SUBARU TRIBECA 2009 1.G Service Workshop Manual

Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1221 of 2453

EN(H6DO)(diag)-60

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

8CHECK STARTER RELAY.

1) Connect the battery to starter relay termi-

nals No. 15 and No. 16.

2) Measure the resistance between starter

relay terminals.

Te r m i n a l s

No. 13 — No. 14:

Is the resistance less than 1

Ω?

Go to step 9.Replace the

starter relay.

9CHECK INPUT VOLTAGE FROM ECM.

1) Turn the ignition switch to OFF.

2) Connect the connector to starter relay.

3) Disconnect the connectors from ECM.

4) Measure the voltage between ECM and

chassis ground.

Connector & terminal

(B136) No. 32 (+) — Chassis ground (–):

(B136) No. 20 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the ECM.

Engine Control

Module (ECM).>

Repair the open or

ground short cir-

cuit of harness

between ECM and

starter relay.

Step Check Yes No

Page 1222 of 2453

EN(H6DO)(diag)-61

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

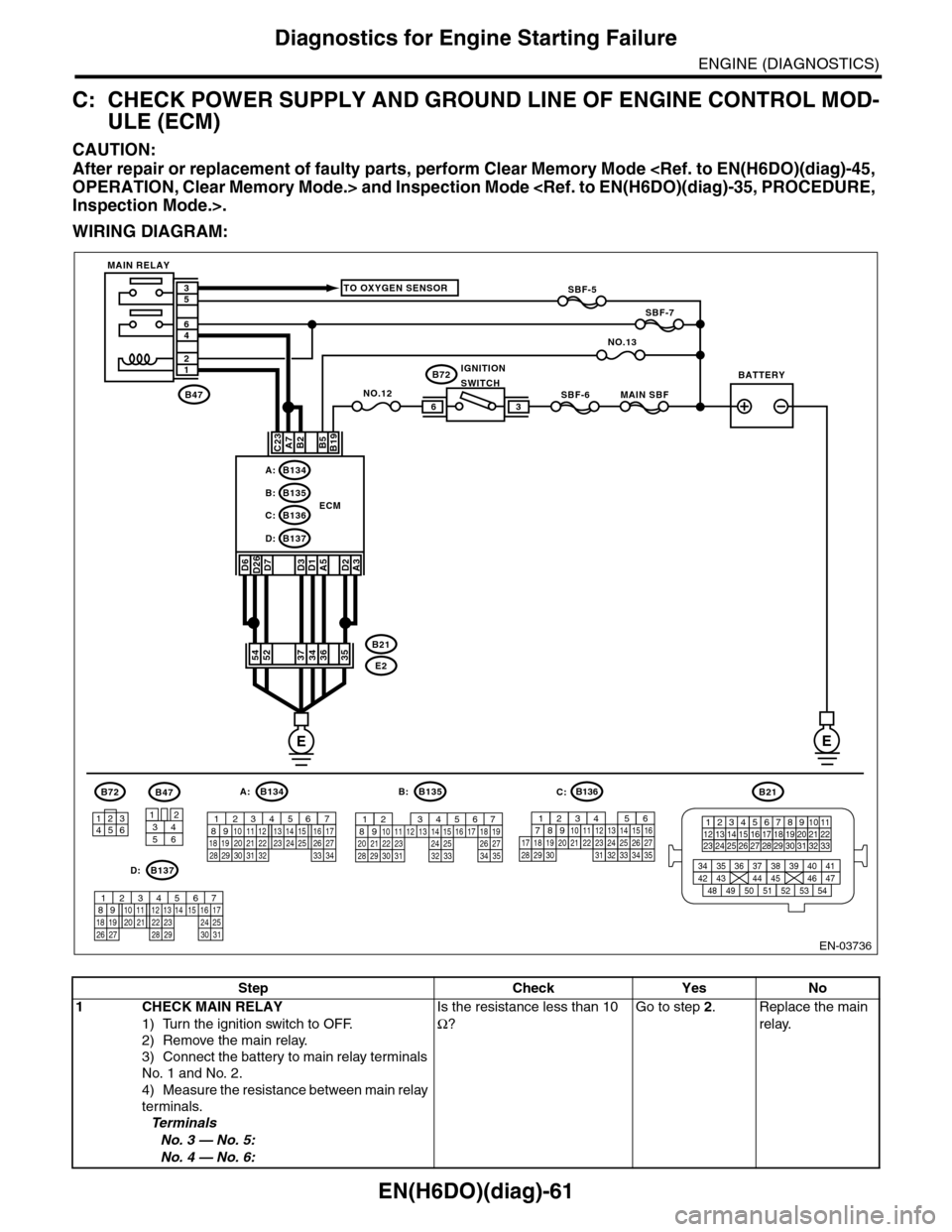

C: CHECK POWER SUPPLY AND GROUND LINE OF ENGINE CONTROL MOD-

ULE (ECM)

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03736

SBF-6MAIN SBF

SBF-7

B72

B2A7C23

D7D3D1A5

B5B19

NO.12B47

E2

B21

12

46

53

ECM

EE

36

B134A:

D:B137

B135B:

B136C:

A3

52373634

3412

56

B47

TO OXYGEN SENSOR

NO.13

D2

35

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

B72

134562

B134

56 7821943102422 23 2511 12 13 14 1526 2728

16 1718 19 20 2133 34293230 31

A:B135

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

B:

B137

5678219431022 2311 12 13 14 1524 2526

16 1718 19 20 2127 28 29 30 31

D:

SBF-5

D6D26

54

MAIN RELAY

BATTERYIGNITIONSWITCH

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:

Step Check Yes No

1CHECK MAIN RELAY

1) Turn the ignition switch to OFF.

2) Remove the main relay.

3) Connect the battery to main relay terminals

No. 1 and No. 2.

4) Measure the resistance between main relay

terminals.

Te r m i n a l s

No. 3 — No. 5:

No. 4 — No. 6:

Is the resistance less than 10

Ω?

Go to step 2.Replace the main

relay.

Page 1223 of 2453

EN(H6DO)(diag)-62

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

2CHECK GROUND CIRCUIT FOR ECM.

1) Disconnect the connectors from ECM.

2) Measure the resistance of harness

between ECM and chassis ground.

Connector & terminal

(B134) No. 3 — Chassis ground:

(B134) No. 5 — Chassis ground:

(B137) No. 1 — Chassis ground:

(B137) No. 2 — Chassis ground:

(B137) No. 3 — Chassis ground:

(B137) No. 6 — Chassis ground:

(B137) No. 7 — Chassis ground:

(B137) No. 26 — Chassis ground:

Is the resistance less than 5

Ω?

Go to step 3.Repair the open

circuit of harness

between ECM

connector and

engine grounding

terminal.

3CHECK INPUT VOLTAGE FROM ECM.

Measure the voltage between ECM connector

and chassis ground.

Connector & terminal

(B135) No. 5 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the open or

ground short cir-

cuit of power sup-

ply circuit.

4CHECK INPUT VOLTAGE FROM ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B135) No. 19 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 5.Repair the open or

ground short cir-

cuit of power sup-

ply circuit.

5CHECK INPUT VOLTAGE OF MAIN RELAY.

Measure the voltage between main relay con-

nector and chassis ground.

Connector & terminal

(B47) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Repair the open

circuit of harness

between ECM

connector and

main relay connec-

tor.

6CHECK INPUT VOLTAGE FROM ECM.

1) Connect the connectors to ECM and main

relay.

2) Turn the ignition switch to ON.

3) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B136) No. 23 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 7.Repair the open or

ground short cir-

cuit of harness

between ECM

connector and

main relay connec-

tor.

7CHECK INPUT VOLTAGE OF MAIN RELAY.

Measure the voltage between main relay con-

nector and chassis ground.

Connector & terminal

(B47) No. 5 (+) — Chassis ground (–):

(B47) No. 6 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 8.Repair the open or

ground short cir-

cuit of harness of

power supply cir-

cuit.

8CHECK INPUT VOLTAGE FROM ECM.

1) Turn the ignition switch to ON.

2) Measure the voltage between ECM con-

nector and chassis ground.

Connector & terminal

(B134) No. 7 (+) — Chassis ground (–):

(B135) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Check ignition

control system.

63, IGNITION

CONTROL SYS-

TEM, Diagnostics

for Engine Star t-

ing Failure.>

Repair the open or

ground short cir-

cuit of harness

between ECM

connector and

main relay connec-

tor.

Step Check Yes No

Page 1224 of 2453

EN(H6DO)(diag)-63

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

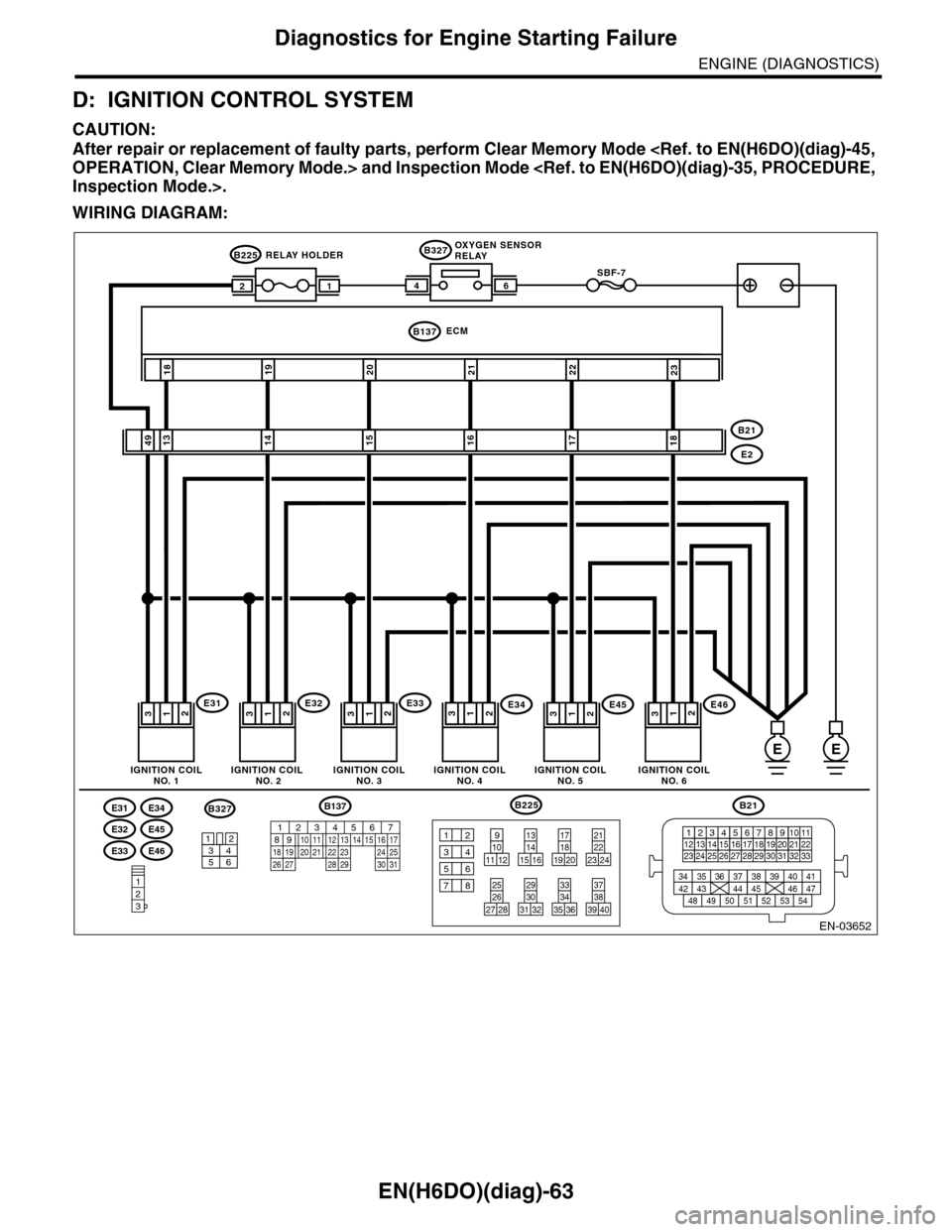

D: IGNITION CONTROL SYSTEM

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03652

E34

E45

E31

E32

E46E33

123

ECMB137

231918212220

SBF-746

B327

E46

E2

B21

E32

1814131617

32312E3432E4532

1549

111E31312E33312

12

B225

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

91012

34

56

78

11 121415 16

131819 20

172223 24

21

3839 40

373435 36

333031 32

292627 28

25

B225B327

3412

56

EE

OXYGEN SENSORRELAY

IGNITION COILNO. 1

RELAY HOLDER

IGNITION COIL NO. 2IGNITION COILNO. 3IGNITION COILNO. 4IGNITION COILNO. 5IGNITION COILNO. 6

B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

Page 1225 of 2453

EN(H6DO)(diag)-64

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

Step Check Yes No

1CHECK SPARK PLUG CONDITION.

1) Remove the spark plug.

2) Check the spark plug condition.

Is the spark plug status OK? Go to step 2.Replace the spark

plug.

2CHECK IGNITION SYSTEM FOR SPARKS.

1) Connect the spark plug to ignition coil.

2) Release the fuel pressure.

3) Contact the spark plug thread portion on

engine.

4) While opening the throttle valve fully, start

the engine to check if spark occurs at each cyl-

inder.

Does spark occur at each cyl-

inder?

Check fuel pump

system.

66, FUEL PUMP

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>

Go to step 3.

3CHECK POWER SUPPLY CIRCUIT FOR IG-

NITION COIL AND IGNITOR ASSEMBLY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from ignition coil

& ignitor assembly.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

ignition coil and ignitor assembly connector

and engine ground.

Connector & terminal

(E31) No. 3 (+) — Engine ground (–):

(E32) No. 3 (+) — Engine ground (–):

(E33) No. 3 (+) — Engine ground (–):

(E34) No. 3 (+) — Engine ground (–):

(E45) No. 3 (+) — Engine ground (–):

(E46) No. 3 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween the igni-

tion coil and

ignitor assem-

bly, and ignition

switch connec-

tor

•Poor contact

of coupling con-

nector

4CHECK HARNESS OF IGNITION COIL AND

IGNITOR ASSEMBLY GROUND CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the resistance between the igni-

tion coil and ignitor assembly connector and

engine ground.

Connector & terminal

(E31) No. 2 — Engine ground:

(E32) No. 2 — Engine ground:

(E33) No. 2 — Engine ground:

(E34) No. 2 — Engine ground:

(E45) No. 2 — Engine ground:

(E46) No. 2 — Engine ground:

Is the resistance less than 5

Ω?

Go to step 5.Repair the har-

ness and connec-

tor.

NOTE:

In this case, repair

the following item:

•Open circuit

of harness be-

tween ignition

coil and ignitor

assembly con-

nector & engine

grounding ter-

minal

Page 1226 of 2453

EN(H6DO)(diag)-65

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

5CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL AND IGNITOR ASSEMBLY

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from ECM.

3) Disconnect the connector from ignition coil

& ignitor assembly.

4) Measure the resistance of harness

between ECM and ignition coil and ignitor

assembly connector.

Connector & terminal

(B137) No. 18 — (E31) No. 1:

(B137) No. 19 — (E32) No. 1:

(B137) No. 20 — (E33) No. 1:

(B137) No. 21 — (E34) No. 1:

(B137) No. 22 — (E45) No. 1:

(B137) No. 23 — (E46) No. 1:

Is the resistance less than 1

Ω?

Go to step 6.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

ignition coil and

ignitor assem-

bly connector

•Poor contact

of coupling con-

nector

6CHECK HARNESS BETWEEN ECM AND IG-

NITION COIL AND IGNITOR ASSEMBLY

CONNECTOR.

Measure the resistance of harness between

ECM and engine ground.

Connector & terminal:

(B137) No. 18 — Engine ground:

(B137) No. 19 — Engine ground:

(B137) No. 20 — Engine ground:

(B137) No. 21 — Engine ground:

(B137) No. 22 — Engine ground:

(B137) No. 23 — Engine ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the ground

short circuit of har-

ness between

ECM and ignition

coil & ignitor

assembly connec-

tor.

7CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Check the fuel

pump circuit.

EN(H6DO)(diag)-

66, FUEL PUMP

CIRCUIT, Diag-

nostics for Engine

Starting Failure.>

Step Check Yes No

Page 1227 of 2453

EN(H6DO)(diag)-66

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

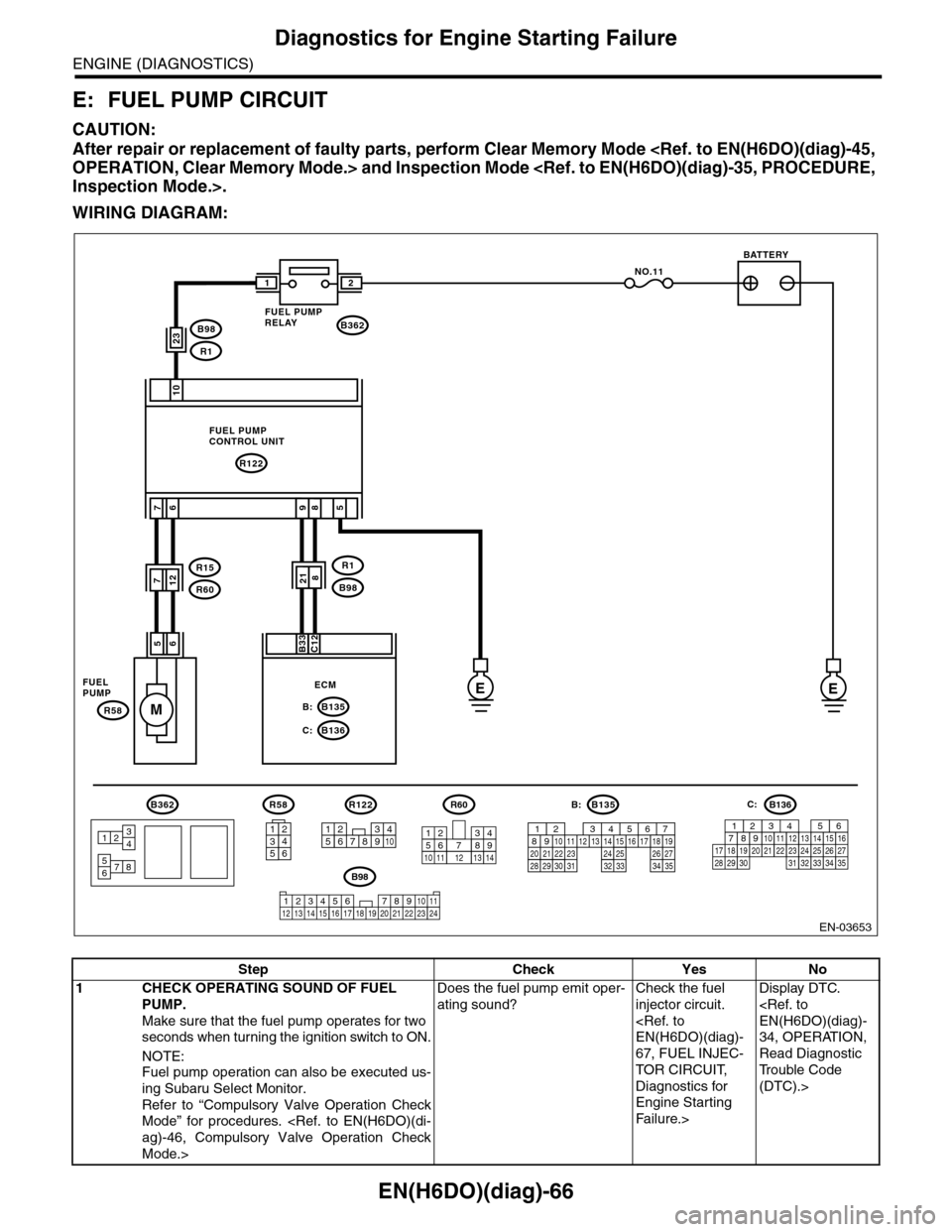

E: FUEL PUMP CIRCUIT

CAUTION:

After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03653

EE

M

10

76

56

NO.11

B362

R122

B135B:

B136C:

R58

7

B33C12

21

985

FUEL PUMPCONTROL UNIT

FUELPUMPECM

BATTERY

FUEL PUMPRELAY

B362

5678

3412

R1

B98218

23B98

R1

R15

R60712

R58

2

546

13

B135B:

567821943102422 23 2511 12 13 14 1526 2728

16 17 18 1920 2129 30 31 32 33 34 35

R122

34125891067

B98

123456 78910 1112 13 16 1714 15 18 19 2021222324

R60

12

10115634897131412

B136

16101112131415252430

9871718192028212223293231

123456

2726333435

C:

Step Check Yes No

1CHECK OPERATING SOUND OF FUEL

PUMP.

Make sure that the fuel pump operates for two

seconds when turning the ignition switch to ON.

NOTE:

Fuel pump operation can also be executed us-

ing Subaru Select Monitor.

Refer to “Compulsory Valve Operation Check

Mode” for procedures.

Mode.>

Does the fuel pump emit oper-

ating sound?

Check the fuel

injector circuit.

67, FUEL INJEC-

TOR CIRCUIT,

Diagnostics for

Engine Starting

Fa il u r e. >

Display DTC.

34, OPERATION,

Read Diagnostic

Tr o u b l e C o d e

(DTC).>

Page 1228 of 2453

EN(H6DO)(diag)-67

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

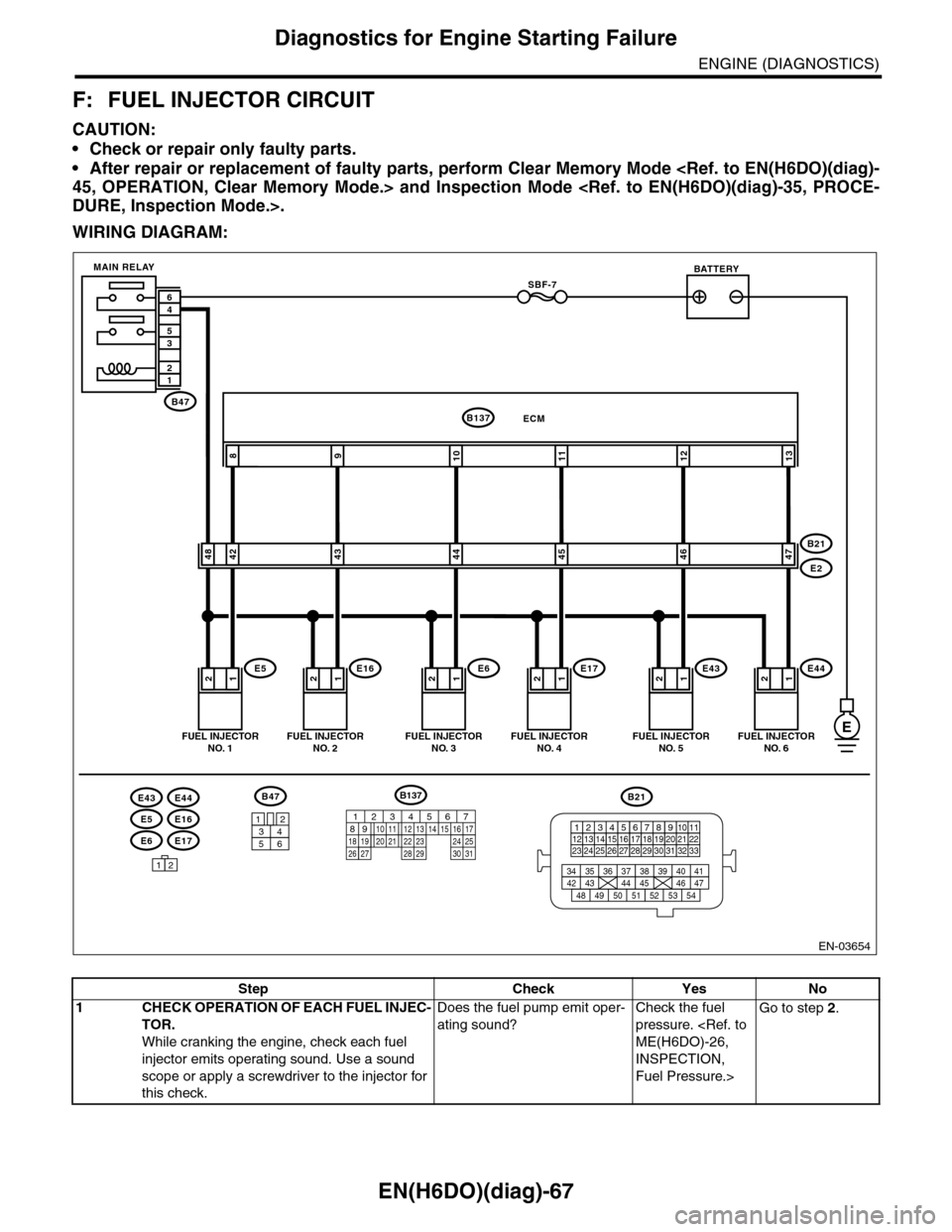

F: FUEL INJECTOR CIRCUIT

CAUTION:

•Check or repair only faulty parts.

•After repair or replacement of faulty parts, perform Clear Memory Mode

WIRING DIAGRAM:

EN-03654

E6E17

E5E16

E43E44

12121212

109811

4248434445

ECMB137

E5E16E6E17

B21

E2

FUEL INJECTORNO. 1FUEL INJECTORNO. 2FUEL INJECTORNO. 3FUEL INJECTORNO. 4

BATTERY

1212

1213

4647

E43E44

FUEL INJECTORNO. 5FUEL INJECTORNO. 6

SBF-7

B47

MAIN RELAY

12

35

46

B47

3412

56

12

B21

123412131415567816171819910 1120212223 24 25 2627 28 29 3031 32 33

3534 37363938 41404342 4445 47464948 51505352 54

E

B137

85610 11 12 13 14 157213416

3019 20 2228 29

91718 2521 23 243126 27

Step Check Yes No

1CHECK OPERATION OF EACH FUEL INJEC-

TOR.

While cranking the engine, check each fuel

injector emits operating sound. Use a sound

scope or apply a screwdriver to the injector for

this check.

Does the fuel pump emit oper-

ating sound?

Check the fuel

pressure.

INSPECTION,

Fuel Pressure.>

Go to step 2.

Page 1229 of 2453

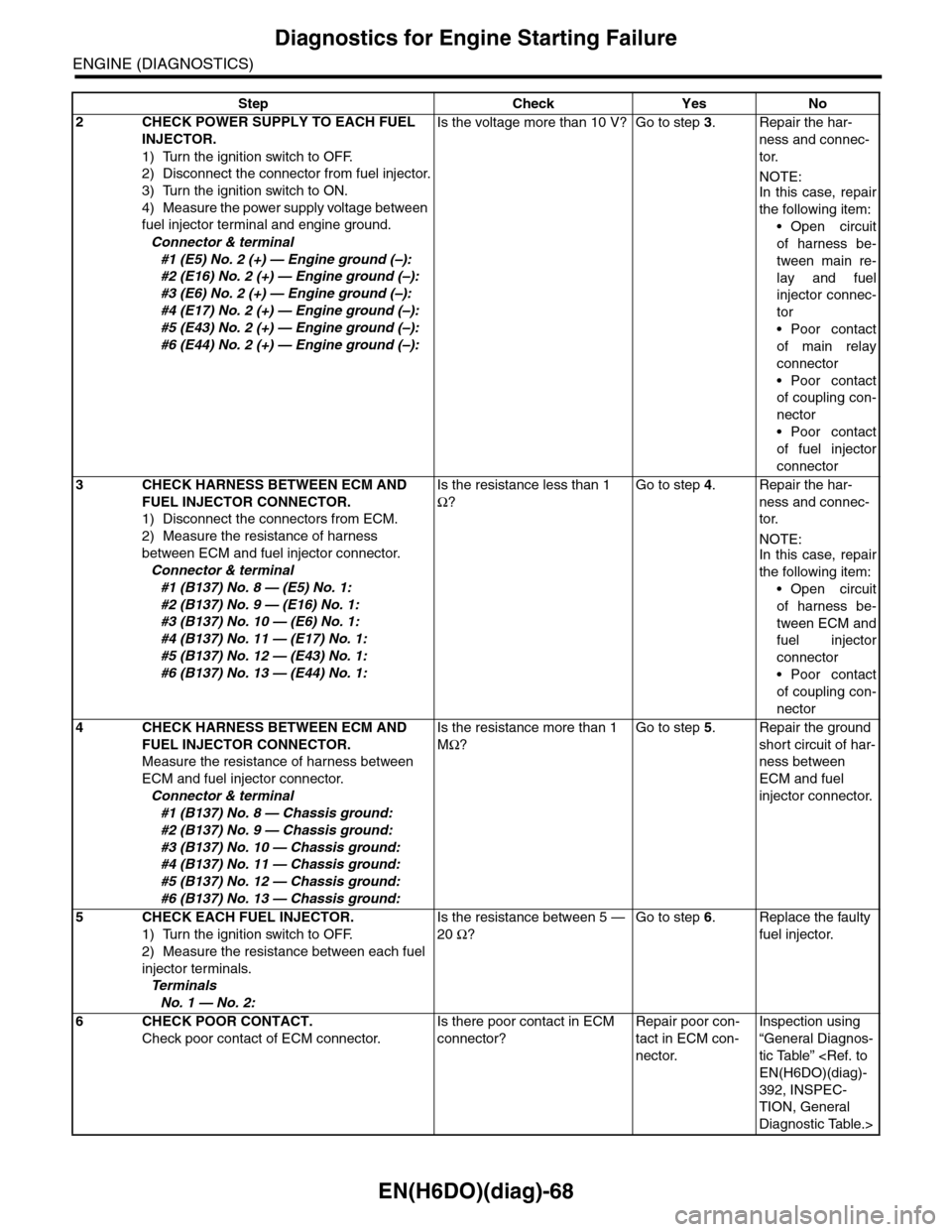

EN(H6DO)(diag)-68

Diagnostics for Engine Starting Failure

ENGINE (DIAGNOSTICS)

2CHECK POWER SUPPLY TO EACH FUEL

INJECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from fuel injector.

3) Turn the ignition switch to ON.

4) Measure the power supply voltage between

fuel injector terminal and engine ground.

Connector & terminal

#1 (E5) No. 2 (+) — Engine ground (–):

#2 (E16) No. 2 (+) — Engine ground (–):

#3 (E6) No. 2 (+) — Engine ground (–):

#4 (E17) No. 2 (+) — Engine ground (–):

#5 (E43) No. 2 (+) — Engine ground (–):

#6 (E44) No. 2 (+) — Engine ground (–):

Is the voltage more than 10 V? Go to step 3.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween main re-

lay and fuel

injector connec-

tor

•Poor contact

of main relay

connector

•Poor contact

of coupling con-

nector

•Poor contact

of fuel injector

connector

3CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

1) Disconnect the connectors from ECM.

2) Measure the resistance of harness

between ECM and fuel injector connector.

Connector & terminal

#1 (B137) No. 8 — (E5) No. 1:

#2 (B137) No. 9 — (E16) No. 1:

#3 (B137) No. 10 — (E6) No. 1:

#4 (B137) No. 11 — (E17) No. 1:

#5 (B137) No. 12 — (E43) No. 1:

#6 (B137) No. 13 — (E44) No. 1:

Is the resistance less than 1

Ω?

Go to step 4.Repair the har-

ness and connec-

tor.

NOTE:In this case, repair

the following item:

•Open circuit

of harness be-

tween ECM and

fuel injector

connector

•Poor contact

of coupling con-

nector

4CHECK HARNESS BETWEEN ECM AND

FUEL INJECTOR CONNECTOR.

Measure the resistance of harness between

ECM and fuel injector connector.

Connector & terminal

#1 (B137) No. 8 — Chassis ground:

#2 (B137) No. 9 — Chassis ground:

#3 (B137) No. 10 — Chassis ground:

#4 (B137) No. 11 — Chassis ground:

#5 (B137) No. 12 — Chassis ground:

#6 (B137) No. 13 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 5.Repair the ground

short circuit of har-

ness between

ECM and fuel

injector connector.

5CHECK EACH FUEL INJECTOR.

1) Turn the ignition switch to OFF.

2) Measure the resistance between each fuel

injector terminals.

Te r m i n a l s

No. 1 — No. 2:

Is the resistance between 5 —

20 Ω?

Go to step 6.Replace the faulty

fuel injector.

6CHECK POOR CONTACT.

Check poor contact of ECM connector.

Is there poor contact in ECM

connector?

Repair poor con-

tact in ECM con-

nector.

Inspection using

“General Diagnos-

tic Table”

392, INSPEC-

TION, General

Diagnostic Table.>

Step Check Yes No

Page 1230 of 2453

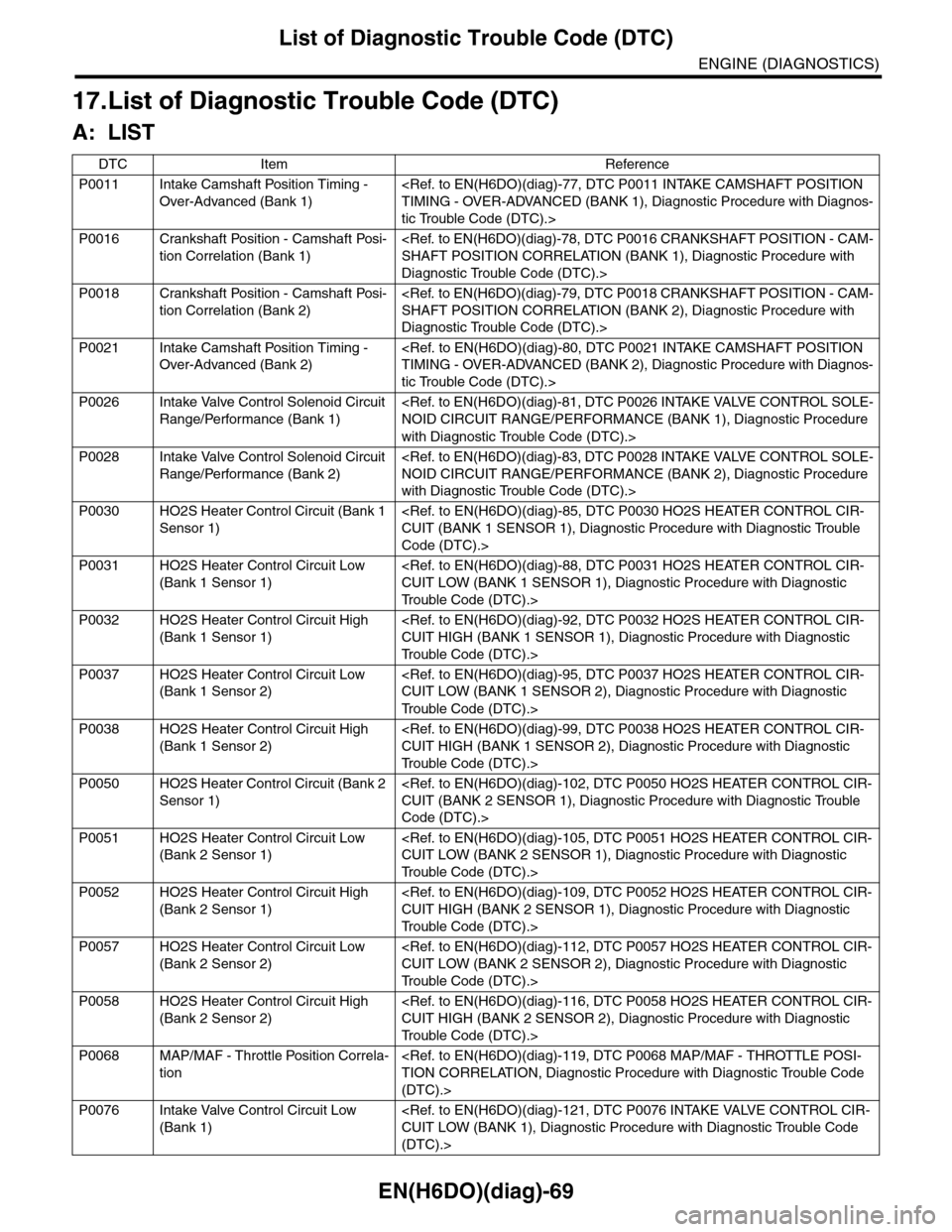

EN(H6DO)(diag)-69

List of Diagnostic Trouble Code (DTC)

ENGINE (DIAGNOSTICS)

17.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Reference

P0011 Intake Camshaft Position Timing -

Over-Advanced (Bank 1)

tic Trouble Code (DTC).>

P0016 Crankshaft Position - Camshaft Posi-

tion Correlation (Bank 1)

Diagnostic Trouble Code (DTC).>

P0018 Crankshaft Position - Camshaft Posi-

tion Correlation (Bank 2)

Diagnostic Trouble Code (DTC).>

P0021 Intake Camshaft Position Timing -

Over-Advanced (Bank 2)

tic Trouble Code (DTC).>

P0026 Intake Valve Control Solenoid Circuit

Range/Performance (Bank 1)

with Diagnostic Trouble Code (DTC).>

P0028 Intake Valve Control Solenoid Circuit

Range/Performance (Bank 2)

with Diagnostic Trouble Code (DTC).>

P0030 HO2S Heater Control Circuit (Bank 1

Sensor 1)

Code (DTC).>

P0031 HO2S Heater Control Circuit Low

(Bank 1 Sensor 1)

Tr o u b l e C o d e ( D T C ) . >

P0032 HO2S Heater Control Circuit High

(Bank 1 Sensor 1)

Tr o u b l e C o d e ( D T C ) . >

P0037 HO2S Heater Control Circuit Low

(Bank 1 Sensor 2)

Tr o u b l e C o d e ( D T C ) . >

P0038 HO2S Heater Control Circuit High

(Bank 1 Sensor 2)

Tr o u b l e C o d e ( D T C ) . >

P0050 HO2S Heater Control Circuit (Bank 2

Sensor 1)

Code (DTC).>

P0051 HO2S Heater Control Circuit Low

(Bank 2 Sensor 1)

Tr o u b l e C o d e ( D T C ) . >

P0052 HO2S Heater Control Circuit High

(Bank 2 Sensor 1)

Tr o u b l e C o d e ( D T C ) . >

P0057 HO2S Heater Control Circuit Low

(Bank 2 Sensor 2)

Tr o u b l e C o d e ( D T C ) . >

P0058 HO2S Heater Control Circuit High

(Bank 2 Sensor 2)

Tr o u b l e C o d e ( D T C ) . >

P0068 MAP/MAF - Throttle Position Correla-

tion

(DTC).>

P0076 Intake Valve Control Circuit Low

(Bank 1)

(DTC).>