stop start SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 758 of 2453

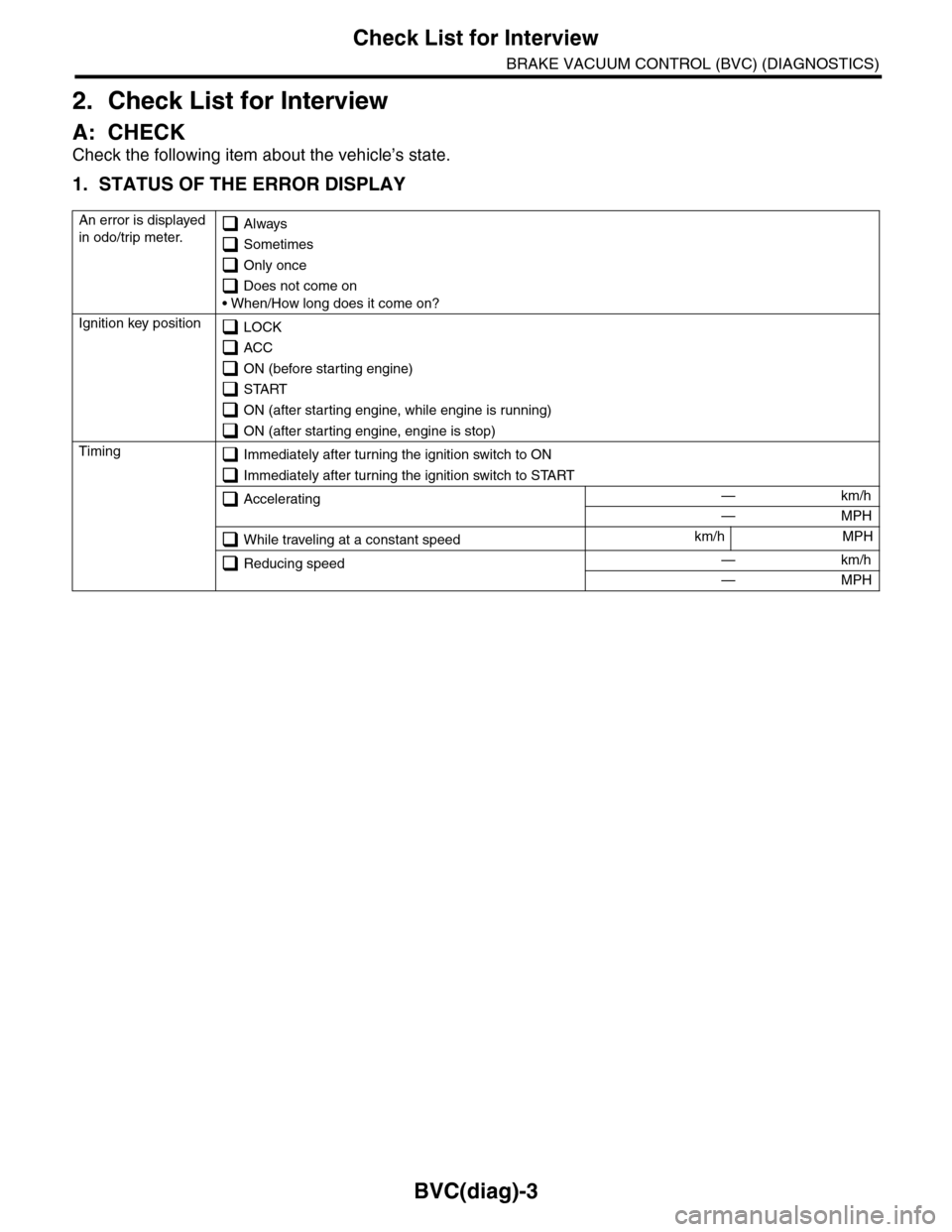

BVC(diag)-3

Check List for Interview

BRAKE VACUUM CONTROL (BVC) (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Check the following item about the vehicle’s state.

1. STATUS OF THE ERROR DISPLAY

An error is displayed

in odo/trip meter. Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

— MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

Page 928 of 2453

PS-48

Power Steering Fluid

POWER ASSISTED SYSTEM (POWER STEERING)

9. Power Steering Fluid

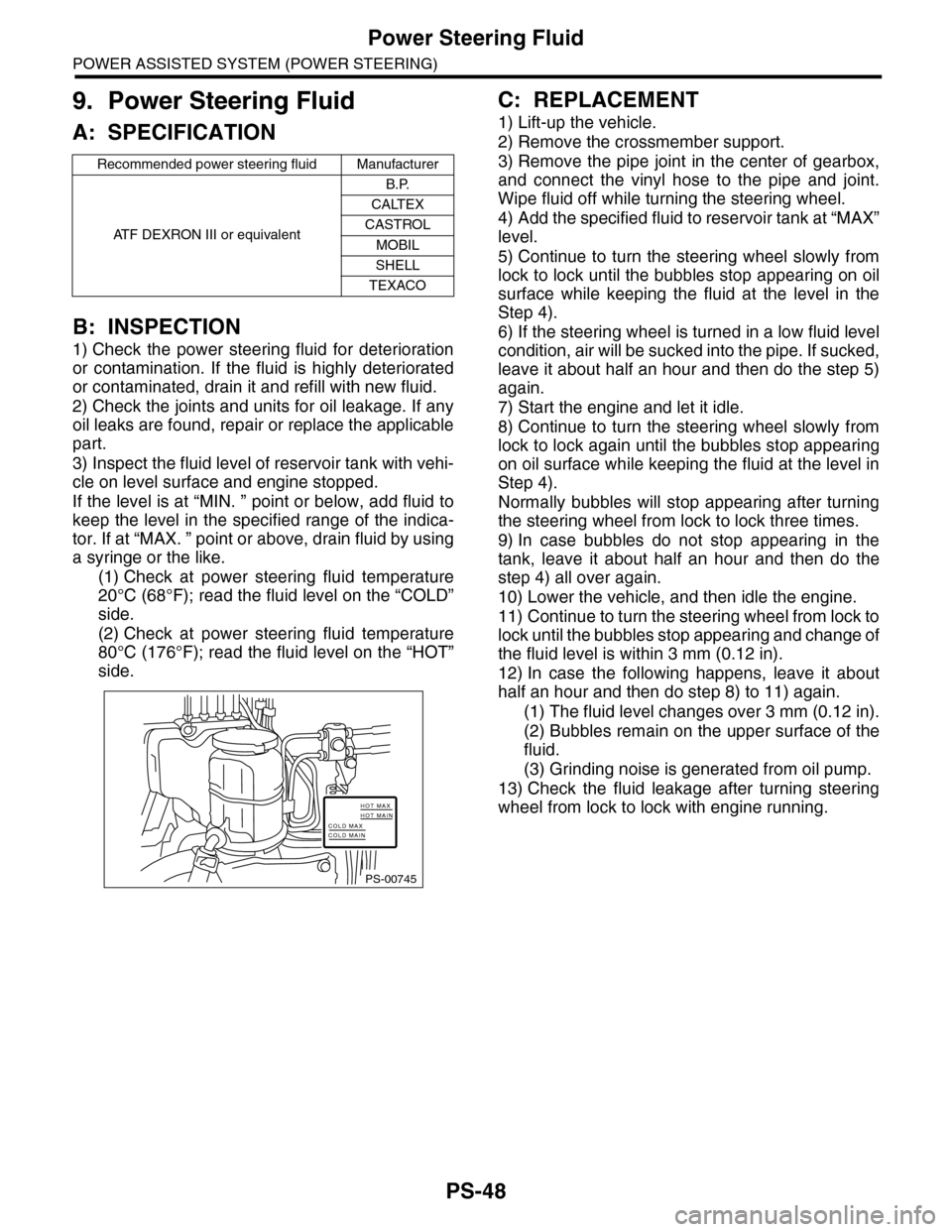

A: SPECIFICATION

B: INSPECTION

1) Check the power steering fluid for deterioration

or contamination. If the fluid is highly deteriorated

or contaminated, drain it and refill with new fluid.

2) Check the joints and units for oil leakage. If any

oil leaks are found, repair or replace the applicable

part.

3) Inspect the fluid level of reservoir tank with vehi-

cle on level surface and engine stopped.

If the level is at “MIN. ” point or below, add fluid to

keep the level in the specified range of the indica-

tor. If at “MAX. ” point or above, drain fluid by using

a syringe or the like.

(1) Check at power steering fluid temperature

20°C (68°F); read the fluid level on the “COLD”

side.

(2) Check at power steering fluid temperature

80°C (176°F); read the fluid level on the “HOT”

side.

C: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the crossmember support.

3) Remove the pipe joint in the center of gearbox,

and connect the vinyl hose to the pipe and joint.

Wipe fluid off while turning the steering wheel.

4) Add the specified fluid to reservoir tank at “MAX”

level.

5) Continue to turn the steering wheel slowly from

lock to lock until the bubbles stop appearing on oil

surface while keeping the fluid at the level in the

Step 4).

6) If the steering wheel is turned in a low fluid level

condition, air will be sucked into the pipe. If sucked,

leave it about half an hour and then do the step 5)

again.

7) Start the engine and let it idle.

8) Continue to turn the steering wheel slowly from

lock to lock again until the bubbles stop appearing

on oil surface while keeping the fluid at the level in

Step 4).

Normally bubbles will stop appearing after turning

the steering wheel from lock to lock three times.

9) In case bubbles do not stop appearing in the

tank, leave it about half an hour and then do the

step 4) all over again.

10) Lower the vehicle, and then idle the engine.

11) Continue to turn the steering wheel from lock to

lock until the bubbles stop appearing and change of

the fluid level is within 3 mm (0.12 in).

12) In case the following happens, leave it about

half an hour and then do step 8) to 11) again.

(1) The fluid level changes over 3 mm (0.12 in).

(2) Bubbles remain on the upper surface of the

fluid.

(3) Grinding noise is generated from oil pump.

13) Check the fluid leakage after turning steering

wheel from lock to lock with engine running.

Recommended power steering fluid Manufacturer

AT F D E X R O N I I I o r e q u i v a l e n t

B.P.

CALTEX

CASTROL

MOBIL

SHELL

TEXACO

PS-00745

HOT MAXHOT MAINCOLD MAXCOLD MAIN

Page 929 of 2453

PS-49

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

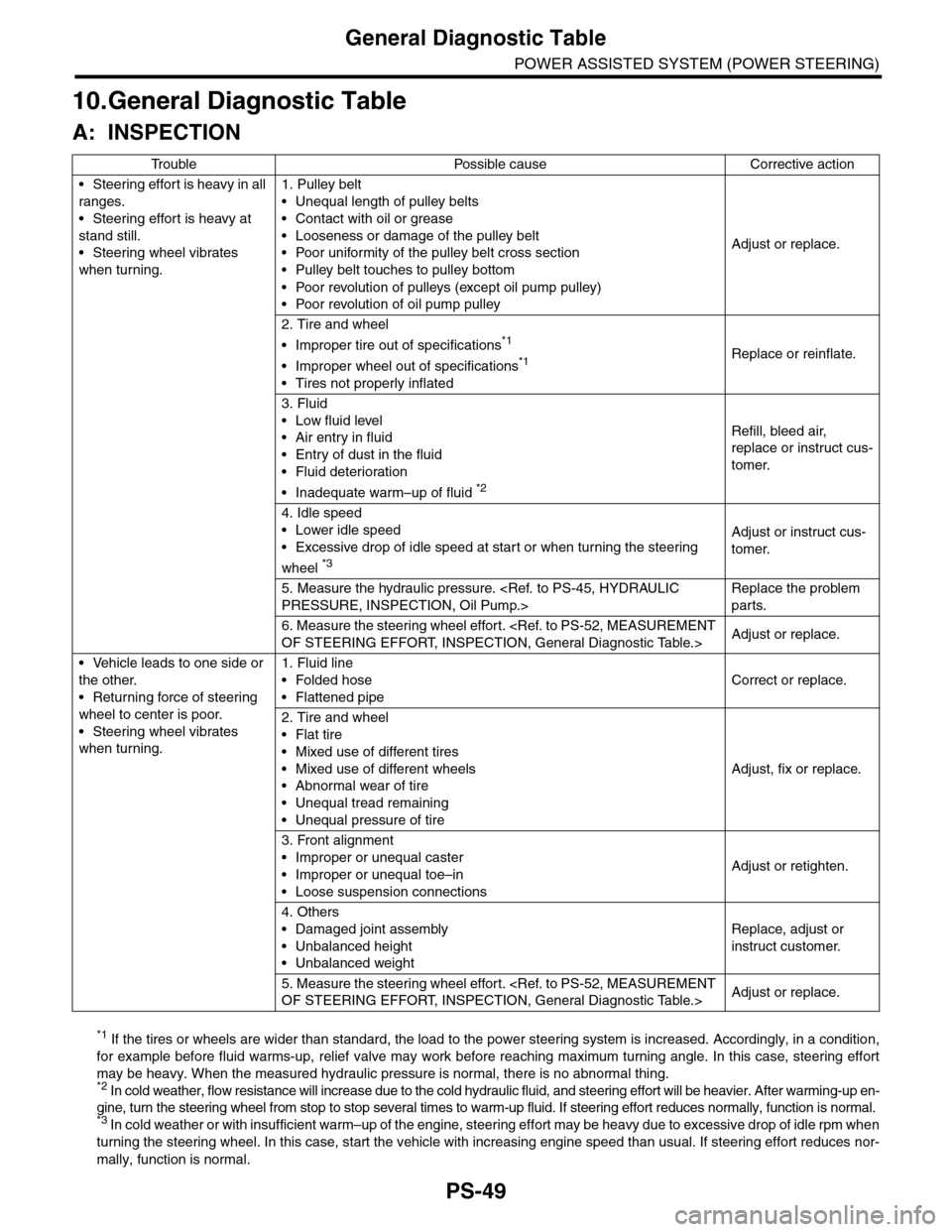

10.General Diagnostic Table

A: INSPECTION

*1 If the tires or wheels are wider than standard, the load to the power steering system is increased. Accordingly, in a condition,

for example before fluid warms-up, relief valve may work before reaching maximum turning angle. In this case, steering effort

may be heavy. When the measured hydraulic pressure is normal, there is no abnormal thing. *2 In cold weather, flow resistance will increase due to the cold hydraulic fluid, and steering effort will be heavier. After warming-up en-

gine, turn the steering wheel from stop to stop several times to warm-up fluid. If steering effort reduces normally, function is normal. *3 I n c o l d w e a t h e r o r w i t h i n s u f f i c i e n t w a r m – u p o f t h e e n g i n e , s t e e r i n g e f f o r t m a y b e h e a v y d u e t o e x c e s s i v e d r o p o f i d l e r p m w h en

turning the steering wheel. In this case, start the vehicle with increasing engine speed than usual. If steering effort reduces nor-

mally, function is normal.

Tr o u b l e P o s s i b l e c a u s e C o r r e c t i v e a c t i o n

•Steering effort is heavy in all

ranges.

•Steering effort is heavy at

stand still.

•Steering wheel vibrates

when turning.

1. Pulley belt

•Unequal length of pulley belts

•Contact with oil or grease

•Looseness or damage of the pulley belt

•Poor uniformity of the pulley belt cross section

•Pulley belt touches to pulley bottom

•Poor revolution of pulleys (except oil pump pulley)

•Poor revolution of oil pump pulley

Adjust or replace.

2. Tire and wheel

•Improper tire out of specifications*1

•Improper wheel out of specifications*1

•Tires not properly inflated

Replace or reinflate.

3. Fluid

•Low fluid level

•Air entry in fluid

•Entry of dust in the fluid

•Fluid deterioration

•Inadequate warm–up of fluid *2

Refill, bleed air,

replace or instruct cus-

tomer.

4. Idle speed

•Lower idle speed

•Excessive drop of idle speed at start or when turning the steering

wheel *3

Adjust or instruct cus-

tomer.

5. Measure the hydraulic pressure.

Replace the problem

parts.

6. Measure the steering wheel effort.

•Vehicle leads to one side or

the other.

•Returning force of steering

wheel to center is poor.

•Steering wheel vibrates

when turning.

1. Fluid line

•Folded hose

•Flattened pipe

Correct or replace.

2. Tire and wheel

•Flat tire

•Mixed use of different tires

•Mixed use of different wheels

•Abnormal wear of tire

•Unequal tread remaining

•Unequal pressure of tire

Adjust, fix or replace.

3. Front alignment

•Improper or unequal caster

•Improper or unequal toe–in

•Loose suspension connections

Adjust or retighten.

4. Others

•Damaged joint assembly

•Unbalanced height

•Unbalanced weight

Replace, adjust or

instruct customer.

5. Measure the steering wheel effort.

Page 932 of 2453

PS-52

General Diagnostic Table

POWER ASSISTED SYSTEM (POWER STEERING)

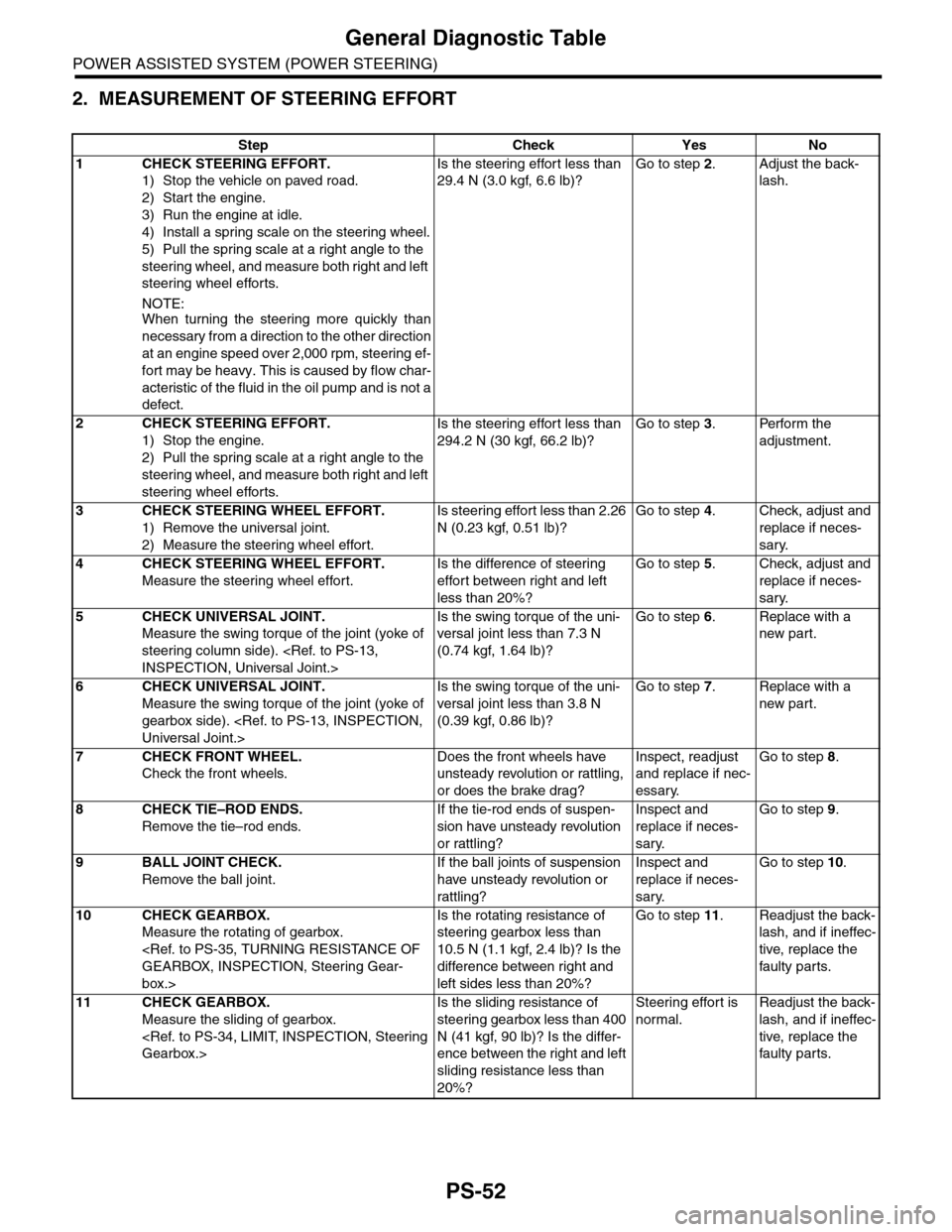

2. MEASUREMENT OF STEERING EFFORT

Step Check Yes No

1CHECK STEERING EFFORT.

1) Stop the vehicle on paved road.

2) Start the engine.

3) Run the engine at idle.

4) Install a spring scale on the steering wheel.

5) Pull the spring scale at a right angle to the

steering wheel, and measure both right and left

steering wheel efforts.

NOTE:When turning the steering more quickly than

necessary from a direction to the other direction

at an engine speed over 2,000 rpm, steering ef-

fort may be heavy. This is caused by flow char-

acteristic of the fluid in the oil pump and is not a

defect.

Is the steering effort less than

29.4 N (3.0 kgf, 6.6 lb)?

Go to step 2.Adjust the back-

lash.

2CHECK STEERING EFFORT.

1) Stop the engine.

2) Pull the spring scale at a right angle to the

steering wheel, and measure both right and left

steering wheel efforts.

Is the steering effort less than

294.2 N (30 kgf, 66.2 lb)?

Go to step 3.Perform the

adjustment.

3CHECK STEERING WHEEL EFFORT.

1) Remove the universal joint.

2) Measure the steering wheel effort.

Is steering effort less than 2.26

N (0.23 kgf, 0.51 lb)?

Go to step 4.Check, adjust and

replace if neces-

sary.

4CHECK STEERING WHEEL EFFORT.

Measure the steering wheel effort.

Is the difference of steering

effort between right and left

less than 20%?

Go to step 5.Check, adjust and

replace if neces-

sary.

5CHECK UNIVERSAL JOINT.

Measure the swing torque of the joint (yoke of

steering column side).

Is the swing torque of the uni-

versal joint less than 7.3 N

(0.74 kgf, 1.64 lb)?

Go to step 6.Replace with a

new part.

6CHECK UNIVERSAL JOINT.

Measure the swing torque of the joint (yoke of

gearbox side).

Is the swing torque of the uni-

versal joint less than 3.8 N

(0.39 kgf, 0.86 lb)?

Go to step 7.Replace with a

new part.

7CHECK FRONT WHEEL.

Check the front wheels.

Does the front wheels have

unsteady revolution or rattling,

or does the brake drag?

Inspect, readjust

and replace if nec-

essary.

Go to step 8.

8CHECK TIE–ROD ENDS.

Remove the tie–rod ends.

If the tie-rod ends of suspen-

sion have unsteady revolution

or rattling?

Inspect and

replace if neces-

sary.

Go to step 9.

9BALL JOINT CHECK.

Remove the ball joint.

If the ball joints of suspension

have unsteady revolution or

rattling?

Inspect and

replace if neces-

sary.

Go to step 10.

10 CHECK GEARBOX.

Measure the rotating of gearbox.

box.>

Is the rotating resistance of

steering gearbox less than

10.5 N (1.1 kgf, 2.4 lb)? Is the

difference between right and

left sides less than 20%?

Go to step 11.Readjust the back-

lash, and if ineffec-

tive, replace the

faulty par ts.

11 CHECK GEARBOX.

Measure the sliding of gearbox.

Is the sliding resistance of

steering gearbox less than 400

N (41 kgf, 90 lb)? Is the differ-

ence between the right and left

sliding resistance less than

20%?

Steering effort is

normal.

Readjust the back-

lash, and if ineffec-

tive, replace the

faulty par ts.

Page 960 of 2453

TPM(diag)-10

Subaru Select Monitor

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

2) Connect the Subaru Select Monitor, on the

«Main Menu» display screen, select the {2. Each

System Check} and press the [YES] key.

3) On the «System Selection Menu» display

screen, select the {Tire Pressure Monitor} and

press the [YES] key.

4) Press the [YES] key after the {Tire Pressure

Monitor} is displayed.

5) On the «Tire Pressure Monitor Diagnosis» dis-

play screen, select the {Transmitter ID regist con-

firm} and press the [YES] key.

6) {When ID registration mode execute, Registered

ID is deleted Proceed?} is displayed then press the

[YES] key.

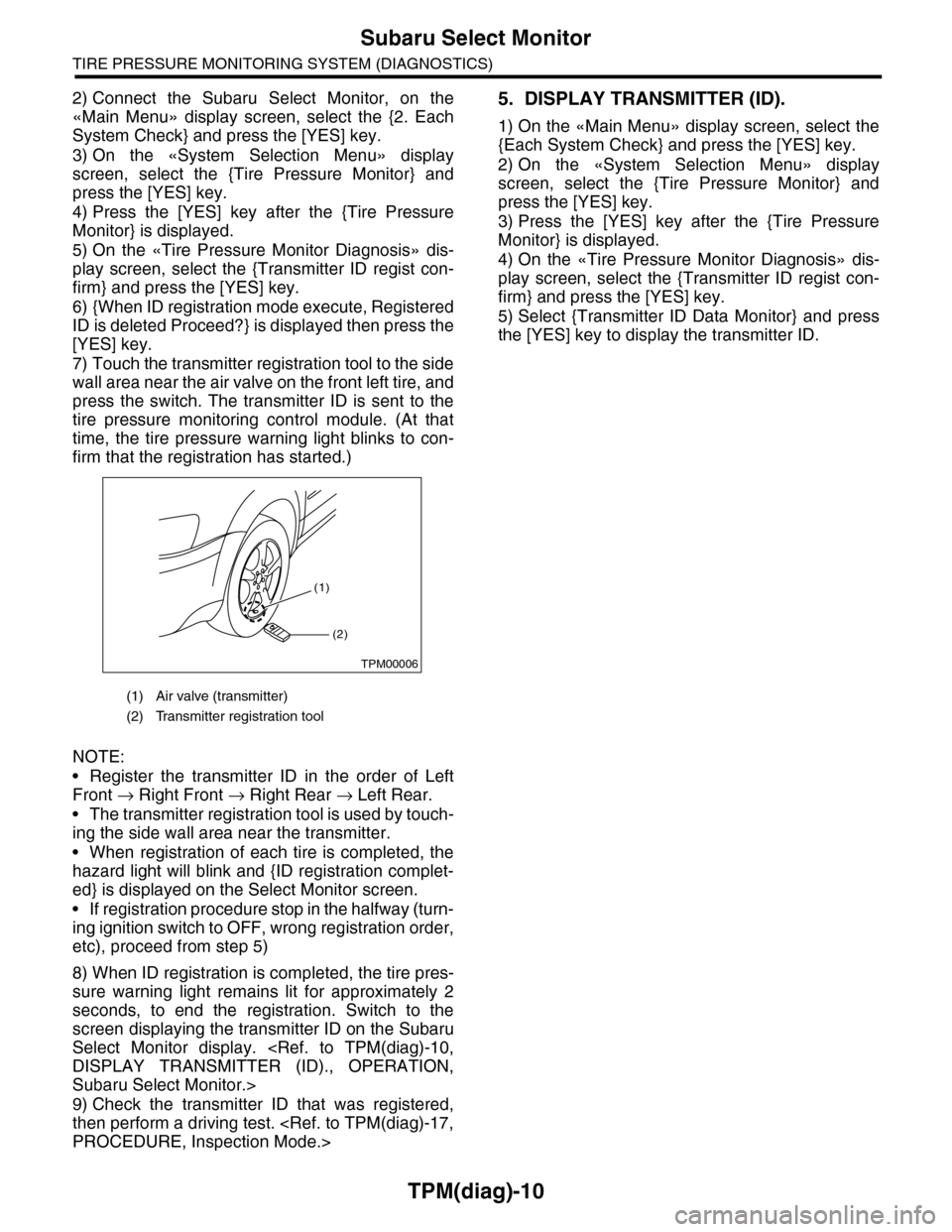

7) Touch the transmitter registration tool to the side

wall area near the air valve on the front left tire, and

press the switch. The transmitter ID is sent to the

tire pressure monitoring control module. (At that

time, the tire pressure warning light blinks to con-

firm that the registration has started.)

NOTE:

•Register the transmitter ID in the order of Left

Front → Right Front → Right Rear → Left Rear.

•The transmitter registration tool is used by touch-

ing the side wall area near the transmitter.

•When registration of each tire is completed, the

hazard light will blink and {ID registration complet-

ed} is displayed on the Select Monitor screen.

•If registration procedure stop in the halfway (turn-

ing ignition switch to OFF, wrong registration order,

etc), proceed from step 5)

8) When ID registration is completed, the tire pres-

sure warning light remains lit for approximately 2

seconds, to end the registration. Switch to the

screen displaying the transmitter ID on the Subaru

Select Monitor display.

Subaru Select Monitor.>

9) Check the transmitter ID that was registered,

then perform a driving test.

5. DISPLAY TRANSMITTER (ID).

1) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display

screen, select the {Tire Pressure Monitor} and

press the [YES] key.

3) Press the [YES] key after the {Tire Pressure

Monitor} is displayed.

4) On the «Tire Pressure Monitor Diagnosis» dis-

play screen, select the {Transmitter ID regist con-

firm} and press the [YES] key.

5) Select {Transmitter ID Data Monitor} and press

the [YES] key to display the transmitter ID.

(1) Air valve (transmitter)

(2) Transmitter registration tool

(1)

(2)

TPM00006

Page 996 of 2453

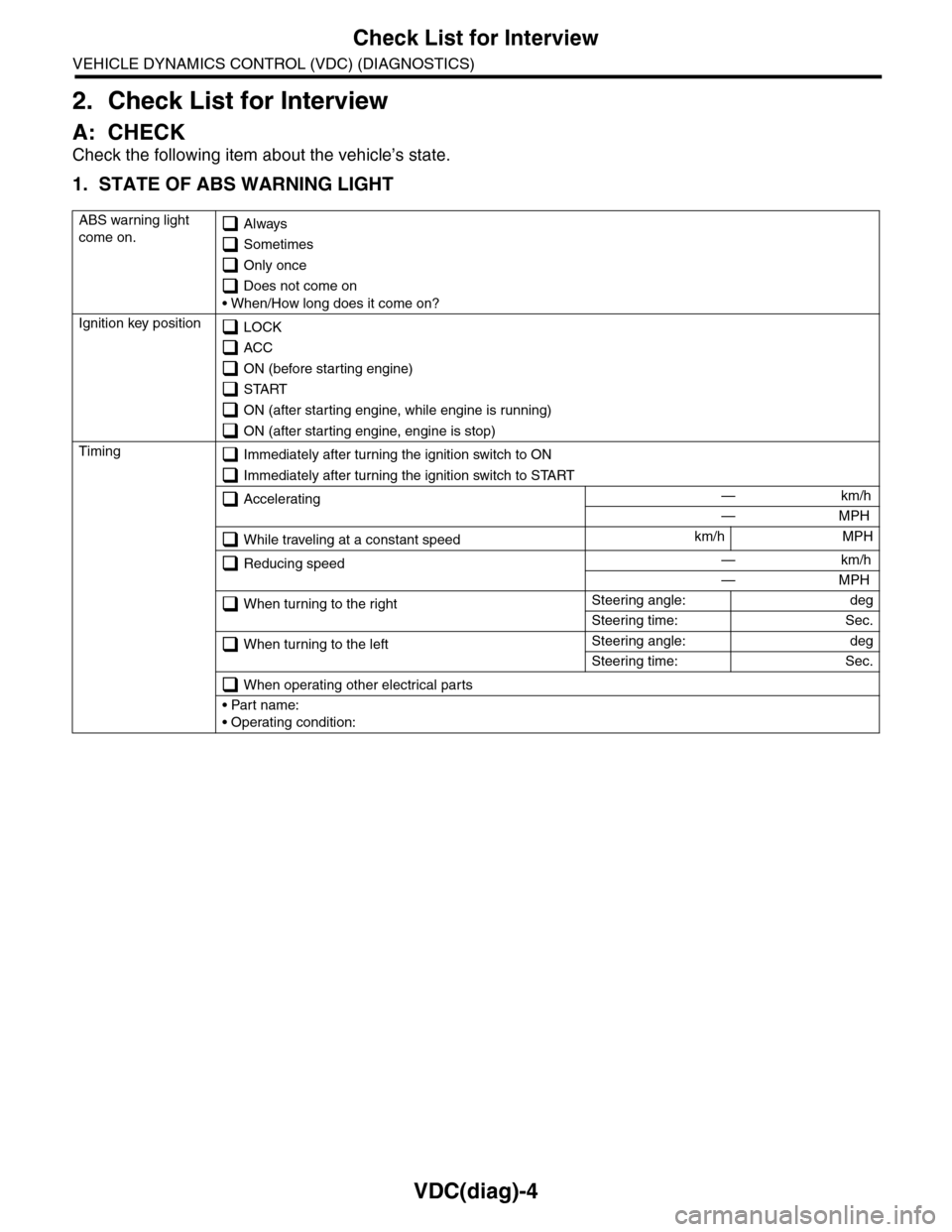

VDC(diag)-4

Check List for Interview

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Check the following item about the vehicle’s state.

1. STATE OF ABS WARNING LIGHT

ABS warning light

come on. Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

— MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

When turning to the rightSteering angle: deg

Steering time: Sec.

When turning to the leftSteering angle: deg

Steering time: Sec.

When operating other electrical parts

• Part name:

• Operating condition:

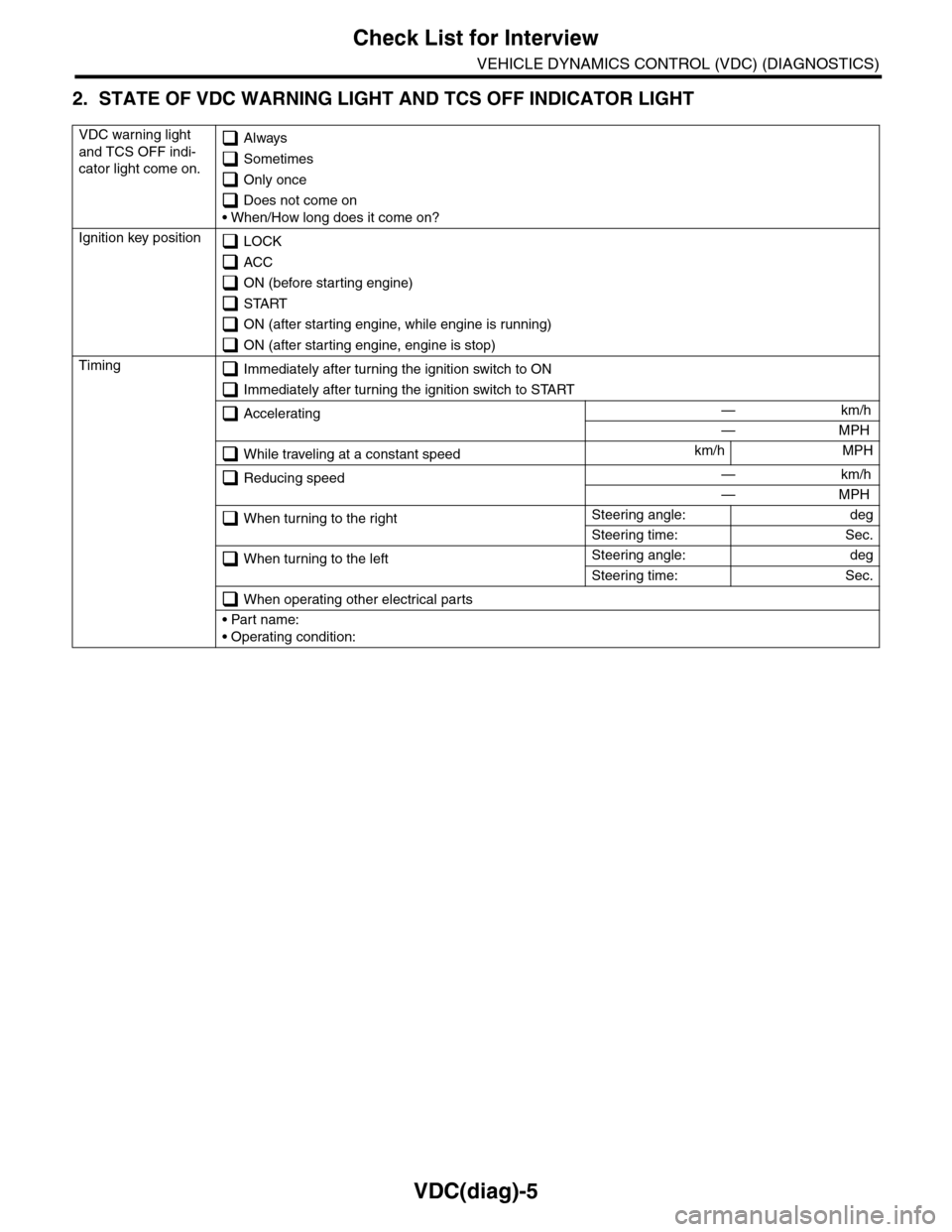

Page 997 of 2453

VDC(diag)-5

Check List for Interview

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

2. STATE OF VDC WARNING LIGHT AND TCS OFF INDICATOR LIGHT

VDC warning light

and TCS OFF indi-

cator light come on.

Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

— MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

When turning to the rightSteering angle: deg

Steering time: Sec.

When turning to the leftSteering angle: deg

Steering time: Sec.

When operating other electrical parts

• Part name:

• Operating condition:

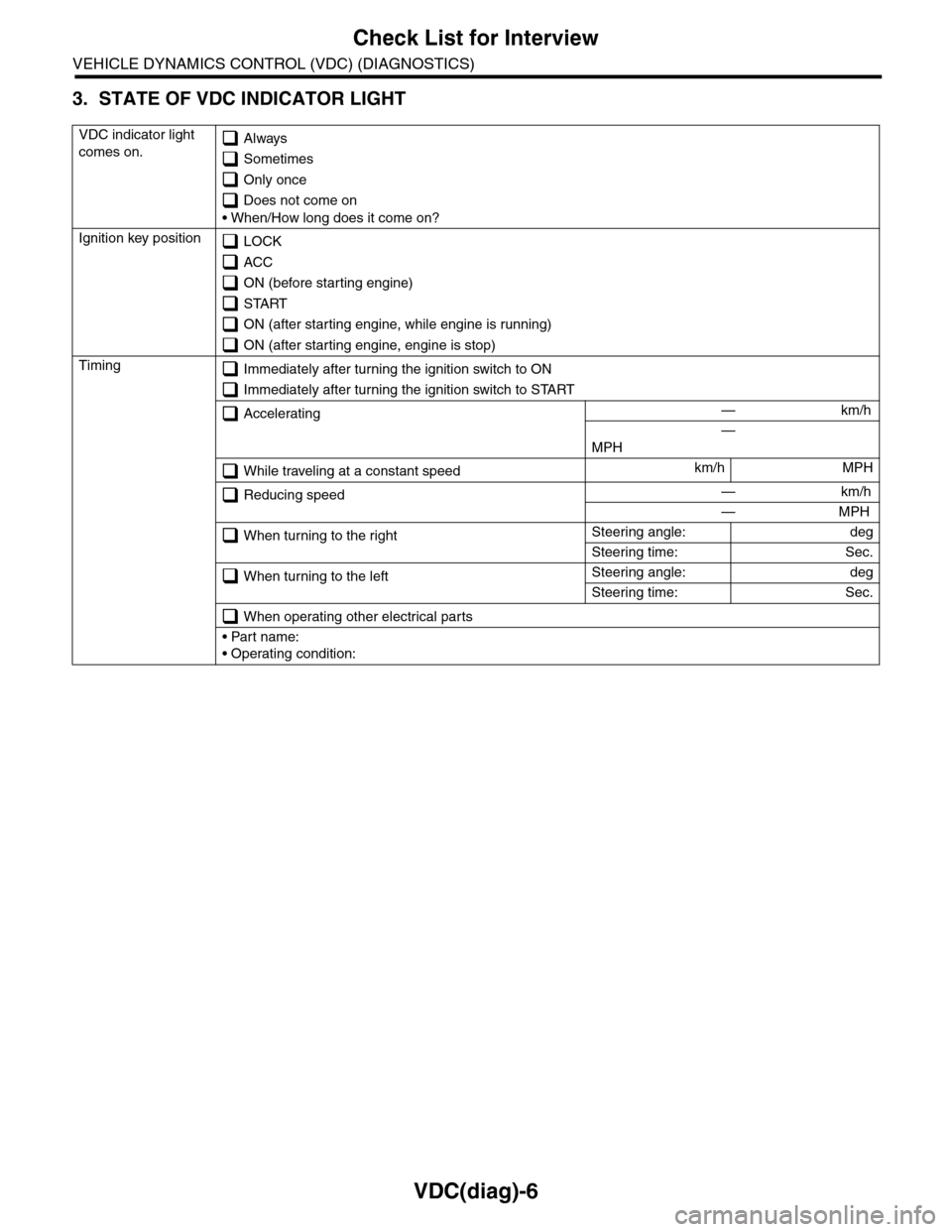

Page 998 of 2453

VDC(diag)-6

Check List for Interview

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

3. STATE OF VDC INDICATOR LIGHT

VDC indicator light

comes on. Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

—

MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

When turning to the rightSteering angle: deg

Steering time: Sec.

When turning to the leftSteering angle: deg

Steering time: Sec.

When operating other electrical parts

• Part name:

• Operating condition:

Page 1006 of 2453

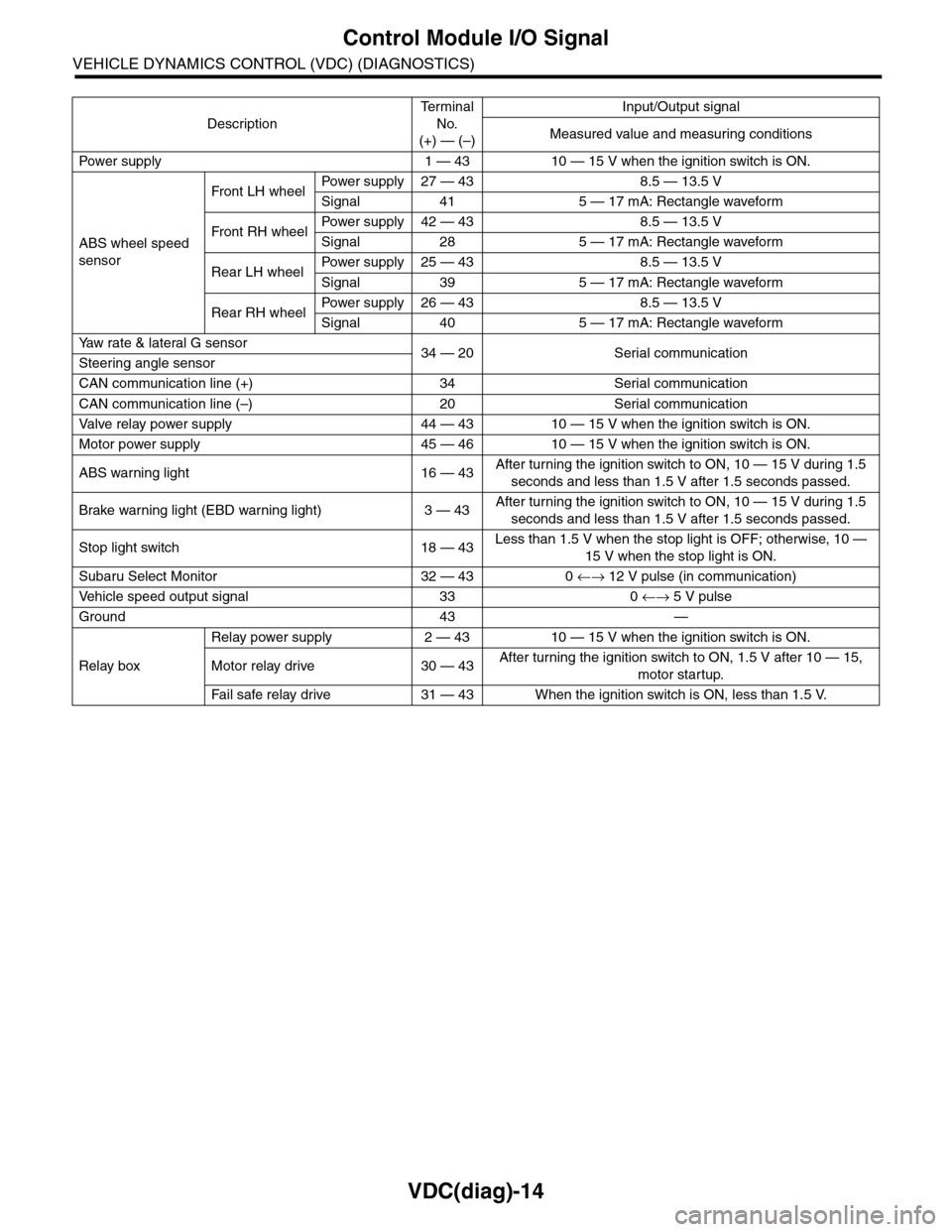

VDC(diag)-14

Control Module I/O Signal

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

Description

Te r m i n a l

No.

(+) — (–)

Input/Output signal

Measured value and measuring conditions

Pow er s up p ly 1 — 43 10 — 15 V w h e n t h e i gn i t io n sw it ch i s ON .

ABS wheel speed

sensor

Front LH wheelPowe r s u pp ly 27 — 4 3 8 . 5 — 1 3. 5 V

Signal 41 5 — 17 mA: Rectangle waveform

Front RH wheelPower supply 42 — 43 8.5 — 13.5 V

Signal 28 5 — 17 mA: Rectangle waveform

Rear LH wheelPower supply 25 — 43 8.5 — 13.5 V

Signal 39 5 — 17 mA: Rectangle waveform

Rear RH wheelPower supply 26 — 43 8.5 — 13.5 V

Signal 40 5 — 17 mA: Rectangle waveform

Ya w r a t e & l a t e r a l G s e n s o r34 — 20 Serial communicationSteering angle sensor

CAN communication line (+) 34 Serial communication

CAN communication line (–) 20 Serial communication

Valve relay power supply 44 — 43 10 — 15 V when the ignition switch is ON.

Motor power supply 45 — 46 10 — 15 V when the ignition switch is ON.

ABS warning light 16 — 43After turning the ignition switch to ON, 10 — 15 V during 1.5

seconds and less than 1.5 V after 1.5 seconds passed.

Brake warning light (EBD warning light) 3 — 43After turning the ignition switch to ON, 10 — 15 V during 1.5

seconds and less than 1.5 V after 1.5 seconds passed.

Stop light switch 18 — 43Less than 1.5 V when the stop light is OFF; otherwise, 10 —

15 V when the stop light is ON.

Subaru Select Monitor 32 — 43 0 ←→ 12 V pulse (in communication)

Ve h i c l e s p e e d o u t p u t s i g n a l 3 3 0 ←→ 5 V pulse

Ground 43 —

Relay box

Relay power supply 2 — 43 10 — 15 V when the ignition switch is ON.

Motor relay drive 30 — 43After turning the ignition switch to ON, 1.5 V after 10 — 15,

motor startup.

Fa i l s afe r e lay d r ive 31 — 4 3 W he n t h e i g ni t io n swit c h i s ON, l es s t ha n 1 . 5 V.

Page 1095 of 2453

VDC-14

ABS Sequence Control

VEHICLE DYNAMICS CONTROL (VDC)

NOTE:

The control operation starts from point A.

B: SPECIFICATION

1. ABS SEQUENCE CONTROL COMPLETE

CONDITION

When the following conditions develop, the ABS

sequence control stops and ABS operation is re-

turned to the normal control mode.

1) When the speed of at least one wheel reaches

10 km/h (6 MPH).

2) When the brake pedal is released during ABS

sequence control and the stop lamp switch is be-

comes OFF.

3) After completion of ABS sequence control.

4) When a malfunction is detected.

(1) All wheel speed (10) RR decompression valve (18) 1.0 seconds

(2) Ignition key (11) RR hold valve (19) 1.4 seconds

(3) ABS warning light (12) RL decompression valve (20) 0.6 seconds

(4) Stop light switch (13) RL hold valve (21) 0.4 seconds

(5) Valve relay (14) Pump motor (22) Point A

(6) FL decompression valve (15) 1.5 seconds (23) Reset

(7) FL hold valve (16) Light OFF (24) Linear valve 1

(8) FR decompression valve (17) Light ON (25) Linear valve 2

(9) FR hold valve