Back up SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1781 of 2453

GD(H6DO)-169

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

CW:DTC P0519 IDLE CONTROL SYSTEM MALFUNCTION (FAIL-SAFE)

1. OUTLINE OF DIAGNOSIS

Detect malfunctions in which the engine RPM continues to rise during idling.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Perform the diagnosis continuously if the vehicle speed at less than 4 km/h (2.49 MPH).

4. DIAGNOSTIC METHOD

Judge as NG when the continuous time until completing the all malfunction criteria below becomes more than

the time needed for diagnosis (2 seconds).

Time Needed for Diagnosis: 2 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear NG when the continuous time until completing the malfunction criteria below be-

comes more than the time needed for diagnosis (5 seconds).

5. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

6. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

7. FAIL SAFE

Fuel cut: Cuts off fuel only #1 and #2 cylinders, or for all cylinders according to vehicle speed, engine RPM,

and throttle position.

8. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Feedback in ISC In operation

Ve h i c l e s p e e d < 4 k m / h ( 2 . 4 9 M P H )

After engine starting 1 second or more

Judgment Value

Malfunction Criteria Threshold Value

Engine RPM - Targeted engine RPM≥ 1500 rpm

Feedback value for ISC≤ 0

Change of engine RPM for every engine

120 °CA

≥ –5 rpm

Judgment Value

Malfunction Criteria Threshold Value

Engine RPM - Targeted engine RPM < 1500 rpm

Page 1794 of 2453

GD(H6DO)-182

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

DF:DTC P1152 O2 SENSOR CIRCUIT RANGE/PERFORMANCE (LOW) (BANK 1

SENSOR 1)

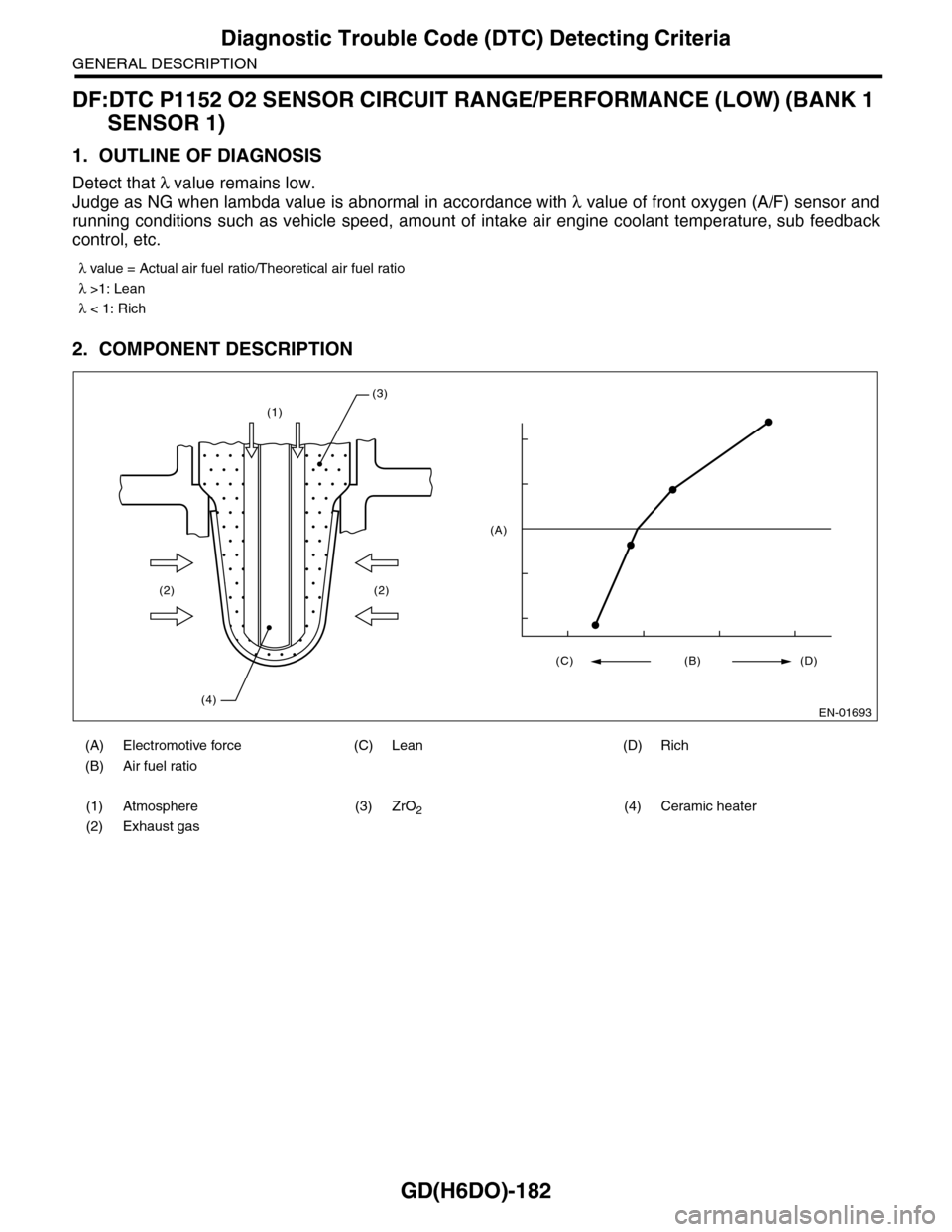

1. OUTLINE OF DIAGNOSIS

Detect that λ value remains low.

Judge as NG when lambda value is abnormal in accordance with λ value of front oxygen (A/F) sensor and

running conditions such as vehicle speed, amount of intake air engine coolant temperature, sub feedback

control, etc.

2. COMPONENT DESCRIPTION

λ value = Actual air fuel ratio/Theoretical air fuel ratio

λ >1: Lean

λ < 1: Rich

(A) Electromotive force (C) Lean (D) Rich

(B) Air fuel ratio

(1) Atmosphere (3) ZrO2(4) Ceramic heater

(2) Exhaust gas

(1)

(2)

(4)

(2)

(3)

EN-01693

(C) (B) (D)

(A)

Page 1795 of 2453

GD(H6DO)-183

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform diagnosis continuously at a constant speed of 20 km/h (12 MPH) or more, starting from 60 seconds

after starting the engine.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time of meeting the malfunction criteria below becomes more than the

time needed for diagnosis (10 seconds). Judge as OK and clear the NG when the malfunction criteria below

are not met.

Time Needed for Diagnosis: 10 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Front oxygen (A/F) sensor main learning compensation: Not allowed to calculate.

•Rear oxygen sensor sub learning compensation: Not allowed to calculate.

•Purge control: Not allowed to purge

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

All secondary parameters enable conditions4 seconds or more

Battery voltage > 10.9 V

Atmospheric pressure > 75.1 kPa (563 mmHg, 22.2 inHg)

Rear oxygen sensor sub feedback Execution

Rear oxygen sensor output voltage –

Feedback target voltage

–0.2 V ←→ 0.1 V

or rear oxygen sensor sub feedback

compensation coefficient

On Min.

or rear oxygen sensor sub feedback

compensation coefficient

On Max.

After engine starting 60 seconds or more

Engine coolant temperature≥ 75°C (167°F)

Ve h i c l e s p e e d≥ 20 km/h (12 MPH)

Amount of intake air≥ 8 g (0.28 oz)/s

Load change in 1/3 engine revolution.≤ 0.02g (0.001 oz)/rev

Fr o nt ox yg e n ( A / F) s en so r im pe d an c e 0 ←→ 50 Ω

Learning value of evaporation gas density≤ 0.12

To t a l t i m e o f o p e r a t i n g c a n i s t e r p u r g e 2 0 s e c o n d s o r m o r e

Ta r g e t e d l a m b d a v a l u e l o a d c o m p e n s a -

tion coefficient

–0.05 ←→ 0.05

Judgment Value

Malfunction Criteria Threshold Value

Output λ value when rear oxygen sensor

sub feedback compensation coefficient

is not at maximum limit

≤ 0.85

Page 1796 of 2453

GD(H6DO)-184

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

DG:DTC P1153 O2 SENSOR CIRCUIT RANGE/PERFORMANCE (HIGH) (BANK 1

SENSOR 1)

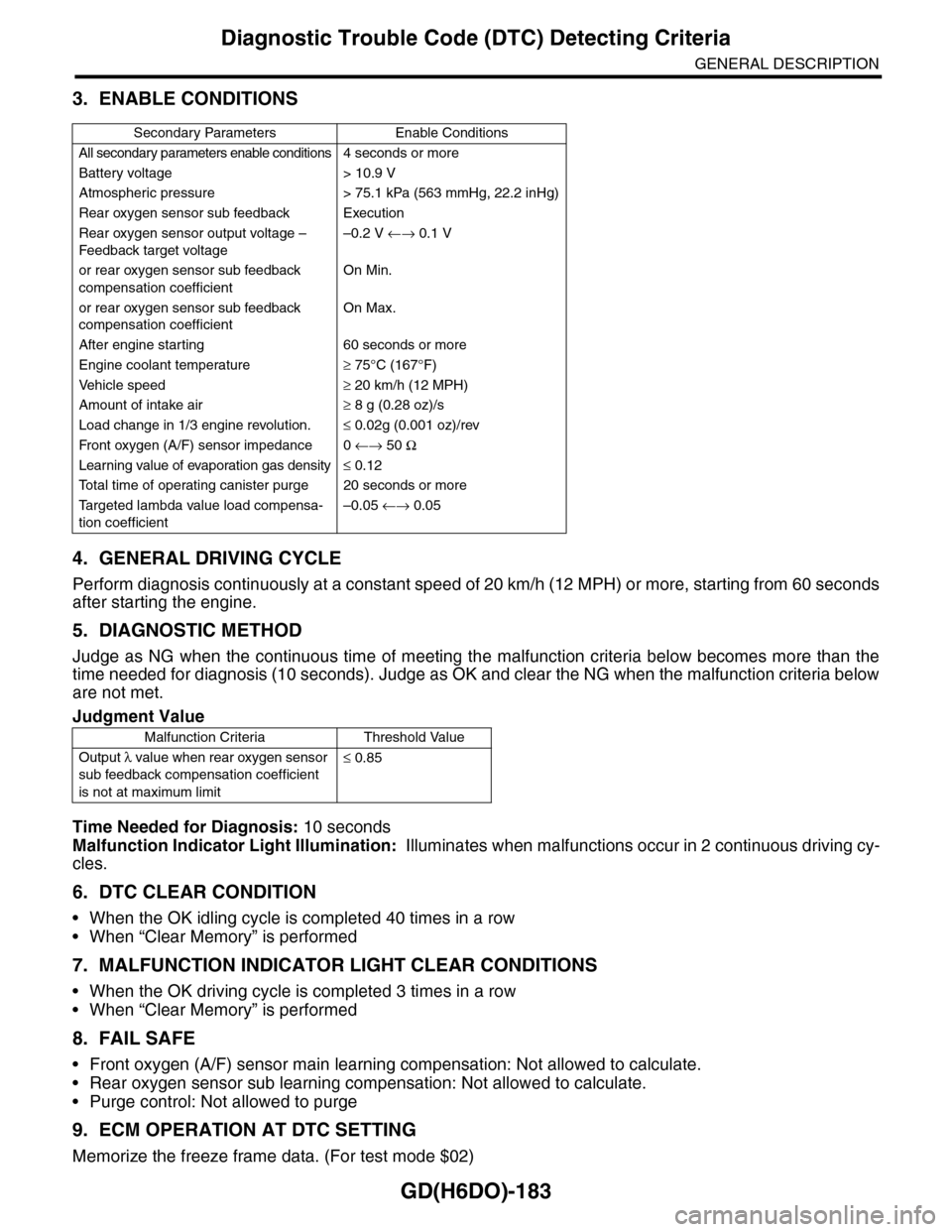

1. OUTLINE OF DIAGNOSIS

Detect that λ value remains high.

Judge as NG when lambda value is abnormal in accordance with λ value of front oxygen (A/F) sensor and

running conditions such as vehicle speed, amount of intake air engine coolant temperature, sub feedback

control, etc.

2. COMPONENT DESCRIPTION

λ value = Actual air fuel ratio/Theoretical air fuel ratio

λ >1: Lean

λ < 1: Rich

(A) Electromotive force (C) Lean (D) Rich

(B) Air fuel ratio

(1) Atmosphere (3) ZrO2(4) Ceramic heater

(2) Exhaust gas

(1)

(2)

(4)

(2)

(3)

EN-01693

(C) (B) (D)

(A)

Page 1797 of 2453

GD(H6DO)-185

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform diagnosis continuously at a constant vehicle speed of 20 km/h (12 MPH) or more, from 60 seconds

after starting the engine.

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time of meeting the malfunction criteria below becomes more than the

time needed for diagnosis (10 seconds). Judge as OK and clear the NG when the malfunction criteria below

are not met.

Time Needed for Diagnosis: 10 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Front oxygen (A/F) sensor main learning compensation: Not allowed to calculate.

•Rear oxygen sensor sub learning compensation: Not allowed to calculate.

•Purge control: Not allowed to purge

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

All secondary parameters enable conditions4 seconds or more

Battery voltage > 10.9 V

Atmospheric pressure > 75.1 kPa (563 mmHg, 22.2 inHg)

Rear oxygen sensor sub feedback Execution

Rear oxygen sensor output voltage –

Feedback target voltage

–0.2 V ←→ 0.1 V

or rear oxygen sensor sub feedback

compensation coefficient

On Min.

or rear oxygen sensor sub feedback

compensation coefficient

On Max.

After engine starting 60 seconds or more

Engine coolant temperature≥ 75°C (167°F)

Ve h i c l e s p e e d≥ 20 km/h (12 MPH)

Intake air flow≥ 8 g (0.28 oz)/s

Load change in 1/3 engine revolution.≤ 0.02g (0.001 oz)/rev

Fr o nt ox yg e n ( A / F) s en so r im pe d an c e 0 ←→ 52 Ω

Learning value of evaporation gas density≤ 0.12

To t a l t i m e o f o p e r a t i n g c a n i s t e r p u r g e 2 0 s e c o n d s o r m o r e

Ta r g e t e d l a m b d a v a l u e l o a d c o m p e n s a -

tion coefficient

–0.05 ←→ 0.05

Judgment Value

Malfunction Criteria Threshold Value

Output λ value when rear oxygen sensor

sub feedback compensation coefficient

cannot be at minimum limit

≥ 1.15

Page 1804 of 2453

GD(H6DO)-192

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

DM:DTC P1560 BACK-UP VOLTAGE CIRCUIT MALFUNCTION

1. OUTLINE OF DIAGNOSIS

Detect the open/short circuit of back-up power supply circuit.

Judge as NG when the backup power voltage is low.

2. ENABLE CONDITIONS

3. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

4. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time of completing the malfunction criteria below becomes more than 2.5

seconds.

Time Needed for Diagnosis: 2.5 seconds

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

5. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

6. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

7. FAIL SAFE

None

8. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Vo l t a g e o f b a c k - u p p o w e r s u p p l y L o w

Battery voltage≥ 10.9 V

Engine speed > 500 rpm

Judgment Value

Malfunction Criteria Threshold Value

Vo l t a g e o f b a c k - u p p o w e r s u p p l y H i g h

Battery voltage≥ 10.9 V

Engine speed > 500 rpm

Page 1809 of 2453

GD(H6DO)-197

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

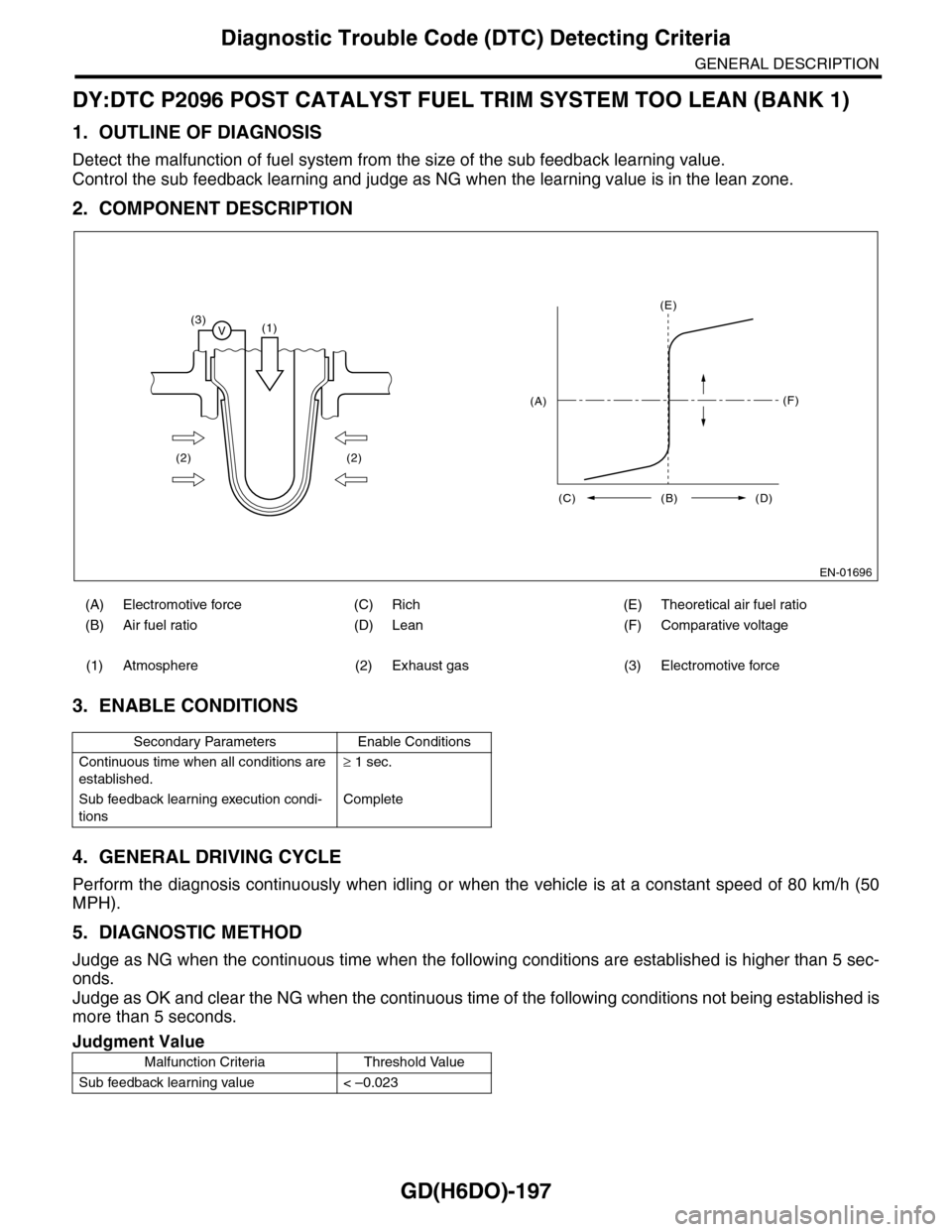

DY:DTC P2096 POST CATALYST FUEL TRIM SYSTEM TOO LEAN (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect the malfunction of fuel system from the size of the sub feedback learning value.

Control the sub feedback learning and judge as NG when the learning value is in the lean zone.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously when idling or when the vehicle is at a constant speed of 80 km/h (50

MPH).

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time when the following conditions are established is higher than 5 sec-

onds.

Judge as OK and clear the NG when the continuous time of the following conditions not being established is

more than 5 seconds.

(A) Electromotive force (C) Rich (E) Theoretical air fuel ratio

(B) Air fuel ratio (D) Lean (F) Comparative voltage

(1) Atmosphere (2) Exhaust gas (3) Electromotive force

Secondary Parameters Enable Conditions

Continuous time when all conditions are

established.

≥ 1 sec.

Sub feedback learning execution condi-

tions

Complete

Judgment Value

Malfunction Criteria Threshold Value

Sub feedback learning value < –0.023

EN-01696

(3)V(1)

(2) (2)

(E)

(F)

(C) (B) (D)

(A)

Page 1811 of 2453

GD(H6DO)-199

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

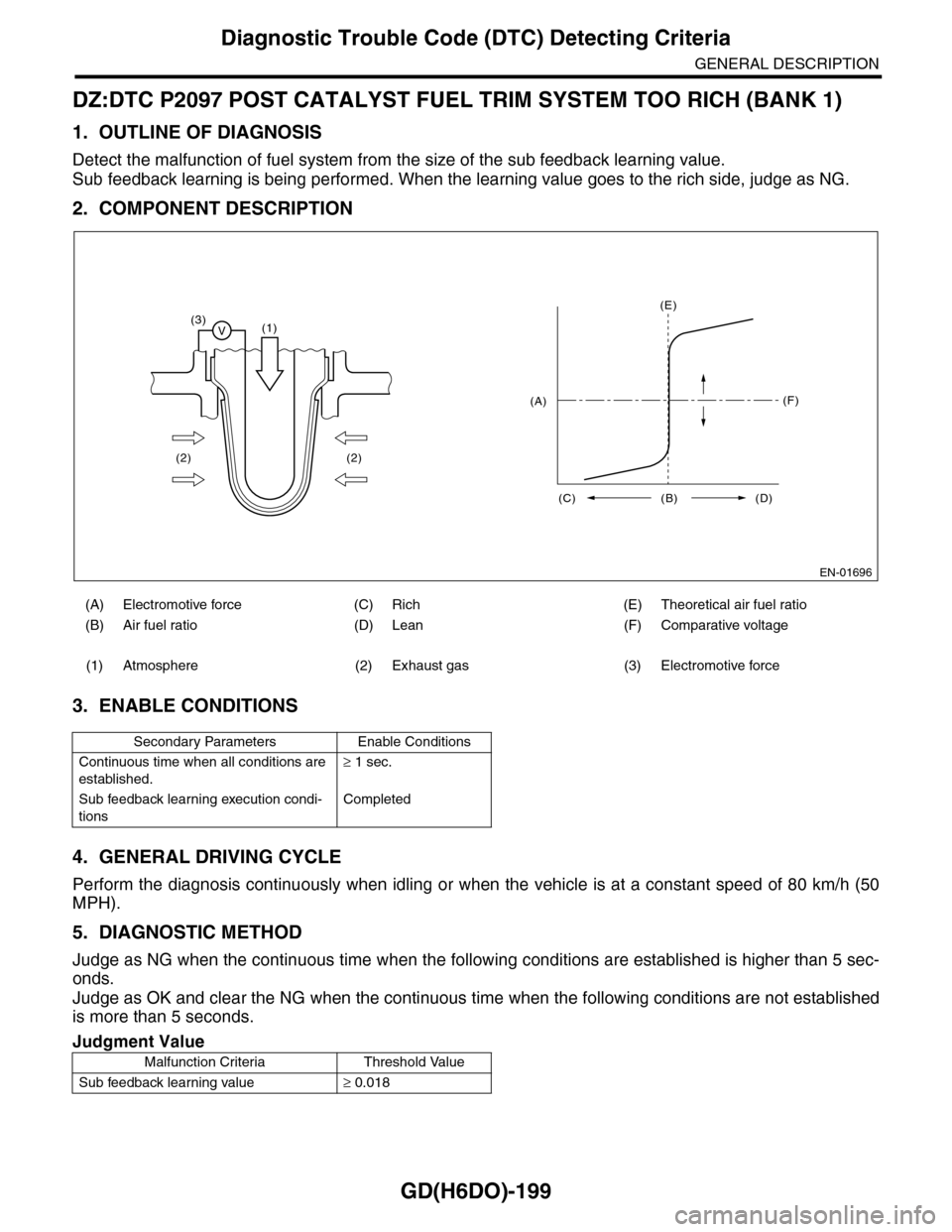

DZ:DTC P2097 POST CATALYST FUEL TRIM SYSTEM TOO RICH (BANK 1)

1. OUTLINE OF DIAGNOSIS

Detect the malfunction of fuel system from the size of the sub feedback learning value.

Sub feedback learning is being performed. When the learning value goes to the rich side, judge as NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis continuously when idling or when the vehicle is at a constant speed of 80 km/h (50

MPH).

5. DIAGNOSTIC METHOD

Judge as NG when the continuous time when the following conditions are established is higher than 5 sec-

onds.

Judge as OK and clear the NG when the continuous time when the following conditions are not established

is more than 5 seconds.

(A) Electromotive force (C) Rich (E) Theoretical air fuel ratio

(B) Air fuel ratio (D) Lean (F) Comparative voltage

(1) Atmosphere (2) Exhaust gas (3) Electromotive force

Secondary Parameters Enable Conditions

Continuous time when all conditions are

established.

≥ 1 sec.

Sub feedback learning execution condi-

tions

Completed

Judgment Value

Malfunction Criteria Threshold Value

Sub feedback learning value≥ 0.018

EN-01696

(3)V(1)

(2) (2)

(E)

(F)

(C) (B) (D)

(A)

Page 1846 of 2453

IN(H6DO)-4

Air Cleaner Element

INTAKE (INDUCTION)

2. Air Cleaner Element

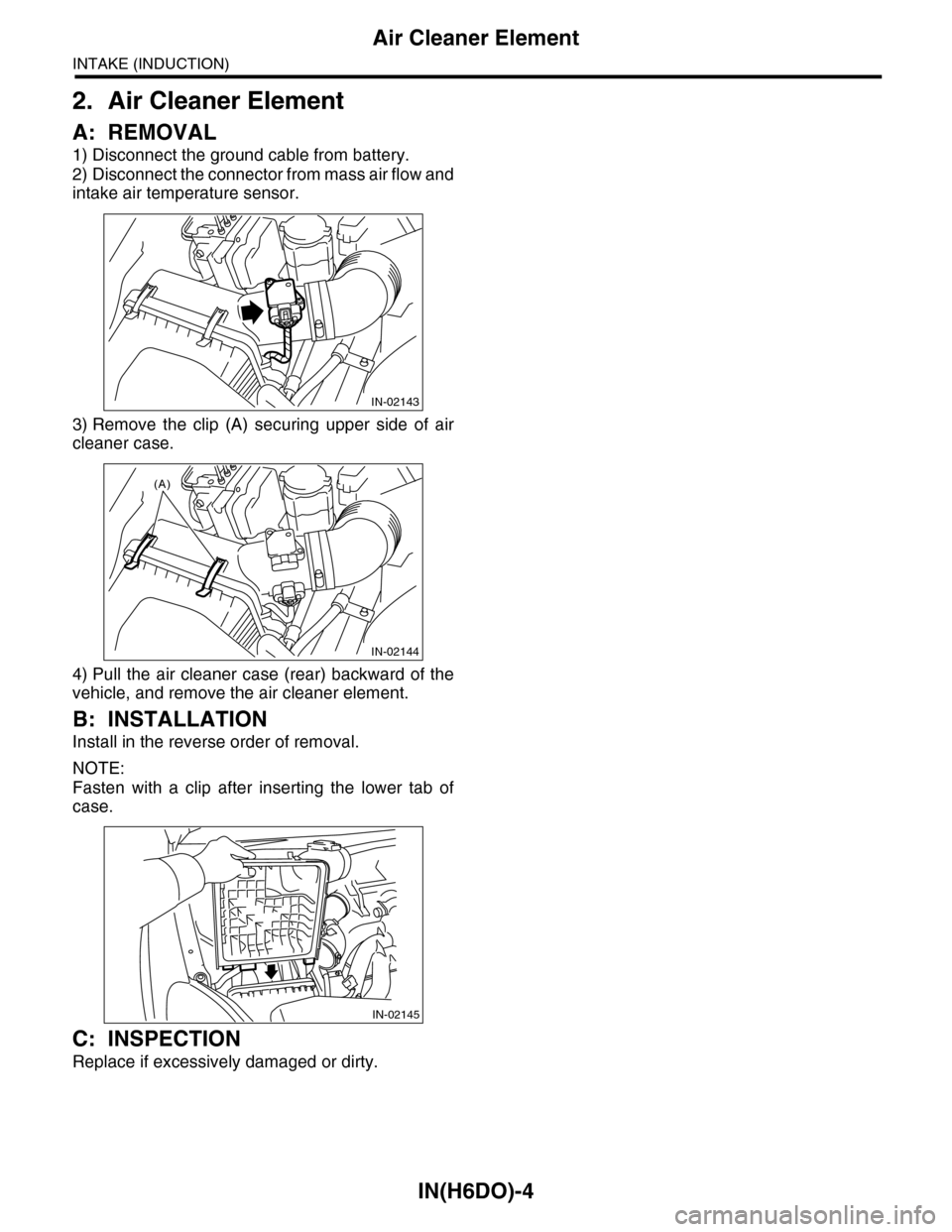

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Disconnect the connector from mass air flow and

intake air temperature sensor.

3) Remove the clip (A) securing upper side of air

cleaner case.

4) Pull the air cleaner case (rear) backward of the

vehicle, and remove the air cleaner element.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

Fasten with a clip after inserting the lower tab of

case.

C: INSPECTION

Replace if excessively damaged or dirty.

IN-02143

IN-02144

(A)

IN-02145

Page 1920 of 2453

ME(H6DO)-54

Camshaft

MECHANICAL

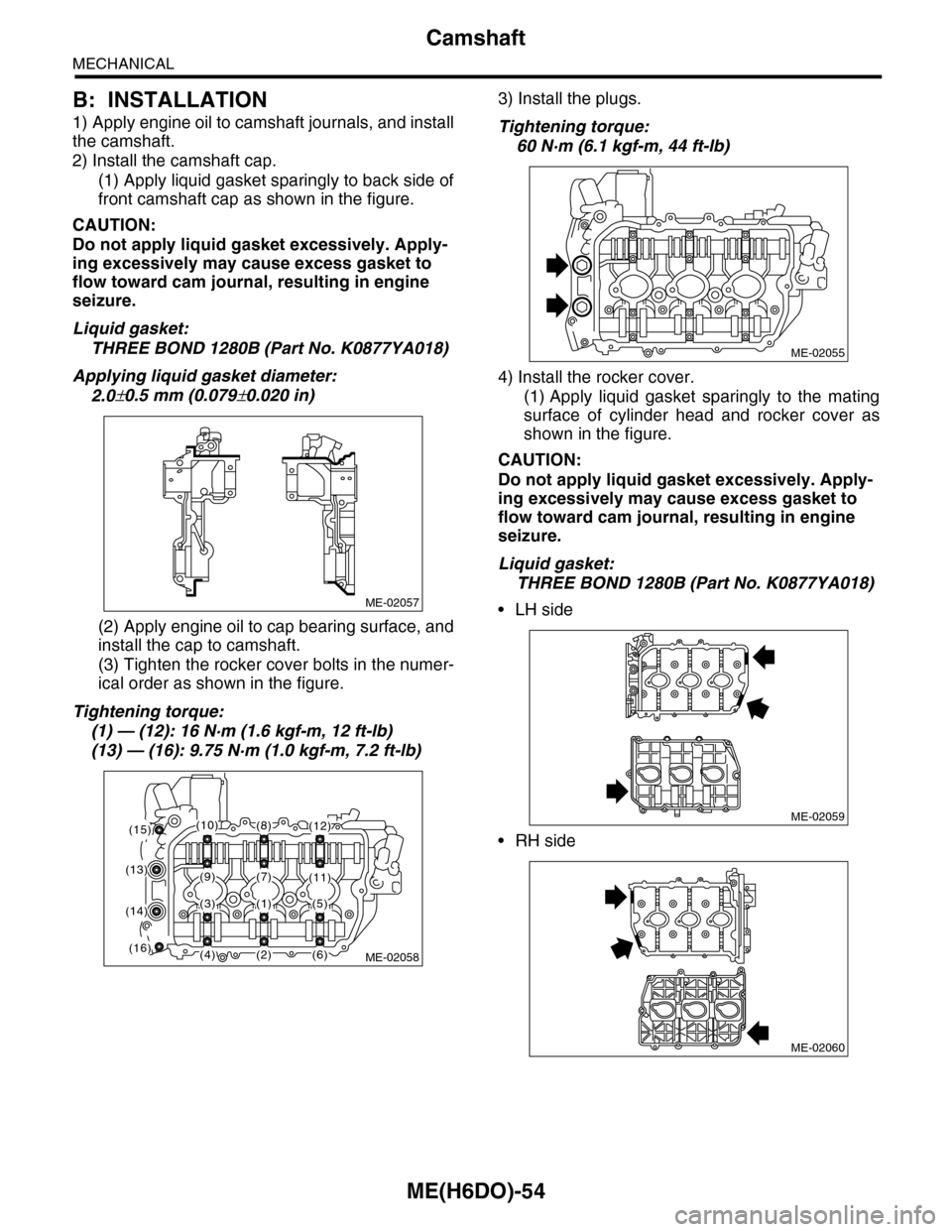

B: INSTALLATION

1) Apply engine oil to camshaft journals, and install

the camshaft.

2) Install the camshaft cap.

(1) Apply liquid gasket sparingly to back side of

front camshaft cap as shown in the figure.

CAUTION:

Do not apply liquid gasket excessively. Apply-

ing excessively may cause excess gasket to

flow toward cam journal, resulting in engine

seizure.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

Applying liquid gasket diameter:

2.0±0.5 mm (0.079±0.020 in)

(2) Apply engine oil to cap bearing surface, and

install the cap to camshaft.

(3) Tighten the rocker cover bolts in the numer-

ical order as shown in the figure.

Tightening torque:

(1) — (12): 16 N·m (1.6 kgf-m, 12 ft-lb)

(13) — (16): 9.75 N·m (1.0 kgf-m, 7.2 ft-lb)

3) Install the plugs.

Tightening torque:

60 N·m (6.1 kgf-m, 44 ft-lb)

4) Install the rocker cover.

(1) Apply liquid gasket sparingly to the mating

surface of cylinder head and rocker cover as

shown in the figure.

CAUTION:

Do not apply liquid gasket excessively. Apply-

ing excessively may cause excess gasket to

flow toward cam journal, resulting in engine

seizure.

Liquid gasket:

THREE BOND 1280B (Part No. K0877YA018)

•LH side

•RH side

ME-02057

ME-02058

(1)

(2)

(8)

(7)(9)

(3)

(4)

(5)

(6)

(10)

(11)(13)

(14)

(15)

(16)

(12)

ME-02055

ME-02059

ME-02060