lock SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 235 of 2453

EB-16

Front Door

EXTERIOR BODY PANELS

4. Front Door

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the front door trim.

3) Remove the outer mirror assembly.

4) Remove the front door speaker.

5) Remove the sealing cover.

6) Remove the front door glass.

7) Remove the door sash, and remove the front

door regulator and motor assemblies.

bly.>

8) Remove the front inner remote.

9) Remove the front door latch assembly.

Lock Actuator Assembly.>

10) Remove the front outer handle.

11) Remove the front door weather strip.

NOTE:

If the weather strip clip is removed with excessive

force, the weather strip may be damaged. Be sure

to use clip remover to remove.

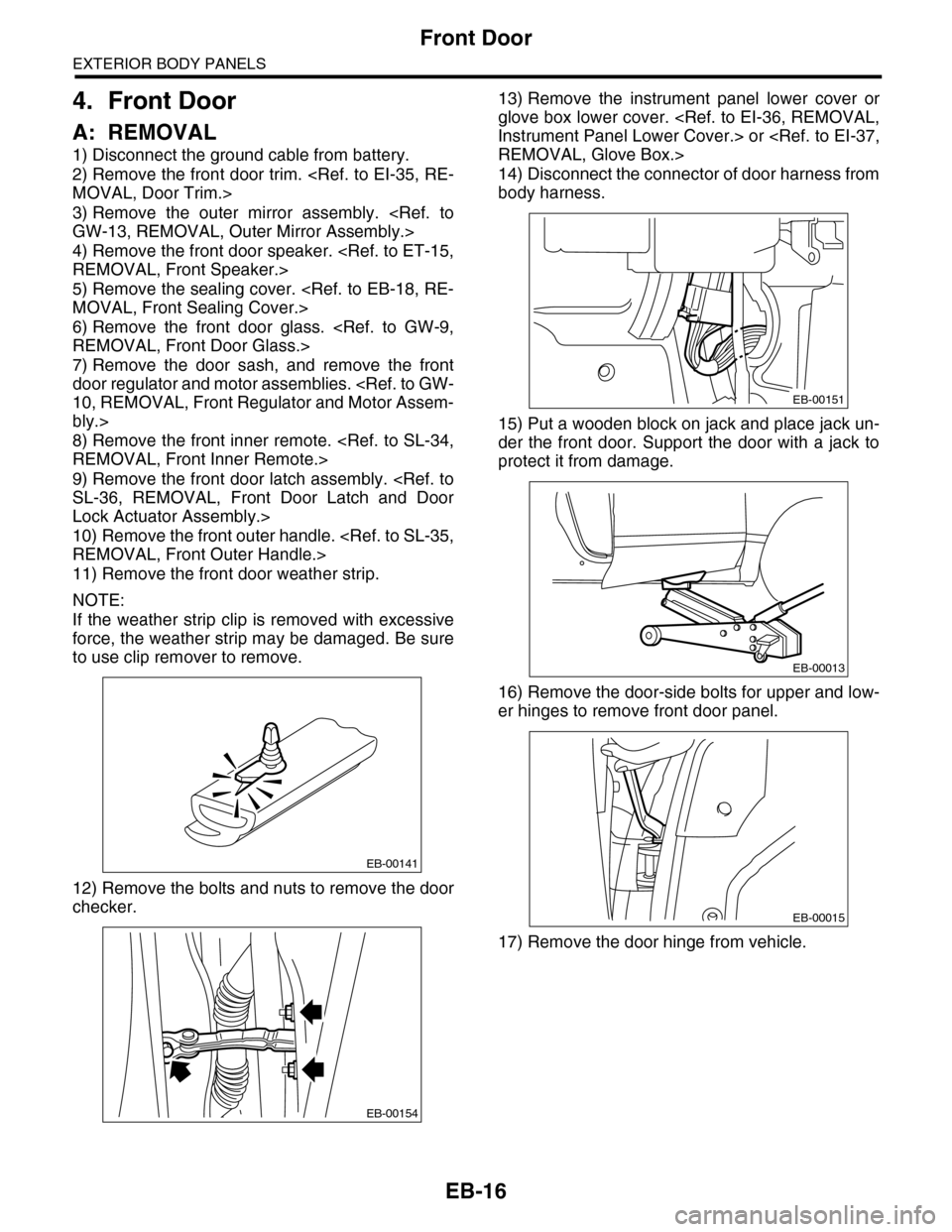

12) Remove the bolts and nuts to remove the door

checker.

13) Remove the instrument panel lower cover or

glove box lower cover.

14) Disconnect the connector of door harness from

body harness.

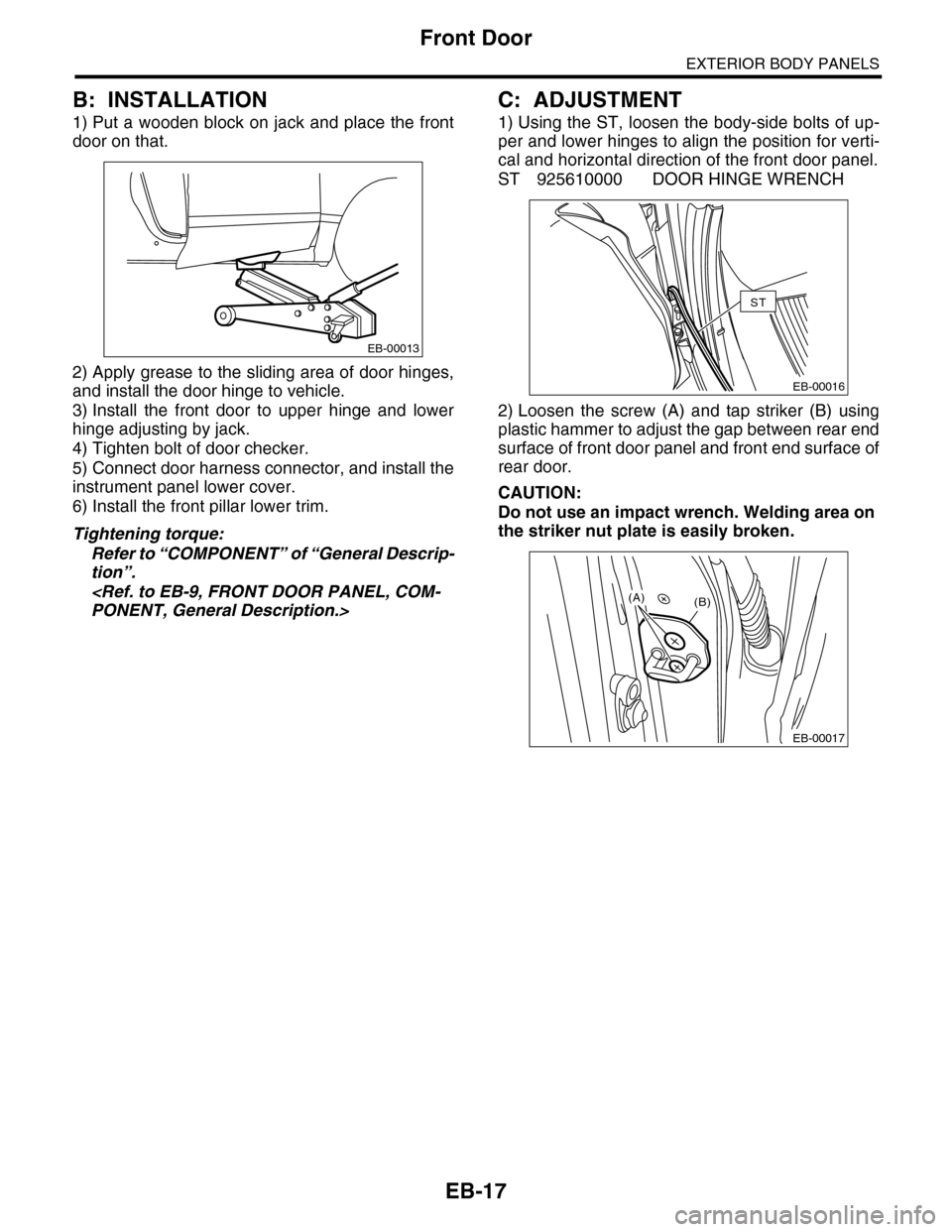

15) Put a wooden block on jack and place jack un-

der the front door. Support the door with a jack to

protect it from damage.

16) Remove the door-side bolts for upper and low-

er hinges to remove front door panel.

17) Remove the door hinge from vehicle.

EB-00141

EB-00154

EB-00151

EB-00013

EB-00015

Page 236 of 2453

EB-17

Front Door

EXTERIOR BODY PANELS

B: INSTALLATION

1) Put a wooden block on jack and place the front

door on that.

2) Apply grease to the sliding area of door hinges,

and install the door hinge to vehicle.

3) Install the front door to upper hinge and lower

hinge adjusting by jack.

4) Tighten bolt of door checker.

5) Connect door harness connector, and install the

instrument panel lower cover.

6) Install the front pillar lower trim.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: ADJUSTMENT

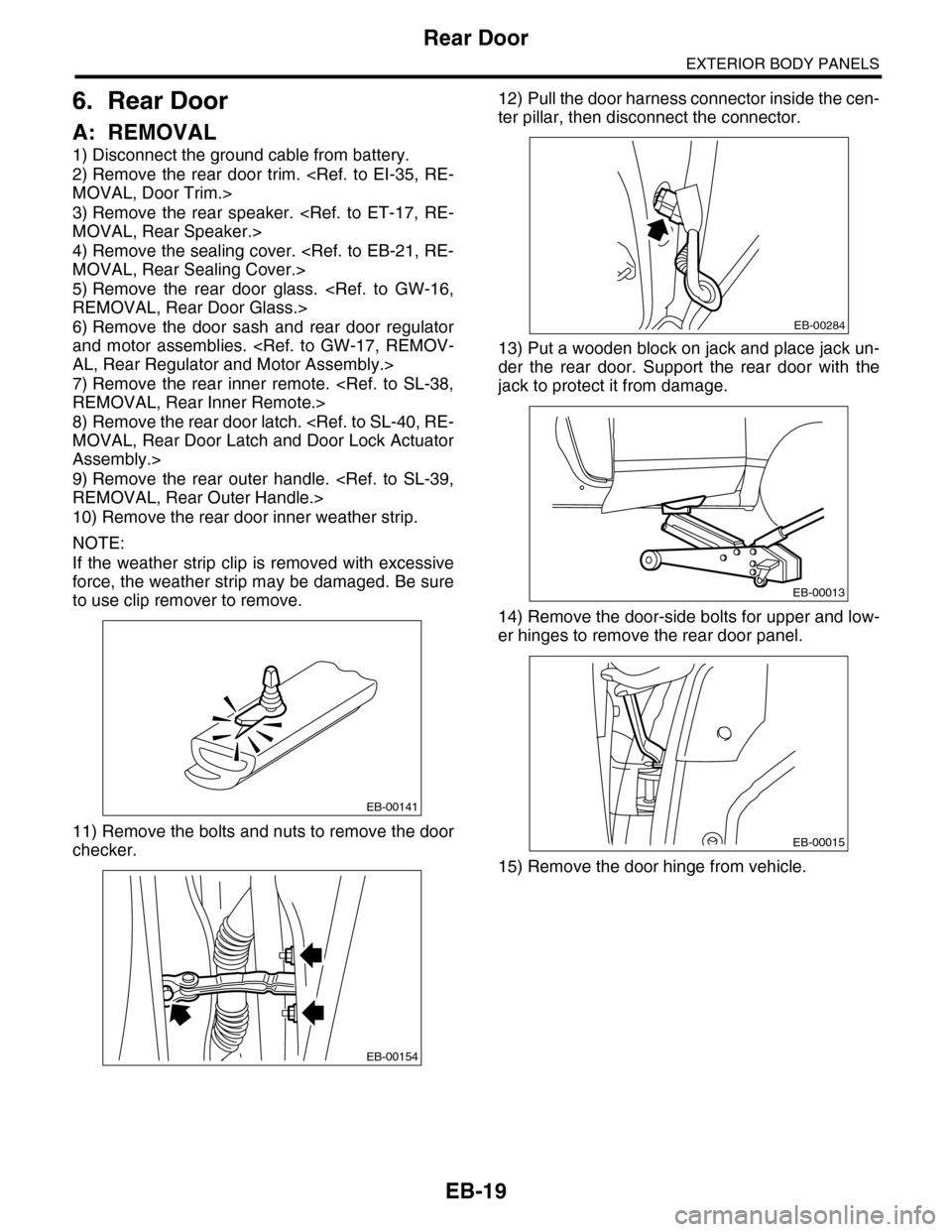

1) Using the ST, loosen the body-side bolts of up-

per and lower hinges to align the position for verti-

cal and horizontal direction of the front door panel.

ST 925610000 DOOR HINGE WRENCH

2) Loosen the screw (A) and tap striker (B) using

plastic hammer to adjust the gap between rear end

surface of front door panel and front end surface of

rear door.

CAUTION:

Do not use an impact wrench. Welding area on

the striker nut plate is easily broken.

EB-00013

EB-00016

ST

EB-00017

(B)(A)

Page 238 of 2453

EB-19

Rear Door

EXTERIOR BODY PANELS

6. Rear Door

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the rear door trim.

3) Remove the rear speaker.

4) Remove the sealing cover.

5) Remove the rear door glass.

6) Remove the door sash and rear door regulator

and motor assemblies.

7) Remove the rear inner remote.

8) Remove the rear door latch.

Assembly.>

9) Remove the rear outer handle.

10) Remove the rear door inner weather strip.

NOTE:

If the weather strip clip is removed with excessive

force, the weather strip may be damaged. Be sure

to use clip remover to remove.

11) Remove the bolts and nuts to remove the door

checker.

12) Pull the door harness connector inside the cen-

ter pillar, then disconnect the connector.

13) Put a wooden block on jack and place jack un-

der the rear door. Support the rear door with the

jack to protect it from damage.

14) Remove the door-side bolts for upper and low-

er hinges to remove the rear door panel.

15) Remove the door hinge from vehicle.

EB-00141

EB-00154

EB-00284

EB-00013

EB-00015

Page 239 of 2453

EB-20

Rear Door

EXTERIOR BODY PANELS

B: INSTALLATION

1) Put a wooden block on jack and place the rear

door on that.

2) Apply grease to the moving part of door hinges.

3) Install the rear door to upper hinge and lower

hinge adjusting by jack.

4) Tighten bolt of door checker.

5) Connect the door harness connector.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

C: ADJUSTMENT

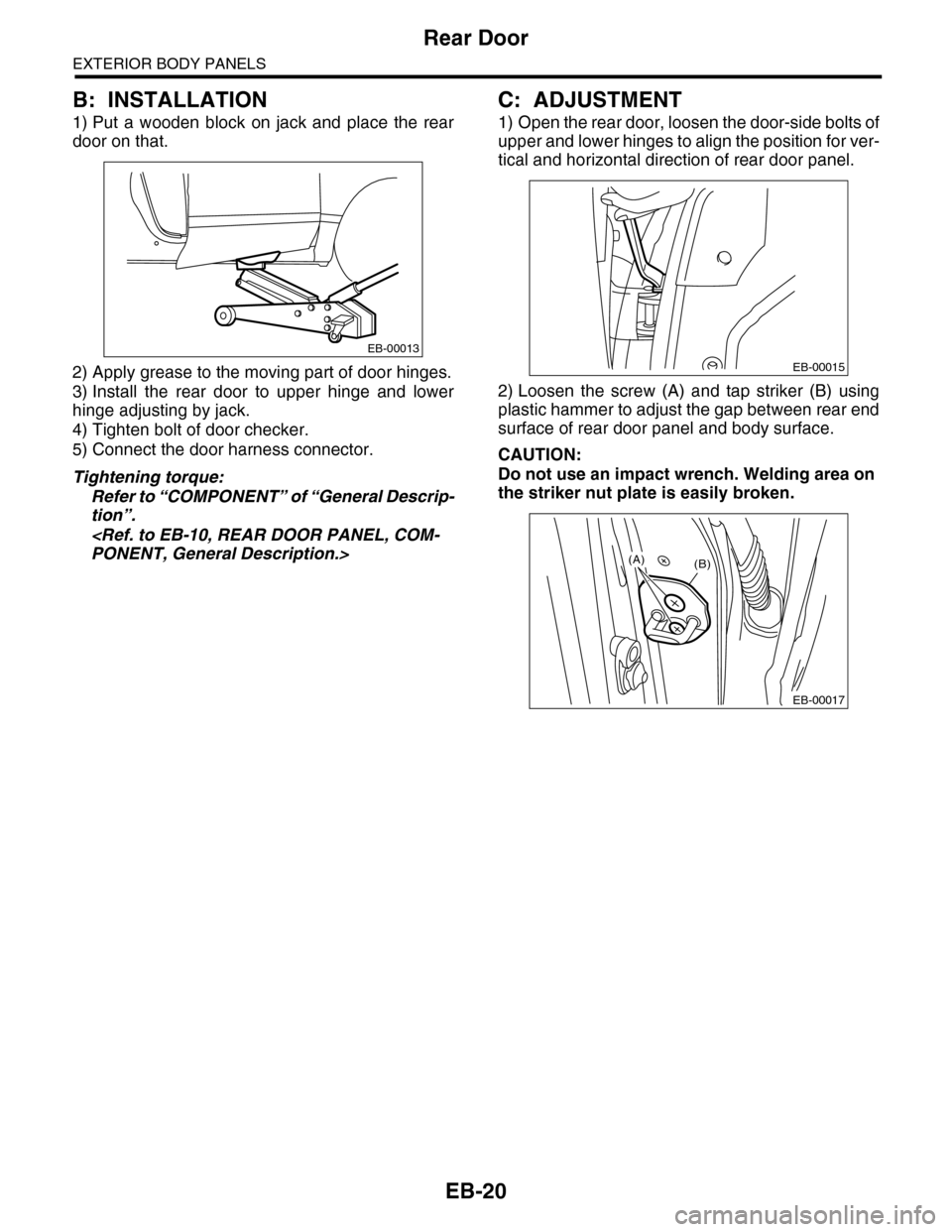

1) Open the rear door, loosen the door-side bolts of

upper and lower hinges to align the position for ver-

tical and horizontal direction of rear door panel.

2) Loosen the screw (A) and tap striker (B) using

plastic hammer to adjust the gap between rear end

surface of rear door panel and body surface.

CAUTION:

Do not use an impact wrench. Welding area on

the striker nut plate is easily broken.

EB-00013

EB-00015

EB-00017

(B)(A)

Page 265 of 2453

EI-23

Front Bumper

EXTERIOR/INTERIOR TRIM

C: REPAIR

1. COATING METHOD FOR PP BUMPER

Process

No.Process name Job contents

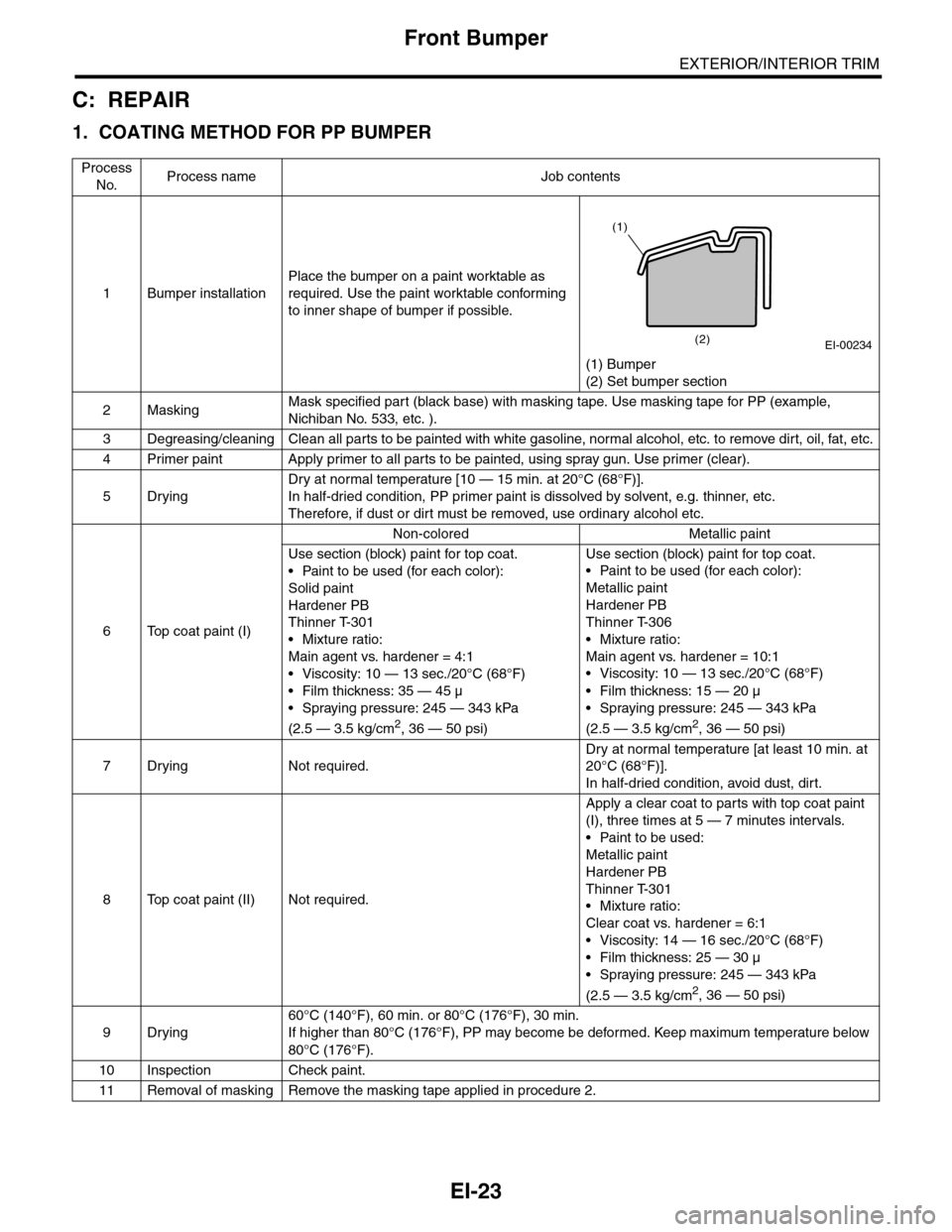

1Bumper installation

Place the bumper on a paint worktable as

required. Use the paint worktable conforming

to inner shape of bumper if possible.

(1) Bumper

(2) Set bumper section

2MaskingMask specified part (black base) with masking tape. Use masking tape for PP (example,

Nichiban No. 533, etc. ).

3Degreasing/cleaningClean all parts to be painted with white gasoline, normal alcohol, etc. to remove dirt, oil, fat, etc.

4Primer paint Apply primer to all parts to be painted, using spray gun. Use primer (clear).

5Drying

Dry at normal temperature [10 — 15 min. at 20°C (68°F)].

In half-dried condition, PP primer paint is dissolved by solvent, e.g. thinner, etc.

Therefore, if dust or dirt must be removed, use ordinary alcohol etc.

6Top coat paint (I)

Non-colored Metallic paint

Use section (block) paint for top coat.

•Paint to be used (for each color):

Solid paint

Hardener PB

Thinner T-301

•Mixture ratio:

Main agent vs. hardener = 4:1

• Viscosity: 10 — 13 sec./20°C (68°F)

•Film thickness: 35 — 45 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

Use section (block) paint for top coat.

•Paint to be used (for each color):

Metallic paint

Hardener PB

Thinner T-306

•Mixture ratio:

Main agent vs. hardener = 10:1

•Viscosity: 10 — 13 sec./20°C (68°F)

•Film thickness: 15 — 20 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

7Drying Not required.

Dry at normal temperature [at least 10 min. at

20°C (68°F)].

In half-dried condition, avoid dust, dirt.

8Top coat paint (II)Not required.

Apply a clear coat to parts with top coat paint

(I), three times at 5 — 7 minutes intervals.

•Paint to be used:

Metallic paint

Hardener PB

Thinner T-301

•Mixture ratio:

Clear coat vs. hardener = 6:1

•Viscosity: 14 — 16 sec./20°C (68°F)

•Film thickness: 25 — 30 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

9Drying

60°C (140°F), 60 min. or 80°C (176°F), 30 min.

If higher than 80°C (176°F), PP may become be deformed. Keep maximum temperature below

80°C (176°F).

10 Inspection Check paint.

11 Removal of masking Remove the masking tape applied in procedure 2.

EI-00234(2)

(1)

Page 269 of 2453

EI-27

Front Bumper

EXTERIOR/INTERIOR TRIM

18Cleaning/degreas-

ingSame as Process No. 12.

19 Top coat (I)

Non-colored Metallic paint

Use a “block” coating method.

•Recommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

•Mixture ratio:

Suncryl (SC) vs. No. 307 Flex Hardener = 3 : 1

•Viscosity: 11 — 13 sec./20°C (68°F)

• Coating film thickness: 40 — 50 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

Use a “block” coating method.

•Recommended paint:

Suncryl (SC)

No. 307 Flex Hardener

SC Reducer (thinner)

•Mixture ratio:

Suncryl (SC) vs. No. 307 Flex Hardener = 3 : 1

•Viscosity: 11 — 13 sec./20°C (68°F)

•Coating film thickness: 20 — 30 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

20 Leave unattended Not required.

Leave unattended at 20°C (68°F) for at least

10 minutes until the topcoat area is half-dry.

NOTE:

Be careful to keep dust or dirt from coming in

contact with the affected area.

21 Top coat (II) Not required.

Apply a clear coat three times at an interval of

3 to 5 minutes.

•Recommended paint:

SC710 Overlay Clear

No. 307 Flex Hardener

SC Reducer (thinner)

•Mixture ratio:

Suncryl (SC) vs. No. 307 Flex Hardener = 3 : 1

•Viscosity: 10 — 13 sec./20°C (68°F)

•Coating film thickness: 20 — 30 µ

•Spraying pressure: 245 — 343 kPa

(2.5 — 3.5 kg/cm2, 36 — 50 psi)

22 Drying

Allow the coated surface to dry for two hours at 20°C (68°F) or 30 minutes at 60°C (140°F)].

NOTE:Do not allow the temperature to exceed 80°C (176°F) since this will deform the PP substrate.

23 Inspection Carefully check the condition of the repaired area.

24Removal of mask-

ingRemove the masking tape applied in Process No. 11 and 13.

25 Parts installation Install parts on the bumper in reverse order of removal.

26 Bumper installation Install the bumper.

Process

No.Process name Job contents

Page 291 of 2453

EI-49

Assist Grip

EXTERIOR/INTERIOR TRIM

22.Assist Grip

A: REMOVAL

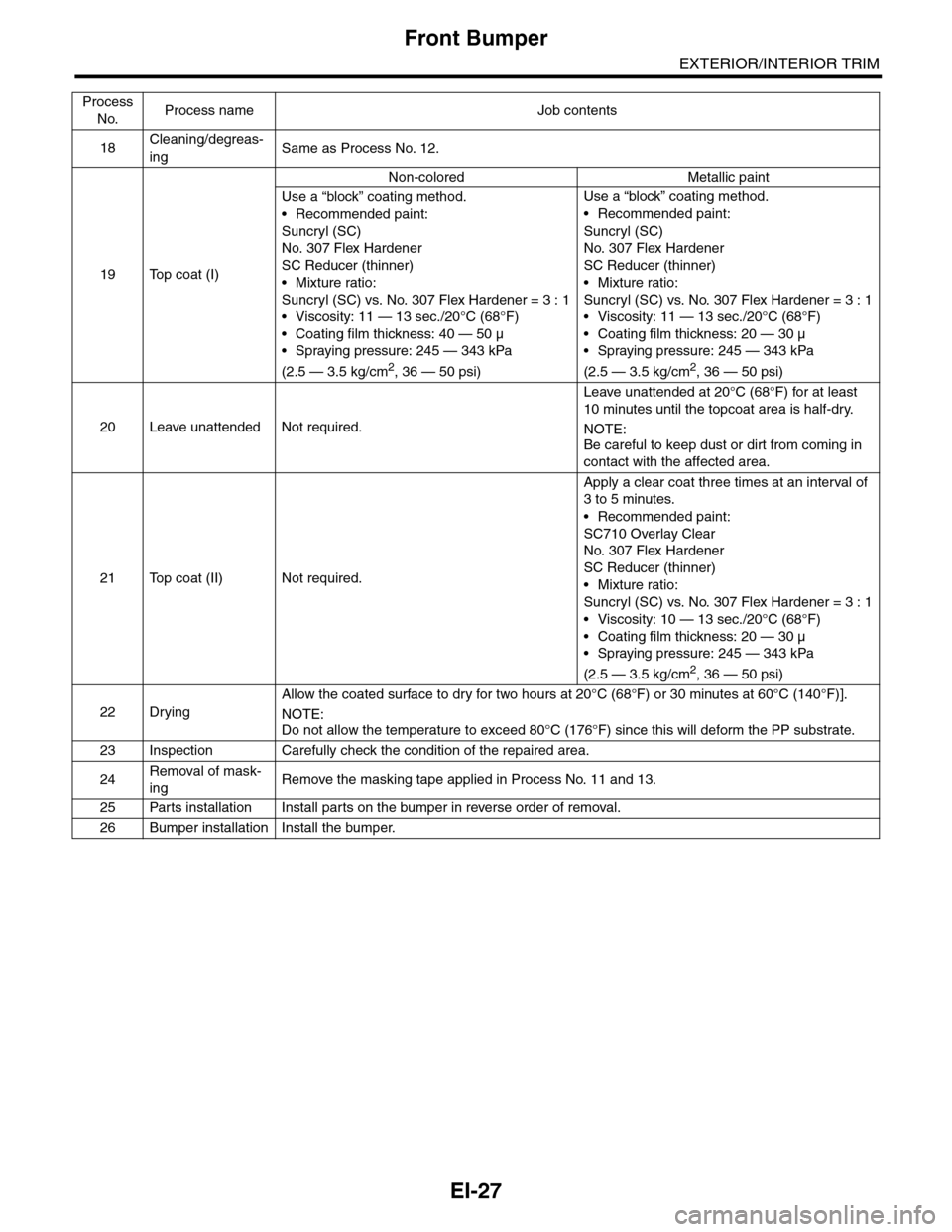

1) Remove the screw cover, and remove the screw

inside.

2) Pull the left side of assist grip toward you, and ro-

tate the right side of it counterclockwise to remove.

3) Remove the roof trim.

4) Remove the bolts, and remove the assist grip

bracket.

B: INSTALLATION

Install in the reverse order of removal.

CAUTION:

Be sure to install the grommet to assist grip

bracket.

When the assist grip is installed with no grom-

met, it ill cause the grip to not return properly.

(A) Grommet

EI-00809

EI-01065

(A)

Page 301 of 2453

GW-6

Power Window System

GLASS/WINDOWS/MIRRORS

2. Power Window System

A: WIRING DIAGRAM

B: INSPECTION

Symptom Repair order

All power windows do not operate.

1. Fuse (SBF-4)

2. Power window circuit breaker

3. Power window relay

4. Wiring Harness

5. Body integrated unit

Par ticular window does not operate.

1. Power window main switch

2. Power window sub switch

3. Power window motor

4. Wiring Harness

“Window Lock” does not operate. Power window main switch

Page 302 of 2453

GW-7

Power Window Control Switch

GLASS/WINDOWS/MIRRORS

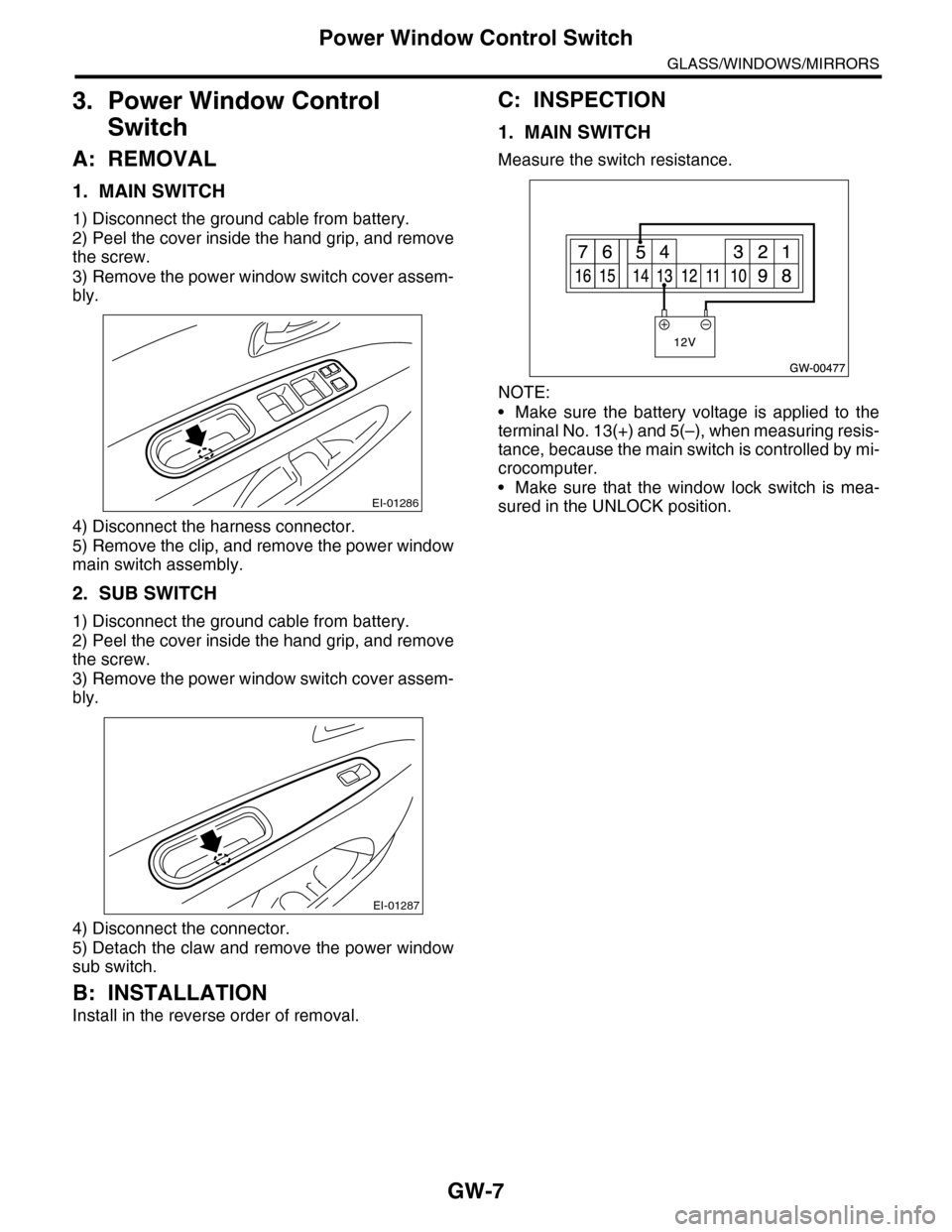

3. Power Window Control

Switch

A: REMOVAL

1. MAIN SWITCH

1) Disconnect the ground cable from battery.

2) Peel the cover inside the hand grip, and remove

the screw.

3) Remove the power window switch cover assem-

bly.

4) Disconnect the harness connector.

5) Remove the clip, and remove the power window

main switch assembly.

2. SUB SWITCH

1) Disconnect the ground cable from battery.

2) Peel the cover inside the hand grip, and remove

the screw.

3) Remove the power window switch cover assem-

bly.

4) Disconnect the connector.

5) Detach the claw and remove the power window

sub switch.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

1. MAIN SWITCH

Measure the switch resistance.

NOTE:

•Make sure the battery voltage is applied to the

terminal No. 13(+) and 5(–), when measuring resis-

tance, because the main switch is controlled by mi-

crocomputer.

•Make sure that the window lock switch is mea-

sured in the UNLOCK position.EI-01286

EI-01287

Page 355 of 2453

AC-29

Blower Resistor (Dual A/C Model)

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

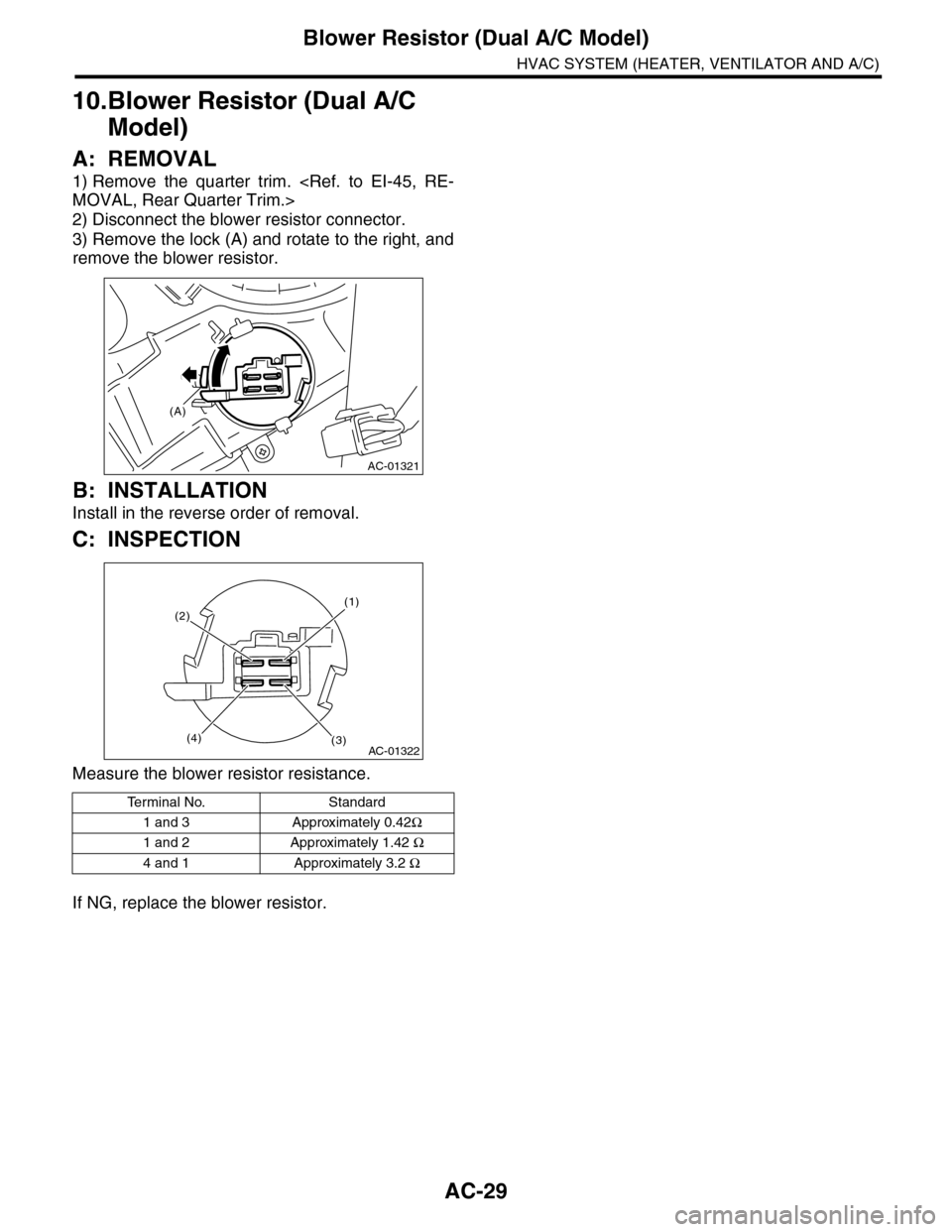

10.Blower Resistor (Dual A/C

Model)

A: REMOVAL

1) Remove the quarter trim.

2) Disconnect the blower resistor connector.

3) Remove the lock (A) and rotate to the right, and

remove the blower resistor.

B: INSTALLATION

Install in the reverse order of removal.

C: INSPECTION

Measure the blower resistor resistance.

If NG, replace the blower resistor.

Te r m i n a l N o . S t a n d a r d

1 and 3 Approximately 0.42Ω

1 and 2 Approximately 1.42 Ω

4 and 1 Approximately 3.2 Ω

AC-01321

(A)

AC-01322(4)(3)

(1)(2)