Diff id SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 11 of 2453

AB-12

Inspection Locations After a Collision

AIRBAG SYSTEM

3. Inspection Locations After a

Collision

A: REPLACEMENT

Replace the following parts when the airbag is de-

ployed.

1. FRONT COLLISION

1) Driver’s airbag module

2) Passenger’s airbag module

3) Driver’s seat belt (Pretensioner)

4) Passenger’s seat belt (Pretensioner)

5) Airbag control module

6) Front sub sensor (L/R)

7) Roll connector

8) Instrument panel (for integrating with passen-

ger’s airbag module)

9) Passenger side seat cushion pad and frame as-

sembly

2. SIDE COLLISION

1) Airbag control module

2) Side airbag module (operating side seat back-

rest)

3) Side airbag sensor (operating side)

4) Curtain airbag module (operating side)

5) Curtain airbag sensor (operating side)

3. INSPECTION OF OTHER PARTS

Check for the following parts, and replace the dam-

aged parts with new parts.

1) Steering wheel and steering shaft

Check the steering shaft for mounting conditions

and deflection of front and rear, upward and down-

ward directions, and deflection of front and rear di-

rection with tilt lever released. (After a collision,

there is a good chance that the shock absorbing

part of steering shaft may have operated.)

2) Check the connectors of airbag module, preten-

sioner, etc. for damage, and also check each har-

ness for pinch and connector damage. Replace the

harness as a unit if damage is found.

3) Check the seat cushion frame, backrest, seat rail

and headrest for deformation, distortion, crack, and

installing condition and play.

4) For passengers seat, replace the seat cushion

frame assembly with new one if the seat cushion

frame is deformed or cracked.

5) If there are tears or loosening in the passenger

side seat cushion cover, it may interfere with the

proper operation of the passenger detection sys-

tem. Replace with a new cushion cover.

6) Be sure to perform the system calibration for the

occupant detection system after removing or re-

placing the passenger seat cushion cover. Failure

to do so may cause improper operation of the pas-

senger detection system.

TION, Subaru Select Monitor.>

7) Use the Subaru Select Monitor to check whether

the drivers seat position sensor and the drivers and

the front left/right seat belt buckle switches are op-

erating normally.

B: INSPECTION

If the vehicle is involved in a collision, even if it is a

slight collision, be sure to check the following sys-

tems.

1. DRIVER’S AIRBAG MODULE

1) Check for the following, and replace the dam-

aged parts with new parts.

•Airbag module is cracked or deformed.

•Harness and/or connector is cracked, deformed

or open. Harness wire is exposed.

•The module surface is fouled with grease, oil,

water or cleaning solvent.

2) When installing a new driver’s airbag module,

check for the following, and replace the damaged

parts with new parts.

•The steering wheel is in the way, making it diffi-

cult to install the airbag module.

•The clearance between the driver’s airbag mod-

ule and steering wheel is not constant.

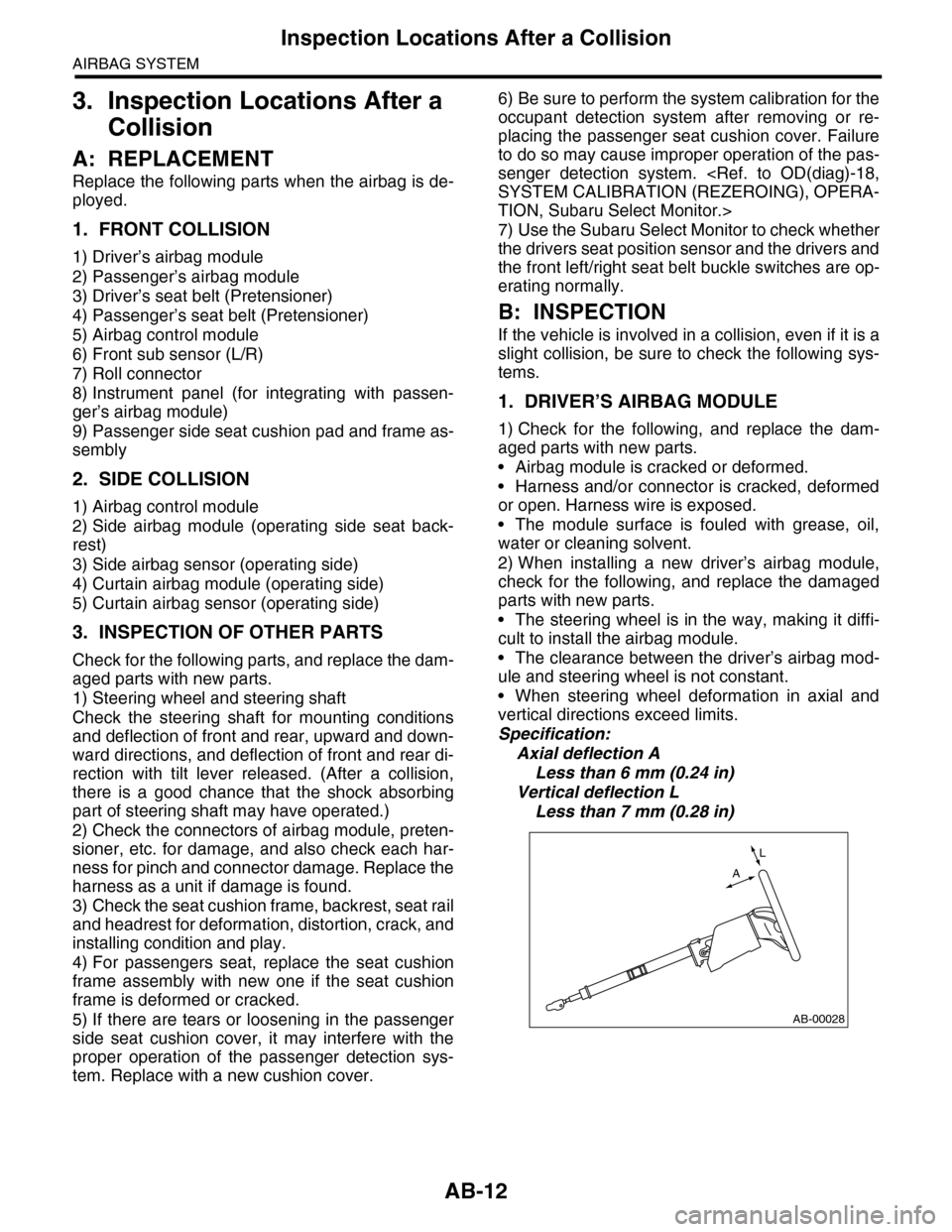

•When steering wheel deformation in axial and

vertical directions exceed limits.

Specification:

Axial deflection A

Less than 6 mm (0.24 in)

Vertical deflection L

Less than 7 mm (0.28 in)

AB-00028

L

A

Page 195 of 2453

ET-9

Rear Entertainment System

ENTERTAINMENT

7. Rear Entertainment System

A: WIRING DIAGRAM

B: INSPECTION

1. CHECK THE DVD-ROM.

Insert a region code 1 DVD-ROM, and check that the display shows images from the DVD when playing back

the media.

NOTE:

Region code 1 is a code for North American DVD-ROM discs. DVD-ROMs of different region codes will not

be played back.

Standard value: Image from DVD should be displayed.

OK: Normal

NG: If the images from the DVD is not displayed, check whether the DVD-ROM is set in the rear entertain-

ment system, whether the correct side is set, type of the DVD-ROM, the existence of any scratches, etc. If

there are no problems on the DVD-ROM, the main body is defective.

NOTE:

The rear entertainment system is not compatible with MP3 files or DVD-Audio.

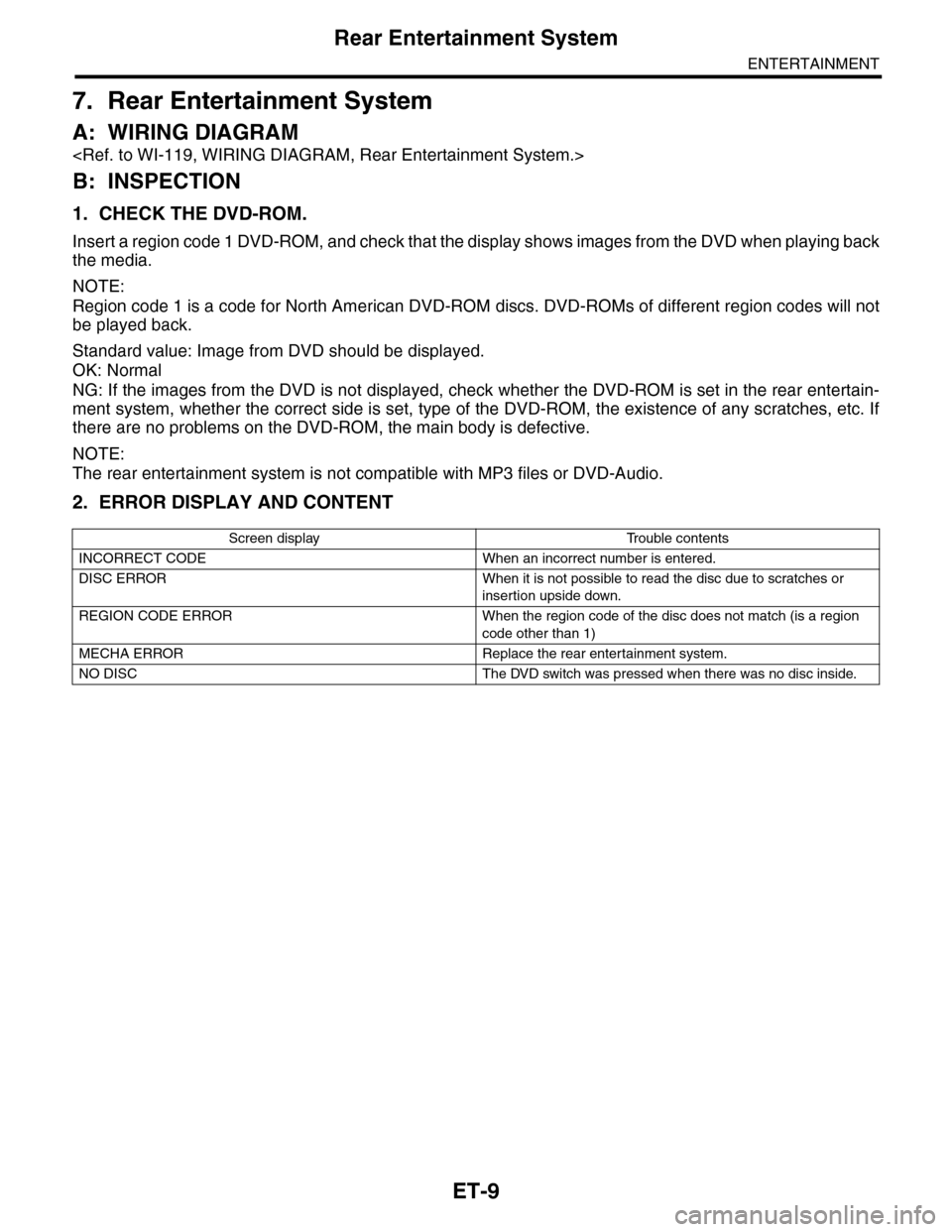

2. ERROR DISPLAY AND CONTENT

Screen display Trouble contents

INCORRECT CODE When an incorrect number is entered.

DISC ERROR When it is not possible to read the disc due to scratches or

insertion upside down.

REGION CODE ERROR When the region code of the disc does not match (is a region

code other than 1)

MECHA ERROR Replace the rear entertainment system.

NO DISC The DVD switch was pressed when there was no disc inside.

Page 274 of 2453

EI-32

Side Garnish

EXTERIOR/INTERIOR TRIM

10.Side Garnish

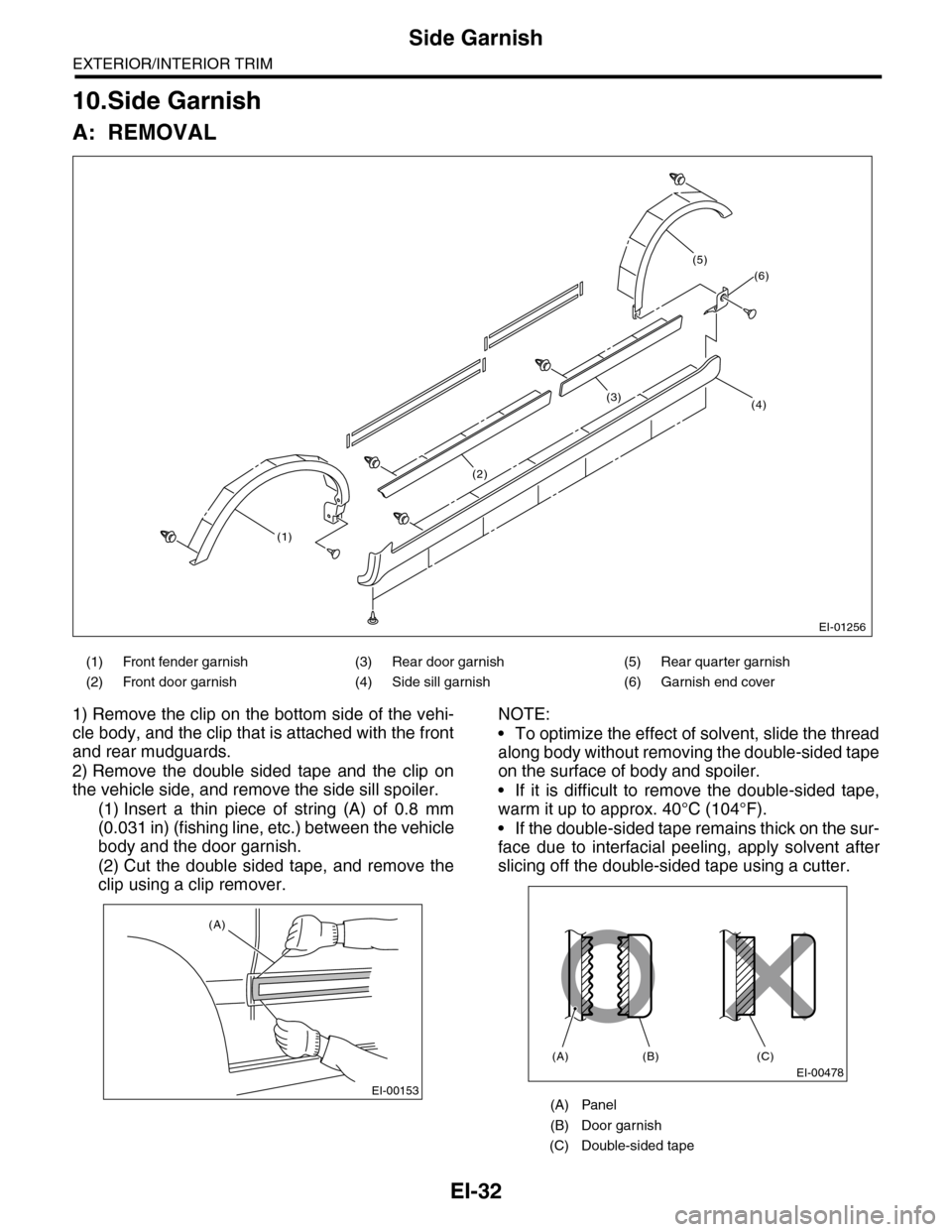

A: REMOVAL

1) Remove the clip on the bottom side of the vehi-

cle body, and the clip that is attached with the front

and rear mudguards.

2) Remove the double sided tape and the clip on

the vehicle side, and remove the side sill spoiler.

(1) Insert a thin piece of string (A) of 0.8 mm

(0.031 in) (fishing line, etc.) between the vehicle

body and the door garnish.

(2) Cut the double sided tape, and remove the

clip using a clip remover.

NOTE:

•To optimize the effect of solvent, slide the thread

along body without removing the double-sided tape

on the surface of body and spoiler.

•If it is difficult to remove the double-sided tape,

warm it up to approx. 40°C (104°F).

•If the double-sided tape remains thick on the sur-

face due to interfacial peeling, apply solvent after

slicing off the double-sided tape using a cutter.

(1) Front fender garnish (3) Rear door garnish (5) Rear quarter garnish

(2) Front door garnish (4) Side sill garnish (6) Garnish end cover

EI-01256

(1)

(2)

(3)

(6)

(4)

(5)

EI-00153

(A)

(A) Panel

(B) Door garnish

(C) Double-sided tape

EI-00478

(A) (B) (C)

Page 328 of 2453

AC-2

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

1. General Description

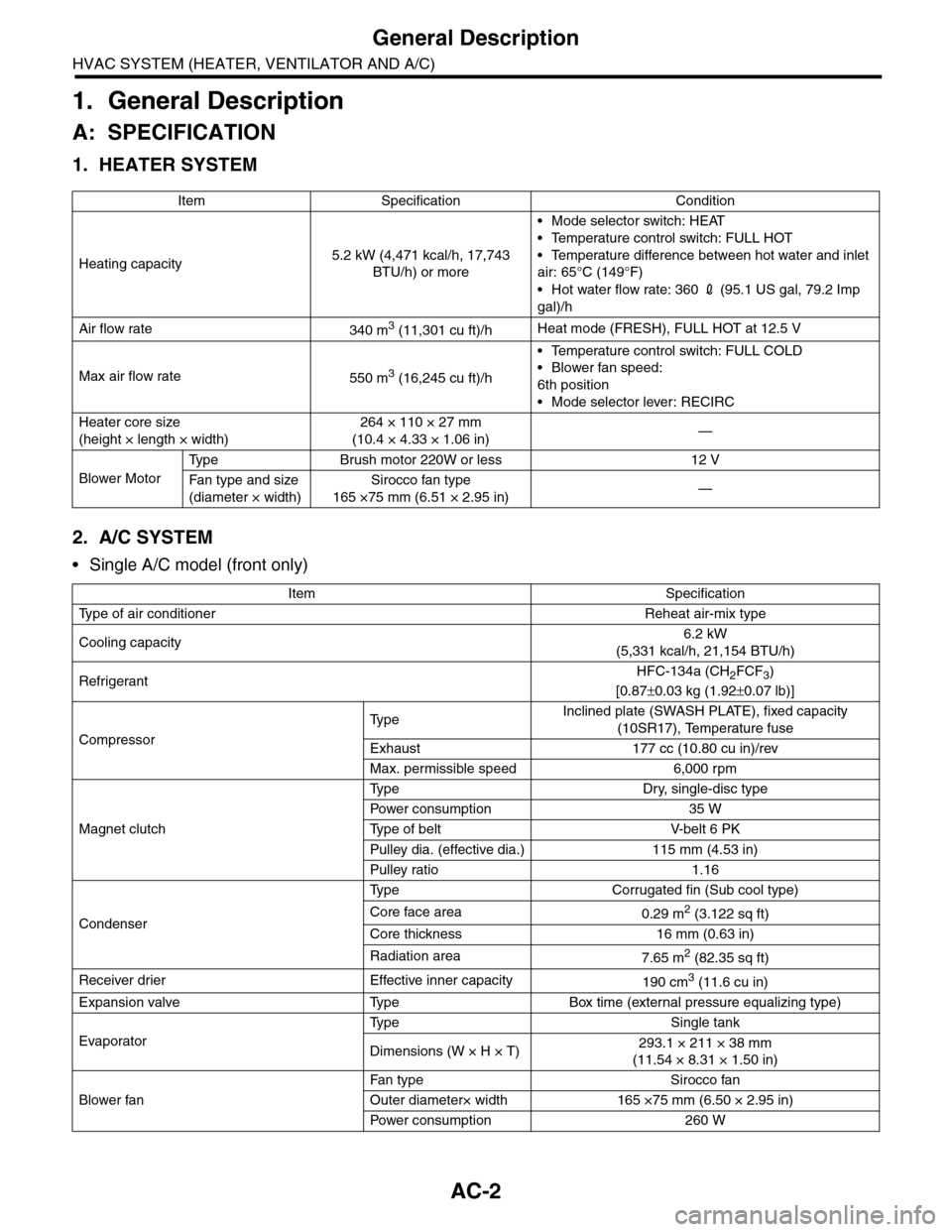

A: SPECIFICATION

1. HEATER SYSTEM

2. A/C SYSTEM

•Single A/C model (front only)

Item Specification Condition

Heating capacity5.2 kW (4,471 kcal/h, 17,743

BTU/h) or more

•Mode selector switch: HEAT

•Temperature control switch: FULL HOT

•Temperature difference between hot water and inlet

air: 65°C (149°F)

•Hot water flow rate: 360 2 (95.1 US gal, 79.2 Imp

gal)/h

Air flow rate340 m3 (11,301 cu ft)/hHeat mode (FRESH), FULL HOT at 12.5 V

Max air flow rate550 m3 (16,245 cu ft)/h

•Temperature control switch: FULL COLD

•Blower fan speed:

6th position

•Mode selector lever: RECIRC

Heater core size

(height × length × width)

264 × 110 × 27 mm

(10.4 × 4.33 × 1.06 in)—

Blower Motor

Ty p e B r u s h m o t o r 2 2 0 W o r l e s s 1 2 V

Fa n t y pe an d si ze

(diameter × width)

Sirocco fan type

165 ×75 mm (6.51 × 2.95 in)—

Item Specification

Ty p e o f a i r c o n d i t i o n e r R e h e a t a i r - m i x t y p e

Cooling capacity6.2 kW

(5,331 kcal/h, 21,154 BTU/h)

RefrigerantHFC-134a (CH2FCF3)

[0.87±0.03 kg (1.92±0.07 lb)]

Compressor

Ty p eInclined plate (SWASH PLATE), fixed capacity

(10SR17), Temperature fuse

Exhaust 177 cc (10.80 cu in)/rev

Max. permissible speed 6,000 rpm

Magnet clutch

Ty p e D r y, s i n g l e - d i s c t y p e

Powe r c on su mp t i on 35 W

Ty p e o f b e l t V- b e l t 6 P K

Pulley dia. (effective dia.) 115 mm (4.53 in)

Pulley ratio 1.16

Condenser

Ty p e C o r r u g a t e d f i n ( S u b c o o l t y p e )

Core face area0.29 m2 (3.122 sq ft)

Core thickness 16 mm (0.63 in)

Radiation area7.65 m2 (82.35 sq ft)

Receiver drier Effective inner capacity190 cm3 (11.6 cu in)

Expansion valve Type Box time (external pressure equalizing type)

Evaporator

Ty p e S i n g l e t a n k

Dimensions (W × H × T)293.1 × 211 × 38 mm

(11.54 × 8.31 × 1.50 in)

Blower fan

Fan t yp e S i r oc co fa n

Outer diameter× width 165 ×75 mm (6.50 × 2.95 in)

Powe r c on su mp t i on 2 60 W

Page 340 of 2453

AC-14

General Description

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

C: CAUTION

1. HFC-134A A/C SYSTEM

•The cooling system components for the HFC-

134a system such as the refrigerant and compres-

sor oil are different from the conventional CFC-12

system components and they are incompatible with

each other.

•Vehicles with the HFC-134a system can be iden-

tified by the label (A) attached to the vehicle.

Before maintenance, check which A/C system is in-

stalled to the vehicle.

2. COMPRESSOR OIL

•HFC-134a compressor oil has no compatibility

with that of CFC-12 system.

•Use only Denso Oil 8, the manufacturer-autho-

rized compressor oil for the HFC-134a system.

•Do not mix multiple compressor oils.

If CFC-12 compressor oil is used in the HFC-134a

A/C system, the compressor may become stuck

due to poor lubrication, or the refrigerant may leak

due to swelling of rubber parts.

On the other hand, if HFC-134a compressor oil is

used in a CFC-12 A/C system, the durability of the

A/C system will be lowered.

•HFC-134a compressor oil is very hygroscopic.

When replacing or installing/removing A/C parts,

immediately isolate the oil from atmosphere using a

plug or tape. In order to avoid moisture, store the oil

in a container with its cap tightly closed.

3. REFRIGERANT

•CFC-12 refrigerant cannot be used in a HFC-

134a A/C system. HFC-134a refrigerant, also can-

not be used in a CFC-12 A/C system.

•If an incorrect or no refrigerant is used, it will re-

sult in poor lubrication and the compressor itself

may be damaged.

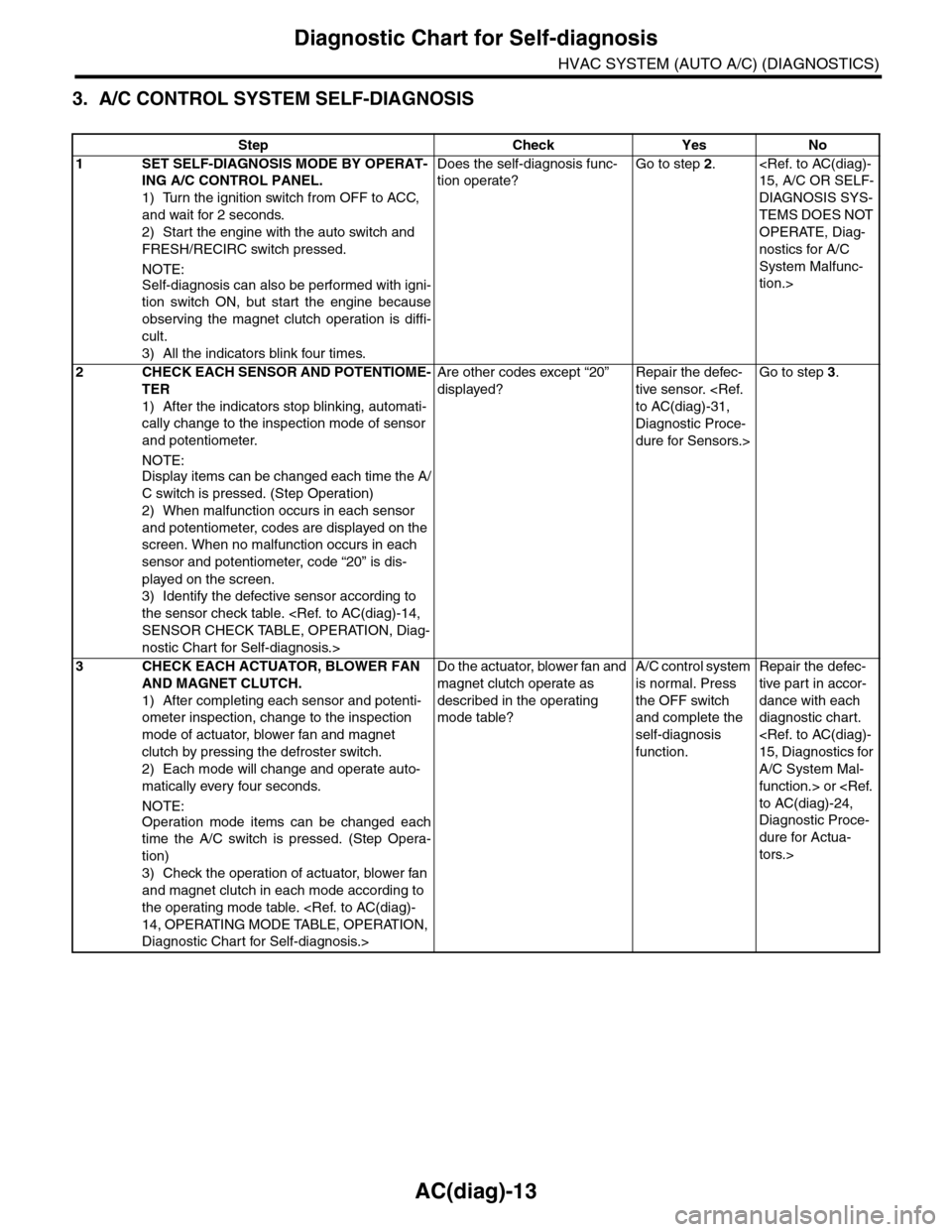

4. HANDLING OF REFRIGERANT

•The refrigerant boils at approx. –30°C (22°F).

When handling it, be sure to wear protective gog-

gles and protective gloves. Direct contact of the re-

frigerant with skin may cause frostbite.

If the refrigerant gets into your eye, avoid rubbing

your eyes with your hands. Wash your eye with

plenty of water, and receive medical treatment from

an eye doctor.

•Do not heat a service can. If a service can is di-

rectly heated, or put into boiling water, the inside

pressure will become extremely high. This may

cause the can to explode. If a service can must be

warmed up, use warm water of 40°C (104°F) or less.

•Do not drop or subject a service can to impacts.

(Observe the precautions and operation procedure

described on the refrigerant can.)

•When the engine is running, do not open the

high-pressure valve of the manifold gauge. High-

pressure gas can back-flow resulting in an explo-

sion of the can.

•Provide good ventilation and do not work in a

closed area.

•In order to prevent global warming, avoid releas-

ing HFC-134a into the atmosphere. Using a refrig-

erant recovery system, discharge and recycle the

gas.

AC-01380

(A) Goggles

(B) Gloves

(C) Avoid open flame

(D) No direct heat on container

(E) Do not discharge

(F) Loosen

(A)(B)

(C) (D)

(E)

(F)

AC-00007

Page 390 of 2453

AC(diag)-13

Diagnostic Chart for Self-diagnosis

HVAC SYSTEM (AUTO A/C) (DIAGNOSTICS)

3. A/C CONTROL SYSTEM SELF-DIAGNOSIS

Step Check Yes No

1SET SELF-DIAGNOSIS MODE BY OPERAT-

ING A/C CONTROL PANEL.

1) Turn the ignition switch from OFF to ACC,

and wait for 2 seconds.

2) Start the engine with the auto switch and

FRESH/RECIRC switch pressed.

NOTE:

Self-diagnosis can also be performed with igni-

tion switch ON, but start the engine because

observing the magnet clutch operation is diffi-

cult.

3) All the indicators blink four times.

Does the self-diagnosis func-

tion operate?

Go to step 2.

DIAGNOSIS SYS-

TEMS DOES NOT

OPERATE, Diag-

nostics for A/C

System Malfunc-

tion.>

2CHECK EACH SENSOR AND POTENTIOME-

TER

1) After the indicators stop blinking, automati-

cally change to the inspection mode of sensor

and potentiometer.

NOTE:

Display items can be changed each time the A/

C switch is pressed. (Step Operation)

2) When malfunction occurs in each sensor

and potentiometer, codes are displayed on the

screen. When no malfunction occurs in each

sensor and potentiometer, code “20” is dis-

played on the screen.

3) Identify the defective sensor according to

the sensor check table.

nostic Chart for Self-diagnosis.>

Are other codes except “20”

displayed?

Repair the defec-

tive sensor.

Diagnostic Proce-

dure for Sensors.>

Go to step 3.

3CHECK EACH ACTUATOR, BLOWER FAN

AND MAGNET CLUTCH.

1) After completing each sensor and potenti-

ometer inspection, change to the inspection

mode of actuator, blower fan and magnet

clutch by pressing the defroster switch.

2) Each mode will change and operate auto-

matically every four seconds.

NOTE:

Operation mode items can be changed each

time the A/C switch is pressed. (Step Opera-

tion)

3) Check the operation of actuator, blower fan

and magnet clutch in each mode according to

the operating mode table.

Diagnostic Chart for Self-diagnosis.>

Do the actuator, blower fan and

magnet clutch operate as

described in the operating

mode table?

A/C control system

is normal. Press

the OFF switch

and complete the

self-diagnosis

function.

Repair the defec-

tive par t in accor-

dance with each

diagnostic chart.

A/C System Mal-

function.> or

Diagnostic Proce-

dure for Actua-

tors.>

Page 419 of 2453

IM (diag)-3

General Description

IMMOBILIZER (DIAGNOSTICS)

2. General Description

A: CAUTION

CAUTION:

•The airbag system wiring harnesses and con-

nectors are yellow. Do not use electrical test

equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness.

•While diagnostic items are being checked, do

not operate radios, portable telephones, etc.

which emit electromagnetic waves near or in-

side the vehicle.

•When turning the ignition switch to ON or

OFF while diagnostic items are being checked,

do not allow keys with different ID codes close

to the ignition switch. If the ignition key is in a

key holder, remove it from the holder before

carrying out diagnosis.

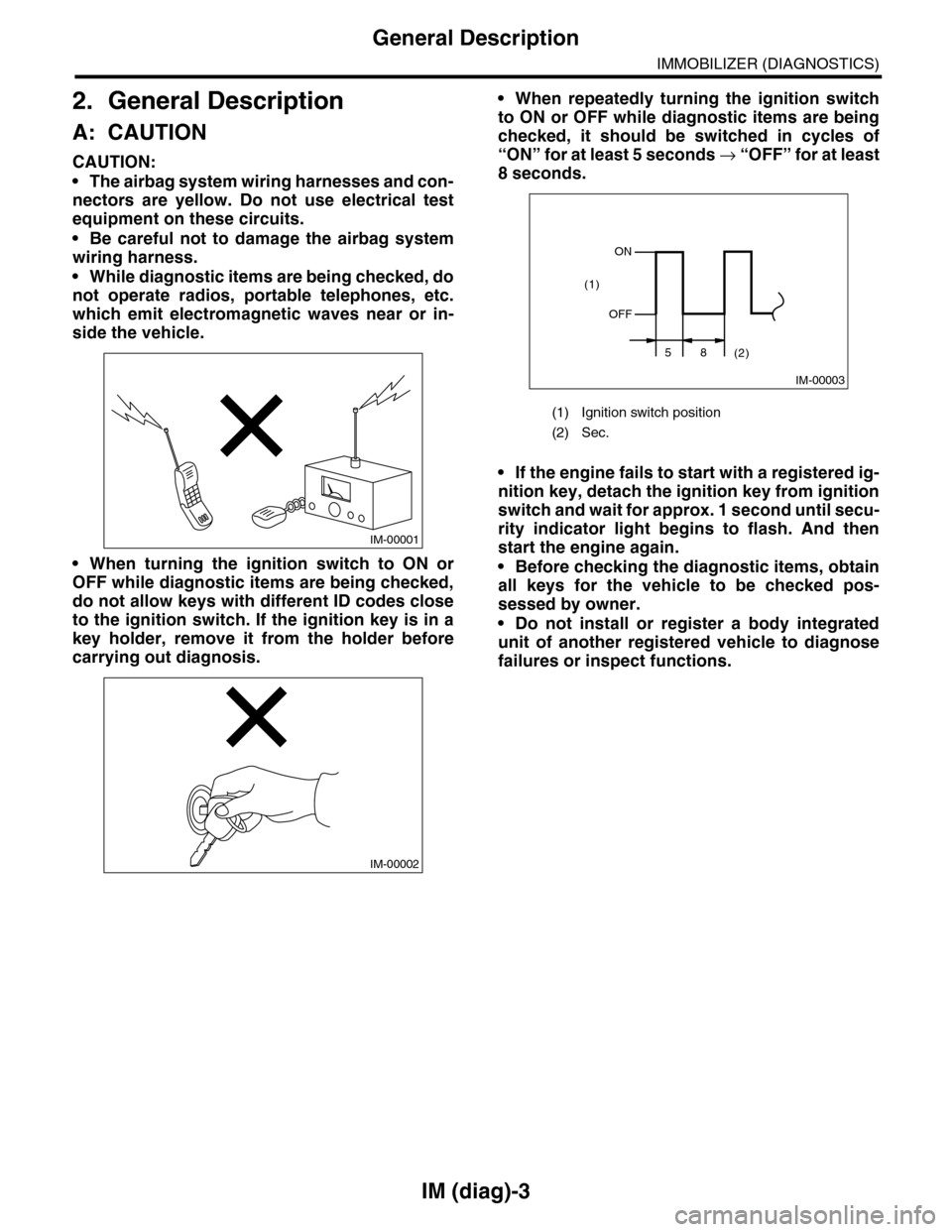

•When repeatedly turning the ignition switch

to ON or OFF while diagnostic items are being

checked, it should be switched in cycles of

“ON” for at least 5 seconds → “O F F ” fo r a t le a s t

8 seconds.

•If the engine fails to start with a registered ig-

nition key, detach the ignition key from ignition

switch and wait for approx. 1 second until secu-

rity indicator light begins to flash. And then

start the engine again.

•Before checking the diagnostic items, obtain

all keys for the vehicle to be checked pos-

sessed by owner.

•Do not install or register a body integrated

unit of another registered vehicle to diagnose

failures or inspect functions.

IM-00001

IM-00002

(1) Ignition switch position

(2) Sec.

IM-00003

ON

OFF

58(2)

(1)

Page 441 of 2453

IDI-2

General Description

INSTRUMENTATION/DRIVER INFO

1. General Description

A: SPECIFICATION

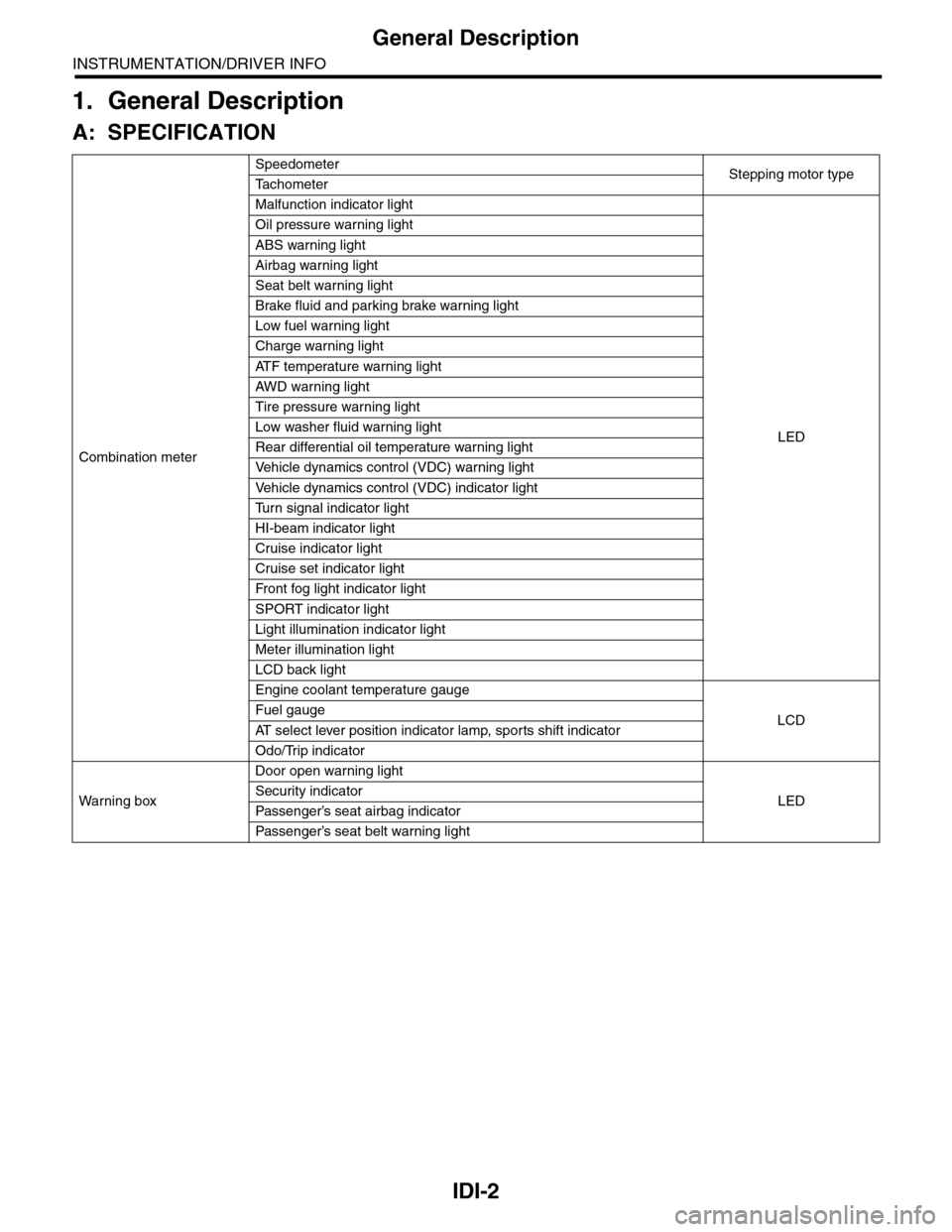

Combination meter

SpeedometerStepping motor typeTa c h o m e t e r

Malfunction indicator light

LED

Oil pressure warning light

ABS warning light

Airbag warning light

Seat belt warning light

Brake fluid and parking brake warning light

Low fuel warning light

Charge warning light

AT F t e m p e r a t u r e w a r n i n g l i g h t

AW D war n in g l i gh t

Tire pressure warning light

Low washer fluid warning light

Rear differential oil temperature warning light

Ve h i c l e d y n a m i c s c o n t r o l ( V D C ) w a r n i n g l i g h t

Ve h i c l e d y n a m i c s c o n t r o l ( V D C ) i n d i c a t o r l i g h t

Tu r n s i g n a l i n d i c a t o r l i g h t

HI-beam indicator light

Cruise indicator light

Cruise set indicator light

Fr o nt fog li g ht i nd i ca to r li g ht

SPORT indicator light

Light illumination indicator light

Meter illumination light

LCD back light

Engine coolant temperature gauge

LCDFuel gauge

AT s e l e c t l e v e r p o s i t i o n i n d i c a t o r l a m p , s p o r t s s h i f t i n d i c a t o r

Odo/Trip indicator

Wa r ni n g b ox

Door open warning light

LEDSecurity indicator

Passenger’s seat airbag indicator

Passenger’s seat belt war ning light

Page 461 of 2453

LAN(diag)-5

General Description

LAN SYSTEM (DIAGNOSTICS)

3. General Description

A: CAUTION

1. SRS AIRBAG SYSTEM

Airbag system wiring harness is routed near the

body integrated unit and twisted pair line.

CAUTION:

•All airbag system wiring harness and con-

nectors are colored yellow. Do not use the elec-

trical test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the body inte-

grated unit and LAN system.

•Refer to “Airbag System” when disconnect-

ing the air bag system connector.

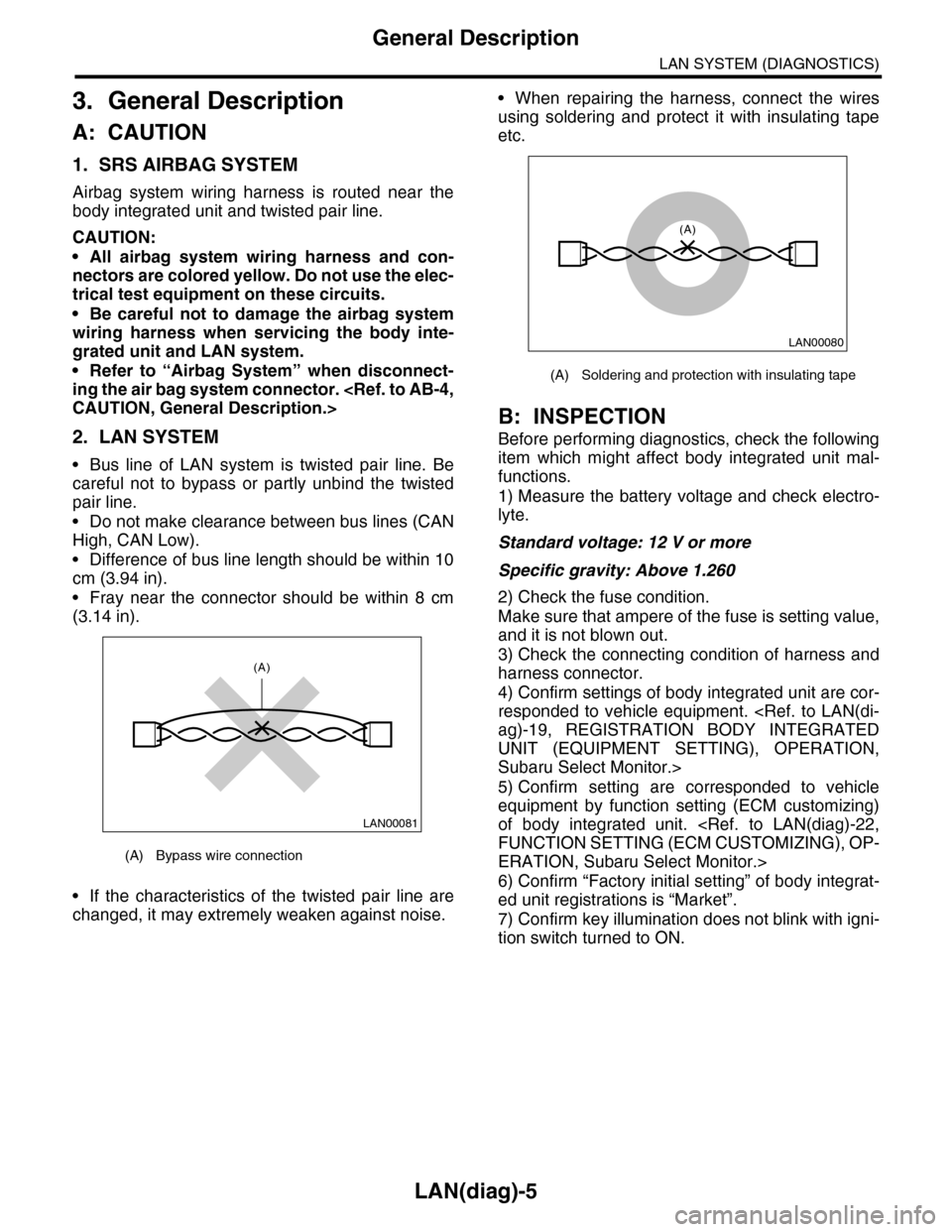

2. LAN SYSTEM

•Bus line of LAN system is twisted pair line. Be

careful not to bypass or partly unbind the twisted

pair line.

•Do not make clearance between bus lines (CAN

High, CAN Low).

•Difference of bus line length should be within 10

cm (3.94 in).

•Fray near the connector should be within 8 cm

(3.14 in).

•If the characteristics of the twisted pair line are

changed, it may extremely weaken against noise.

•When repairing the harness, connect the wires

using soldering and protect it with insulating tape

etc.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect body integrated unit mal-

functions.

1) Measure the battery voltage and check electro-

lyte.

Standard voltage: 12 V or more

Specific gravity: Above 1.260

2) Check the fuse condition.

Make sure that ampere of the fuse is setting value,

and it is not blown out.

3) Check the connecting condition of harness and

harness connector.

4) Confirm settings of body integrated unit are cor-

responded to vehicle equipment.

UNIT (EQUIPMENT SETTING), OPERATION,

Subaru Select Monitor.>

5) Confirm setting are corresponded to vehicle

equipment by function setting (ECM customizing)

of body integrated unit.

ERATION, Subaru Select Monitor.>

6) Confirm “Factory initial setting” of body integrat-

ed unit registrations is “Market”.

7) Confirm key illumination does not blink with igni-

tion switch turned to ON.

(A) Bypass wire connection

LAN00081

(A)

(A) Soldering and protection with insulating tape

LAN00080

(A)

Page 466 of 2453

LAN(diag)-10

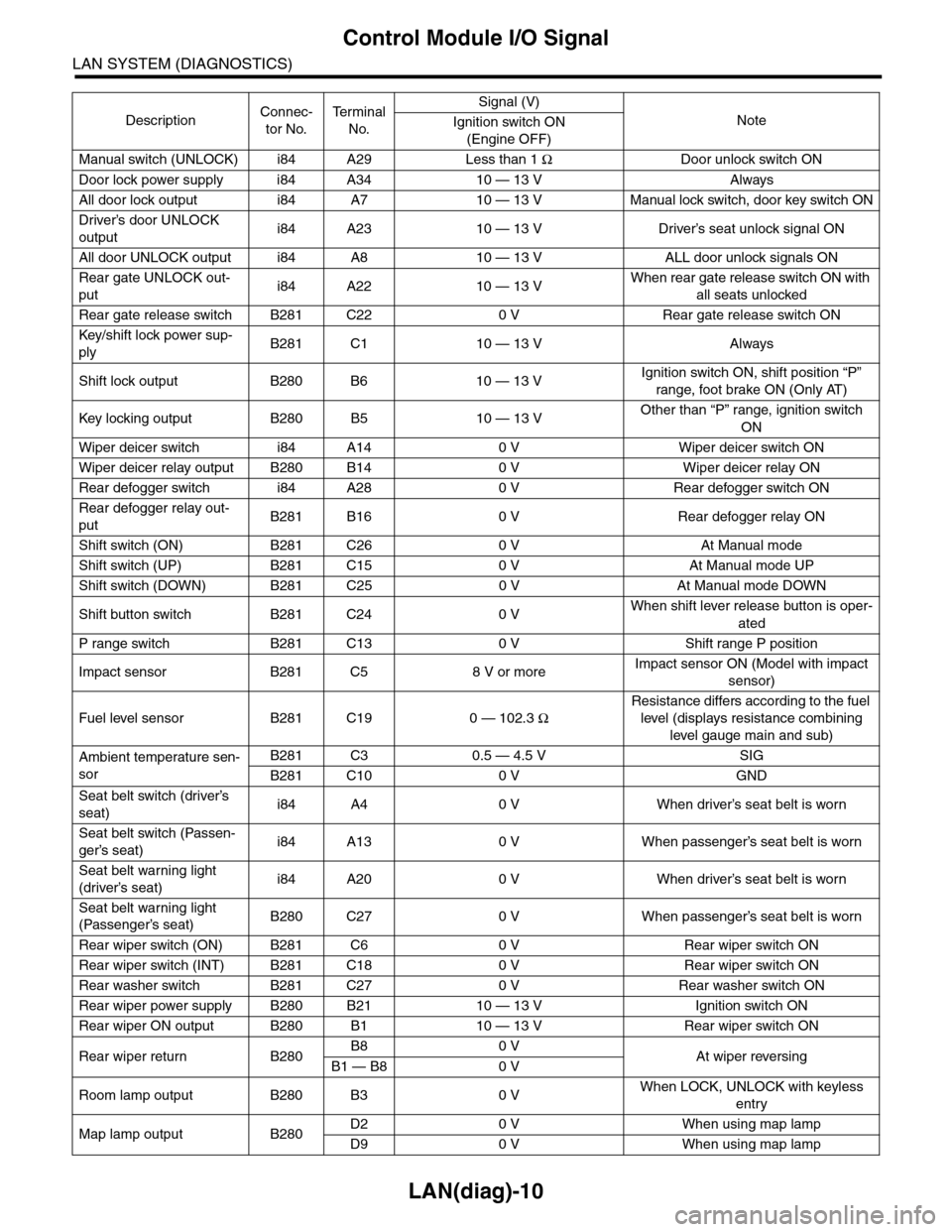

Control Module I/O Signal

LAN SYSTEM (DIAGNOSTICS)

Manual switch (UNLOCK) i84 A29 Less than 1 ΩDoor unlock switch ON

Door lock power supply i84 A34 10 — 13 V Always

All door lock output i84 A7 10 — 13 V Manual lock switch, door key switch ON

Driver’s door UNLOCK

outputi84 A23 10 — 13 V Driver’s seat unlock signal ON

All door UNLOCK output i84 A8 10 — 13 V ALL door unlock signals ON

Rear gate UNLOCK out-

puti84 A22 10 — 13 VWhen rear gate release switch ON with

all seats unlocked

Rear gate release switch B281 C22 0 V Rear gate release switch ON

Key/shift lock power sup-

plyB281 C1 10 — 13 V Always

Shift lock output B280 B6 10 — 13 VIgnition switch ON, shift position “P”

range, foot brake ON (Only AT)

Key locking output B280 B5 10 — 13 VOther than “P” range, ignition switch

ON

Wiper deicer switch i84 A14 0 V Wiper deicer switch ON

Wiper deicer relay output B280 B14 0 V Wiper deicer relay ON

Rear defogger switch i84 A28 0 V Rear defogger switch ON

Rear defogger relay out-

putB281 B16 0 V Rear defogger relay ON

Shift switch (ON) B281 C26 0 V At Manual mode

Shift switch (UP) B281 C15 0 V At Manual mode UP

Shift switch (DOWN) B281 C25 0 V At Manual mode DOWN

Shift button switch B281 C24 0 VWhen shift lever release button is oper-

ated

P range switch B281 C13 0 V Shift range P position

Impact sensor B281 C5 8 V or moreImpact sensor ON (Model with impact

sensor)

Fuel level sensor B281 C19 0 — 102.3 Ω

Resistance differs according to the fuel

level (displays resistance combining

level gauge main and sub)

Ambient temperature sen-

sor

B281 C3 0.5 — 4.5 V SIG

B281 C10 0 V GND

Seat belt switch (driver’s

seat)i84 A4 0 V When driver’s seat belt is worn

Seat belt switch (Passen-

ger’s seat)i84 A13 0 V When passenger’s seat belt is worn

Seat belt warning light

(driver’s seat)i84 A20 0 V When driver’s seat belt is worn

Seat belt warning light

(Passenger’s seat)B280 C27 0 V When passenger’s seat belt is worn

Rear wiper switch (ON) B281 C6 0 V Rear wiper switch ON

Rear wiper switch (INT) B281 C18 0 V Rear wiper switch ON

Rear washer switch B281 C27 0 V Rear washer switch ON

Rear wiper power supply B280 B21 10 — 13 V Ignition switch ON

Rear wiper ON output B280 B1 10 — 13 V Rear wiper switch ON

Rear wiper return B280B8 0 VAt wiper reversingB1 — B8 0 V

Room lamp output B280 B3 0 VWhen LOCK, UNLOCK with keyless

entry

Map lamp output B280D2 0 V When using map lamp

D9 0 V When using map lamp

DescriptionConnec-

tor No.

Te r m i n a l

No.

Signal (V)

NoteIgnition switch ON

(Engine OFF)