Heat SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1813 of 2453

GD(H6DO)-201

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

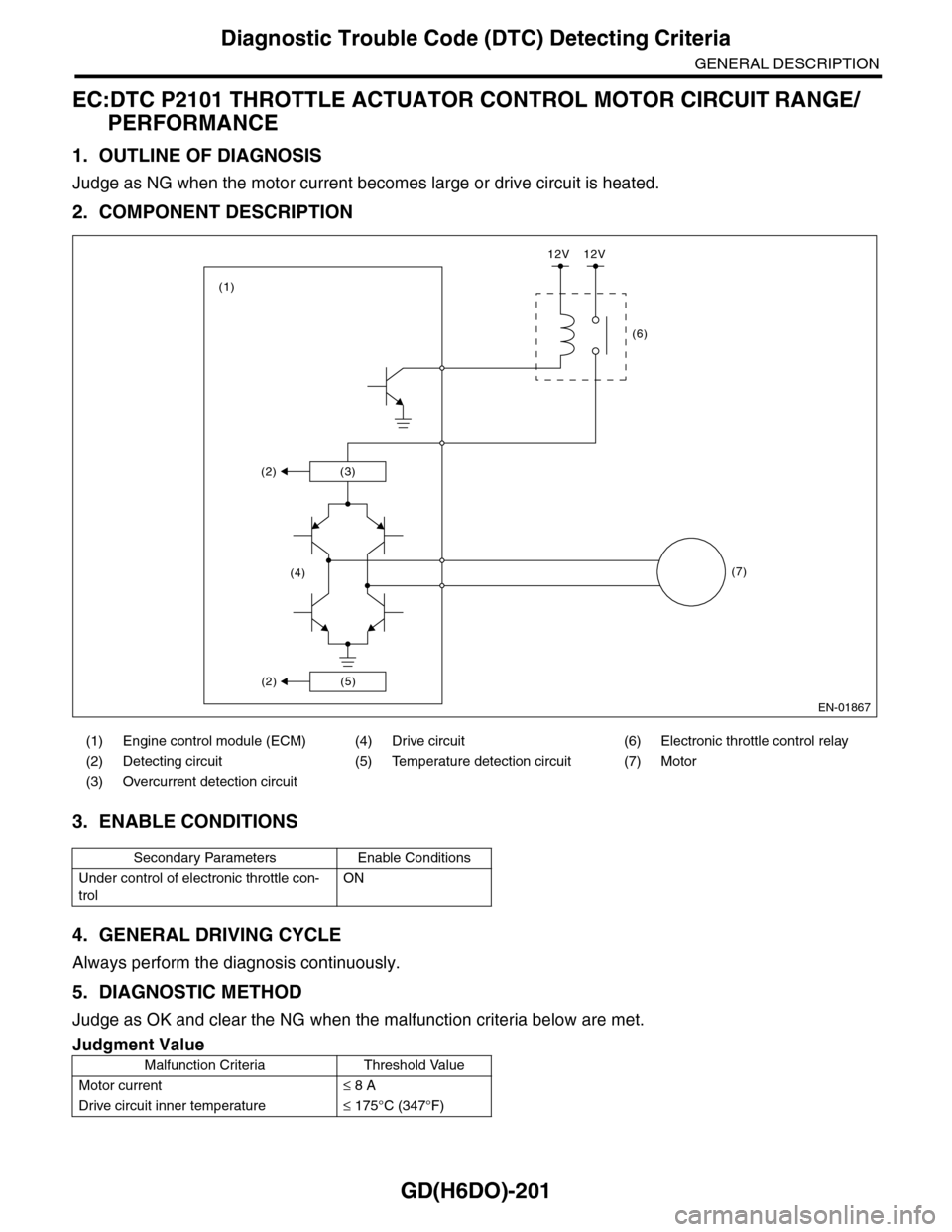

EC:DTC P2101 THROTTLE ACTUATOR CONTROL MOTOR CIRCUIT RANGE/

PERFORMANCE

1. OUTLINE OF DIAGNOSIS

Judge as NG when the motor current becomes large or drive circuit is heated.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Judge as OK and clear the NG when the malfunction criteria below are met.

(1) Engine control module (ECM) (4) Drive circuit (6) Electronic throttle control relay

(2) Detecting circuit (5) Temperature detection circuit (7) Motor

(3) Overcurrent detection circuit

Secondary Parameters Enable Conditions

Under control of electronic throttle con-

trol

ON

Judgment Value

Malfunction Criteria Threshold Value

Motor current≤ 8 A

Drive circuit inner temperature≤ 175°C (347°F)

EN-01867

(3)(2)

(5)(2)

(4)

(1)

(6)

(7)

12V 12V

Page 1839 of 2453

IG(H6DO)-4

Spark Plug

IGNITION

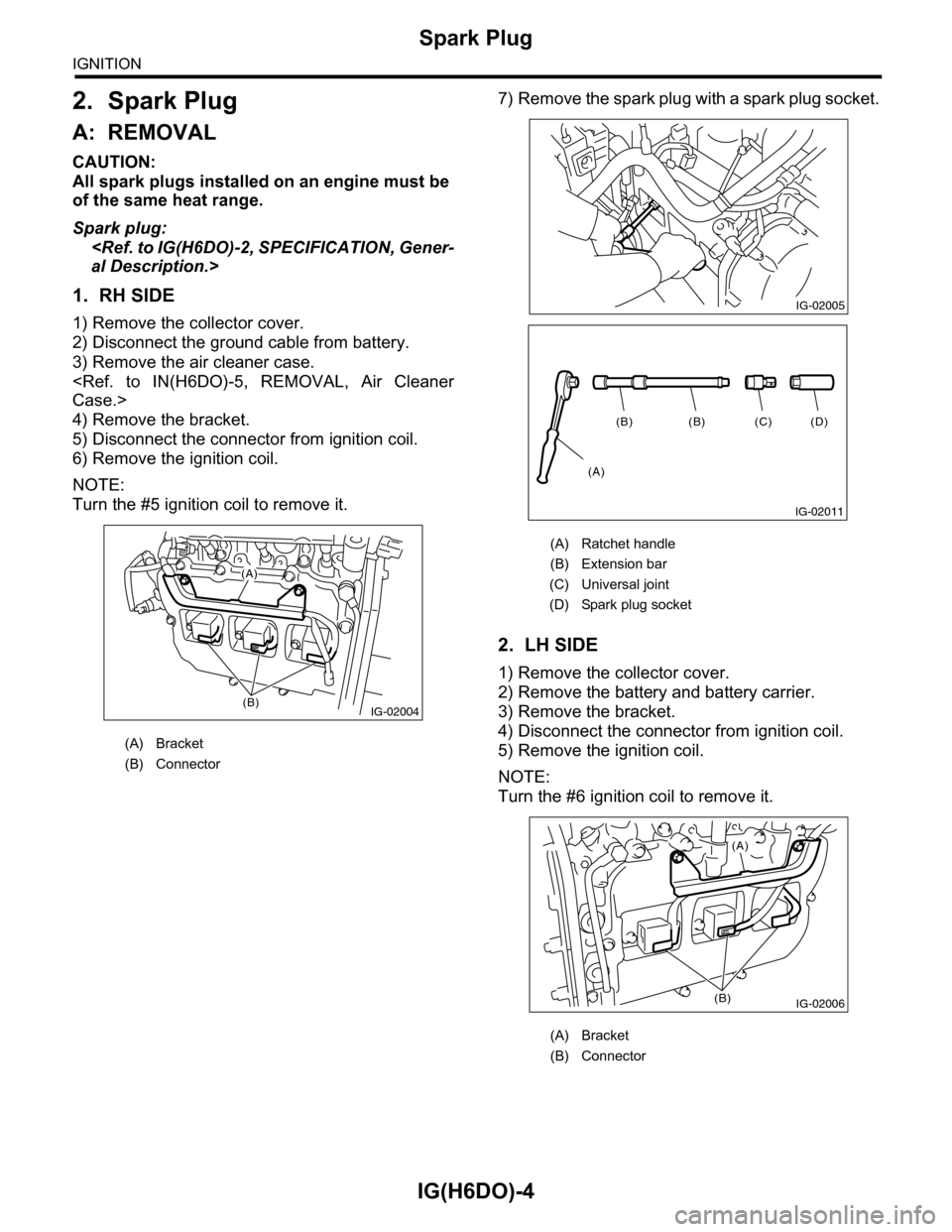

2. Spark Plug

A: REMOVAL

CAUTION:

All spark plugs installed on an engine must be

of the same heat range.

Spark plug:

1. RH SIDE

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Remove the air cleaner case.

4) Remove the bracket.

5) Disconnect the connector from ignition coil.

6) Remove the ignition coil.

NOTE:

Turn the #5 ignition coil to remove it.

7) Remove the spark plug with a spark plug socket.

2. LH SIDE

1) Remove the collector cover.

2) Remove the battery and battery carrier.

3) Remove the bracket.

4) Disconnect the connector from ignition coil.

5) Remove the ignition coil.

NOTE:

Turn the #6 ignition coil to remove it.

(A) Bracket

(B) Connector

IG-02004(B)

(A)

(A) Ratchet handle

(B) Extension bar

(C) Universal joint

(D) Spark plug socket

(A) Bracket

(B) Connector

IG-02005

(D)(C)(B)(B)

(A)

IG-02011

IG-02006

(A)

(B)

Page 1840 of 2453

IG(H6DO)-5

Spark Plug

IGNITION

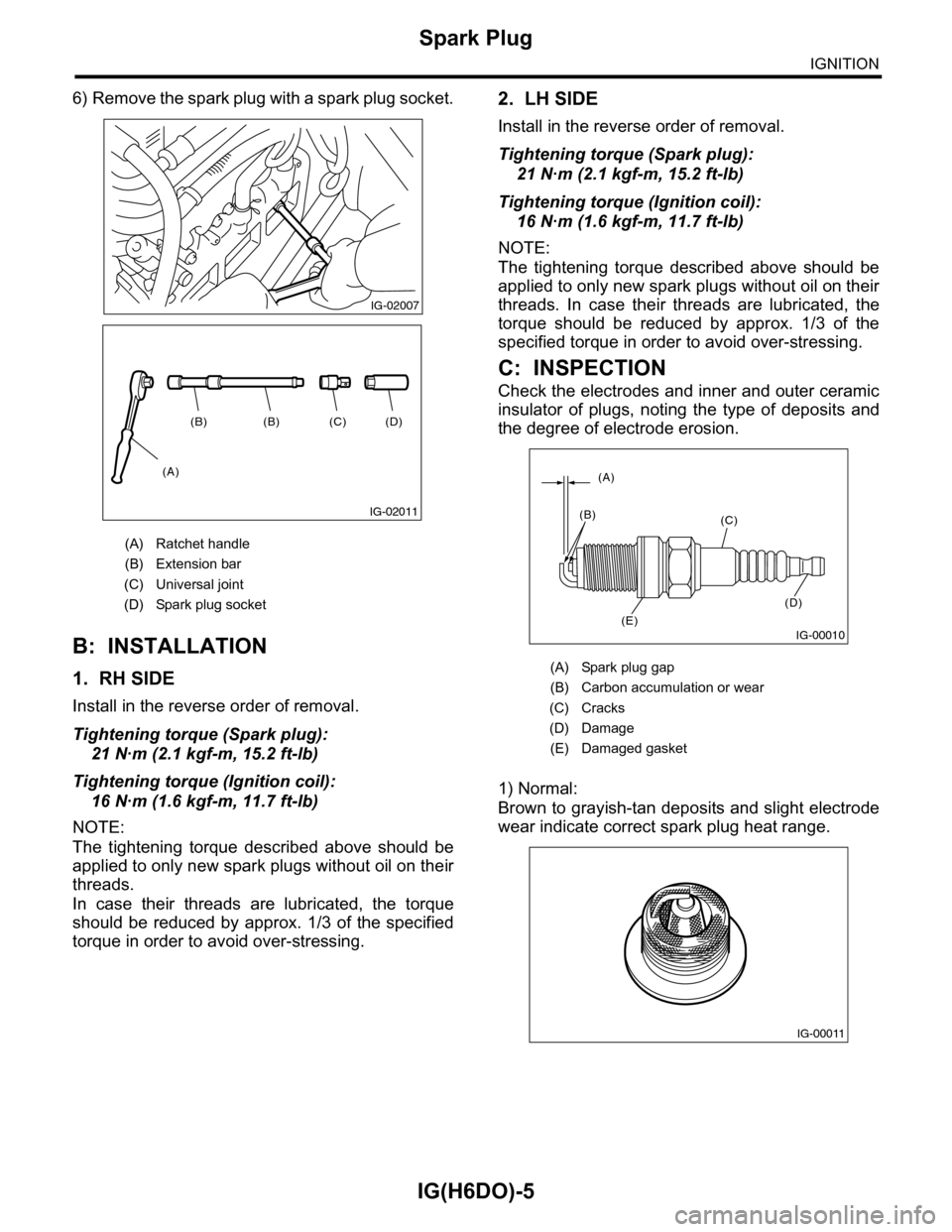

6) Remove the spark plug with a spark plug socket.

B: INSTALLATION

1. RH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N·m (2.1 kgf-m, 15.2 ft-lb)

Tightening torque (Ignition coil):

16 N·m (1.6 kgf-m, 11.7 ft-lb)

NOTE:

The tightening torque described above should be

applied to only new spark plugs without oil on their

threads.

In case their threads are lubricated, the torque

should be reduced by approx. 1/3 of the specified

torque in order to avoid over-stressing.

2. LH SIDE

Install in the reverse order of removal.

Tightening torque (Spark plug):

21 N·m (2.1 kgf-m, 15.2 ft-lb)

Tightening torque (Ignition coil):

16 N·m (1.6 kgf-m, 11.7 ft-lb)

NOTE:

The tightening torque described above should be

applied to only new spark plugs without oil on their

threads. In case their threads are lubricated, the

torque should be reduced by approx. 1/3 of the

specified torque in order to avoid over-stressing.

C: INSPECTION

Check the electrodes and inner and outer ceramic

insulator of plugs, noting the type of deposits and

the degree of electrode erosion.

1) Normal:

Brown to grayish-tan deposits and slight electrode

wear indicate correct spark plug heat range.

(A) Ratchet handle

(B) Extension bar

(C) Universal joint

(D) Spark plug socket

IG-02007

(D)(C)(B)(B)

(A)

IG-02011

(A) Spark plug gap

(B) Carbon accumulation or wear

(C) Cracks

(D) Damage

(E) Damaged gasket

IG-00010

(A)

(B)(C)

(D)

(E)

IG-00011

Page 1841 of 2453

IG(H6DO)-6

Spark Plug

IGNITION

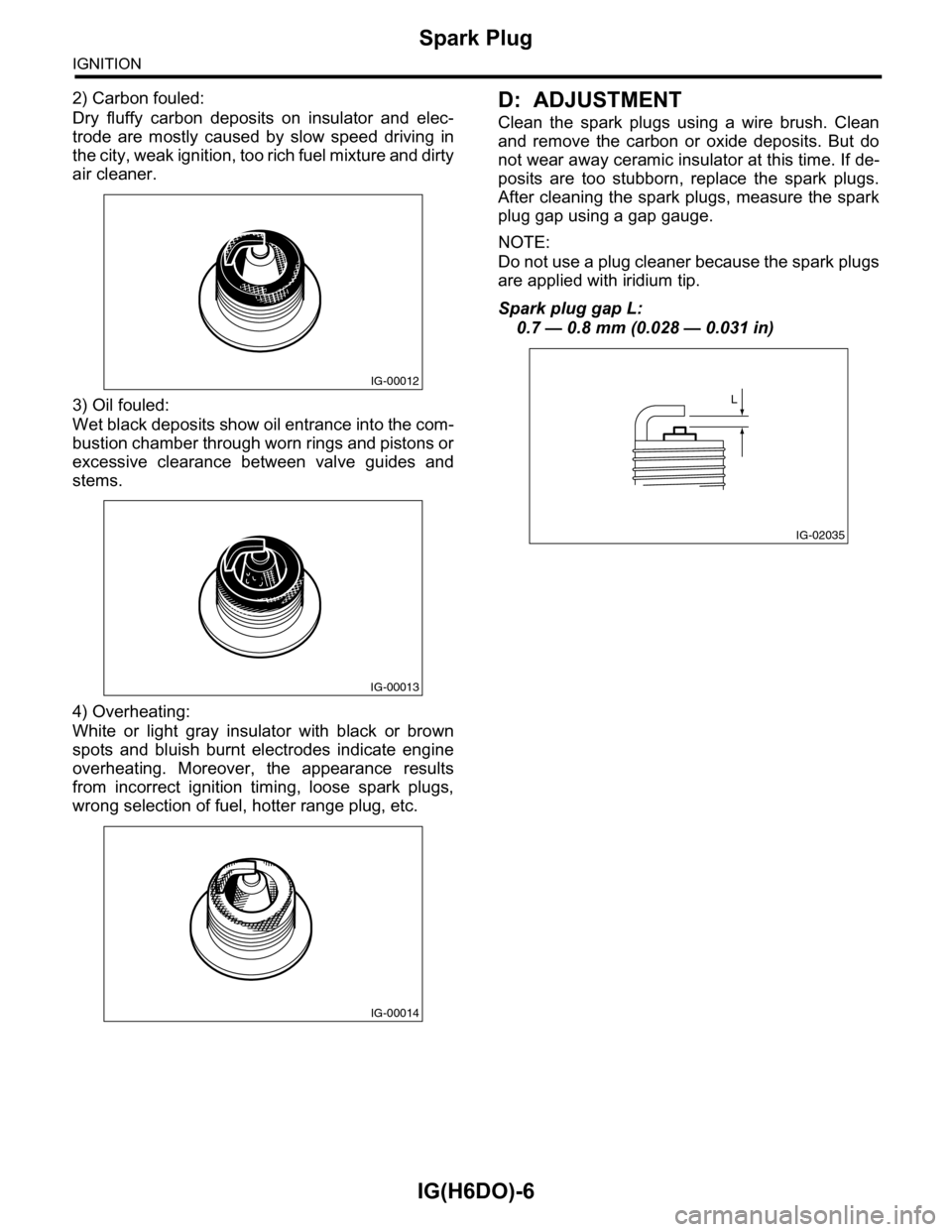

2) Carbon fouled:

Dry fluffy carbon deposits on insulator and elec-

trode are mostly caused by slow speed driving in

the city, weak ignition, too rich fuel mixture and dirty

air cleaner.

3) Oil fouled:

Wet black deposits show oil entrance into the com-

bustion chamber through worn rings and pistons or

excessive clearance between valve guides and

stems.

4) Overheating:

White or light gray insulator with black or brown

spots and bluish burnt electrodes indicate engine

overheating. Moreover, the appearance results

from incorrect ignition timing, loose spark plugs,

wrong selection of fuel, hotter range plug, etc.

D: ADJUSTMENT

Clean the spark plugs using a wire brush. Clean

and remove the carbon or oxide deposits. But do

not wear away ceramic insulator at this time. If de-

posits are too stubborn, replace the spark plugs.

After cleaning the spark plugs, measure the spark

plug gap using a gap gauge.

NOTE:

Do not use a plug cleaner because the spark plugs

are applied with iridium tip.

Spark plug gap L:

0.7 — 0.8 mm (0.028 — 0.031 in)

IG-00012

IG-00013

IG-00014

IG-02035

L

Page 1888 of 2453

ME(H6DO)-22

Idle Speed

MECHANICAL

3. Idle Speed

A: INSPECTION

1) Before checking the idle speed, check the fol-

lowing item:

(1) Check the air cleaner element is free from

clogging, ignition timing is correct, spark plugs

are in good condition, and hoses are connected

properly.

(2) Check the malfunction indicator light does

not illuminate.

2) Idle the engine.

3) Stop the engine, and turn the ignition switch to

OFF.

4) Insert the cartridge to Subaru Select Monitor.

5) Connect the Subaru Select Monitor to data link

connector.

6) Turn the ignition switch to ON and Subaru Select

Monitor switch to ON.

7) Select {Each System Check} in Main Menu.

8) Select {Engine} in Selection Menu.

9) Select {Current Data Display & Save} in Engine

Control System Diagnosis.

10) Select {Data Display} in Data Display Menu.

11) Start the engine, and read the engine idle

speed.

12) Check the idle speed when no-loaded. (Head-

light, heater fan, rear defroster, radiator fan, A/C

and etc. are OFF)

Idle speed [No load and gears in neutral]:

650±50 rpm

13) Check the idle speed when loaded. (Turn the A/

C switch to “ON” and operate the compressor for at

least one minute before measurement.)

Idle speed [A/C ON and gears in neutral]:

770±50 rpm

NOTE:

Idle speed cannot be adjusted manually, because

the idle speed is automatically adjusted. If the pre-

scribed idle speed cannot be maintained, refer to

General On-board Diagnosis Table under “Engine

Control System”.

Page 1899 of 2453

ME(H6DO)-33

Engine Assembly

MECHANICAL

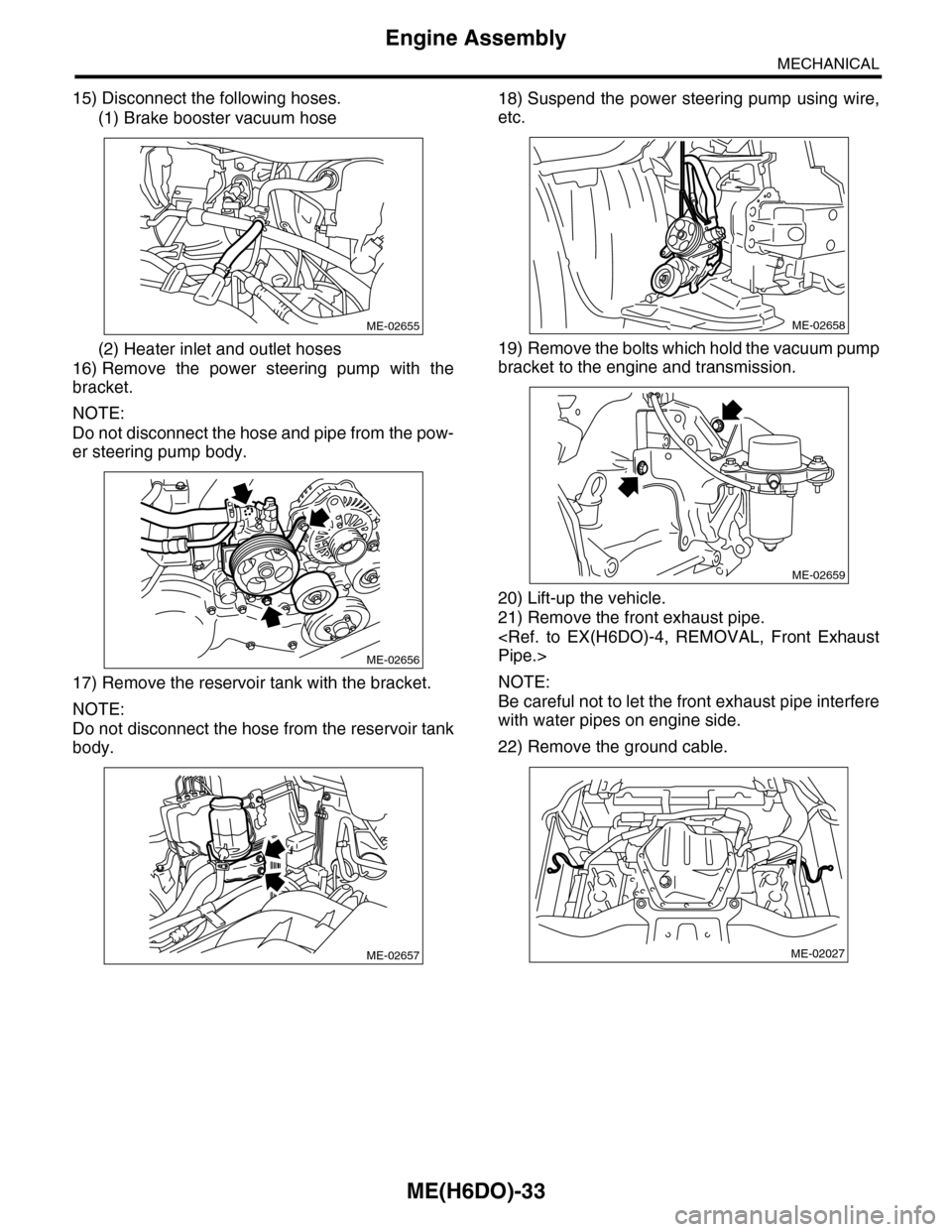

15) Disconnect the following hoses.

(1) Brake booster vacuum hose

(2) Heater inlet and outlet hoses

16) Remove the power steering pump with the

bracket.

NOTE:

Do not disconnect the hose and pipe from the pow-

er steering pump body.

17) Remove the reservoir tank with the bracket.

NOTE:

Do not disconnect the hose from the reservoir tank

body.

18) Suspend the power steering pump using wire,

etc.

19) Remove the bolts which hold the vacuum pump

bracket to the engine and transmission.

20) Lift-up the vehicle.

21) Remove the front exhaust pipe.

NOTE:

Be careful not to let the front exhaust pipe interfere

with water pipes on engine side.

22) Remove the ground cable.

ME-02655

ME-02656

ME-02657

ME-02658

ME-02659

ME-02027

Page 1904 of 2453

ME(H6DO)-38

Engine Assembly

MECHANICAL

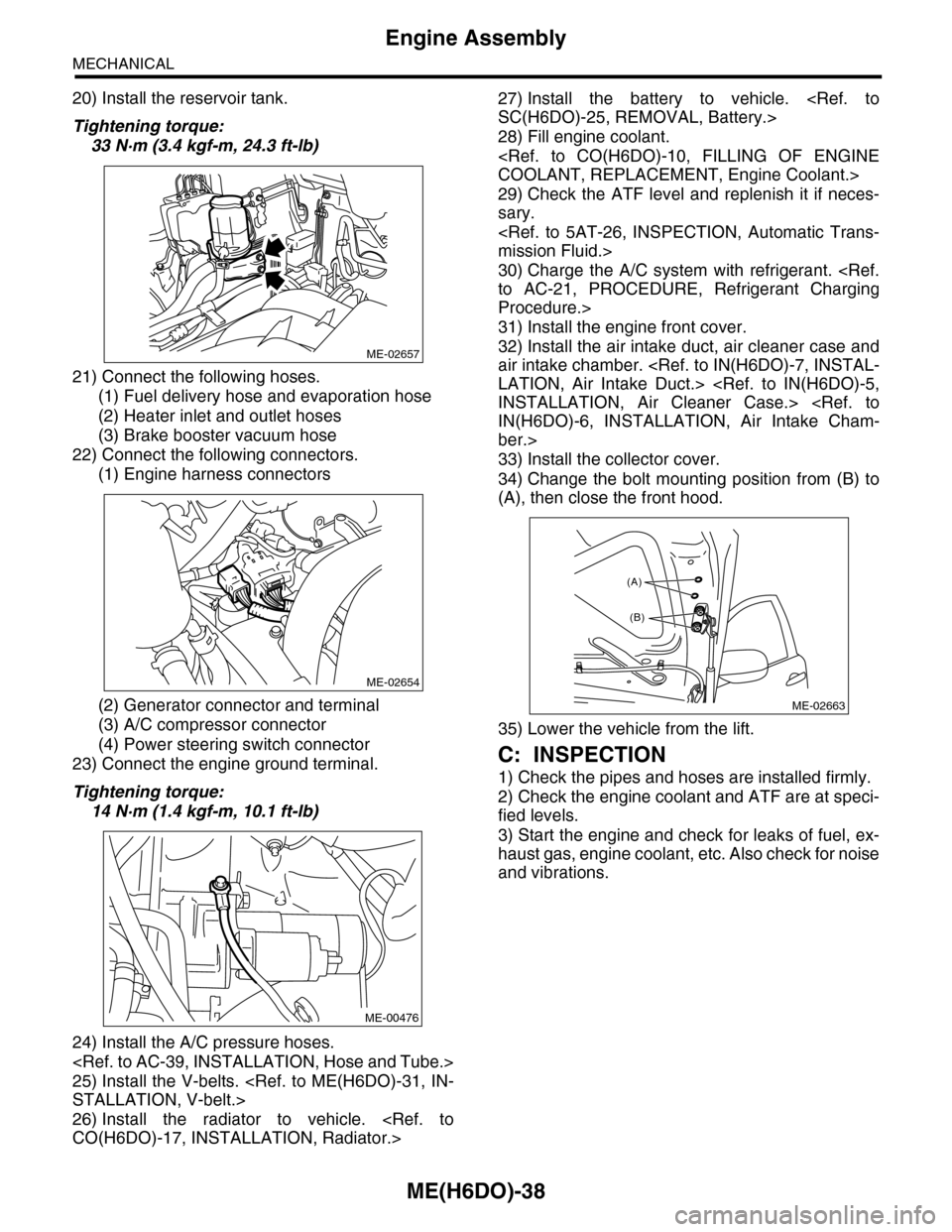

20) Install the reservoir tank.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

21) Connect the following hoses.

(1) Fuel delivery hose and evaporation hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

22) Connect the following connectors.

(1) Engine harness connectors

(2) Generator connector and terminal

(3) A/C compressor connector

(4) Power steering switch connector

23) Connect the engine ground terminal.

Tightening torque:

14 N·m (1.4 kgf-m, 10.1 ft-lb)

24) Install the A/C pressure hoses.

25) Install the V-belts.

26) Install the radiator to vehicle.

27) Install the battery to vehicle.

28) Fill engine coolant.

29) Check the ATF level and replenish it if neces-

sary.

30) Charge the A/C system with refrigerant.

Procedure.>

31) Install the engine front cover.

32) Install the air intake duct, air cleaner case and

air intake chamber.

ber.>

33) Install the collector cover.

34) Change the bolt mounting position from (B) to

(A), then close the front hood.

35) Lower the vehicle from the lift.

C: INSPECTION

1) Check the pipes and hoses are installed firmly.

2) Check the engine coolant and ATF are at speci-

fied levels.

3) Start the engine and check for leaks of fuel, ex-

haust gas, engine coolant, etc. Also check for noise

and vibrations.

ME-02657

ME-02654

ME-00476

ME-02663

(A)

(B)

Page 1951 of 2453

ME(H6DO)-85

Engine Trouble in General

MECHANICAL

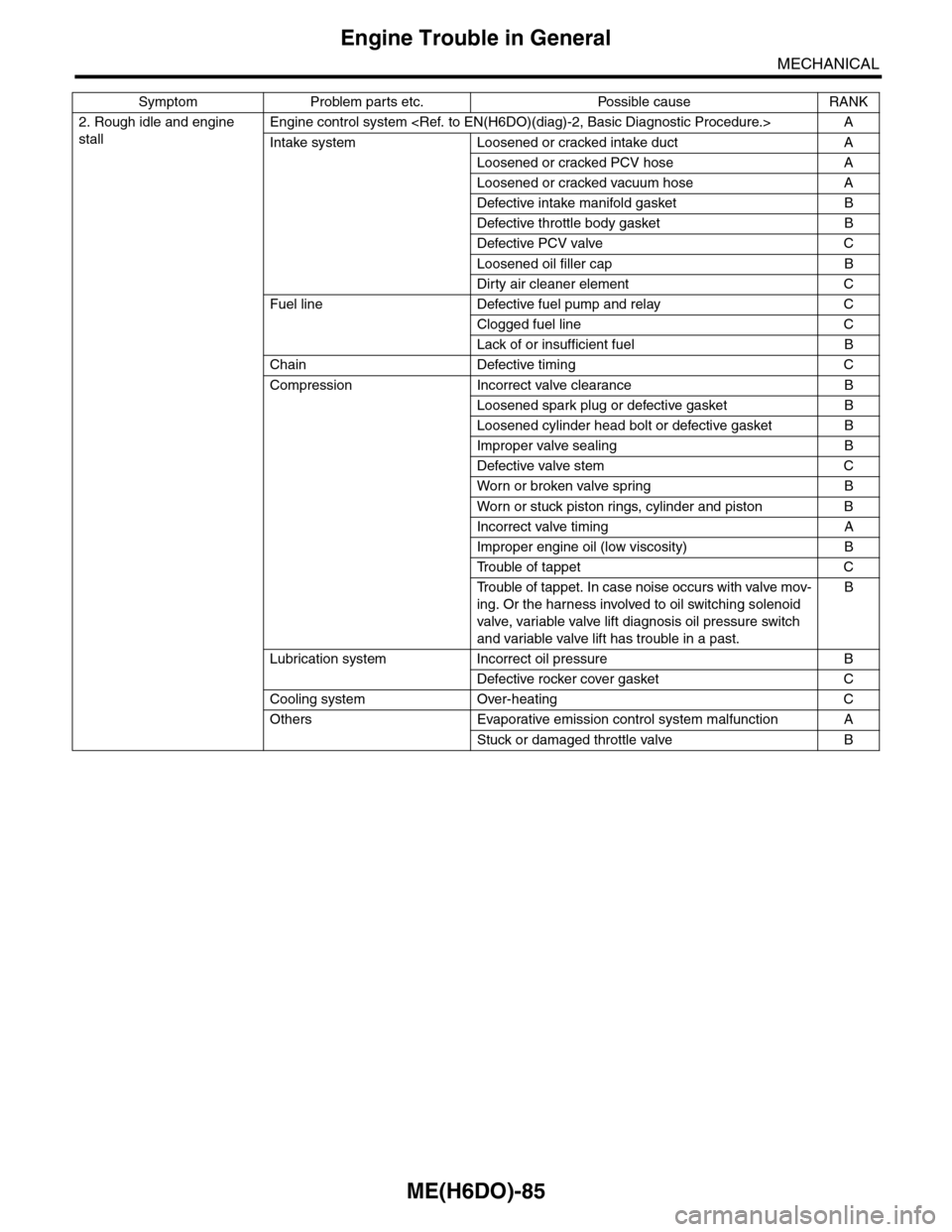

2. Rough idle and engine

stall

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve C

Loosened oil filler cap B

Dirty air cleaner element C

Fuel line Defective fuel pump and relay C

Clogged fuel line C

Lack of or insufficient fuel B

Chain Defective timing C

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston B

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Defective rocker cover gasket C

Cooling system Over-heating C

Others Evaporative emission control system malfunction A

Stuck or damaged throttle valve B

Symptom Problem parts etc. Possible cause RANK

Page 1952 of 2453

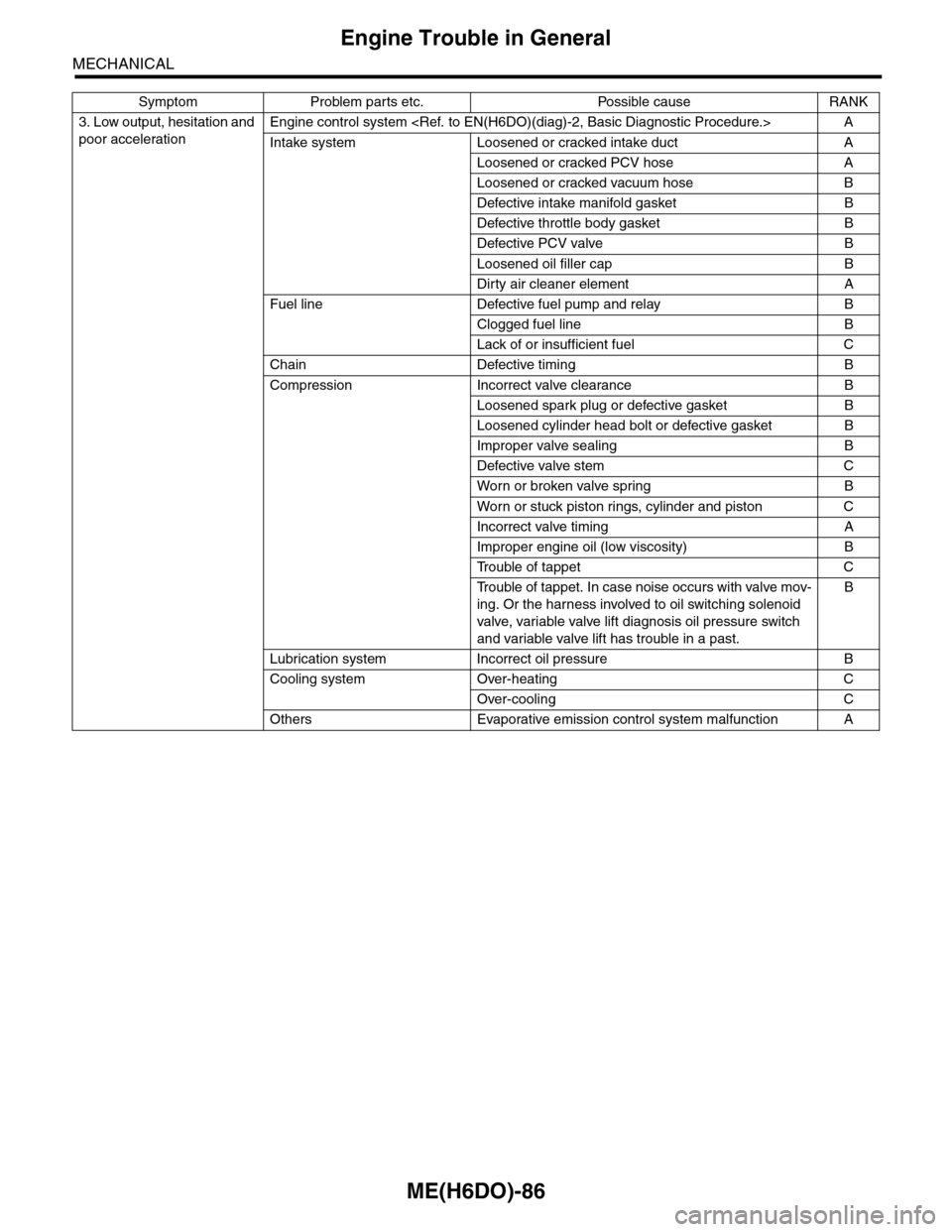

ME(H6DO)-86

Engine Trouble in General

MECHANICAL

3. Low output, hesitation and

poor acceleration

Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose B

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element A

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket B

Loosened cylinder head bolt or defective gasket B

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing B

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure B

Cooling system Over-heating C

Over-cooling C

Others Evaporative emission control system malfunction A

Symptom Problem parts etc. Possible cause RANK

Page 1953 of 2453

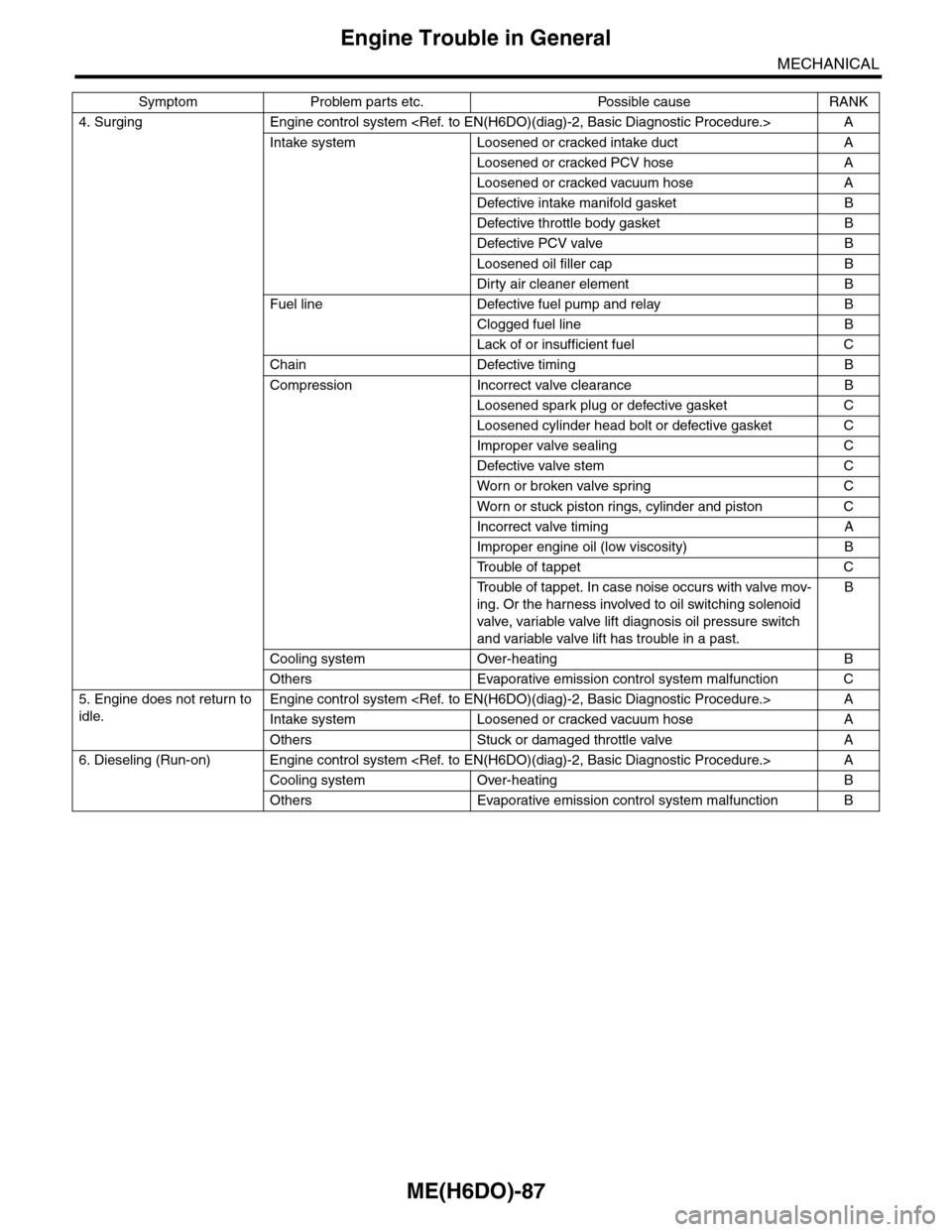

ME(H6DO)-87

Engine Trouble in General

MECHANICAL

4. Surging Engine control system

Intake system Loosened or cracked intake duct A

Loosened or cracked PCV hose A

Loosened or cracked vacuum hose A

Defective intake manifold gasket B

Defective throttle body gasket B

Defective PCV valve B

Loosened oil filler cap B

Dirty air cleaner element B

Fuel line Defective fuel pump and relay B

Clogged fuel line B

Lack of or insufficient fuel C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing C

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Improper engine oil (low viscosity) B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating B

Others Evaporative emission control system malfunction C

5. Engine does not return to

idle.

Engine control system

Intake system Loosened or cracked vacuum hose A

Others Stuck or damaged throttle valve A

6. Dieseling (Run-on) Engine control system

Cooling system Over-heating B

Others Evaporative emission control system malfunction B

Symptom Problem parts etc. Possible cause RANK