automatic SUBARU TRIBECA 2009 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2085 of 2453

5AT-69

Reduction Driven Gear

AUTOMATIC TRANSMISSION

4) Using the ST, remove the parking gear.

ST 18767AA000 REMOVER

D: ASSEMBLY

1) Using the ST, install the parking gear.

ST 499755602 PRESS

2) Install the snap ring.

3) Install the new ball bearing to reduction driven

gear using press.

ST 18654AA000 INSTALLER

4) Install the ball bearing on the reverse side with

the same procedure as step 3).

ST 18654AA000 INSTALLER

E: INSPECTION

Make sure the ball bearing and gear is not de-

formed or damaged.

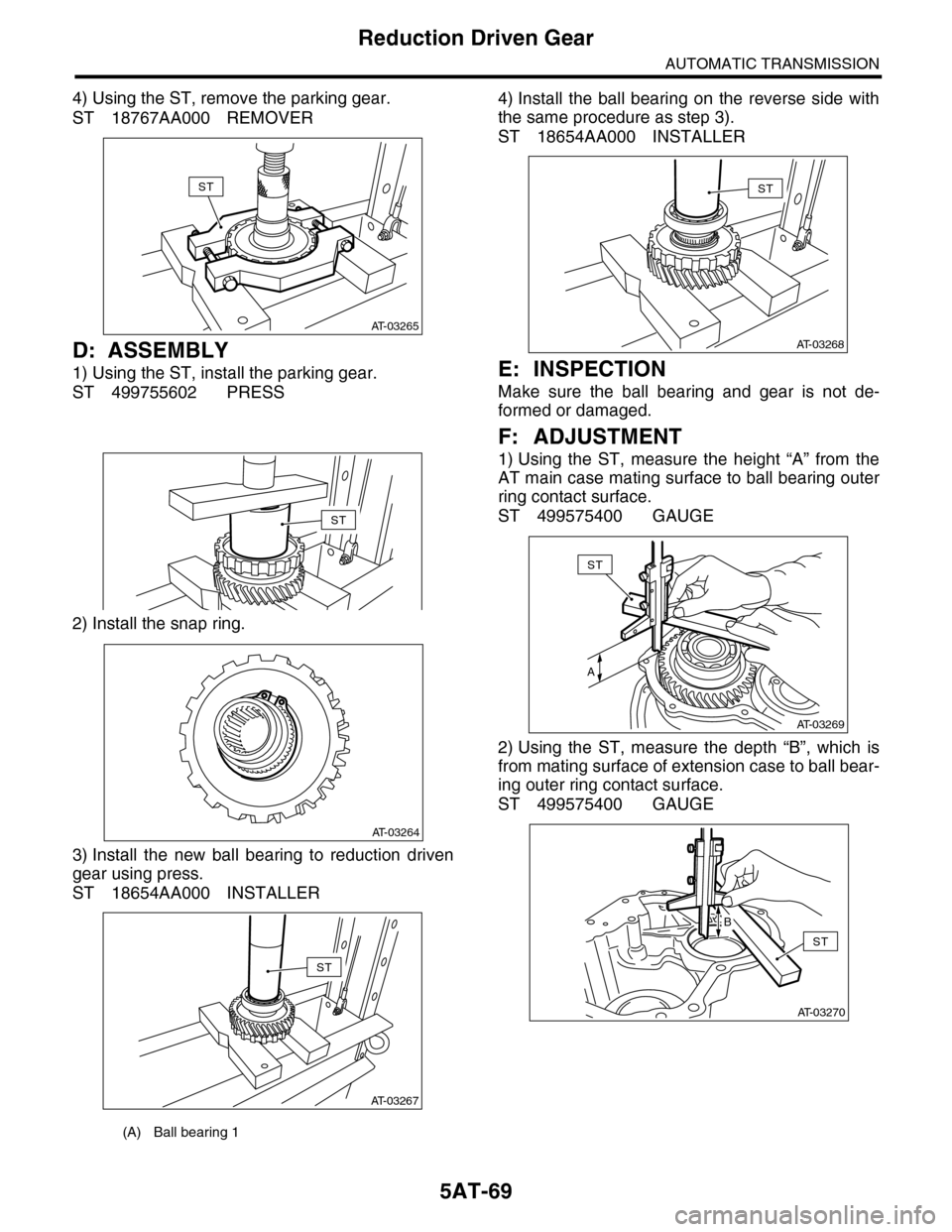

F: ADJUSTMENT

1) Using the ST, measure the height “A” from the

AT main case mating surface to ball bearing outer

ring contact surface.

ST 499575400 GAUGE

2) Using the ST, measure the depth “B”, which is

from mating surface of extension case to ball bear-

ing outer ring contact surface.

ST 499575400 GAUGE

(A) Ball bearing 1

AT-03265

ST

ST

AT-03264

AT-03267

ST

AT-03268

ST

AT-03269

ST

A

AT-03270

ST

B

Page 2086 of 2453

5AT-70

Reduction Driven Gear

AUTOMATIC TRANSMISSION

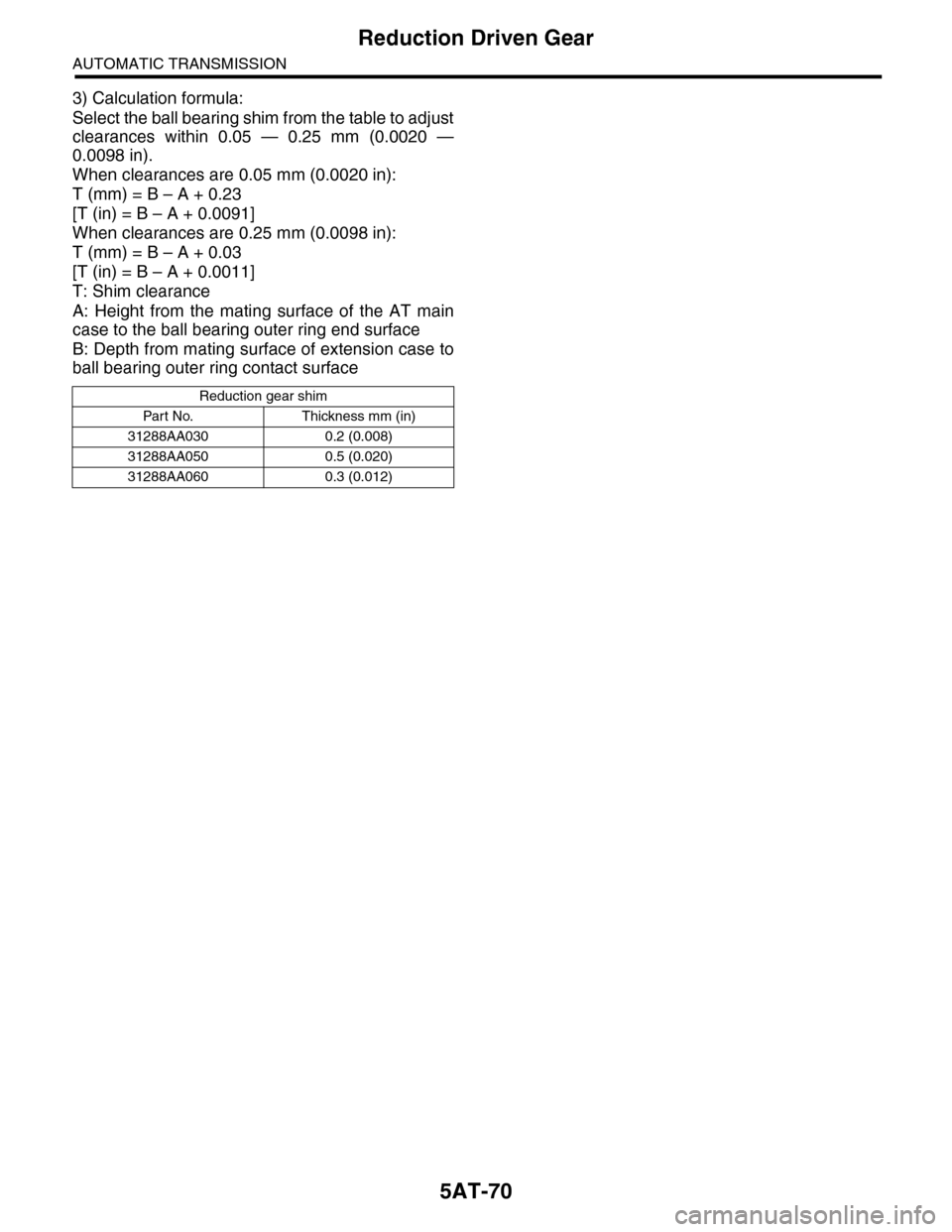

3) Calculation formula:

Select the ball bearing shim from the table to adjust

clearances within 0.05 — 0.25 mm (0.0020 —

0.0098 in).

When clearances are 0.05 mm (0.0020 in):

T (mm) = B – A + 0.23

[T (in) = B – A + 0.0091]

When clearances are 0.25 mm (0.0098 in):

T (mm) = B – A + 0.03

[T (in) = B – A + 0.0011]

T: Shim clearance

A: Height from the mating surface of the AT main

case to the ball bearing outer ring end surface

B: Depth from mating surface of extension case to

ball bearing outer ring contact surface

Reduction gear shim

Par t No. Thickness mm (in)

31288AA030 0.2 (0.008)

31288AA050 0.5 (0.020)

31288AA060 0.3 (0.012)

Page 2087 of 2453

5AT-71

Center Differential Carrier

AUTOMATIC TRANSMISSION

28.Center Differential Carrier

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the rear wheel speed sensor, and sep-

arate the extension case from transmission case.

3) Extract the rear drive shaft.

4) Pull out the center differential carrier assembly.

5) Pull out the shim(s) from transmission case.

B: INSTALLATION

1) Install the center differential assembly with the

shim(s).

NOTE:

Press-fit it to the bottom of bearing shoulder com-

pletely.

2) Insert the rear driveshaft assembly.

3) Join the transmission case and the extension

case, and then install the rear vehicle speed sen-

sor.

4) Install the transmission assembly to the vehicle.

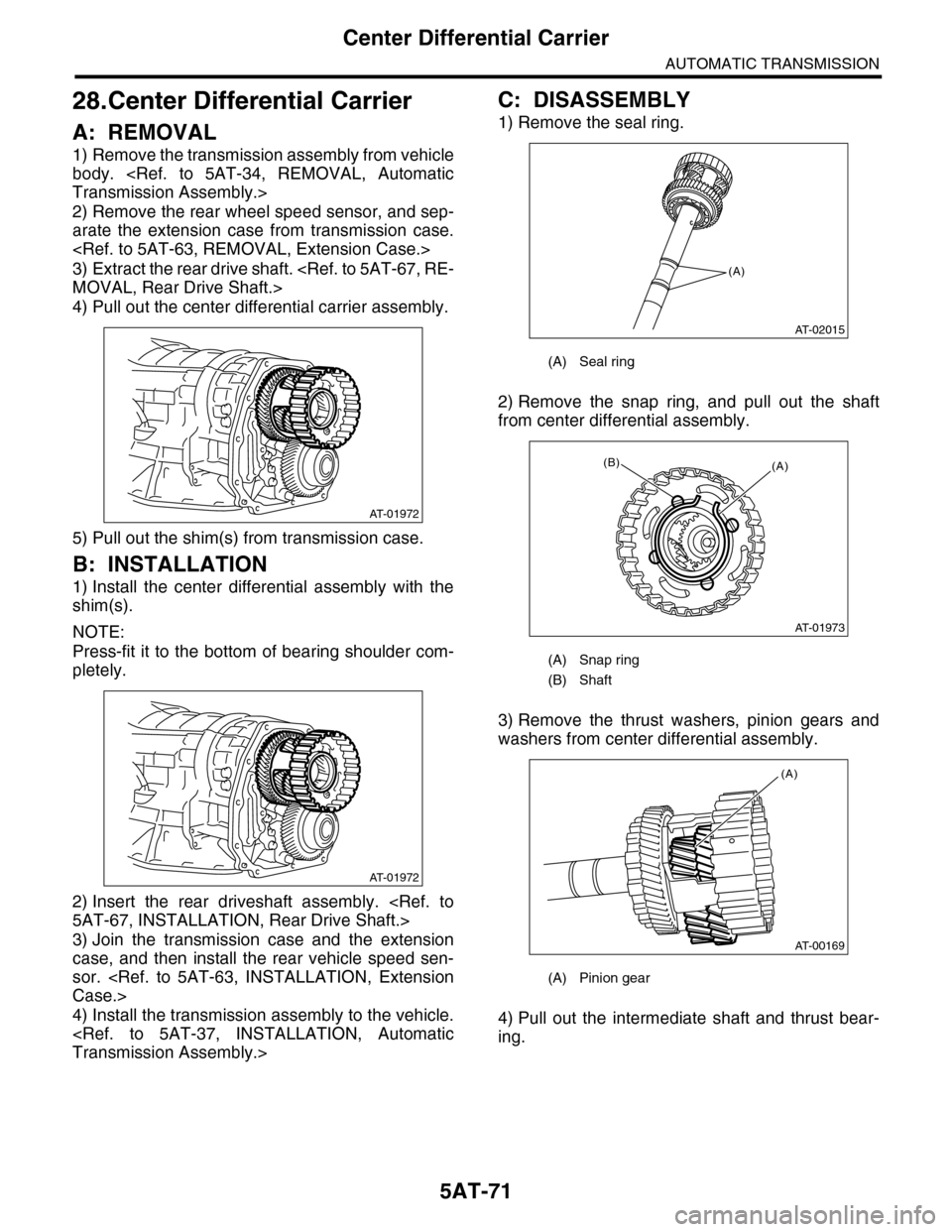

C: DISASSEMBLY

1) Remove the seal ring.

2) Remove the snap ring, and pull out the shaft

from center differential assembly.

3) Remove the thrust washers, pinion gears and

washers from center differential assembly.

4) Pull out the intermediate shaft and thrust bear-

ing.

AT-01972

AT-01972

(A) Seal ring

(A) Snap ring

(B) Shaft

(A) Pinion gear

(A)

AT-02015

AT-01973

(A)(B)

AT-00169

(A)

Page 2088 of 2453

5AT-72

Center Differential Carrier

AUTOMATIC TRANSMISSION

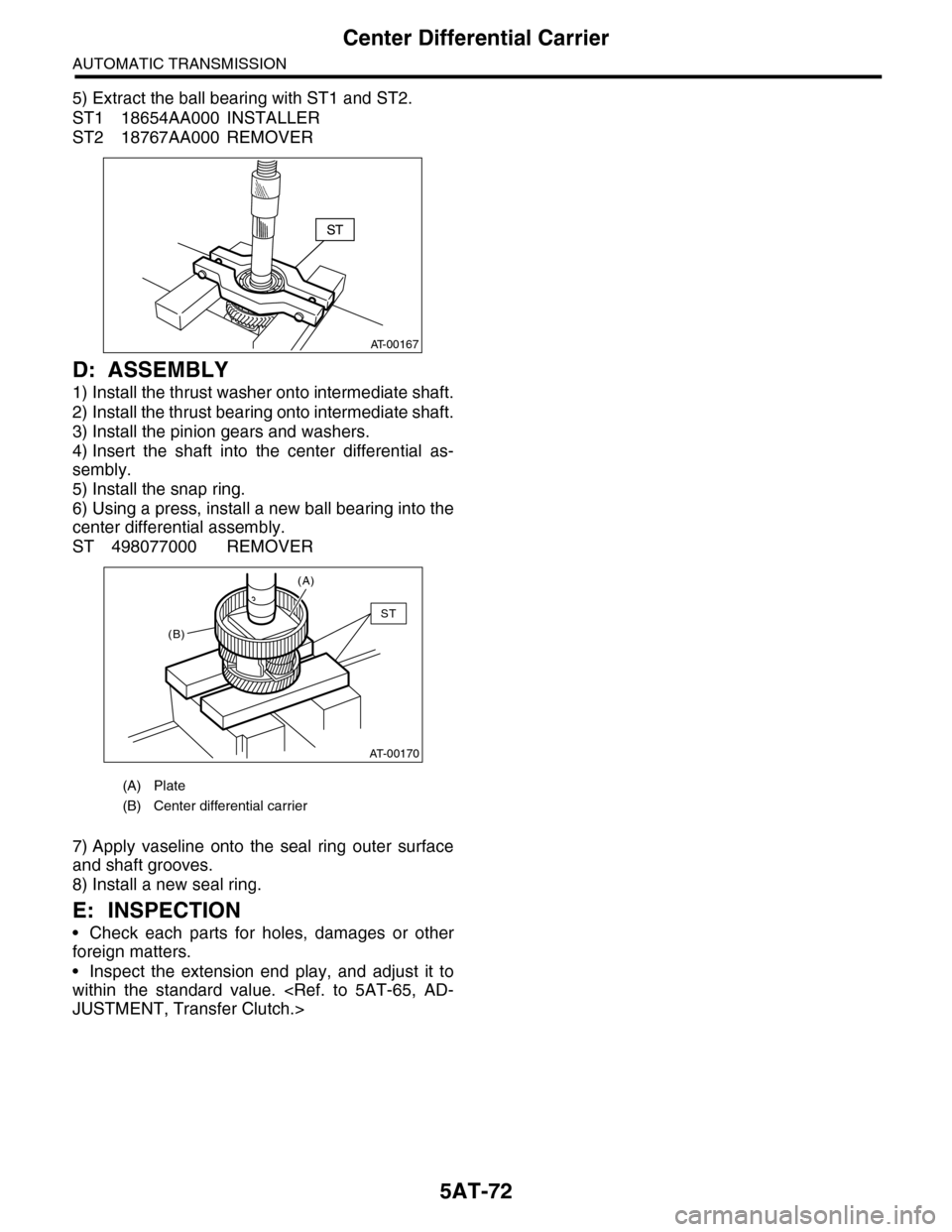

5) Extract the ball bearing with ST1 and ST2.

ST1 18654AA000 INSTALLER

ST2 18767AA000 REMOVER

D: ASSEMBLY

1) Install the thrust washer onto intermediate shaft.

2) Install the thrust bearing onto intermediate shaft.

3) Install the pinion gears and washers.

4) Insert the shaft into the center differential as-

sembly.

5) Install the snap ring.

6) Using a press, install a new ball bearing into the

center differential assembly.

ST 498077000 REMOVER

7) Apply vaseline onto the seal ring outer surface

and shaft grooves.

8) Install a new seal ring.

E: INSPECTION

•Check each parts for holes, damages or other

foreign matters.

•Inspect the extension end play, and adjust it to

within the standard value.

(A) Plate

(B) Center differential carrier

AT-00167

AT-00170

(A)

(B)

ST

Page 2089 of 2453

5AT-73

Parking Pawl

AUTOMATIC TRANSMISSION

29.Parking Pawl

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the extension case.

3) Remove the center differential carrier.

4) Remove the front vehicle speed sensor.

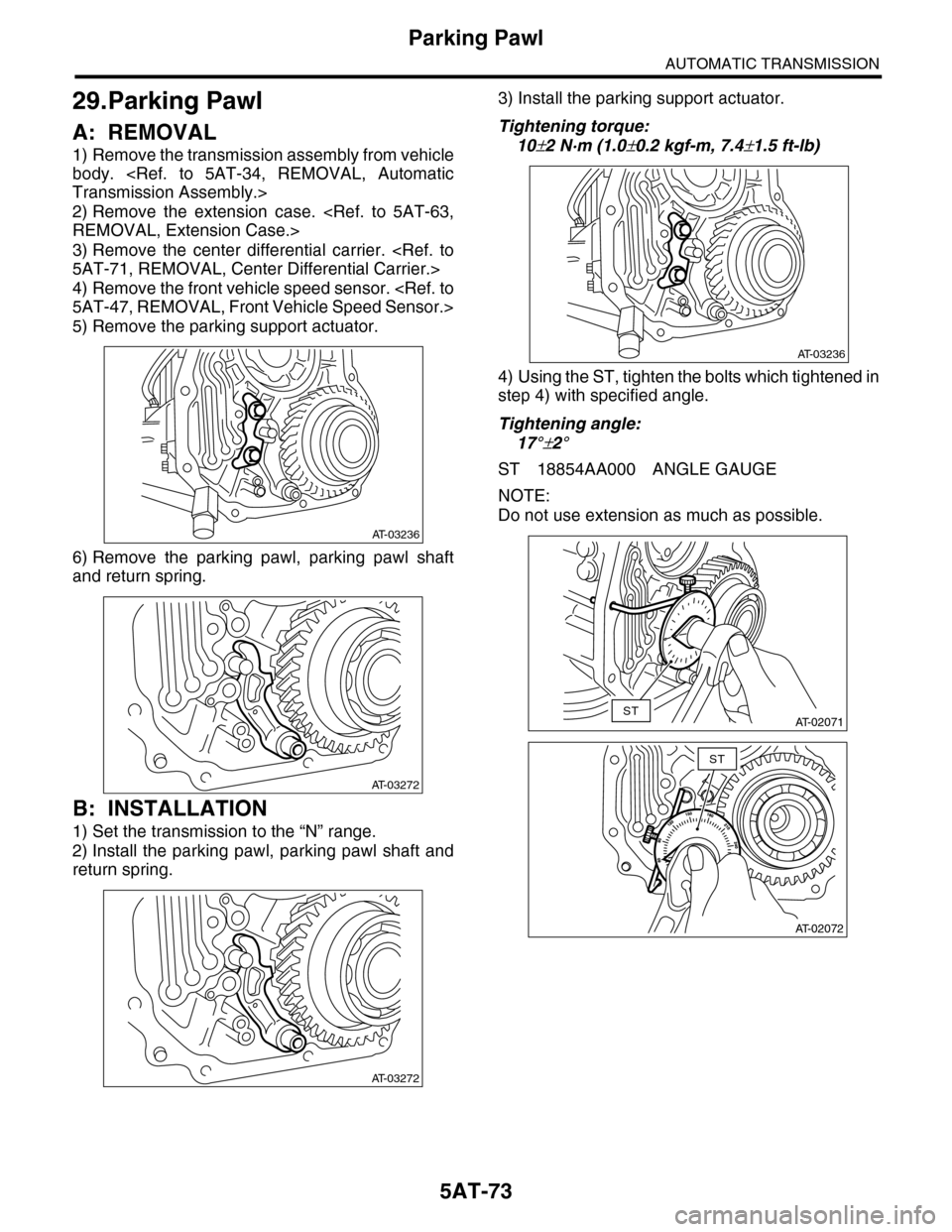

5) Remove the parking support actuator.

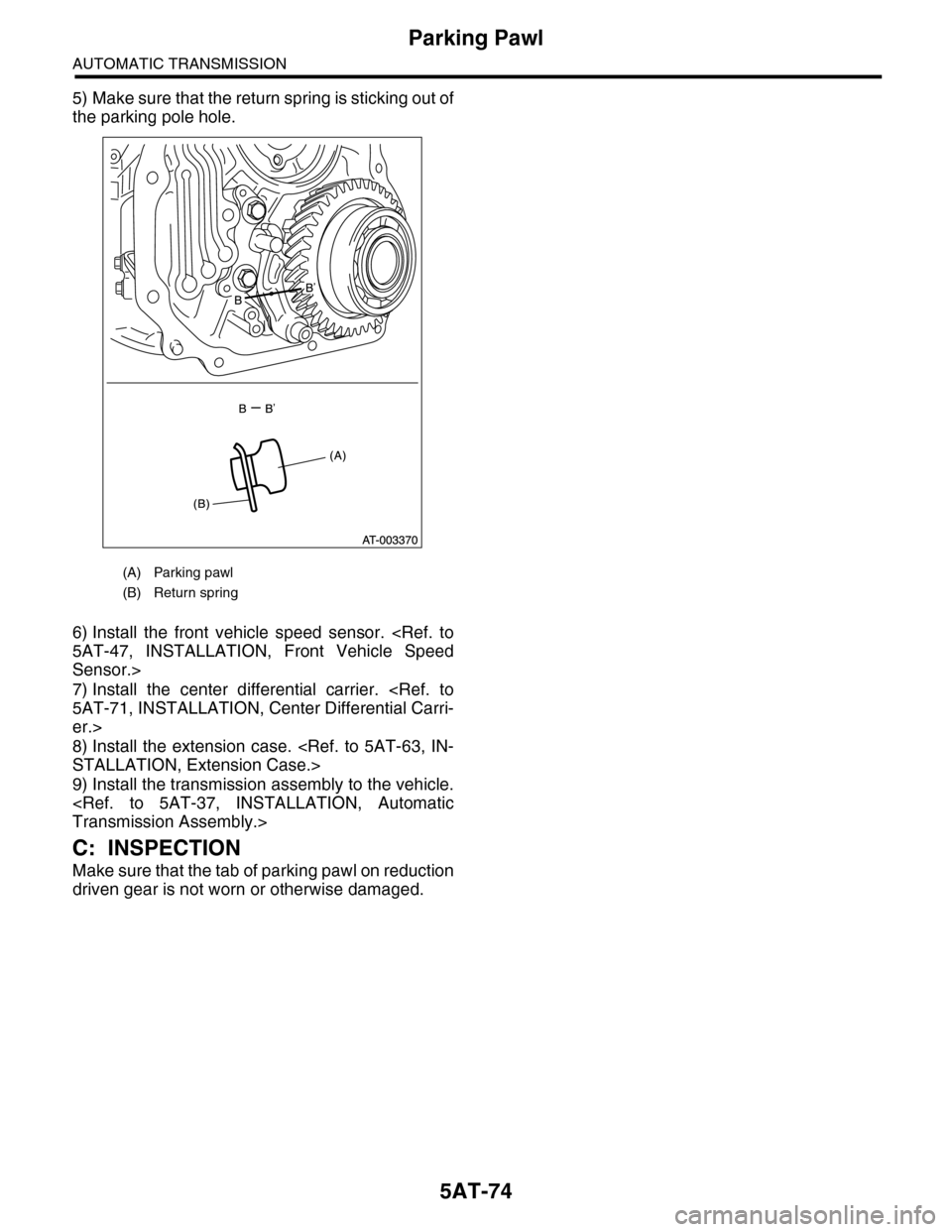

6) Remove the parking pawl, parking pawl shaft

and return spring.

B: INSTALLATION

1) Set the transmission to the “N” range.

2) Install the parking pawl, parking pawl shaft and

return spring.

3) Install the parking support actuator.

Tightening torque:

10±2 N·m (1.0±0.2 kgf-m, 7.4±1.5 ft-lb)

4) Using the ST, tighten the bolts which tightened in

step 4) with specified angle.

Tightening angle:

17°±2°

ST 18854AA000 ANGLE GAUGE

NOTE:

Do not use extension as much as possible.

AT-03236

AT-03272

AT-03272

AT-03236

AT-02071ST

AT-02072

ST

Page 2090 of 2453

5AT-74

Parking Pawl

AUTOMATIC TRANSMISSION

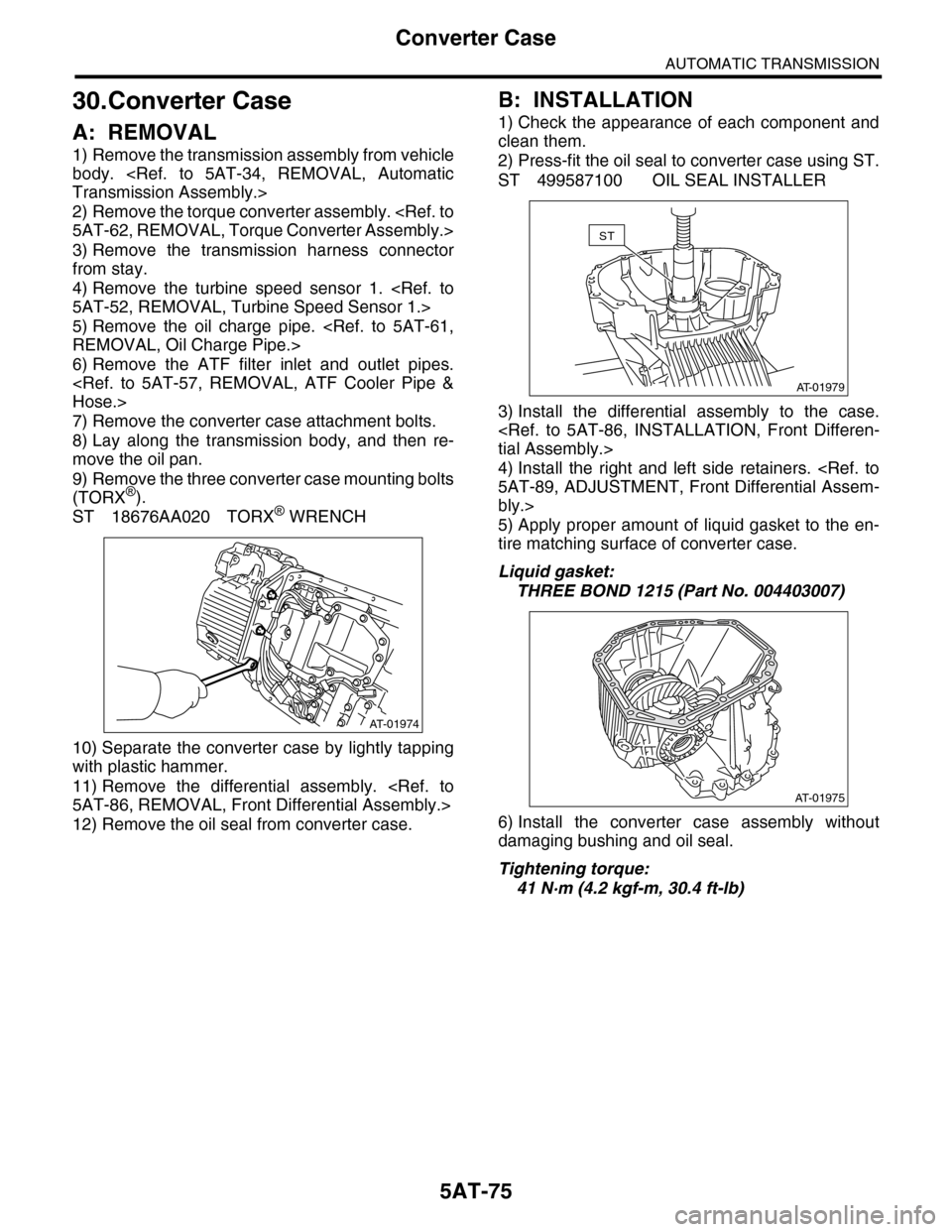

5) Make sure that the return spring is sticking out of

the parking pole hole.

6) Install the front vehicle speed sensor.

Sensor.>

7) Install the center differential carrier.

er.>

8) Install the extension case.

9) Install the transmission assembly to the vehicle.

C: INSPECTION

Make sure that the tab of parking pawl on reduction

driven gear is not worn or otherwise damaged.

(A) Parking pawl

(B) Return spring

Page 2091 of 2453

5AT-75

Converter Case

AUTOMATIC TRANSMISSION

30.Converter Case

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Remove the turbine speed sensor 1.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

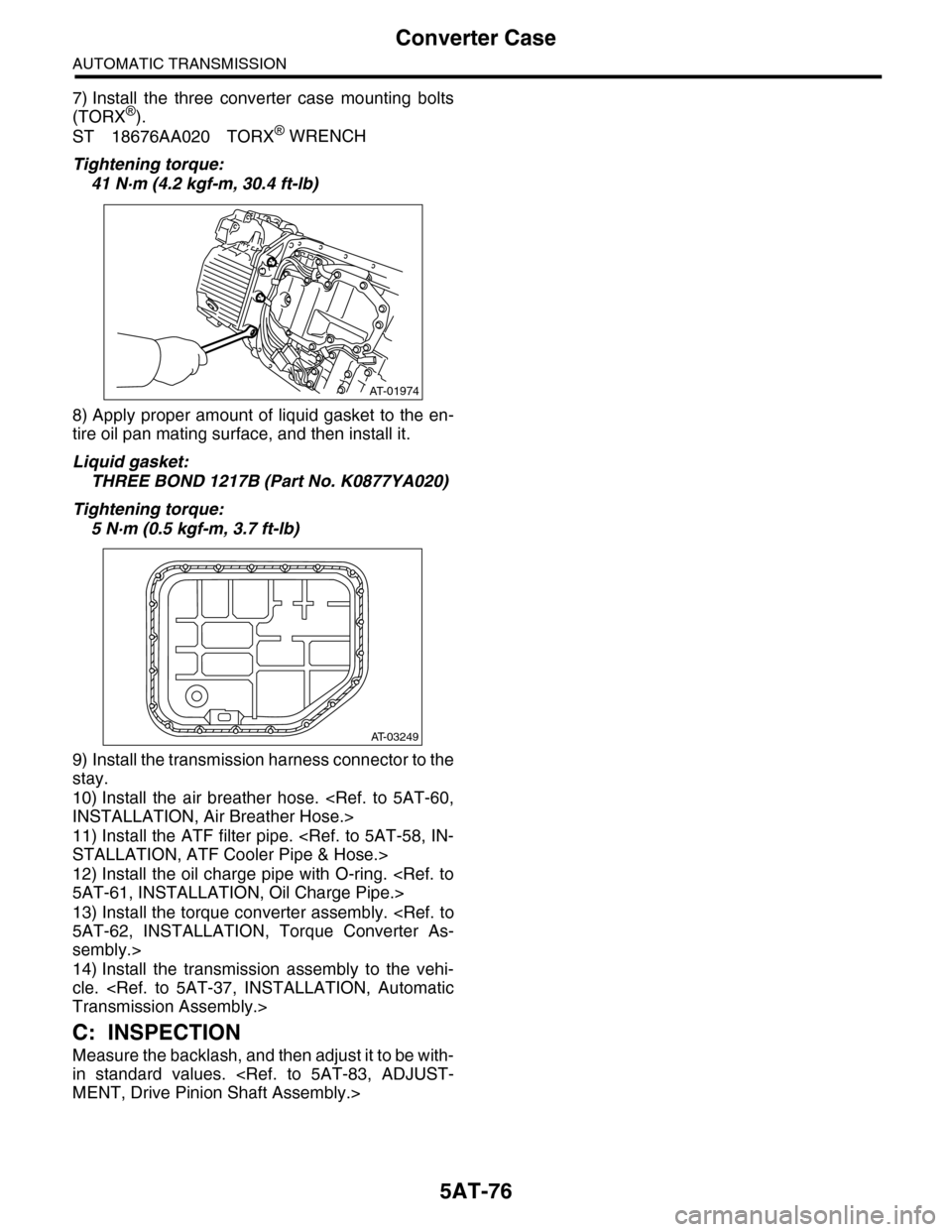

7) Remove the converter case attachment bolts.

8) Lay along the transmission body, and then re-

move the oil pan.

9) Remove the three converter case mounting bolts

(TORX®).

ST 18676AA020 TORX® WRENCH

10) Separate the converter case by lightly tapping

with plastic hammer.

11) Remove the differential assembly.

12) Remove the oil seal from converter case.

B: INSTALLATION

1) Check the appearance of each component and

clean them.

2) Press-fit the oil seal to converter case using ST.

ST 499587100 OIL SEAL INSTALLER

3) Install the differential assembly to the case.

4) Install the right and left side retainers.

bly.>

5) Apply proper amount of liquid gasket to the en-

tire matching surface of converter case.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007)

6) Install the converter case assembly without

damaging bushing and oil seal.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

AT-01974

AT-01979

ST

AT-01975

Page 2092 of 2453

5AT-76

Converter Case

AUTOMATIC TRANSMISSION

7) Install the three converter case mounting bolts

(TORX®).

ST 18676AA020 TORX® WRENCH

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

8) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface, and then install it.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

Tightening torque:

5 N·m (0.5 kgf-m, 3.7 ft-lb)

9) Install the transmission harness connector to the

stay.

10) Install the air breather hose.

11) Install the ATF filter pipe.

12) Install the oil charge pipe with O-ring.

13) Install the torque converter assembly.

sembly.>

14) Install the transmission assembly to the vehi-

cle.

C: INSPECTION

Measure the backlash, and then adjust it to be with-

in standard values.

AT-01974

AT-03249

Page 2093 of 2453

5AT-77

Oil Pump Cover

AUTOMATIC TRANSMISSION

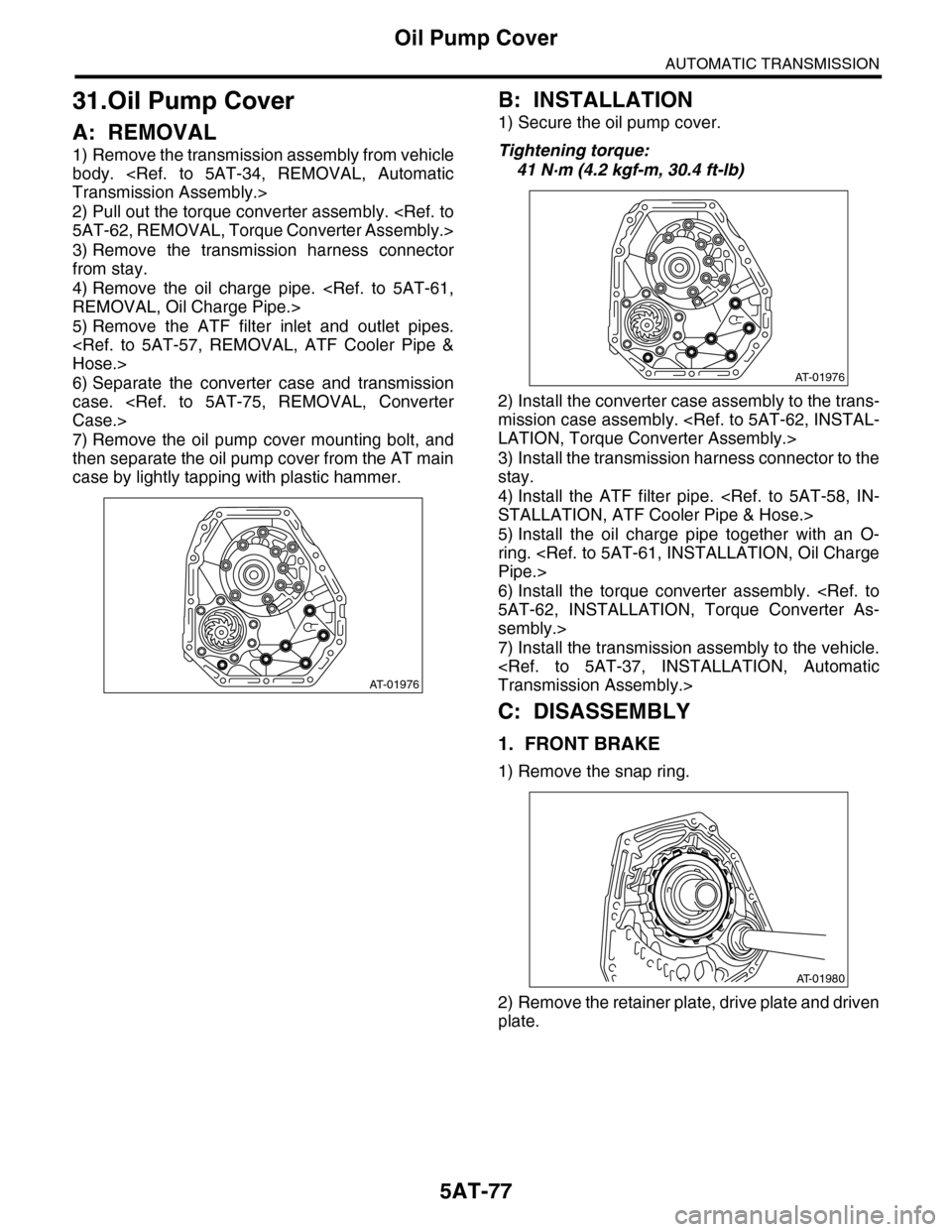

31.Oil Pump Cover

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Pull out the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Remove the oil charge pipe.

5) Remove the ATF filter inlet and outlet pipes.

6) Separate the converter case and transmission

case.

7) Remove the oil pump cover mounting bolt, and

then separate the oil pump cover from the AT main

case by lightly tapping with plastic hammer.

B: INSTALLATION

1) Secure the oil pump cover.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

2) Install the converter case assembly to the trans-

mission case assembly.

3) Install the transmission harness connector to the

stay.

4) Install the ATF filter pipe.

5) Install the oil charge pipe together with an O-

ring.

6) Install the torque converter assembly.

sembly.>

7) Install the transmission assembly to the vehicle.

C: DISASSEMBLY

1. FRONT BRAKE

1) Remove the snap ring.

2) Remove the retainer plate, drive plate and driven

plate.

AT-01976

AT-01976

AT-01980

Page 2094 of 2453

5AT-78

Oil Pump Cover

AUTOMATIC TRANSMISSION

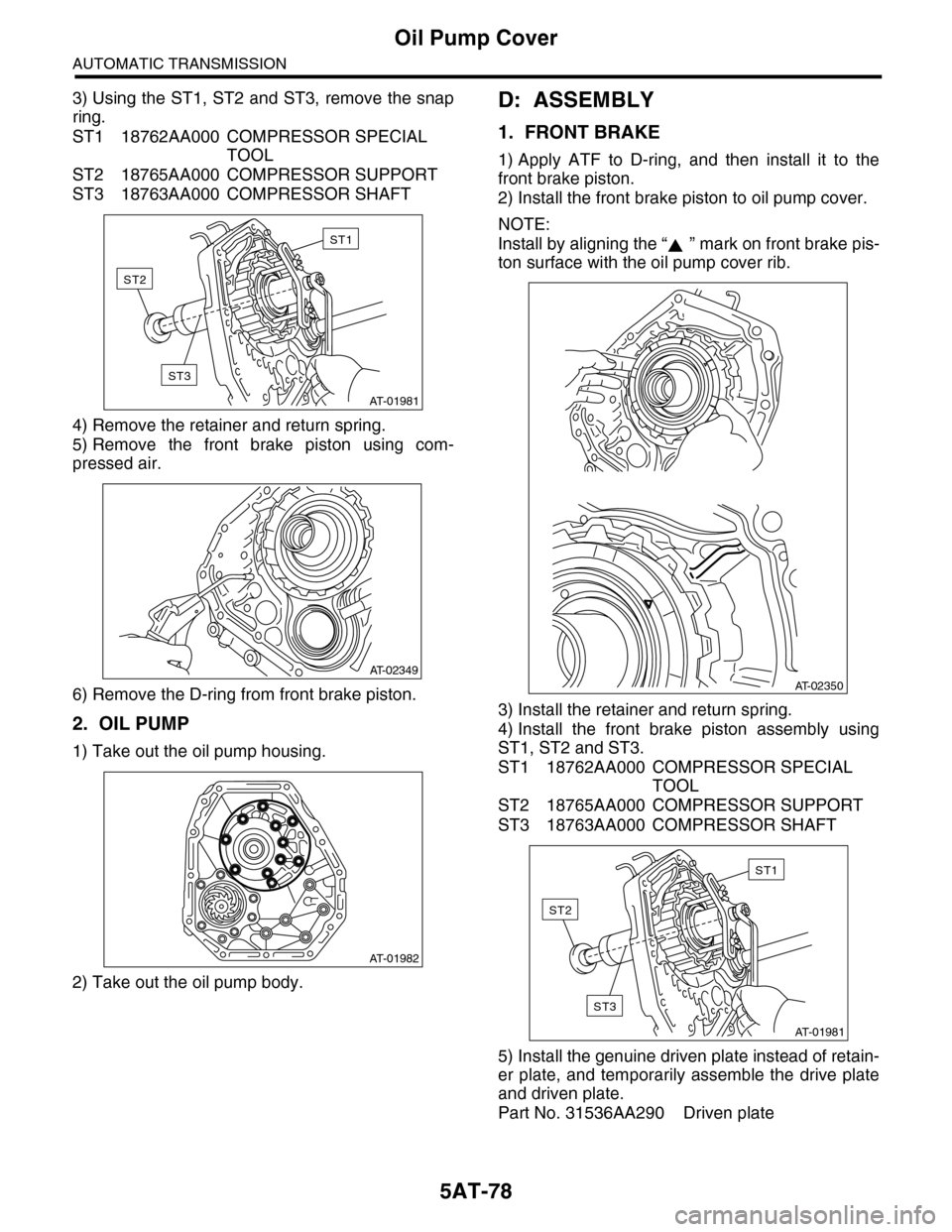

3) Using the ST1, ST2 and ST3, remove the snap

ring.

ST1 18762AA000 COMPRESSOR SPECIAL

TOOL

ST2 18765AA000 COMPRESSOR SUPPORT

ST3 18763AA000 COMPRESSOR SHAFT

4) Remove the retainer and return spring.

5) Remove the front brake piston using com-

pressed air.

6) Remove the D-ring from front brake piston.

2. OIL PUMP

1) Take out the oil pump housing.

2) Take out the oil pump body.

D: ASSEMBLY

1. FRONT BRAKE

1) Apply ATF to D-ring, and then install it to the

front brake piston.

2) Install the front brake piston to oil pump cover.

NOTE:

Install by aligning the “ ” mark on front brake pis-

ton surface with the oil pump cover rib.

3) Install the retainer and return spring.

4) Install the front brake piston assembly using

ST1, ST2 and ST3.

ST1 18762AA000 COMPRESSOR SPECIAL

TOOL

ST2 18765AA000 COMPRESSOR SUPPORT

ST3 18763AA000 COMPRESSOR SHAFT

5) Install the genuine driven plate instead of retain-

er plate, and temporarily assemble the drive plate

and driven plate.

Part No. 31536AA290 Driven plate

AT-01981

ST1

ST2

ST3

AT-02349

AT-01982

AT-02350

AT-01981

ST1

ST2

ST3