV 6 or 7

HEAT 5 or 6

DEF/HEAT 4 or 5

DEF 3or4

12

4-6[W6A0]SERVICE PROCEDURE

6. Mode Door Motor

Page 976 of 1456

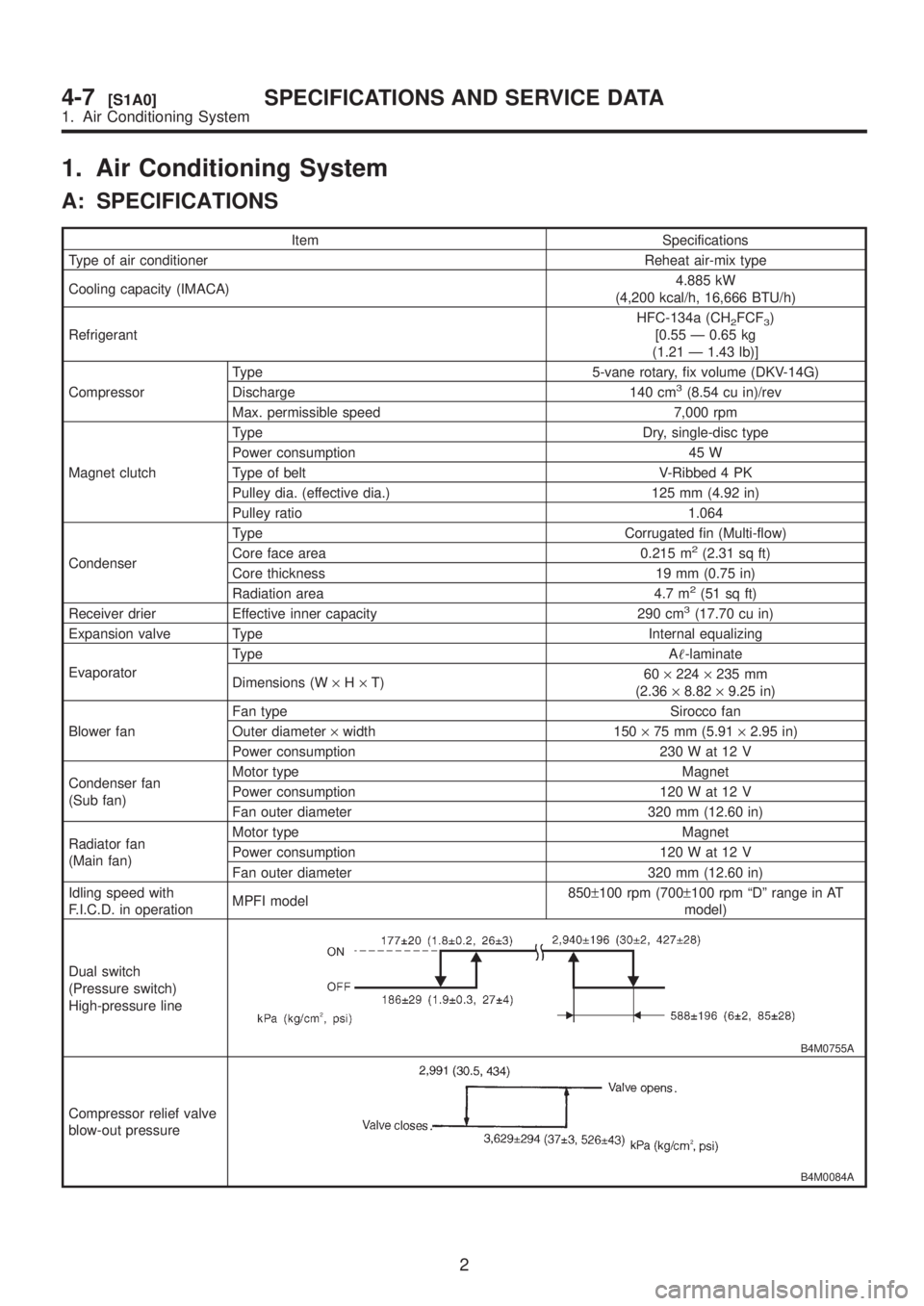

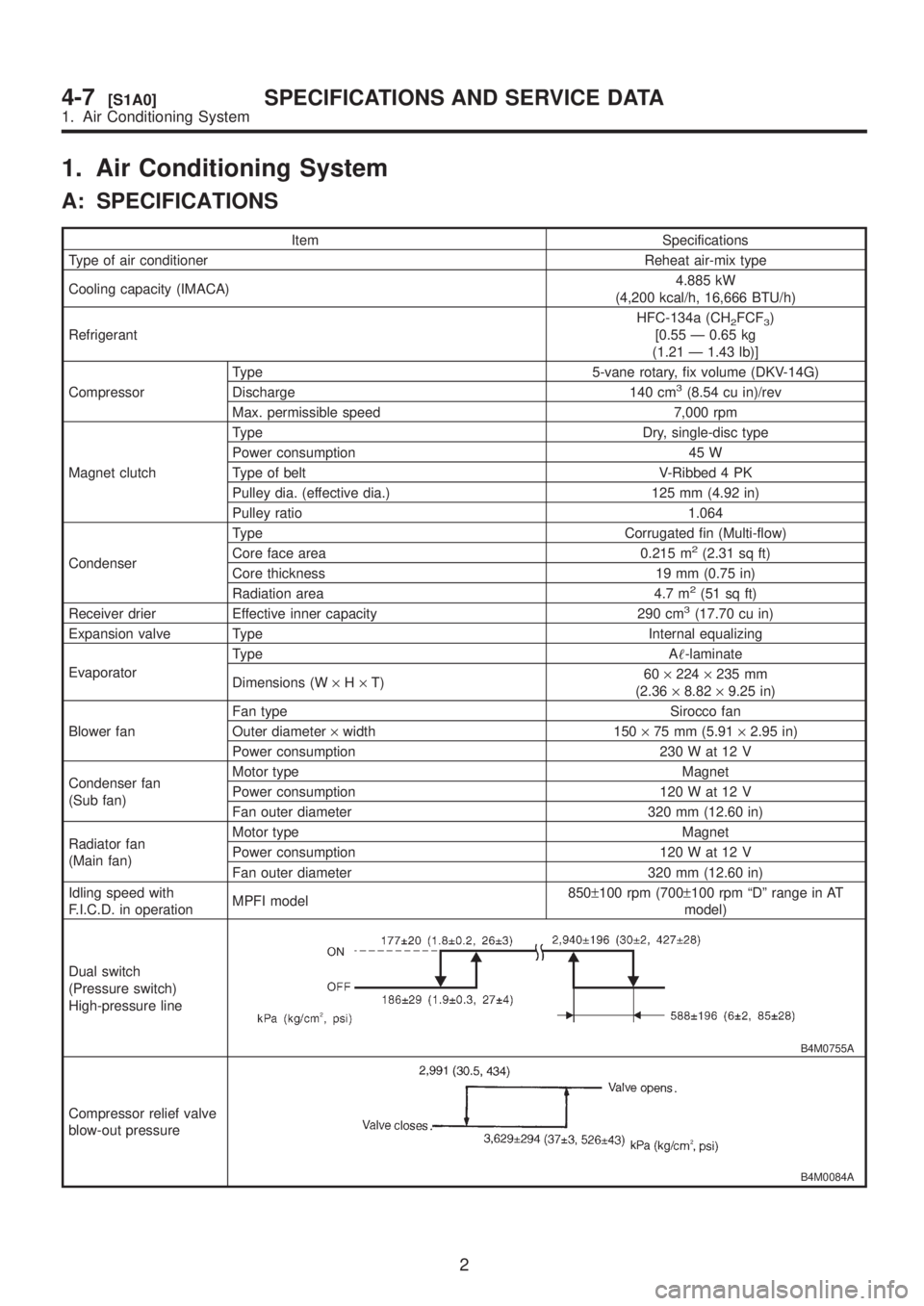

1. Air Conditioning System

A: SPECIFICATIONS

Item Specifications

Type of air conditioner Reheat air-mix type

Cooling capacity (IMACA)4.885 kW

(4,200 kcal/h, 16,666 BTU/h)

RefrigerantHFC-134a (CH

2FCF3)

[0.55 Ð 0.65 kg

(1.21 Ð 1.43 lb)]

CompressorType 5-vane rotary, fix volume (DKV-14G)

Discharge 140 cm

3(8.54 cu in)/rev

Max. permissible speed 7,000 rpm

Magnet clutchType Dry, single-disc type

Power consumption 45 W

Type of belt V-Ribbed 4 PK

Pulley dia. (effective dia.) 125 mm (4.92 in)

Pulley ratio 1.064

CondenserType Corrugated fin (Multi-flow)

Core face area 0.215 m

2(2.31 sq ft)

Core thickness 19 mm (0.75 in)

Radiation area 4.7 m

2(51 sq ft)

Receiver drier Effective inner capacity 290 cm3(17.70 cu in)

Expansion valve Type Internal equalizing

EvaporatorType A-laminate

Dimensions (W´H´T)60´224´235 mm

(2.36´8.82´9.25 in)

Blower fanFan type Sirocco fan

Outer diameter´width 150´75 mm (5.91´2.95 in)

Power consumption 230 W at 12 V

Condenser fan

(Sub fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Radiator fan

(Main fan)Motor type Magnet

Power consumption 120 W at 12 V

Fan outer diameter 320 mm (12.60 in)

Idling speed with

F.I.C.D. in operationMPFI model850±100 rpm (700±100 rpm ªDº range in AT

model)

Dual switch

(Pressure switch)

High-pressure line

B4M0755A

Compressor relief valve

blow-out pressure

B4M0084A

2

4-7[S1A0]SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System

Page 977 of 1456

Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System

Page 978 of 1456

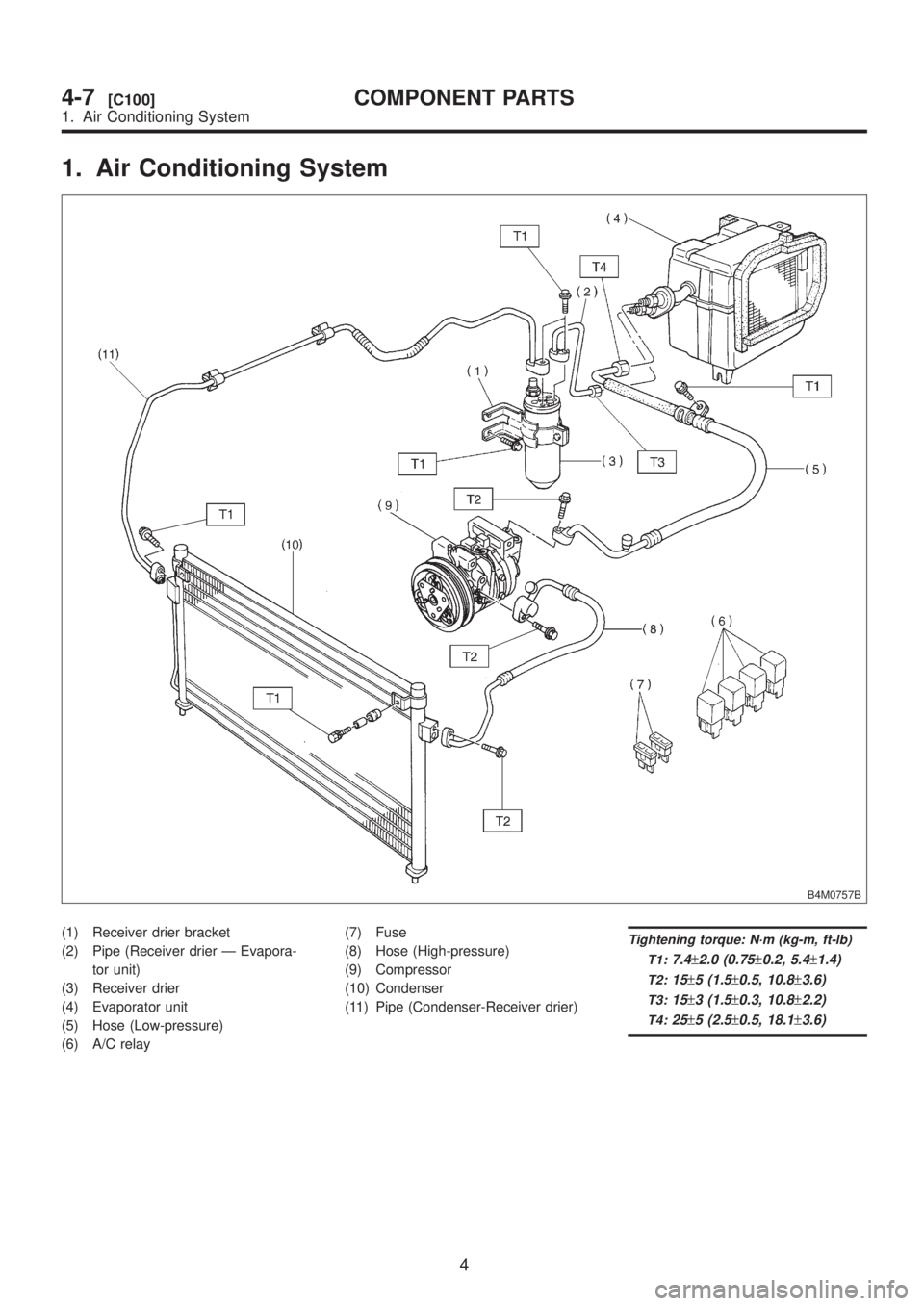

1. Air Conditioning System

B4M0757B

(1) Receiver drier bracket

(2) Pipe (Receiver drier Ð Evapora-

tor unit)

(3) Receiver drier

(4) Evaporator unit

(5) Hose (Low-pressure)

(6) A/C relay(7) Fuse

(8) Hose (High-pressure)

(9) Compressor

(10) Condenser

(11) Pipe (Condenser-Receiver drier)Tightening torque: N´m (kg-m, ft-lb)

T1:

7.4±2.0 (0.75±0.2, 5.4±1.4)

T2:15±5 (1.5±0.5, 10.8±3.6)

T3:15±3 (1.5±0.3, 10.8±2.2)

T4:25±5 (2.5±0.5, 18.1±3.6)

4

4-7[C100]COMPONENT PARTS

1. Air Conditioning System

Page 979 of 1456

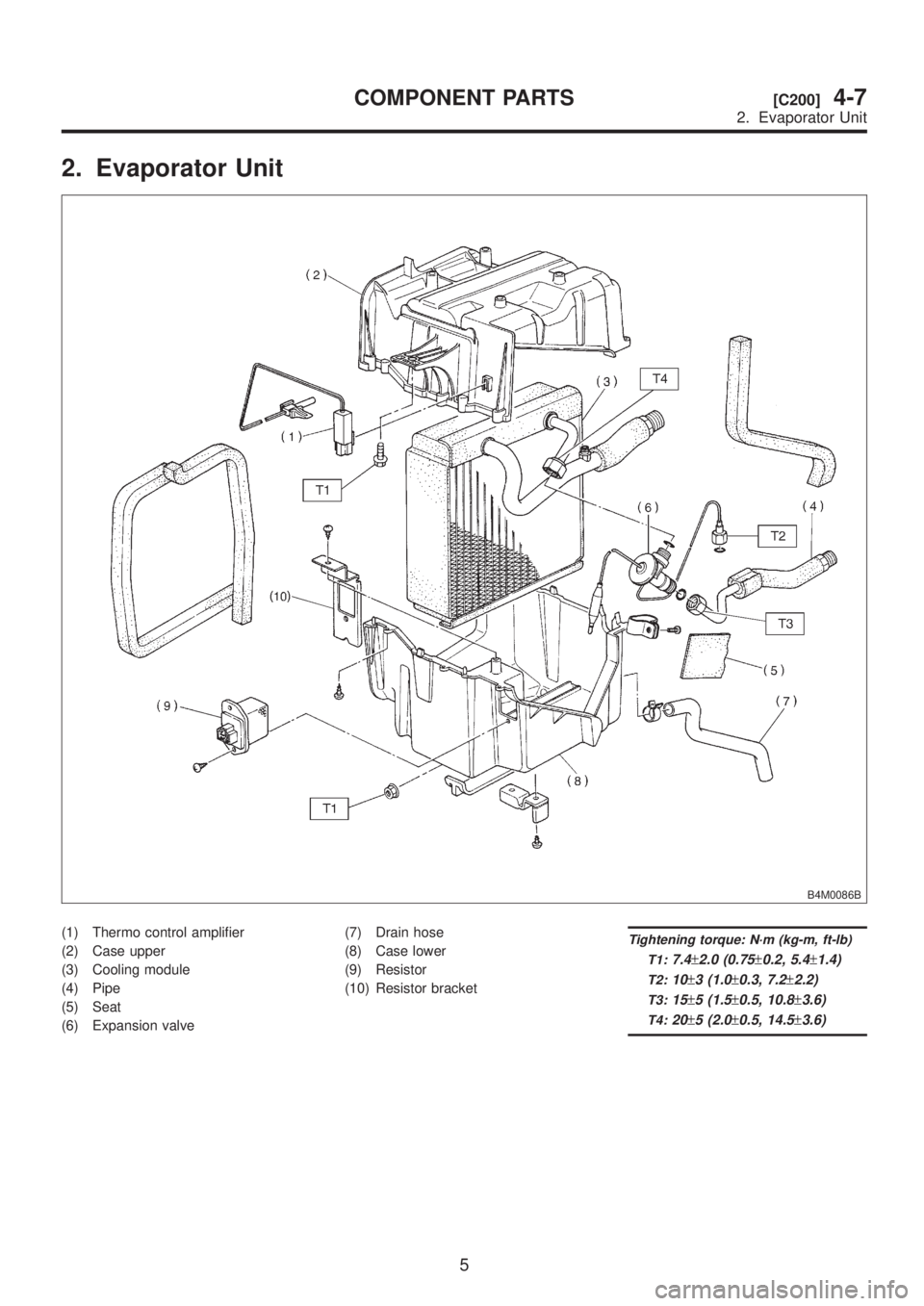

2. Evaporator Unit

B4M0086B

(1) Thermo control amplifier

(2) Case upper

(3) Cooling module

(4) Pipe

(5) Seat

(6) Expansion valve(7) Drain hose

(8) Case lower

(9) Resistor

(10) Resistor bracketTightening torque: N´m (kg-m, ft-lb)

T1:

7.4±2.0 (0.75±0.2, 5.4±1.4)

T2:10±3 (1.0±0.3, 7.2±2.2)

T3:15±5 (1.5±0.5, 10.8±3.6)

T4:20±5 (2.0±0.5, 14.5±3.6)

5

[C200]4-7COMPONENT PARTS

2. Evaporator Unit

Page 980 of 1456

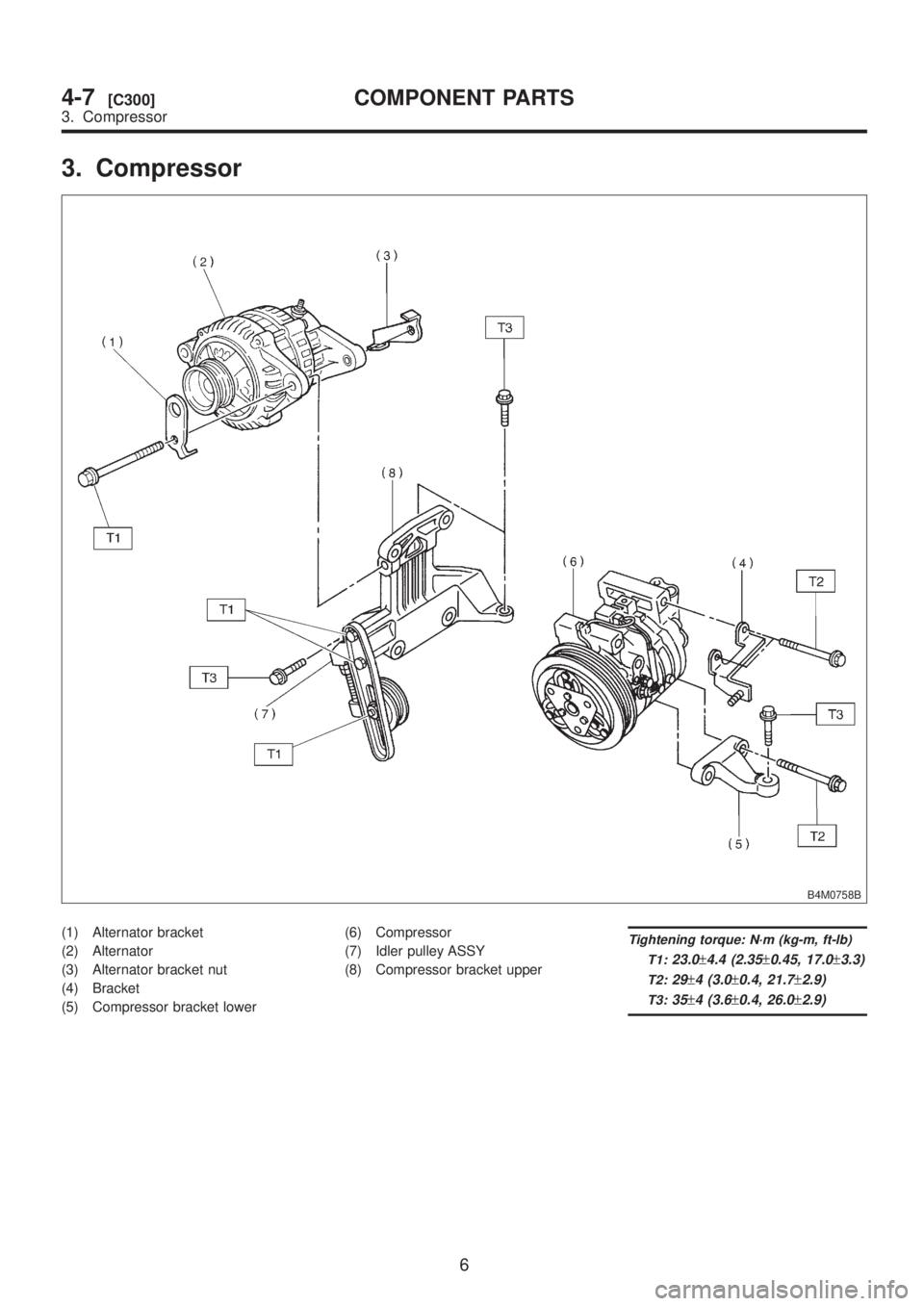

3. Compressor

B4M0758B

(1) Alternator bracket

(2) Alternator

(3) Alternator bracket nut

(4) Bracket

(5) Compressor bracket lower(6) Compressor

(7) Idler pulley ASSY

(8) Compressor bracket upperTightening torque: N´m (kg-m, ft-lb)

T1:

23.0±4.4 (2.35±0.45, 17.0±3.3)

T2:29±4 (3.0±0.4, 21.7±2.9)

T3:35±4 (3.6±0.4, 26.0±2.9)

6

4-7[C300]COMPONENT PARTS

3. Compressor

Trending: fuel tank capacity, jump start, fuel cap release, Wheel bearing, steering, fuse chart, O2 sensor

![SUBARU LEGACY 1999 Service Repair Manual 6. Mode Door Motor

A: REMOVAL AND INSTALLATION

1) Remove instrument panel. <Ref. to 5-4 [W1A0].>

2) Remove mode door motor.

B4M0063

3) Installation is in the reverse order of removal.

B: INSPECTION

1) SUBARU LEGACY 1999 Service Repair Manual 6. Mode Door Motor

A: REMOVAL AND INSTALLATION

1) Remove instrument panel. <Ref. to 5-4 [W1A0].>

2) Remove mode door motor.

B4M0063

3) Installation is in the reverse order of removal.

B: INSPECTION

1)](/img/17/57435/w960_57435-974.png)

![SUBARU LEGACY 1999 Service Repair Manual Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System SUBARU LEGACY 1999 Service Repair Manual Item Specifications

Thermo control amplifier

working temperature

(Evaporator outlet air)

B4M0756B

3

[S1A0]4-7SPECIFICATIONS AND SERVICE DATA

1. Air Conditioning System](/img/17/57435/w960_57435-976.png)