fuel type SUBARU LEGACY 1999 Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 1999, Model line: LEGACY, Model: SUBARU LEGACY 1999Pages: 1456, PDF Size: 59.93 MB

Page 36 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-35.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 37 of 1456

![SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng SUBARU LEGACY 1999 Service Repair Manual CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

<Ref. to 2-7 [T6A0].>4. Eng](/img/17/57435/w960_57435-36.png)

CAUTION:

Never rotate idle adjusting screw. If idle speed

is out of specifications, refer to General On-

board Diagnosis Table under ª2-7 On-Board

Diagnostics II Systemº.

A: MEASUREMENT

1. 2200 cc MODEL

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

G2M0098

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (200 Ð 300 rpm and fully open

throttle):

Standard;

1,079 Ð 1,275 kPa (11.0 Ð 13.0 kg/cm

2,

156 Ð 185 psi)

Limit;

883 kPa (9.0 kg/cm

2, 128 psi)

Difference between cylinders;

196 kPa (2.0 kg/cm

2, 28 psi)

4

2-2[W4A1]SERVICE PROCEDURE

4. Engine Compression

Page 38 of 1456

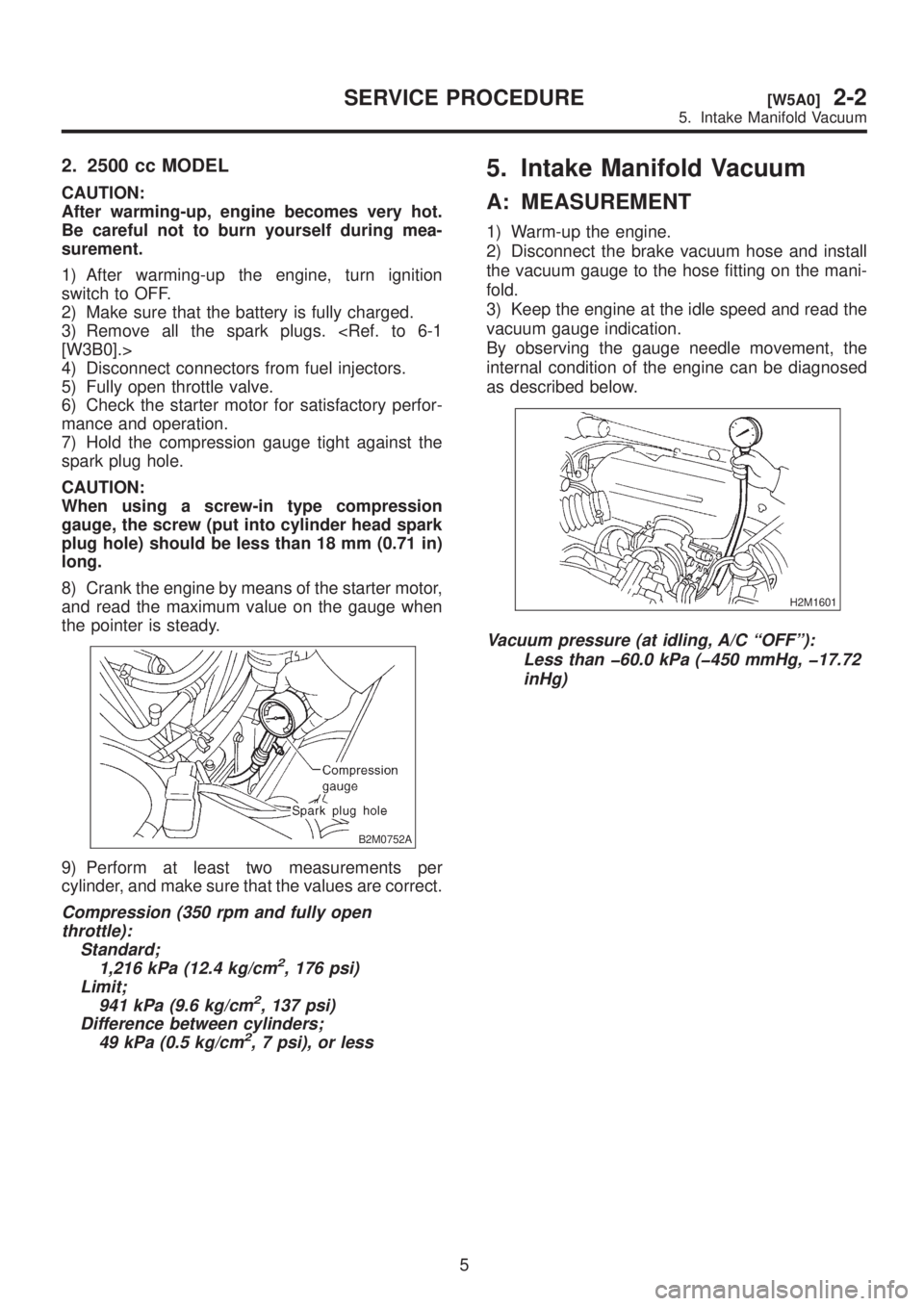

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

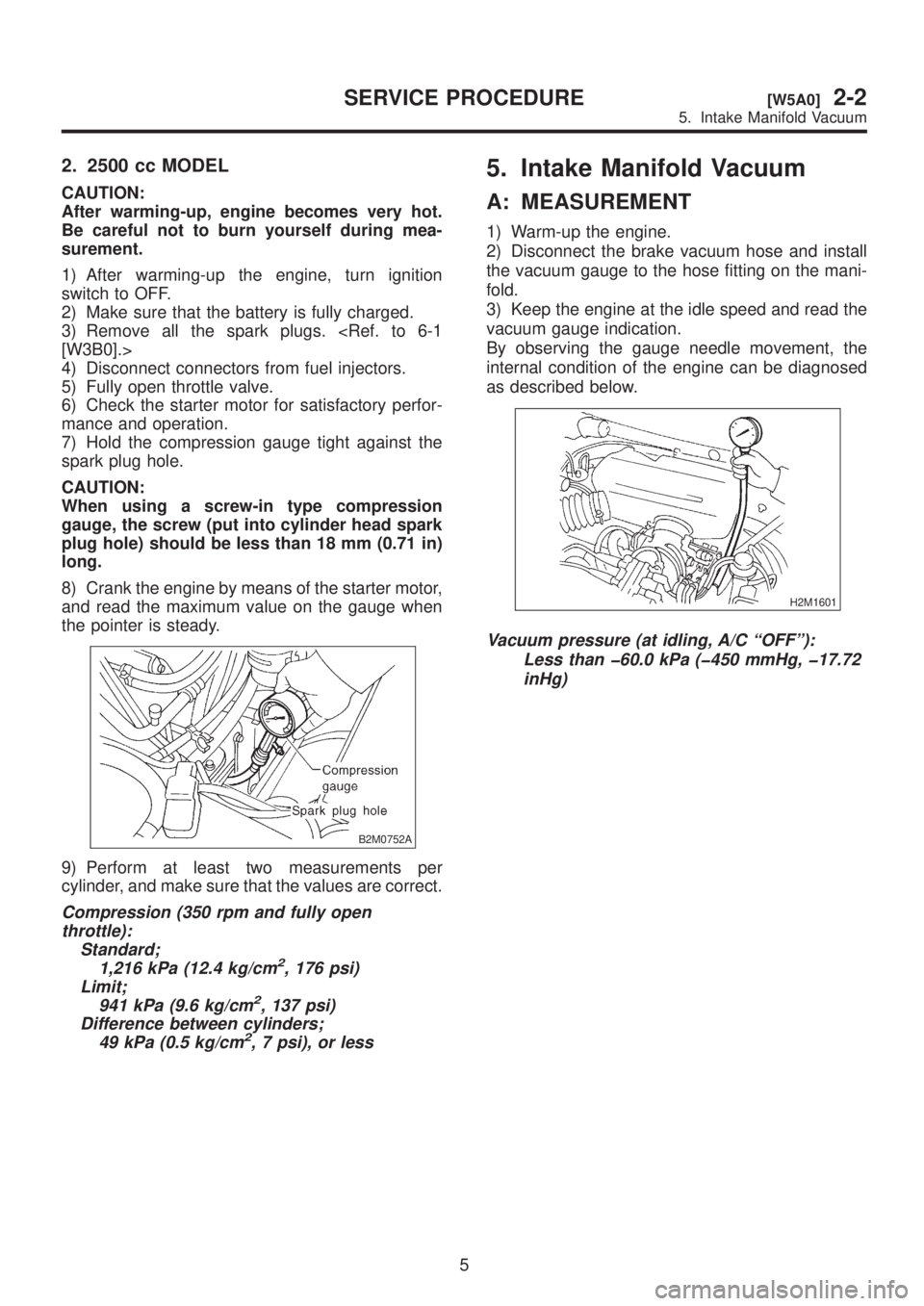

5. Intake Manifold Vacuum

A: MEASUREMENT

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 39 of 1456

2. 2500 cc MODEL

CAUTION:

After warming-up, engine becomes very hot.

Be careful not to burn yourself during mea-

surement.

1) After warming-up the engine, turn ignition

switch to OFF.

2) Make sure that the battery is fully charged.

3) Remove all the spark plugs.

4) Disconnect connectors from fuel injectors.

5) Fully open throttle valve.

6) Check the starter motor for satisfactory perfor-

mance and operation.

7) Hold the compression gauge tight against the

spark plug hole.

CAUTION:

When using a screw-in type compression

gauge, the screw (put into cylinder head spark

plug hole) should be less than 18 mm (0.71 in)

long.

8) Crank the engine by means of the starter motor,

and read the maximum value on the gauge when

the pointer is steady.

B2M0752A

9) Perform at least two measurements per

cylinder, and make sure that the values are correct.

Compression (350 rpm and fully open

throttle):

Standard;

1,216 kPa (12.4 kg/cm

2, 176 psi)

Limit;

941 kPa (9.6 kg/cm

2, 137 psi)

Difference between cylinders;

49 kPa (0.5 kg/cm

2, 7 psi), or less

5. Intake Manifold Vacuum

A: MEASUREMENT

1) Warm-up the engine.

2) Disconnect the brake vacuum hose and install

the vacuum gauge to the hose fitting on the mani-

fold.

3) Keep the engine at the idle speed and read the

vacuum gauge indication.

By observing the gauge needle movement, the

internal condition of the engine can be diagnosed

as described below.

H2M1601

Vacuum pressure (at idling, A/C ªOFFº):

Less than þ60.0 kPa (þ450 mmHg, þ17.72

inHg)

5

[W5A0]2-2SERVICE PROCEDURE

5. Intake Manifold Vacuum

Page 132 of 1456

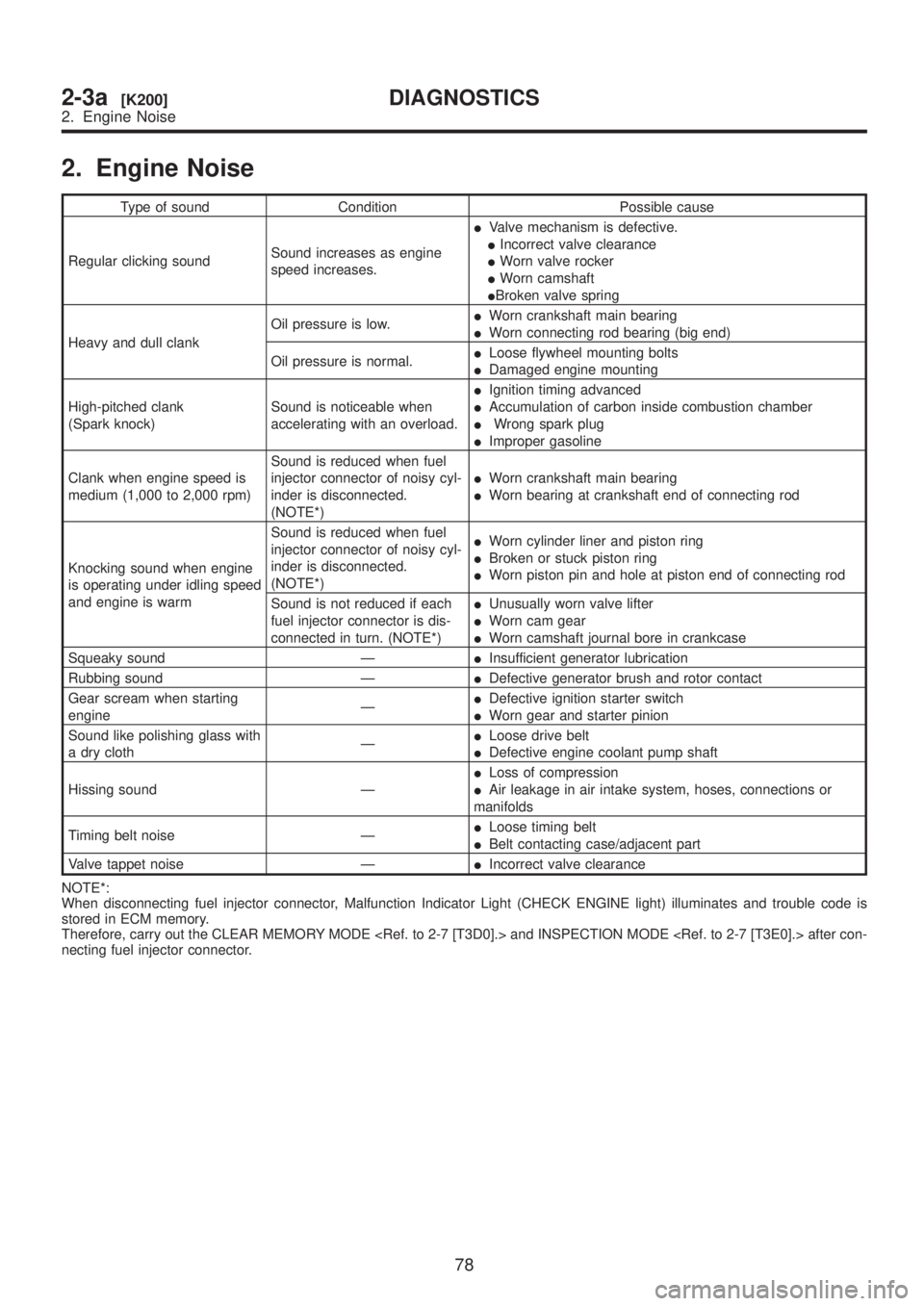

2. Engine Noise

Type of sound Condition Possible cause

Regular clicking soundSound increases as engine

speed increases.IValve mechanism is defective.

IIncorrect valve clearance

IWorn valve rocker

IWorn camshaft

IBroken valve spring

Heavy and dull clankOil pressure is low.IWorn crankshaft main bearing

IWorn connecting rod bearing (big end)

Oil pressure is normal.ILoose flywheel mounting bolts

IDamaged engine mounting

High-pitched clank

(Spark knock)Sound is noticeable when

accelerating with an overload.IIgnition timing advanced

IAccumulation of carbon inside combustion chamber

IWrong spark plug

IImproper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm)Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn crankshaft main bearing

IWorn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warmSound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn cylinder liner and piston ring

IBroken or stuck piston ring

IWorn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn. (NOTE*)IUnusually worn valve lifter

IWorn cam gear

IWorn camshaft journal bore in crankcase

Squeaky sound ÐIInsufficient generator lubrication

Rubbing sound ÐIDefective generator brush and rotor contact

Gear scream when starting

engineÐIDefective ignition starter switch

IWorn gear and starter pinion

Sound like polishing glass with

a dry clothÐILoose drive belt

IDefective engine coolant pump shaft

Hissing sound ÐILoss of compression

IAir leakage in air intake system, hoses, connections or

manifolds

Timing belt noise ÐILoose timing belt

IBelt contacting case/adjacent part

Valve tappet noise ÐIIncorrect valve clearance

NOTE*:

When disconnecting fuel injector connector, Malfunction Indicator Light (CHECK ENGINE light) illuminates and trouble code is

stored in ECM memory.

Therefore, carry out the CLEAR MEMORY MODE

necting fuel injector connector.

78

2-3a[K200]DIAGNOSTICS

2. Engine Noise

Page 207 of 1456

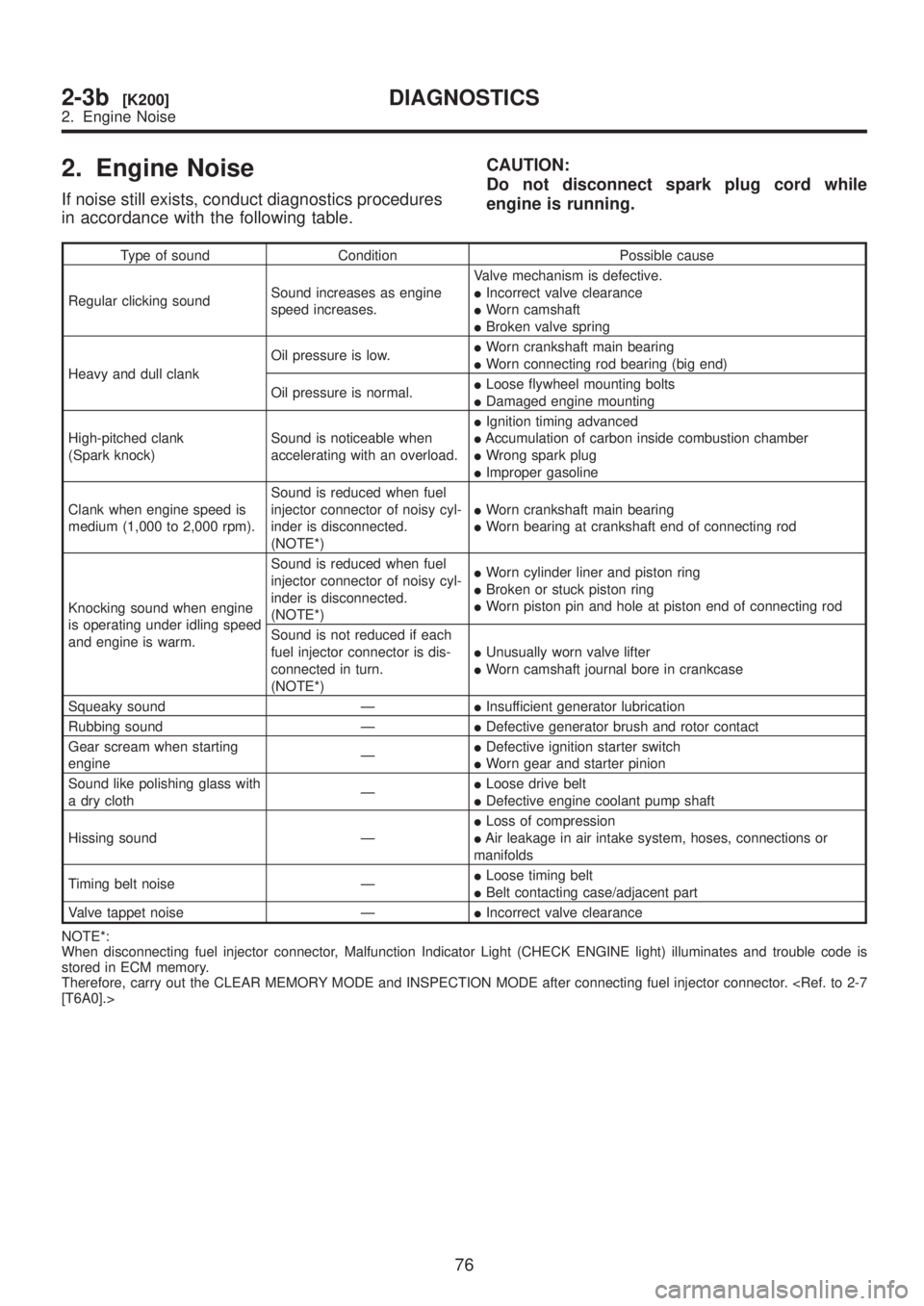

2. Engine Noise

If noise still exists, conduct diagnostics procedures

in accordance with the following table.CAUTION:

Do not disconnect spark plug cord while

engine is running.

Type of sound Condition Possible cause

Regular clicking soundSound increases as engine

speed increases.Valve mechanism is defective.

IIncorrect valve clearance

IWorn camshaft

IBroken valve spring

Heavy and dull clankOil pressure is low.IWorn crankshaft main bearing

IWorn connecting rod bearing (big end)

Oil pressure is normal.ILoose flywheel mounting bolts

IDamaged engine mounting

High-pitched clank

(Spark knock)Sound is noticeable when

accelerating with an overload.IIgnition timing advanced

IAccumulation of carbon inside combustion chamber

IWrong spark plug

IImproper gasoline

Clank when engine speed is

medium (1,000 to 2,000 rpm).Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn crankshaft main bearing

IWorn bearing at crankshaft end of connecting rod

Knocking sound when engine

is operating under idling speed

and engine is warm.Sound is reduced when fuel

injector connector of noisy cyl-

inder is disconnected.

(NOTE*)IWorn cylinder liner and piston ring

IBroken or stuck piston ring

IWorn piston pin and hole at piston end of connecting rod

Sound is not reduced if each

fuel injector connector is dis-

connected in turn.

(NOTE*)IUnusually worn valve lifter

IWorn camshaft journal bore in crankcase

Squeaky sound ÐIInsufficient generator lubrication

Rubbing sound ÐIDefective generator brush and rotor contact

Gear scream when starting

engineÐIDefective ignition starter switch

IWorn gear and starter pinion

Sound like polishing glass with

a dry clothÐILoose drive belt

IDefective engine coolant pump shaft

Hissing sound ÐILoss of compression

IAir leakage in air intake system, hoses, connections or

manifolds

Timing belt noise ÐILoose timing belt

IBelt contacting case/adjacent part

Valve tappet noise ÐIIncorrect valve clearance

NOTE*:

When disconnecting fuel injector connector, Malfunction Indicator Light (CHECK ENGINE light) illuminates and trouble code is

stored in ECM memory.

Therefore, carry out the CLEAR MEMORY MODE and INSPECTION MODE after connecting fuel injector connector.

76

2-3b[K200]DIAGNOSTICS

2. Engine Noise

Page 363 of 1456

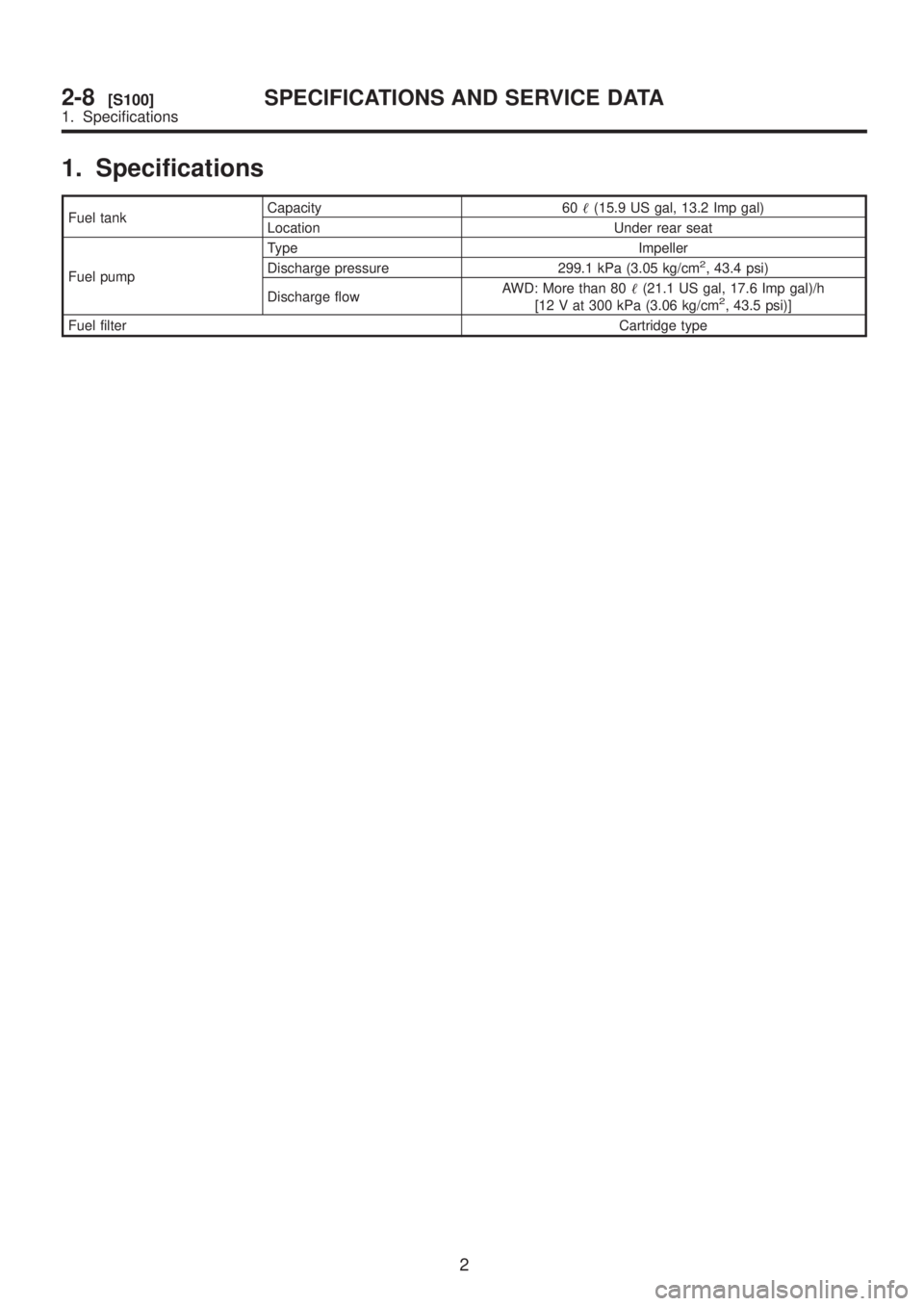

1. Specifications

Fuel tankCapacity 60(15.9 US gal, 13.2 Imp gal)

Location Under rear seat

Fuel pumpType Impeller

Discharge pressure 299.1 kPa (3.05 kg/cm

2, 43.4 psi)

Discharge flowAWD: More than 80(21.1 US gal, 17.6 Imp gal)/h

[12 V at 300 kPa (3.06 kg/cm

2, 43.5 psi)]

Fuel filterCartridge type

2

2-8[S100]SPECIFICATIONS AND SERVICE DATA

1. Specifications

Page 375 of 1456

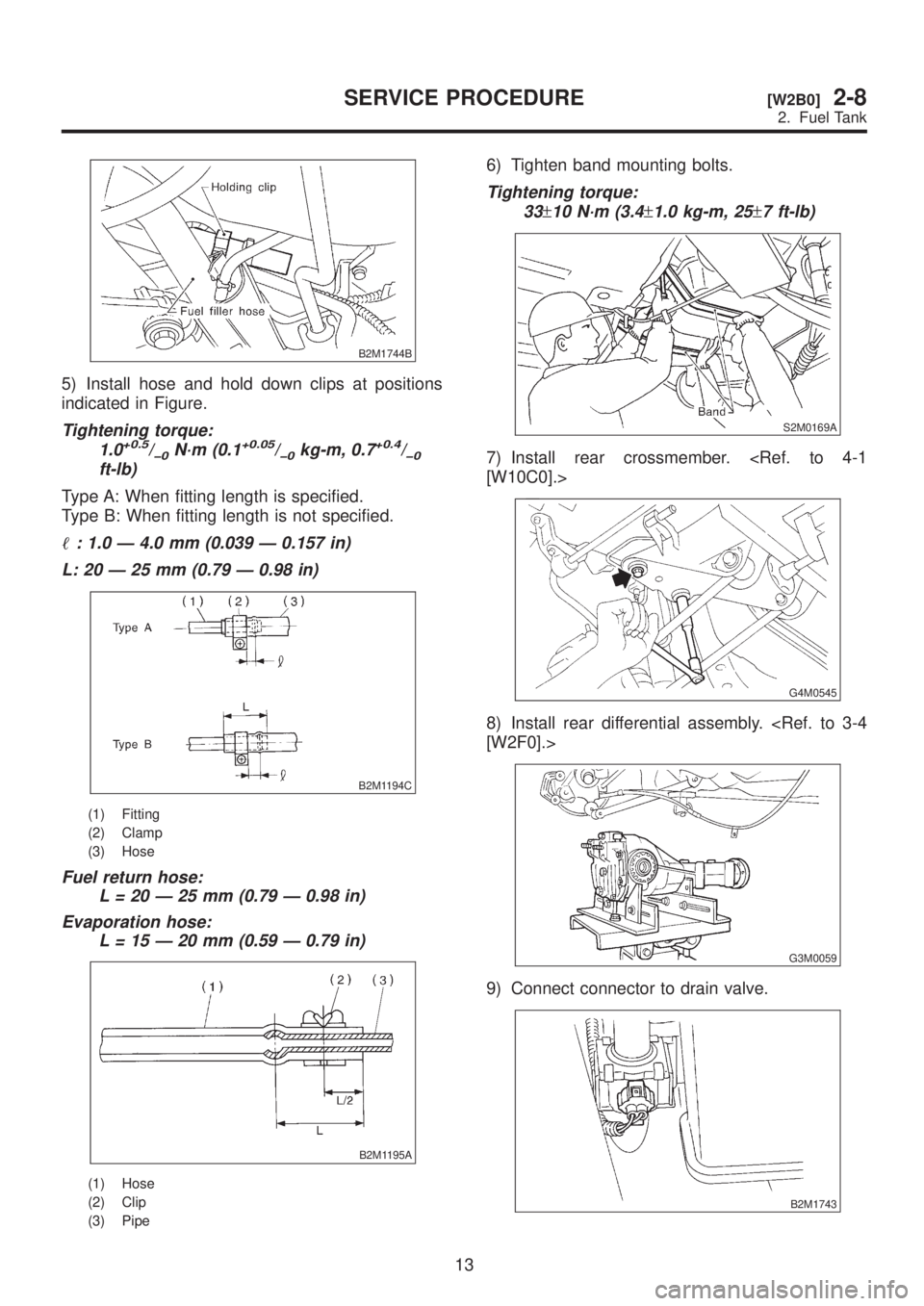

B2M1744B

5) Install hose and hold down clips at positions

indicated in Figure.

Tightening torque:

1.0+0.5/þ0N´m (0.1+0.05/þ0kg-m, 0.7+0.4/þ0ft-lb)

Type A: When fitting length is specified.

Type B: When fitting length is not specified.

: 1.0 Ð 4.0 mm (0.039 Ð 0.157 in)

L: 20 Ð 25 mm (0.79 Ð 0.98 in)

B2M1194C

(1) Fitting

(2) Clamp

(3) Hose

Fuel return hose:

L = 20 Ð 25 mm (0.79 Ð 0.98 in)

Evaporation hose:

L = 15 Ð 20 mm (0.59 Ð 0.79 in)

B2M1195A

(1) Hose

(2) Clip

(3) Pipe

6) Tighten band mounting bolts.

Tightening torque:

33

±10 N´m (3.4±1.0 kg-m, 25±7 ft-lb)

S2M0169A

7) Install rear crossmember.

G4M0545

8) Install rear differential assembly.

G3M0059

9) Connect connector to drain valve.

B2M1743

13

[W2B0]2-8SERVICE PROCEDURE

2. Fuel Tank

Page 389 of 1456

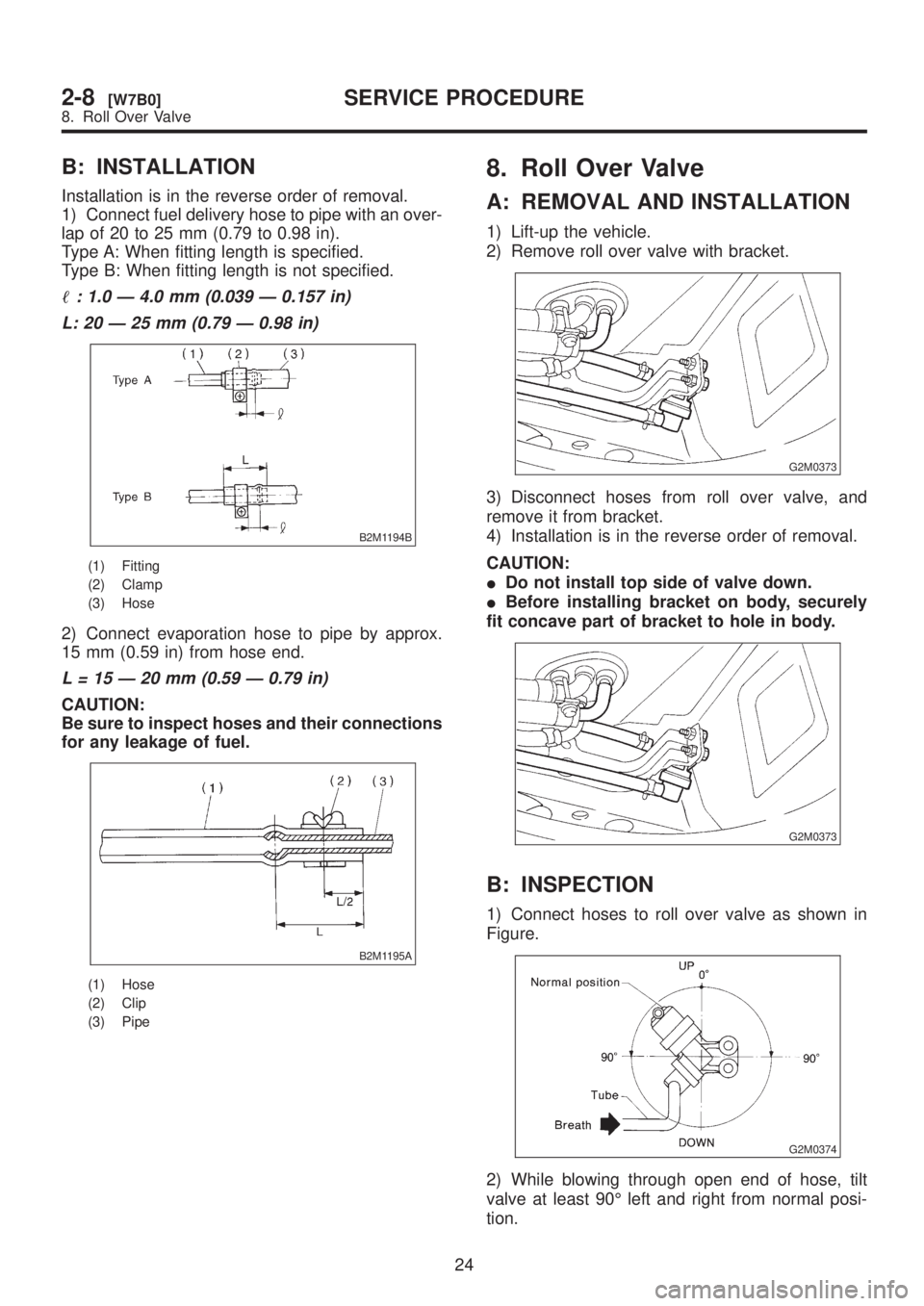

B: INSTALLATION

Installation is in the reverse order of removal.

1) Connect fuel delivery hose to pipe with an over-

lap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When fitting length is specified.

Type B: When fitting length is not specified.

: 1.0 Ð 4.0 mm (0.039 Ð 0.157 in)

L: 20 Ð 25 mm (0.79 Ð 0.98 in)

B2M1194B

(1) Fitting

(2) Clamp

(3) Hose

2) Connect evaporation hose to pipe by approx.

15 mm (0.59 in) from hose end.

L = 15 Ð 20 mm (0.59 Ð 0.79 in)

CAUTION:

Be sure to inspect hoses and their connections

for any leakage of fuel.

B2M1195A

(1) Hose

(2) Clip

(3) Pipe

8. Roll Over Valve

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Remove roll over valve with bracket.

G2M0373

3) Disconnect hoses from roll over valve, and

remove it from bracket.

4) Installation is in the reverse order of removal.

CAUTION:

IDo not install top side of valve down.

IBefore installing bracket on body, securely

fit concave part of bracket to hole in body.

G2M0373

B: INSPECTION

1) Connect hoses to roll over valve as shown in

Figure.

G2M0374

2) While blowing through open end of hose, tilt

valve at least 90É left and right from normal posi-

tion.

24

2-8[W7B0]SERVICE PROCEDURE

8. Roll Over Valve

Page 390 of 1456

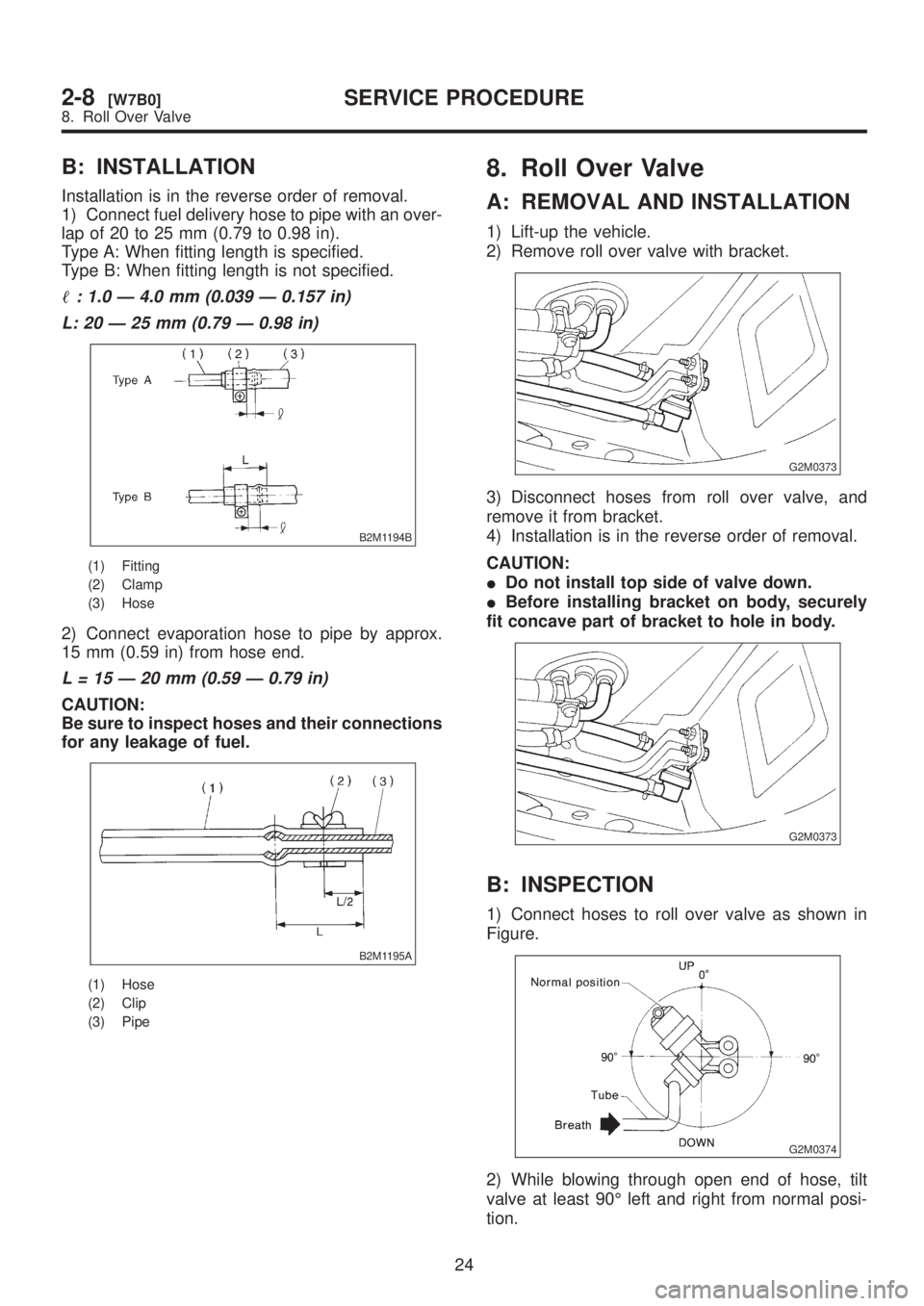

B: INSTALLATION

Installation is in the reverse order of removal.

1) Connect fuel delivery hose to pipe with an over-

lap of 20 to 25 mm (0.79 to 0.98 in).

Type A: When fitting length is specified.

Type B: When fitting length is not specified.

: 1.0 Ð 4.0 mm (0.039 Ð 0.157 in)

L: 20 Ð 25 mm (0.79 Ð 0.98 in)

B2M1194B

(1) Fitting

(2) Clamp

(3) Hose

2) Connect evaporation hose to pipe by approx.

15 mm (0.59 in) from hose end.

L = 15 Ð 20 mm (0.59 Ð 0.79 in)

CAUTION:

Be sure to inspect hoses and their connections

for any leakage of fuel.

B2M1195A

(1) Hose

(2) Clip

(3) Pipe

8. Roll Over Valve

A: REMOVAL AND INSTALLATION

1) Lift-up the vehicle.

2) Remove roll over valve with bracket.

G2M0373

3) Disconnect hoses from roll over valve, and

remove it from bracket.

4) Installation is in the reverse order of removal.

CAUTION:

IDo not install top side of valve down.

IBefore installing bracket on body, securely

fit concave part of bracket to hole in body.

G2M0373

B: INSPECTION

1) Connect hoses to roll over valve as shown in

Figure.

G2M0374

2) While blowing through open end of hose, tilt

valve at least 90É left and right from normal posi-

tion.

24

2-8[W7B0]SERVICE PROCEDURE

8. Roll Over Valve