checking oil SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 4 of 2453

AB-5

General Description

AIRBAG SYSTEM

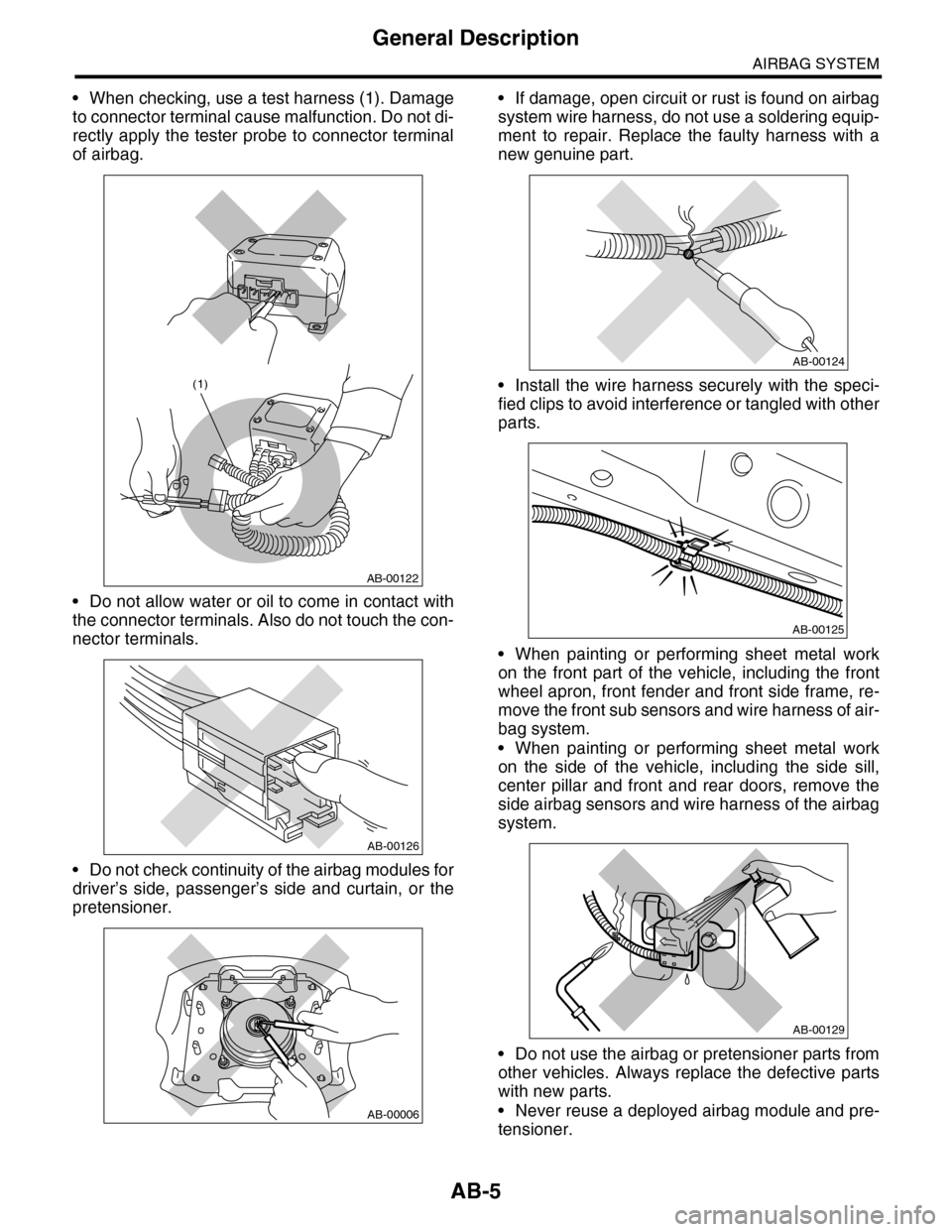

•When checking, use a test harness (1). Damage

to connector terminal cause malfunction. Do not di-

rectly apply the tester probe to connector terminal

of airbag.

•Do not allow water or oil to come in contact with

the connector terminals. Also do not touch the con-

nector terminals.

•Do not check continuity of the airbag modules for

driver’s side, passenger’s side and curtain, or the

pretensioner.

•If damage, open circuit or rust is found on airbag

system wire harness, do not use a soldering equip-

ment to repair. Replace the faulty harness with a

new genuine part.

•Install the wire harness securely with the speci-

fied clips to avoid interference or tangled with other

parts.

•When painting or performing sheet metal work

on the front part of the vehicle, including the front

wheel apron, front fender and front side frame, re-

move the front sub sensors and wire harness of air-

bag system.

•When painting or performing sheet metal work

on the side of the vehicle, including the side sill,

center pillar and front and rear doors, remove the

side airbag sensors and wire harness of the airbag

system.

•Do not use the airbag or pretensioner parts from

other vehicles. Always replace the defective parts

with new parts.

•Never reuse a deployed airbag module and pre-

tensioner.

AB-00122

(1)

AB-00126

AB-00006

AB-00124

AB-00125

AB-00129

Page 28 of 2453

AB(diag)-4

General Description

AIRBAG SYSTEM (DIAGNOSTICS)

3. General Description

A: CAUTION

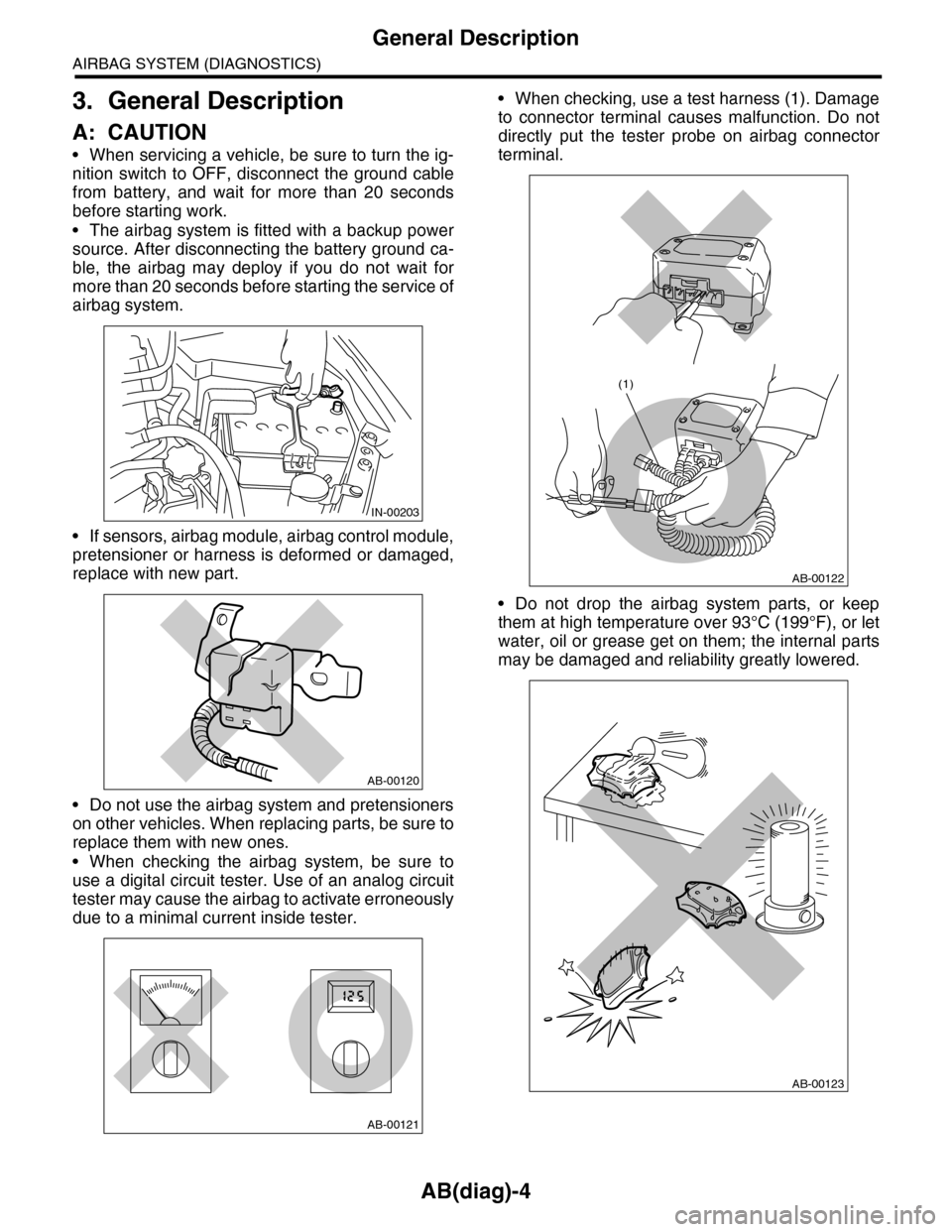

•When servicing a vehicle, be sure to turn the ig-

nition switch to OFF, disconnect the ground cable

from battery, and wait for more than 20 seconds

before starting work.

•The airbag system is fitted with a backup power

source. After disconnecting the battery ground ca-

ble, the airbag may deploy if you do not wait for

more than 20 seconds before starting the service of

airbag system.

•If sensors, airbag module, airbag control module,

pretensioner or harness is deformed or damaged,

replace with new part.

•Do not use the airbag system and pretensioners

on other vehicles. When replacing parts, be sure to

replace them with new ones.

•When checking the airbag system, be sure to

use a digital circuit tester. Use of an analog circuit

tester may cause the airbag to activate erroneously

due to a minimal current inside tester.

•When checking, use a test harness (1). Damage

to connector terminal causes malfunction. Do not

directly put the tester probe on airbag connector

terminal.

•Do not drop the airbag system parts, or keep

them at high temperature over 93°C (199°F), or let

water, oil or grease get on them; the internal parts

may be damaged and reliability greatly lowered.

IN-00203

AB-00120

AB-00121

AB-00122

(1)

AB-00123

Page 204 of 2453

ET-19

Antenna

ENTERTAINMENT

14.Antenna

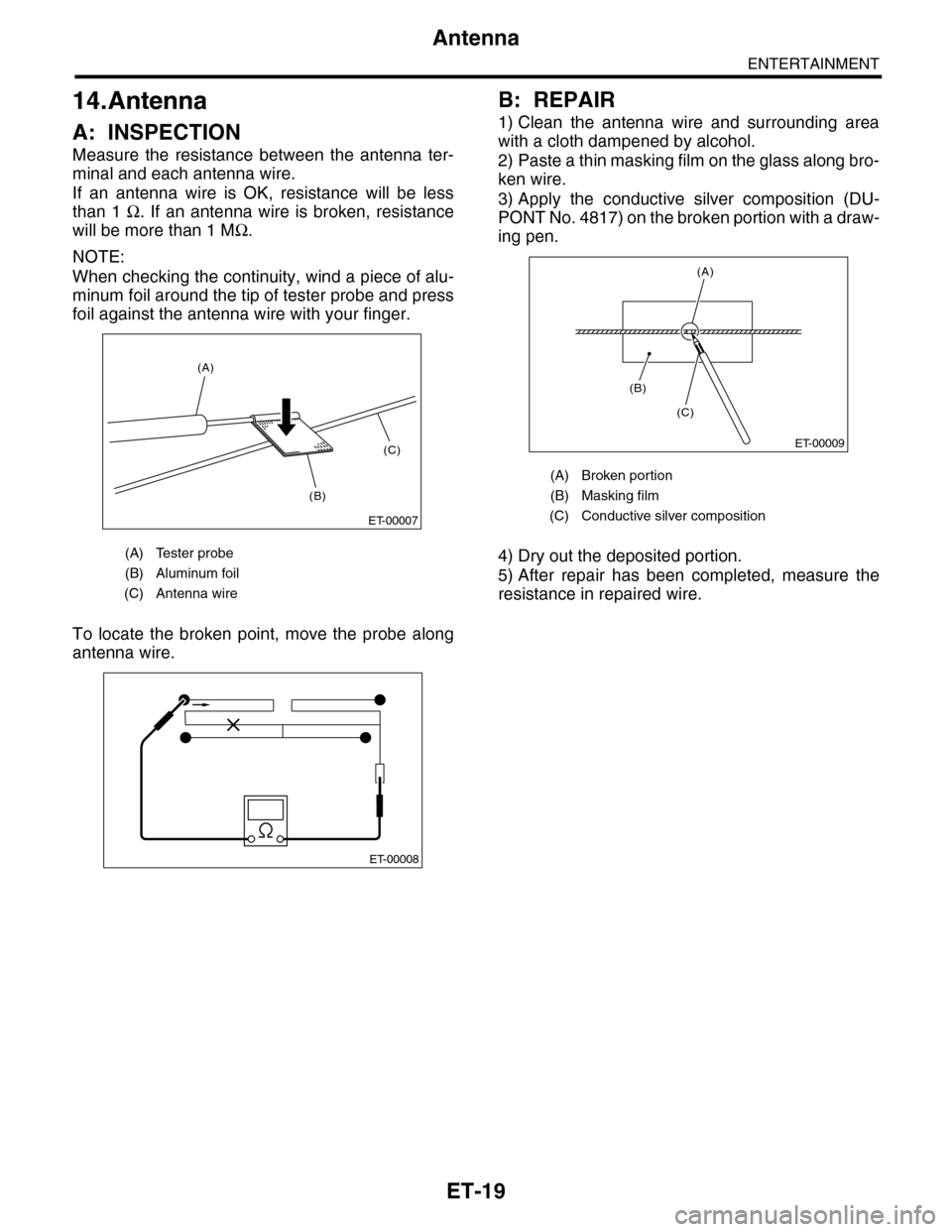

A: INSPECTION

Measure the resistance between the antenna ter-

minal and each antenna wire.

If an antenna wire is OK, resistance will be less

than 1 Ω. If an antenna wire is broken, resistance

will be more than 1 MΩ.

NOTE:

When checking the continuity, wind a piece of alu-

minum foil around the tip of tester probe and press

foil against the antenna wire with your finger.

To locate the broken point, move the probe along

antenna wire.

B: REPAIR

1) Clean the antenna wire and surrounding area

with a cloth dampened by alcohol.

2) Paste a thin masking film on the glass along bro-

ken wire.

3) Apply the conductive silver composition (DU-

PONT No. 4817) on the broken portion with a draw-

ing pen.

4) Dry out the deposited portion.

5) After repair has been completed, measure the

resistance in repaired wire.

(A) Tester probe

(B) Aluminum foil

(C) Antenna wire

ET-00007

(B)

(C)

(A)

ET-00008

(A) Broken portion

(B) Masking film

(C) Conductive silver composition

ET-00009

(B)

(C)

(A)

Page 818 of 2453

DI-34

General Diagnostic Table

DIFFERENTIALS

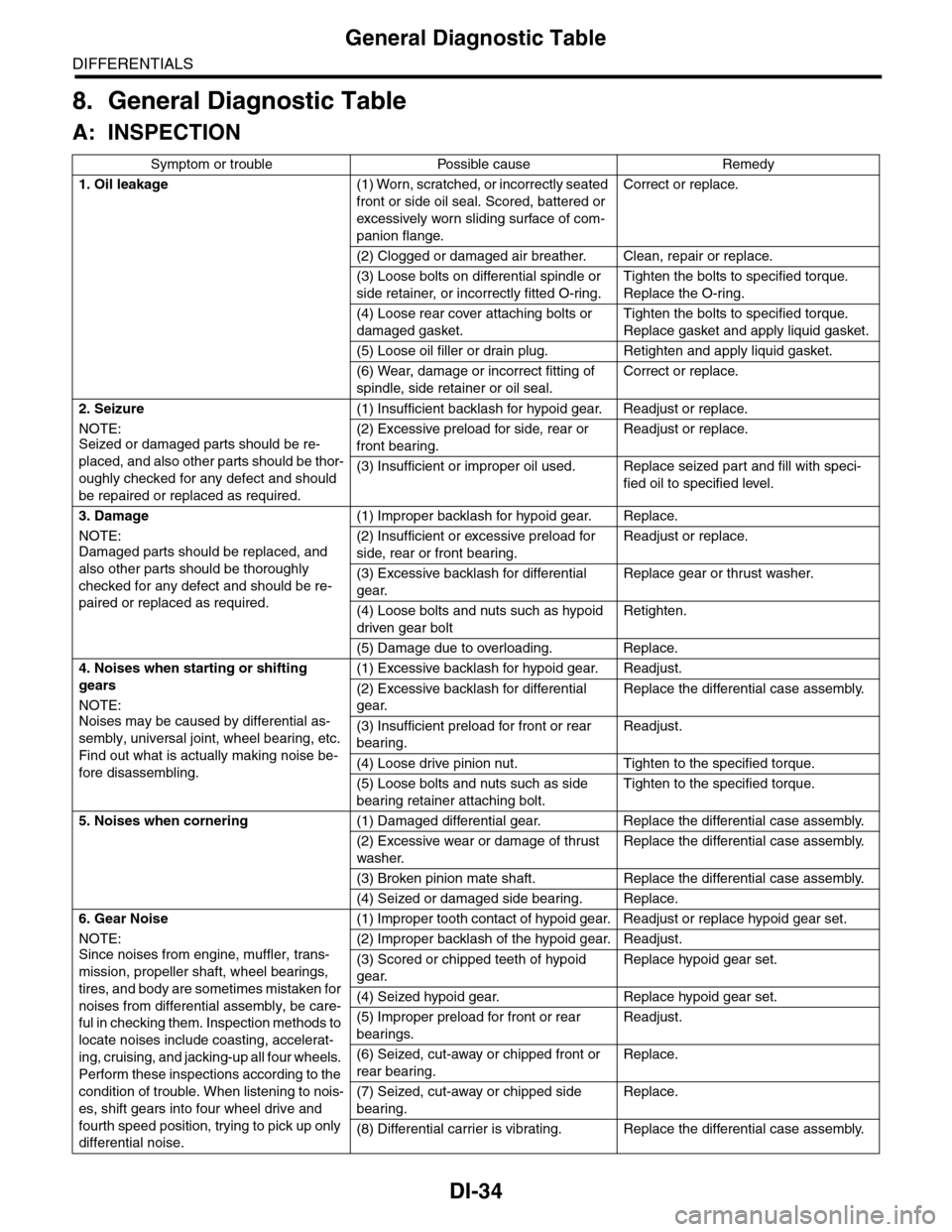

8. General Diagnostic Table

A: INSPECTION

Symptom or trouble Possible cause Remedy

1. Oil leakage(1) Worn, scratched, or incorrectly seated

front or side oil seal. Scored, battered or

excessively wor n sliding surface of com-

panion flange.

Correct or replace.

(2) Clogged or damaged air breather. Clean, repair or replace.

(3) Loose bolts on differential spindle or

side retainer, or incorrectly fitted O-ring.

Tighten the bolts to specified torque.

Replace the O-ring.

(4) Loose rear cover attaching bolts or

damaged gasket.

Tighten the bolts to specified torque.

Replace gasket and apply liquid gasket.

(5) Loose oil filler or drain plug. Retighten and apply liquid gasket.

(6) Wear, damage or incorrect fitting of

spindle, side retainer or oil seal.

Correct or replace.

2. Seizure

NOTE:Seized or damaged parts should be re-

placed, and also other parts should be thor-

oughly checked for any defect and should

be repaired or replaced as required.

(1) Insufficient backlash for hypoid gear. Readjust or replace.

(2) Excessive preload for side, rear or

front bearing.

Readjust or replace.

(3) Insufficient or improper oil used. Replace seized part and fill with speci-

fied oil to specified level.

3. Damage

NOTE:Damaged parts should be replaced, and

also other parts should be thoroughly

checked for any defect and should be re-

paired or replaced as required.

(1) Improper backlash for hypoid gear. Replace.

(2) Insufficient or excessive preload for

side, rear or front bearing.

Readjust or replace.

(3) Excessive backlash for differential

gear.

Replace gear or thrust washer.

(4) Loose bolts and nuts such as hypoid

driven gear bolt

Retighten.

(5) Damage due to overloading. Replace.

4. Noises when starting or shifting

gears

NOTE:

Noises may be caused by differential as-

sembly, universal joint, wheel bearing, etc.

Find out what is actually making noise be-

fore disassembling.

(1) Excessive backlash for hypoid gear. Readjust.

(2) Excessive backlash for differential

gear.

Replace the differential case assembly.

(3) Insufficient preload for front or rear

bearing.

Readjust.

(4) Loose drive pinion nut. Tighten to the specified torque.

(5) Loose bolts and nuts such as side

bearing retainer attaching bolt.

Tighten to the specified torque.

5. Noises when cornering(1) Damaged differential gear. Replace the differential case assembly.

(2) Excessive wear or damage of thrust

washer.

Replace the differential case assembly.

(3) Broken pinion mate shaft. Replace the differential case assembly.

(4) Seized or damaged side bearing. Replace.

6. Gear Noise

NOTE:

Since noises from engine, muffler, trans-

mission, propeller shaft, wheel bearings,

tires, and body are sometimes mistaken for

noises from differential assembly, be care-

ful in checking them. Inspection methods to

locate noises include coasting, accelerat-

ing, cruising, and jacking-up all four wheels.

Perform these inspections according to the

condition of trouble. When listening to nois-

es, shift gears into four wheel drive and

fourth speed position, trying to pick up only

differential noise.

(1) Improper tooth contact of hypoid gear. Readjust or replace hypoid gear set.

(2) Improper backlash of the hypoid gear. Readjust.

(3) Scored or chipped teeth of hypoid

gear.

Replace hypoid gear set.

(4) Seized hypoid gear. Replace hypoid gear set.

(5) Improper preload for front or rear

bearings.

Readjust.

(6) Seized, cut-away or chipped front or

rear bearing.

Replace.

(7) Seized, cut-away or chipped side

bearing.

Replace.

(8) Differential carrier is vibrating. Replace the differential case assembly.

Page 868 of 2453

FS-20

Front Strut

FRONT SUSPENSION

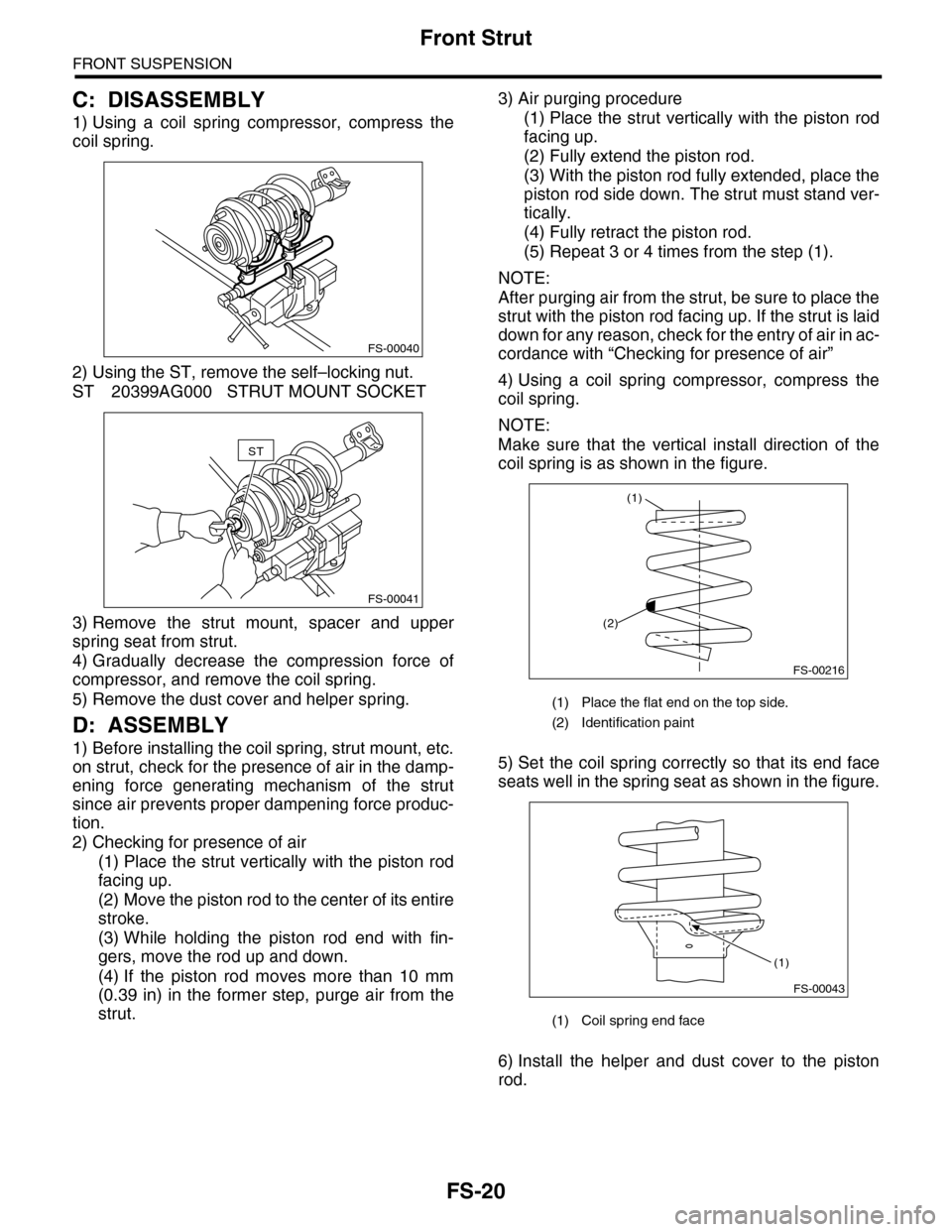

C: DISASSEMBLY

1) Using a coil spring compressor, compress the

coil spring.

2) Using the ST, remove the self–locking nut.

ST 20399AG000 STRUT MOUNT SOCKET

3) Remove the strut mount, spacer and upper

spring seat from strut.

4) Gradually decrease the compression force of

compressor, and remove the coil spring.

5) Remove the dust cover and helper spring.

D: ASSEMBLY

1) Before installing the coil spring, strut mount, etc.

on strut, check for the presence of air in the damp-

ening force generating mechanism of the strut

since air prevents proper dampening force produc-

tion.

2) Checking for presence of air

(1) Place the strut vertically with the piston rod

facing up.

(2) Move the piston rod to the center of its entire

stroke.

(3) While holding the piston rod end with fin-

gers, move the rod up and down.

(4) If the piston rod moves more than 10 mm

(0.39 in) in the former step, purge air from the

strut.

3) Air purging procedure

(1) Place the strut vertically with the piston rod

facing up.

(2) Fully extend the piston rod.

(3) With the piston rod fully extended, place the

piston rod side down. The strut must stand ver-

tically.

(4) Fully retract the piston rod.

(5) Repeat 3 or 4 times from the step (1).

NOTE:

After purging air from the strut, be sure to place the

strut with the piston rod facing up. If the strut is laid

down for any reason, check for the entry of air in ac-

cordance with “Checking for presence of air”

4) Using a coil spring compressor, compress the

coil spring.

NOTE:

Make sure that the vertical install direction of the

coil spring is as shown in the figure.

5) Set the coil spring correctly so that its end face

seats well in the spring seat as shown in the figure.

6) Install the helper and dust cover to the piston

rod.

FS-00040

FS-00041

ST

(1) Place the flat end on the top side.

(2) Identification paint

(1) Coil spring end face

FS-00216

(2)

(1)

FS-00043

(1)

Page 1089 of 2453

VDC-8

VDC Control Module & Hydraulic Control Unit (VDCCM&H/U)

VEHICLE DYNAMICS CONTROL (VDC)

4) Connect the VDCCM&H/U connectors.

NOTE:

•Be sure to remove all foreign matter from inside

the connector before connecting.

•Make sure the VDCCM&H/U connector is se-

curely locked.

5) Bleed air from the brake system.

C: INSPECTION

1) Check the condition of connection and settle-

ment of connector.

2) Check the mark used for VDCCM&H/U identifi-

cation.

Refer to “SPECIFICATION” for the identification

mark.

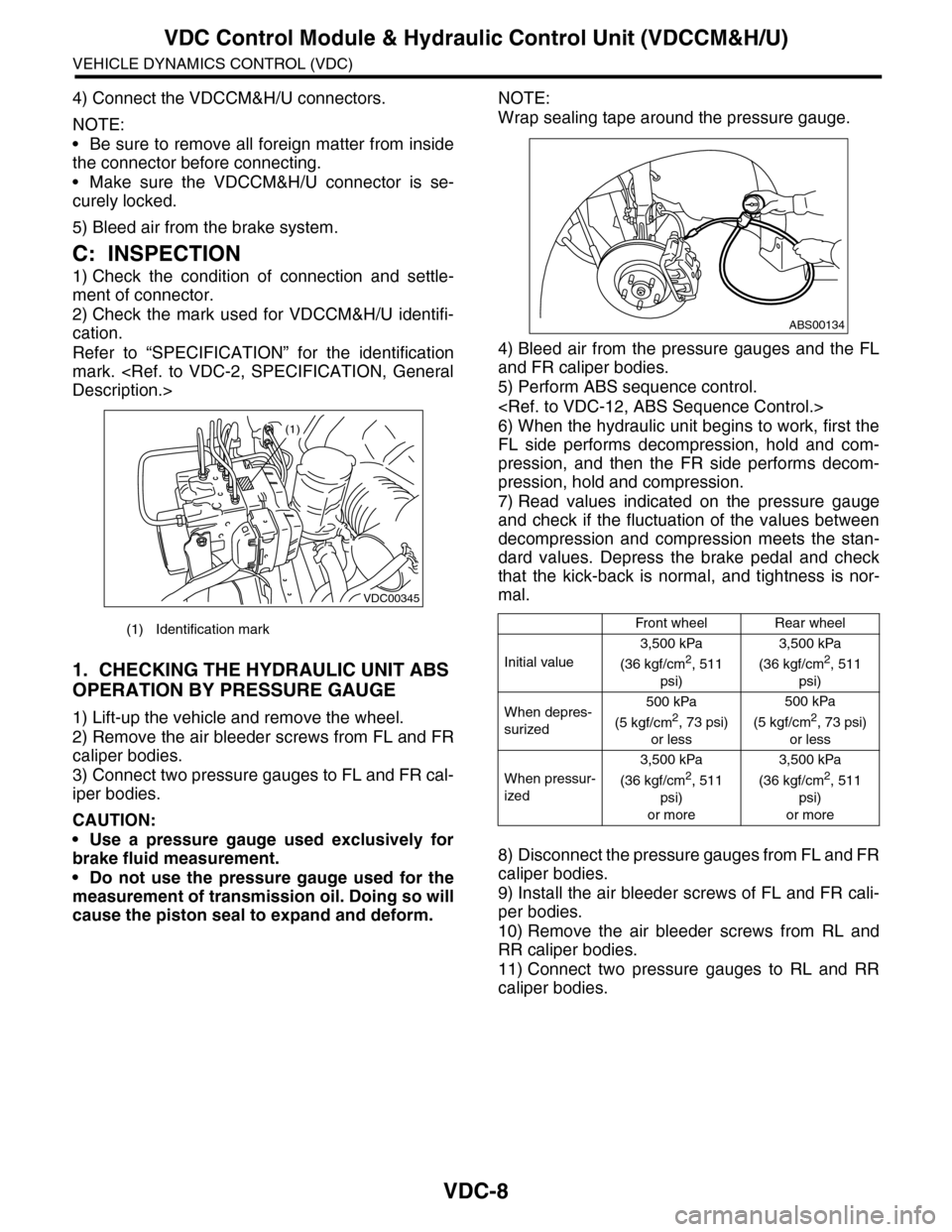

1. CHECKING THE HYDRAULIC UNIT ABS

OPERATION BY PRESSURE GAUGE

1) Lift-up the vehicle and remove the wheel.

2) Remove the air bleeder screws from FL and FR

caliper bodies.

3) Connect two pressure gauges to FL and FR cal-

iper bodies.

CAUTION:

•Use a pressure gauge used exclusively for

brake fluid measurement.

•Do not use the pressure gauge used for the

measurement of transmission oil. Doing so will

cause the piston seal to expand and deform.

NOTE:

Wrap sealing tape around the pressure gauge.

4) Bleed air from the pressure gauges and the FL

and FR caliper bodies.

5) Perform ABS sequence control.

6) When the hydraulic unit begins to work, first the

FL side performs decompression, hold and com-

pression, and then the FR side performs decom-

pression, hold and compression.

7) Read values indicated on the pressure gauge

and check if the fluctuation of the values between

decompression and compression meets the stan-

dard values. Depress the brake pedal and check

that the kick-back is normal, and tightness is nor-

mal.

8) Disconnect the pressure gauges from FL and FR

caliper bodies.

9) Install the air bleeder screws of FL and FR cali-

per bodies.

10) Remove the air bleeder screws from RL and

RR caliper bodies.

11) Connect two pressure gauges to RL and RR

caliper bodies.

(1) Identification mark

VDC00345

(1)

Front wheelRear wheel

Initial value

3,500 kPa

(36 kgf/cm2, 511

psi)

3,500 kPa

(36 kgf/cm2, 511

psi)

When depres-

surized

500 kPa

(5 kgf/cm2, 73 psi)

or less

500 kPa

(5 kgf/cm2, 73 psi)

or less

When pressur-

ized

3,500 kPa

(36 kgf/cm2, 511

psi)

or more

3,500 kPa

(36 kgf/cm2, 511

psi)

or more

ABS00134

Page 1090 of 2453

VDC-9

VDC Control Module & Hydraulic Control Unit (VDCCM&H/U)

VEHICLE DYNAMICS CONTROL (VDC)

12) Bleed air from the brake system.

13) Bleed air from RL and RR caliper bodies, and

pressure gauge.

14) Perform ABS sequence control.

15) When the hydraulic unit begins to work, first the

RR side performs decompression, hold and com-

pression, and then the RL side performs decom-

pression, hold and compression.

16) Read values indicated on the pressure gauge

and check if the fluctuation of the values between

decompression and compression meets specifica-

tion. Depress the brake pedal and check that the

kick-back is normal, and tightness is normal.

17) Disconnect the pressure gauge from the RL

and RR caliper bodies.

18) Install the air bleeder screws of RL and RR cal-

iper bodies.

19) Bleed air from the brake system.

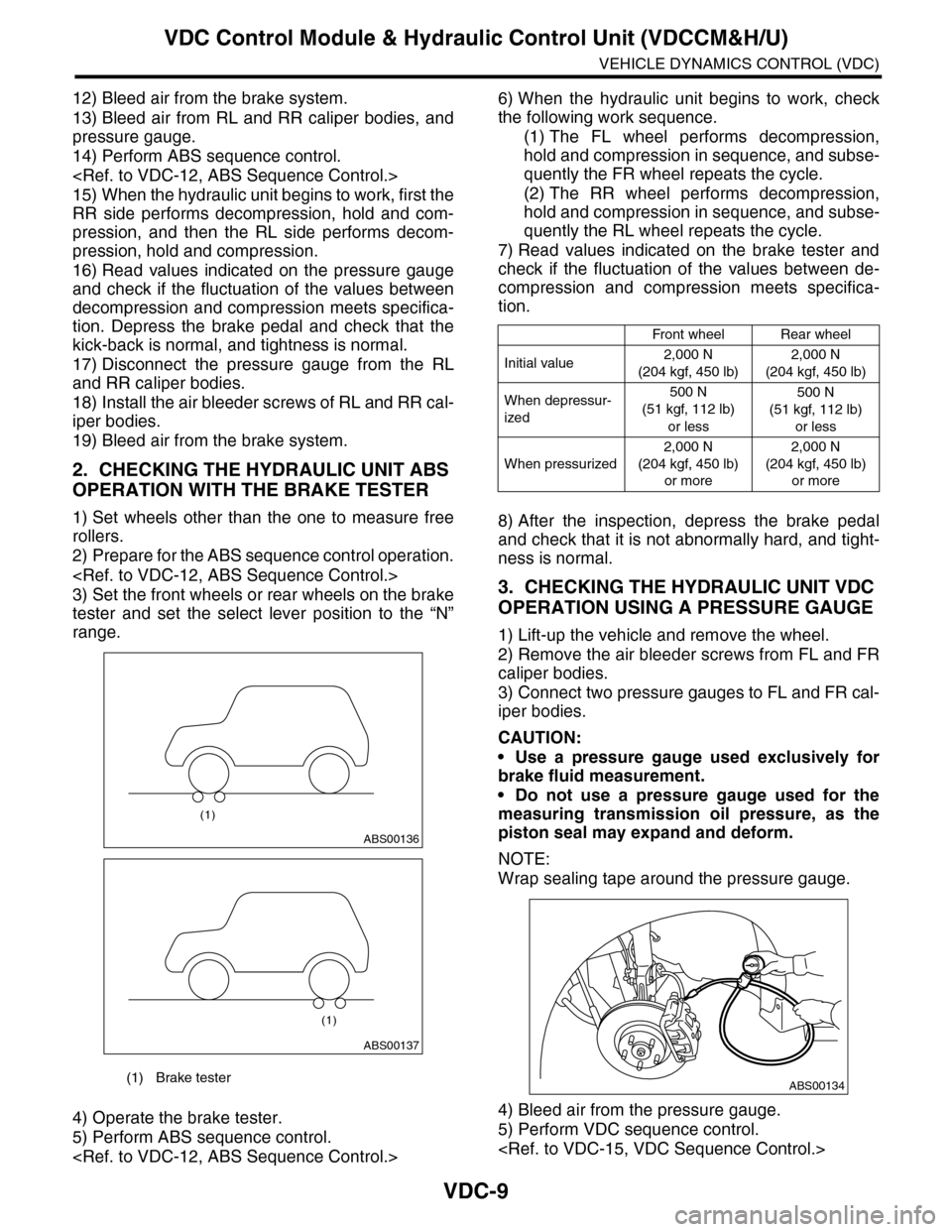

2. CHECKING THE HYDRAULIC UNIT ABS

OPERATION WITH THE BRAKE TESTER

1) Set wheels other than the one to measure free

rollers.

2) Prepare for the ABS sequence control operation.

3) Set the front wheels or rear wheels on the brake

tester and set the select lever position to the “N”

range.

4) Operate the brake tester.

5) Perform ABS sequence control.

6) When the hydraulic unit begins to work, check

the following work sequence.

(1) The FL wheel performs decompression,

hold and compression in sequence, and subse-

quently the FR wheel repeats the cycle.

(2) The RR wheel performs decompression,

hold and compression in sequence, and subse-

quently the RL wheel repeats the cycle.

7) Read values indicated on the brake tester and

check if the fluctuation of the values between de-

compression and compression meets specifica-

tion.

8) After the inspection, depress the brake pedal

and check that it is not abnormally hard, and tight-

ness is normal.

3. CHECKING THE HYDRAULIC UNIT VDC

OPERATION USING A PRESSURE GAUGE

1) Lift-up the vehicle and remove the wheel.

2) Remove the air bleeder screws from FL and FR

caliper bodies.

3) Connect two pressure gauges to FL and FR cal-

iper bodies.

CAUTION:

•Use a pressure gauge used exclusively for

brake fluid measurement.

•Do not use a pressure gauge used for the

measuring transmission oil pressure, as the

piston seal may expand and deform.

NOTE:

Wrap sealing tape around the pressure gauge.

4) Bleed air from the pressure gauge.

5) Perform VDC sequence control.

(1) Brake tester

ABS00136

(1)

ABS00137

(1)

Front wheelRear wheel

Initial value2,000 N

(204 kgf, 450 lb)

2,000 N

(204 kgf, 450 lb)

When depressur-

ized

500 N

(51 kgf, 112 lb)

or less

500 N

(51 kgf, 112 lb)

or less

When pressurized

2,000 N

(204 kgf, 450 lb)

or more

2,000 N

(204 kgf, 450 lb)

or more

ABS00134

Page 1856 of 2453

LU(H6DO)-7

Engine Oil

LUBRICATION

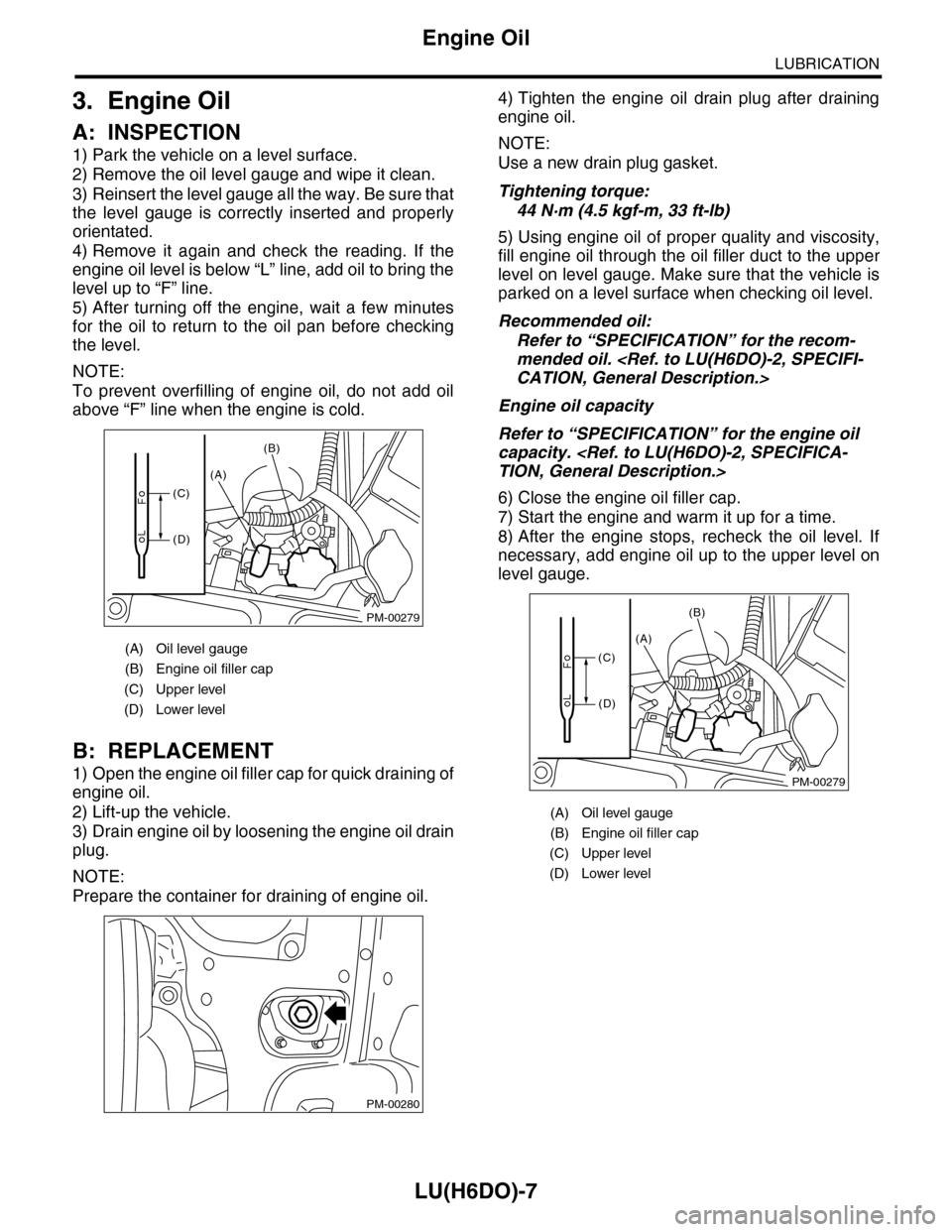

3. Engine Oil

A: INSPECTION

1) Park the vehicle on a level surface.

2) Remove the oil level gauge and wipe it clean.

3) Reinsert the level gauge all the way. Be sure that

the level gauge is correctly inserted and properly

orientated.

4) Remove it again and check the reading. If the

engine oil level is below “L” line, add oil to bring the

level up to “F” line.

5) After turning off the engine, wait a few minutes

for the oil to return to the oil pan before checking

the level.

NOTE:

To prevent overfilling of engine oil, do not add oil

above “F” line when the engine is cold.

B: REPLACEMENT

1) Open the engine oil filler cap for quick draining of

engine oil.

2) Lift-up the vehicle.

3) Drain engine oil by loosening the engine oil drain

plug.

NOTE:

Prepare the container for draining of engine oil.

4) Tighten the engine oil drain plug after draining

engine oil.

NOTE:

Use a new drain plug gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

5) Using engine oil of proper quality and viscosity,

fill engine oil through the oil filler duct to the upper

level on level gauge. Make sure that the vehicle is

parked on a level surface when checking oil level.

Recommended oil:

Refer to “SPECIFICATION” for the recom-

mended oil.

Engine oil capacity

Refer to “SPECIFICATION” for the engine oil

capacity.

6) Close the engine oil filler cap.

7) Start the engine and warm it up for a time.

8) After the engine stops, recheck the oil level. If

necessary, add engine oil up to the upper level on

level gauge.

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)

PM-00280

(A) Oil level gauge

(B) Engine oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)

Page 1936 of 2453

ME(H6DO)-70

Cylinder Block

MECHANICAL

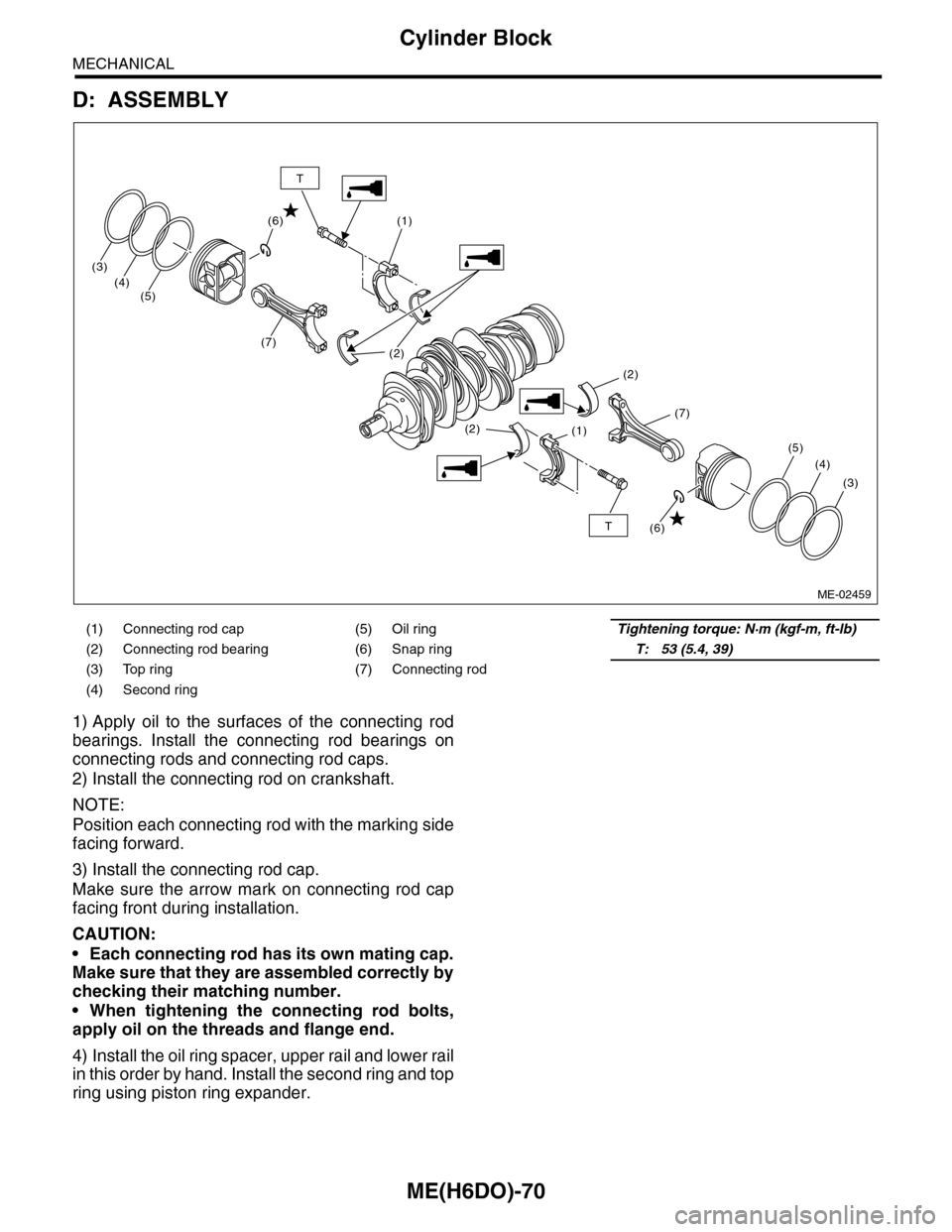

D: ASSEMBLY

1) Apply oil to the surfaces of the connecting rod

bearings. Install the connecting rod bearings on

connecting rods and connecting rod caps.

2) Install the connecting rod on crankshaft.

NOTE:

Position each connecting rod with the marking side

facing forward.

3) Install the connecting rod cap.

Make sure the arrow mark on connecting rod cap

facing front during installation.

CAUTION:

•Each connecting rod has its own mating cap.

Make sure that they are assembled correctly by

checking their matching number.

•When tightening the connecting rod bolts,

apply oil on the threads and flange end.

4) Install the oil ring spacer, upper rail and lower rail

in this order by hand. Install the second ring and top

ring using piston ring expander.

(1) Connecting rod cap (5) Oil ringTightening torque: N·m (kgf-m, ft-lb)

(2) Connecting rod bearing (6) Snap ringT: 53 (5.4, 39)

(3) Top ring (7) Connecting rod

(4) Second ring

(1)

(1)

(2)

(2)

(2)

(7)

(3)

(4)(5)

(7)

(3)

(4)

(5)

(6)

(6)T

T

ME-02459

Page 1980 of 2453

SC(H6DO)-22

Generator

STARTING/CHARGING SYSTEMS

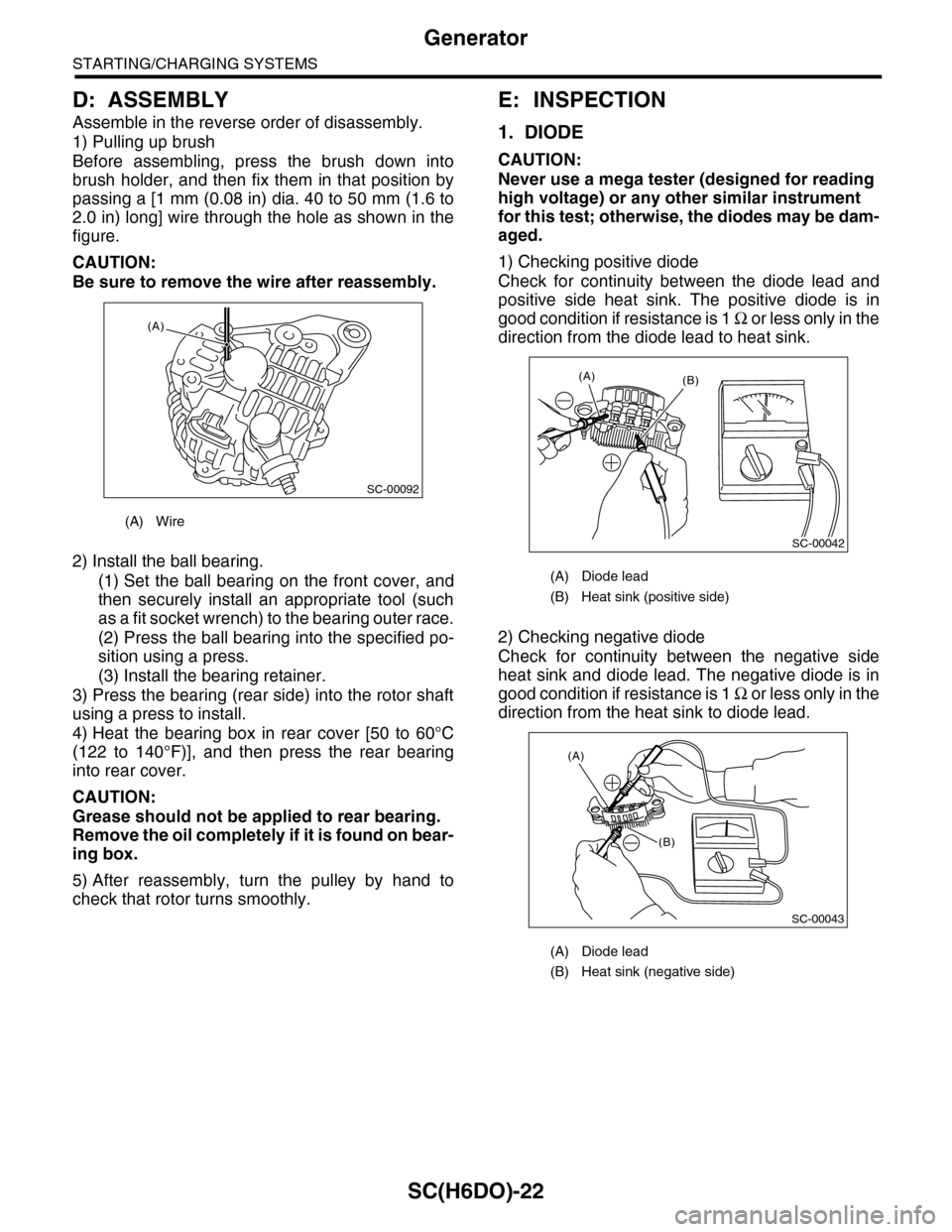

D: ASSEMBLY

Assemble in the reverse order of disassembly.

1) Pulling up brush

Before assembling, press the brush down into

brush holder, and then fix them in that position by

passing a [1 mm (0.08 in) dia. 40 to 50 mm (1.6 to

2.0 in) long] wire through the hole as shown in the

figure.

CAUTION:

Be sure to remove the wire after reassembly.

2) Install the ball bearing.

(1) Set the ball bearing on the front cover, and

then securely install an appropriate tool (such

as a fit socket wrench) to the bearing outer race.

(2) Press the ball bearing into the specified po-

sition using a press.

(3) Install the bearing retainer.

3) Press the bearing (rear side) into the rotor shaft

using a press to install.

4) Heat the bearing box in rear cover [50 to 60°C

(122 to 140°F)], and then press the rear bearing

into rear cover.

CAUTION:

Grease should not be applied to rear bearing.

Remove the oil completely if it is found on bear-

ing box.

5) After reassembly, turn the pulley by hand to

check that rotor turns smoothly.

E: INSPECTION

1. DIODE

CAUTION:

Never use a mega tester (designed for reading

high voltage) or any other similar instrument

for this test; otherwise, the diodes may be dam-

aged.

1) Checking positive diode

Check for continuity between the diode lead and

positive side heat sink. The positive diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the diode lead to heat sink.

2) Checking negative diode

Check for continuity between the negative side

heat sink and diode lead. The negative diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the heat sink to diode lead.

(A) Wire

SC-00092

(A)

(A) Diode lead

(B) Heat sink (positive side)

(A) Diode lead

(B) Heat sink (negative side)

SC-00042

(B)(A)

(A)

(B)

SC-00043