automatic SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2115 of 2453

5AT-99

AT Main Case

AUTOMATIC TRANSMISSION

F: ADJUSTMENT

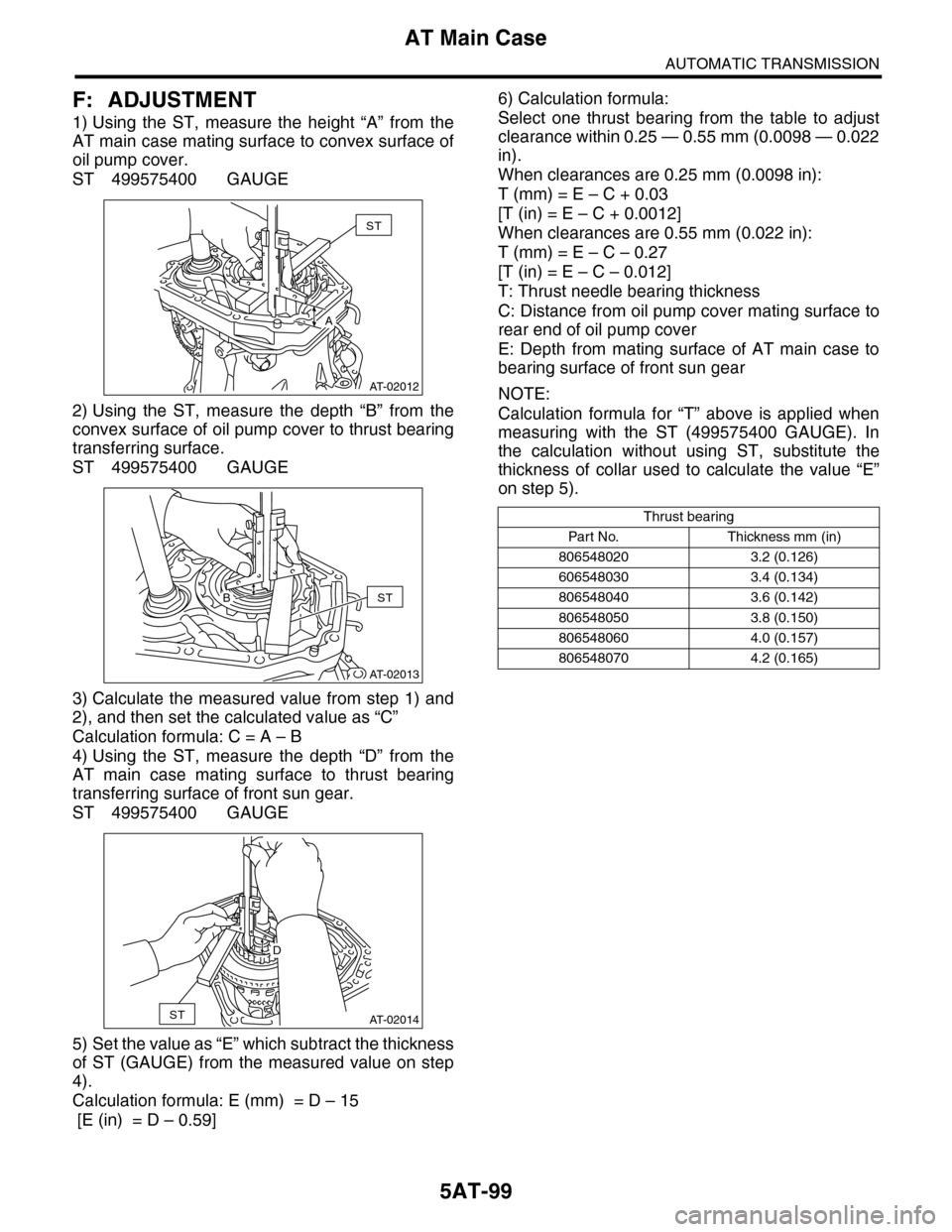

1) Using the ST, measure the height “A” from the

AT main case mating surface to convex surface of

oil pump cover.

ST 499575400 GAUGE

2) Using the ST, measure the depth “B” from the

convex surface of oil pump cover to thrust bearing

transferring surface.

ST 499575400 GAUGE

3) Calculate the measured value from step 1) and

2), and then set the calculated value as “C”

Calculation formula: C = A – B

4) Using the ST, measure the depth “D” from the

AT main case mating surface to thrust bearing

transferring surface of front sun gear.

ST 499575400 GAUGE

5) Set the value as “E” which subtract the thickness

of ST (GAUGE) from the measured value on step

4).

Calculation formula: E (mm) = D – 15

[E (in) = D – 0.59]

6) Calculation formula:

Select one thrust bearing from the table to adjust

clearance within 0.25 — 0.55 mm (0.0098 — 0.022

in).

When clearances are 0.25 mm (0.0098 in):

T (mm) = E – C + 0.03

[T (in) = E – C + 0.0012]

When clearances are 0.55 mm (0.022 in):

T (mm) = E – C – 0.27

[T (in) = E – C – 0.012]

T: Thrust needle bearing thickness

C: Distance from oil pump cover mating surface to

rear end of oil pump cover

E: Depth from mating surface of AT main case to

bearing surface of front sun gear

NOTE:

Calculation formula for “T” above is applied when

measuring with the ST (499575400 GAUGE). In

the calculation without using ST, substitute the

thickness of collar used to calculate the value “E”

on step 5).

AT-02012

ST

A

AT-02013

STB

AT-02014ST

D

Thrust bearing

Par t N o. Thickness mm (in)

806548020 3.2 (0.126)

606548030 3.4 (0.134)

806548040 3.6 (0.142)

806548050 3.8 (0.150)

806548060 4.0 (0.157)

806548070 4.2 (0.165)

Page 2116 of 2453

5AT-100

Transmission Control Device

AUTOMATIC TRANSMISSION

35.Transmission Control Device

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Lift-up the lever on the rear side of transmission

harness connector, and then disconnect it from the

stay.

4) Disconnect the air breather hose.

5) Wrap vinyl tape around the nipple attached to

the air breather hose.

6) Remove the pitching stopper bracket.

7) Remove the control valve body assembly.

8) Pull out the straight pin of manual plate.

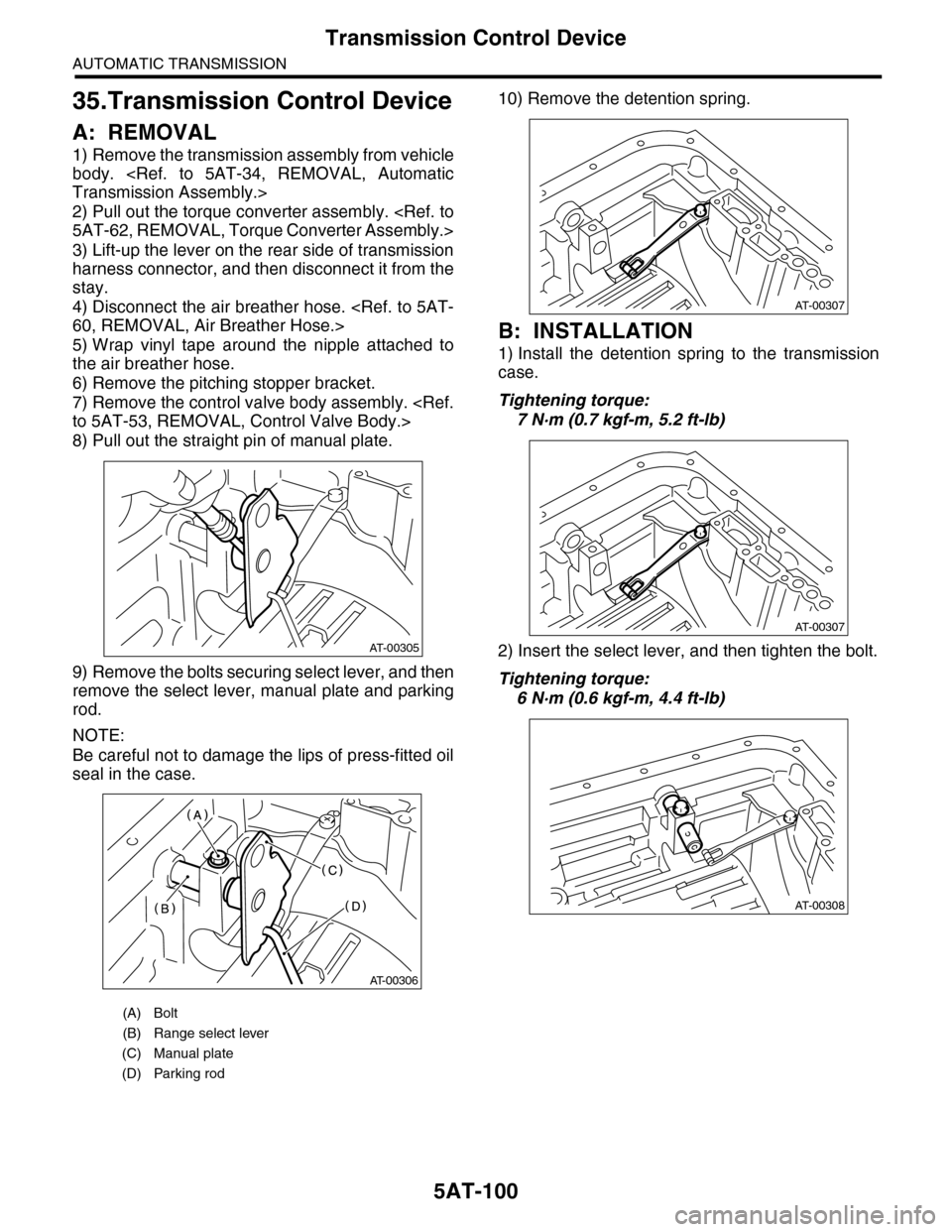

9) Remove the bolts securing select lever, and then

remove the select lever, manual plate and parking

rod.

NOTE:

Be careful not to damage the lips of press-fitted oil

seal in the case.

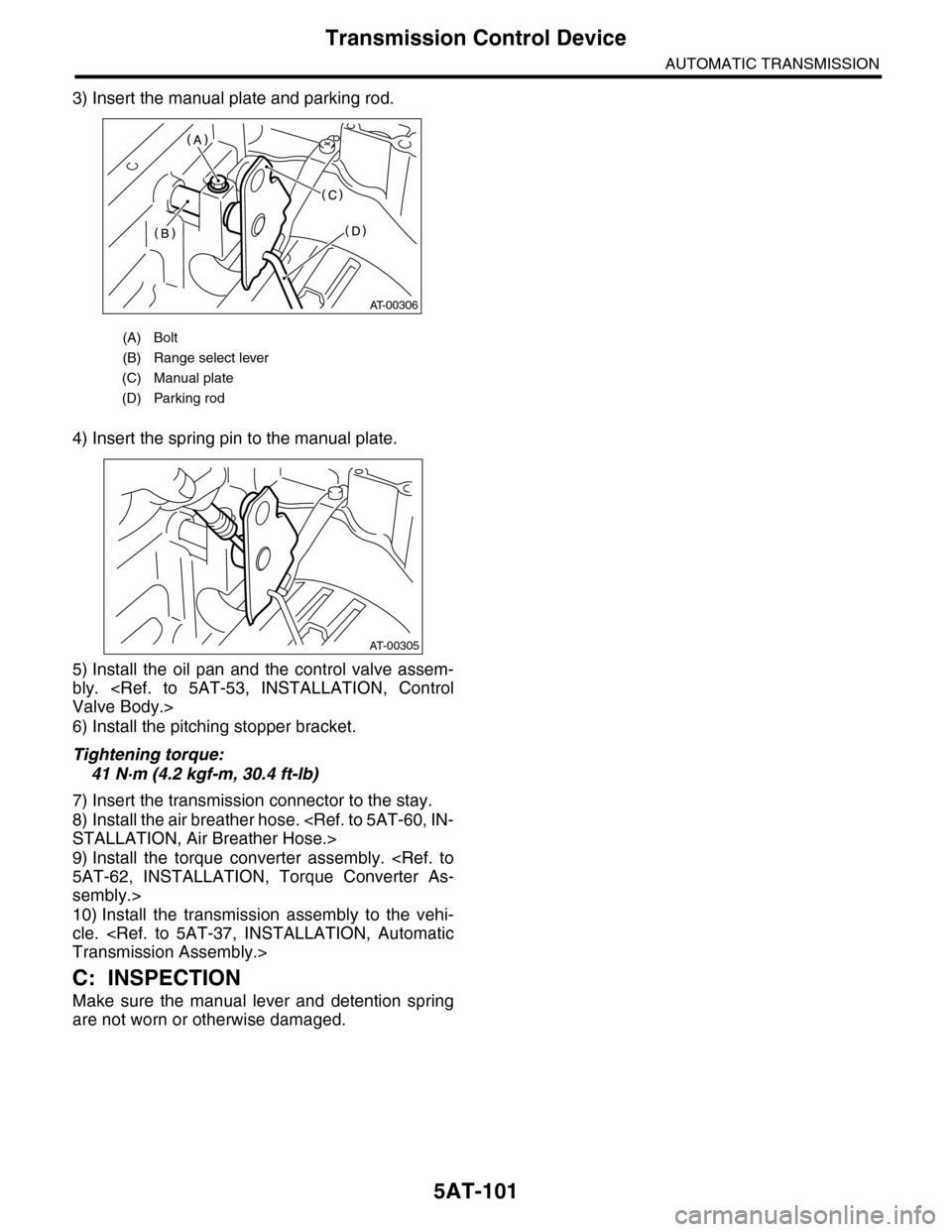

10) Remove the detention spring.

B: INSTALLATION

1) Install the detention spring to the transmission

case.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

2) Insert the select lever, and then tighten the bolt.

Tightening torque:

6 N·m (0.6 kgf-m, 4.4 ft-lb)

(A) Bolt

(B) Range select lever

(C) Manual plate

(D) Parking rod

AT-00305

AT-00306

AT-00307

AT-00307

AT-00308

Page 2117 of 2453

5AT-101

Transmission Control Device

AUTOMATIC TRANSMISSION

3) Insert the manual plate and parking rod.

4) Insert the spring pin to the manual plate.

5) Install the oil pan and the control valve assem-

bly.

6) Install the pitching stopper bracket.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

7) Insert the transmission connector to the stay.

8) Install the air breather hose.

9) Install the torque converter assembly.

sembly.>

10) Install the transmission assembly to the vehi-

cle.

C: INSPECTION

Make sure the manual lever and detention spring

are not worn or otherwise damaged.

(A) Bolt

(B) Range select lever

(C) Manual plate

(D) Parking rod

AT-00306

AT-00305

Page 2118 of 2453

5AT-102

Transmission Control Device

AUTOMATIC TRANSMISSION

Page 2119 of 2453

5AT(diag)-2

Basic Diagnostic Procedure

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

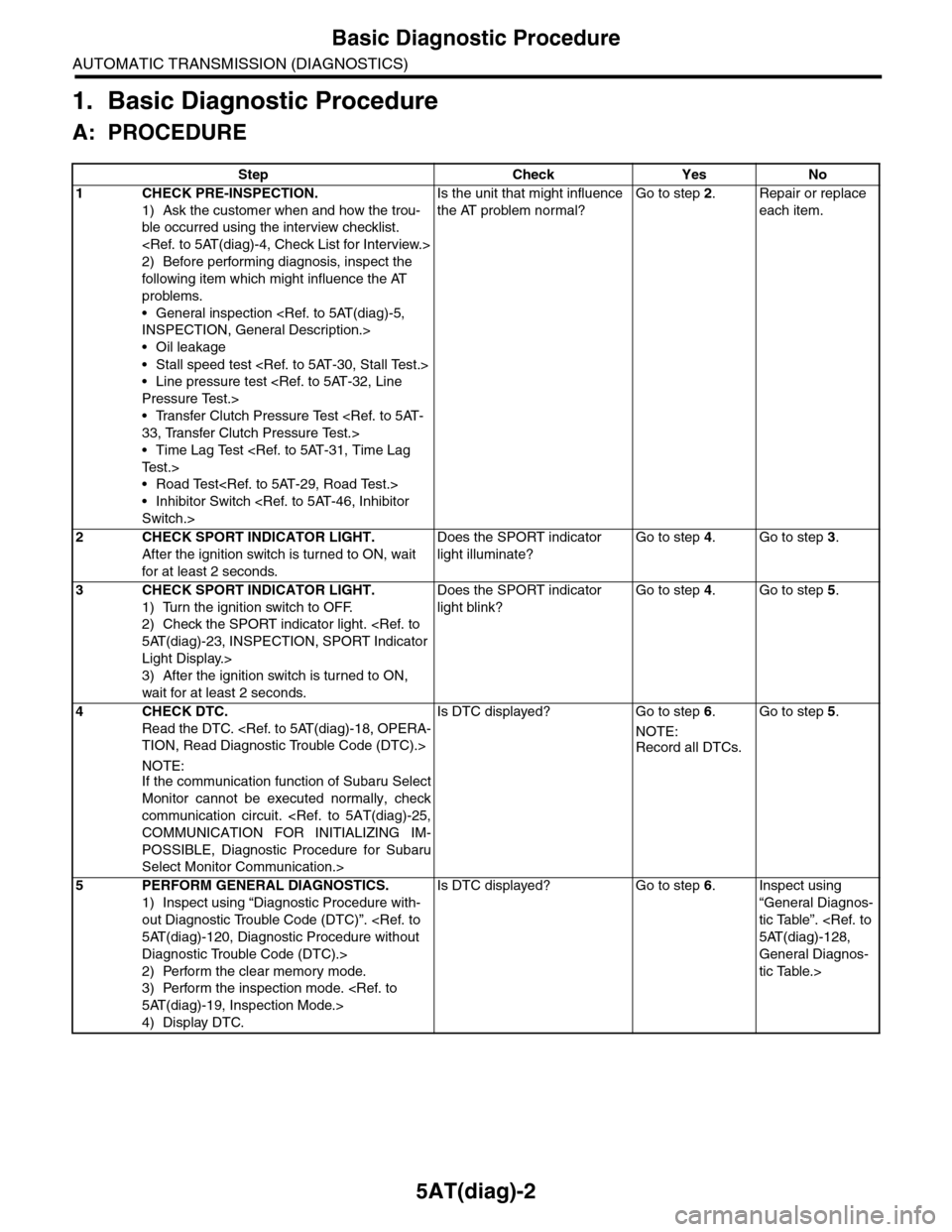

1. Basic Diagnostic Procedure

A: PROCEDURE

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using the interview checklist.

2) Before performing diagnosis, inspect the

following item which might influence the AT

problems.

•General inspection

•Oil leakage

•Stall speed test

•Line pressure test

•Transfer Clutch Pressure Test

•Time Lag Test

•Road Test

•Inhibitor Switch

Is the unit that might influence

the AT problem normal?

Go to step 2.Repair or replace

each item.

2CHECK SPORT INDICATOR LIGHT.

After the ignition switch is turned to ON, wait

for at least 2 seconds.

Does the SPORT indicator

light illuminate?

Go to step 4.Go to step 3.

3CHECK SPORT INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Check the SPORT indicator light.

Light Display.>

3) After the ignition switch is turned to ON,

wait for at least 2 seconds.

Does the SPORT indicator

light blink?

Go to step 4.Go to step 5.

4CHECK DTC.

Read the DTC.

NOTE:If the communication function of Subaru Select

Monitor cannot be executed normally, check

communication circuit.

POSSIBLE, Diagnostic Procedure for Subaru

Select Monitor Communication.>

Is DTC displayed? Go to step 6.

NOTE:

Record all DTCs.

Go to step 5.

5PERFORM GENERAL DIAGNOSTICS.

1) Inspect using “Diagnostic Procedure with-

out Diagnostic Trouble Code (DTC)”.

Diagnostic Trouble Code (DTC).>

2) Perform the clear memory mode.

3) Perform the inspection mode.

4) Display DTC.

Is DTC displayed? Go to step 6.Inspect using

“General Diagnos-

tic Table”.

General Diagnos-

tic Table.>

Page 2120 of 2453

5AT(diag)-3

Basic Diagnostic Procedure

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

6PERFORM THE DIAGNOSIS.

1) Inspect using the “Diagnostic Procedure

with Diagnostic Trouble Code (DTC)”.

nostic Trouble Code (DTC).>

NOTE:

For DTC table, refer to “List of Diagnostic Trou-

ble Code (DTC).”

2) Repair the trouble cause.

3) Perform the clear memory mode.

4) Perform the inspection mode.

5) Display DTC.

Is DTC displayed? Inspect using the

“Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC)”.

Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC).>

Inspect using

“General Diagnos-

tic Table”.

General Diagnos-

tic Table.>

Step Check Yes No

Page 2121 of 2453

5AT(diag)-4

Check List for Interview

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Check the following item when problem has occurred.

NOTE:

Use copies of this page for interviewing customers.

Customer’s name

Date of sale

Date of repair

Tr a n s m i s s i o n m o d e l Tr a n s m i s s i o n V. I . N .

Odometer readingkm (miles)

Symptom No up-shift

No down-shift

No kick down

Vehicle does not move ( Any position Particular position)

Lock-up malfunction

Noise or vibration

Shift shock or slip

Select lever does not move

Others

()

Fr e qu e nc y Continuous Intermittent ( times a day)

Weather Fine Cloudy Rainy Snowy

Others

()

Place Highland Suburbs Inner city Uphill Rough road

Others

()

Ambient air temperature Hot Warm Cool Cold

Ve h i c l e s p e e dkm/h (MPH)

AT w a r n i n g l i g h t ( S P O R T i n d i c a t o r

light) Blinks continuously Not blink

Select lever position P R N D Manual mode

Driving condition Not affected

At racing

Reducing speed

At starting

Accelerating

W h i l e t u r n i n g ( R H /

LH)

While idling

While cruising

Manual mode ON OFF

Page 2122 of 2453

5AT(diag)-5

General Description

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

3. General Description

A: CAUTION

•SRS AIRBAG SYSTEM

The airbag system wiring harness is routed near

the TCM.

CAUTION:

•All air bag system wiring harnesses and con-

nectors are colored yellow. Do not use an elec-

tric test equipment to check these circuits.

•Be careful not to damage the airbag system

wiring harness when performing diagnostics or

servicing the TCM.

•MEASUREMENT

When measuring the voltage and resistance of the

ECM, TCM or each sensor, use a tapered pin with

a diameter of less than 0.64 mm (0.025 in) in order

to avoid poor contact. Do not insert a pin of more

than 0.65 mm (0.026 in) diameter.

B: INSPECTION

1. BATTERY

Measure the battery voltage and specific gravity of

electrolyte.

Standard voltage: 12 V or more

Specific gravity: 1.260 or more

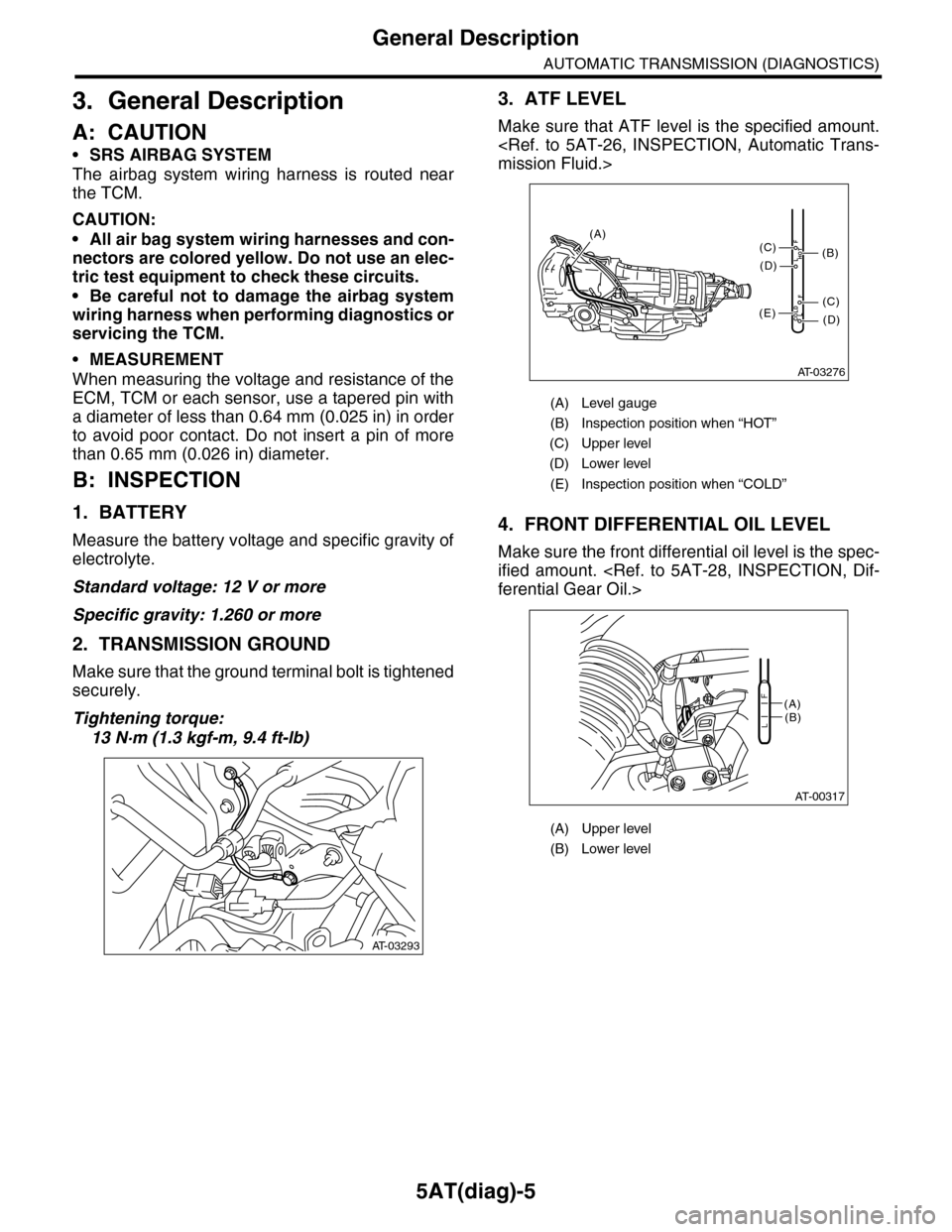

2. TRANSMISSION GROUND

Make sure that the ground terminal bolt is tightened

securely.

Tightening torque:

13 N·m (1.3 kgf-m, 9.4 ft-lb)

3. ATF LEVEL

Make sure that ATF level is the specified amount.

4. FRONT DIFFERENTIAL OIL LEVEL

Make sure the front differential oil level is the spec-

ified amount.

AT-03293

(A) Level gauge

(B) Inspection position when “HOT”

(C) Upper level

(D) Lower level

(E) Inspection position when “COLD”

(A) Upper level

(B) Lower level

AT-03276

COLDLF

HOTLF

(C)

(D)

(C)

(D)

(E)

(B)

(A)

AT-00317

(A)(B)L

F

Page 2123 of 2453

5AT(diag)-6

General Description

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

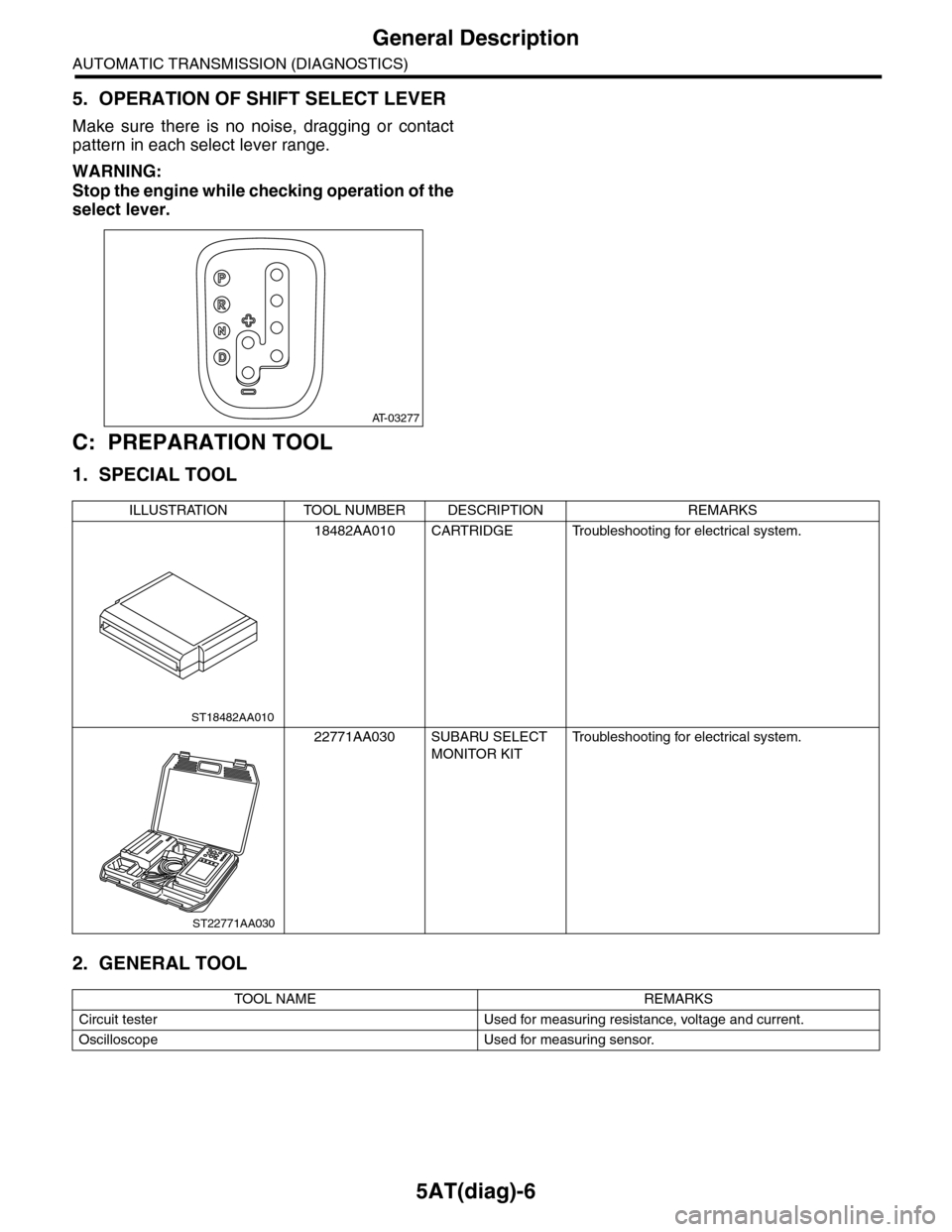

5. OPERATION OF SHIFT SELECT LEVER

Make sure there is no noise, dragging or contact

pattern in each select lever range.

WARNING:

Stop the engine while checking operation of the

select lever.

C: PREPARATION TOOL

1. SPECIAL TOOL

2. GENERAL TOOL

AT-03277

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

18482AA010 CARTRIDGE Troubleshooting for electrical system.

22771AA030 SUBARU SELECT

MONITOR KIT

Tr o u b l e s h o o t i n g f o r e l e c t r i c a l s y s t e m .

TOOL NAME REMARKS

Circuit tester Used for measuring resistance, voltage and current.

Oscilloscope Used for measuring sensor.

ST18482AA010

ST22771AA030

Page 2124 of 2453

5AT(diag)-7

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

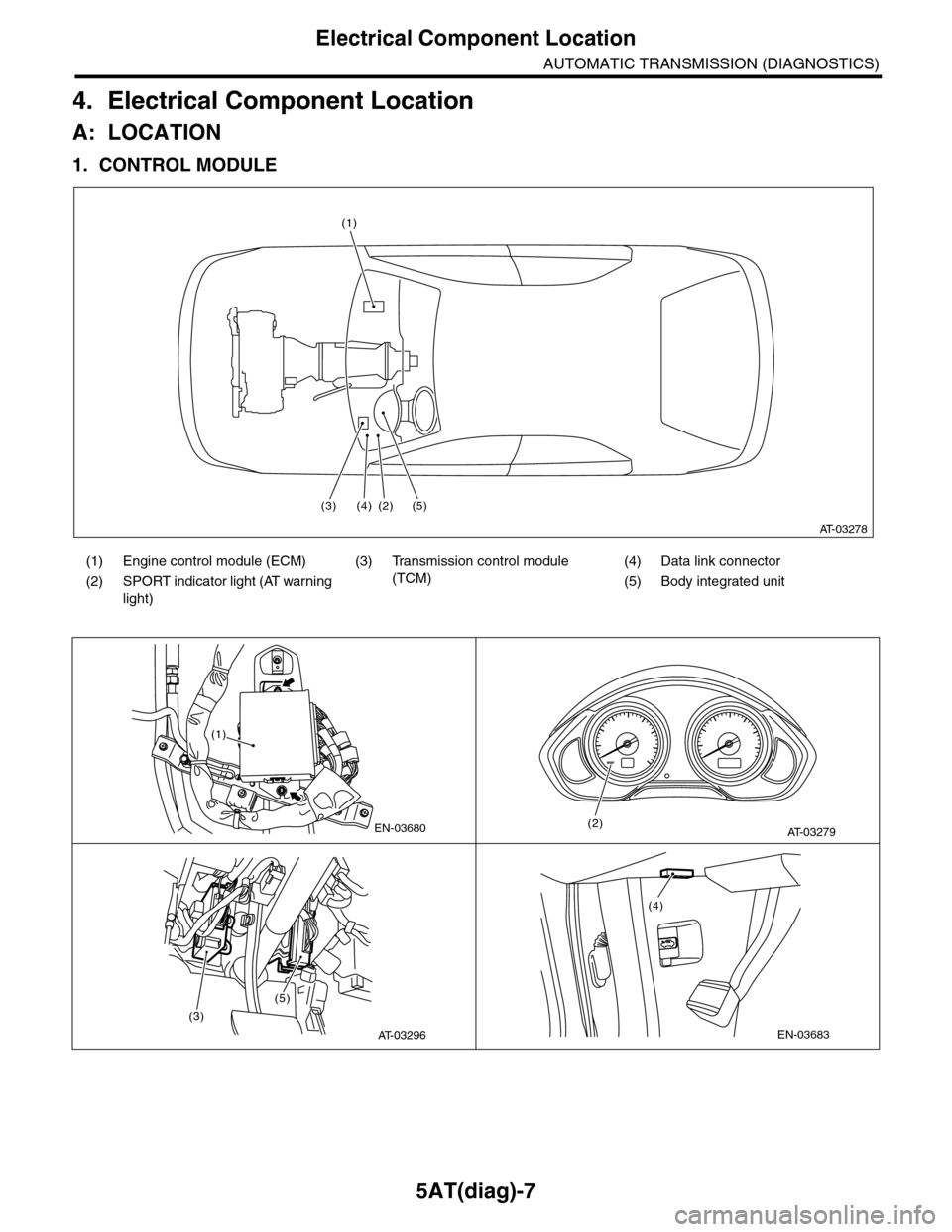

4. Electrical Component Location

A: LOCATION

1. CONTROL MODULE

(1) Engine control module (ECM) (3) Transmission control module

(TCM)

(4) Data link connector

(2) SPORT indicator light (AT warning

light)

(5) Body integrated unit

AT-03278

(1)

(3)(4) (2) (5)

EN-03680

(1)

AT-03279(2)

(3)

(5)

AT-03296EN-03683

(4)