ECU SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 921 of 2453

PS-41

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

7. Oil Pump

A: REMOVAL

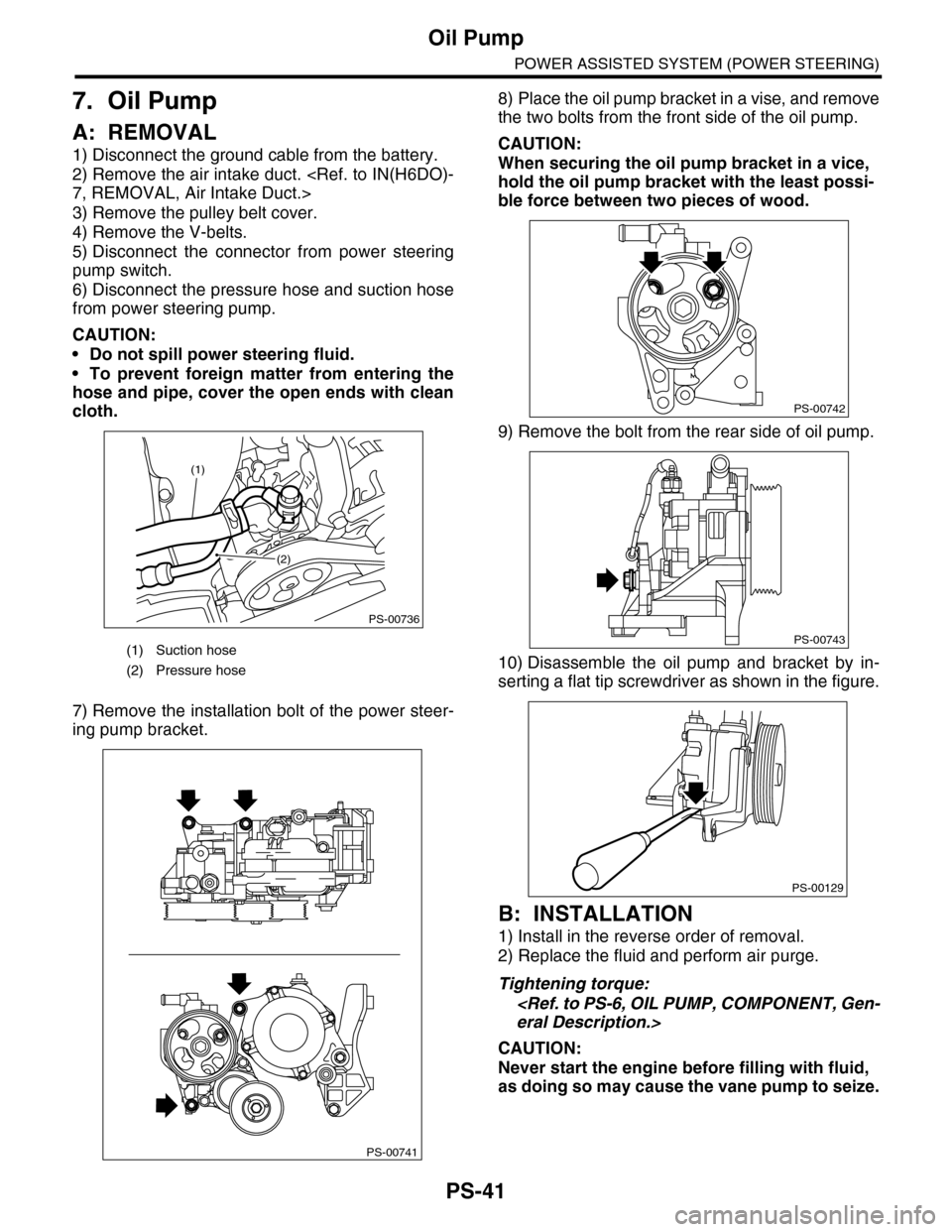

1) Disconnect the ground cable from the battery.

2) Remove the air intake duct.

3) Remove the pulley belt cover.

4) Remove the V-belts.

5) Disconnect the connector from power steering

pump switch.

6) Disconnect the pressure hose and suction hose

from power steering pump.

CAUTION:

•Do not spill power steering fluid.

•To prevent foreign matter from entering the

hose and pipe, cover the open ends with clean

cloth.

7) Remove the installation bolt of the power steer-

ing pump bracket.

8) Place the oil pump bracket in a vise, and remove

the two bolts from the front side of the oil pump.

CAUTION:

When securing the oil pump bracket in a vice,

hold the oil pump bracket with the least possi-

ble force between two pieces of wood.

9) Remove the bolt from the rear side of oil pump.

10) Disassemble the oil pump and bracket by in-

serting a flat tip screwdriver as shown in the figure.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Replace the fluid and perform air purge.

Tightening torque:

CAUTION:

Never start the engine before filling with fluid,

as doing so may cause the vane pump to seize.

(1) Suction hose

(2) Pressure hose

PS-00736

(1)

(2)

PS-00741

PS-00742

PS-00743

PS-00129

Page 924 of 2453

PS-44

Oil Pump

POWER ASSISTED SYSTEM (POWER STEERING)

E: INSPECTION

1. BASIC INSPECTION

Perform the following inspection procedures and replace faulty parts.

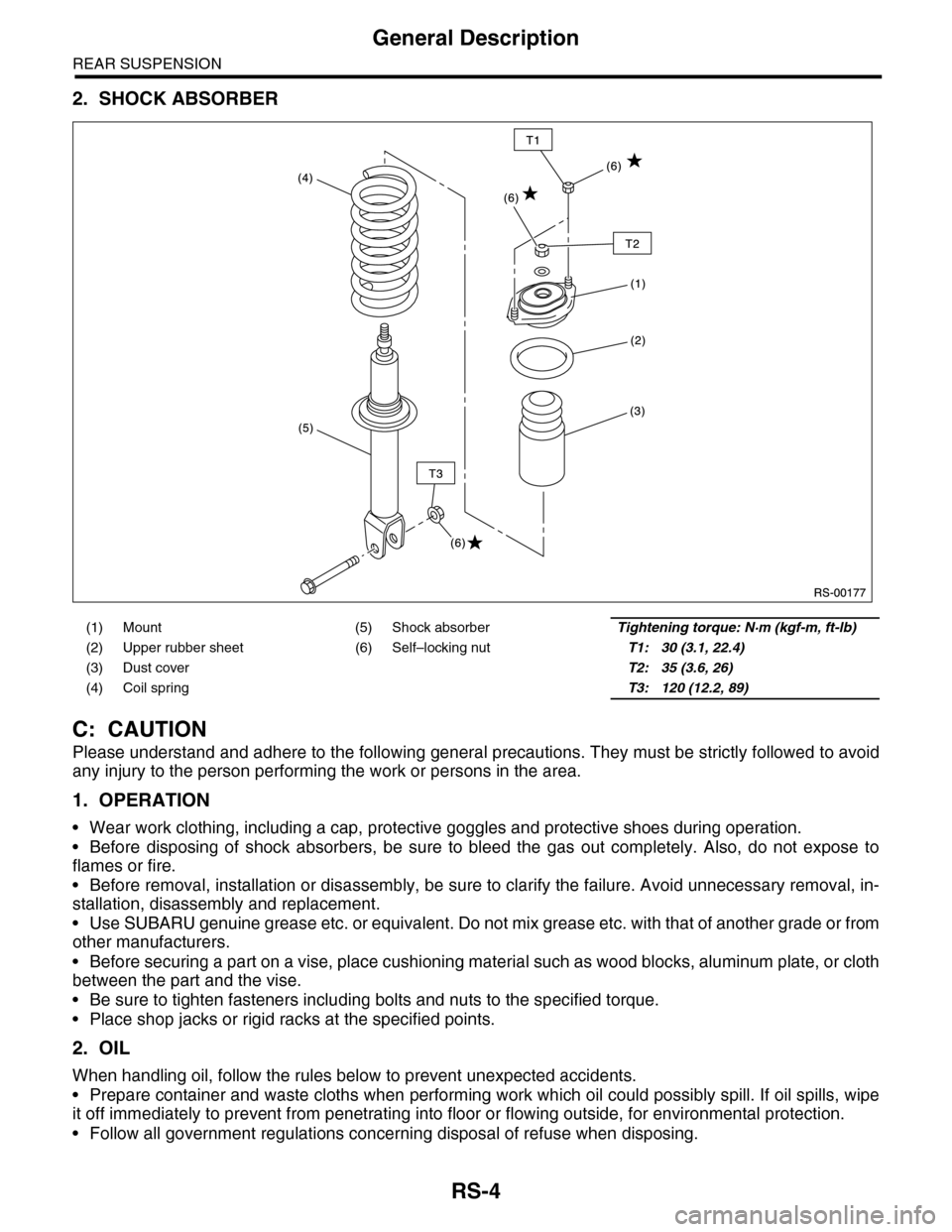

2. SERVICE LIMIT

Make a measurements as follows. If it exceeds the

service limit, replace with a new one.

CAUTION:

•When securing the oil pump on a vise, hold

the oil pump with the least possible force be-

tween two pieces of wood.

•Do not set the outside of flow control valve or

pulley on a vise; otherwise outside or pulley

might be deformed. Select properly sized wood

pieces.

1) Play of the pulley shaft

Condition:

P: When applying the force of 9.8 N (1.0 kgf,

2.2 lb)

Service limit:

Play in the radial direction (Direction )

Less than 0.2 mm (0.008 in)

Axial play (Direction )

Less than 0.6 mm (0.024 in)

2) Deflection of the pulley groove

Service limit:

Less than 1.0 mm (0.039 in)

NOTE:

Read the value for one surface of V ditch, and then

the value for another off the dial.

No. Parts Inspection Corrective action

1Oil pump

(Exterior)

(1) Crack, damage or oil leakage Replace the oil pump with a new one.

(2) Play of pulley shaft

Measure the radial play and axial play.

If any of these exceeds the service limit, replace the oil pump

with a new one.

2Pulley

(1) Damage Replace with a new part.

(2) BendMeasure the V groove deflection.

If it exceeds the service limit, replace the pulley with a new one.

3Oil pump

(Interior)

(1) Faulty or seized of vane pumpCheck the rotating resistance of pulley.

If it exceeds the service limit, replace the oil pump with new one.

(2) Bend in the shaft or damage

to bearing

If the a string is wrapped on the pulley and rotated, and the oil

pump emits a noise that is markedly different in tone and loud-

ness from a sound of a new oil pump, replace the oil pump with

a new one.

4O–ring Cracking or deterioration Replace with a new part.

5Bracket Cracking Replace with a new part.

(1) Dial gauge

PS-00145P

(1)

(1) Dial gauge

(1) Dial gauge

PS-00146P

(1)

PS-00147

Page 937 of 2453

RS-4

General Description

REAR SUSPENSION

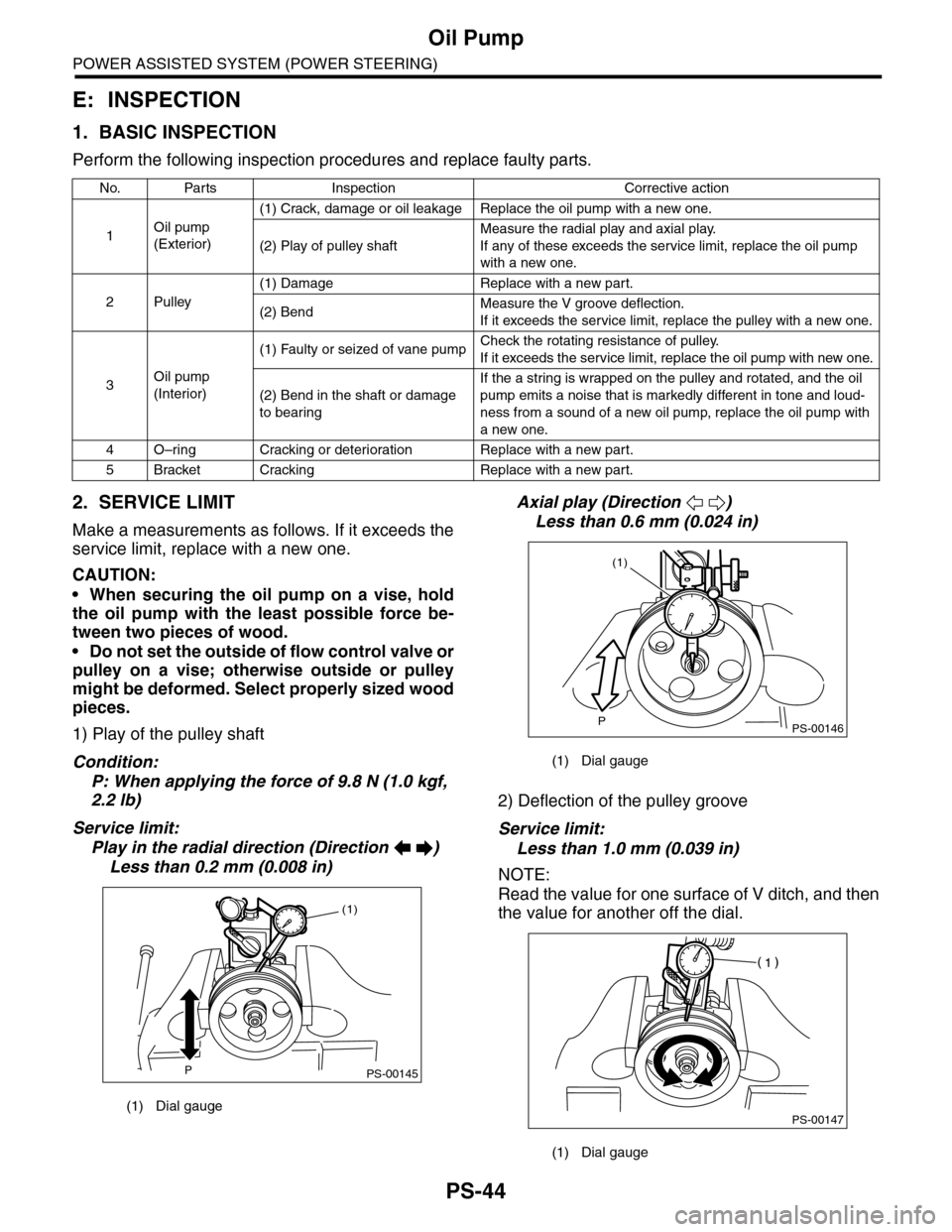

2. SHOCK ABSORBER

C: CAUTION

Please understand and adhere to the following general precautions. They must be strictly followed to avoid

any injury to the person performing the work or persons in the area.

1. OPERATION

•Wear work clothing, including a cap, protective goggles and protective shoes during operation.

•Before disposing of shock absorbers, be sure to bleed the gas out completely. Also, do not expose to

flames or fire.

•Before removal, installation or disassembly, be sure to clarify the failure. Avoid unnecessary removal, in-

stallation, disassembly and replacement.

•Use SUBARU genuine grease etc. or equivalent. Do not mix grease etc. with that of another grade or from

other manufacturers.

•Before securing a part on a vise, place cushioning material such as wood blocks, aluminum plate, or cloth

between the part and the vise.

•Be sure to tighten fasteners including bolts and nuts to the specified torque.

•Place shop jacks or rigid racks at the specified points.

2. OIL

When handling oil, follow the rules below to prevent unexpected accidents.

•Prepare container and waste cloths when performing work which oil could possibly spill. If oil spills, wipe

it off immediately to prevent from penetrating into floor or flowing outside, for environmental protection.

•Follow all government regulations concerning disposal of refuse when disposing.

(1) Mount (5) Shock absorberTightening torque: N·m (kgf-m, ft-lb)

(2) Upper rubber sheet (6) Self–locking nutT1: 30 (3.1, 22.4)

(3) Dust cover T2: 35 (3.6, 26)

(4) Coil spring T3: 120 (12.2, 89)

Page 947 of 2453

RS-14

Front Lateral Link

REAR SUSPENSION

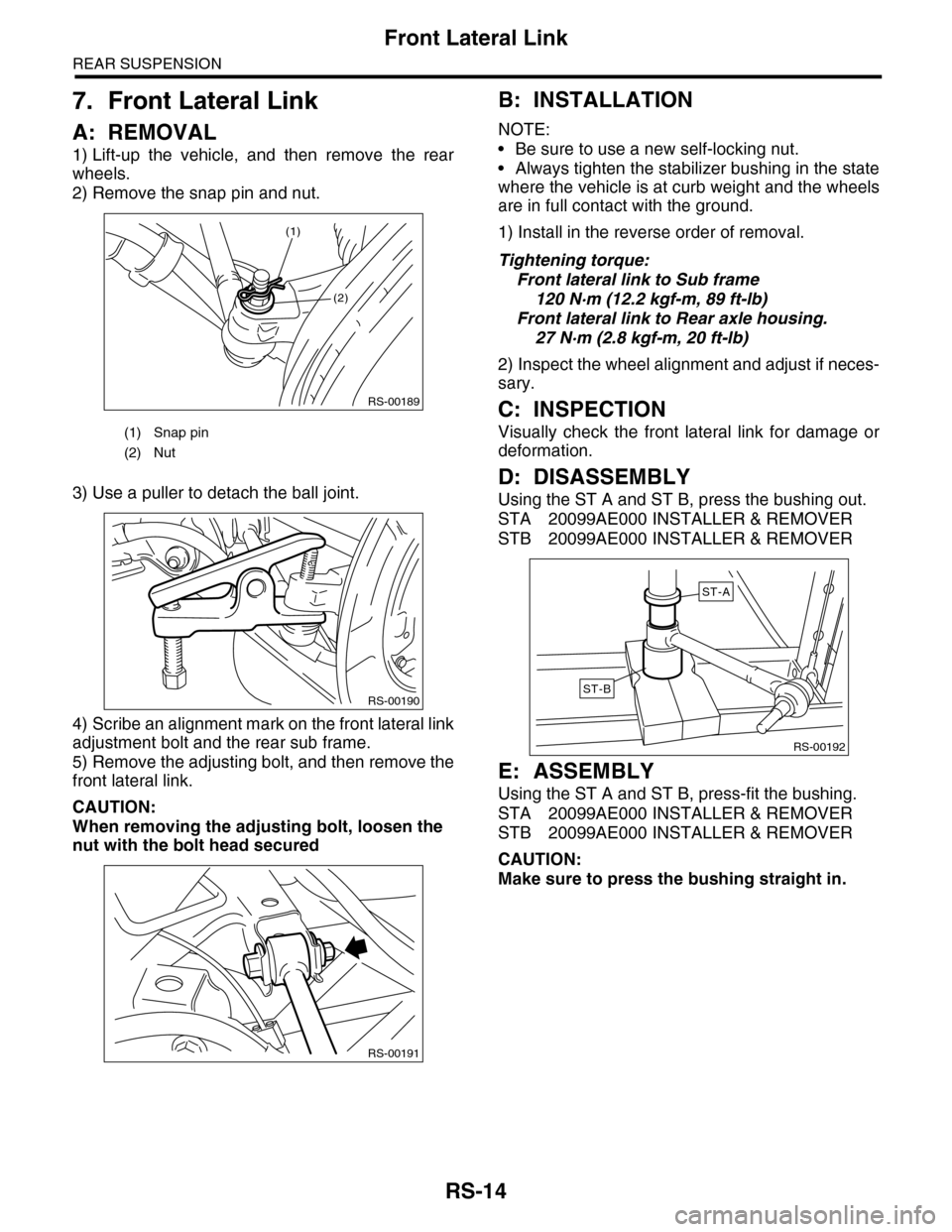

7. Front Lateral Link

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Remove the snap pin and nut.

3) Use a puller to detach the ball joint.

4) Scribe an alignment mark on the front lateral link

adjustment bolt and the rear sub frame.

5) Remove the adjusting bolt, and then remove the

front lateral link.

CAUTION:

When removing the adjusting bolt, loosen the

nut with the bolt head secured

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

1) Install in the reverse order of removal.

Tightening torque:

Front lateral link to Sub frame

120 N·m (12.2 kgf-m, 89 ft-lb)

Front lateral link to Rear axle housing.

27 N·m (2.8 kgf-m, 20 ft-lb)

2) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Visually check the front lateral link for damage or

deformation.

D: DISASSEMBLY

Using the ST A and ST B, press the bushing out.

STA 20099AE000 INSTALLER & REMOVER

STB 20099AE000 INSTALLER & REMOVER

E: ASSEMBLY

Using the ST A and ST B, press-fit the bushing.

STA 20099AE000 INSTALLER & REMOVER

STB 20099AE000 INSTALLER & REMOVER

CAUTION:

Make sure to press the bushing straight in.

(1) Snap pin

(2) Nut

RS-00189

(2)

(1)

RS-00190

RS-00191

RS-00192

ST-A

ST-B

Page 952 of 2453

TPM(diag)-2

Basic Diagnostic Procedure

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

CAUTION:

Remove foreign matter (dust, water, oil etc.) from the tire pressure monitoring control module con-

nector when removing or installing.

NOTE:

To check harness for broken wires or short circuits, shake trouble spot or connector.

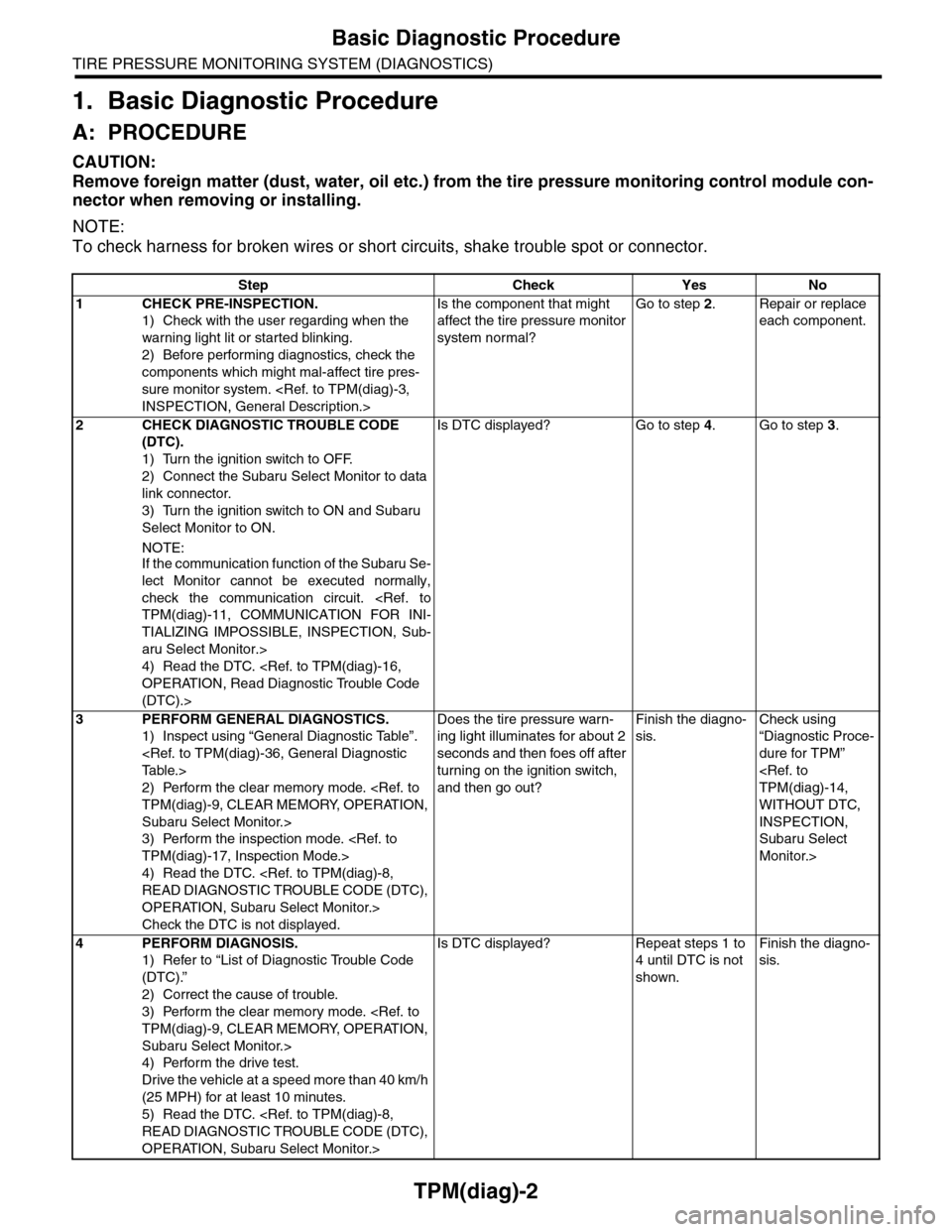

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Check with the user regarding when the

warning light lit or started blinking.

2) Before performing diagnostics, check the

components which might mal-affect tire pres-

sure monitor system.

Is the component that might

affect the tire pressure monitor

system normal?

Go to step 2.Repair or replace

each component.

2CHECK DIAGNOSTIC TROUBLE CODE

(DTC).

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON and Subaru

Select Monitor to ON.

NOTE:If the communication function of the Subaru Se-

lect Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, INSPECTION, Sub-

aru Select Monitor.>

4) Read the DTC.

(DTC).>

Is DTC displayed? Go to step 4.Go to step 3.

3PERFORM GENERAL DIAGNOSTICS.

1) Inspect using “General Diagnostic Table”.

2) Perform the clear memory mode.

Subaru Select Monitor.>

3) Perform the inspection mode.

4) Read the DTC.

OPERATION, Subaru Select Monitor.>

Check the DTC is not displayed.

Does the tire pressure warn-

ing light illuminates for about 2

seconds and then foes off after

turning on the ignition switch,

and then go out?

Finish the diagno-

sis.

Check using

“Diagnostic Proce-

dure for TPM”

WITHOUT DTC,

INSPECTION,

Subaru Select

Monitor.>

4PERFORM DIAGNOSIS.

1) Refer to “List of Diagnostic Trouble Code

(DTC).”

2) Correct the cause of trouble.

3) Perform the clear memory mode.

Subaru Select Monitor.>

4) Perform the drive test.

Drive the vehicle at a speed more than 40 km/h

(25 MPH) for at least 10 minutes.

5) Read the DTC.

OPERATION, Subaru Select Monitor.>

Is DTC displayed? Repeat steps 1 to

4 until DTC is not

shown.

Finish the diagno-

sis.

Page 960 of 2453

TPM(diag)-10

Subaru Select Monitor

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

2) Connect the Subaru Select Monitor, on the

«Main Menu» display screen, select the {2. Each

System Check} and press the [YES] key.

3) On the «System Selection Menu» display

screen, select the {Tire Pressure Monitor} and

press the [YES] key.

4) Press the [YES] key after the {Tire Pressure

Monitor} is displayed.

5) On the «Tire Pressure Monitor Diagnosis» dis-

play screen, select the {Transmitter ID regist con-

firm} and press the [YES] key.

6) {When ID registration mode execute, Registered

ID is deleted Proceed?} is displayed then press the

[YES] key.

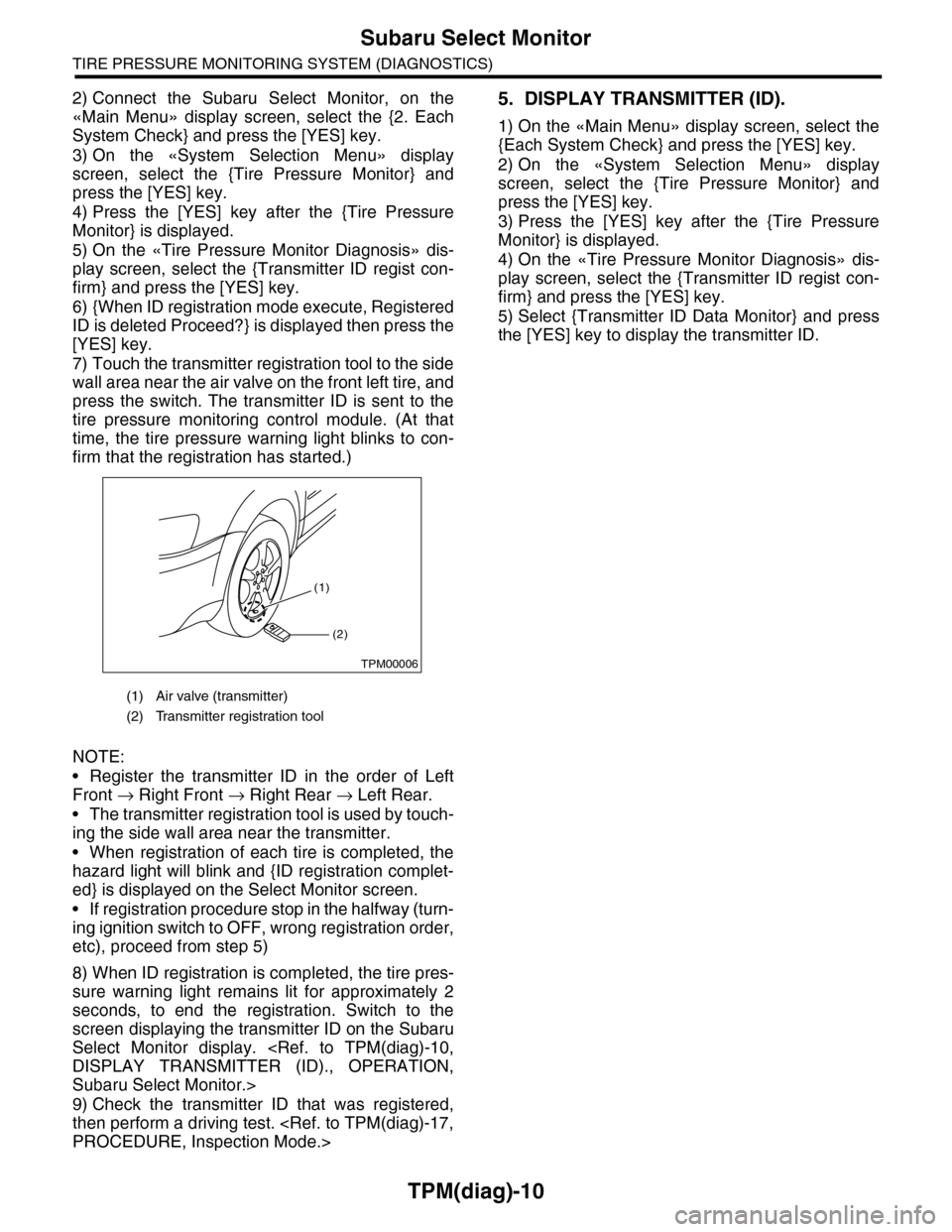

7) Touch the transmitter registration tool to the side

wall area near the air valve on the front left tire, and

press the switch. The transmitter ID is sent to the

tire pressure monitoring control module. (At that

time, the tire pressure warning light blinks to con-

firm that the registration has started.)

NOTE:

•Register the transmitter ID in the order of Left

Front → Right Front → Right Rear → Left Rear.

•The transmitter registration tool is used by touch-

ing the side wall area near the transmitter.

•When registration of each tire is completed, the

hazard light will blink and {ID registration complet-

ed} is displayed on the Select Monitor screen.

•If registration procedure stop in the halfway (turn-

ing ignition switch to OFF, wrong registration order,

etc), proceed from step 5)

8) When ID registration is completed, the tire pres-

sure warning light remains lit for approximately 2

seconds, to end the registration. Switch to the

screen displaying the transmitter ID on the Subaru

Select Monitor display.

Subaru Select Monitor.>

9) Check the transmitter ID that was registered,

then perform a driving test.

5. DISPLAY TRANSMITTER (ID).

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display

screen, select the {Tire Pressure Monitor} and

press the [YES] key.

3) Press the [YES] key after the {Tire Pressure

Monitor} is displayed.

4) On the «Tire Pressure Monitor Diagnosis» dis-

play screen, select the {Transmitter ID regist con-

firm} and press the [YES] key.

5) Select {Transmitter ID Data Monitor} and press

the [YES] key to display the transmitter ID.

(1) Air valve (transmitter)

(2) Transmitter registration tool

(1)

(2)

TPM00006

Page 962 of 2453

TPM(diag)-12

Subaru Select Monitor

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

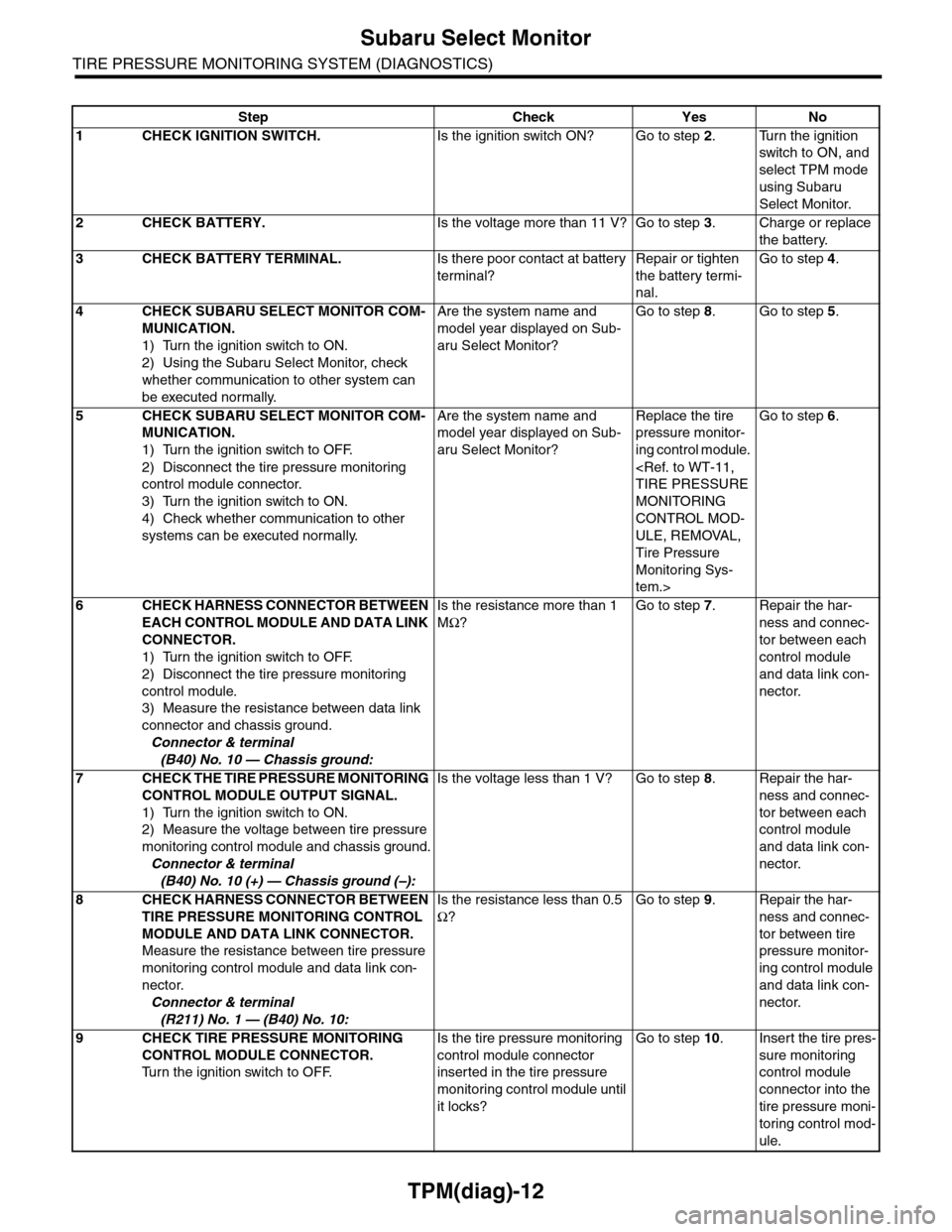

Step Check Yes No

1CHECK IGNITION SWITCH.Is the ignition switch ON? Go to step 2.Turn the ignition

switch to ON, and

select TPM mode

using Subaru

Select Monitor.

2CHECK BATTERY.Is the voltage more than 11 V? Go to step 3.Charge or replace

the battery.

3CHECK BATTERY TERMINAL.Is there poor contact at battery

terminal?

Repair or tighten

the battery termi-

nal.

Go to step 4.

4CHECK SUBARU SELECT MONITOR COM-

MUNICATION.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, check

whether communication to other system can

be executed normally.

Are the system name and

model year displayed on Sub-

aru Select Monitor?

Go to step 8.Go to step 5.

5CHECK SUBARU SELECT MONITOR COM-

MUNICATION.

1) Turn the ignition switch to OFF.

2) Disconnect the tire pressure monitoring

control module connector.

3) Turn the ignition switch to ON.

4) Check whether communication to other

systems can be executed normally.

Are the system name and

model year displayed on Sub-

aru Select Monitor?

Replace the tire

pressure monitor-

ing control module.

MONITORING

CONTROL MOD-

ULE, REMOVAL,

Tire Pressure

Monitoring Sys-

tem.>

Go to step 6.

6CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL MODULE AND DATA LINK

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the tire pressure monitoring

control module.

3) Measure the resistance between data link

connector and chassis ground.

Connector & terminal

(B40) No. 10 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the har-

ness and connec-

tor between each

control module

and data link con-

nector.

7CHECK THE TIRE PRESSURE MONITORING

CONTROL MODULE OUTPUT SIGNAL.

1) Turn the ignition switch to ON.

2) Measure the voltage between tire pressure

monitoring control module and chassis ground.

Connector & terminal

(B40) No. 10 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 8.Repair the har-

ness and connec-

tor between each

control module

and data link con-

nector.

8CHECK HARNESS CONNECTOR BETWEEN

TIRE PRESSURE MONITORING CONTROL

MODULE AND DATA LINK CONNECTOR.

Measure the resistance between tire pressure

monitoring control module and data link con-

nector.

Connector & terminal

(R211) No. 1 — (B40) No. 10:

Is the resistance less than 0.5

Ω?

Go to step 9.Repair the har-

ness and connec-

tor between tire

pressure monitor-

ing control module

and data link con-

nector.

9CHECK TIRE PRESSURE MONITORING

CONTROL MODULE CONNECTOR.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is the tire pressure monitoring

control module connector

inserted in the tire pressure

monitoring control module until

it locks?

Go to step 10.Insert the tire pres-

sure monitoring

control module

connector into the

tire pressure moni-

toring control mod-

ule.

Page 994 of 2453

VDC(diag)-2

Basic Diagnostic Procedure

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

NOTE:

•To check the harness for broken wires or short circuits, shake problem spot or connector.

•Refer to “Check List for Interview”.

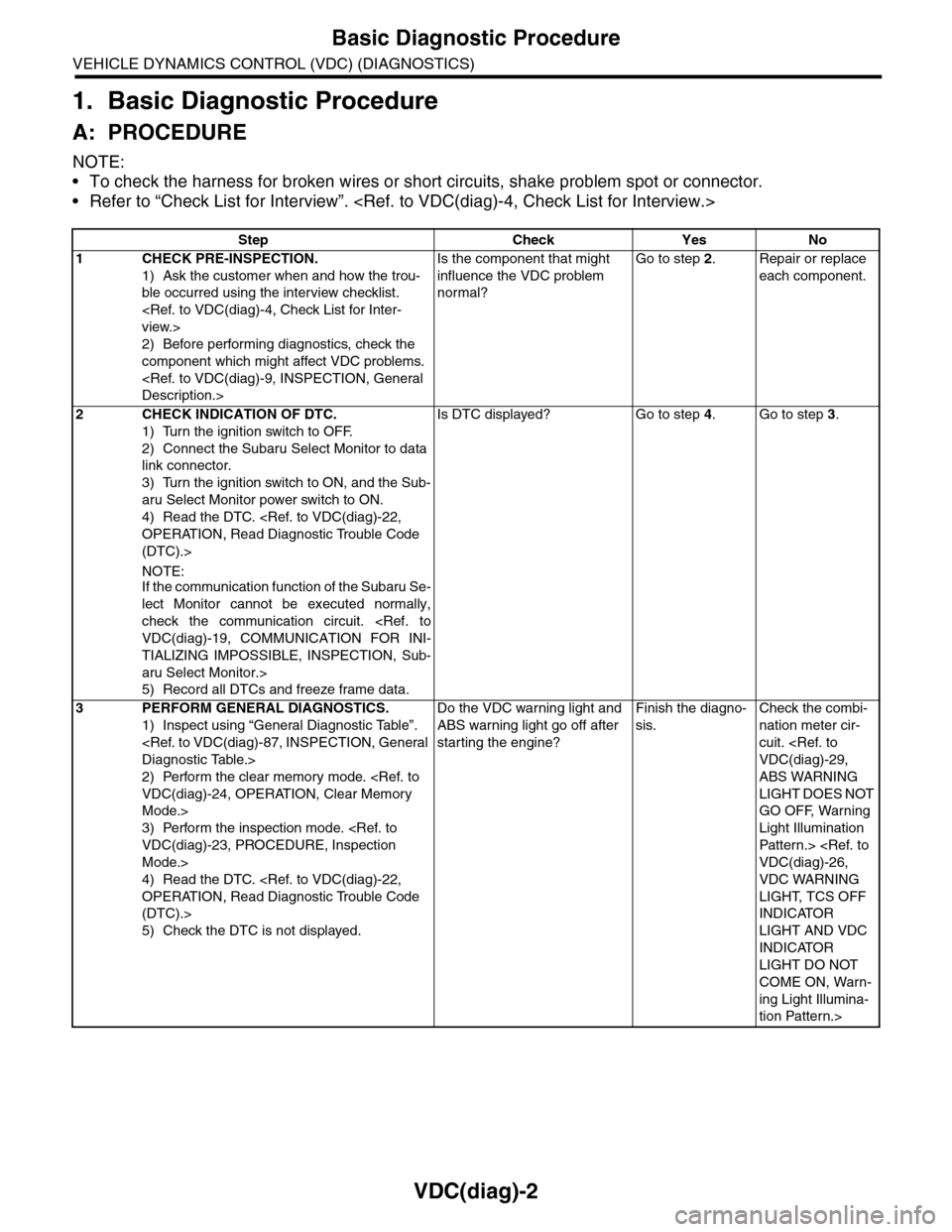

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using the interview checklist.

2) Before performing diagnostics, check the

component which might affect VDC problems.

Is the component that might

influence the VDC problem

normal?

Go to step 2.Repair or replace

each component.

2CHECK INDICATION OF DTC.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Read the DTC.

(DTC).>

NOTE:If the communication function of the Subaru Se-

lect Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, INSPECTION, Sub-

aru Select Monitor.>

5) Record all DTCs and freeze frame data.

Is DTC displayed? Go to step 4.Go to step 3.

3PERFORM GENERAL DIAGNOSTICS.

1) Inspect using “General Diagnostic Table”.

2) Perform the clear memory mode.

Mode.>

3) Perform the inspection mode.

Mode.>

4) Read the DTC.

(DTC).>

5) Check the DTC is not displayed.

Do the VDC warning light and

ABS warning light go off after

starting the engine?

Finish the diagno-

sis.

Check the combi-

nation meter cir-

cuit.

ABS WARNING

LIGHT DOES NOT

GO OFF, Warning

Light Illumination

Patter n.>

VDC WARNING

LIGHT, TCS OFF

INDICATOR

LIGHT AND VDC

INDICATOR

LIGHT DO NOT

COME ON, Warn-

ing Light Illumina-

tion Pattern.>

Page 1012 of 2453

VDC(diag)-20

Subaru Select Monitor

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

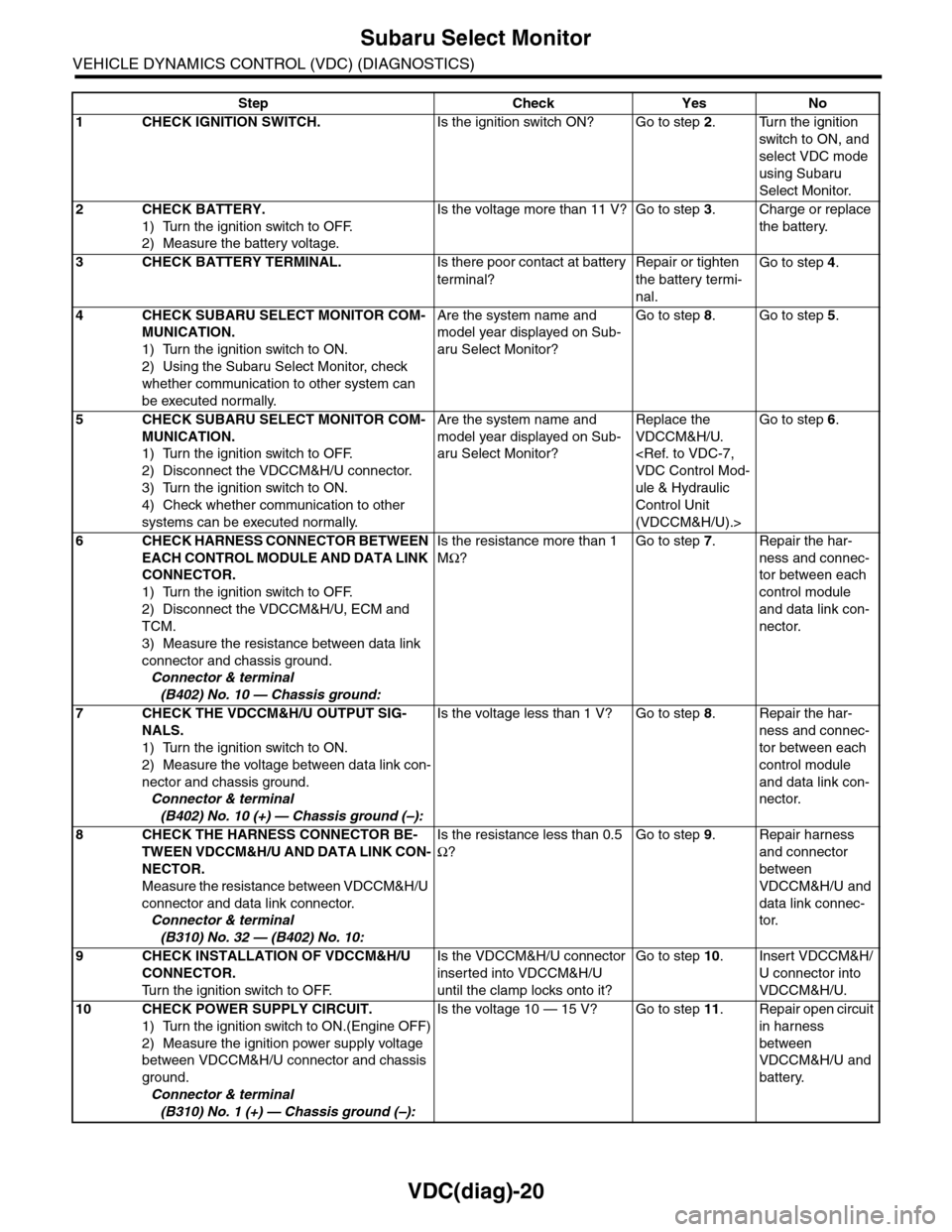

Step Check Yes No

1CHECK IGNITION SWITCH.Is the ignition switch ON? Go to step 2.Turn the ignition

switch to ON, and

select VDC mode

using Subaru

Select Monitor.

2CHECK BATTERY.

1) Turn the ignition switch to OFF.

2) Measure the battery voltage.

Is the voltage more than 11 V? Go to step 3.Charge or replace

the battery.

3CHECK BATTERY TERMINAL.Is there poor contact at battery

terminal?

Repair or tighten

the battery termi-

nal.

Go to step 4.

4CHECK SUBARU SELECT MONITOR COM-

MUNICATION.

1) Turn the ignition switch to ON.

2) Using the Subaru Select Monitor, check

whether communication to other system can

be executed normally.

Are the system name and

model year displayed on Sub-

aru Select Monitor?

Go to step 8.Go to step 5.

5CHECK SUBARU SELECT MONITOR COM-

MUNICATION.

1) Turn the ignition switch to OFF.

2) Disconnect the VDCCM&H/U connector.

3) Turn the ignition switch to ON.

4) Check whether communication to other

systems can be executed normally.

Are the system name and

model year displayed on Sub-

aru Select Monitor?

Replace the

VDCCM&H/U.

ule & Hydraulic

Control Unit

(VDCCM&H/U).>

Go to step 6.

6CHECK HARNESS CONNECTOR BETWEEN

EACH CONTROL MODULE AND DATA LINK

CONNECTOR.

1) Turn the ignition switch to OFF.

2) Disconnect the VDCCM&H/U, ECM and

TCM.

3) Measure the resistance between data link

connector and chassis ground.

Connector & terminal

(B402) No. 10 — Chassis ground:

Is the resistance more than 1

MΩ?

Go to step 7.Repair the har-

ness and connec-

tor between each

control module

and data link con-

nector.

7CHECK THE VDCCM&H/U OUTPUT SIG-

NALS.

1) Turn the ignition switch to ON.

2) Measure the voltage between data link con-

nector and chassis ground.

Connector & terminal

(B402) No. 10 (+) — Chassis ground (–):

Is the voltage less than 1 V? Go to step 8.Repair the har-

ness and connec-

tor between each

control module

and data link con-

nector.

8CHECK THE HARNESS CONNECTOR BE-

TWEEN VDCCM&H/U AND DATA LINK CON-

NECTOR.

Measure the resistance between VDCCM&H/U

connector and data link connector.

Connector & terminal

(B310) No. 32 — (B402) No. 10:

Is the resistance less than 0.5

Ω?

Go to step 9.Repair harness

and connector

between

VDCCM&H/U and

data link connec-

tor.

9CHECK INSTALLATION OF VDCCM&H/U

CONNECTOR.

Tu r n t h e i g n i t i o n s w i t c h t o O F F.

Is the VDCCM&H/U connector

inserted into VDCCM&H/U

until the clamp locks onto it?

Go to step 10.Insert VDCCM&H/

U connector into

VDCCM&H/U.

10 CHECK POWER SUPPLY CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the ignition power supply voltage

between VDCCM&H/U connector and chassis

ground.

Connector & terminal

(B310) No. 1 (+) — Chassis ground (–):

Is the voltage 10 — 15 V? Go to step 11.Repair open circuit

in harness

between

VDCCM&H/U and

battery.

Page 1093 of 2453

VDC-12

ABS Sequence Control

VEHICLE DYNAMICS CONTROL (VDC)

3. ABS Sequence Control

A: OPERATION

1) While the ABS sequence control is being per-

formed, the operation of the hydraulic unit can be

checked using the brake tester or pressure gauge

after the hydraulic unit solenoid valve operation.

2) ABS sequence control can be started by the

Subaru Select Monitor.

1. ABS SEQUENCE CONTROL WITH SUB-

ARU SELECT MONITOR

NOTE:

In the event of any trouble, the ABS sequence con-

trol will not operate.

1) Connect the Subaru Select Monitor to data link

connector under the driver's side instrument panel

lower cover.

2) Turn the ignition switch ON.

3) Set the Subaru Select Monitor switch to ON.

4) Set the Subaru Select Monitor to “Brake Control”

mode.

5) When the “Function check sequence” is select-

ed, the “ABS sequence control” will start.

6) Execute the following operations when the mes-

sage “Press the brake pedal so that the brake ped-

al force is between 100 and 150 kgf” is displayed.

(1) [When the brake tester is used, press brake

pedal pad with a force of 1,000 N (102 kgf, 225

lb). ]

(2) When using a pressure gauge, press the

brake pedal so that the pressure gauge indi-

cates 3,500 kPa (36 kg/cm2, 511 psi).

7) “Press the “YES” key” will be displayed. Press

the [YES] key.

8) The brake system being operated is displayed

on the Subaru Select Monitor.