Heat SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1954 of 2453

ME(H6DO)-88

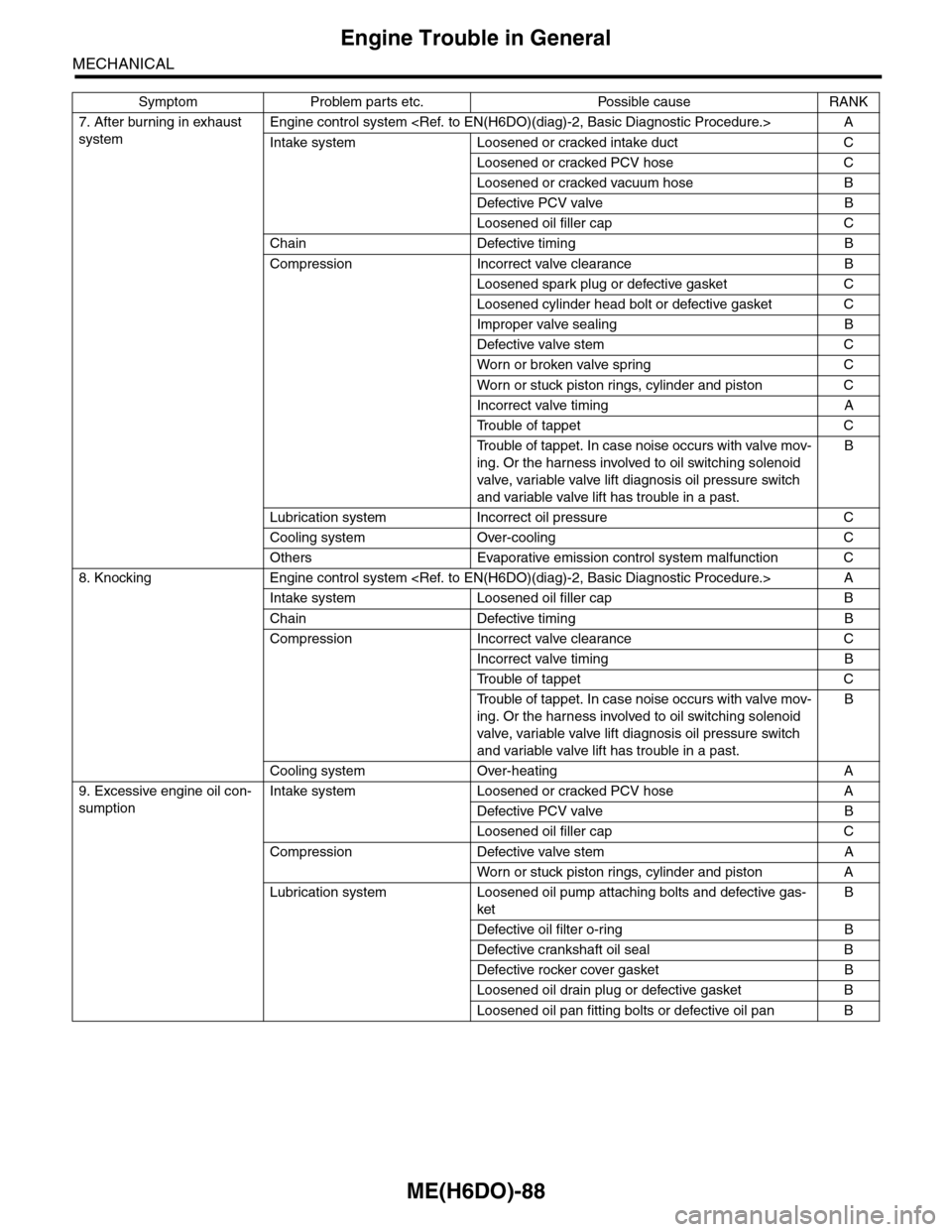

Engine Trouble in General

MECHANICAL

7. After burning in exhaust

system

Engine control system

Intake system Loosened or cracked intake duct C

Loosened or cracked PCV hose C

Loosened or cracked vacuum hose B

Defective PCV valve B

Loosened oil filler cap C

Chain Defective timing B

Compression Incorrect valve clearance B

Loosened spark plug or defective gasket C

Loosened cylinder head bolt or defective gasket C

Improper valve sealing B

Defective valve stem C

Wor n or broken valve spr ing C

Wor n or stuck piston r ings, cylinder and piston C

Incorrect valve timing A

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Lubrication system Incorrect oil pressure C

Cooling system Over-cooling C

Others Evaporative emission control system malfunction C

8. Knocking Engine control system

Intake system Loosened oil filler cap B

Chain Defective timing B

Compression Incorrect valve clearance C

Incorrect valve timing B

Tr o u b l e o f t a p p e t C

Tr o u b l e o f t a p p e t . I n c a s e n o i s e o c c u r s w i t h v a l v e m o v -

ing. Or the harness involved to oil switching solenoid

valve, variable valve lift diagnosis oil pressure switch

and variable valve lift has trouble in a past.

B

Cooling system Over-heating A

9. Excessive engine oil con-

sumption

Intake system Loosened or cracked PCV hose A

Defective PCV valve B

Loosened oil filler cap C

Compression Defective valve stem A

Wor n or stuck piston r ings, cylinder and piston A

Lubrication system Loosened oil pump attaching bolts and defective gas-

ket

B

Defective oil filter o-ring B

Defective crankshaft oil seal B

Defective rocker cover gasket B

Loosened oil drain plug or defective gasket B

Loosened oil pan fitting bolts or defective oil pan B

Symptom Problem parts etc. Possible cause RANK

Page 1977 of 2453

SC(H6DO)-19

Generator

STARTING/CHARGING SYSTEMS

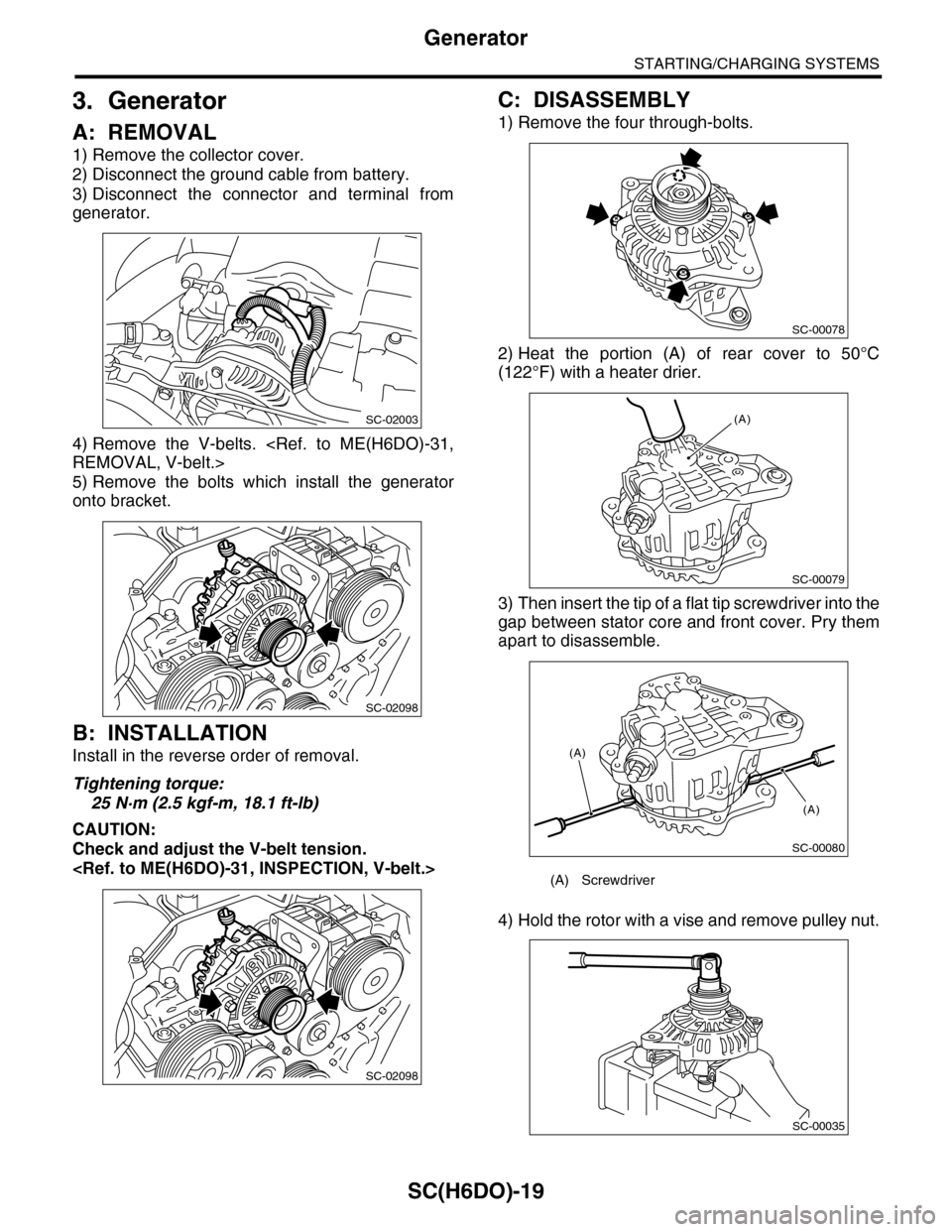

3. Generator

A: REMOVAL

1) Remove the collector cover.

2) Disconnect the ground cable from battery.

3) Disconnect the connector and terminal from

generator.

4) Remove the V-belts.

5) Remove the bolts which install the generator

onto bracket.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

25 N·m (2.5 kgf-m, 18.1 ft-lb)

CAUTION:

Check and adjust the V-belt tension.

C: DISASSEMBLY

1) Remove the four through-bolts.

2) Heat the portion (A) of rear cover to 50°C

(122°F) with a heater drier.

3) Then insert the tip of a flat tip screwdriver into the

gap between stator core and front cover. Pry them

apart to disassemble.

4) Hold the rotor with a vise and remove pulley nut.

SC-02003

SC-02098

SC-02098

(A) Screwdriver

SC-00078

SC-00079

(A)

SC-00080

(A)

(A)

SC-00035

Page 1978 of 2453

SC(H6DO)-20

Generator

STARTING/CHARGING SYSTEMS

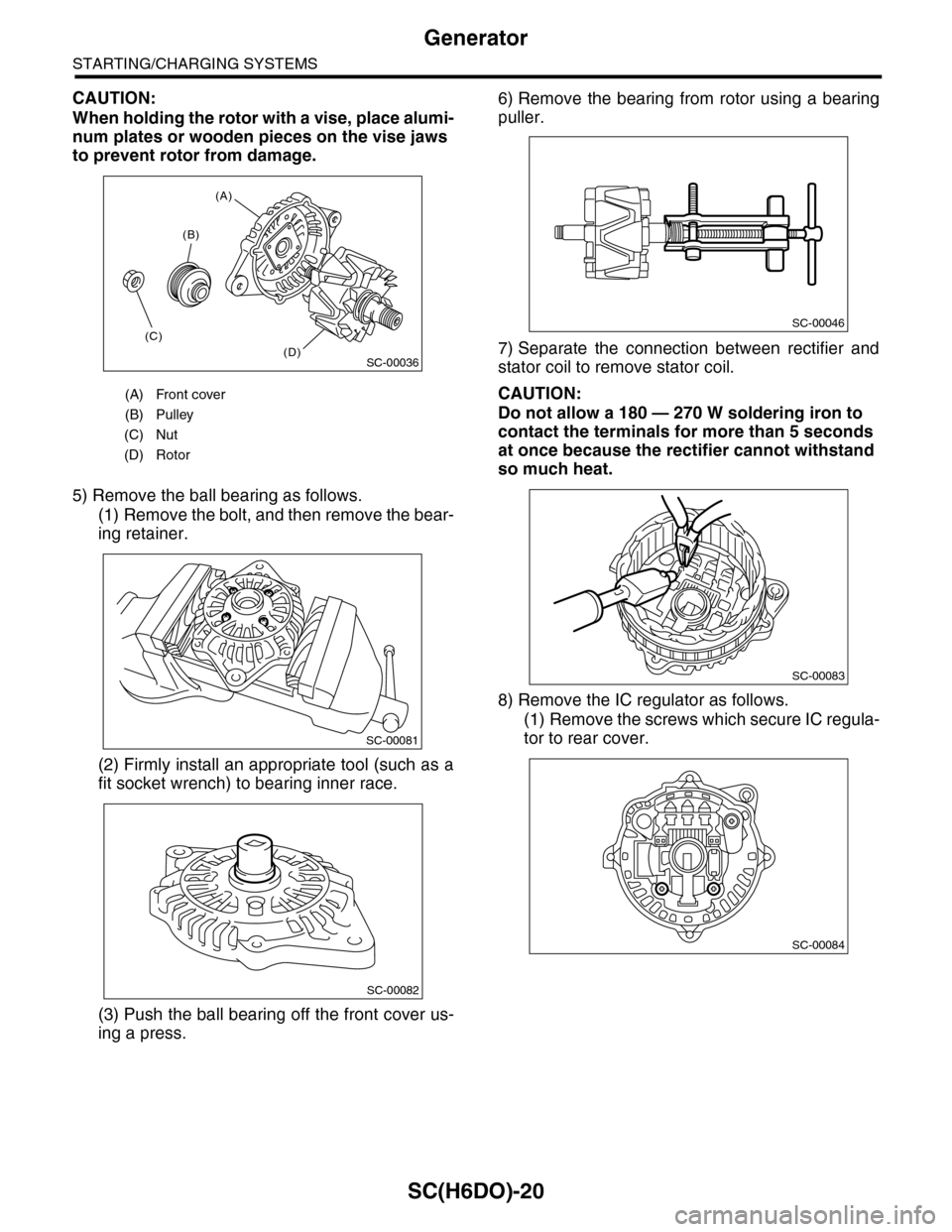

CAUTION:

When holding the rotor with a vise, place alumi-

num plates or wooden pieces on the vise jaws

to prevent rotor from damage.

5) Remove the ball bearing as follows.

(1) Remove the bolt, and then remove the bear-

ing retainer.

(2) Firmly install an appropriate tool (such as a

fit socket wrench) to bearing inner race.

(3) Push the ball bearing off the front cover us-

ing a press.

6) Remove the bearing from rotor using a bearing

puller.

7) Separate the connection between rectifier and

stator coil to remove stator coil.

CAUTION:

Do not allow a 180 — 270 W soldering iron to

contact the terminals for more than 5 seconds

at once because the rectifier cannot withstand

so much heat.

8) Remove the IC regulator as follows.

(1) Remove the screws which secure IC regula-

tor to rear cover.

(A) Front cover

(B) Pulley

(C) Nut

(D) Rotor

(A)

(B)

(C)

(D)SC-00036

SC-00081

SC-00082

SC-00046

SC-00083

SC-00084

Page 1980 of 2453

SC(H6DO)-22

Generator

STARTING/CHARGING SYSTEMS

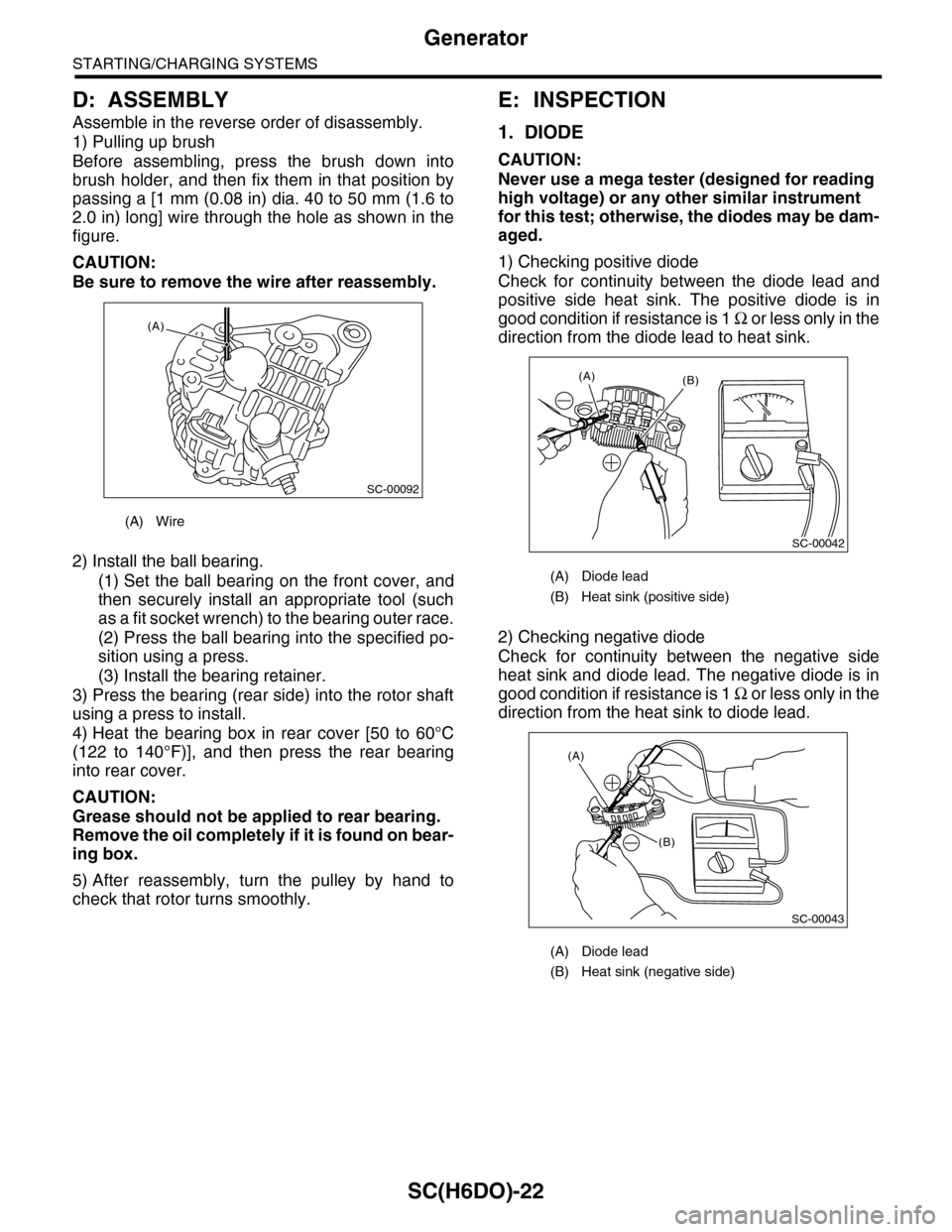

D: ASSEMBLY

Assemble in the reverse order of disassembly.

1) Pulling up brush

Before assembling, press the brush down into

brush holder, and then fix them in that position by

passing a [1 mm (0.08 in) dia. 40 to 50 mm (1.6 to

2.0 in) long] wire through the hole as shown in the

figure.

CAUTION:

Be sure to remove the wire after reassembly.

2) Install the ball bearing.

(1) Set the ball bearing on the front cover, and

then securely install an appropriate tool (such

as a fit socket wrench) to the bearing outer race.

(2) Press the ball bearing into the specified po-

sition using a press.

(3) Install the bearing retainer.

3) Press the bearing (rear side) into the rotor shaft

using a press to install.

4) Heat the bearing box in rear cover [50 to 60°C

(122 to 140°F)], and then press the rear bearing

into rear cover.

CAUTION:

Grease should not be applied to rear bearing.

Remove the oil completely if it is found on bear-

ing box.

5) After reassembly, turn the pulley by hand to

check that rotor turns smoothly.

E: INSPECTION

1. DIODE

CAUTION:

Never use a mega tester (designed for reading

high voltage) or any other similar instrument

for this test; otherwise, the diodes may be dam-

aged.

1) Checking positive diode

Check for continuity between the diode lead and

positive side heat sink. The positive diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the diode lead to heat sink.

2) Checking negative diode

Check for continuity between the negative side

heat sink and diode lead. The negative diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the heat sink to diode lead.

(A) Wire

SC-00092

(A)

(A) Diode lead

(B) Heat sink (positive side)

(A) Diode lead

(B) Heat sink (negative side)

SC-00042

(B)(A)

(A)

(B)

SC-00043

Page 1996 of 2453

PM-13

Cooling System

PERIODIC MAINTENANCE SERVICES

9. Cooling System

A: INSPECTION

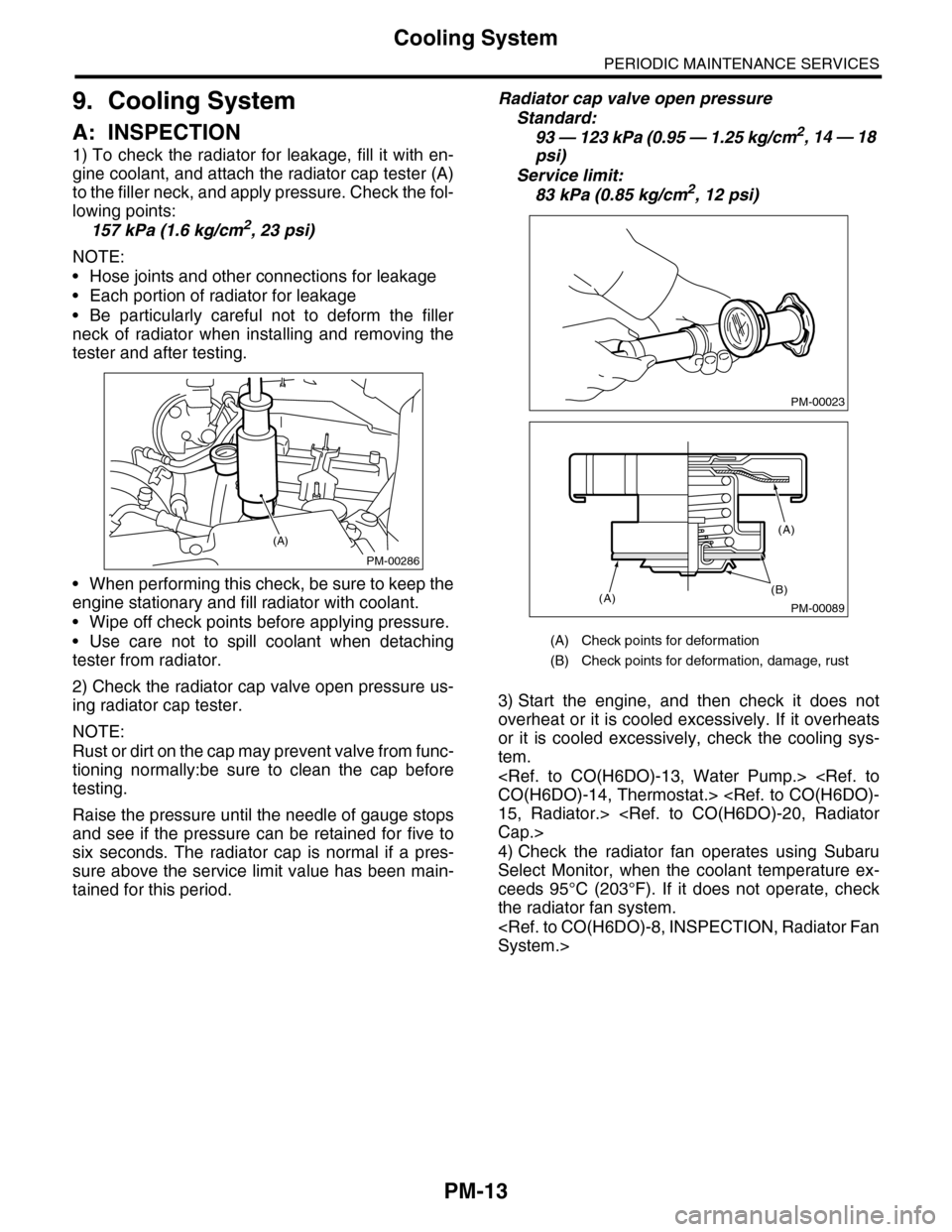

1) To check the radiator for leakage, fill it with en-

gine coolant, and attach the radiator cap tester (A)

to the filler neck, and apply pressure. Check the fol-

lowing points:

157 kPa (1.6 kg/cm2, 23 psi)

NOTE:

•Hose joints and other connections for leakage

•Each portion of radiator for leakage

•Be particularly careful not to deform the filler

neck of radiator when installing and removing the

tester and after testing.

•When performing this check, be sure to keep the

engine stationary and fill radiator with coolant.

•Wipe off check points before applying pressure.

•Use care not to spill coolant when detaching

tester from radiator.

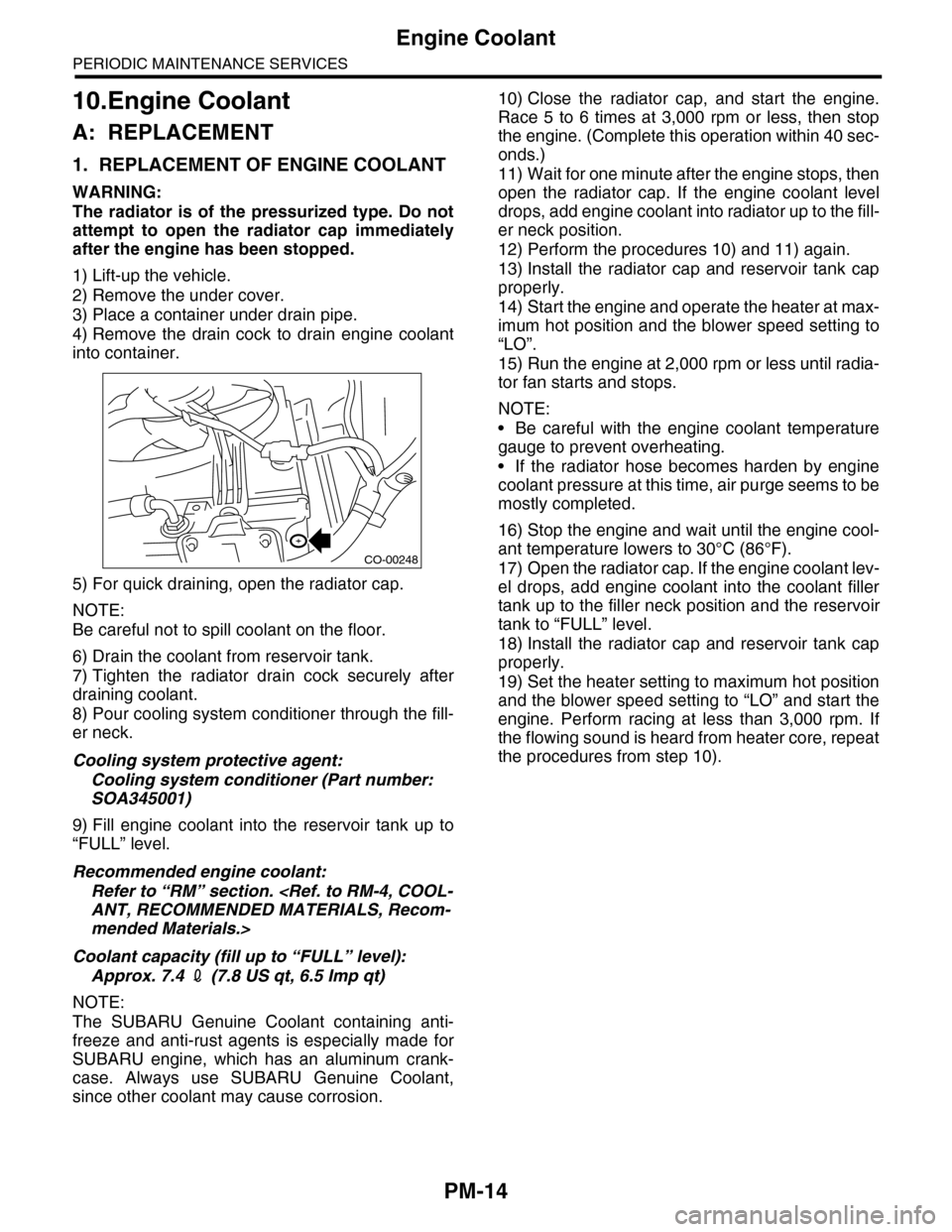

2) Check the radiator cap valve open pressure us-

ing radiator cap tester.

NOTE:

Rust or dirt on the cap may prevent valve from func-

tioning normally:be sure to clean the cap before

testing.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for five to

six seconds. The radiator cap is normal if a pres-

sure above the service limit value has been main-

tained for this period.

Radiator cap valve open pressure

Standard:

93 — 123 kPa (0.95 — 1.25 kg/cm2, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm2, 12 psi)

3) Start the engine, and then check it does not

overheat or it is cooled excessively. If it overheats

or it is cooled excessively, check the cooling sys-

tem.

4) Check the radiator fan operates using Subaru

Select Monitor, when the coolant temperature ex-

ceeds 95°C (203°F). If it does not operate, check

the radiator fan system.

PM-00286

(A)

(A) Check points for deformation

(B) Check points for deformation, damage, rust

PM-00023

PM-00089

(B)(A)

(A)

Page 1997 of 2453

PM-14

Engine Coolant

PERIODIC MAINTENANCE SERVICES

10.Engine Coolant

A: REPLACEMENT

1. REPLACEMENT OF ENGINE COOLANT

WARNING:

The radiator is of the pressurized type. Do not

attempt to open the radiator cap immediately

after the engine has been stopped.

1) Lift-up the vehicle.

2) Remove the under cover.

3) Place a container under drain pipe.

4) Remove the drain cock to drain engine coolant

into container.

5) For quick draining, open the radiator cap.

NOTE:

Be careful not to spill coolant on the floor.

6) Drain the coolant from reservoir tank.

7) Tighten the radiator drain cock securely after

draining coolant.

8) Pour cooling system conditioner through the fill-

er neck.

Cooling system protective agent:

Cooling system conditioner (Part number:

SOA345001)

9) Fill engine coolant into the reservoir tank up to

“FULL” level.

Recommended engine coolant:

Refer to “RM” section.

mended Materials.>

Coolant capacity (fill up to “FULL” level):

Approx. 7.4 2 (7.8 US qt, 6.5 Imp qt)

NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

10) Close the radiator cap, and start the engine.

Race 5 to 6 times at 3,000 rpm or less, then stop

the engine. (Complete this operation within 40 sec-

onds.)

11) Wait for one minute after the engine stops, then

open the radiator cap. If the engine coolant level

drops, add engine coolant into radiator up to the fill-

er neck position.

12) Perform the procedures 10) and 11) again.

13) Install the radiator cap and reservoir tank cap

properly.

14) Start the engine and operate the heater at max-

imum hot position and the blower speed setting to

“LO”.

15) Run the engine at 2,000 rpm or less until radia-

tor fan starts and stops.

NOTE:

•Be careful with the engine coolant temperature

gauge to prevent overheating.

•If the radiator hose becomes harden by engine

coolant pressure at this time, air purge seems to be

mostly completed.

16) Stop the engine and wait until the engine cool-

ant temperature lowers to 30°C (86°F).

17) Open the radiator cap. If the engine coolant lev-

el drops, add engine coolant into the coolant filler

tank up to the filler neck position and the reservoir

tank to “FULL” level.

18) Install the radiator cap and reservoir tank cap

properly.

19) Set the heater setting to maximum hot position

and the blower speed setting to “LO” and start the

engine. Perform racing at less than 3,000 rpm. If

the flowing sound is heard from heater core, repeat

the procedures from step 10).

CO-00248

Page 2049 of 2453

5AT-33

Transfer Clutch Pressure Test

AUTOMATIC TRANSMISSION

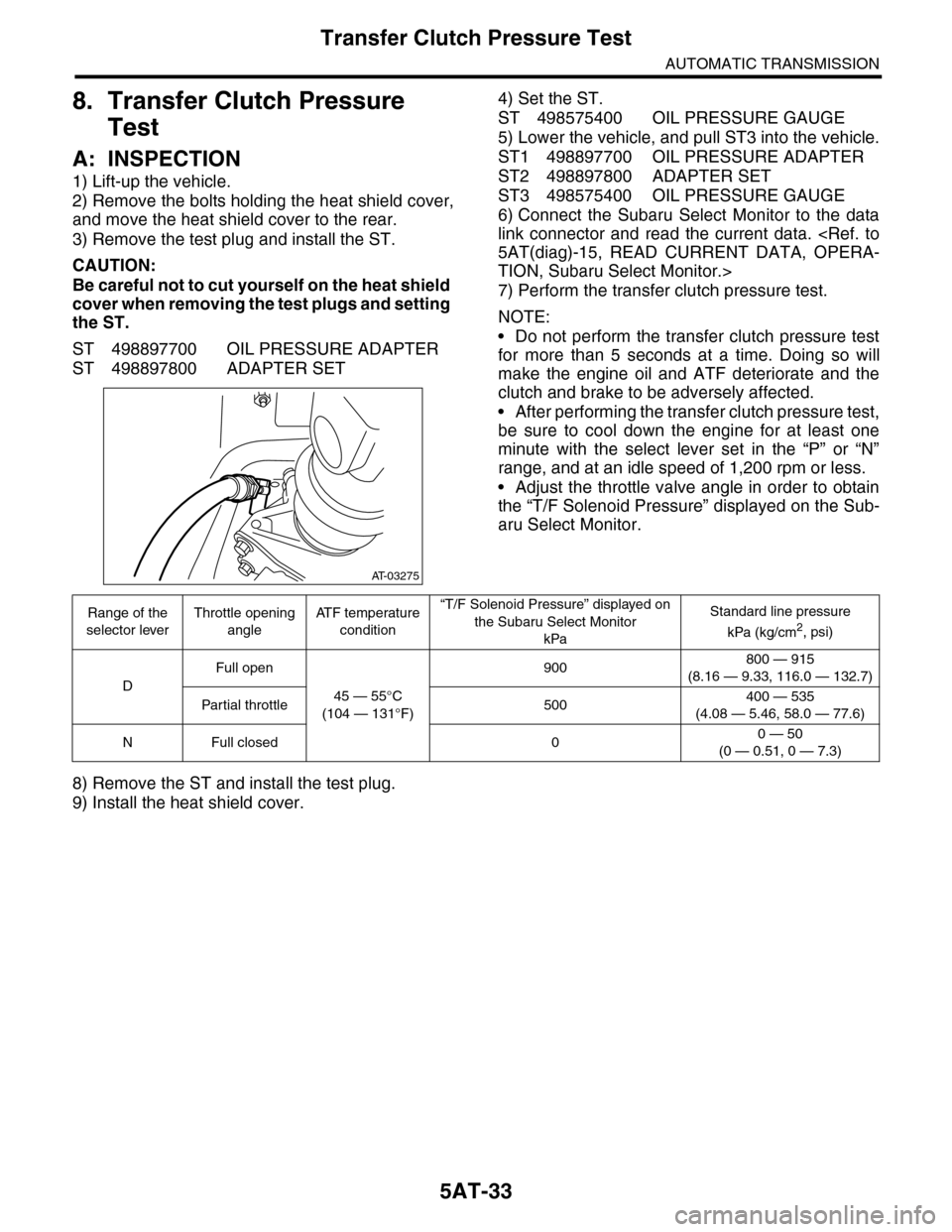

8. Transfer Clutch Pressure

Test

A: INSPECTION

1) Lift-up the vehicle.

2) Remove the bolts holding the heat shield cover,

and move the heat shield cover to the rear.

3) Remove the test plug and install the ST.

CAUTION:

Be careful not to cut yourself on the heat shield

cover when removing the test plugs and setting

the ST.

ST 498897700 OIL PRESSURE ADAPTER

ST 498897800 ADAPTER SET

4) Set the ST.

ST 498575400 OIL PRESSURE GAUGE

5) Lower the vehicle, and pull ST3 into the vehicle.

ST1 498897700 OIL PRESSURE ADAPTER

ST2 498897800 ADAPTER SET

ST3 498575400 OIL PRESSURE GAUGE

6) Connect the Subaru Select Monitor to the data

link connector and read the current data.

TION, Subaru Select Monitor.>

7) Perform the transfer clutch pressure test.

NOTE:

•Do not perform the transfer clutch pressure test

for more than 5 seconds at a time. Doing so will

make the engine oil and ATF deteriorate and the

clutch and brake to be adversely affected.

•After performing the transfer clutch pressure test,

be sure to cool down the engine for at least one

minute with the select lever set in the “P” or “N”

range, and at an idle speed of 1,200 rpm or less.

•Adjust the throttle valve angle in order to obtain

the “T/F Solenoid Pressure” displayed on the Sub-

aru Select Monitor.

8) Remove the ST and install the test plug.

9) Install the heat shield cover.

AT-03275

Range of the

selector lever

Throttle opening

angle

AT F t e m p e r a t u r e

condition

“T/F Solenoid Pressure” displayed on

the Subaru Select Monitor

kPa

Standard line pressure

kPa (kg/cm2, psi)

D

Full open

45 — 55°C

(104 — 131°F)

900800 — 915

(8.16 — 9.33, 116.0 — 132.7)

Par tial throttle 500400 — 535

(4.08 — 5.46, 58.0 — 77.6)

NFull closed 00 — 50

(0 — 0.51, 0 — 7.3)

Page 2051 of 2453

5AT-35

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

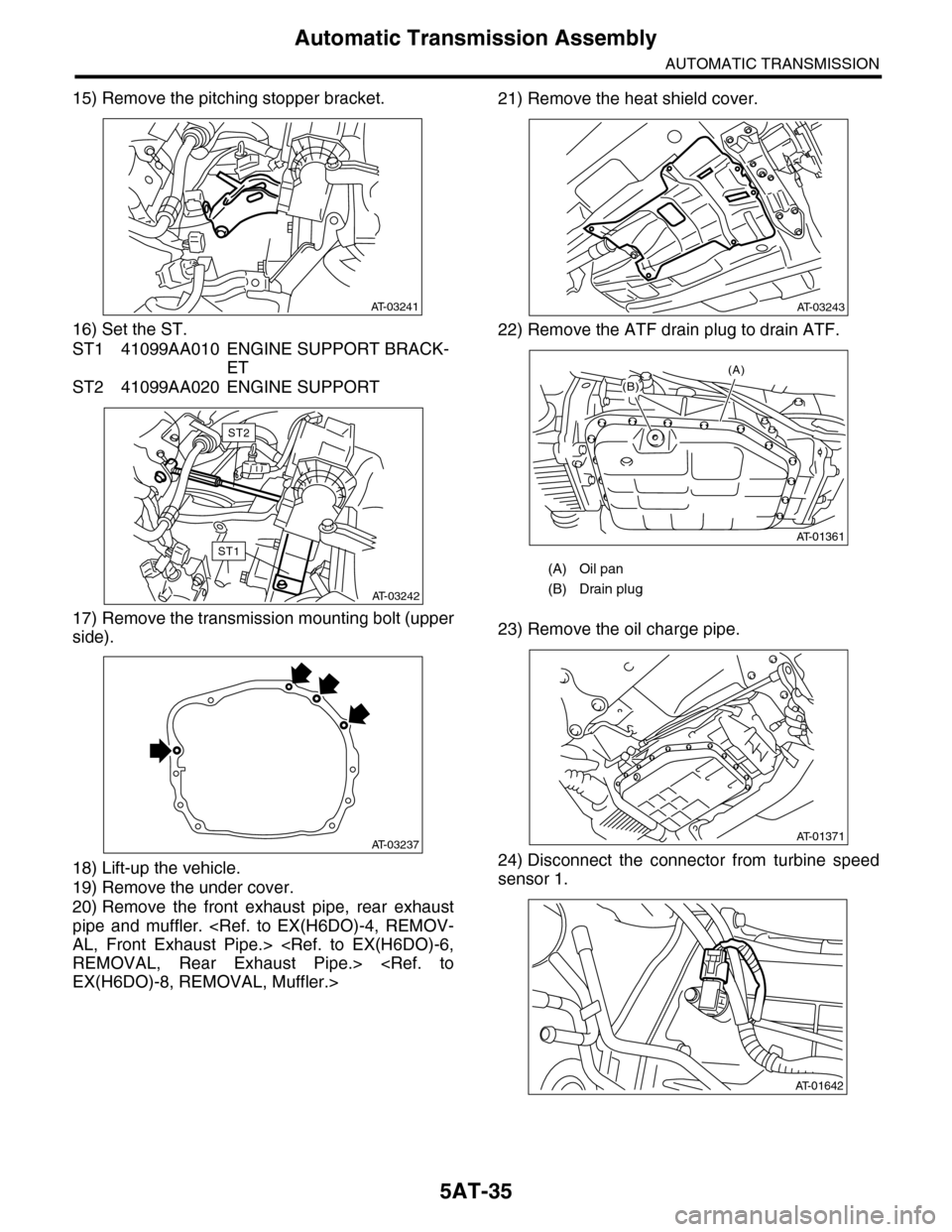

15) Remove the pitching stopper bracket.

16) Set the ST.

ST1 41099AA010 ENGINE SUPPORT BRACK-

ET

ST2 41099AA020 ENGINE SUPPORT

17) Remove the transmission mounting bolt (upper

side).

18) Lift-up the vehicle.

19) Remove the under cover.

20) Remove the front exhaust pipe, rear exhaust

pipe and muffler.

21) Remove the heat shield cover.

22) Remove the ATF drain plug to drain ATF.

23) Remove the oil charge pipe.

24) Disconnect the connector from turbine speed

sensor 1.

AT-03241

AT-03242

ST2

ST1

AT-03237

(A) Oil pan

(B) Drain plug

AT-03243

(A)

AT-01361

(B)

AT-01371

AT-01642

Page 2055 of 2453

5AT-39

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

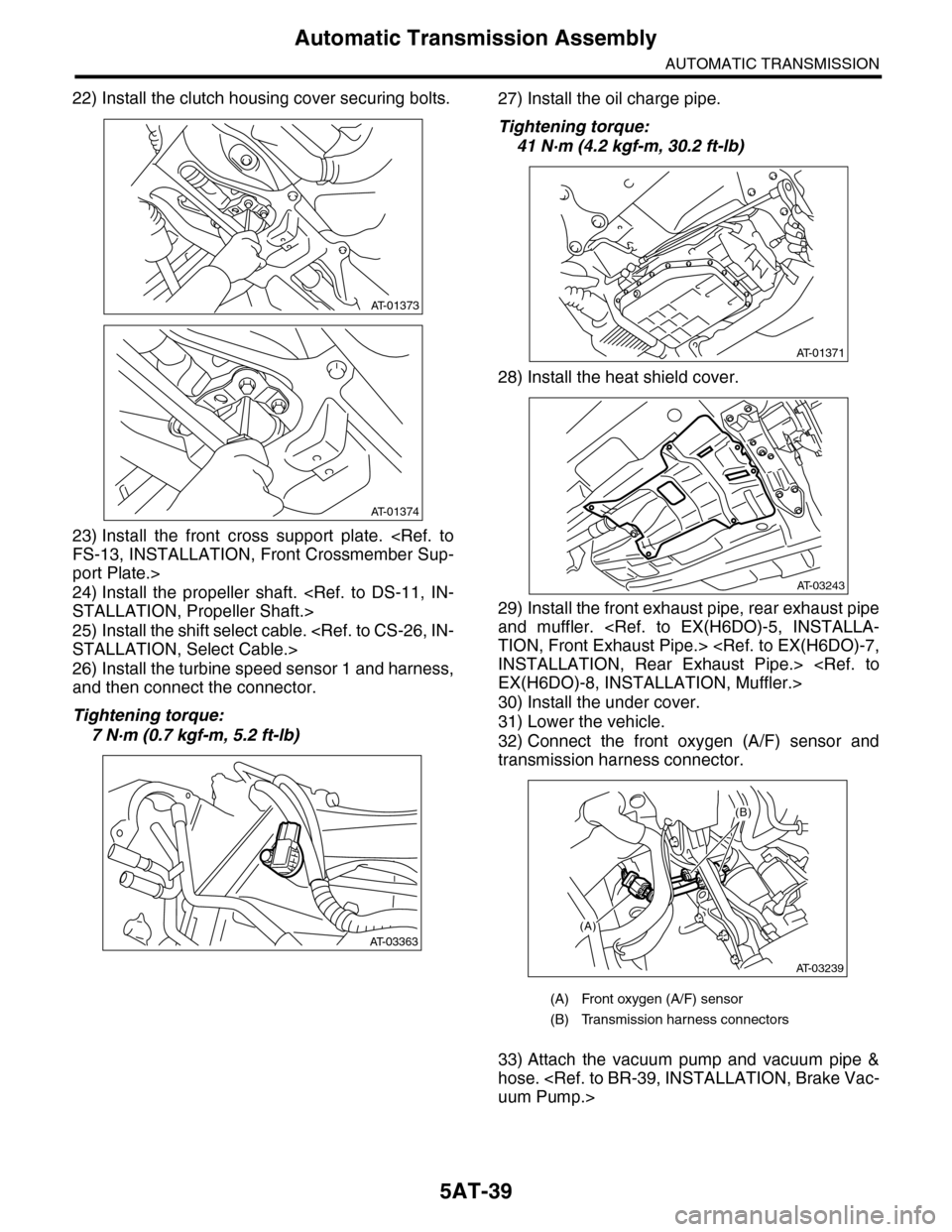

22) Install the clutch housing cover securing bolts.

23) Install the front cross support plate.

port Plate.>

24) Install the propeller shaft.

25) Install the shift select cable.

26) Install the turbine speed sensor 1 and harness,

and then connect the connector.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

27) Install the oil charge pipe.

Tightening torque:

41 N·m (4.2 kgf-m, 30.2 ft-lb)

28) Install the heat shield cover.

29) Install the front exhaust pipe, rear exhaust pipe

and muffler.

30) Install the under cover.

31) Lower the vehicle.

32) Connect the front oxygen (A/F) sensor and

transmission harness connector.

33) Attach the vacuum pump and vacuum pipe &

hose.

AT-01373

AT-01374

AT-03363

(A) Front oxygen (A/F) sensor

(B) Transmission harness connectors

AT-01371

AT-03243

(A)

(B)

AT-03239

Page 2057 of 2453

5AT-41

Transmission Mounting System

AUTOMATIC TRANSMISSION

10.Transmission Mounting Sys-

tem

A: REMOVAL

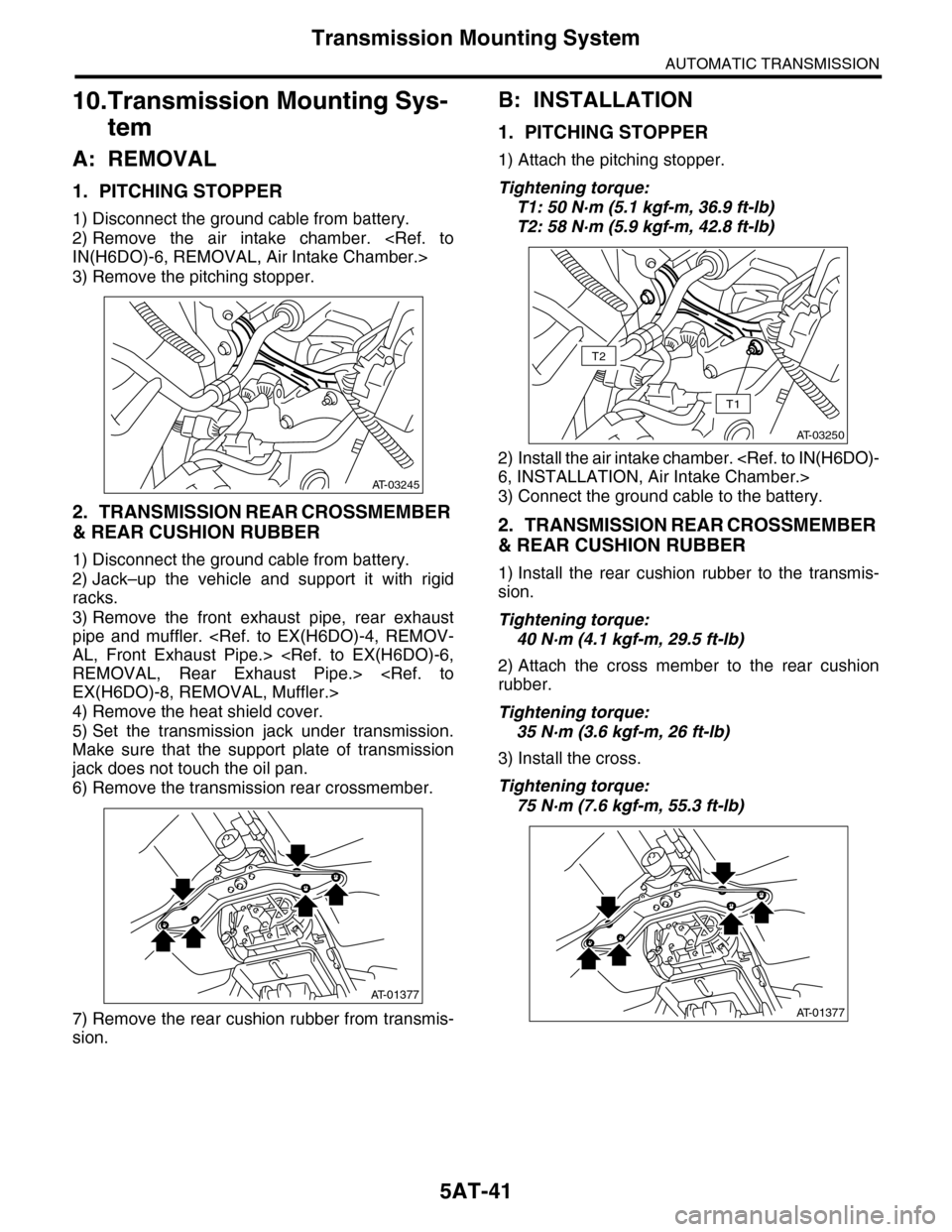

1. PITCHING STOPPER

1) Disconnect the ground cable from battery.

2) Remove the air intake chamber.

3) Remove the pitching stopper.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Disconnect the ground cable from battery.

2) Jack–up the vehicle and support it with rigid

racks.

3) Remove the front exhaust pipe, rear exhaust

pipe and muffler.

4) Remove the heat shield cover.

5) Set the transmission jack under transmission.

Make sure that the support plate of transmission

jack does not touch the oil pan.

6) Remove the transmission rear crossmember.

7) Remove the rear cushion rubber from transmis-

sion.

B: INSTALLATION

1. PITCHING STOPPER

1) Attach the pitching stopper.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N·m (5.9 kgf-m, 42.8 ft-lb)

2) Install the air intake chamber.

3) Connect the ground cable to the battery.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Install the rear cushion rubber to the transmis-

sion.

Tightening torque:

40 N·m (4.1 kgf-m, 29.5 ft-lb)

2) Attach the cross member to the rear cushion

rubber.

Tightening torque:

35 N·m (3.6 kgf-m, 26 ft-lb)

3) Install the cross.

Tightening torque:

75 N·m (7.6 kgf-m, 55.3 ft-lb)

AT-03245

AT-01377

AT-03250

T2

T1

AT-01377