Back up SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 882 of 2453

PS-2

General Description

POWER ASSISTED SYSTEM (POWER STEERING)

1. General Description

A: SPECIFICATION

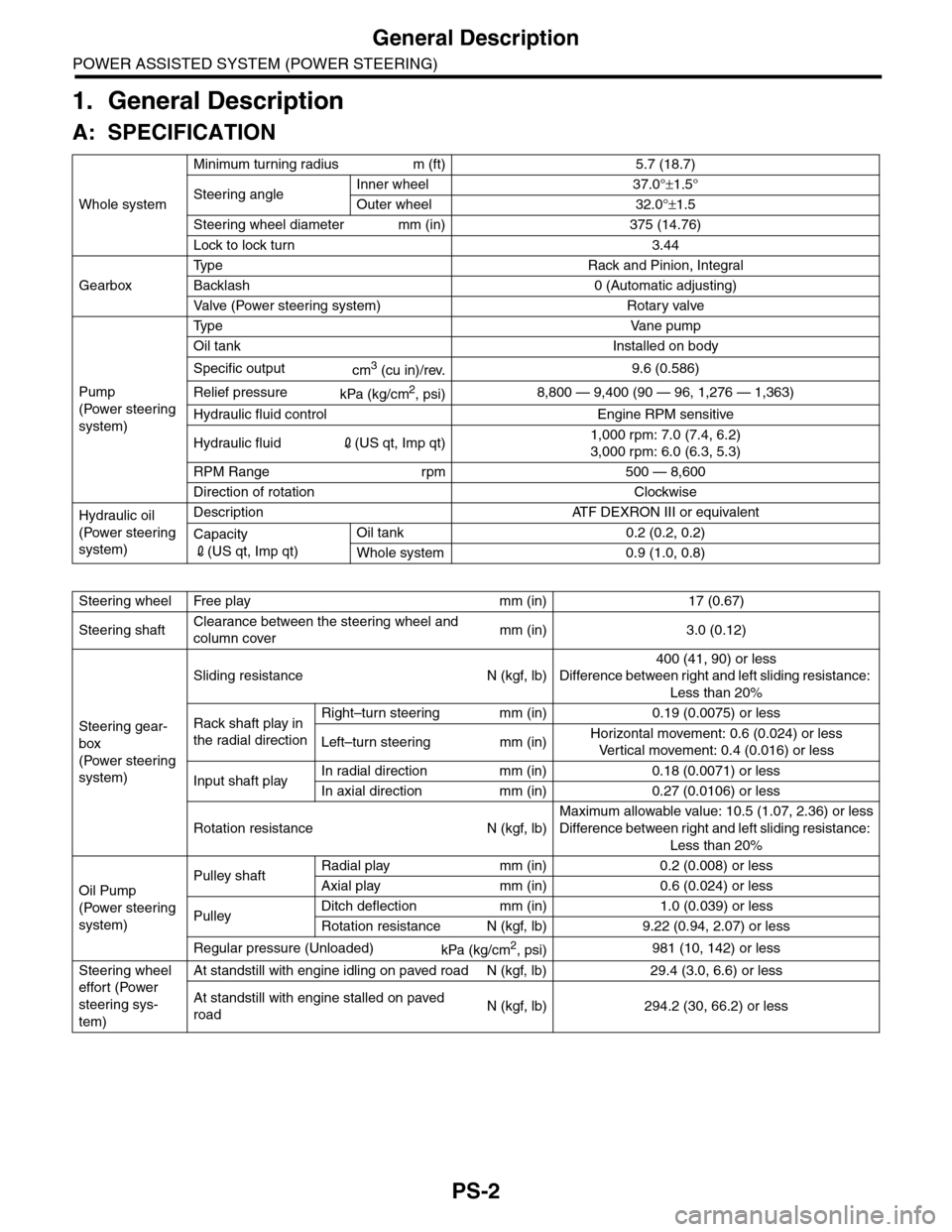

Whole system

Minimum turning radius m (ft) 5.7 (18.7)

Steering angleInner wheel 37.0°±1.5°

Outer wheel 32.0°±1.5

Steering wheel diameter mm (in) 375 (14.76)

Lock to lock turn 3.44

Gearbox

Ty p e R a c k a n d P i n i o n , I n t e g r a l

Backlash 0 (Automatic adjusting)

Va l ve ( Po w e r s t e e r i n g s y s t e m ) R o t a r y va l ve

Pump

(Power steering

system)

Ty p e Va n e p u m p

Oil tank Installed on body

Specific outputcm3 (cu in)/rev.9.6 (0.586)

Relief pressurekPa (kg/cm2, psi)8,800 — 9,400 (90 — 96, 1,276 — 1,363)

Hydraulic fluid control Engine RPM sensitive

Hydraulic fluid2(US qt, Imp qt)1,000 rpm: 7.0 (7.4, 6.2)

3,000 rpm: 6.0 (6.3, 5.3)

RPM Range rpm 500 — 8,600

Direction of rotation Clockwise

Hydraulic oil

(Power steering

system)

Description ATF DEXRON III or equivalent

Capacity

2(US qt, Imp qt)

Oil tank 0.2 (0.2, 0.2)

Whole system 0.9 (1.0, 0.8)

Steering wheel Free play mm (in) 17 (0.67)

Steering shaftClearance between the steering wheel and

column covermm (in) 3.0 (0.12)

Steering gear-

box

(Power steering

system)

Sliding resistance N (kgf, lb)

400 (41, 90) or less

Difference between right and left sliding resistance:

Less than 20%

Rack shaft play in

the radial direction

Right–turn steering mm (in) 0.19 (0.0075) or less

Left–turn steering mm (in)Horizontal movement: 0.6 (0.024) or less

Ve r t i c a l m o v e m e n t : 0 . 4 ( 0 . 0 1 6 ) o r l e s s

Input shaft playIn radial direction mm (in) 0.18 (0.0071) or less

In axial direction mm (in) 0.27 (0.0106) or less

Rotation resistance N (kgf, lb)

Maximum allowable value: 10.5 (1.07, 2.36) or less

Difference between right and left sliding resistance:

Less than 20%

Oil Pump

(Power steering

system)

Pulley shaftRadial play mm (in) 0.2 (0.008) or less

Axial play mm (in) 0.6 (0.024) or less

PulleyDitch deflection mm (in) 1.0 (0.039) or less

Rotation resistance N (kgf, lb) 9.22 (0.94, 2.07) or less

Regular pressure (Unloaded)kPa (kg/cm2, psi)981 (10, 142) or less

Steering wheel

effort (Power

steering sys-

tem)

At standstill with engine idling on paved road N (kgf, lb) 29.4 (3.0, 6.6) or less

At standstill with engine stalled on paved

roadN (kgf, lb) 294.2 (30, 66.2) or less

Page 885 of 2453

PS-5

General Description

POWER ASSISTED SYSTEM (POWER STEERING)

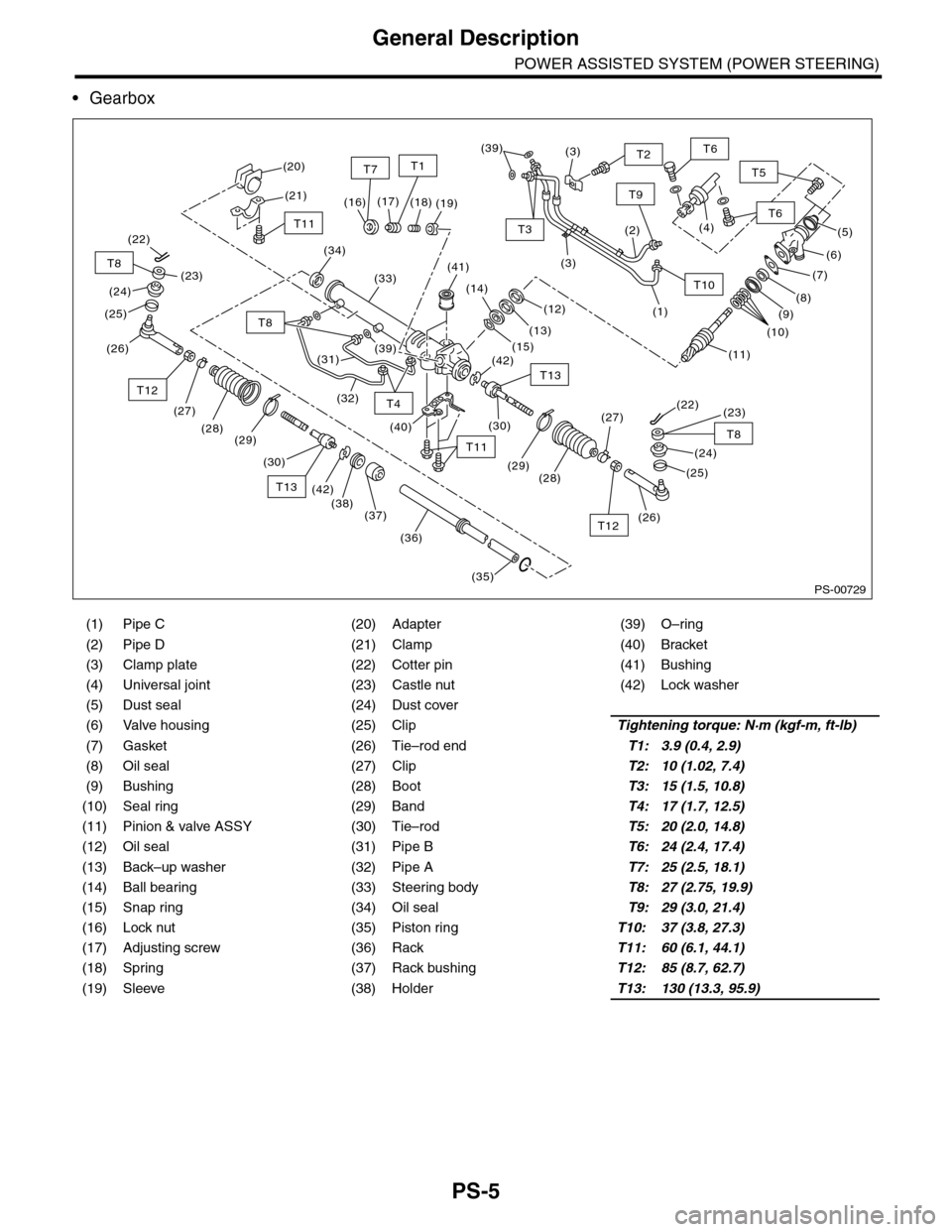

•Gearbox

(1) Pipe C (20) Adapter (39) O–ring

(2) Pipe D (21) Clamp (40) Bracket

(3) Clamp plate (22) Cotter pin (41) Bushing

(4) Universal joint (23) Castle nut (42) Lock washer

(5) Dust seal (24) Dust cover

(6) Valve housing (25) ClipTightening torque: N·m (kgf-m, ft-lb)

(7) Gasket (26) Tie–rod endT1: 3.9 (0.4, 2.9)

(8) Oil seal (27) ClipT2: 10 (1.02, 7.4)

(9) Bushing (28) BootT3: 15 (1.5, 10.8)

(10) Seal ring (29) BandT4: 17 (1.7, 12.5)

(11) Pinion & valve ASSY (30) Tie–rodT5: 20 (2.0, 14.8)

(12) Oil seal (31) Pipe BT6: 24 (2.4, 17.4)

(13) Back–up washer (32) Pipe AT7: 25 (2.5, 18.1)

(14) Ball bearing (33) Steering bodyT8: 27 (2.75, 19.9)

(15) Snap ring (34) Oil sealT9: 29 (3.0, 21.4)

(16) Lock nut (35) Piston ringT10: 37 (3.8, 27.3)

(17) Adjusting screw (36) RackT11: 60 (6.1, 44.1)

(18) Spring (37) Rack bushingT12: 85 (8.7, 62.7)

(19) Sleeve (38) HolderT13: 130 (13.3, 95.9)

PS-00729

T11

T8

T3

T12

T8

T13

T4

T13

T12

T8

(2)

(3)

T10

T5

T9

T6

T6T2

(22)

(20)

(23)

(24)

(25)

(26)

(27)

(28)(29)

(30)

(37)

(32)

(36)

(35)

(30)

(28)

(27)

(26)

(25)

(24)

(7)

(8)

(9)

(10)

(11)

(22)(23)

(5)

(6)

(4)

(1)

(3)

(12)

(13)

(15)(42)

(38)(42)

(14)(33)

(19)(18)(17)(16)(21)

(34)

(31)(39)

(39)

T7T1

(29)

(40)

T11

(41)

Page 888 of 2453

PS-8

General Description

POWER ASSISTED SYSTEM (POWER STEERING)

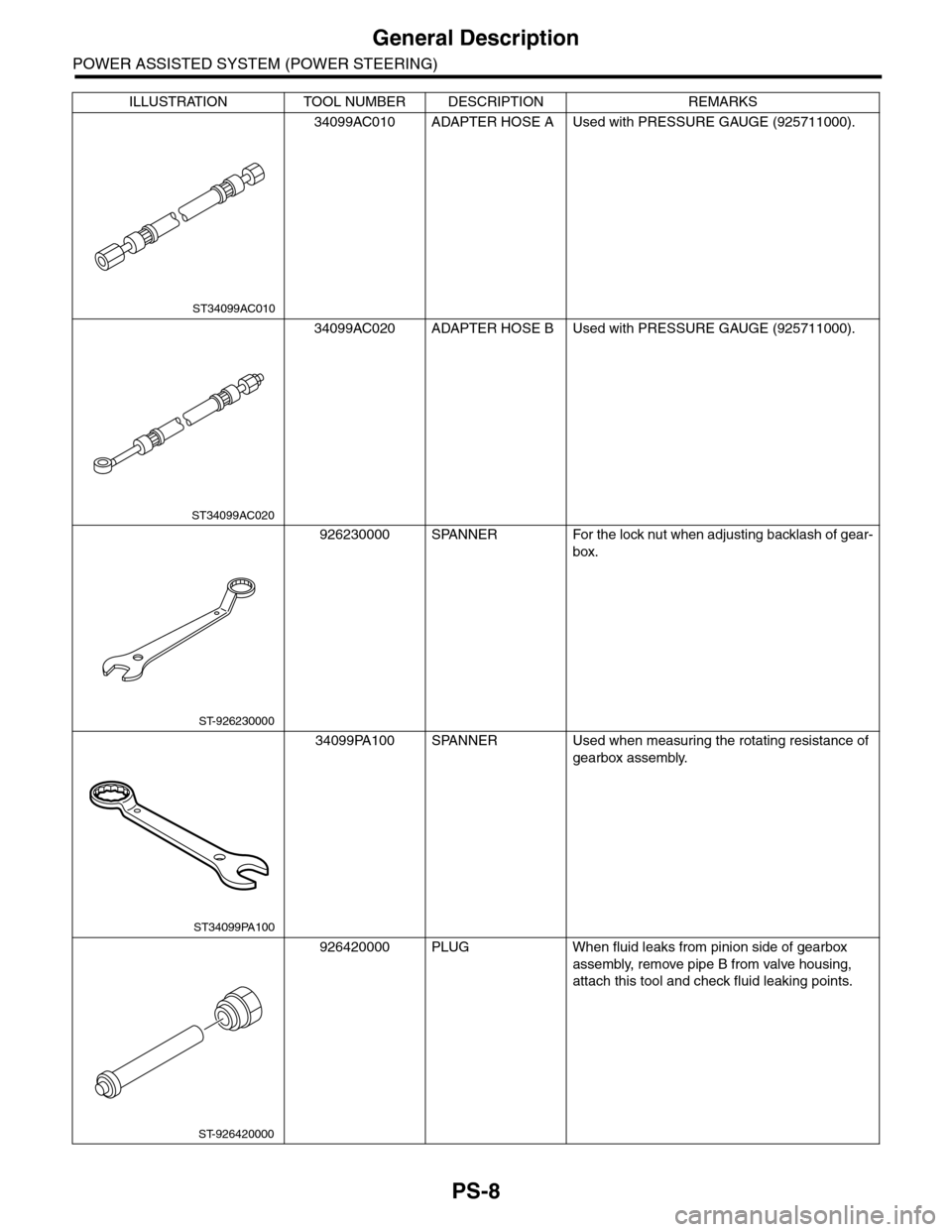

34099AC010 ADAPTER HOSE A Used with PRESSURE GAUGE (925711000).

34099AC020 ADAPTER HOSE B Used with PRESSURE GAUGE (925711000).

926230000 SPANNER For the lock nut when adjusting backlash of gear-

box.

34099PA100 SPANNER Used when measuring the rotating resistance of

gearbox assembly.

926420000 PLUG When fluid leaks from pinion side of gearbox

assembly, remove pipe B from valve housing,

attach this tool and check fluid leaking points.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST34099AC010

ST34099AC020

ST-926230000

ST34099PA100

ST-926420000

Page 903 of 2453

PS-23

Steering Gearbox

POWER ASSISTED SYSTEM (POWER STEERING)

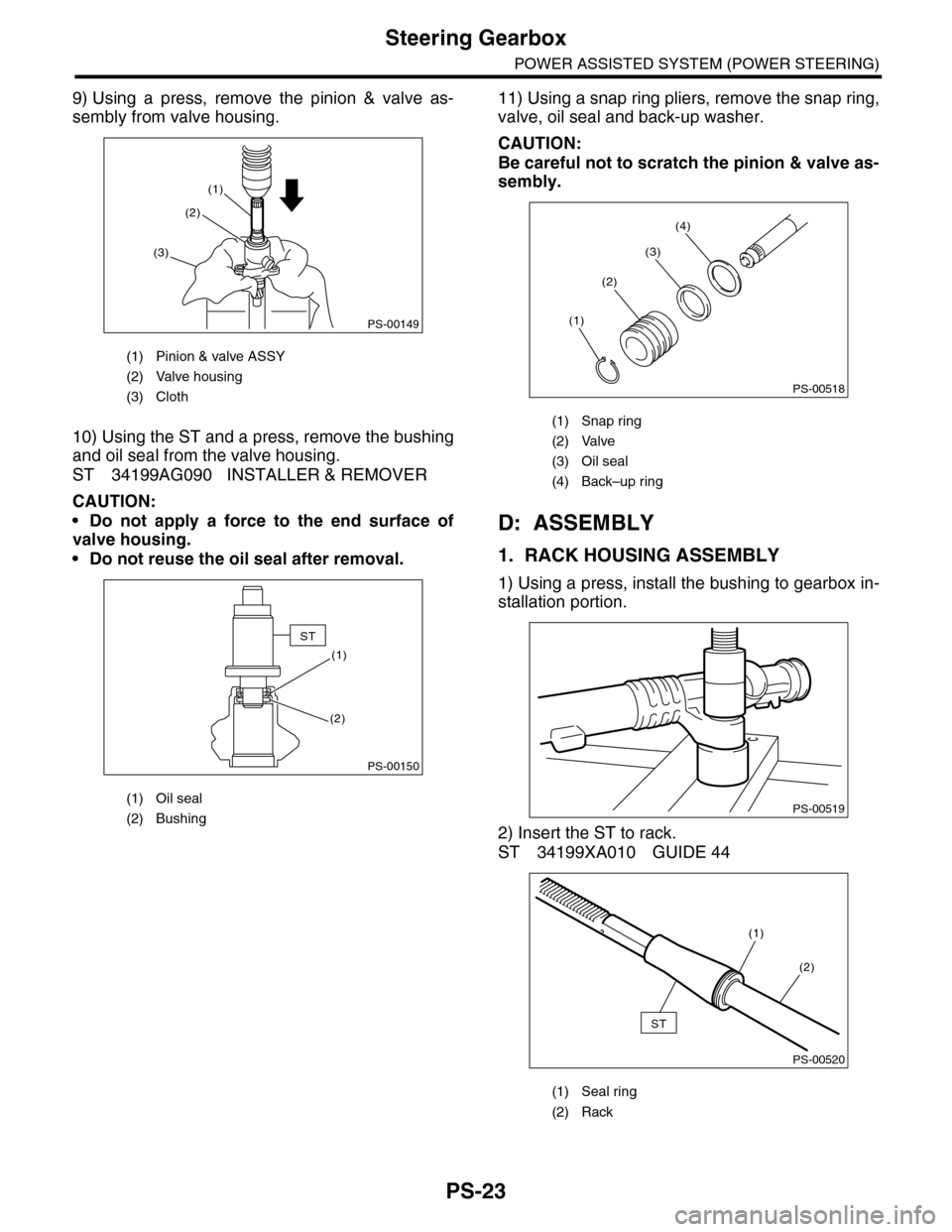

9) Using a press, remove the pinion & valve as-

sembly from valve housing.

10) Using the ST and a press, remove the bushing

and oil seal from the valve housing.

ST 34199AG090 INSTALLER & REMOVER

CAUTION:

•Do not apply a force to the end surface of

valve housing.

•Do not reuse the oil seal after removal.

11) Using a snap ring pliers, remove the snap ring,

valve, oil seal and back-up washer.

CAUTION:

Be careful not to scratch the pinion & valve as-

sembly.

D: ASSEMBLY

1. RACK HOUSING ASSEMBLY

1) Using a press, install the bushing to gearbox in-

stallation portion.

2) Insert the ST to rack.

ST 34199XA010 GUIDE 44

(1) Pinion & valve ASSY

(2) Valve housing

(3) Cloth

(1) Oil seal

(2) Bushing

(2)

(3)

(1)

PS-00149

(2)

(1)

PS-00150

ST

(1) Snap ring

(2) Valve

(3) Oil seal

(4) Back–up ring

(1) Seal ring

(2) Rack

PS-00518

(1)

(2)

(3)

(4)

PS-00519

PS-00520

ST

(1)

(2)

Page 904 of 2453

PS-24

Steering Gearbox

POWER ASSISTED SYSTEM (POWER STEERING)

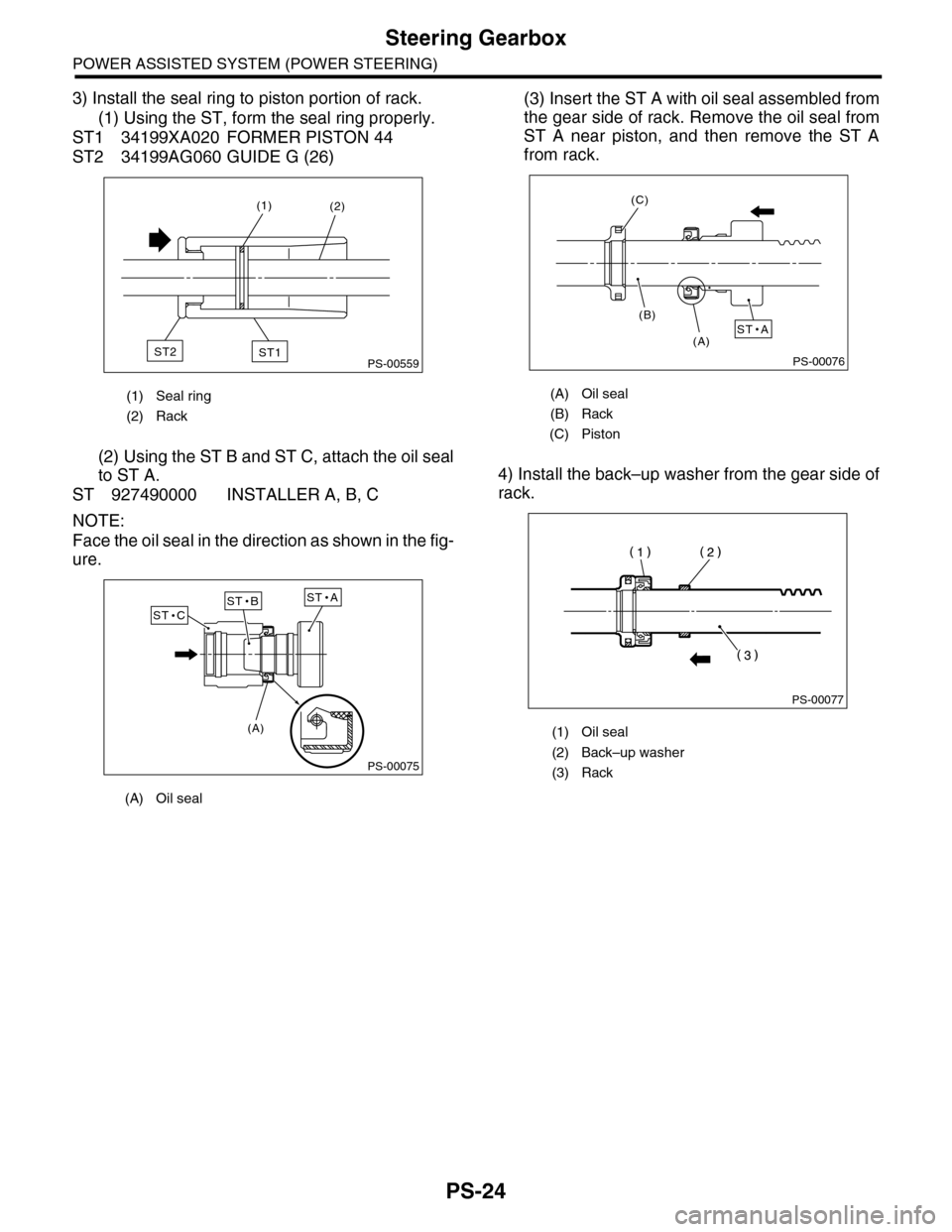

3) Install the seal ring to piston portion of rack.

(1) Using the ST, form the seal ring properly.

ST1 34199XA020 FORMER PISTON 44

ST2 34199AG060 GUIDE G (26)

(2) Using the ST B and ST C, attach the oil seal

to ST A.

ST 927490000 INSTALLER A, B, C

NOTE:

Face the oil seal in the direction as shown in the fig-

ure.

(3) Insert the ST A with oil seal assembled from

the gear side of rack. Remove the oil seal from

ST A near piston, and then remove the ST A

from rack.

4) Install the back–up washer from the gear side of

rack.

(1) Seal ring

(2) Rack

(A) Oil seal

PS-00559

(2)(1)

ST1ST2

PS-00075

ST AST BST C

(A)

(A) Oil seal

(B) Rack

(C) Piston

(1) Oil seal

(2) Back–up washer

(3) Rack

PS-00076

ST A(A)

(B)

(C)

PS-00077

Page 910 of 2453

PS-30

Steering Gearbox

POWER ASSISTED SYSTEM (POWER STEERING)

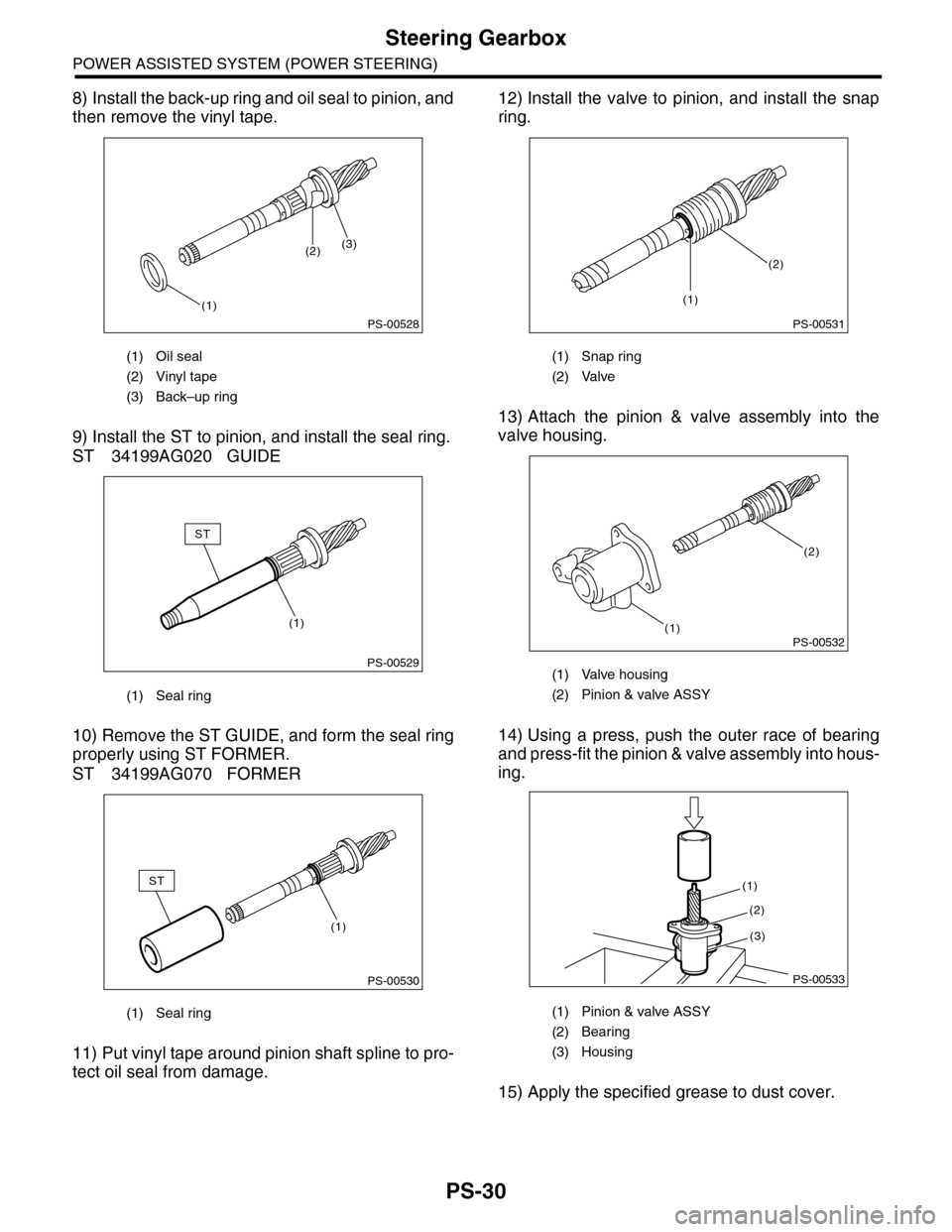

8) Install the back-up ring and oil seal to pinion, and

then remove the vinyl tape.

9) Install the ST to pinion, and install the seal ring.

ST 34199AG020 GUIDE

10) Remove the ST GUIDE, and form the seal ring

properly using ST FORMER.

ST 34199AG070 FORMER

11) Put vinyl tape around pinion shaft spline to pro-

tect oil seal from damage.

12) Install the valve to pinion, and install the snap

ring.

13) Attach the pinion & valve assembly into the

valve housing.

14) Using a press, push the outer race of bearing

and press-fit the pinion & valve assembly into hous-

ing.

15) Apply the specified grease to dust cover.

(1) Oil seal

(2) Vinyl tape

(3) Back–up ring

(1) Seal ring

(1) Seal ring

PS-00528

(1)

(2)(3)

PS-00529

(1)

ST

PS-00530

ST

(1)

(1) Snap ring

(2) Valve

(1) Valve housing

(2) Pinion & valve ASSY

(1) Pinion & valve ASSY

(2) Bearing

(3) Housing

PS-00531

(2)

(1)

PS-00532(1)

(2)

PS-00533

(1)

(2)

(3)

Page 913 of 2453

PS-33

Steering Gearbox

POWER ASSISTED SYSTEM (POWER STEERING)

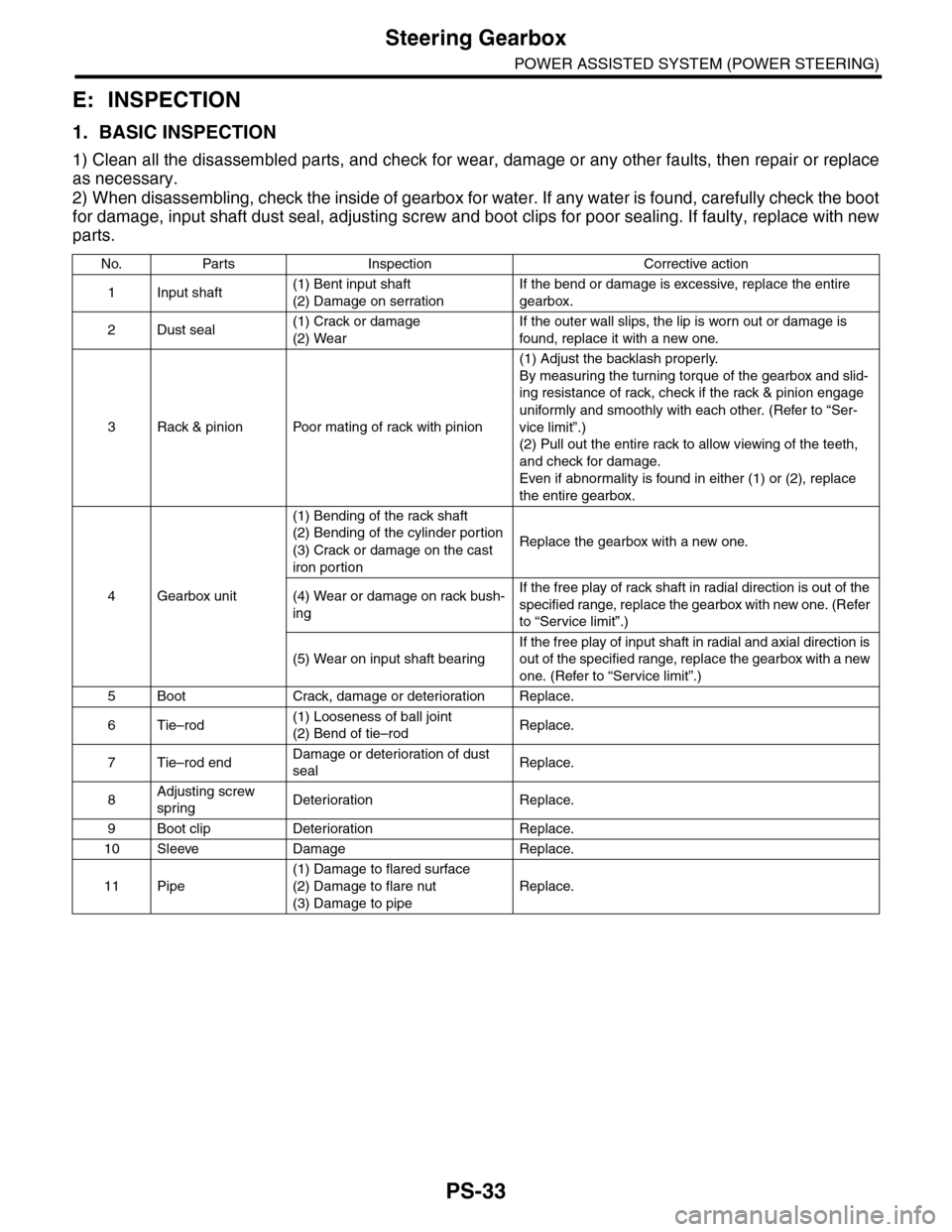

E: INSPECTION

1. BASIC INSPECTION

1) Clean all the disassembled parts, and check for wear, damage or any other faults, then repair or replace

as necessary.

2) When disassembling, check the inside of gearbox for water. If any water is found, carefully check the boot

for damage, input shaft dust seal, adjusting screw and boot clips for poor sealing. If faulty, replace with new

parts.

No. Parts Inspection Corrective action

1Input shaft(1) Bent input shaft

(2) Damage on serration

If the bend or damage is excessive, replace the entire

gearbox.

2Dust seal(1) Crack or damage

(2) Wear

If the outer wall slips, the lip is worn out or damage is

found, replace it with a new one.

3Rack & pinion Poor mating of rack with pinion

(1) Adjust the backlash properly.

By measuring the turning torque of the gearbox and slid-

ing resistance of rack, check if the rack & pinion engage

uniformly and smoothly with each other. (Refer to “Ser-

vice limit”.)

(2) Pull out the entire rack to allow viewing of the teeth,

and check for damage.

Even if abnormality is found in either (1) or (2), replace

the entire gearbox.

4Gearbox unit

(1) Bending of the rack shaft

(2) Bending of the cylinder portion

(3) Crack or damage on the cast

iron portion

Replace the gearbox with a new one.

(4) Wear or damage on rack bush-

ing

If the free play of rack shaft in radial direction is out of the

specified range, replace the gearbox with new one. (Refer

to “Service limit”.)

(5) Wear on input shaft bearing

If the free play of input shaft in radial and axial direction is

out of the specified range, replace the gearbox with a new

one. (Refer to “Service limit”.)

5Boot Crack, damage or deteriorationReplace.

6Tie–rod(1) Looseness of ball joint

(2) Bend of tie–rodReplace.

7Tie–rod endDamage or deterioration of dust

sealReplace.

8Adjusting screw

springDeterioration Replace.

9Boot clip Deterioration Replace.

10 Sleeve Damage Replace.

11 Pipe

(1) Damage to flared surface

(2) Damage to flare nut

(3) Damage to pipe

Replace.

Page 930 of 2453

PS-50

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

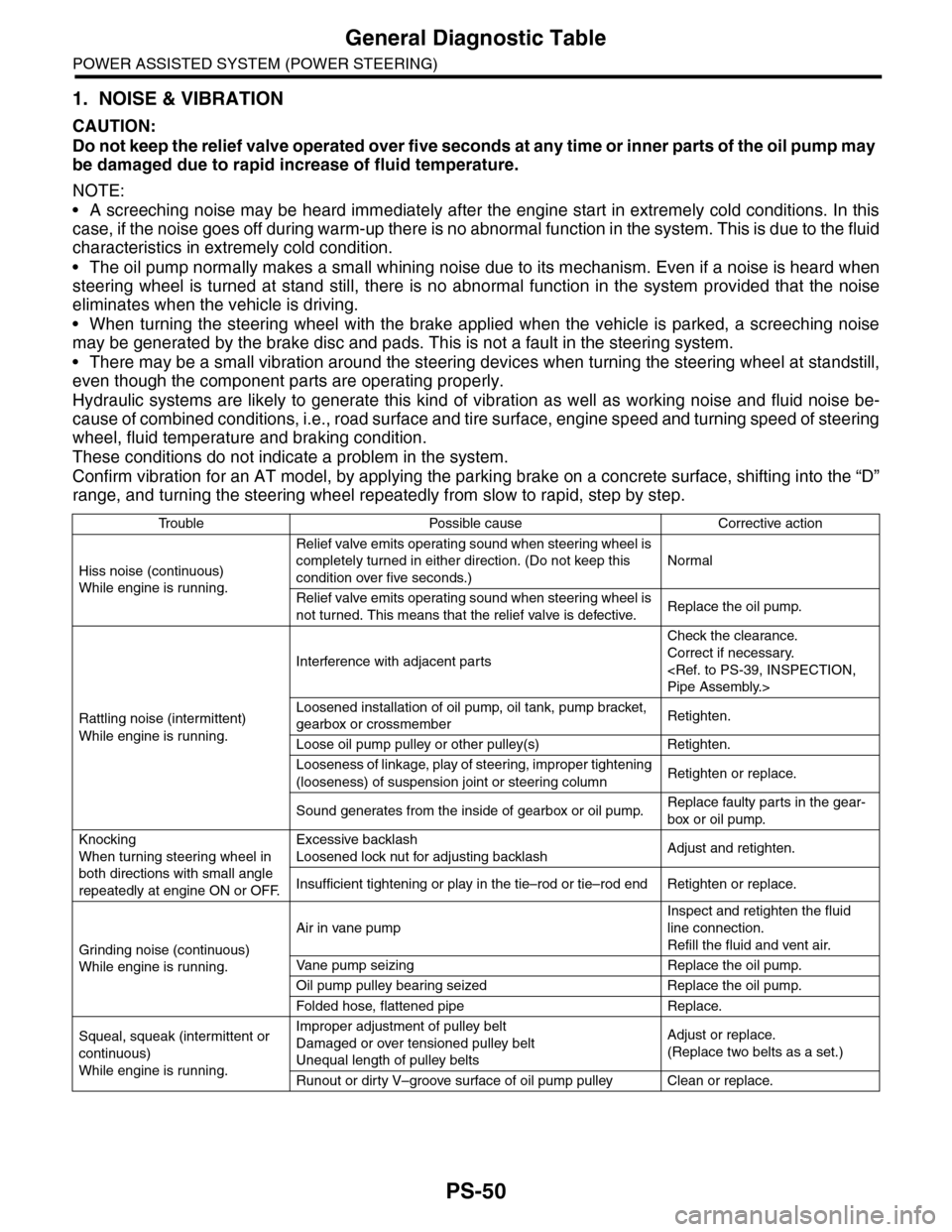

1. NOISE & VIBRATION

CAUTION:

Do not keep the relief valve operated over five seconds at any time or inner parts of the oil pump may

be damaged due to rapid increase of fluid temperature.

NOTE:

•A screeching noise may be heard immediately after the engine start in extremely cold conditions. In this

case, if the noise goes off during warm-up there is no abnormal function in the system. This is due to the fluid

characteristics in extremely cold condition.

•The oil pump normally makes a small whining noise due to its mechanism. Even if a noise is heard when

steering wheel is turned at stand still, there is no abnormal function in the system provided that the noise

eliminates when the vehicle is driving.

•When turning the steering wheel with the brake applied when the vehicle is parked, a screeching noise

may be generated by the brake disc and pads. This is not a fault in the steering system.

•There may be a small vibration around the steering devices when turning the steering wheel at standstill,

even though the component parts are operating properly.

Hydraulic systems are likely to generate this kind of vibration as well as working noise and fluid noise be-

cause of combined conditions, i.e., road surface and tire surface, engine speed and turning speed of steering

wheel, fluid temperature and braking condition.

These conditions do not indicate a problem in the system.

Confirm vibration for an AT model, by applying the parking brake on a concrete surface, shifting into the “D”

range, and turning the steering wheel repeatedly from slow to rapid, step by step.

Tr o u b l e P o s s i b l e c a u s e C o r r e c t i v e a c t i o n

Hiss noise (continuous)

While engine is running.

Relief valve emits operating sound when steering wheel is

completely turned in either direction. (Do not keep this

condition over five seconds.)

Normal

Relief valve emits operating sound when steering wheel is

not turned. This means that the relief valve is defective. Replace the oil pump.

Rattling noise (intermittent)

While engine is running.

Interference with adjacent parts

Check the clearance.

Correct if necessary.

Loosened installation of oil pump, oil tank, pump bracket,

gearbox or crossmemberRetighten.

Loose oil pump pulley or other pulley(s) Retighten.

Looseness of linkage, play of steering, improper tightening

(looseness) of suspension joint or steering columnRetighten or replace.

Sound generates from the inside of gearbox or oil pump.Replace faulty parts in the gear-

box or oil pump.

Knocking

When turning steering wheel in

both directions with small angle

repeatedly at engine ON or OFF.

Excessive backlash

Loosened lock nut for adjusting backlashAdjust and retighten.

Insufficient tightening or play in the tie–rod or tie–rod end Retighten or replace.

Grinding noise (continuous)

While engine is running.

Air in vane pump

Inspect and retighten the fluid

line connection.

Refill the fluid and vent air.

Va n e p u m p s e i z i n g R e p l a c e t h e o i l p u m p.

Oil pump pulley bearing seized Replace the oil pump.

Folded hose, flattened pipe Replace.

Squeal, squeak (intermittent or

continuous)

While engine is running.

Improper adjustment of pulley belt

Damaged or over tensioned pulley belt

Unequal length of pulley belts

Adjust or replace.

(Replace two belts as a set.)

Runout or dirty V–groove surface of oil pump pulley Clean or replace.

Page 932 of 2453

PS-52

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

2. MEASUREMENT OF STEERING EFFORT

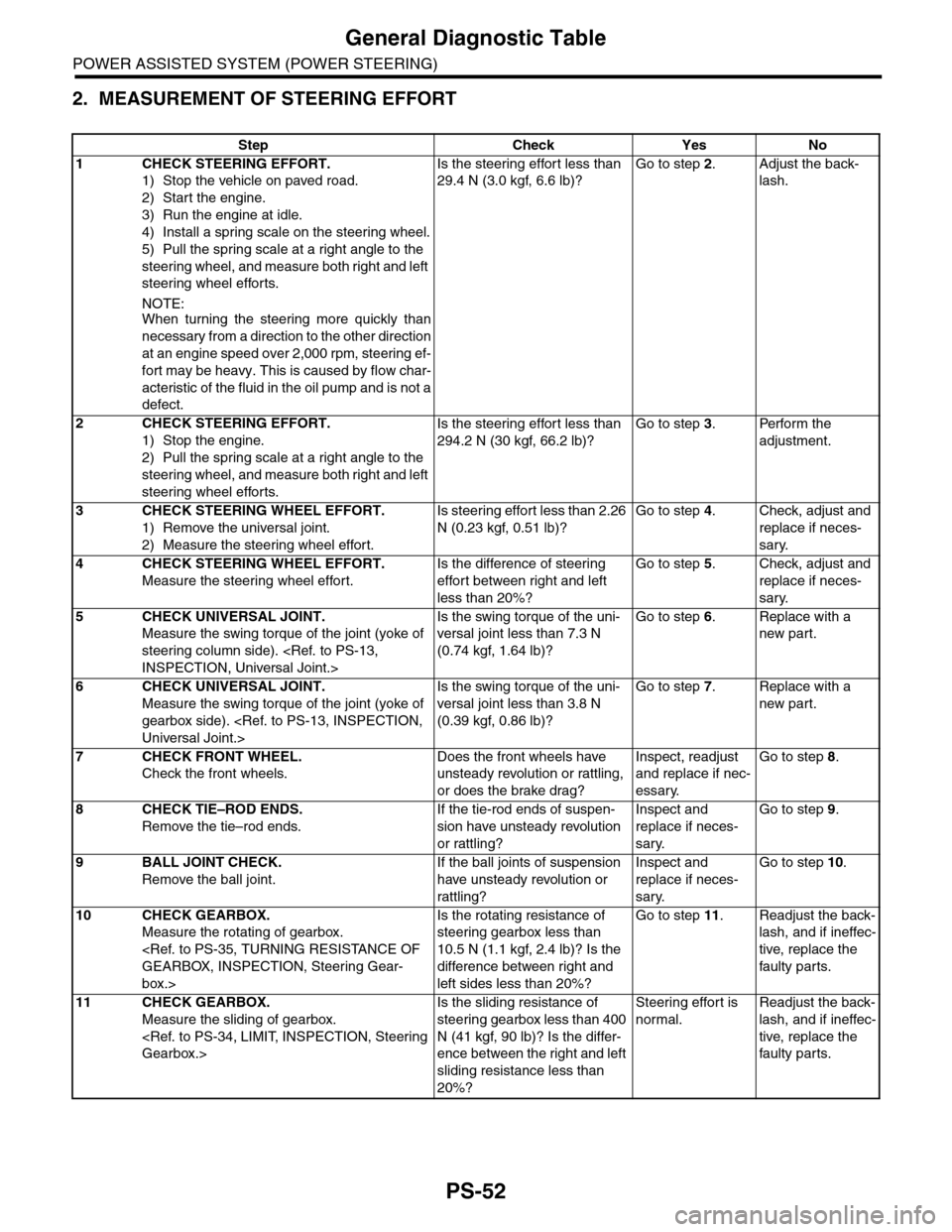

Step Check Yes No

1CHECK STEERING EFFORT.

1) Stop the vehicle on paved road.

2) Start the engine.

3) Run the engine at idle.

4) Install a spring scale on the steering wheel.

5) Pull the spring scale at a right angle to the

steering wheel, and measure both right and left

steering wheel efforts.

NOTE:When turning the steering more quickly than

necessary from a direction to the other direction

at an engine speed over 2,000 rpm, steering ef-

fort may be heavy. This is caused by flow char-

acteristic of the fluid in the oil pump and is not a

defect.

Is the steering effort less than

29.4 N (3.0 kgf, 6.6 lb)?

Go to step 2.Adjust the back-

lash.

2CHECK STEERING EFFORT.

1) Stop the engine.

2) Pull the spring scale at a right angle to the

steering wheel, and measure both right and left

steering wheel efforts.

Is the steering effort less than

294.2 N (30 kgf, 66.2 lb)?

Go to step 3.Perform the

adjustment.

3CHECK STEERING WHEEL EFFORT.

1) Remove the universal joint.

2) Measure the steering wheel effort.

Is steering effort less than 2.26

N (0.23 kgf, 0.51 lb)?

Go to step 4.Check, adjust and

replace if neces-

sary.

4CHECK STEERING WHEEL EFFORT.

Measure the steering wheel effort.

Is the difference of steering

effort between right and left

less than 20%?

Go to step 5.Check, adjust and

replace if neces-

sary.

5CHECK UNIVERSAL JOINT.

Measure the swing torque of the joint (yoke of

steering column side).

Is the swing torque of the uni-

versal joint less than 7.3 N

(0.74 kgf, 1.64 lb)?

Go to step 6.Replace with a

new part.

6CHECK UNIVERSAL JOINT.

Measure the swing torque of the joint (yoke of

gearbox side).

Is the swing torque of the uni-

versal joint less than 3.8 N

(0.39 kgf, 0.86 lb)?

Go to step 7.Replace with a

new part.

7CHECK FRONT WHEEL.

Check the front wheels.

Does the front wheels have

unsteady revolution or rattling,

or does the brake drag?

Inspect, readjust

and replace if nec-

essary.

Go to step 8.

8CHECK TIE–ROD ENDS.

Remove the tie–rod ends.

If the tie-rod ends of suspen-

sion have unsteady revolution

or rattling?

Inspect and

replace if neces-

sary.

Go to step 9.

9BALL JOINT CHECK.

Remove the ball joint.

If the ball joints of suspension

have unsteady revolution or

rattling?

Inspect and

replace if neces-

sary.

Go to step 10.

10 CHECK GEARBOX.

Measure the rotating of gearbox.

box.>

Is the rotating resistance of

steering gearbox less than

10.5 N (1.1 kgf, 2.4 lb)? Is the

difference between right and

left sides less than 20%?

Go to step 11.Readjust the back-

lash, and if ineffec-

tive, replace the

faulty par ts.

11 CHECK GEARBOX.

Measure the sliding of gearbox.

Is the sliding resistance of

steering gearbox less than 400

N (41 kgf, 90 lb)? Is the differ-

ence between the right and left

sliding resistance less than

20%?

Steering effort is

normal.

Readjust the back-

lash, and if ineffec-

tive, replace the

faulty par ts.

Page 936 of 2453

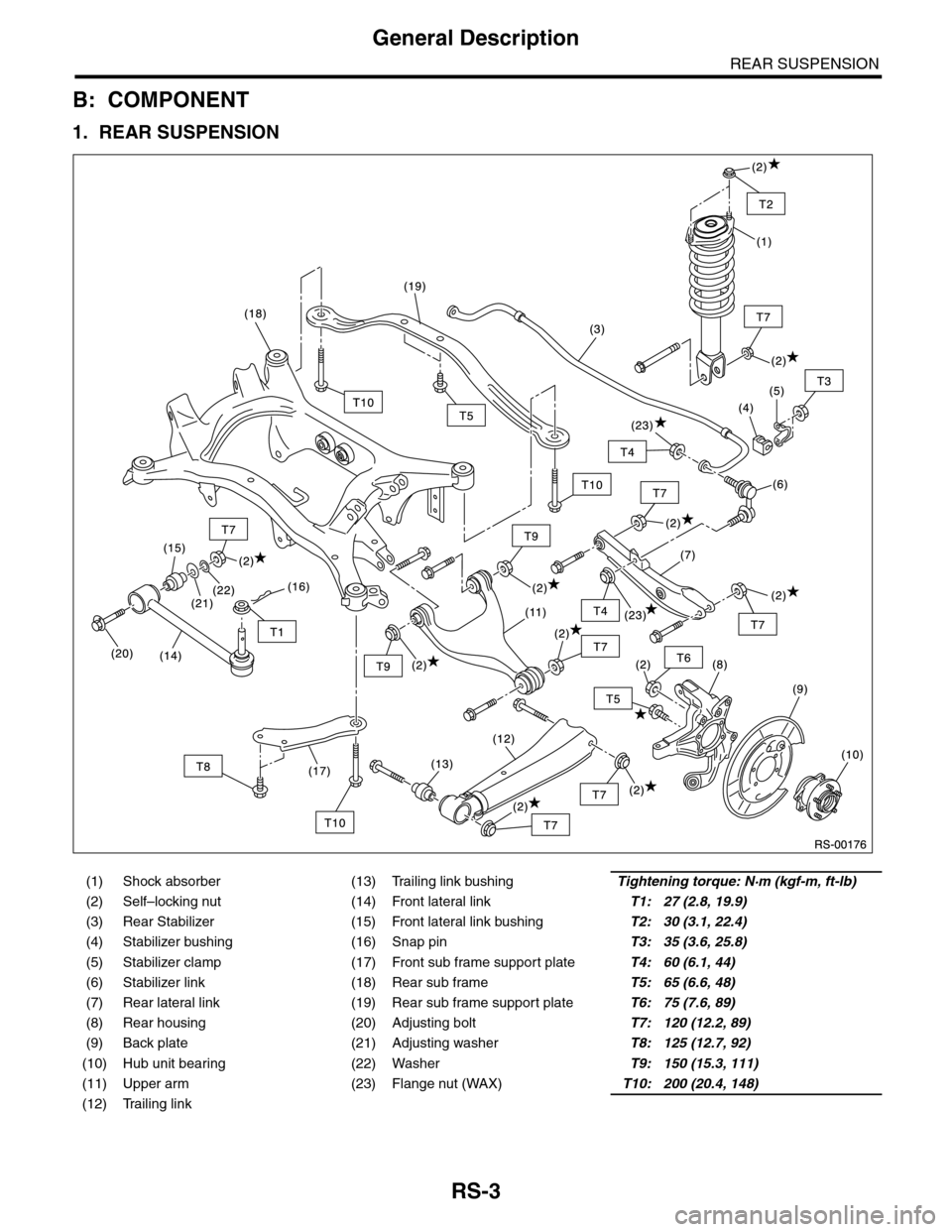

RS-3

General Description

REAR SUSPENSION

B: COMPONENT

1. REAR SUSPENSION

(1) Shock absorber (13) Trailing link bushingTightening torque: N·m (kgf-m, ft-lb)

(2) Self–locking nut (14) Front lateral linkT1: 27 (2.8, 19.9)

(3) Rear Stabilizer (15) Front lateral link bushingT2: 30 (3.1, 22.4)

(4) Stabilizer bushing (16) Snap pinT3: 35 (3.6, 25.8)

(5) Stabilizer clamp (17) Front sub frame support plateT4: 60 (6.1, 44)

(6) Stabilizer link (18) Rear sub frameT5: 65 (6.6, 48)

(7) Rear lateral link (19) Rear sub frame support plateT6: 75 (7.6, 89)

(8) Rear housing (20) Adjusting boltT7: 120 (12.2, 89)

(9) Back plate (21) Adjusting washerT8: 125 (12.7, 92)

(10) Hub unit bearing (22) WasherT9: 150 (15.3, 111)

(11) Upper arm (23) Flange nut (WAX)T10: 200 (20.4, 148)

(12) Trailing link