SUBARU LEGACY 1999 Service Repair Manual

LEGACY 1999

SUBARU

SUBARU

https://www.carmanualsonline.info/img/17/57435/w960_57435-0.png

SUBARU LEGACY 1999 Service Repair Manual

Trending: coolant temperature, relay, fog light, replacement, rear view mirror, rear suspension, traction control

Page 1011 of 1456

![SUBARU LEGACY 1999 Service Repair Manual 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA SUBARU LEGACY 1999 Service Repair Manual 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA](/img/17/57435/w960_57435-1010.png)

16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system.

3) Remove low-pressure hose:

CAUTION:

With the following cautions, replace flexible

hoses with new ones if they are damaged or

swollen.

IThe flexible hoses should be free from twists

and tension after they have been connected.

IThe flexible hoses must not be bent or

twisted forcibly.

(1) Remove hose attaching bolts.

CAUTION:

Plug the opening to prevent foreign matter

from getting in.

(2) Disconnect the connector at evaporator

unit.

B4M0103

4) Remove high-pressure hose:

CAUTION:

With the following cautions, replace flexible

hoses with new ones if they are damaged or

swollen.

IThe flexible hoses should be free from twists

and tension after they have been connected.

IThe flexible hoses must not be bent or

twisted forcibly.

(1) Disconnect hose attaching bolt (compressor

side).

(2) Disconnect hose attaching bolt (condenser

side).

CAUTION:

Plug the opening to prevent foreign matter

from getting in.

B4M0764

5) Installation is in the reverse order of removal.

6) Charge refrigerant.

31

[W16A0]4-7SERVICE PROCEDURE

16. Flexible Hose

Page 1012 of 1456

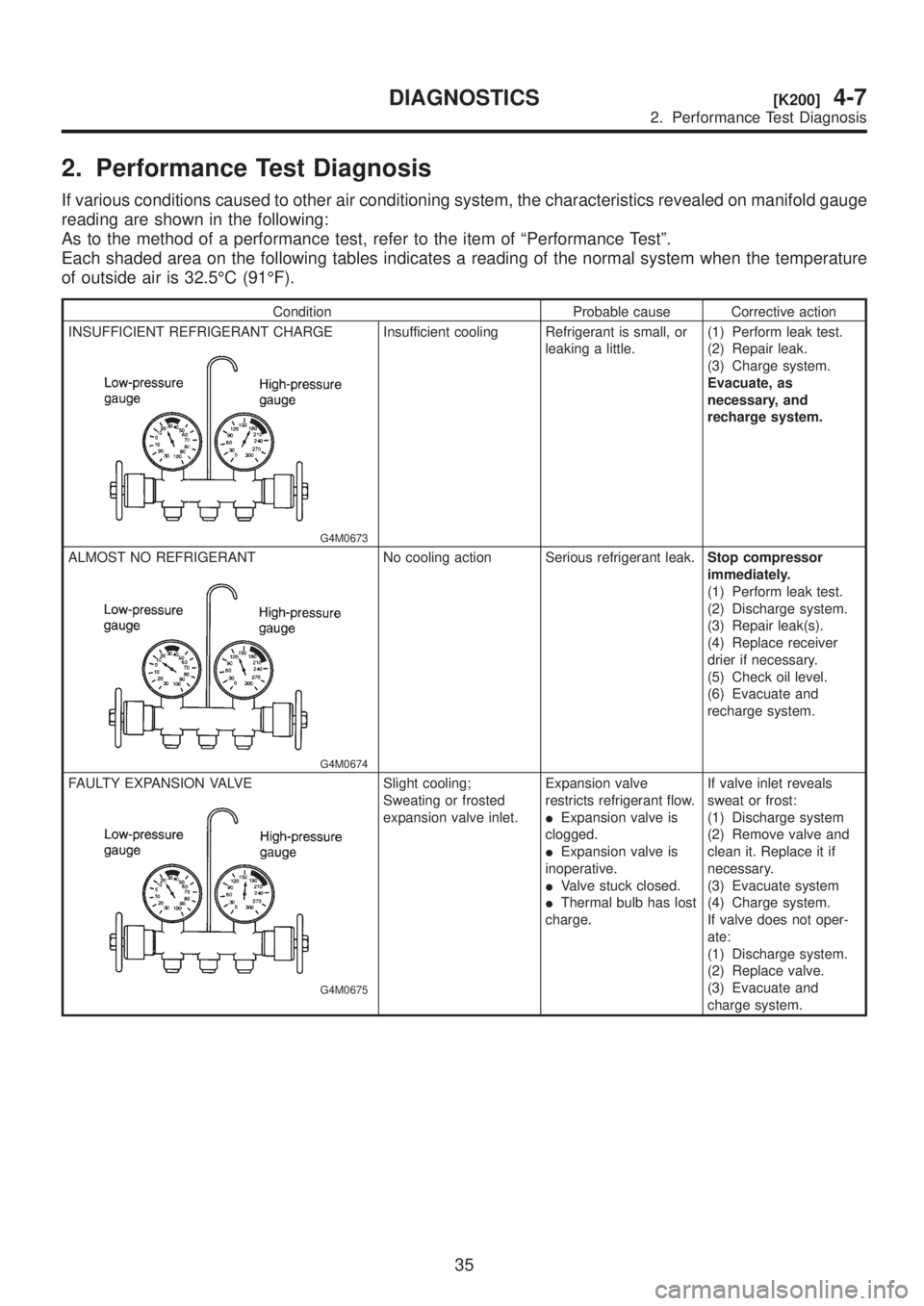

17. Relay and Fuse

A: LOCATION

Relays used with A/C system are located as shown

in figure.

IA/C relay

IMain fan (radiator fan) relay

ISub fan (condenser fan) relay

ISub fan (condenser fan) water temperature

relay

IFuses (10 A and 20 A)

G4M0649

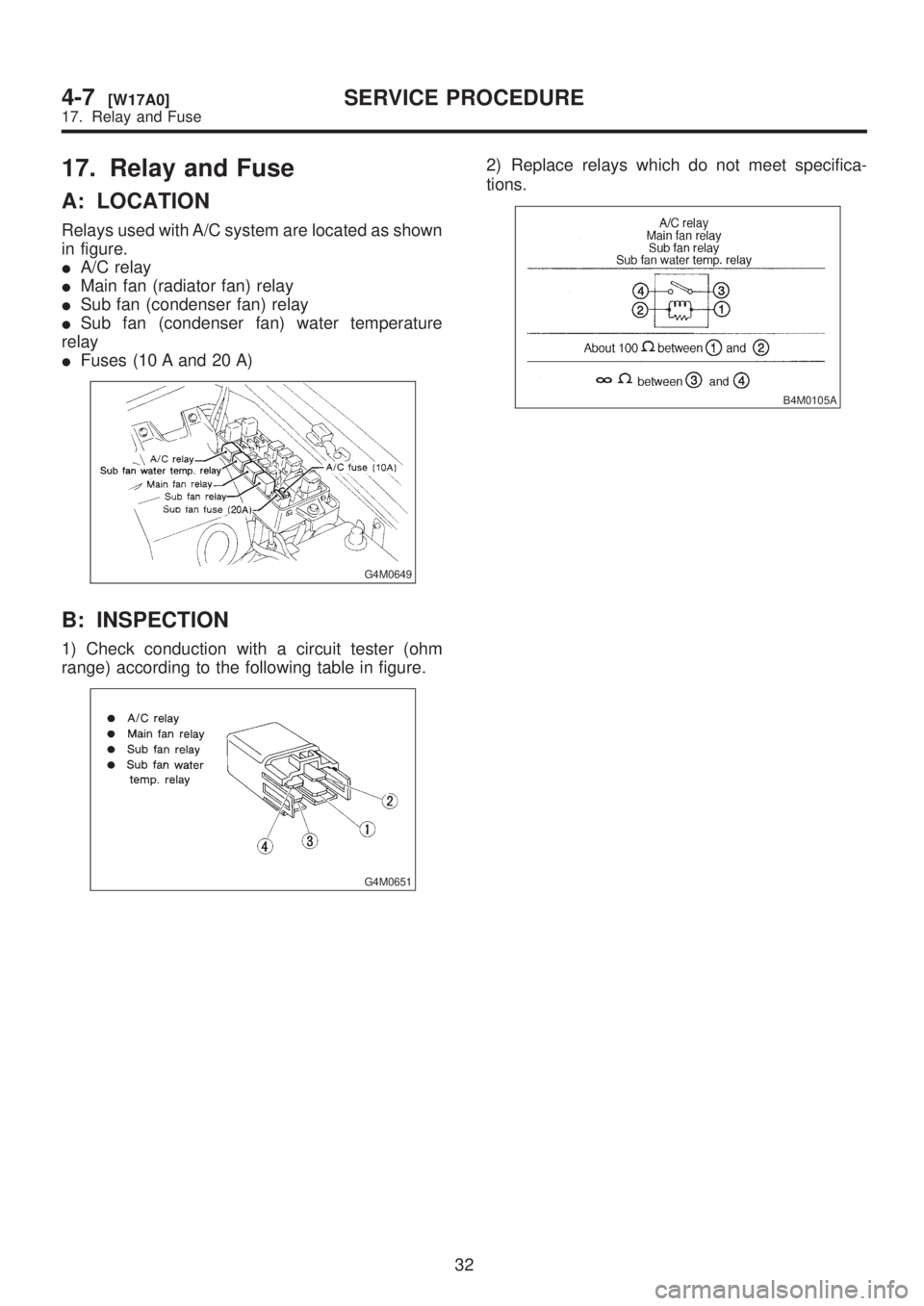

B: INSPECTION

1) Check conduction with a circuit tester (ohm

range) according to the following table in figure.

G4M0651

2) Replace relays which do not meet specifica-

tions.

B4M0105A

32

4-7[W17A0]SERVICE PROCEDURE

17. Relay and Fuse

Page 1013 of 1456

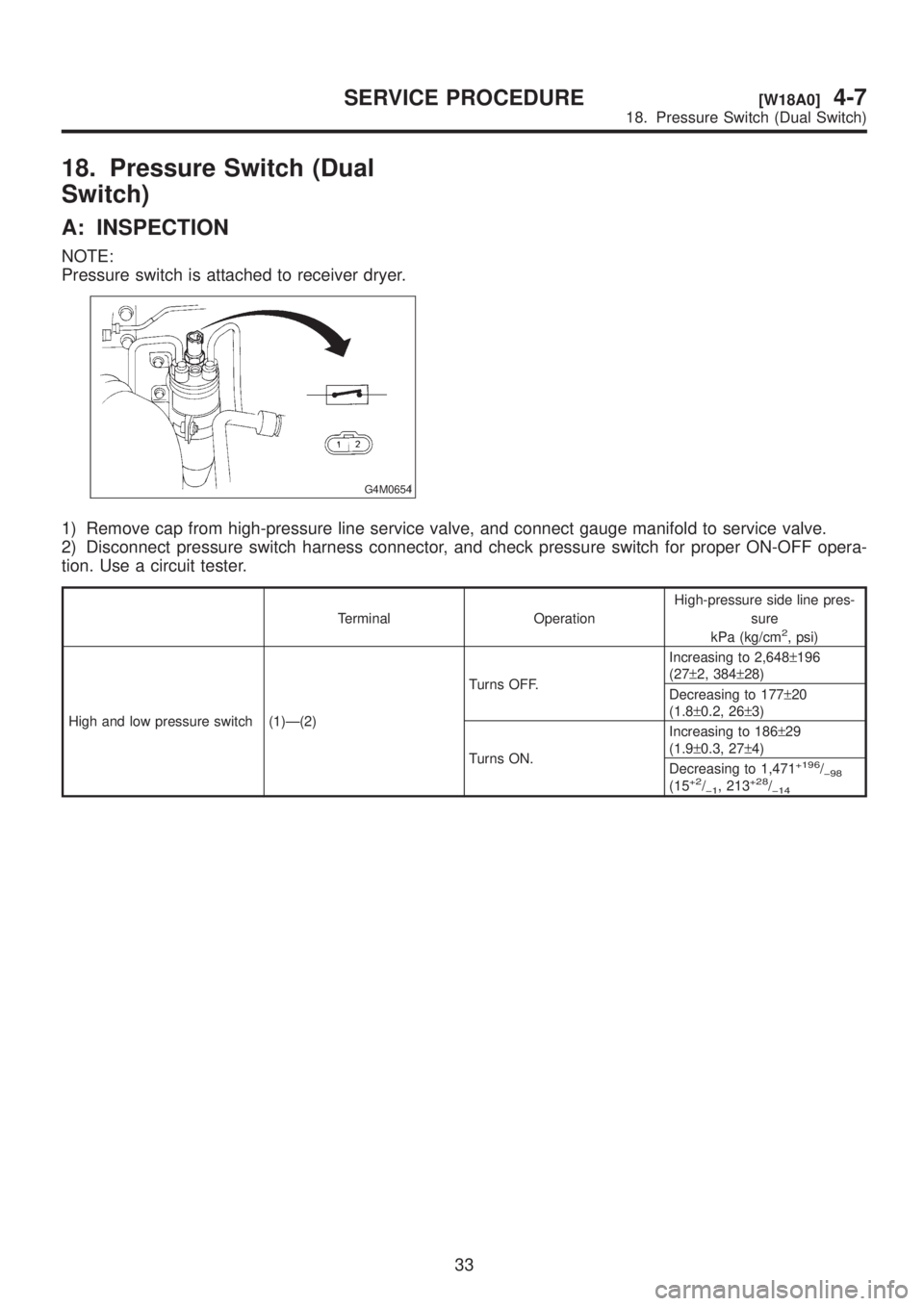

18. Pressure Switch (Dual

Switch)

A: INSPECTION

NOTE:

Pressure switch is attached to receiver dryer.

G4M0654

1) Remove cap from high-pressure line service valve, and connect gauge manifold to service valve.

2) Disconnect pressure switch harness connector, and check pressure switch for proper ON-OFF opera-

tion. Use a circuit tester.

Terminal OperationHigh-pressure side line pres-

sure

kPa (kg/cm2, psi)

High and low pressure switch (1)Ð(2)Turns OFF.Increasing to 2,648±196

(27±2, 384±28)

Decreasing to 177±20

(1.8±0.2, 26±3)

Turns ON.Increasing to 186±29

(1.9±0.3, 27±4)

Decreasing to 1,471

+196/þ98(15+2/þ1, 213+28/þ14

33

[W18A0]4-7SERVICE PROCEDURE

18. Pressure Switch (Dual Switch)

Page 1014 of 1456

1. Air Conditioning System

Diagnosis

B4M1099A

34

4-7[K100]DIAGNOSTICS

1. Air Conditioning System Diagnosis

Page 1015 of 1456

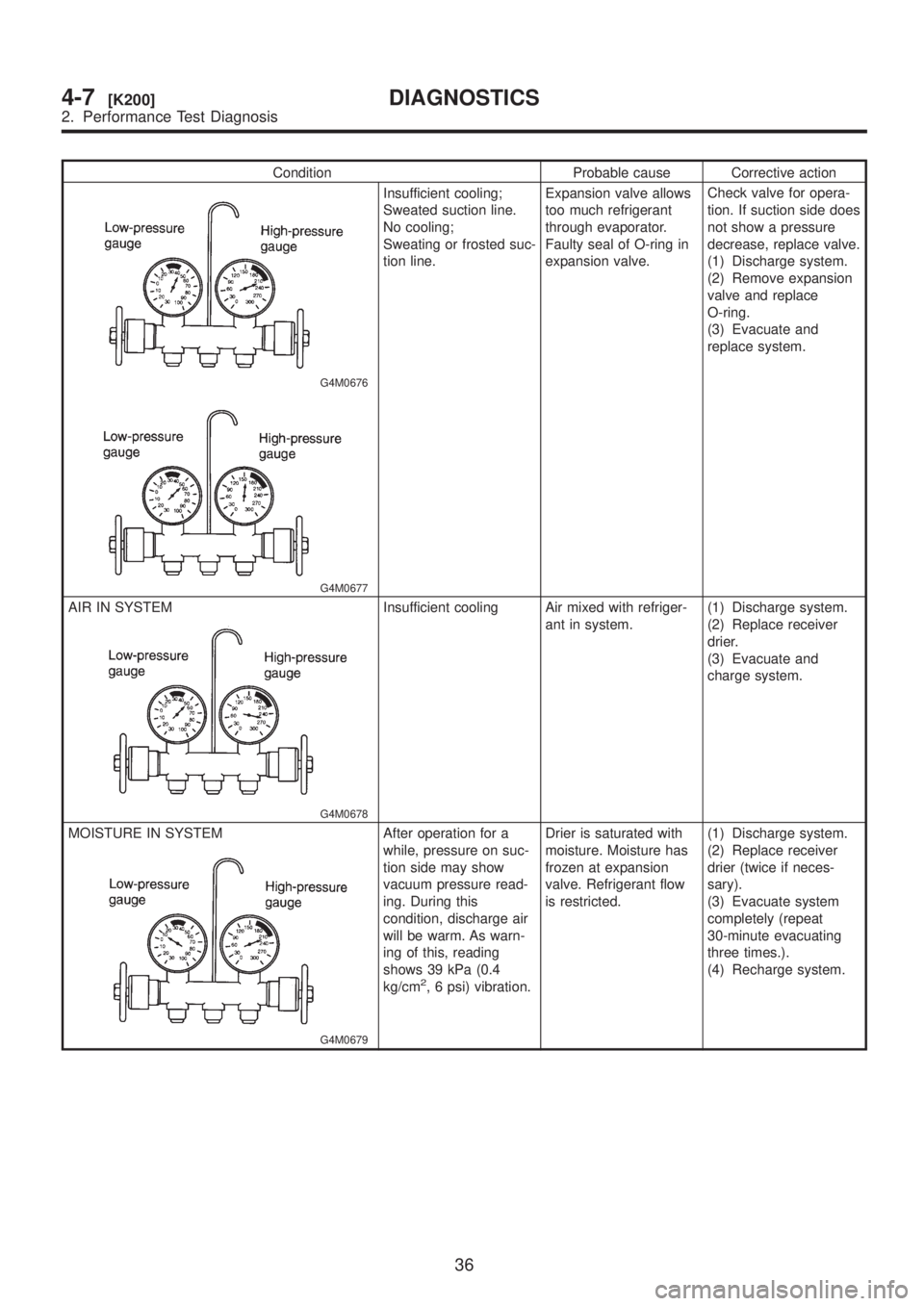

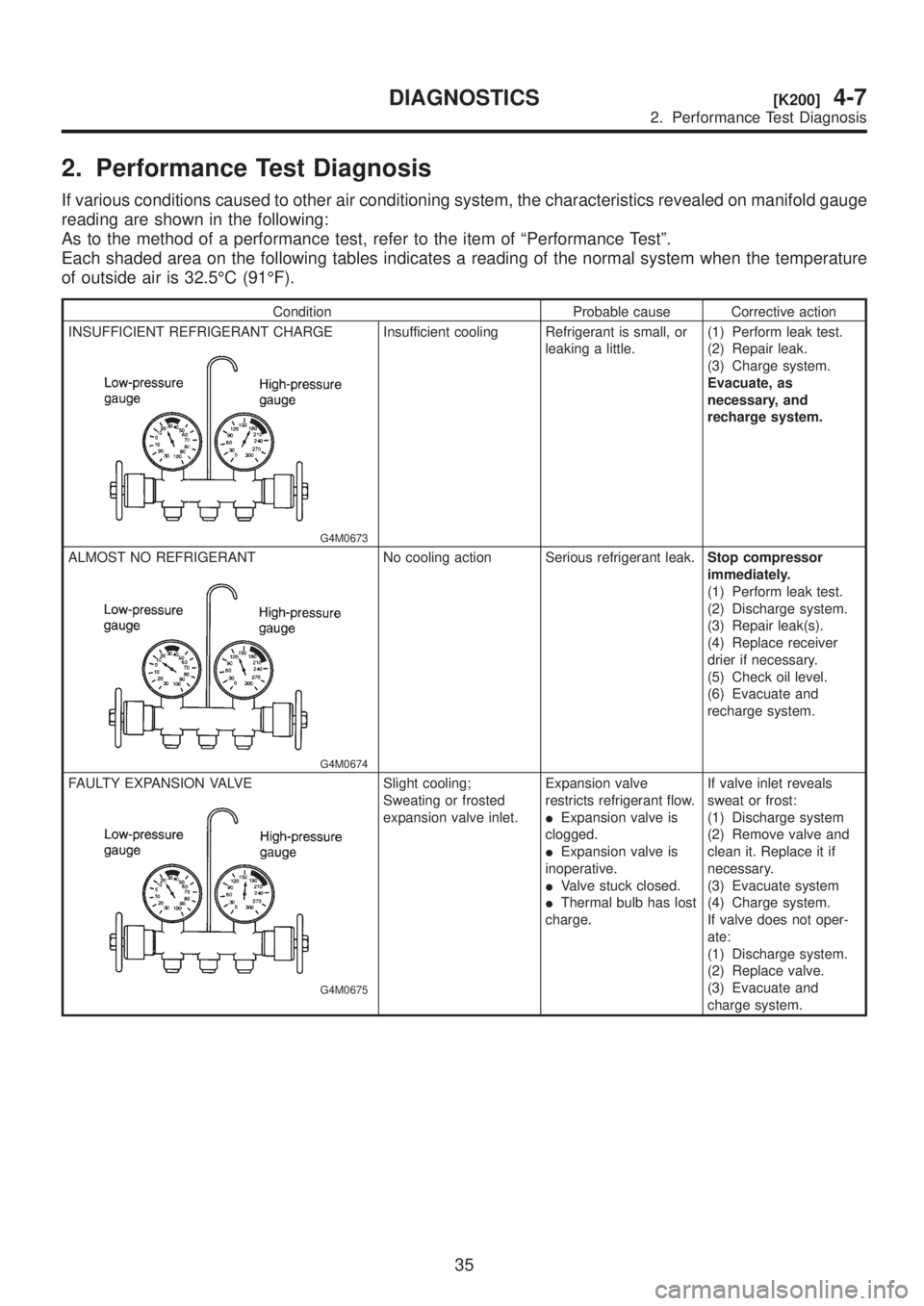

2. Performance Test Diagnosis

If various conditions caused to other air conditioning system, the characteristics revealed on manifold gauge

reading are shown in the following:

As to the method of a performance test, refer to the item of ªPerformance Testº.

Each shaded area on the following tables indicates a reading of the normal system when the temperature

of outside air is 32.5ÉC (91ÉF).

Condition Probable cause Corrective action

INSUFFICIENT REFRIGERANT CHARGE

G4M0673

Insufficient cooling Refrigerant is small, or

leaking a little.(1) Perform leak test.

(2) Repair leak.

(3) Charge system.

Evacuate, as

necessary, and

recharge system.

ALMOST NO REFRIGERANT

G4M0674

No cooling action Serious refrigerant leak.Stop compressor

immediately.

(1) Perform leak test.

(2) Discharge system.

(3) Repair leak(s).

(4) Replace receiver

drier if necessary.

(5) Check oil level.

(6) Evacuate and

recharge system.

FAULTY EXPANSION VALVE

G4M0675

Slight cooling;

Sweating or frosted

expansion valve inlet.Expansion valve

restricts refrigerant flow.

IExpansion valve is

clogged.

IExpansion valve is

inoperative.

IValve stuck closed.

IThermal bulb has lost

charge.If valve inlet reveals

sweat or frost:

(1) Discharge system

(2) Remove valve and

clean it. Replace it if

necessary.

(3) Evacuate system

(4) Charge system.

If valve does not oper-

ate:

(1) Discharge system.

(2) Replace valve.

(3) Evacuate and

charge system.

35

[K200]4-7DIAGNOSTICS

2. Performance Test Diagnosis

Page 1016 of 1456

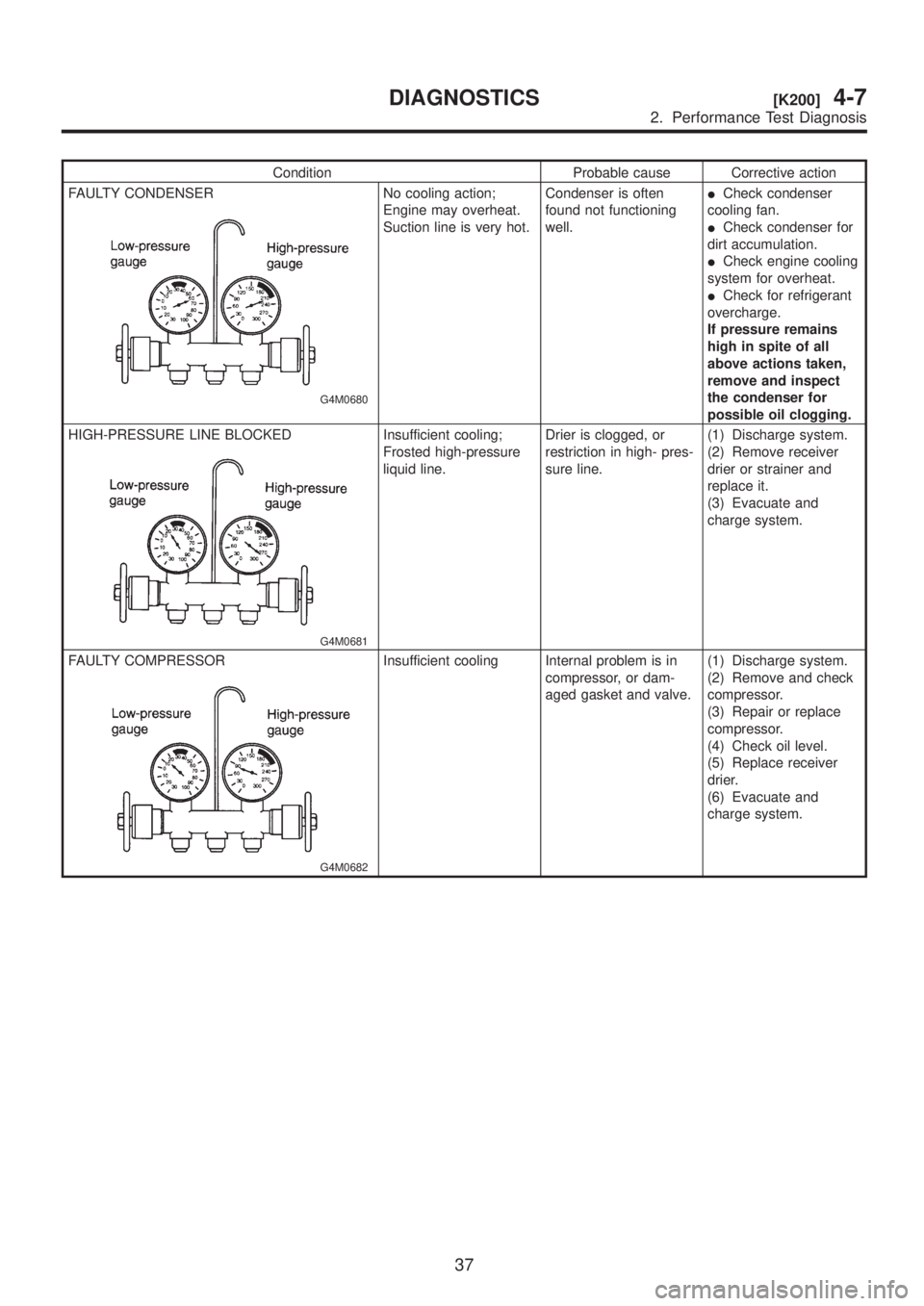

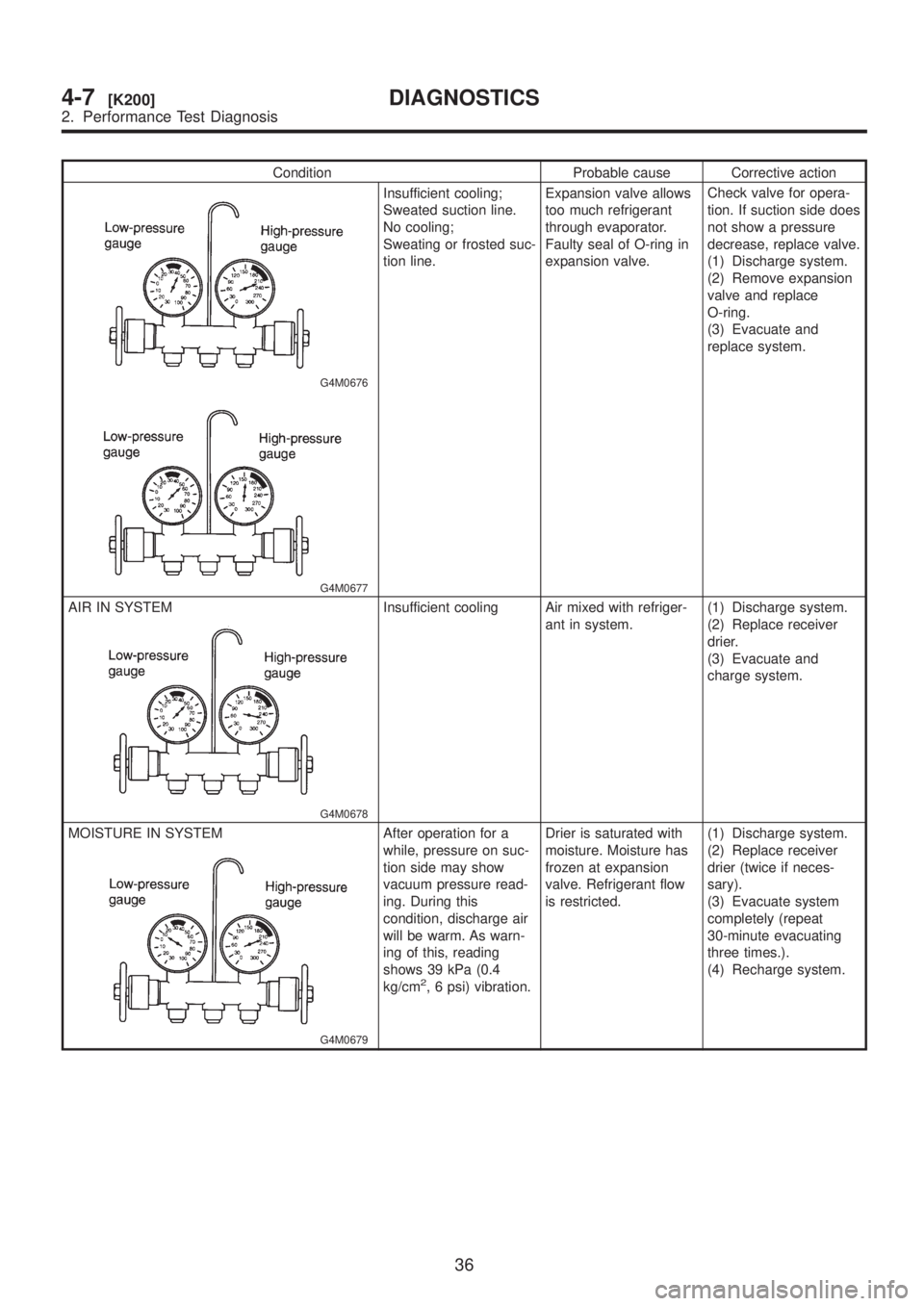

Condition Probable cause Corrective action

G4M0676

G4M0677

Insufficient cooling;

Sweated suction line.

No cooling;

Sweating or frosted suc-

tion line.Expansion valve allows

too much refrigerant

through evaporator.

Faulty seal of O-ring in

expansion valve.Check valve for opera-

tion. If suction side does

not show a pressure

decrease, replace valve.

(1) Discharge system.

(2) Remove expansion

valve and replace

O-ring.

(3) Evacuate and

replace system.

AIR IN SYSTEM

G4M0678

Insufficient cooling Air mixed with refriger-

ant in system.(1) Discharge system.

(2) Replace receiver

drier.

(3) Evacuate and

charge system.

MOISTURE IN SYSTEM

G4M0679

After operation for a

while, pressure on suc-

tion side may show

vacuum pressure read-

ing. During this

condition, discharge air

will be warm. As warn-

ing of this, reading

shows 39 kPa (0.4

kg/cm

2, 6 psi) vibration.Drier is saturated with

moisture. Moisture has

frozen at expansion

valve. Refrigerant flow

is restricted.(1) Discharge system.

(2) Replace receiver

drier (twice if neces-

sary).

(3) Evacuate system

completely (repeat

30-minute evacuating

three times.).

(4) Recharge system.

36

4-7[K200]DIAGNOSTICS

2. Performance Test Diagnosis

Page 1017 of 1456

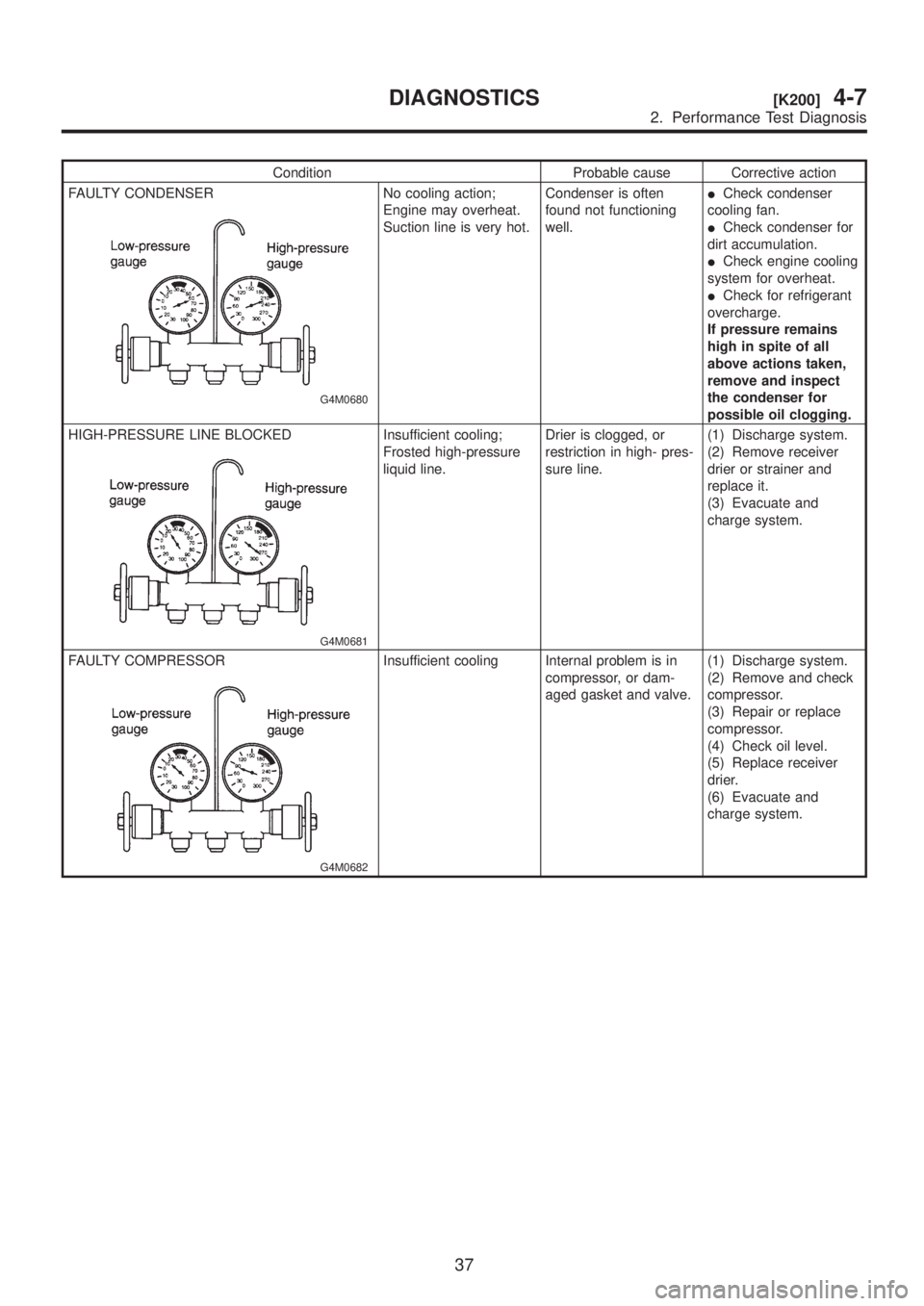

Condition Probable cause Corrective action

FAULTY CONDENSER

G4M0680

No cooling action;

Engine may overheat.

Suction line is very hot.Condenser is often

found not functioning

well.ICheck condenser

cooling fan.

ICheck condenser for

dirt accumulation.

ICheck engine cooling

system for overheat.

ICheck for refrigerant

overcharge.

If pressure remains

high in spite of all

above actions taken,

remove and inspect

the condenser for

possible oil clogging.

HIGH-PRESSURE LINE BLOCKED

G4M0681

Insufficient cooling;

Frosted high-pressure

liquid line.Drier is clogged, or

restriction in high- pres-

sure line.(1) Discharge system.

(2) Remove receiver

drier or strainer and

replace it.

(3) Evacuate and

charge system.

FAULTY COMPRESSOR

G4M0682

Insufficient cooling Internal problem is in

compressor, or dam-

aged gasket and valve.(1) Discharge system.

(2) Remove and check

compressor.

(3) Repair or replace

compressor.

(4) Check oil level.

(5) Replace receiver

drier.

(6) Evacuate and

charge system.

37

[K200]4-7DIAGNOSTICS

2. Performance Test Diagnosis

Page 1018 of 1456

3. Blower Motor Diagnosis

B4M1103A

38

4-7[K300]DIAGNOSTICS

3. Blower Motor Diagnosis

Page 1019 of 1456

4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis

Page 1020 of 1456

5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis

Trending: warning lights, oil, air bleeding, change wheel, hood open, reset, compression ratio

![SUBARU LEGACY 1999 Service Repair Manual 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA SUBARU LEGACY 1999 Service Repair Manual 16. Flexible Hose

A: REMOVAL AND INSTALLATION

1) Disconnect battery negative terminal.

2) Discharge refrigerant using refrigerant recovery

system. <Ref. to 4-7 [W6A0].>

3) Remove low-pressure hose:

CA](/img/17/57435/w960_57435-1010.png)

![SUBARU LEGACY 1999 Service Repair Manual 1. Air Conditioning System

Diagnosis

B4M1099A

34

4-7[K100]DIAGNOSTICS

1. Air Conditioning System Diagnosis SUBARU LEGACY 1999 Service Repair Manual 1. Air Conditioning System

Diagnosis

B4M1099A

34

4-7[K100]DIAGNOSTICS

1. Air Conditioning System Diagnosis](/img/17/57435/w960_57435-1013.png)

![SUBARU LEGACY 1999 Service Repair Manual 3. Blower Motor Diagnosis

B4M1103A

38

4-7[K300]DIAGNOSTICS

3. Blower Motor Diagnosis SUBARU LEGACY 1999 Service Repair Manual 3. Blower Motor Diagnosis

B4M1103A

38

4-7[K300]DIAGNOSTICS

3. Blower Motor Diagnosis](/img/17/57435/w960_57435-1017.png)

![SUBARU LEGACY 1999 Service Repair Manual 4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis SUBARU LEGACY 1999 Service Repair Manual 4. Compressor Diagnosis

B4M1104A

39

[K400]4-7DIAGNOSTICS

4. Compressor Diagnosis](/img/17/57435/w960_57435-1018.png)

![SUBARU LEGACY 1999 Service Repair Manual 5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis SUBARU LEGACY 1999 Service Repair Manual 5. Compressor Clutch Diagnosis

B4M1105A

40

4-7[K500]DIAGNOSTICS

5. Compressor Clutch Diagnosis](/img/17/57435/w960_57435-1019.png)