Back up SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2147 of 2453

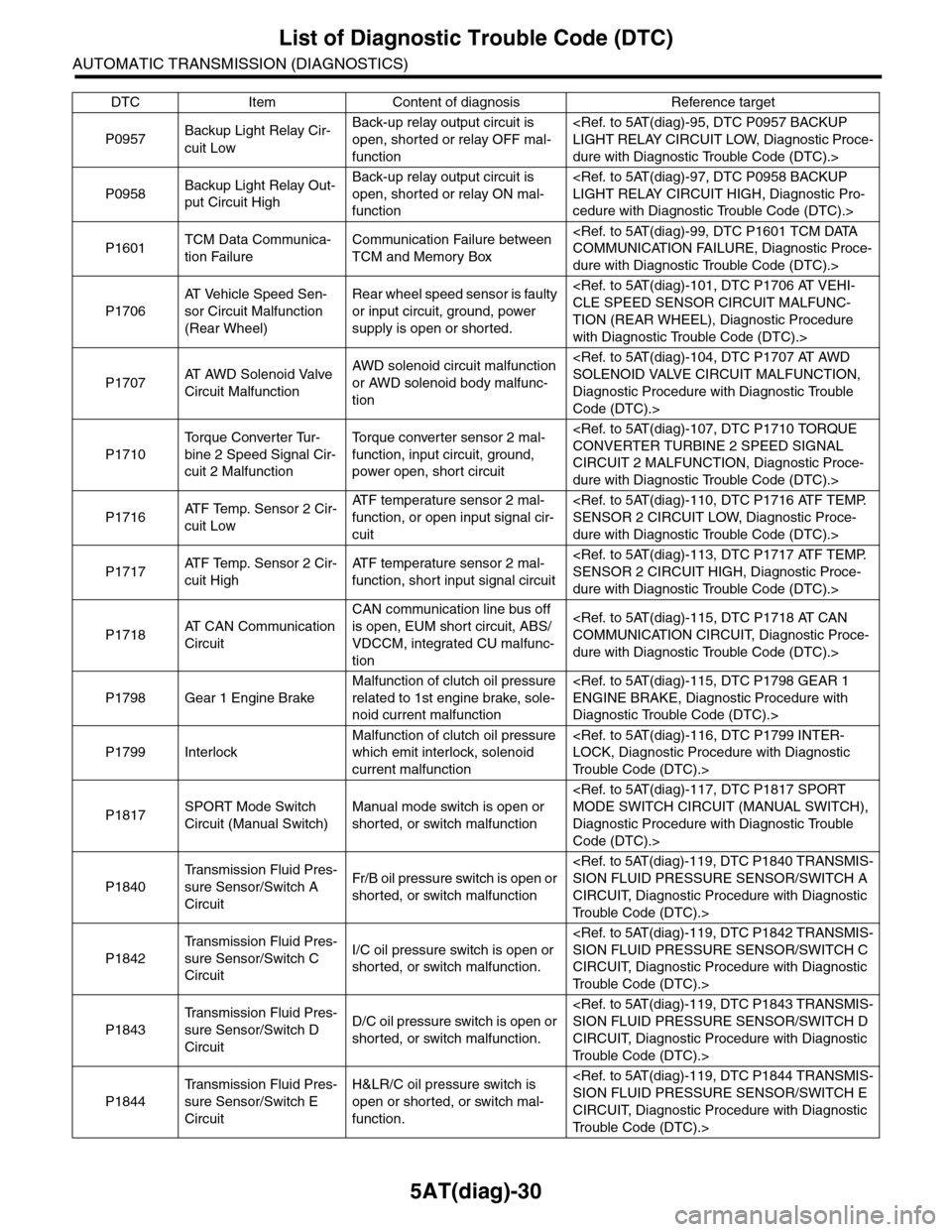

5AT(diag)-30

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

P0957Backup Light Relay Cir-

cuit Low

Back-up relay output circuit is

open, shorted or relay OFF mal-

function

dure with Diagnostic Trouble Code (DTC).>

P0958Backup Light Relay Out-

put Circuit High

Back-up relay output circuit is

open, shorted or relay ON mal-

function

cedure with Diagnostic Trouble Code (DTC).>

P1601TCM Data Communica-

tion Failure

Communication Failure between

TCM and Memory Box

dure with Diagnostic Trouble Code (DTC).>

P1706

AT Ve h i c l e S p e e d S e n -

sor Circuit Malfunction

(Rear Wheel)

Rear wheel speed sensor is faulty

or input circuit, ground, power

supply is open or shorted.

TION (REAR WHEEL), Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1707AT A W D S o l e n o i d V a l v e

Circuit Malfunction

AWD solenoid circuit malfunction

or AWD solenoid body malfunc-

tion

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1710

To r q u e C o n v e r t e r Tu r -

bine 2 Speed Signal Cir-

cuit 2 Malfunction

To r q u e c o n v e r t e r s e n s o r 2 m a l -

function, input circuit, ground,

power open, short circuit

CIRCUIT 2 MALFUNCTION, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1716AT F Te m p . S e n s o r 2 C i r -

cuit Low

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, or open input signal cir-

cuit

dure with Diagnostic Trouble Code (DTC).>

P1717AT F Te m p . S e n s o r 2 C i r -

cuit High

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, short input signal circuit

dure with Diagnostic Trouble Code (DTC).>

P1718AT C A N C o m m u n i c a t i o n

Circuit

CAN communication line bus off

is open, EUM short circuit, ABS/

VDCCM, integrated CU malfunc-

tion

dure with Diagnostic Trouble Code (DTC).>

P1798 Gear 1 Engine Brake

Malfunction of clutch oil pressure

related to 1st engine brake, sole-

noid current malfunction

Diagnostic Trouble Code (DTC).>

P1799 Interlock

Malfunction of clutch oil pressure

which emit interlock, solenoid

current malfunction

Tr o u b l e C o d e ( D T C ) . >

P1817SPORT Mode Switch

Circuit (Manual Switch)

Manual mode switch is open or

shorted, or switch malfunction

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1840

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch A

Circuit

Fr/B oil pressure switch is open or

shorted, or switch malfunction

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1842

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch C

Circuit

I/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1843

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch D

Circuit

D/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1844

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch E

Circuit

H&LR/C oil pressure switch is

open or shorted, or switch mal-

function.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

DTC Item Content of diagnosis Reference target

Page 2212 of 2453

5AT(diag)-95

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

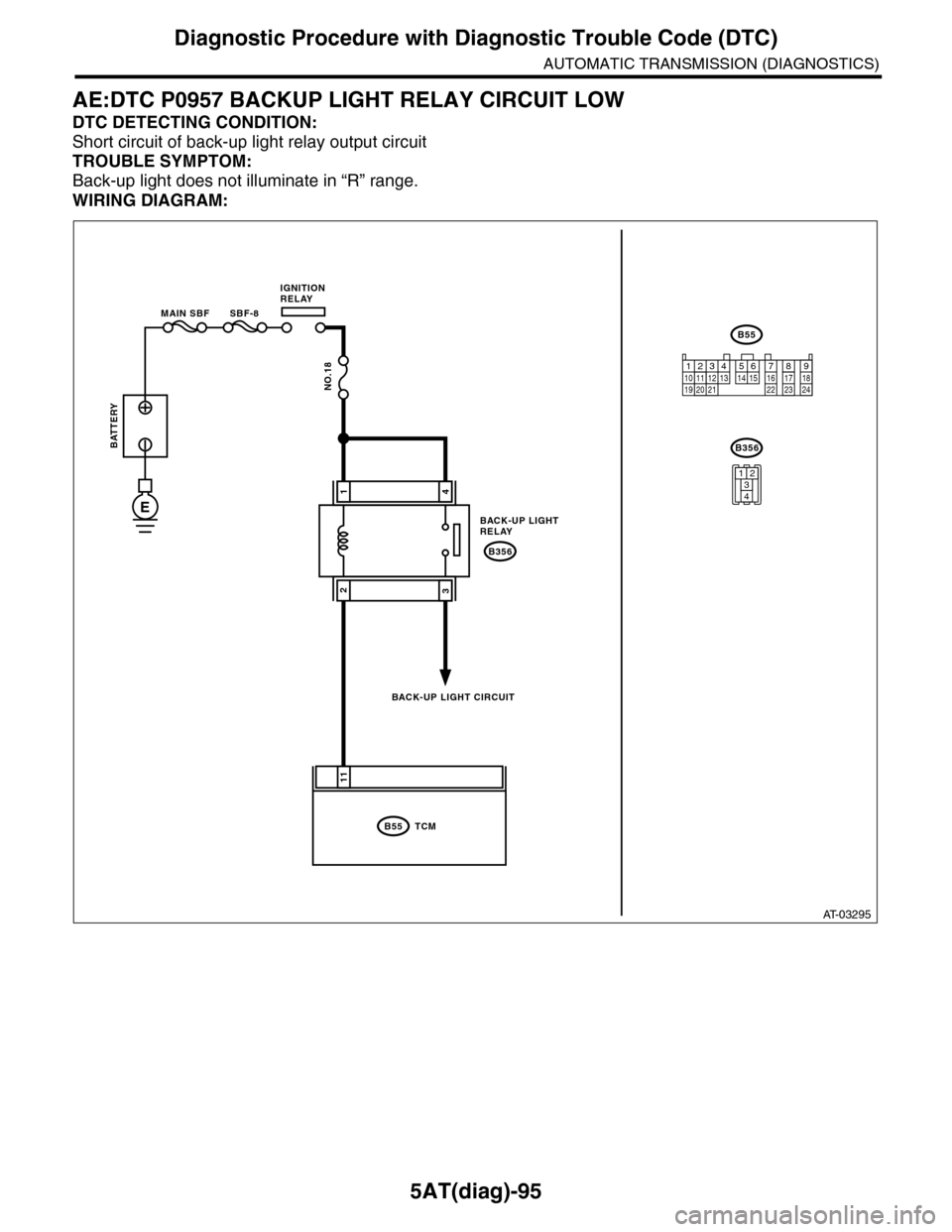

AE:DTC P0957 BACKUP LIGHT RELAY CIRCUIT LOW

DTC DETECTING CONDITION:

Short circuit of back-up light relay output circuit

TROUBLE SYMPTOM:

Back-up light does not illuminate in “R” range.

WIRING DIAGRAM:

AT-03295

11

B55

B356

TCM

B55

BATTERY

MAIN SBF SBF-8

IGNITIONRELAY

BACK-UP LIGHT CIRCUIT

NO.18

E

41

32

12341011 121920 21135614 1578916 17 1822 23 24

B356

1234

BACK-UP LIGHTRELAY

Page 2213 of 2453

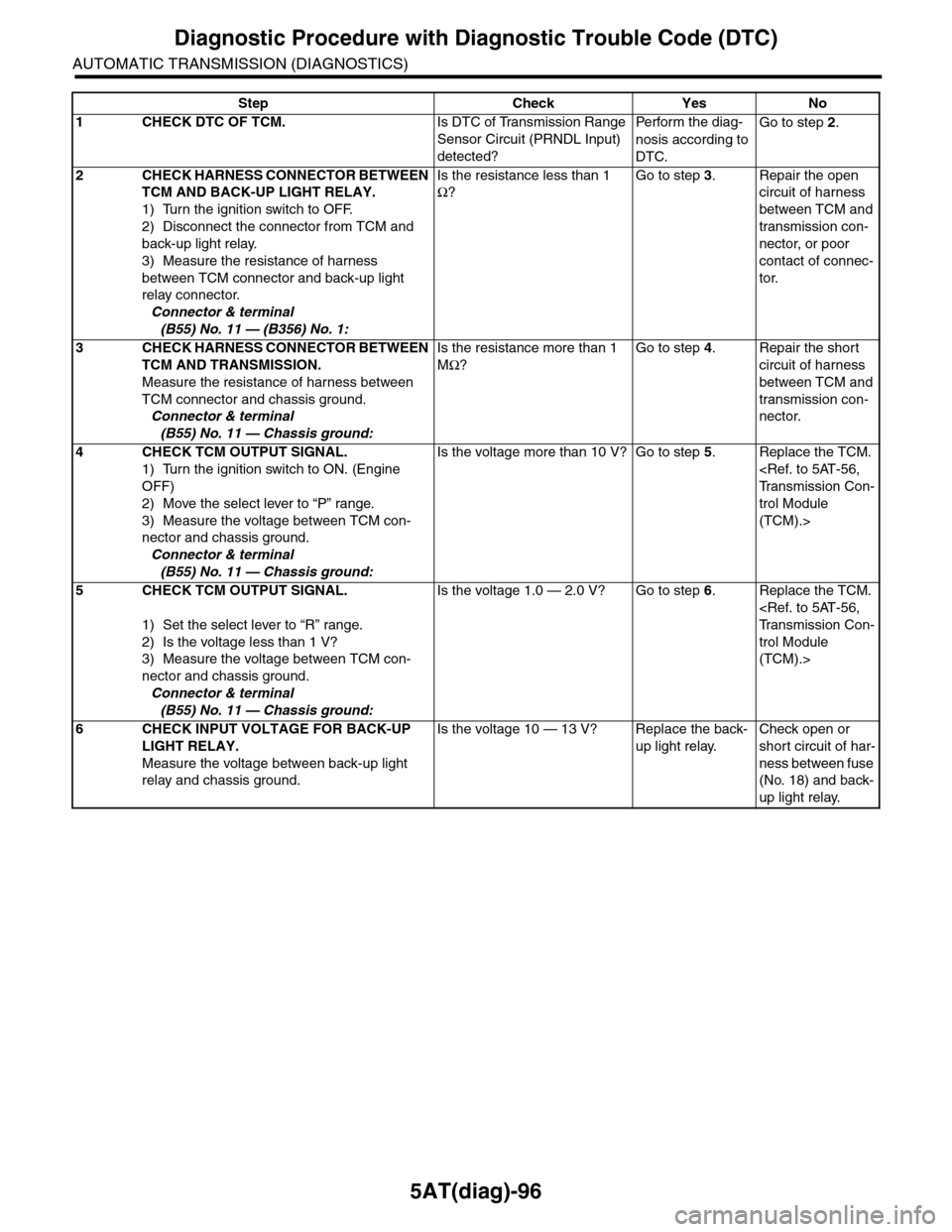

5AT(diag)-96

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

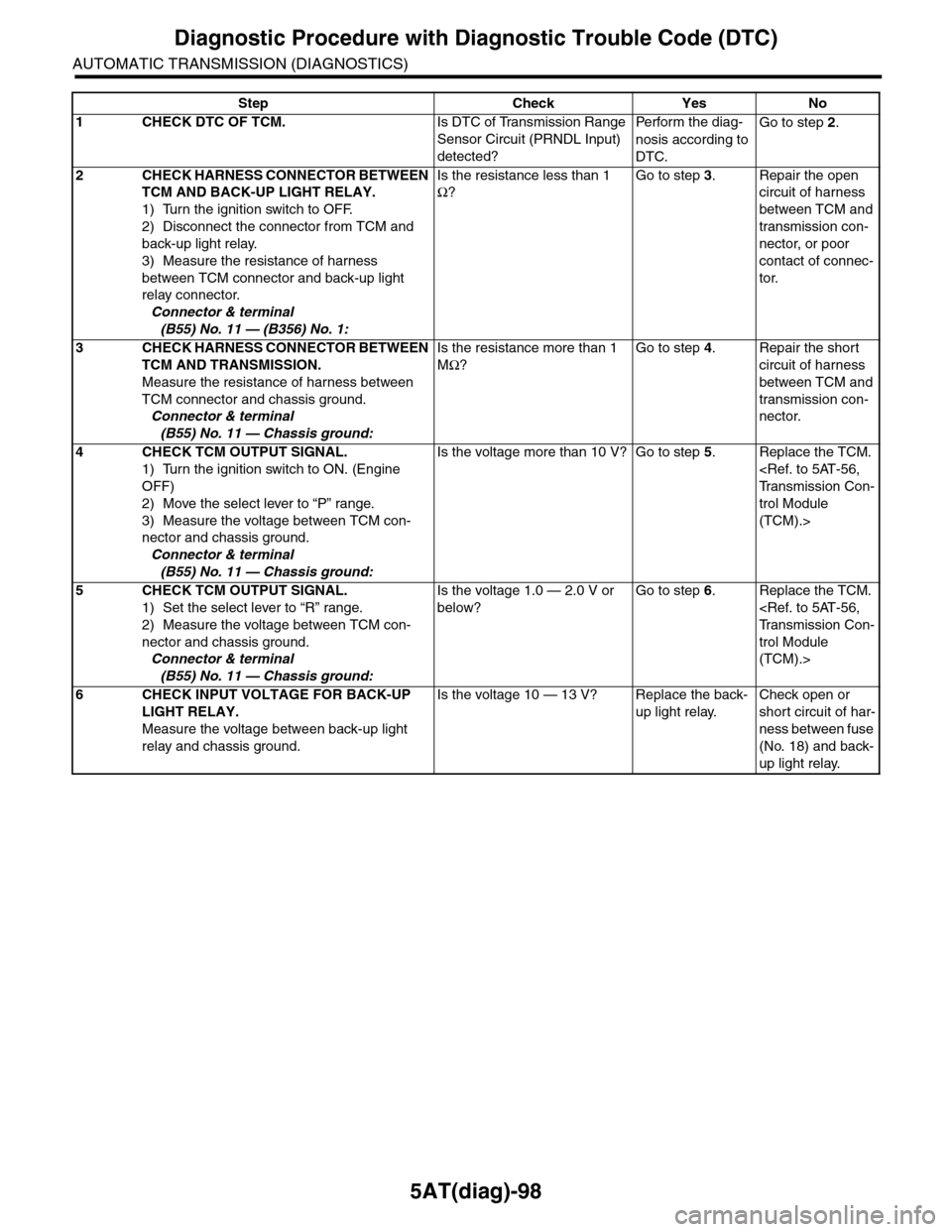

Step Check Yes No

1CHECK DTC OF TCM.Is DTC of Transmission Range

Sensor Circuit (PRNDL Input)

detected?

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND BACK-UP LIGHT RELAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

back-up light relay.

3) Measure the resistance of harness

between TCM connector and back-up light

relay connector.

Connector & terminal

(B55) No. 11 — (B356) No. 1:

Is the resistance less than 1

Ω?

Go to step 3.Repair the open

circuit of harness

between TCM and

transmission con-

nector, or poor

contact of connec-

tor.

3CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 4.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

4CHECK TCM OUTPUT SIGNAL.

1) Turn the ignition switch to ON. (Engine

OFF)

2) Move the select lever to “P” range.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage more than 10 V? Go to step 5.Replace the TCM.

trol Module

(TCM).>

5CHECK TCM OUTPUT SIGNAL.

1) Set the select lever to “R” range.

2) Is the voltage less than 1 V?

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage 1.0 — 2.0 V? Go to step 6.Replace the TCM.

trol Module

(TCM).>

6CHECK INPUT VOLTAGE FOR BACK-UP

LIGHT RELAY.

Measure the voltage between back-up light

relay and chassis ground.

Is the voltage 10 — 13 V? Replace the back-

up light relay.

Check open or

short circuit of har-

ness between fuse

(No. 18) and back-

up light relay.

Page 2214 of 2453

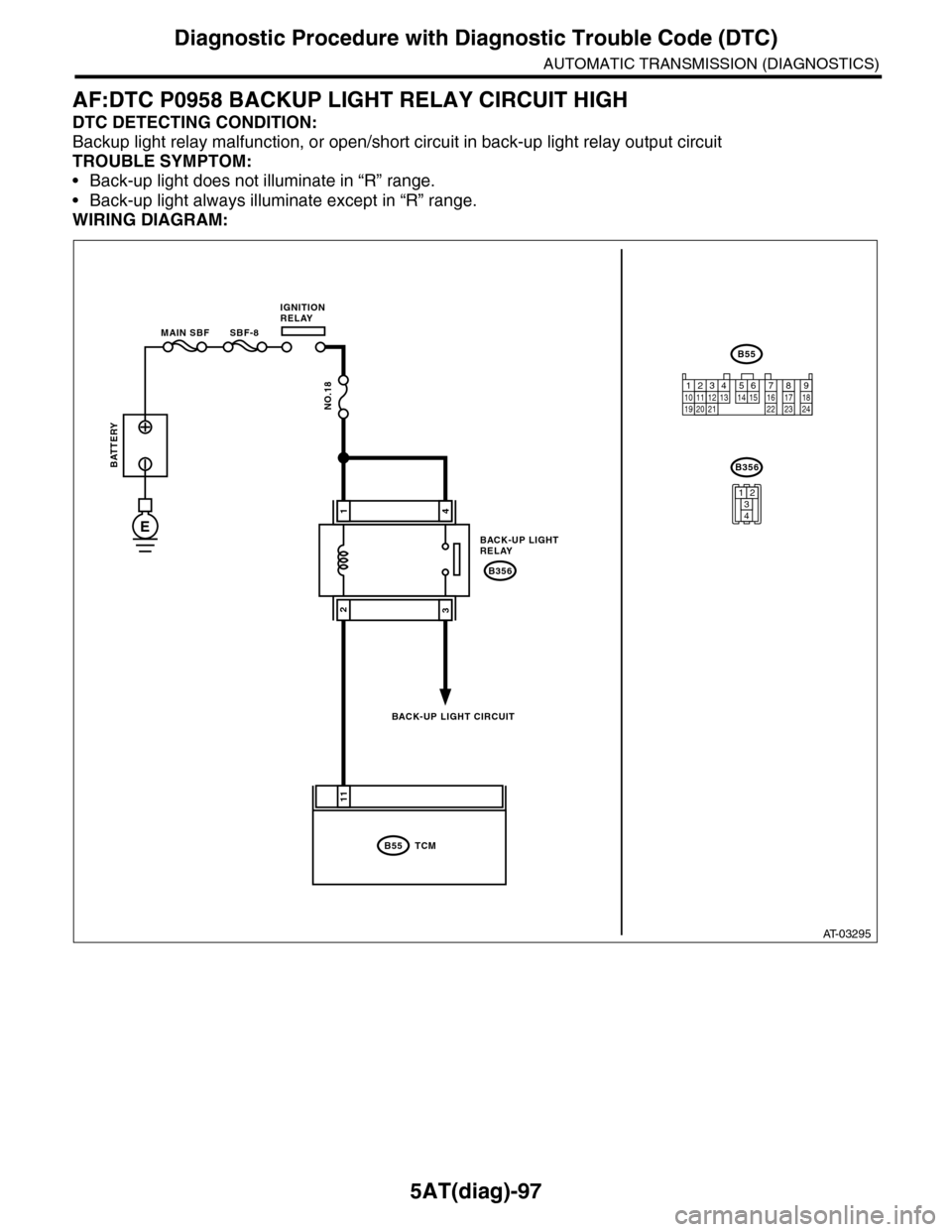

5AT(diag)-97

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

AF:DTC P0958 BACKUP LIGHT RELAY CIRCUIT HIGH

DTC DETECTING CONDITION:

Backup light relay malfunction, or open/short circuit in back-up light relay output circuit

TROUBLE SYMPTOM:

•Back-up light does not illuminate in “R” range.

•Back-up light always illuminate except in “R” range.

WIRING DIAGRAM:

AT-03295

11

B55

B356

TCM

B55

BATTERY

MAIN SBF SBF-8

IGNITIONRELAY

BACK-UP LIGHT CIRCUIT

NO.18

E

41

32

12341011 121920 21135614 1578916 17 1822 23 24

B356

1234

BACK-UP LIGHTRELAY

Page 2215 of 2453

5AT(diag)-98

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Step Check Yes No

1CHECK DTC OF TCM.Is DTC of Transmission Range

Sensor Circuit (PRNDL Input)

detected?

Pe r for m t h e d ia g -

nosis according to

DTC.

Go to step 2.

2CHECK HARNESS CONNECTOR BETWEEN

TCM AND BACK-UP LIGHT RELAY.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from TCM and

back-up light relay.

3) Measure the resistance of harness

between TCM connector and back-up light

relay connector.

Connector & terminal

(B55) No. 11 — (B356) No. 1:

Is the resistance less than 1

Ω?

Go to step 3.Repair the open

circuit of harness

between TCM and

transmission con-

nector, or poor

contact of connec-

tor.

3CHECK HARNESS CONNECTOR BETWEEN

TCM AND TRANSMISSION.

Measure the resistance of harness between

TCM connector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 4.Repair the short

circuit of harness

between TCM and

transmission con-

nector.

4CHECK TCM OUTPUT SIGNAL.

1) Turn the ignition switch to ON. (Engine

OFF)

2) Move the select lever to “P” range.

3) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage more than 10 V? Go to step 5.Replace the TCM.

trol Module

(TCM).>

5CHECK TCM OUTPUT SIGNAL.

1) Set the select lever to “R” range.

2) Measure the voltage between TCM con-

nector and chassis ground.

Connector & terminal

(B55) No. 11 — Chassis ground:

Is the voltage 1.0 — 2.0 V or

below?

Go to step 6.Replace the TCM.

trol Module

(TCM).>

6CHECK INPUT VOLTAGE FOR BACK-UP

LIGHT RELAY.

Measure the voltage between back-up light

relay and chassis ground.

Is the voltage 10 — 13 V? Replace the back-

up light relay.

Check open or

short circuit of har-

ness between fuse

(No. 18) and back-

up light relay.

Page 2261 of 2453

CS-9

AT Shift Lock Control System

CONTROL SYSTEMS

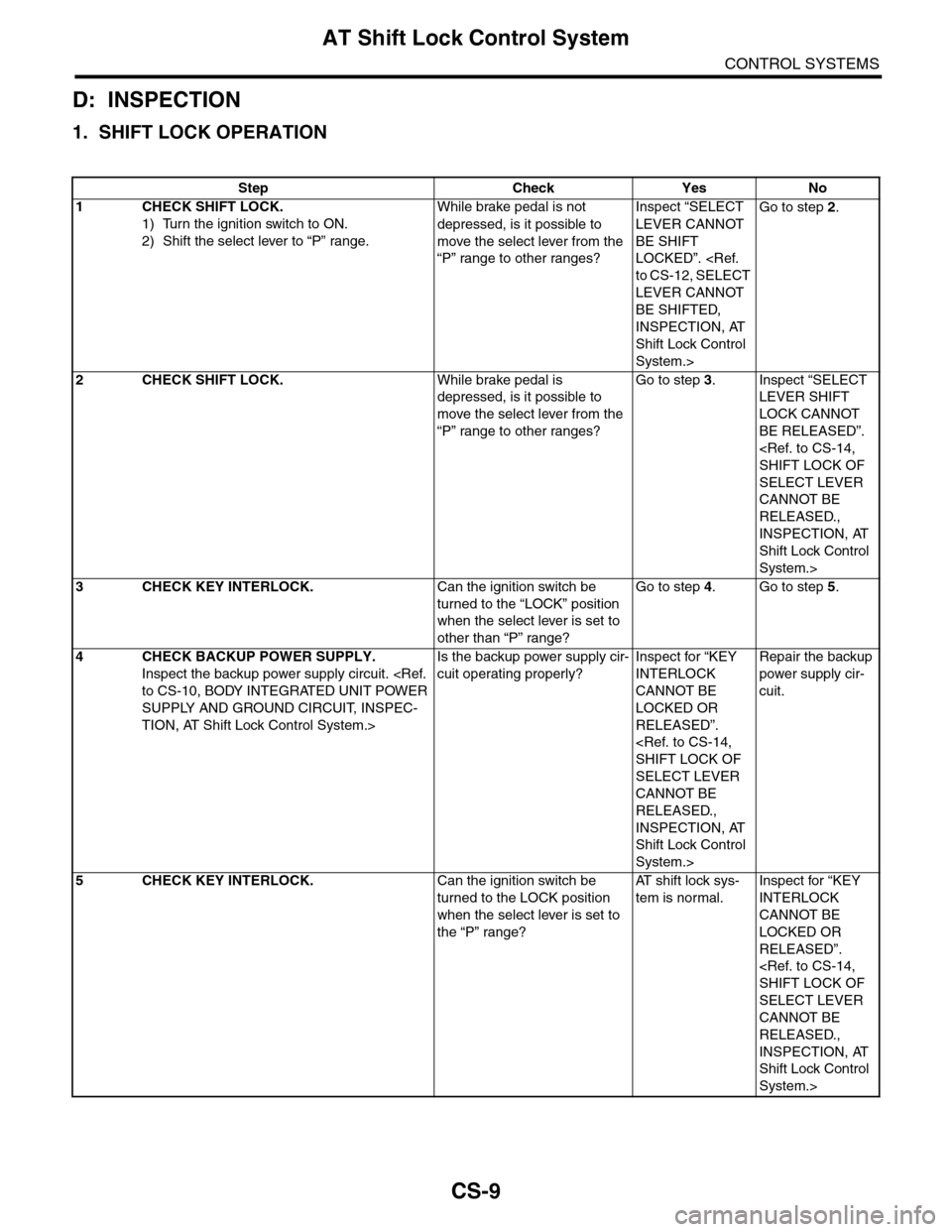

D: INSPECTION

1. SHIFT LOCK OPERATION

Step Check Yes No

1CHECK SHIFT LOCK.

1) Turn the ignition switch to ON.

2) Shift the select lever to “P” range.

While brake pedal is not

depressed, is it possible to

move the select lever from the

“P” range to other ranges?

Inspect “SELECT

LEVER CANNOT

BE SHIFT

LOCKED”.

LEVER CANNOT

BE SHIFTED,

INSPECTION, AT

Shift Lock Control

System.>

Go to step 2.

2CHECK SHIFT LOCK.While brake pedal is

depressed, is it possible to

move the select lever from the

“P” range to other ranges?

Go to step 3.Inspect “SELECT

LEVER SHIFT

LOCK CANNOT

BE RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

3CHECK KEY INTERLOCK.Can the ignition switch be

turned to the “LOCK” position

when the select lever is set to

other than “P” range?

Go to step 4.Go to step 5.

4CHECK BACKUP POWER SUPPLY.

Inspect the backup power supply circuit.

SUPPLY AND GROUND CIRCUIT, INSPEC-

TION, AT Shift Lock Control System.>

Is the backup power supply cir-

cuit operating properly?

Inspect for “KEY

INTERLOCK

CANNOT BE

LOCKED OR

RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

Repair the backup

power supply cir-

cuit.

5CHECK KEY INTERLOCK.Can the ignition switch be

turned to the LOCK position

when the select lever is set to

the “P” range?

AT s h i f t l o c k s y s -

tem is normal.

Inspect for “KEY

INTERLOCK

CANNOT BE

LOCKED OR

RELEASED”.

SELECT LEVER

CANNOT BE

RELEASED.,

INSPECTION, AT

Shift Lock Control

System.>

Page 2270 of 2453

CS-18

AT Shift Lock Control System

CONTROL SYSTEMS

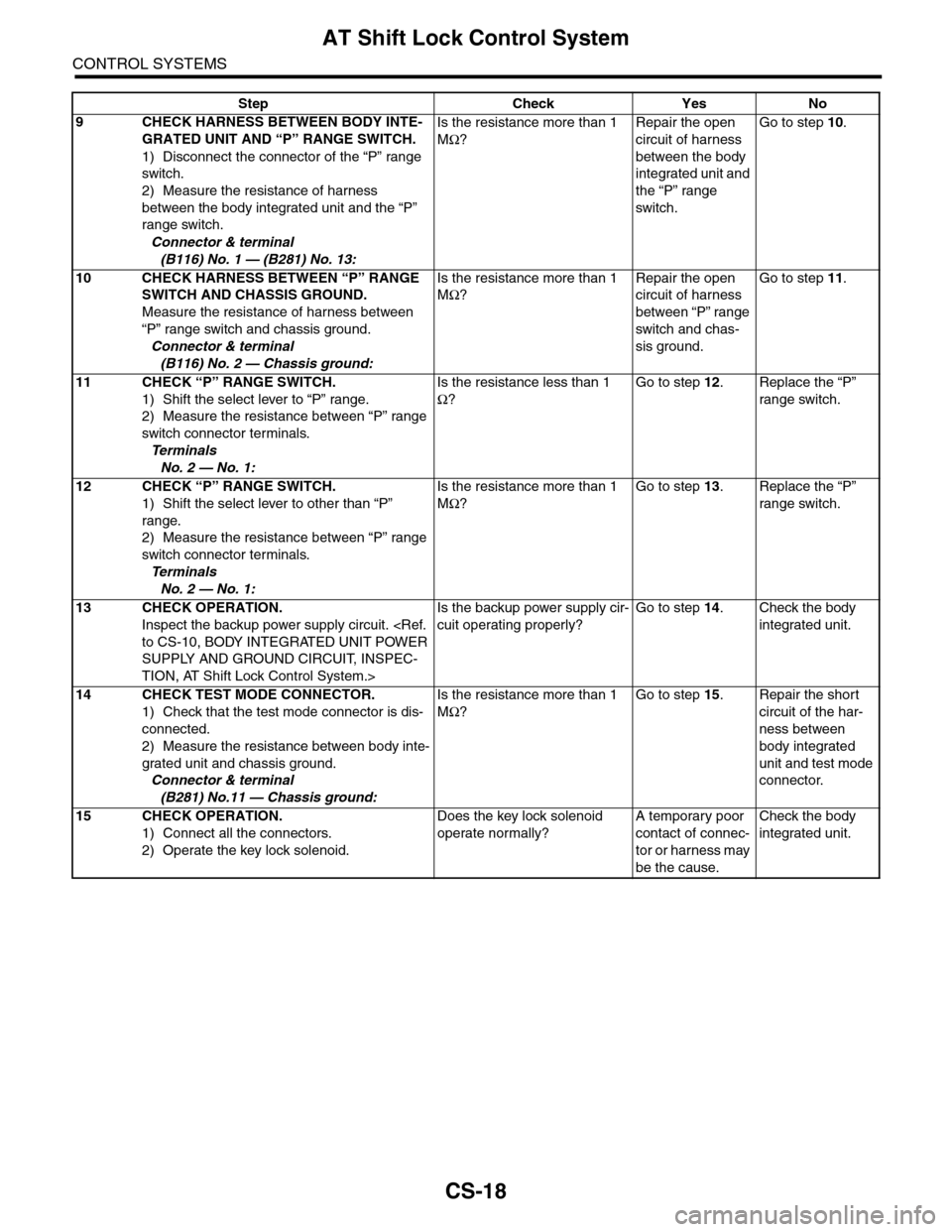

9CHECK HARNESS BETWEEN BODY INTE-

GRATED UNIT AND “P” RANGE SWITCH.

1) Disconnect the connector of the “P” range

switch.

2) Measure the resistance of harness

between the body integrated unit and the “P”

range switch.

Connector & terminal

(B116) No. 1 — (B281) No. 13:

Is the resistance more than 1

MΩ?

Repair the open

circuit of harness

between the body

integrated unit and

the “P” range

switch.

Go to step 10.

10 CHECK HARNESS BETWEEN “P” RANGE

SWITCH AND CHASSIS GROUND.

Measure the resistance of harness between

“P” range switch and chassis ground.

Connector & terminal

(B116) No. 2 — Chassis ground:

Is the resistance more than 1

MΩ?

Repair the open

circuit of harness

between “P” range

switch and chas-

sis ground.

Go to step 11.

11 CHECK “P” RANGE SWITCH.

1) Shift the select lever to “P” range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 2 — No. 1:

Is the resistance less than 1

Ω?

Go to step 12.Replace the “P”

range switch.

12 CHECK “P” RANGE SWITCH.

1) Shift the select lever to other than “P”

range.

2) Measure the resistance between “P” range

switch connector terminals.

Te r m i n a l s

No. 2 — No. 1:

Is the resistance more than 1

MΩ?

Go to step 13.Replace the “P”

range switch.

13 CHECK OPERATION.

Inspect the backup power supply circuit.

SUPPLY AND GROUND CIRCUIT, INSPEC-

TION, AT Shift Lock Control System.>

Is the backup power supply cir-

cuit operating properly?

Go to step 14.Check the body

integrated unit.

14 CHECK TEST MODE CONNECTOR.

1) Check that the test mode connector is dis-

connected.

2) Measure the resistance between body inte-

grated unit and chassis ground.

Connector & terminal

(B281) No.11 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 15.Repair the short

circuit of the har-

ness between

body integrated

unit and test mode

connector.

15 CHECK OPERATION.

1) Connect all the connectors.

2) Operate the key lock solenoid.

Does the key lock solenoid

operate normally?

A temporary poor

contact of connec-

tor or harness may

be the cause.

Check the body

integrated unit.

Step Check Yes No

Page 2272 of 2453

CS-20

Select Lever

CONTROL SYSTEMS

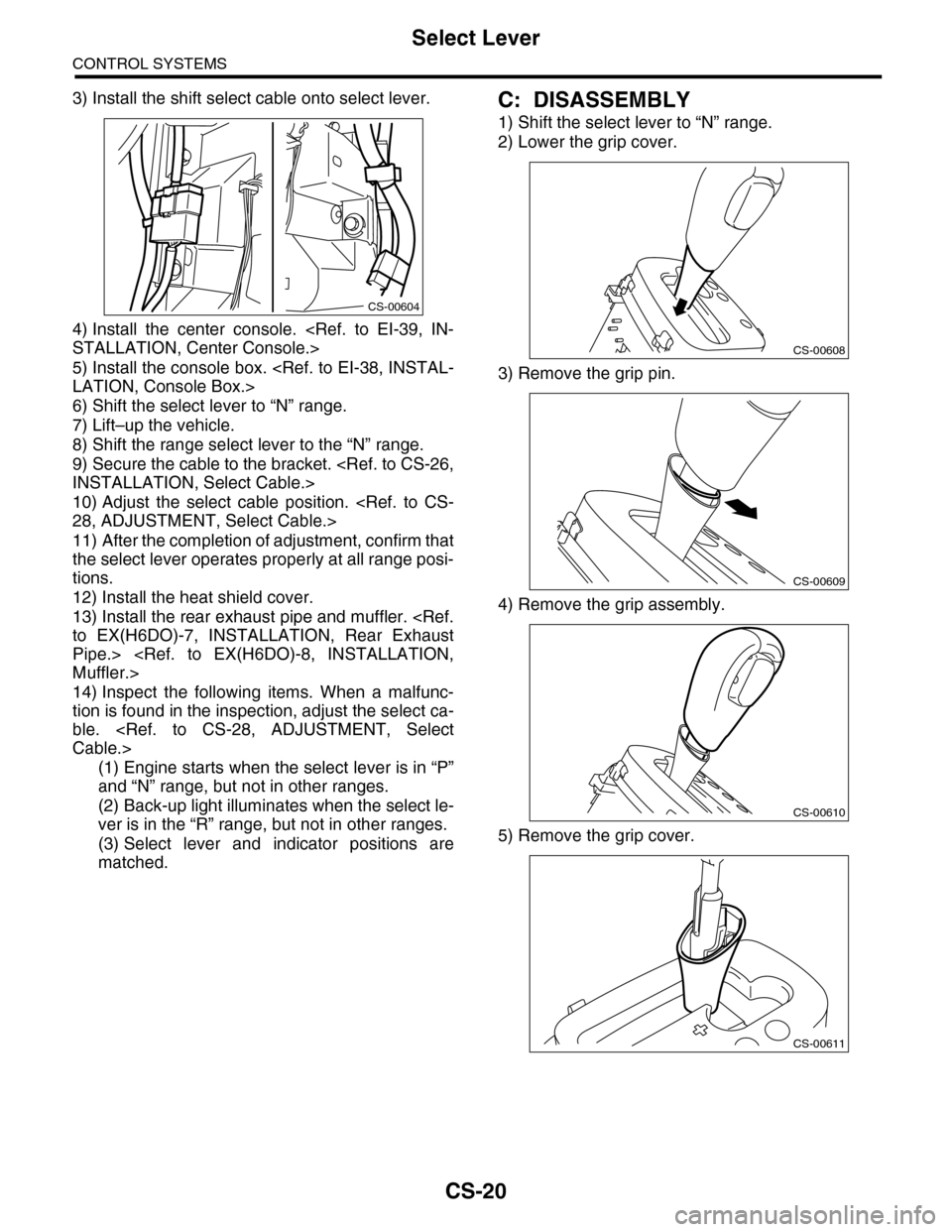

3) Install the shift select cable onto select lever.

4) Install the center console.

5) Install the console box.

6) Shift the select lever to “N” range.

7) Lift–up the vehicle.

8) Shift the range select lever to the “N” range.

9) Secure the cable to the bracket.

10) Adjust the select cable position.

11) After the completion of adjustment, confirm that

the select lever operates properly at all range posi-

tions.

12) Install the heat shield cover.

13) Install the rear exhaust pipe and muffler.

Pipe.>

14) Inspect the following items. When a malfunc-

tion is found in the inspection, adjust the select ca-

ble.

(1) Engine starts when the select lever is in “P”

and “N” range, but not in other ranges.

(2) Back-up light illuminates when the select le-

ver is in the “R” range, but not in other ranges.

(3) Select lever and indicator positions are

matched.

C: DISASSEMBLY

1) Shift the select lever to “N” range.

2) Lower the grip cover.

3) Remove the grip pin.

4) Remove the grip assembly.

5) Remove the grip cover.

CS-00604

CS-00608

CS-00609

CS-00610

CS-00611

Page 2279 of 2453

CS-27

Select Cable

CONTROL SYSTEMS

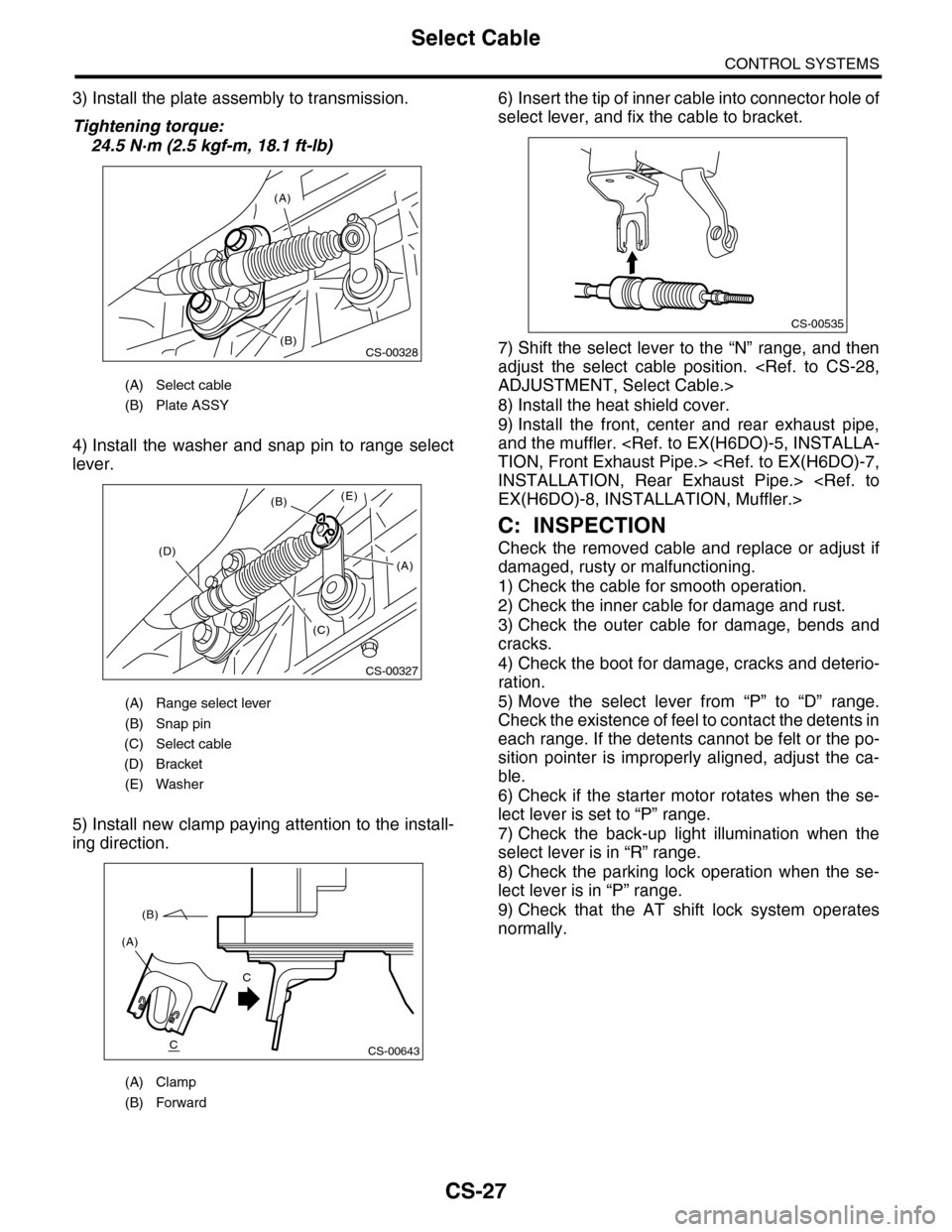

3) Install the plate assembly to transmission.

Tightening torque:

24.5 N·m (2.5 kgf-m, 18.1 ft-lb)

4) Install the washer and snap pin to range select

lever.

5) Install new clamp paying attention to the install-

ing direction.

6) Insert the tip of inner cable into connector hole of

select lever, and fix the cable to bracket.

7) Shift the select lever to the “N” range, and then

adjust the select cable position.

8) Install the heat shield cover.

9) Install the front, center and rear exhaust pipe,

and the muffler.

C: INSPECTION

Check the removed cable and replace or adjust if

damaged, rusty or malfunctioning.

1) Check the cable for smooth operation.

2) Check the inner cable for damage and rust.

3) Check the outer cable for damage, bends and

cracks.

4) Check the boot for damage, cracks and deterio-

ration.

5) Move the select lever from “P” to “D” range.

Check the existence of feel to contact the detents in

each range. If the detents cannot be felt or the po-

sition pointer is improperly aligned, adjust the ca-

ble.

6) Check if the starter motor rotates when the se-

lect lever is set to “P” range.

7) Check the back-up light illumination when the

select lever is in “R” range.

8) Check the parking lock operation when the se-

lect lever is in “P” range.

9) Check that the AT shift lock system operates

normally.

(A) Select cable

(B) Plate ASSY

(A) Range select lever

(B) Snap pin

(C) Select cable

(D) Bracket

(E) Washer

(A) Clamp

(B) Forward

(A)

(B)CS-00328

CS-00327

(B)

(D)

(C)

(E)

(A)

CS-00643

(A)

(B)

C

C

CS-00535

Page 2285 of 2453

CS-33

General Diagnostic Table

CONTROL SYSTEMS

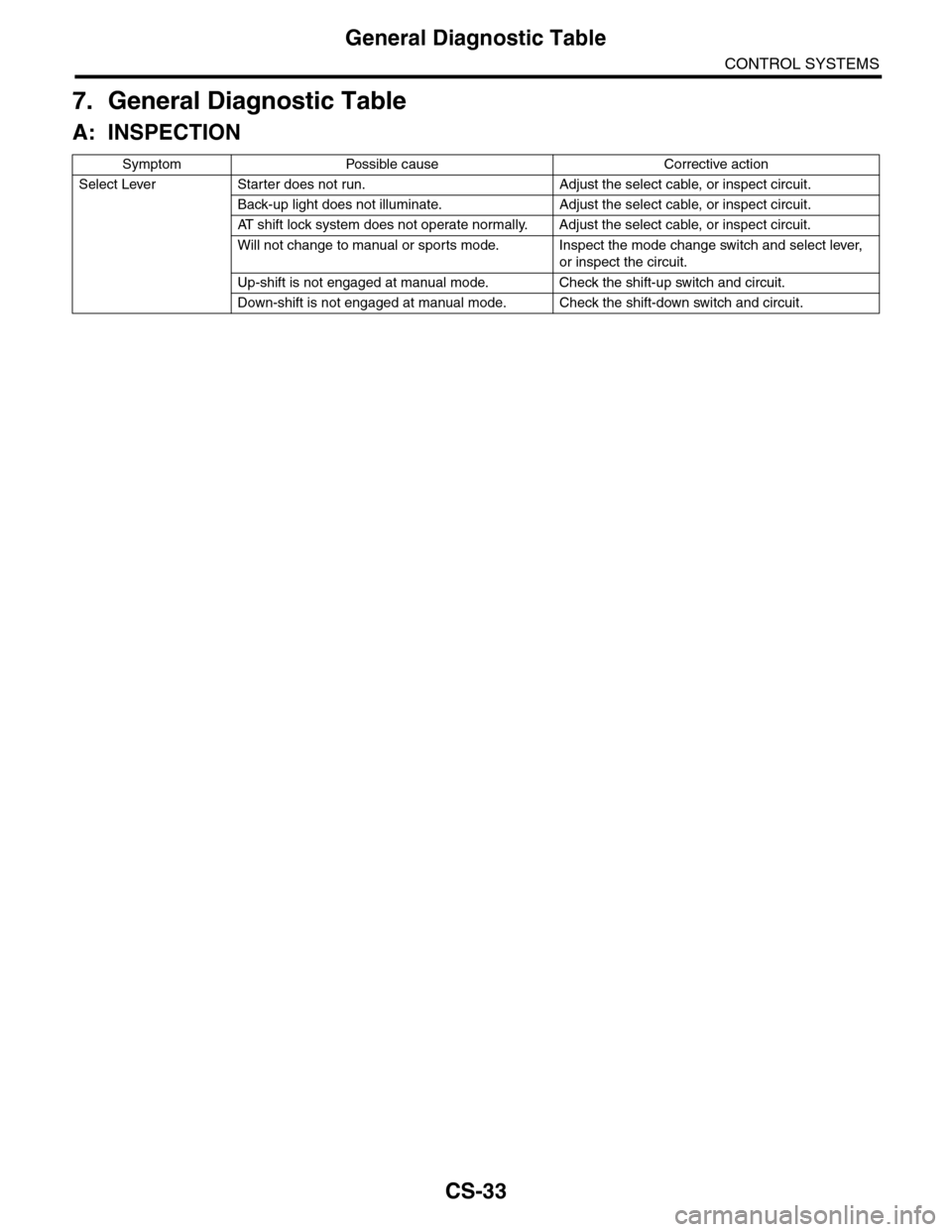

7. General Diagnostic Table

A: INSPECTION

Symptom Possible cause Corrective action

Select Lever Starter does not run. Adjust the select cable, or inspect circuit.

Back-up light does not illuminate. Adjust the select cable, or inspect circuit.

AT s h i f t l o c k s y s t e m d o e s n o t o p e r a t e n o r m a l l y. A d j u s t t h e s e l e c t c a b l e , o r i n s p e c t c i r c u i t .

Will not change to manual or sports mode. Inspect the mode change switch and select lever,

or inspect the circuit.

Up-shift is not engaged at manual mode. Check the shift-up switch and circuit.

Down-shift is not engaged at manual mode. Check the shift-down switch and circuit.