Diff id SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 472 of 2453

LAN(diag)-16

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

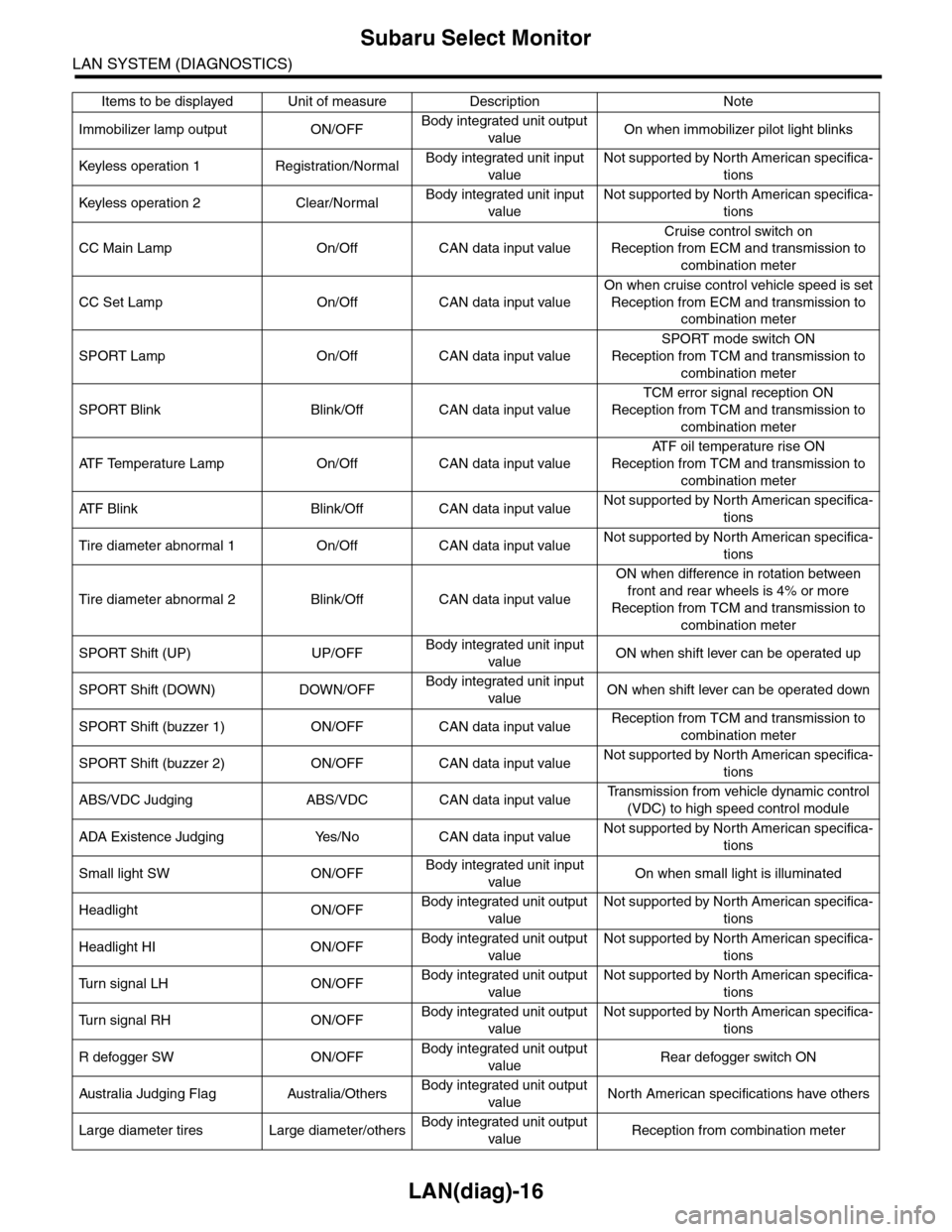

Immobilizer lamp output ON/OFFBody integrated unit output

valueOn when immobilizer pilot light blinks

Keyless operation 1 Registration/Nor malBody integrated unit input

value

Not supported by North American specifica-

tions

Keyless operation 2 Clear/Nor malBody integrated unit input

value

Not supported by North American specifica-

tions

CC Main Lamp On/Off CAN data input value

Cruise control switch on

Reception from ECM and transmission to

combination meter

CC Set Lamp On/Off CAN data input value

On when cruise control vehicle speed is set

Reception from ECM and transmission to

combination meter

SPORT Lamp On/Off CAN data input value

SPORT mode switch ON

Reception from TCM and transmission to

combination meter

SPORT Blink Blink/Off CAN data input value

TCM error signal reception ON

Reception from TCM and transmission to

combination meter

AT F Te m p e r a t u r e L a m p O n / O f f C A N d a t a i n p u t v a l u e

AT F o i l t e m p e r a t u r e r i s e O N

Reception from TCM and transmission to

combination meter

AT F B l i n k B l i n k / O f f C A N d a t a i n p u t v a l u eNot supported by North American specifica-

tions

Tire diameter abnormal 1 On/Off CAN data input valueNot supported by North American specifica-

tions

Tire diameter abnormal 2 Blink/Off CAN data input value

ON when difference in rotation between

front and rear wheels is 4% or more

Reception from TCM and transmission to

combination meter

SPORT Shift (UP) UP/OFFBody integrated unit input

valueON when shift lever can be operated up

SPORT Shift (DOWN) DOWN/OFFBody integrated unit input

valueON when shift lever can be operated down

SPORT Shift (buzzer 1) ON/OFF CAN data input valueReception from TCM and transmission to

combination meter

SPORT Shift (buzzer 2) ON/OFF CAN data input valueNot supported by North American specifica-

tions

ABS/VDC Judging ABS/VDC CAN data input valueTr a n s m i s s i o n f r o m v e h i c l e d y n a m i c c o n t r o l

(VDC) to high speed control module

ADA Existence Judging Yes/No CAN data input valueNot supported by North American specifica-

tions

Small light SW ON/OFFBody integrated unit input

valueOn when small light is illuminated

Headlight ON/OFFBody integrated unit output

value

Not supported by North American specifica-

tions

Headlight HI ON/OFFBody integrated unit output

value

Not supported by North American specifica-

tions

Tu r n s i g n a l L H O N / O F FBody integrated unit output

value

Not supported by North American specifica-

tions

Tu r n s i g n a l R H O N / O F FBody integrated unit output

value

Not supported by North American specifica-

tions

R defogger SW ON/OFFBody integrated unit output

valueRear defogger switch ON

Australia Judging Flag Australia/OthersBody integrated unit output

valueNorth American specifications have others

Large diameter tires Large diameter/othersBody integrated unit output

valueReception from combination meter

Items to be displayed Unit of measure Description Note

Page 475 of 2453

LAN(diag)-19

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

6. REGISTRATION BODY INTEGRATED

UNIT (EQUIPMENT SETTING)

CAUTION:

Body integrated unit is core of LAN system, and

also can select the function of all vehicle sys-

tem control. It is possible to control the original

functions of vehicle when registrations of body

integrated unit and function setting are corre-

sponded to vehicle equipment.

If registrations and function setting are differ-

ent from vehicle equipment, vehicle system

does not operate normally and diagnosis can-

not be performed correctly. Pay attention to fol-

lowing item.

•Be sure to correspond registrations and

function settings to vehicle equipment.

•Do not change the settings of vehicle improp-

erly.

•Confirm key illumination does not blink or

“Factory initial setting” of body integrated unit

registrations is “Market.” If “Factory initial set-

ting” is set to “Factory,” key illumination blinks

with ignition key turned to ON to give warning

of unconfirmed settings.

•Key illumination does not blink with ignition

switch turned to ON and go off with door

closed.

•Be sure to register immobilizer if body inte-

grated unit is replaced with a new one. (Model

with immobilizer)

•Make a registration of immobilizer when the

parts related to immobilizer have been re-

placed. Refer to the “REGISTRATION MANUAL

FOR IMMOBILIZER”.

•Do not install or register an immobilizer relat-

ed module of other registered vehicles to diag-

nose failures or inspect functions.

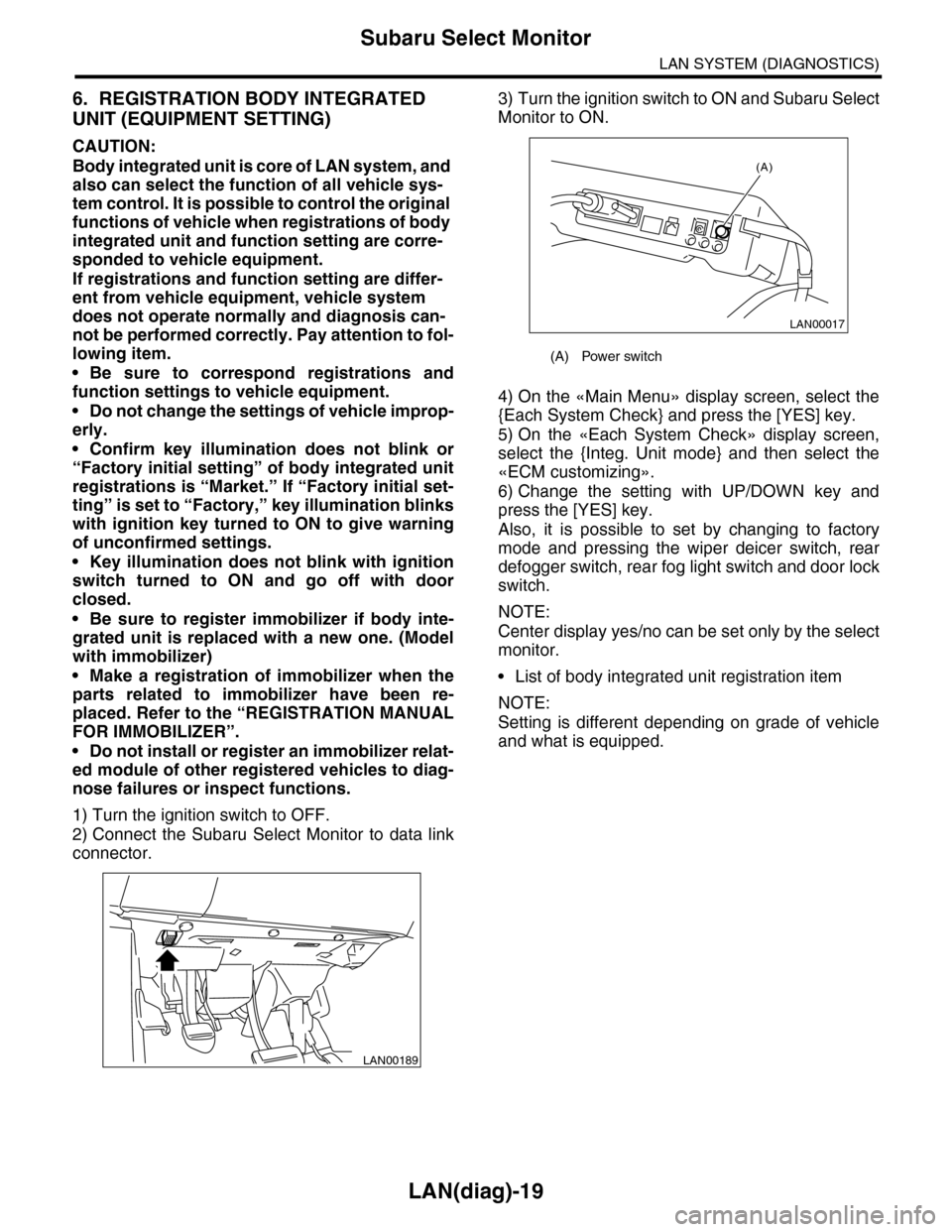

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data link

connector.

3) Turn the ignition switch to ON and Subaru Select

Monitor to ON.

4) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

5) On the «Each System Check» display screen,

select the {Integ. Unit mode} and then select the

«ECM customizing».

6) Change the setting with UP/DOWN key and

press the [YES] key.

Also, it is possible to set by changing to factory

mode and pressing the wiper deicer switch, rear

defogger switch, rear fog light switch and door lock

switch.

NOTE:

Center display yes/no can be set only by the select

monitor.

•List of body integrated unit registration item

NOTE:

Setting is different depending on grade of vehicle

and what is equipped.

LAN00189

(A) Power switch

LAN00017

(A)

Page 476 of 2453

LAN(diag)-20

Subaru Select Monitor

LAN SYSTEM (DIAGNOSTICS)

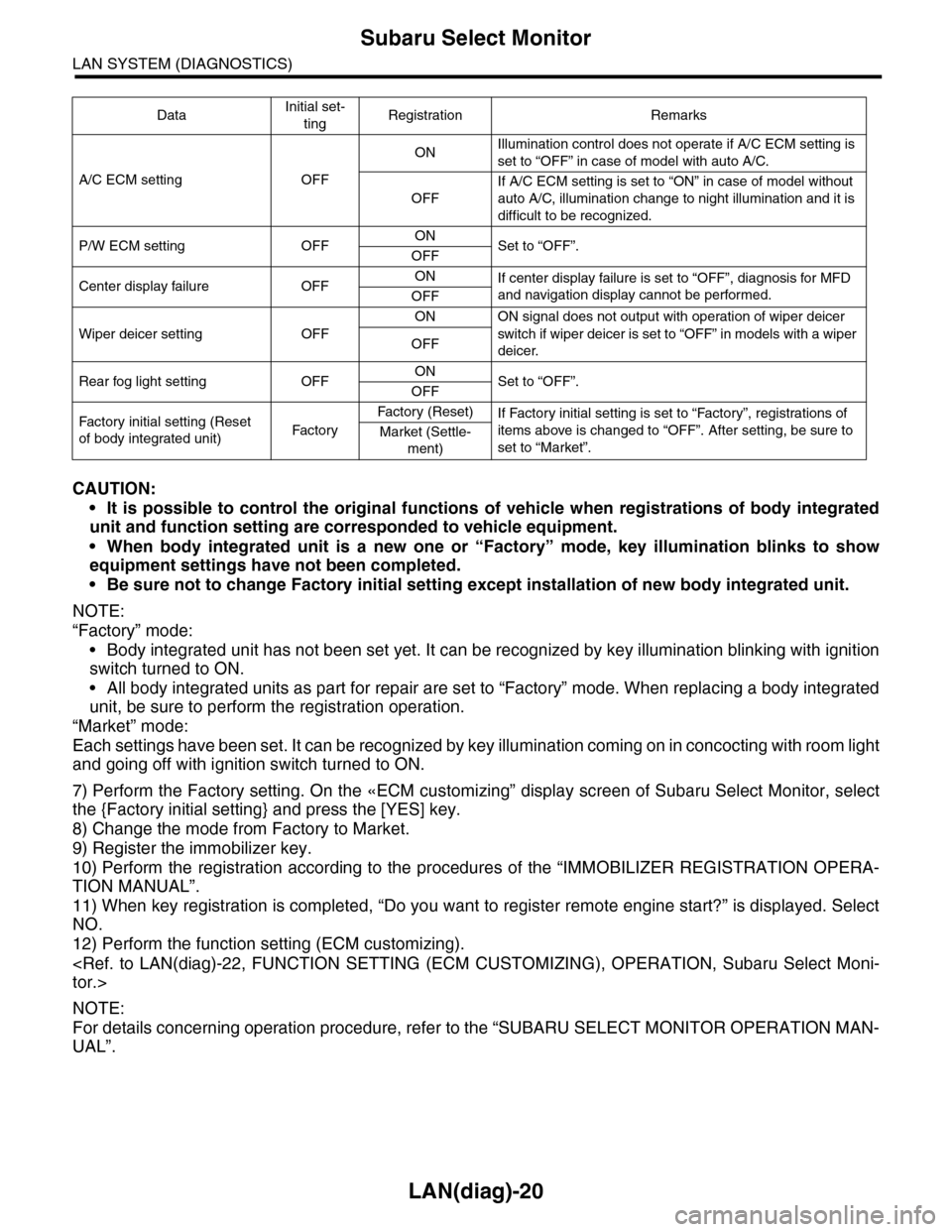

CAUTION:

•It is possible to control the original functions of vehicle when registrations of body integrated

unit and function setting are corresponded to vehicle equipment.

•When body integrated unit is a new one or “Factory” mode, key illumination blinks to show

equipment settings have not been completed.

•Be sure not to change Factory initial setting except installation of new body integrated unit.

NOTE:

“Factory” mode:

•Body integrated unit has not been set yet. It can be recognized by key illumination blinking with ignition

switch turned to ON.

•All body integrated units as part for repair are set to “Factory” mode. When replacing a body integrated

unit, be sure to perform the registration operation.

“Market” mode:

Each settings have been set. It can be recognized by key illumination coming on in concocting with room light

and going off with ignition switch turned to ON.

7) Perform the Factory setting. On the «ECM customizing” display screen of Subaru Select Monitor, select

the {Factory initial setting} and press the [YES] key.

8) Change the mode from Factory to Market.

9) Register the immobilizer key.

10) Perform the registration according to the procedures of the “IMMOBILIZER REGISTRATION OPERA-

TION MANUAL”.

11) When key registration is completed, “Do you want to register remote engine start?” is displayed. Select

NO.

12) Perform the function setting (ECM customizing).

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MAN-

UAL”.

DataInitial set-

tingRegistration Remarks

A/C ECM setting OFF

ONIllumination control does not operate if A/C ECM setting is

set to “OFF” in case of model with auto A/C.

OFF

If A/C ECM setting is set to “ON” in case of model without

auto A/C, illumination change to night illumination and it is

difficult to be recognized.

P/W ECM setting OFFONSet to “OFF”.OFF

Center display failure OFFONIf center display failure is set to “OFF”, diagnosis for MFD

and navigation display cannot be performed.OFF

Wiper deicer setting OFF

ON ON signal does not output with operation of wiper deicer

switch if wiper deicer is set to “OFF” in models with a wiper

deicer.OFF

Rear fog light setting OFFONSet to “OFF”.OFF

Fac t or y in i ti a l s et t i ng ( Res et

of body integrated unit)Fac to r y

Fa ct or y ( Re se t )If Factory initial setting is set to “Factory”, registrations of

items above is changed to “OFF”. After setting, be sure to

set to “Market”.Market (Settle-

ment)

Page 606 of 2453

SB-9

Seat Belt Warning System

SEAT BELT SYSTEM

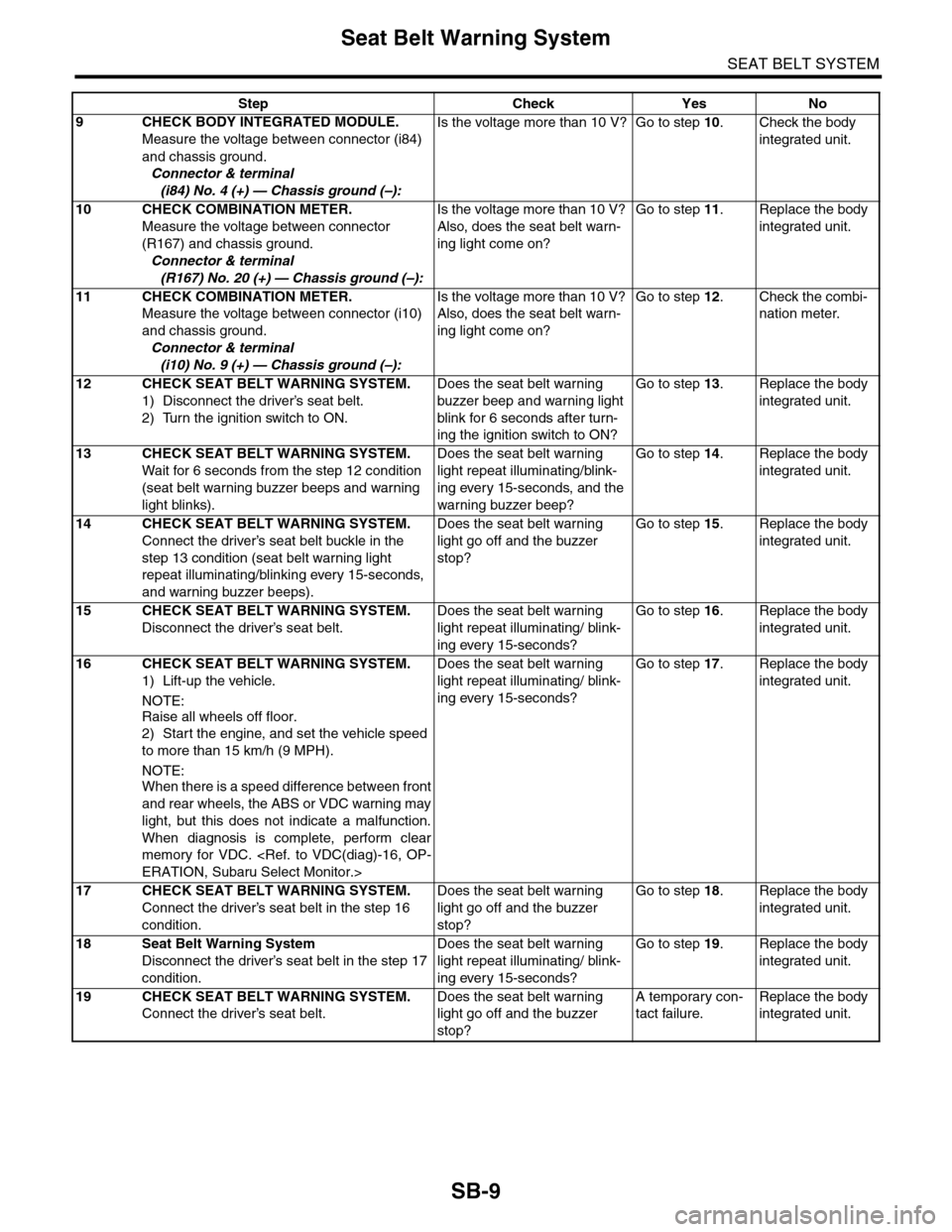

9CHECK BODY INTEGRATED MODULE.

Measure the voltage between connector (i84)

and chassis ground.

Connector & terminal

(i84) No. 4 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 10.Check the body

integrated unit.

10 CHECK COMBINATION METER.

Measure the voltage between connector

(R167) and chassis ground.

Connector & terminal

(R167) No. 20 (+) — Chassis ground (–):

Is the voltage more than 10 V?

Also, does the seat belt warn-

ing light come on?

Go to step 11.Replace the body

integrated unit.

11 CHECK COMBINATION METER.

Measure the voltage between connector (i10)

and chassis ground.

Connector & terminal

(i10) No. 9 (+) — Chassis ground (–):

Is the voltage more than 10 V?

Also, does the seat belt warn-

ing light come on?

Go to step 12.Check the combi-

nation meter.

12 CHECK SEAT BELT WARNING SYSTEM.

1) Disconnect the driver’s seat belt.

2) Turn the ignition switch to ON.

Does the seat belt warning

buzzer beep and warning light

blink for 6 seconds after turn-

ing the ignition switch to ON?

Go to step 13.Replace the body

integrated unit.

13 CHECK SEAT BELT WARNING SYSTEM.

Wait for 6 seconds from the step 12 condition

(seat belt warning buzzer beeps and warning

light blinks).

Does the seat belt warning

light repeat illuminating/blink-

ing every 15-seconds, and the

warning buzzer beep?

Go to step 14.Replace the body

integrated unit.

14 CHECK SEAT BELT WARNING SYSTEM.

Connect the driver’s seat belt buckle in the

step 13 condition (seat belt warning light

repeat illuminating/blinking every 15-seconds,

and warning buzzer beeps).

Does the seat belt warning

light go off and the buzzer

stop?

Go to step 15.Replace the body

integrated unit.

15 CHECK SEAT BELT WARNING SYSTEM.

Disconnect the driver’s seat belt.

Does the seat belt warning

light repeat illuminating/ blink-

ing every 15-seconds?

Go to step 16.Replace the body

integrated unit.

16 CHECK SEAT BELT WARNING SYSTEM.

1) Lift-up the vehicle.

NOTE:

Raise all wheels off floor.

2) Start the engine, and set the vehicle speed

to more than 15 km/h (9 MPH).

NOTE:

When there is a speed difference between front

and rear wheels, the ABS or VDC warning may

light, but this does not indicate a malfunction.

When diagnosis is complete, perform clear

memory for VDC.

Does the seat belt warning

light repeat illuminating/ blink-

ing every 15-seconds?

Go to step 17.Replace the body

integrated unit.

17 CHECK SEAT BELT WARNING SYSTEM.

Connect the driver’s seat belt in the step 16

condition.

Does the seat belt warning

light go off and the buzzer

stop?

Go to step 18.Replace the body

integrated unit.

18 Seat Belt Warning System

Disconnect the driver’s seat belt in the step 17

condition.

Does the seat belt warning

light repeat illuminating/ blink-

ing every 15-seconds?

Go to step 19.Replace the body

integrated unit.

19 CHECK SEAT BELT WARNING SYSTEM.

Connect the driver’s seat belt.

Does the seat belt warning

light go off and the buzzer

stop?

A temporary con-

tact failure.

Replace the body

integrated unit.

Step Check Yes No

Page 681 of 2453

SL-52

Body Integrated Unit

SECURITY AND LOCKS

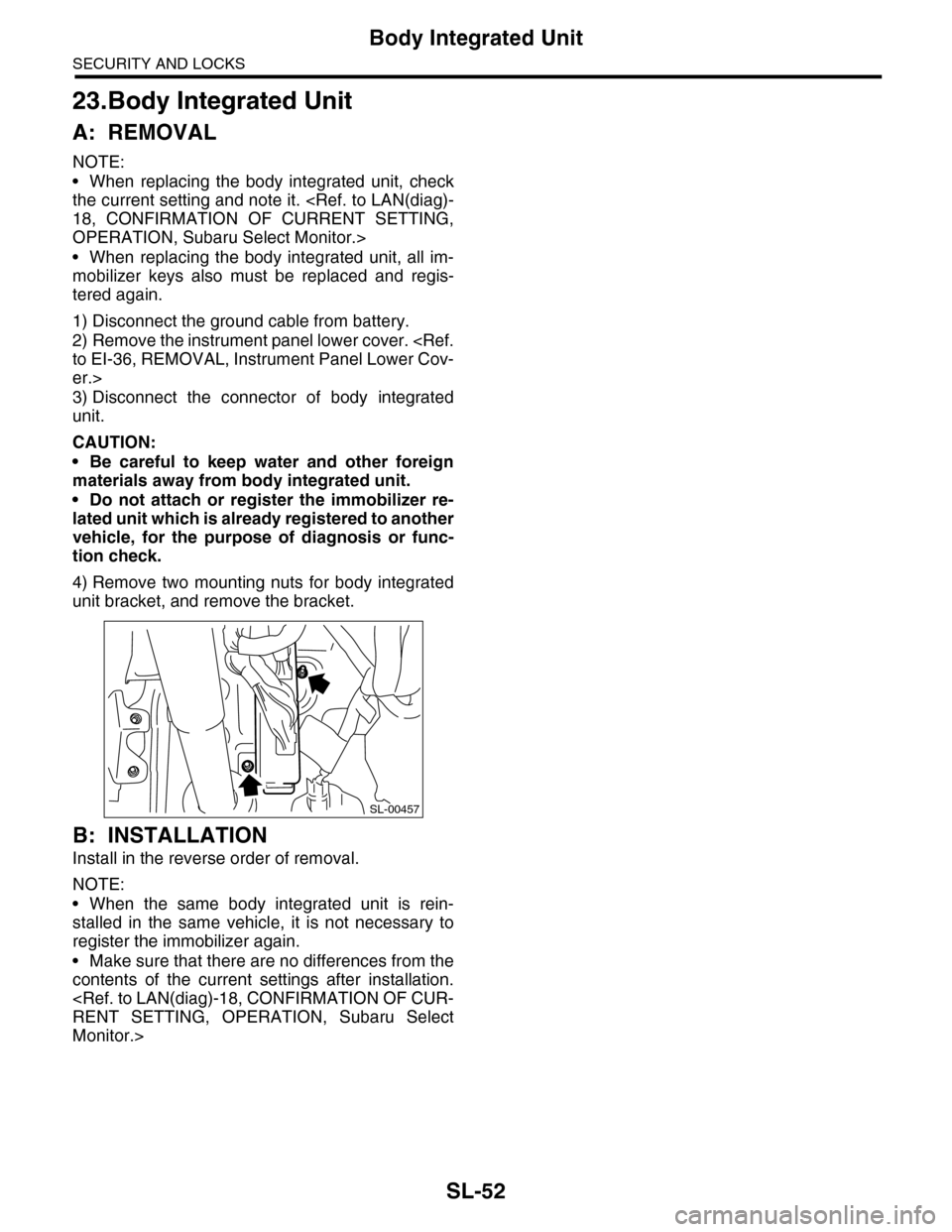

23.Body Integrated Unit

A: REMOVAL

NOTE:

•When replacing the body integrated unit, check

the current setting and note it.

OPERATION, Subaru Select Monitor.>

•When replacing the body integrated unit, all im-

mobilizer keys also must be replaced and regis-

tered again.

1) Disconnect the ground cable from battery.

2) Remove the instrument panel lower cover.

er.>

3) Disconnect the connector of body integrated

unit.

CAUTION:

•Be careful to keep water and other foreign

materials away from body integrated unit.

•Do not attach or register the immobilizer re-

lated unit which is already registered to another

vehicle, for the purpose of diagnosis or func-

tion check.

4) Remove two mounting nuts for body integrated

unit bracket, and remove the bracket.

B: INSTALLATION

Install in the reverse order of removal.

NOTE:

•When the same body integrated unit is rein-

stalled in the same vehicle, it is not necessary to

register the immobilizer again.

•Make sure that there are no differences from the

contents of the current settings after installation.

Monitor.>

SL-00457

Page 689 of 2453

SR-5

Glass Lid

SUNROOF/T-TOP/CONVERTIBLE TOP (SUNROOF)

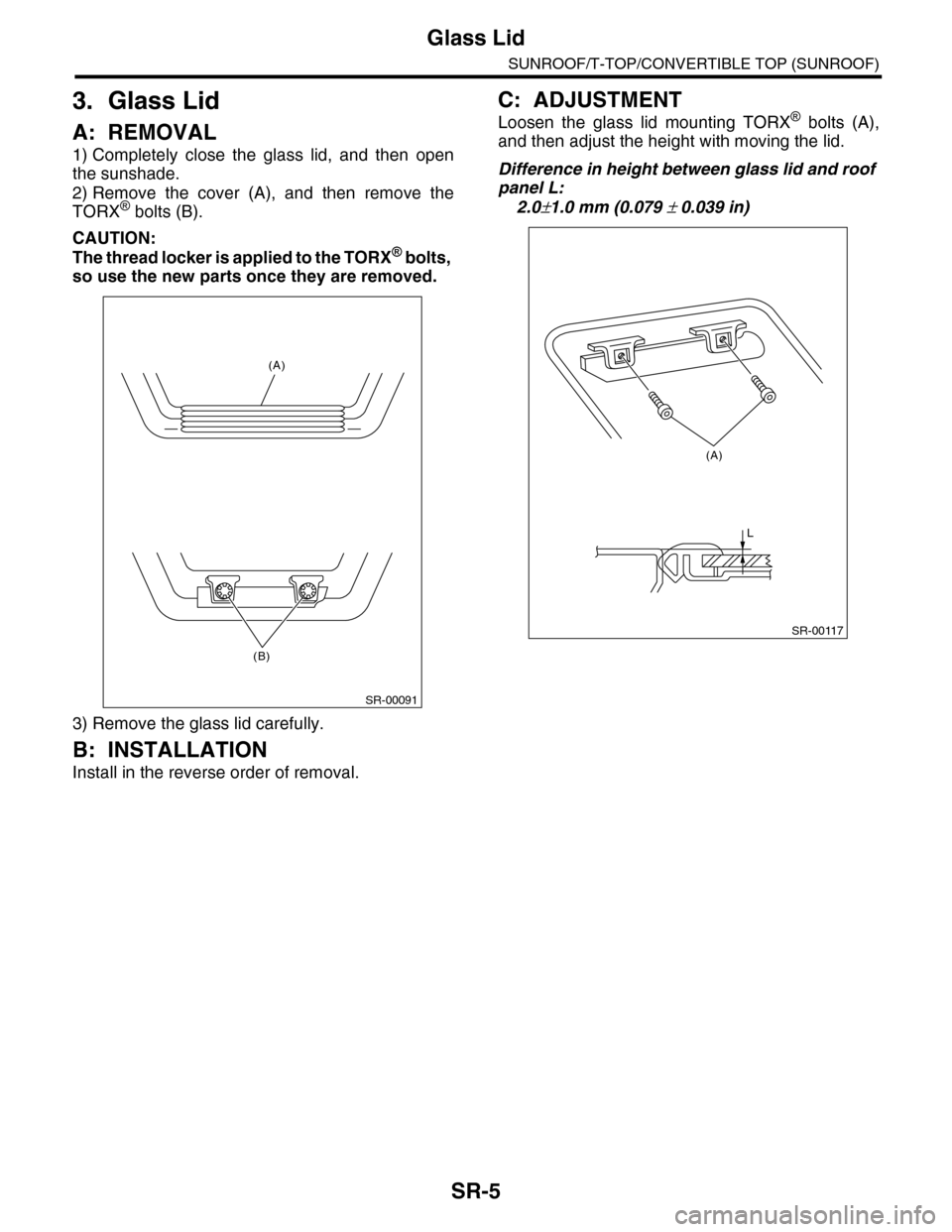

3. Glass Lid

A: REMOVAL

1) Completely close the glass lid, and then open

the sunshade.

2) Remove the cover (A), and then remove the

TORX® bolts (B).

CAUTION:

The thread locker is applied to the TORX® b o l t s ,

so use the new parts once they are removed.

3) Remove the glass lid carefully.

B: INSTALLATION

Install in the reverse order of removal.

C: ADJUSTMENT

Loosen the glass lid mounting TORX® bolts (A),

and then adjust the height with moving the lid.

Difference in height between glass lid and roof

panel L:

2.0±1.0 mm (0.079 ± 0.039 in)

(A)

(B)

SR-00091

(A)

SR-00117

L

Page 709 of 2453

WW-14

Wiper Relay Unit

WIPER AND WASHER SYSTEMS

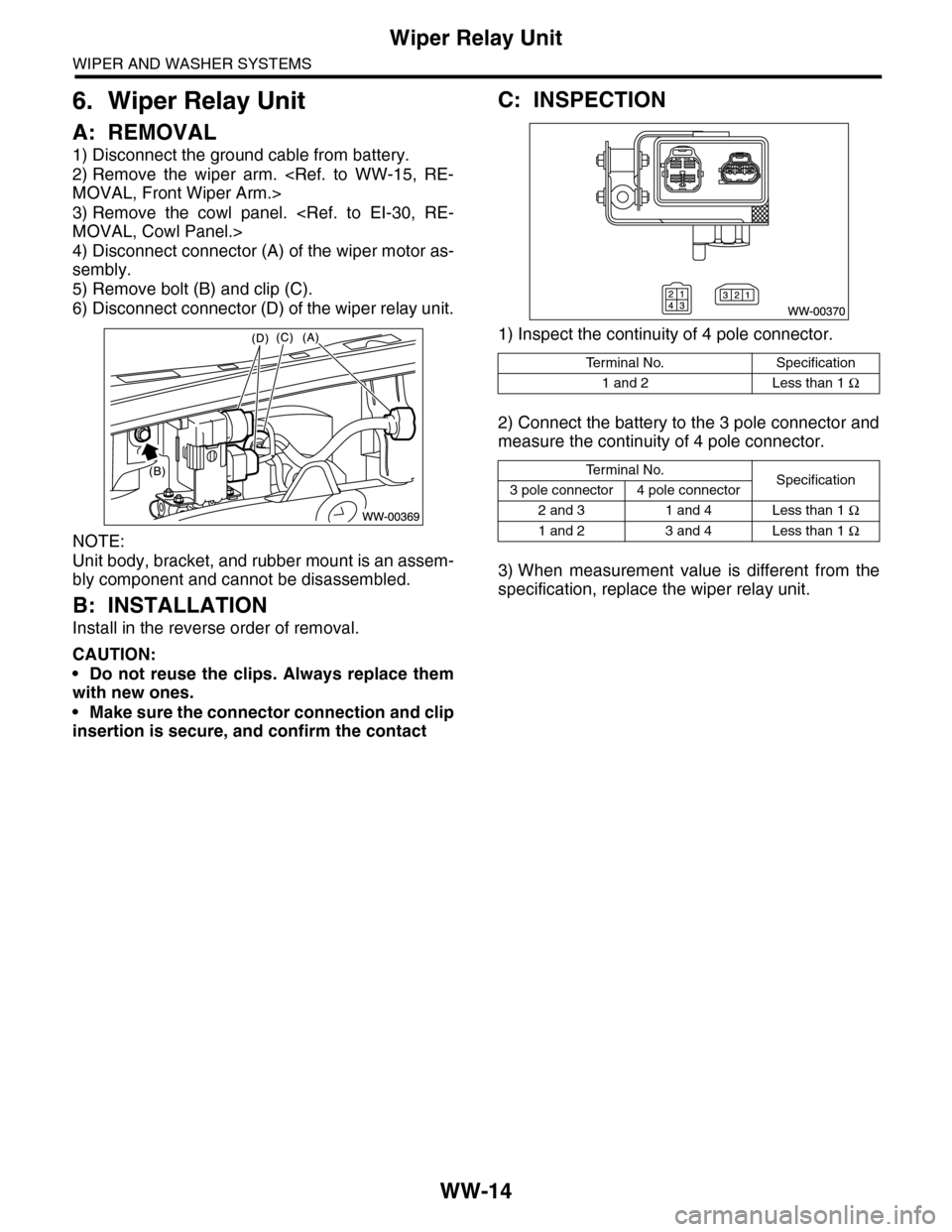

6. Wiper Relay Unit

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the wiper arm.

3) Remove the cowl panel.

4) Disconnect connector (A) of the wiper motor as-

sembly.

5) Remove bolt (B) and clip (C).

6) Disconnect connector (D) of the wiper relay unit.

NOTE:

Unit body, bracket, and rubber mount is an assem-

bly component and cannot be disassembled.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

•Do not reuse the clips. Always replace them

with new ones.

•Make sure the connector connection and clip

insertion is secure, and confirm the contact

C: INSPECTION

1) Inspect the continuity of 4 pole connector.

2) Connect the battery to the 3 pole connector and

measure the continuity of 4 pole connector.

3) When measurement value is different from the

specification, replace the wiper relay unit.

Te r m i n a l N o . S p e c i f i c a t i o n

1 and 2 Less than 1 Ω

Te r m i n a l N o .Specification3 pole connector 4 pole connector

2 and 3 1 and 4 Less than 1 Ω

1 and 2 3 and 4 Less than 1 Ω

Page 716 of 2453

BR-2

General Description

BRAKE

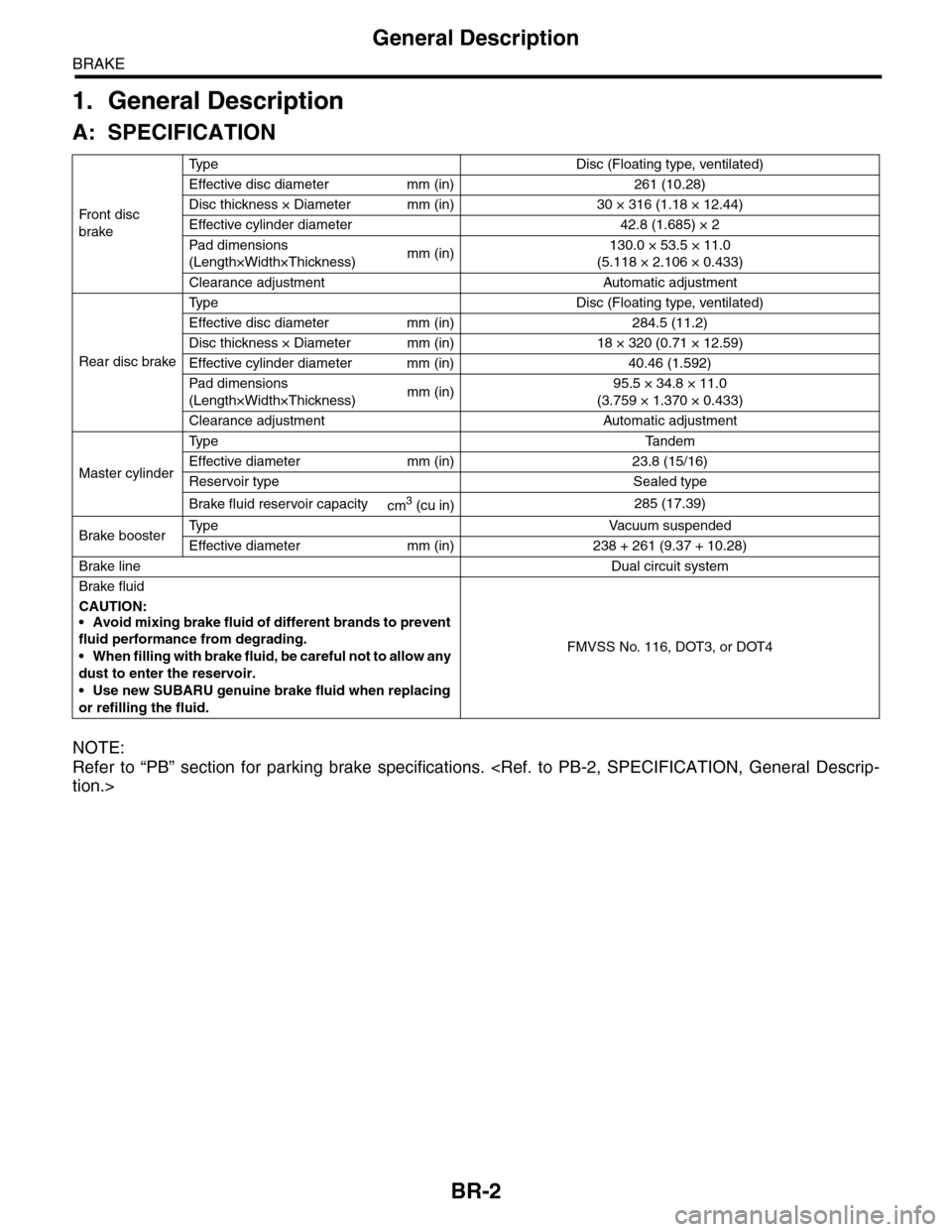

1. General Description

A: SPECIFICATION

NOTE:

Refer to “PB” section for parking brake specifications.

Fr o nt d is c

brake

Ty p e D i s c ( F l o a t i n g t y p e , v e n t i l a t e d )

Effective disc diameter mm (in) 261 (10.28)

Disc thickness × Diameter mm (in) 30 × 316 (1.18 × 12.44)

Effective cylinder diameter 42.8 (1.685) × 2

Pad dimensions

(Length×Width×Thickness)mm (in)130.0 × 53.5 × 11.0

(5.118 × 2.106 × 0.433)

Clearance adjustment Automatic adjustment

Rear disc brake

Ty p e D i s c ( F l o a t i n g t y p e , v e n t i l a t e d )

Effective disc diameter mm (in) 284.5 (11.2)

Disc thickness × Diameter mm (in) 18 × 320 (0.71 × 12.59)

Effective cylinder diameter mm (in) 40.46 (1.592)

Pad dimensions

(Length×Width×Thickness)mm (in)95.5 × 34.8 × 11.0

(3.759 × 1.370 × 0.433)

Clearance adjustment Automatic adjustment

Master cylinder

Ty p e Ta n d e m

Effective diameter mm (in) 23.8 (15/16)

Reservoir type Sealed type

Brake fluid reservoir capacitycm3 (cu in)285 (17.39)

Brake boosterTy p e V a c u u m s u s p e n d e d

Effective diameter mm (in) 238 + 261 (9.37 + 10.28)

Brake lineDual circuit system

Brake fluid

CAUTION:

•Avoid mixing brake fluid of different brands to prevent

fluid performance from degrading.

•When filling with brake fluid, be careful not to allow any

dust to enter the reservoir.

•Use new SUBARU genuine brake fluid when replacing

or refilling the fluid.

FMVSS No. 116, DOT3, or DOT4

Page 728 of 2453

BR-14

Front Disc Rotor

BRAKE

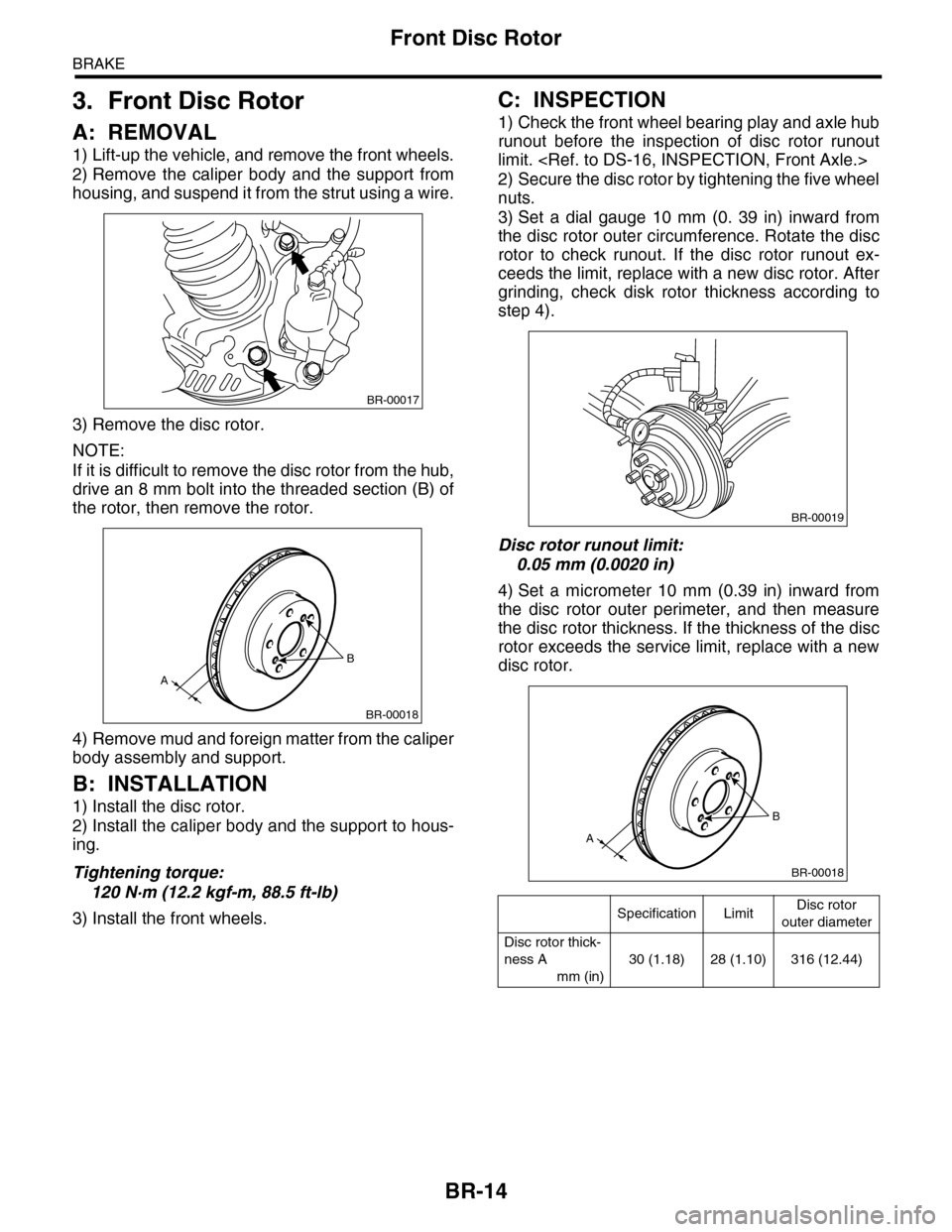

3. Front Disc Rotor

A: REMOVAL

1) Lift-up the vehicle, and remove the front wheels.

2) Remove the caliper body and the support from

housing, and suspend it from the strut using a wire.

3) Remove the disc rotor.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive an 8 mm bolt into the threaded section (B) of

the rotor, then remove the rotor.

4) Remove mud and foreign matter from the caliper

body assembly and support.

B: INSTALLATION

1) Install the disc rotor.

2) Install the caliper body and the support to hous-

ing.

Tightening torque:

120 N·m (12.2 kgf-m, 88.5 ft-lb)

3) Install the front wheels.

C: INSPECTION

1) Check the front wheel bearing play and axle hub

runout before the inspection of disc rotor runout

limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

4) Set a micrometer 10 mm (0.39 in) inward from

the disc rotor outer perimeter, and then measure

the disc rotor thickness. If the thickness of the disc

rotor exceeds the service limit, replace with a new

disc rotor.

BR-00017

B

A

BR-00018

Specification LimitDisc rotor

outer diameter

Disc rotor thick-

ness A

mm (in)

30 (1.18) 28 (1.10) 316 (12.44)

BR-00019

B

A

BR-00018

Page 734 of 2453

BR-20

Rear Disc Rotor

BRAKE

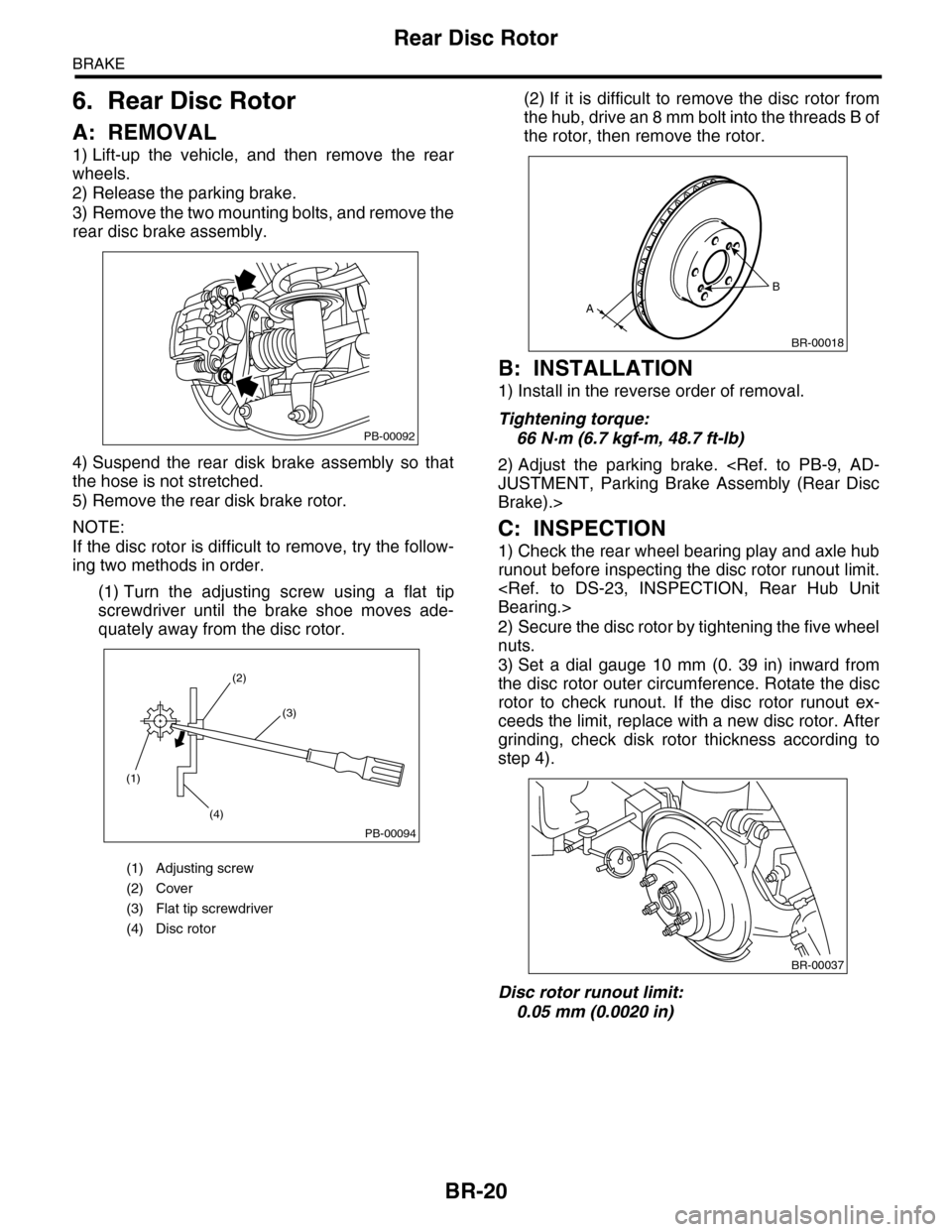

6. Rear Disc Rotor

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Release the parking brake.

3) Remove the two mounting bolts, and remove the

rear disc brake assembly.

4) Suspend the rear disk brake assembly so that

the hose is not stretched.

5) Remove the rear disk brake rotor.

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

(2) If it is difficult to remove the disc rotor from

the hub, drive an 8 mm bolt into the threads B of

the rotor, then remove the rotor.

B: INSTALLATION

1) Install in the reverse order of removal.

Tightening torque:

66 N·m (6.7 kgf-m, 48.7 ft-lb)

2) Adjust the parking brake.

Brake).>

C: INSPECTION

1) Check the rear wheel bearing play and axle hub

runout before inspecting the disc rotor runout limit.

2) Secure the disc rotor by tightening the five wheel

nuts.

3) Set a dial gauge 10 mm (0. 39 in) inward from

the disc rotor outer circumference. Rotate the disc

rotor to check runout. If the disc rotor runout ex-

ceeds the limit, replace with a new disc rotor. After

grinding, check disk rotor thickness according to

step 4).

Disc rotor runout limit:

0.05 mm (0.0020 in)

(1) Adjusting screw

(2) Cover

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094

B

A

BR-00018

BR-00037