boot SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 827 of 2453

DS-10

Propeller Shaft

DRIVE SHAFT SYSTEM

2. Propeller Shaft

A: REMOVAL

NOTE:

•Before removing propeller shaft, wrap metal

parts with a cloth or rubber material.

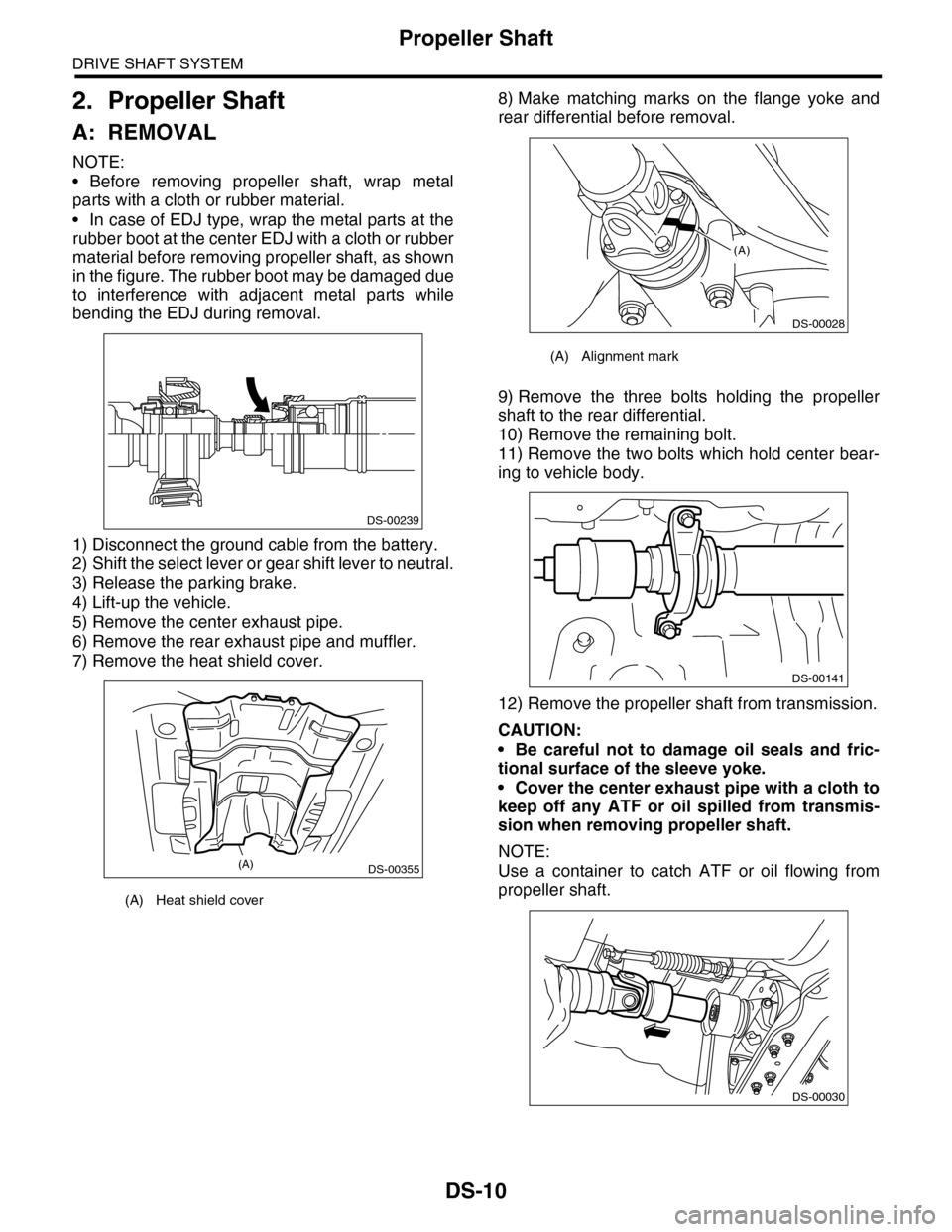

•In case of EDJ type, wrap the metal parts at the

rubber boot at the center EDJ with a cloth or rubber

material before removing propeller shaft, as shown

in the figure. The rubber boot may be damaged due

to interference with adjacent metal parts while

bending the EDJ during removal.

1) Disconnect the ground cable from the battery.

2) Shift the select lever or gear shift lever to neutral.

3) Release the parking brake.

4) Lift-up the vehicle.

5) Remove the center exhaust pipe.

6) Remove the rear exhaust pipe and muffler.

7) Remove the heat shield cover.

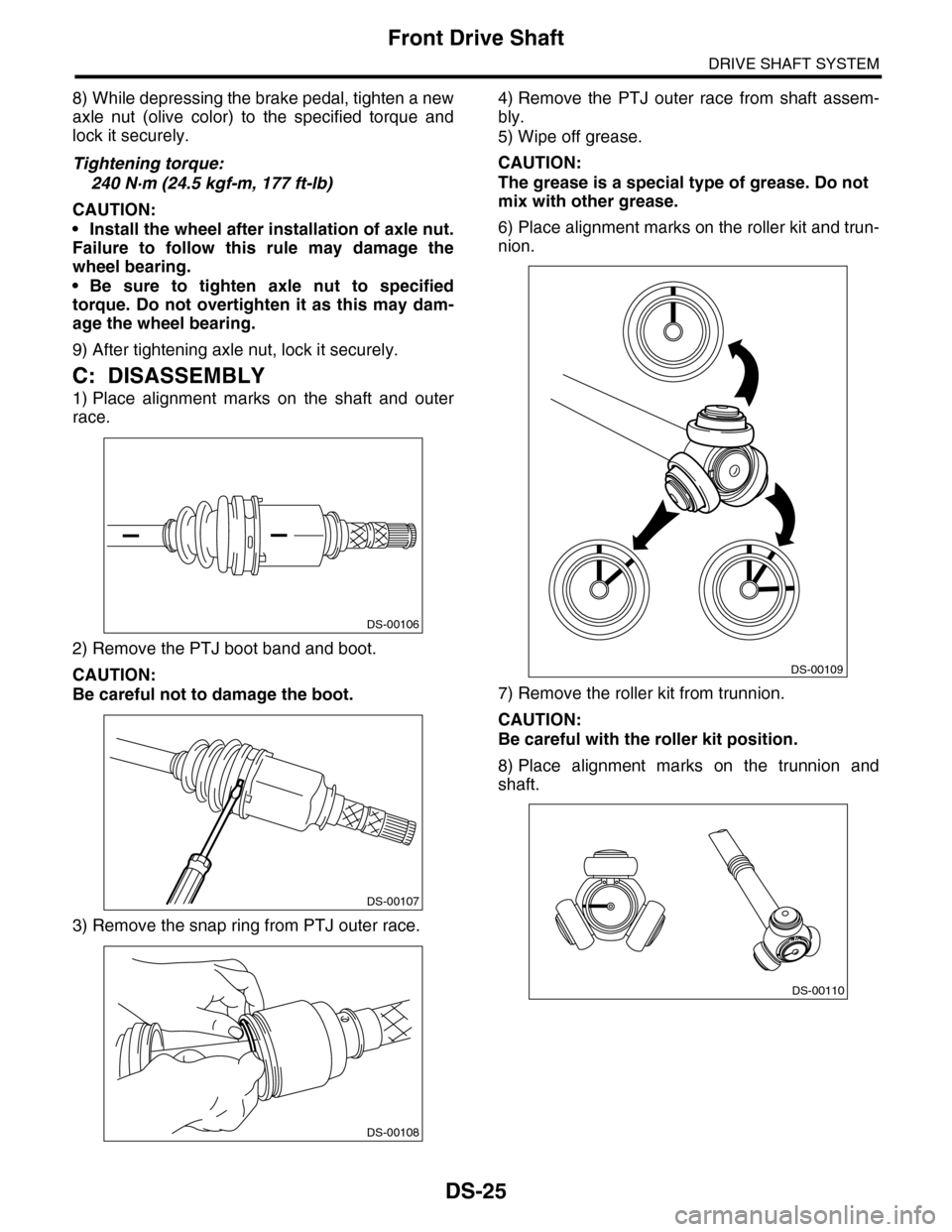

8) Make matching marks on the flange yoke and

rear differential before removal.

9) Remove the three bolts holding the propeller

shaft to the rear differential.

10) Remove the remaining bolt.

11) Remove the two bolts which hold center bear-

ing to vehicle body.

12) Remove the propeller shaft from transmission.

CAUTION:

•Be careful not to damage oil seals and fric-

tional surface of the sleeve yoke.

•Cover the center exhaust pipe with a cloth to

keep off any ATF or oil spilled from transmis-

sion when removing propeller shaft.

NOTE:

Use a container to catch ATF or oil flowing from

propeller shaft.(A) Heat shield cover

DS-00239

DS-00355(A)

(A) Alignment mark

DS-00028

(A)

DS-00141

DS-00030

Page 842 of 2453

DS-25

Front Drive Shaft

DRIVE SHAFT SYSTEM

8) While depressing the brake pedal, tighten a new

axle nut (olive color) to the specified torque and

lock it securely.

Tightening torque:

240 N·m (24.5 kgf-m, 177 ft-lb)

CAUTION:

•Install the wheel after installation of axle nut.

Failure to follow this rule may damage the

wheel bearing.

•Be sure to tighten axle nut to specified

torque. Do not overtighten it as this may dam-

age the wheel bearing.

9) After tightening axle nut, lock it securely.

C: DISASSEMBLY

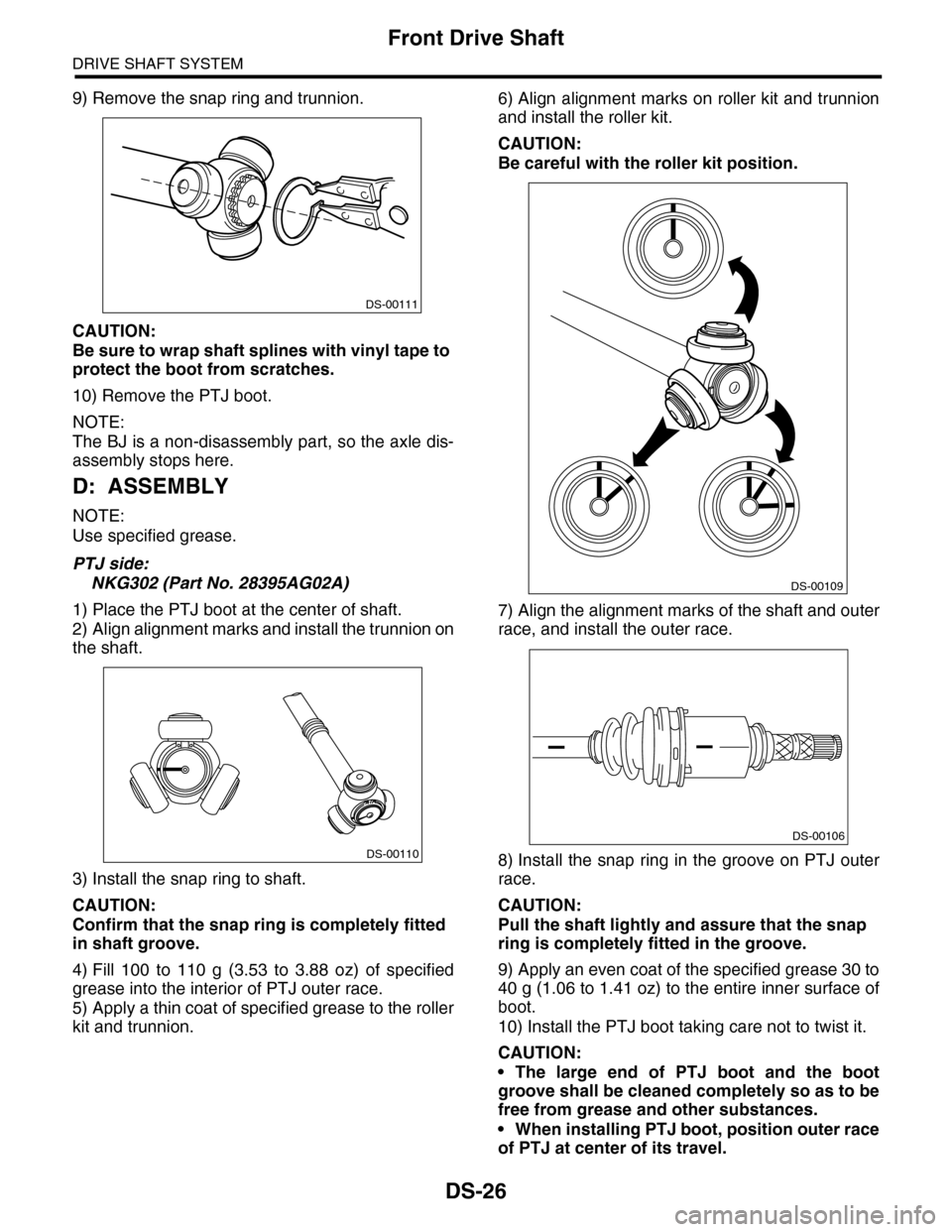

1) Place alignment marks on the shaft and outer

race.

2) Remove the PTJ boot band and boot.

CAUTION:

Be careful not to damage the boot.

3) Remove the snap ring from PTJ outer race.

4) Remove the PTJ outer race from shaft assem-

bly.

5) Wipe off grease.

CAUTION:

The grease is a special type of grease. Do not

mix with other grease.

6) Place alignment marks on the roller kit and trun-

nion.

7) Remove the roller kit from trunnion.

CAUTION:

Be careful with the roller kit position.

8) Place alignment marks on the trunnion and

shaft.

DS-00106

DS-00107

DS-00108

DS-00109

DS-00110

Page 843 of 2453

DS-26

Front Drive Shaft

DRIVE SHAFT SYSTEM

9) Remove the snap ring and trunnion.

CAUTION:

Be sure to wrap shaft splines with vinyl tape to

protect the boot from scratches.

10) Remove the PTJ boot.

NOTE:

The BJ is a non-disassembly part, so the axle dis-

assembly stops here.

D: ASSEMBLY

NOTE:

Use specified grease.

PTJ side:

NKG302 (Part No. 28395AG02A)

1) Place the PTJ boot at the center of shaft.

2) Align alignment marks and install the trunnion on

the shaft.

3) Install the snap ring to shaft.

CAUTION:

Confirm that the snap ring is completely fitted

in shaft groove.

4) Fill 100 to 110 g (3.53 to 3.88 oz) of specified

grease into the interior of PTJ outer race.

5) Apply a thin coat of specified grease to the roller

kit and trunnion.

6) Align alignment marks on roller kit and trunnion

and install the roller kit.

CAUTION:

Be careful with the roller kit position.

7) Align the alignment marks of the shaft and outer

race, and install the outer race.

8) Install the snap ring in the groove on PTJ outer

race.

CAUTION:

Pull the shaft lightly and assure that the snap

ring is completely fitted in the groove.

9) Apply an even coat of the specified grease 30 to

40 g (1.06 to 1.41 oz) to the entire inner surface of

boot.

10) Install the PTJ boot taking care not to twist it.

CAUTION:

•The large end of PTJ boot and the boot

groove shall be cleaned completely so as to be

free from grease and other substances.

•When installing PTJ boot, position outer race

of PTJ at center of its travel.

DS-00111

DS-00110

DS-00109

DS-00106

Page 844 of 2453

DS-27

Front Drive Shaft

DRIVE SHAFT SYSTEM

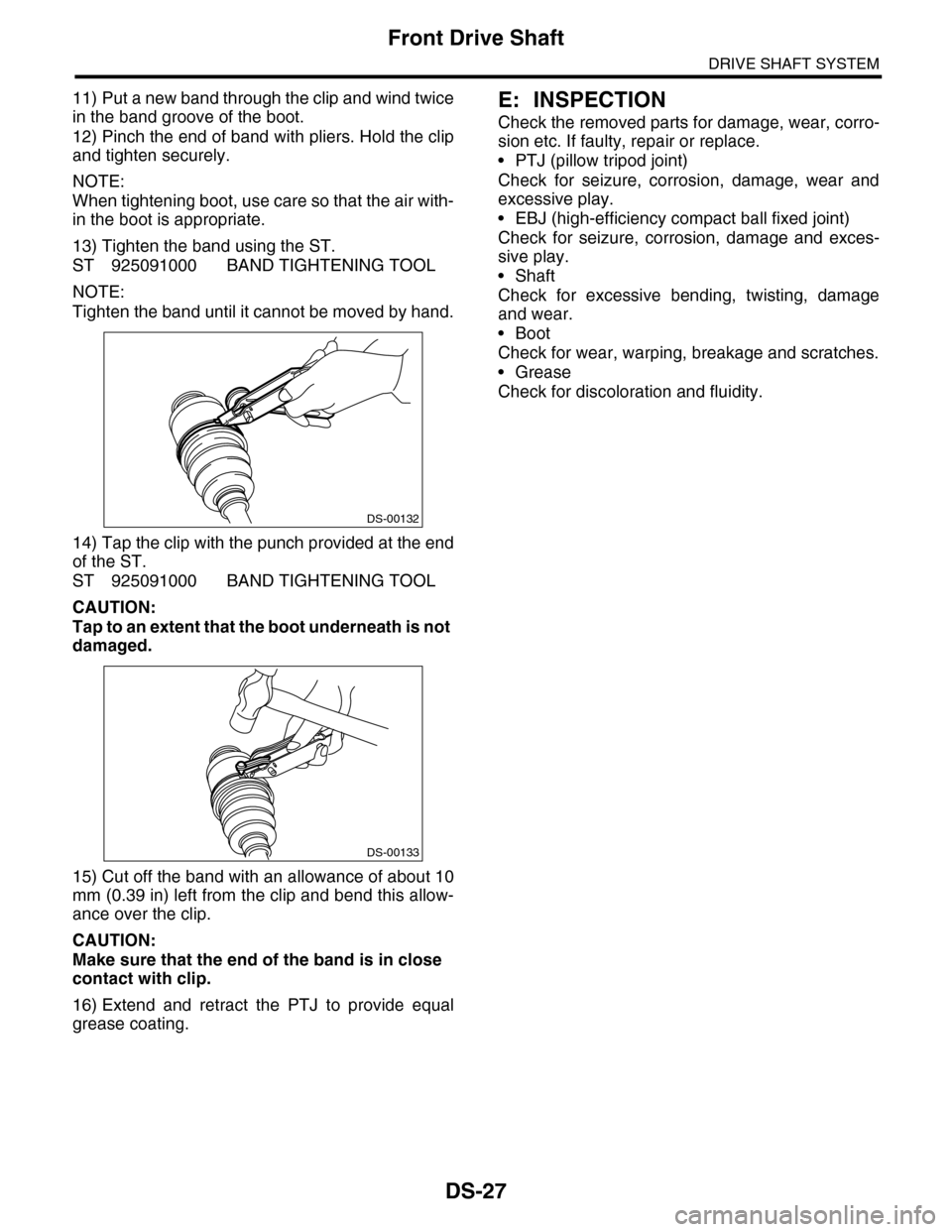

11) Put a new band through the clip and wind twice

in the band groove of the boot.

12) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, use care so that the air with-

in the boot is appropriate.

13) Tighten the band using the ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tighten the band until it cannot be moved by hand.

14) Tap the clip with the punch provided at the end

of the ST.

ST 925091000 BAND TIGHTENING TOOL

CAUTION:

Tap to an extent that the boot underneath is not

damaged.

15) Cut off the band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

CAUTION:

Make sure that the end of the band is in close

contact with clip.

16) Extend and retract the PTJ to provide equal

grease coating.

E: INSPECTION

Check the removed parts for damage, wear, corro-

sion etc. If faulty, repair or replace.

•PTJ (pillow tripod joint)

Check for seizure, corrosion, damage, wear and

excessive play.

•EBJ (high-efficiency compact ball fixed joint)

Check for seizure, corrosion, damage and exces-

sive play.

•Shaft

Check for excessive bending, twisting, damage

and wear.

•Boot

Check for wear, warping, breakage and scratches.

•Grease

Check for discoloration and fluidity.

DS-00132

DS-00133

Page 846 of 2453

DS-29

Rear Drive Shaft

DRIVE SHAFT SYSTEM

7) Install the wheel.

Tightening torque:

110 N·m (11.2 kgf-m, 81.1 ft-lb)

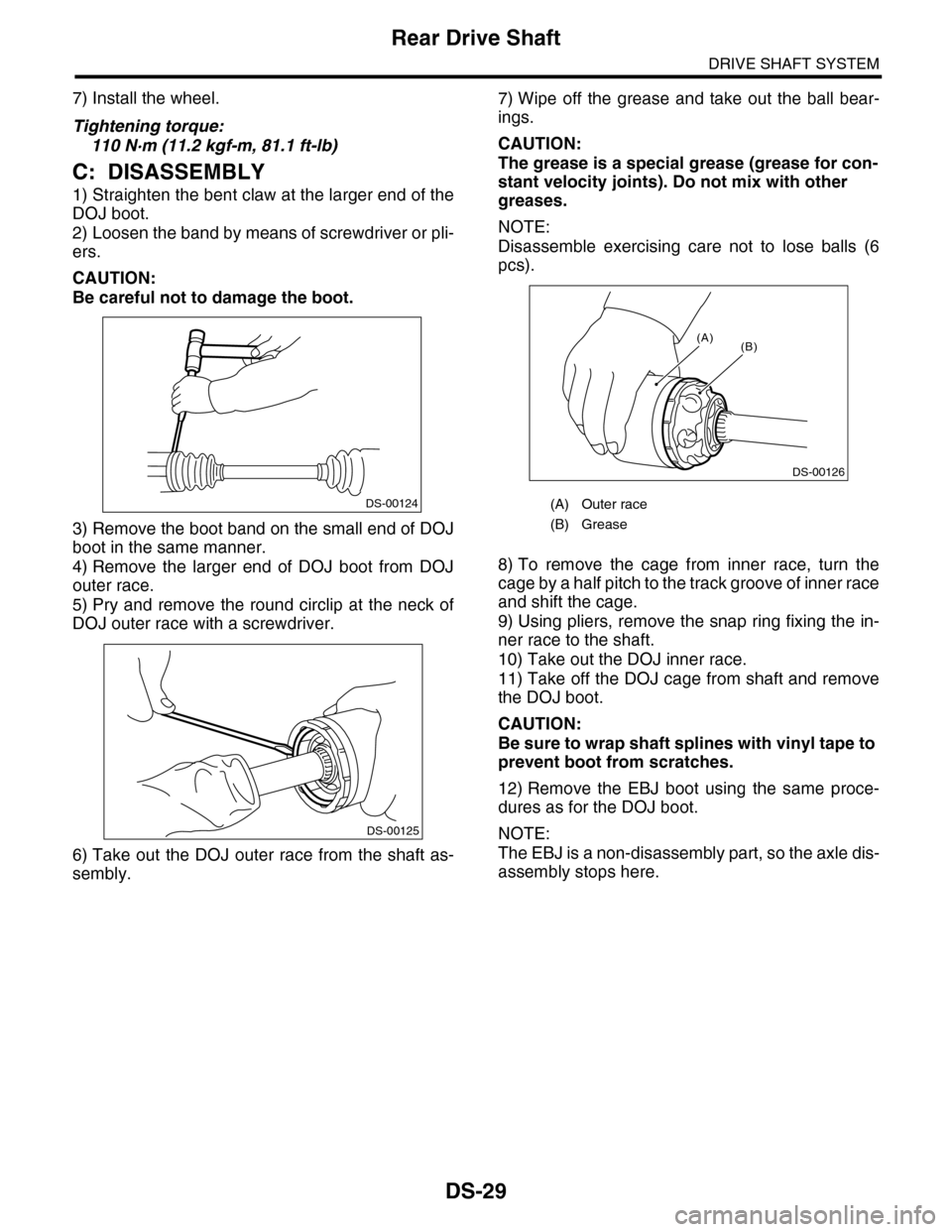

C: DISASSEMBLY

1) Straighten the bent claw at the larger end of the

DOJ boot.

2) Loosen the band by means of screwdriver or pli-

ers.

CAUTION:

Be careful not to damage the boot.

3) Remove the boot band on the small end of DOJ

boot in the same manner.

4) Remove the larger end of DOJ boot from DOJ

outer race.

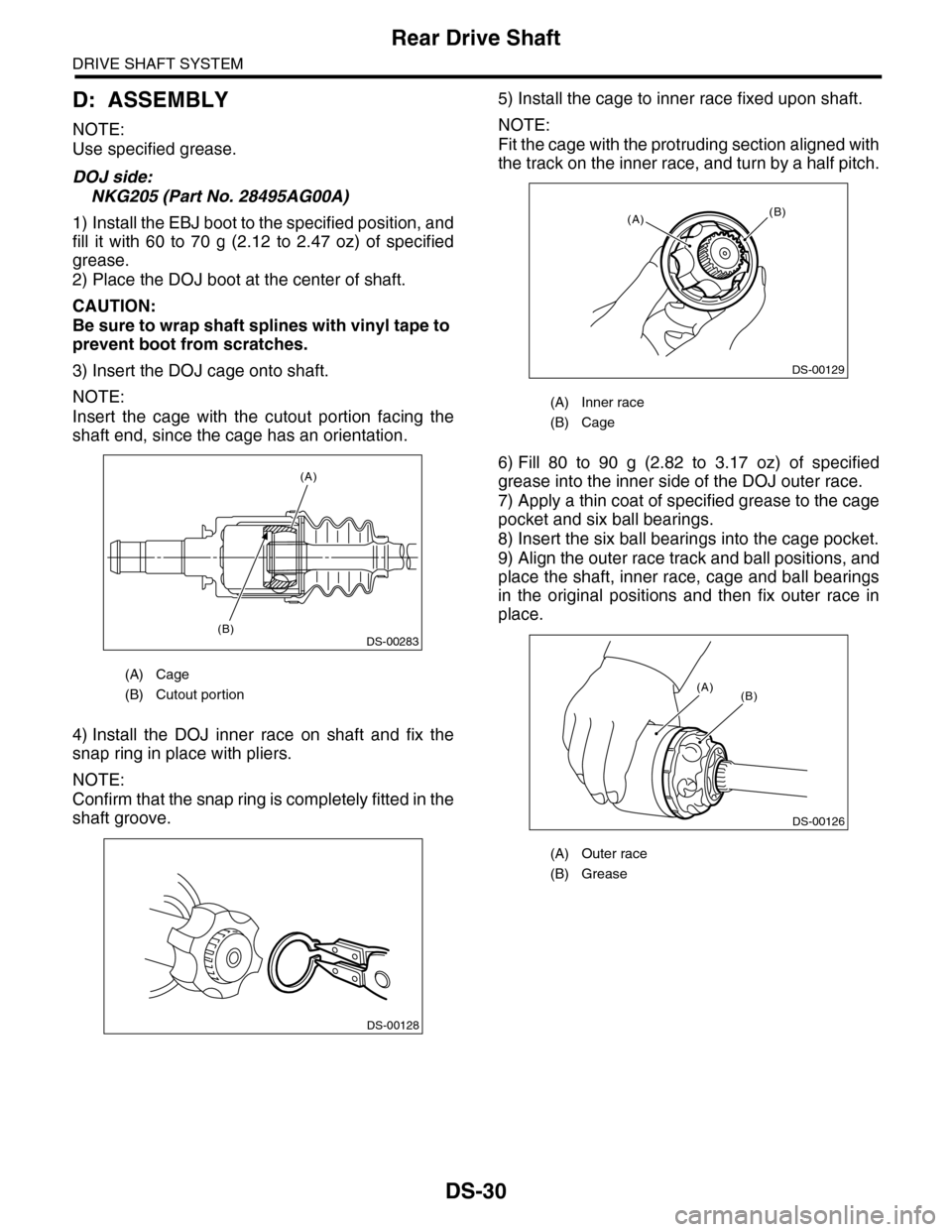

5) Pry and remove the round circlip at the neck of

DOJ outer race with a screwdriver.

6) Take out the DOJ outer race from the shaft as-

sembly.

7) Wipe off the grease and take out the ball bear-

ings.

CAUTION:

The grease is a special grease (grease for con-

stant velocity joints). Do not mix with other

greases.

NOTE:

Disassemble exercising care not to lose balls (6

pcs).

8) To remove the cage from inner race, turn the

cage by a half pitch to the track groove of inner race

and shift the cage.

9) Using pliers, remove the snap ring fixing the in-

ner race to the shaft.

10) Take out the DOJ inner race.

11) Take off the DOJ cage from shaft and remove

the DOJ boot.

CAUTION:

Be sure to wrap shaft splines with vinyl tape to

prevent boot from scratches.

12) Remove the EBJ boot using the same proce-

dures as for the DOJ boot.

NOTE:

The EBJ is a non-disassembly part, so the axle dis-

assembly stops here.

DS-00124

DS-00125

(A) Outer race

(B) Grease

DS-00126

(B)(A)

Page 847 of 2453

DS-30

Rear Drive Shaft

DRIVE SHAFT SYSTEM

D: ASSEMBLY

NOTE:

Use specified grease.

DOJ side:

NKG205 (Part No. 28495AG00A)

1) Install the EBJ boot to the specified position, and

fill it with 60 to 70 g (2.12 to 2.47 oz) of specified

grease.

2) Place the DOJ boot at the center of shaft.

CAUTION:

Be sure to wrap shaft splines with vinyl tape to

prevent boot from scratches.

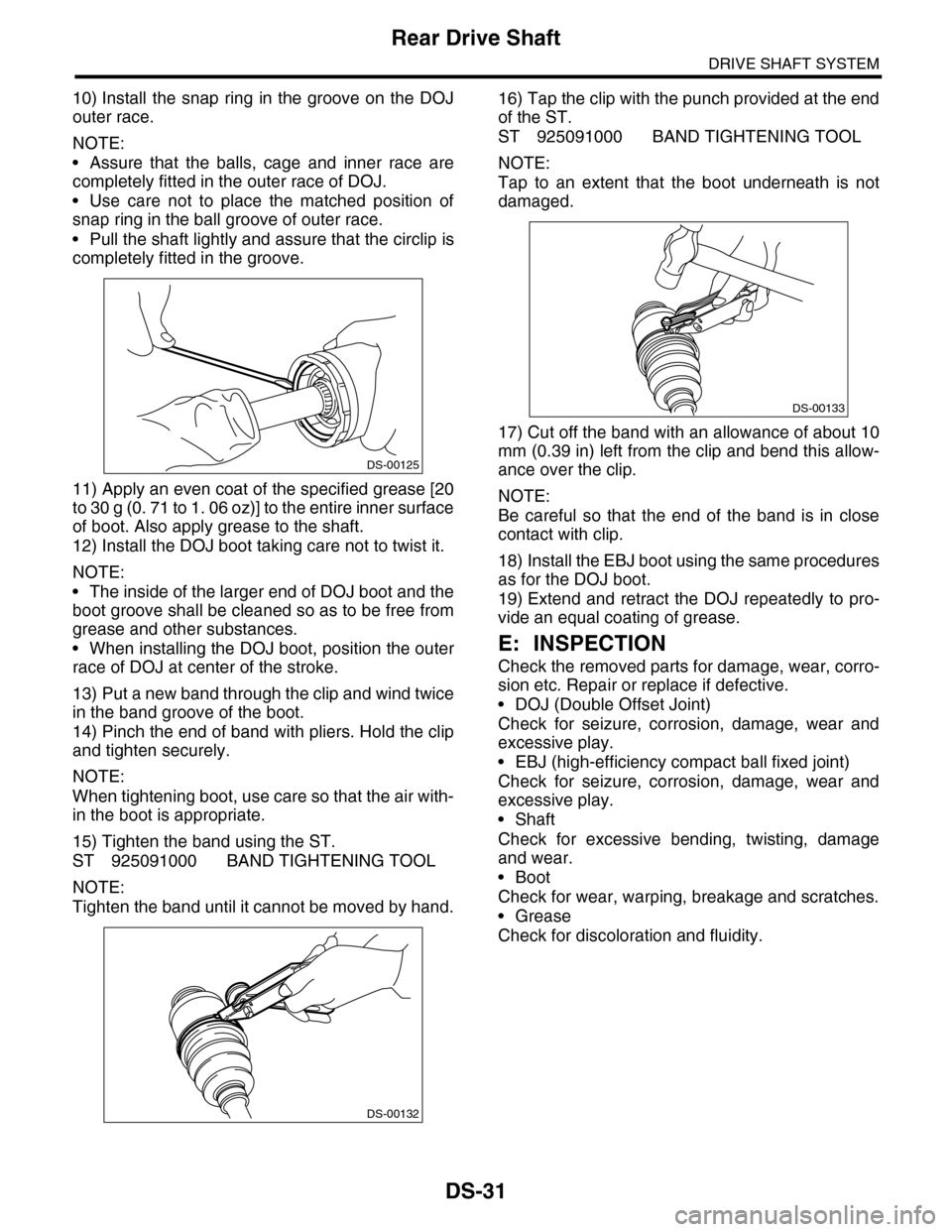

3) Insert the DOJ cage onto shaft.

NOTE:

Insert the cage with the cutout portion facing the

shaft end, since the cage has an orientation.

4) Install the DOJ inner race on shaft and fix the

snap ring in place with pliers.

NOTE:

Confirm that the snap ring is completely fitted in the

shaft groove.

5) Install the cage to inner race fixed upon shaft.

NOTE:

Fit the cage with the protruding section aligned with

the track on the inner race, and turn by a half pitch.

6) Fill 80 to 90 g (2.82 to 3.17 oz) of specified

grease into the inner side of the DOJ outer race.

7) Apply a thin coat of specified grease to the cage

pocket and six ball bearings.

8) Insert the six ball bearings into the cage pocket.

9) Align the outer race track and ball positions, and

place the shaft, inner race, cage and ball bearings

in the original positions and then fix outer race in

place.

(A) Cage

(B) Cutout portion

(A)

(B)DS-00283

DS-00128

(A) Inner race

(B) Cage

(A) Outer race

(B) Grease

(B)(A)

DS-00129

DS-00126

(B)(A)

Page 848 of 2453

DS-31

Rear Drive Shaft

DRIVE SHAFT SYSTEM

10) Install the snap ring in the groove on the DOJ

outer race.

NOTE:

•Assure that the balls, cage and inner race are

completely fitted in the outer race of DOJ.

•Use care not to place the matched position of

snap ring in the ball groove of outer race.

•Pull the shaft lightly and assure that the circlip is

completely fitted in the groove.

11) Apply an even coat of the specified grease [20

to 30 g (0. 71 to 1. 06 oz)] to the entire inner surface

of boot. Also apply grease to the shaft.

12) Install the DOJ boot taking care not to twist it.

NOTE:

•The inside of the larger end of DOJ boot and the

boot groove shall be cleaned so as to be free from

grease and other substances.

•When installing the DOJ boot, position the outer

race of DOJ at center of the stroke.

13) Put a new band through the clip and wind twice

in the band groove of the boot.

14) Pinch the end of band with pliers. Hold the clip

and tighten securely.

NOTE:

When tightening boot, use care so that the air with-

in the boot is appropriate.

15) Tighten the band using the ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tighten the band until it cannot be moved by hand.

16) Tap the clip with the punch provided at the end

of the ST.

ST 925091000 BAND TIGHTENING TOOL

NOTE:

Tap to an extent that the boot underneath is not

damaged.

17) Cut off the band with an allowance of about 10

mm (0.39 in) left from the clip and bend this allow-

ance over the clip.

NOTE:

Be careful so that the end of the band is in close

contact with clip.

18) Install the EBJ boot using the same procedures

as for the DOJ boot.

19) Extend and retract the DOJ repeatedly to pro-

vide an equal coating of grease.

E: INSPECTION

Check the removed parts for damage, wear, corro-

sion etc. Repair or replace if defective.

•DOJ (Double Offset Joint)

Check for seizure, corrosion, damage, wear and

excessive play.

•EBJ (high-efficiency compact ball fixed joint)

Check for seizure, corrosion, damage, wear and

excessive play.

•Shaft

Check for excessive bending, twisting, damage

and wear.

•Boot

Check for wear, warping, breakage and scratches.

•Grease

Check for discoloration and fluidity.

DS-00125

DS-00132

DS-00133

Page 858 of 2453

FS-10

Wheel Alignment

FRONT SUSPENSION

4. STEERING ANGLE

•INSPECTION

•ADJUSTMENT

1) Turn the tie-rod to adjust the steering angle of

both inner and outer wheels.

2) Check the toe–in.

NOTE:

Correct the boot if it is twisted.

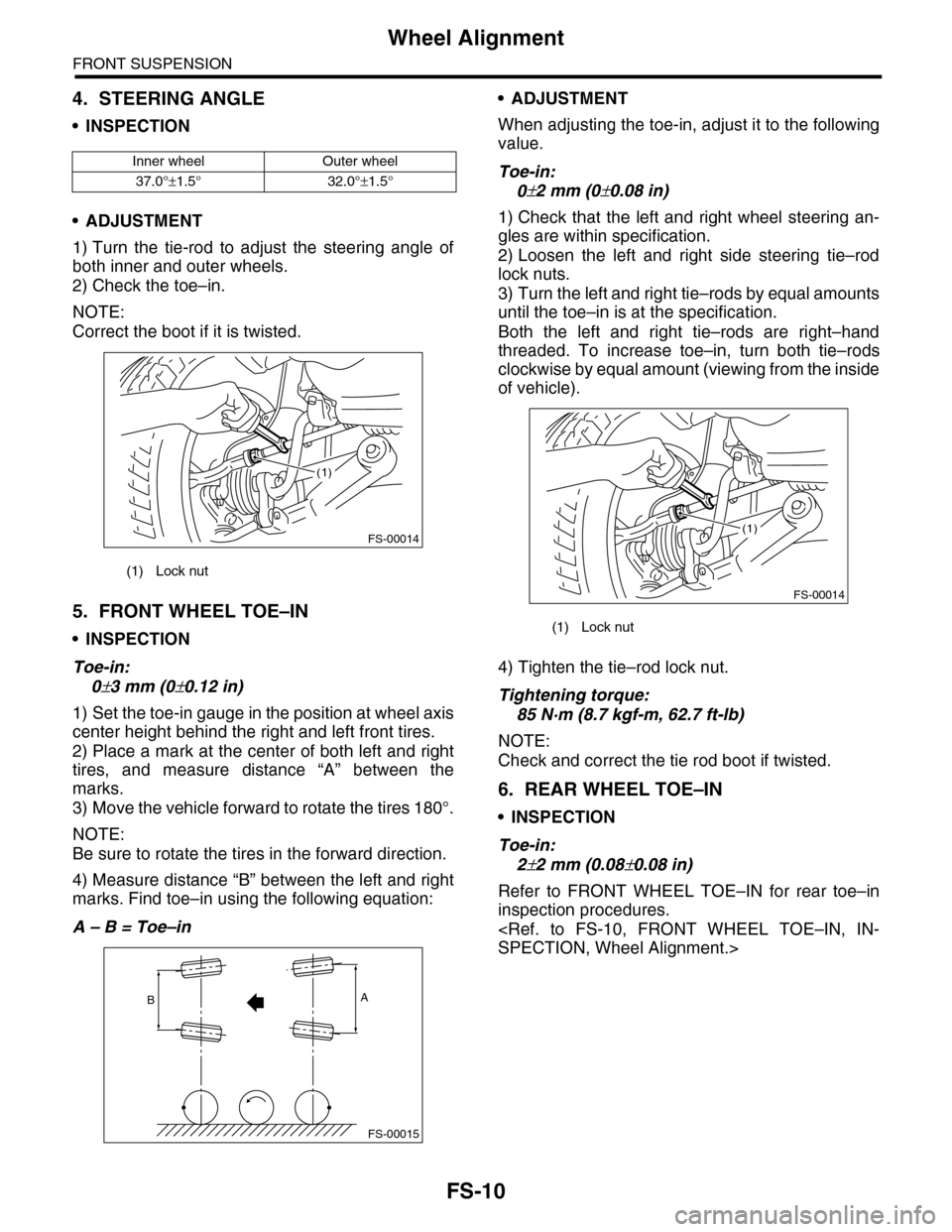

5. FRONT WHEEL TOE–IN

•INSPECTION

Toe-in:

0±3 mm (0±0.12 in)

1) Set the toe-in gauge in the position at wheel axis

center height behind the right and left front tires.

2) Place a mark at the center of both left and right

tires, and measure distance “A” between the

marks.

3) Move the vehicle forward to rotate the tires 180°.

NOTE:

Be sure to rotate the tires in the forward direction.

4) Measure distance “B” between the left and right

marks. Find toe–in using the following equation:

A – B = Toe–in

•ADJUSTMENT

When adjusting the toe-in, adjust it to the following

value.

Toe-in:

0±2 mm (0±0.08 in)

1) Check that the left and right wheel steering an-

gles are within specification.

2) Loosen the left and right side steering tie–rod

lock nuts.

3) Turn the left and right tie–rods by equal amounts

until the toe–in is at the specification.

Both the left and right tie–rods are right–hand

threaded. To increase toe–in, turn both tie–rods

clockwise by equal amount (viewing from the inside

of vehicle).

4) Tighten the tie–rod lock nut.

Tightening torque:

85 N·m (8.7 kgf-m, 62.7 ft-lb)

NOTE:

Check and correct the tie rod boot if twisted.

6. REAR WHEEL TOE–IN

•INSPECTION

Toe-in:

2±2 mm (0.08±0.08 in)

Refer to FRONT WHEEL TOE–IN for rear toe–in

inspection procedures.

Inner wheel Outer wheel

37.0°±1.5° 32.0°±1.5°

(1) Lock nut

FS-00014

(1)

FS-00015

AB

(1) Lock nut

FS-00014

(1)

Page 871 of 2453

FS-23

Front Crossmember

FRONT SUSPENSION

8. Front Crossmember

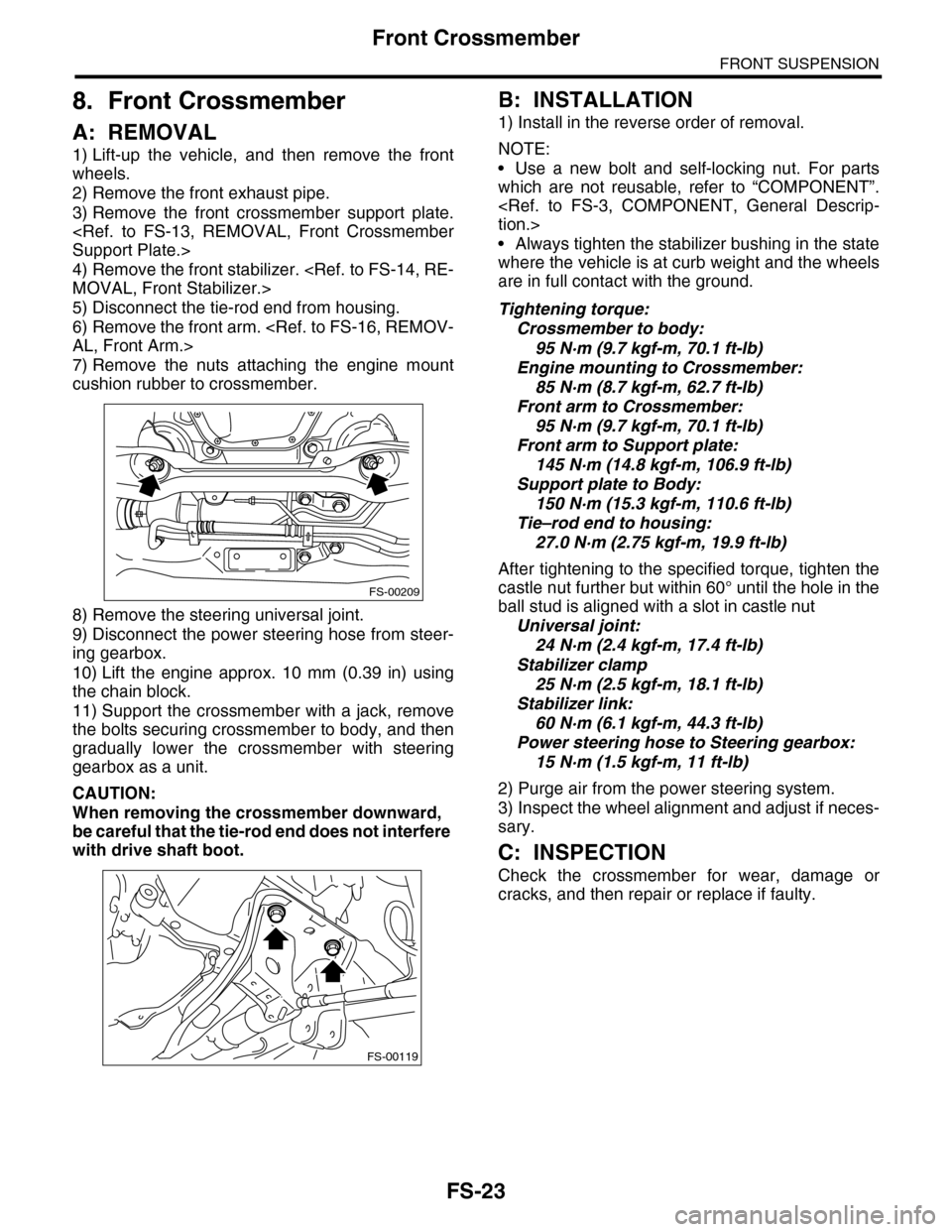

A: REMOVAL

1) Lift-up the vehicle, and then remove the front

wheels.

2) Remove the front exhaust pipe.

3) Remove the front crossmember support plate.

4) Remove the front stabilizer.

5) Disconnect the tie-rod end from housing.

6) Remove the front arm.

7) Remove the nuts attaching the engine mount

cushion rubber to crossmember.

8) Remove the steering universal joint.

9) Disconnect the power steering hose from steer-

ing gearbox.

10) Lift the engine approx. 10 mm (0.39 in) using

the chain block.

11) Support the crossmember with a jack, remove

the bolts securing crossmember to body, and then

gradually lower the crossmember with steering

gearbox as a unit.

CAUTION:

When removing the crossmember downward,

be careful that the tie-rod end does not interfere

with drive shaft boot.

B: INSTALLATION

1) Install in the reverse order of removal.

NOTE:

•Use a new bolt and self-locking nut. For parts

which are not reusable, refer to “COMPONENT”.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Tightening torque:

Crossmember to body:

95 N·m (9.7 kgf-m, 70.1 ft-lb)

Engine mounting to Crossmember:

85 N·m (8.7 kgf-m, 62.7 ft-lb)

Front arm to Crossmember:

95 N·m (9.7 kgf-m, 70.1 ft-lb)

Front arm to Support plate:

145 N·m (14.8 kgf-m, 106.9 ft-lb)

Support plate to Body:

150 N·m (15.3 kgf-m, 110.6 ft-lb)

Tie–rod end to housing:

27.0 N·m (2.75 kgf-m, 19.9 ft-lb)

After tightening to the specified torque, tighten the

castle nut further but within 60° until the hole in the

ball stud is aligned with a slot in castle nut

Universal joint:

24 N·m (2.4 kgf-m, 17.4 ft-lb)

Stabilizer clamp

25 N·m (2.5 kgf-m, 18.1 ft-lb)

Stabilizer link:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

Power steering hose to Steering gearbox:

15 N·m (1.5 kgf-m, 11 ft-lb)

2) Purge air from the power steering system.

3) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Check the crossmember for wear, damage or

cracks, and then repair or replace if faulty.

FS-00209

FS-00119

Page 877 of 2453

PB-6

Parking Brake Cable

PARKING BRAKE

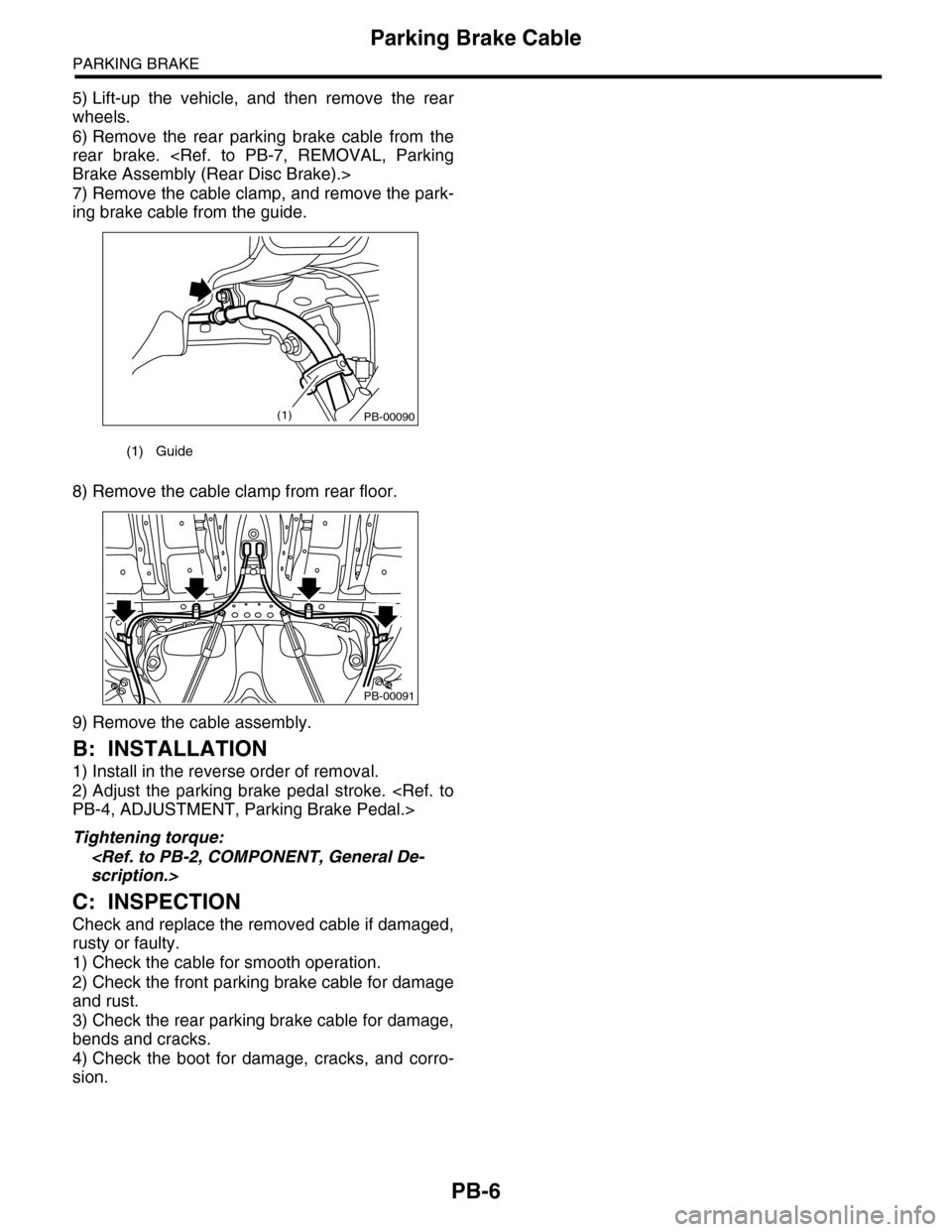

5) Lift-up the vehicle, and then remove the rear

wheels.

6) Remove the rear parking brake cable from the

rear brake.

7) Remove the cable clamp, and remove the park-

ing brake cable from the guide.

8) Remove the cable clamp from rear floor.

9) Remove the cable assembly.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Adjust the parking brake pedal stroke.

Tightening torque:

C: INSPECTION

Check and replace the removed cable if damaged,

rusty or faulty.

1) Check the cable for smooth operation.

2) Check the front parking brake cable for damage

and rust.

3) Check the rear parking brake cable for damage,

bends and cracks.

4) Check the boot for damage, cracks, and corro-

sion.

(1) Guide

PB-00090(1)

PB-00091