ECU SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 709 of 2453

WW-14

Wiper Relay Unit

WIPER AND WASHER SYSTEMS

6. Wiper Relay Unit

A: REMOVAL

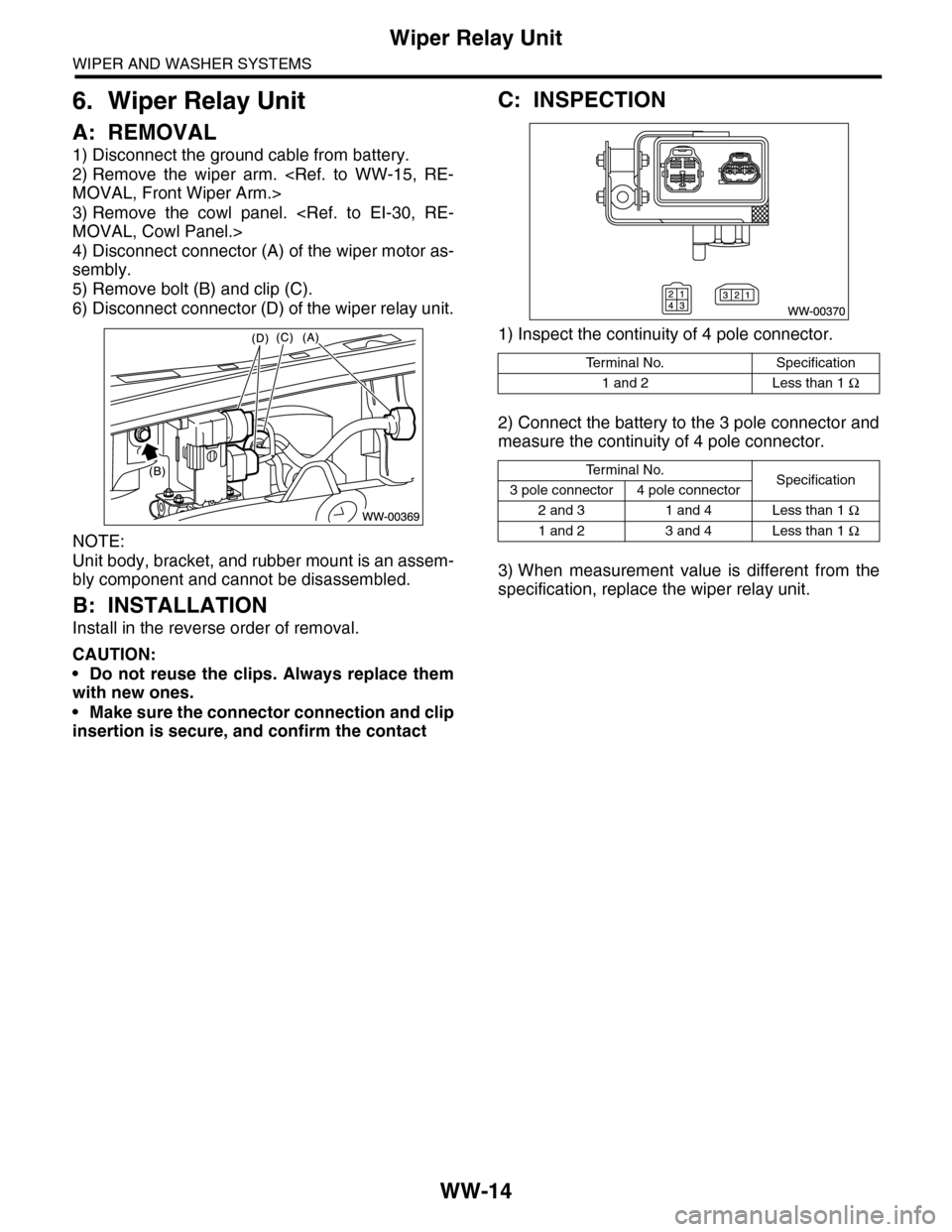

1) Disconnect the ground cable from battery.

2) Remove the wiper arm.

3) Remove the cowl panel.

4) Disconnect connector (A) of the wiper motor as-

sembly.

5) Remove bolt (B) and clip (C).

6) Disconnect connector (D) of the wiper relay unit.

NOTE:

Unit body, bracket, and rubber mount is an assem-

bly component and cannot be disassembled.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

•Do not reuse the clips. Always replace them

with new ones.

•Make sure the connector connection and clip

insertion is secure, and confirm the contact

C: INSPECTION

1) Inspect the continuity of 4 pole connector.

2) Connect the battery to the 3 pole connector and

measure the continuity of 4 pole connector.

3) When measurement value is different from the

specification, replace the wiper relay unit.

Te r m i n a l N o . S p e c i f i c a t i o n

1 and 2 Less than 1 Ω

Te r m i n a l N o .Specification3 pole connector 4 pole connector

2 and 3 1 and 4 Less than 1 Ω

1 and 2 3 and 4 Less than 1 Ω

Page 725 of 2453

BR-11

General Description

BRAKE

C: CAUTION

Please clearly understand and adhere to the follow-

ing general precautions. They must be strictly fol-

lowed to avoid any injury to the person doing the

work or people in the area.

1. OPERATION

•Wear work clothing, including a cap, protective

goggles and protective shoes during operation.

•Before removal, installation or disassembly, be

sure to clarify the failure. Avoid unnecessary re-

moval, installation, disassembly and replacement.

•Use SUBARU genuine grease etc. or equivalent.

Do not mix grease etc. with that of another grade or

from other manufacturers.

•Before securing a part in a vise, place cushioning

material such as wood blocks, aluminum plate or

cloth between the part and the vise.

•Be sure to tighten fasteners including bolts and

nuts to the specified torque.

•Place shop jacks or rigid racks at the specified

points.

2. OIL

When handling oil, follow the rules below to prevent

unexpected accidents.

•Prepare container and waste cloths when per-

forming work which oil could possibly spill. If oil

spills, wipe it off immediately to prevent from pene-

trating into floor or flowing outside, for environmen-

tal protection.

•Follow all government and local regulations con-

cerning waste disposal.

3. BRAKE FLUID

If brake fluid gets in your eyes or on your skin, do

the following:

•Wash eyes and seek immediate medical atten-

tion.

•Wash your skin with soap and then rinse thor-

oughly with water.

Follow all government and local regulations con-

cerning waste disposal.

D: PREPARATION TOOL

1. GENERAL TOOL

TOOL NAME REMARKS

Snap ring pliers Used for removing and installing snap rings.

Page 728 of 2453

BR-14

Front Disc Rotor

BRAKE

3. Front Disc Rotor

A: REMOVAL

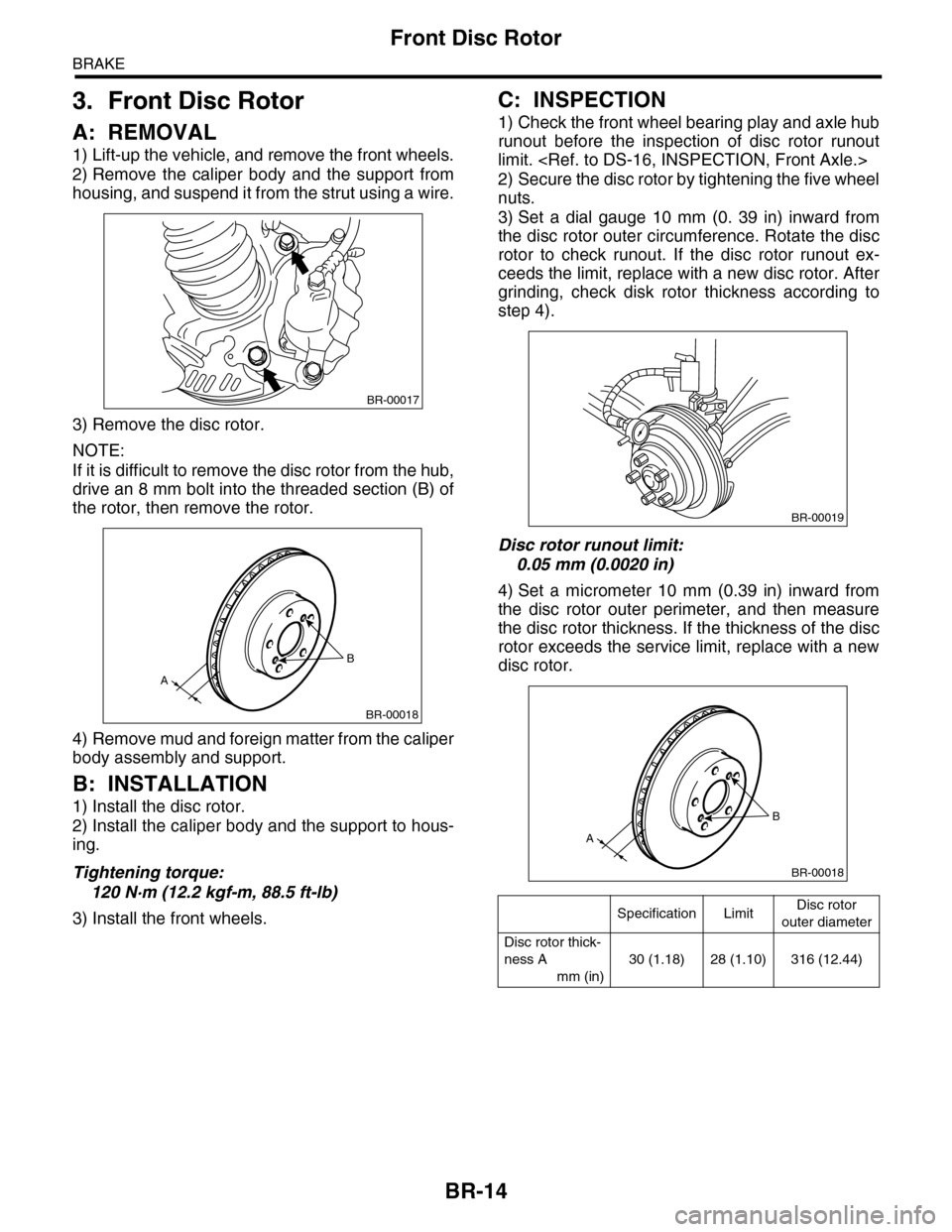

1) Lift-up the vehicle, and remove the front wheels.

2) Remove the caliper body and the support from

housing, and suspend it from the strut using a wire.

3) Remove the disc rotor.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive an 8 mm bolt into the threaded section (B) of

the rotor, then remove the rotor.

4) Remove mud and foreign matter from the caliper

body assembly and support.

B: INSTALLATION

1) Install the disc rotor.

2) Install the caliper body and the support to hous-

ing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

3) Install the front wheels.

C: INSPECTION

1) Check the front wheel bearing play and axle hub

runout before the inspection of disc rotor runout

limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

4) Set a micrometer 10 mm (0.39 in) inward from

the disc rotor outer perimeter, and then measure

the disc rotor thickness. If the thickness of the disc

rotor exceeds the service limit, replace with a new

disc rotor.

BR-00017

B

A

BR-00018

Specification LimitDisc rotor

outer diameter

Disc rotor thick-

ness A

mm (in)

30 (1.18) 28 (1.10) 316 (12.44)

BR-00019

B

A

BR-00018

Page 729 of 2453

BR-15

Front Disc Brake Assembly

BRAKE

4. Front Disc Brake Assembly

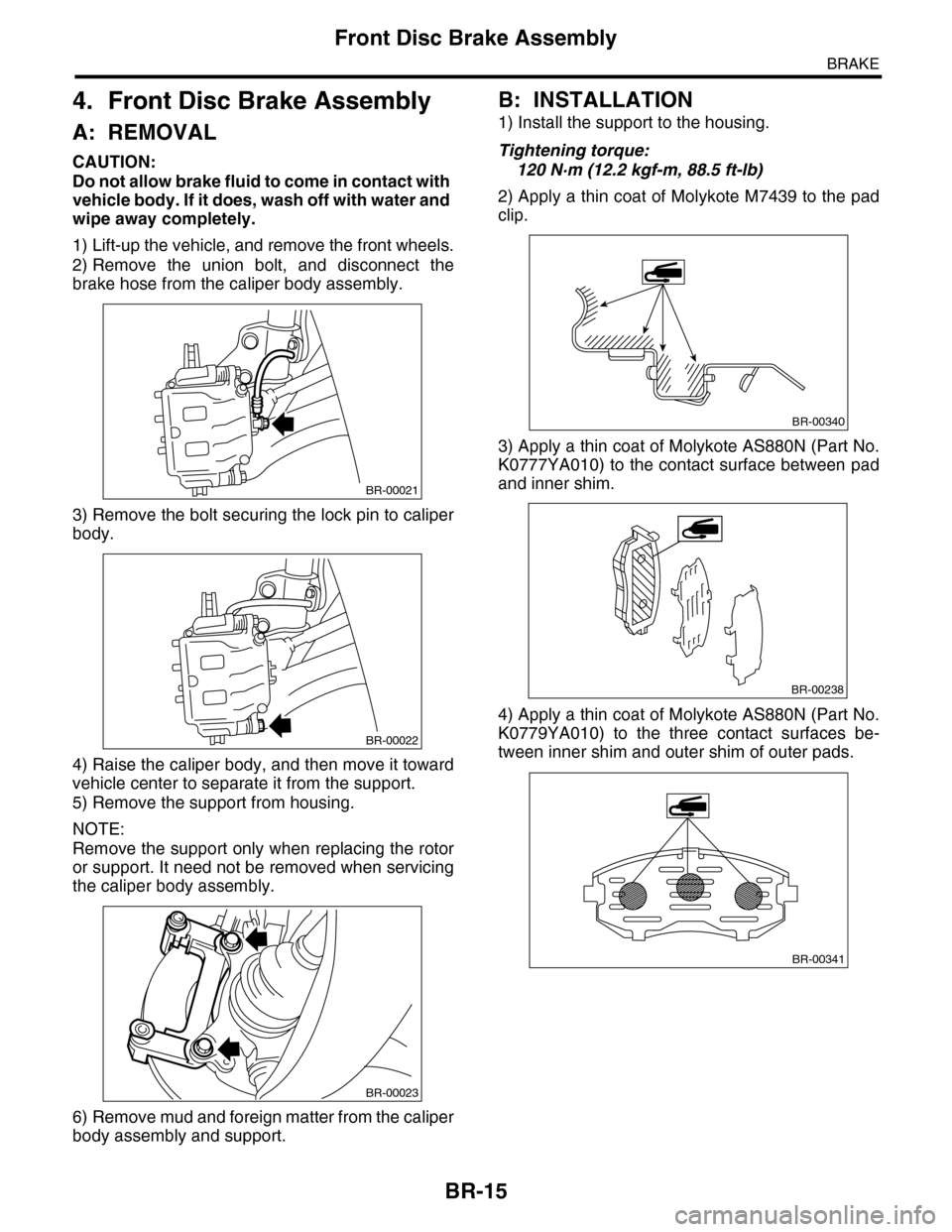

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with

vehicle body. If it does, wash off with water and

wipe away completely.

1) Lift-up the vehicle, and remove the front wheels.

2) Remove the union bolt, and disconnect the

brake hose from the caliper body assembly.

3) Remove the bolt securing the lock pin to caliper

body.

4) Raise the caliper body, and then move it toward

vehicle center to separate it from the support.

5) Remove the support from housing.

NOTE:

Remove the support only when replacing the rotor

or support. It need not be removed when servicing

the caliper body assembly.

6) Remove mud and foreign matter from the caliper

body assembly and support.

B: INSTALLATION

1) Install the support to the housing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

2) Apply a thin coat of Molykote M7439 to the pad

clip.

3) Apply a thin coat of Molykote AS880N (Part No.

K0777YA010) to the contact surface between pad

and inner shim.

4) Apply a thin coat of Molykote AS880N (Part No.

K0779YA010) to the three contact surfaces be-

tween inner shim and outer shim of outer pads.

BR-00021

BR-00022

BR-00023

BR-00340

BR-00238

BR-00341

Page 734 of 2453

BR-20

Rear Disc Rotor

BRAKE

6. Rear Disc Rotor

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Release the parking brake.

3) Remove the two mounting bolts, and remove the

rear disc brake assembly.

4) Suspend the rear disk brake assembly so that

the hose is not stretched.

5) Remove the rear disk brake rotor.

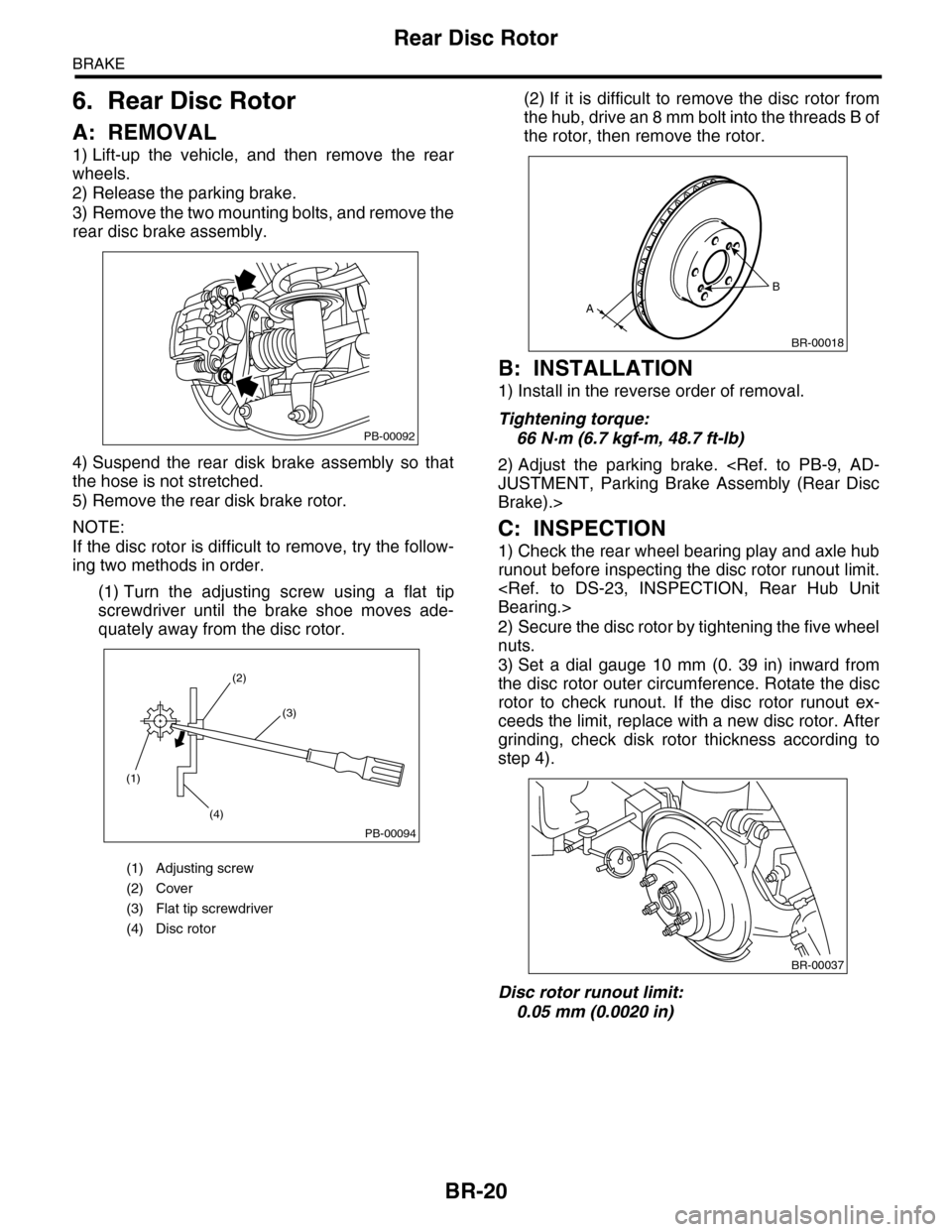

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

(2) If it is difficult to remove the disc rotor from

the hub, drive an 8 mm bolt into the threads B of

the rotor, then remove the rotor.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Adjust the parking brake.

Brake).>

C: INSPECTION

1) Check the rear wheel bearing play and axle hub

runout before inspecting the disc rotor runout limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

(1) Adjusting screw

(2) Cover

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094

B

A

BR-00018

BR-00037

Page 738 of 2453

BR-24

Master Cylinder

BRAKE

8. Master Cylinder

A: REMOVAL

CAUTION:

Do not allow brake fluid to come in contact with

vehicle body. If it does, wash off with water and

wipe away completely.

1) Drain brake fluid from the reservoir tank com-

pletely.

2) Disconnect the harness connector of the fluid

level gauge.

3) Remove the brake pipe from the master cylinder.

4) Remove the master cylinder mounting nuts, and

remove the master cylinder from the brake booster.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

Master cylinder mounting nut

25 N·m (2.5 kgf-m, 18.4 ft-lb)

Brake pipe

19 N·m (1.9 kgf-m, 14.0 ft-lb)

CAUTION:

Be sure to use recommended brake fluid.

2) Bleed air from brake system.

C: REPLACEMENT

1) Remove mud and dirt from the surface of brake

master cylinder.

2) Secure the master cylinder in a vise.

NOTE:

To avoid damaging the master cylinder, place be-

tween aluminum plates or other material when

holding with a vise.

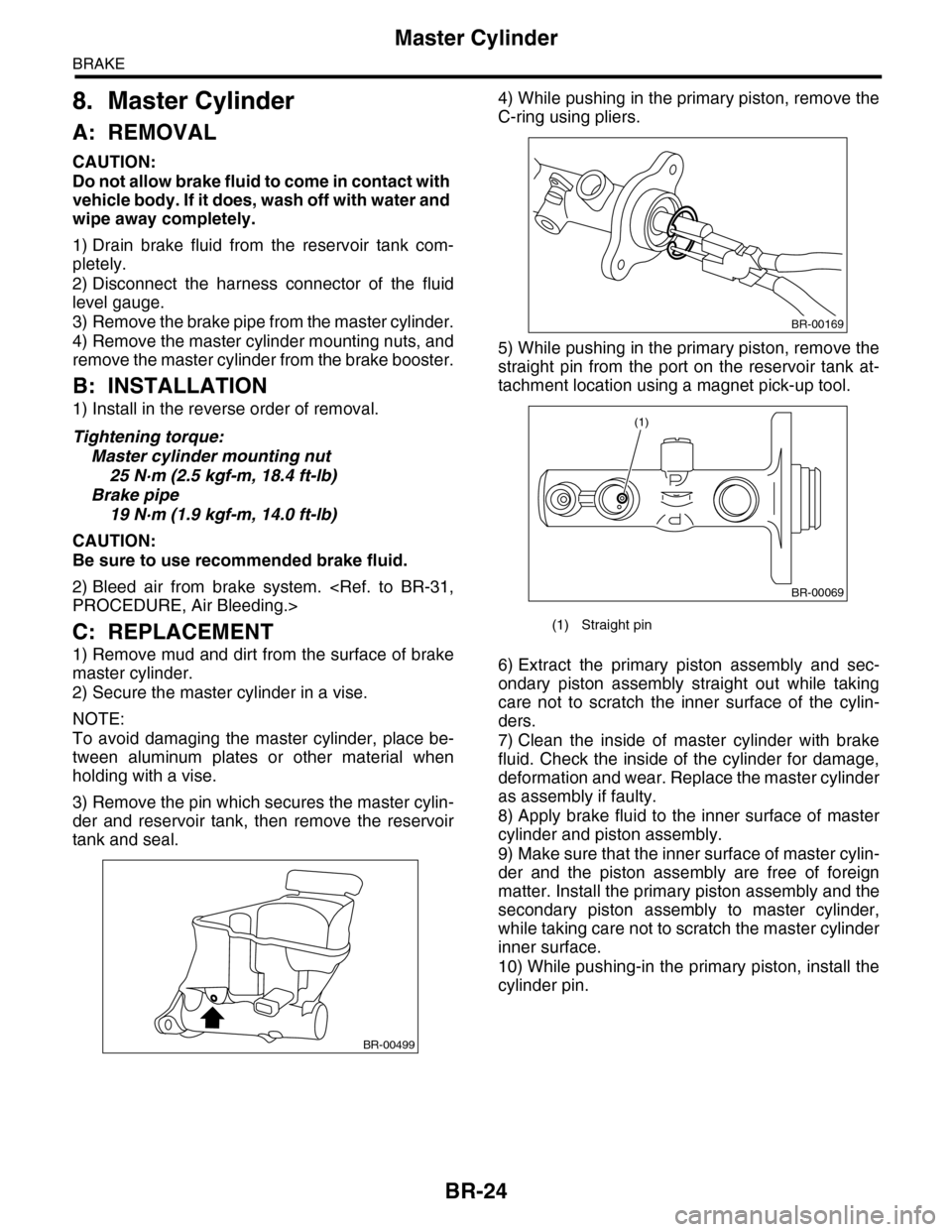

3) Remove the pin which secures the master cylin-

der and reservoir tank, then remove the reservoir

tank and seal.

4) While pushing in the primary piston, remove the

C-ring using pliers.

5) While pushing in the primary piston, remove the

straight pin from the port on the reservoir tank at-

tachment location using a magnet pick-up tool.

6) Extract the primary piston assembly and sec-

ondary piston assembly straight out while taking

care not to scratch the inner surface of the cylin-

ders.

7) Clean the inside of master cylinder with brake

fluid. Check the inside of the cylinder for damage,

deformation and wear. Replace the master cylinder

as assembly if faulty.

8) Apply brake fluid to the inner surface of master

cylinder and piston assembly.

9) Make sure that the inner surface of master cylin-

der and the piston assembly are free of foreign

matter. Install the primary piston assembly and the

secondary piston assembly to master cylinder,

while taking care not to scratch the master cylinder

inner surface.

10) While pushing-in the primary piston, install the

cylinder pin.

BR-00499

(1) Straight pin

BR-00169

(1)

BR-00069

Page 739 of 2453

BR-25

Master Cylinder

BRAKE

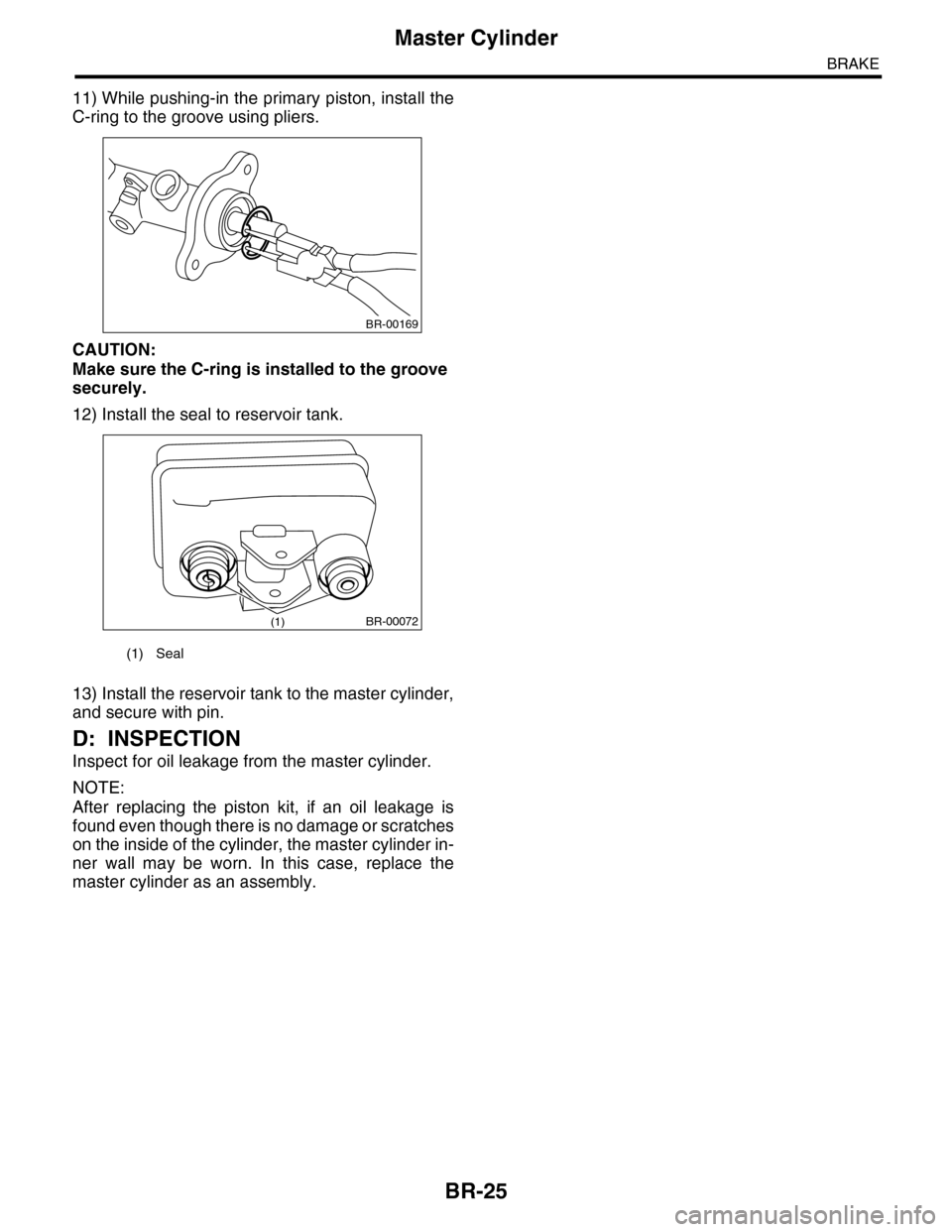

11) While pushing-in the primary piston, install the

C-ring to the groove using pliers.

CAUTION:

Make sure the C-ring is installed to the groove

securely.

12) Install the seal to reservoir tank.

13) Install the reservoir tank to the master cylinder,

and secure with pin.

D: INSPECTION

Inspect for oil leakage from the master cylinder.

NOTE:

After replacing the piston kit, if an oil leakage is

found even though there is no damage or scratches

on the inside of the cylinder, the master cylinder in-

ner wall may be worn. In this case, replace the

master cylinder as an assembly.

(1) Seal

BR-00169

(1) BR-00072

Page 741 of 2453

BR-27

Brake Booster

BRAKE

B: INSTALLATION

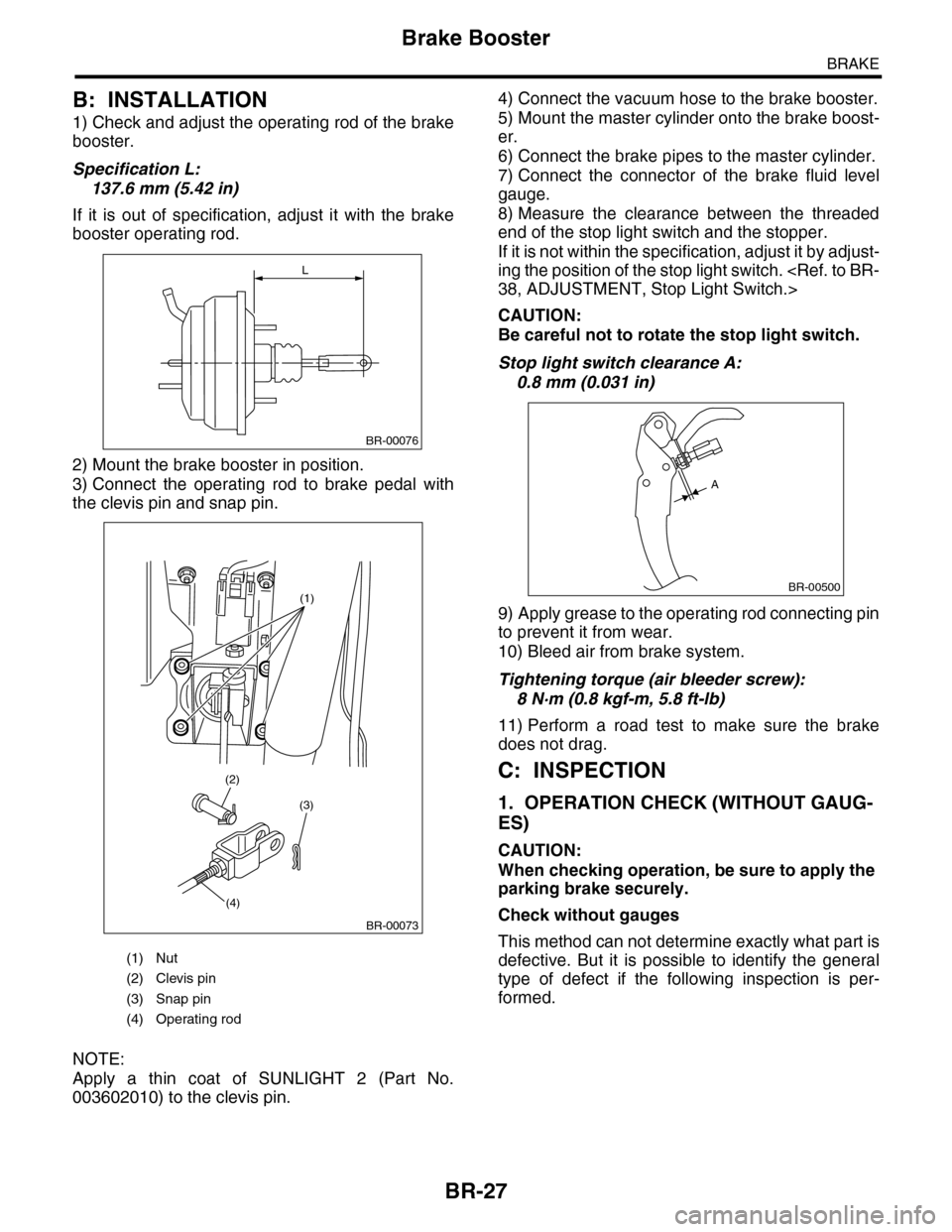

1) Check and adjust the operating rod of the brake

booster.

Specification L:

137.6 mm (5.42 in)

If it is out of specification, adjust it with the brake

booster operating rod.

2) Mount the brake booster in position.

3) Connect the operating rod to brake pedal with

the clevis pin and snap pin.

NOTE:

Apply a thin coat of SUNLIGHT 2 (Part No.

003602010) to the clevis pin.

4) Connect the vacuum hose to the brake booster.

5) Mount the master cylinder onto the brake boost-

er.

6) Connect the brake pipes to the master cylinder.

7) Connect the connector of the brake fluid level

gauge.

8) Measure the clearance between the threaded

end of the stop light switch and the stopper.

If it is not within the specification, adjust it by adjust-

ing the position of the stop light switch.

CAUTION:

Be careful not to rotate the stop light switch.

Stop light switch clearance A:

0.8 mm (0.031 in)

9) Apply grease to the operating rod connecting pin

to prevent it from wear.

10) Bleed air from brake system.

Tightening torque (air bleeder screw):

8 N·m (0.8 kgf-m, 5.8 ft-lb)

11) Perform a road test to make sure the brake

does not drag.

C: INSPECTION

1. OPERATION CHECK (WITHOUT GAUG-

ES)

CAUTION:

When checking operation, be sure to apply the

parking brake securely.

Check without gauges

This method can not determine exactly what part is

defective. But it is possible to identify the general

type of defect if the following inspection is per-

formed.

(1) Nut

(2) Clevis pin

(3) Snap pin

(4) Operating rod

L

BR-00076

(1)

(3)

(4)

(2)

BR-00073

BR-00500

A

Page 742 of 2453

BR-28

Brake Booster

BRAKE

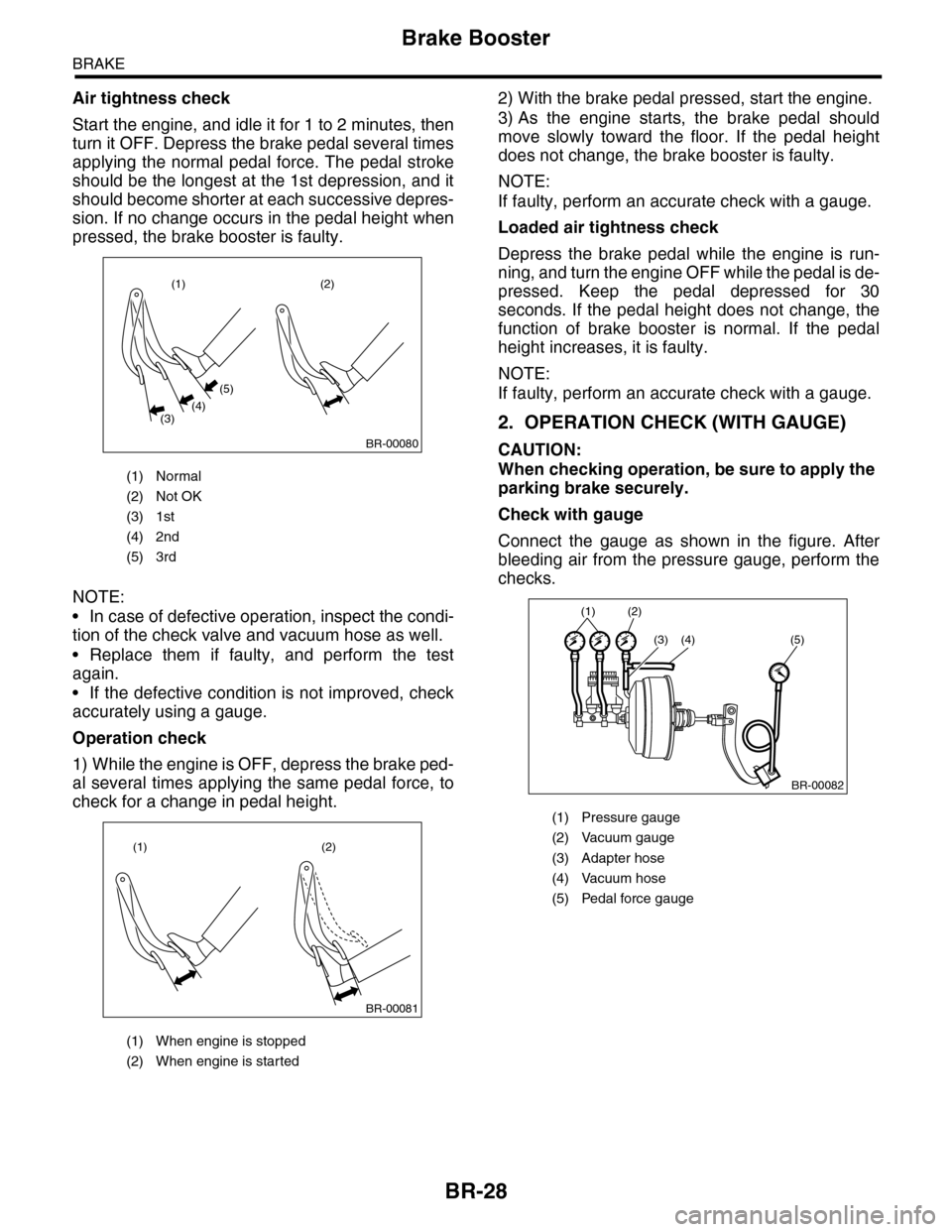

Air tightness check

Start the engine, and idle it for 1 to 2 minutes, then

turn it OFF. Depress the brake pedal several times

applying the normal pedal force. The pedal stroke

should be the longest at the 1st depression, and it

should become shorter at each successive depres-

sion. If no change occurs in the pedal height when

pressed, the brake booster is faulty.

NOTE:

•In case of defective operation, inspect the condi-

tion of the check valve and vacuum hose as well.

•Replace them if faulty, and perform the test

again.

•If the defective condition is not improved, check

accurately using a gauge.

Operation check

1) While the engine is OFF, depress the brake ped-

al several times applying the same pedal force, to

check for a change in pedal height.

2) With the brake pedal pressed, start the engine.

3) As the engine starts, the brake pedal should

move slowly toward the floor. If the pedal height

does not change, the brake booster is faulty.

NOTE:

If faulty, perform an accurate check with a gauge.

Loaded air tightness check

Depress the brake pedal while the engine is run-

ning, and turn the engine OFF while the pedal is de-

pressed. Keep the pedal depressed for 30

seconds. If the pedal height does not change, the

function of brake booster is normal. If the pedal

height increases, it is faulty.

NOTE:

If faulty, perform an accurate check with a gauge.

2. OPERATION CHECK (WITH GAUGE)

CAUTION:

When checking operation, be sure to apply the

parking brake securely.

Check with gauge

Connect the gauge as shown in the figure. After

bleeding air from the pressure gauge, perform the

checks.

(1) Normal

(2) Not OK

(3) 1st

(4) 2nd

(5) 3rd

(1) When engine is stopped

(2) When engine is started

(1)

(3)(4)

(5)

(2)

BR-00080

(1) (2)

BR-00081

(1) Pressure gauge

(2) Vacuum gauge

(3) Adapter hose

(4) Vacuum hose

(5) Pedal force gauge

(1) (2)

(3) (4) (5)

BR-00082

Page 745 of 2453

BR-31

Air Bleeding

BRAKE

11.Air Bleeding

A: PROCEDURE

CAUTION:

•Do not let brake fluid come into contact with

the painted surface of the vehicle body. Wash

away with water immediately and wipe off if it is

spilled by accident.

•Avoid mixing brake fluids of different brands

to prevent fluid performance from degrading.

•Be careful not to allow dirt or dust to enter the

reservoir tank.

1. MASTER CYLINDER

NOTE:

•When the master cylinder is disassembled or the

reservoir tank is empty, bleed the master cylinder.

•If bleeding of the master cylinder is not neces-

sary, omit the following procedures, and perform

bleeding of the brake line.

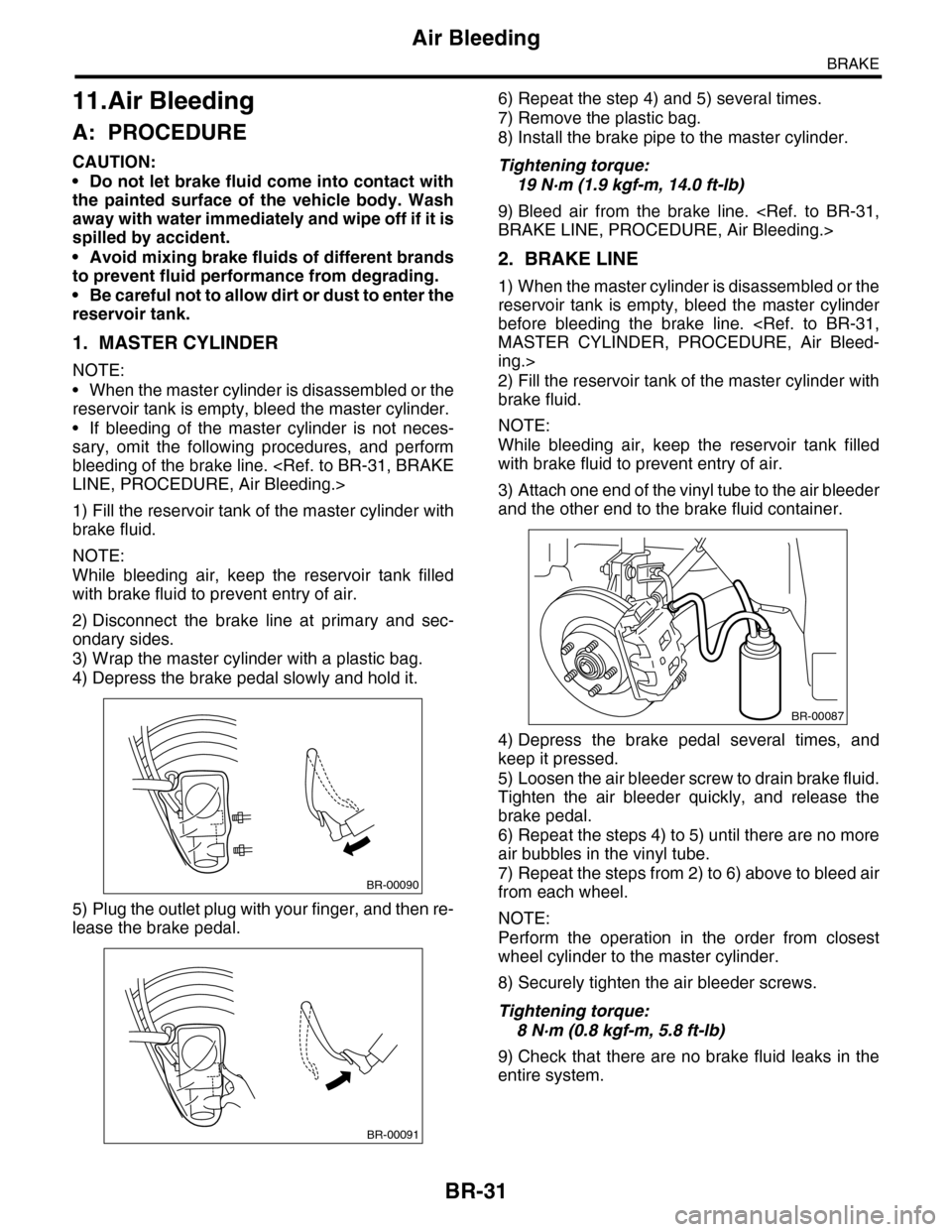

1) Fill the reservoir tank of the master cylinder with

brake fluid.

NOTE:

While bleeding air, keep the reservoir tank filled

with brake fluid to prevent entry of air.

2) Disconnect the brake line at primary and sec-

ondary sides.

3) Wrap the master cylinder with a plastic bag.

4) Depress the brake pedal slowly and hold it.

5) Plug the outlet plug with your finger, and then re-

lease the brake pedal.

6) Repeat the step 4) and 5) several times.

7) Remove the plastic bag.

8) Install the brake pipe to the master cylinder.

Tightening torque:

19 N·m (1.9 kgf-m, 14.0 ft-lb)

9) Bleed air from the brake line.

2. BRAKE LINE

1) When the master cylinder is disassembled or the

reservoir tank is empty, bleed the master cylinder

before bleeding the brake line.

ing.>

2) Fill the reservoir tank of the master cylinder with

brake fluid.

NOTE:

While bleeding air, keep the reservoir tank filled

with brake fluid to prevent entry of air.

3) Attach one end of the vinyl tube to the air bleeder

and the other end to the brake fluid container.

4) Depress the brake pedal several times, and

keep it pressed.

5) Loosen the air bleeder screw to drain brake fluid.

Tighten the air bleeder quickly, and release the

brake pedal.

6) Repeat the steps 4) to 5) until there are no more

air bubbles in the vinyl tube.

7) Repeat the steps from 2) to 6) above to bleed air

from each wheel.

NOTE:

Perform the operation in the order from closest

wheel cylinder to the master cylinder.

8) Securely tighten the air bleeder screws.

Tightening torque:

8 N·m (0.8 kgf-m, 5.8 ft-lb)

9) Check that there are no brake fluid leaks in the

entire system.

BR-00090

BR-00091

BR-00087