stop start SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1098 of 2453

VDC-17

VDC Sequence Control

VEHICLE DYNAMICS CONTROL (VDC)

NOTE:

The control operation starts from point A.

B: SPECIFICATION

1. CONDITIONS FOR COMPLETION OF

VDC SEQUENCE CONTROL

When the following conditions develop, the VDC

sequence control stops and VDC operation is re-

turned to the normal control mode.

1) When the speed of at least one wheel reaches

10 km/h (6 MPH).

2) When the brake pedal is pressed during se-

quence control and the stop light switch is set to

ON.

3) After completion of VDC sequence control.

4) When a malfunction is detected.

(1) All wheel speed (11) FR compression valve (21) Light OFF

(2) Ignition key (12) RR decompression valve (22) Light ON

(3) ABS warning light (13) RR compression valve (23) 3.4 seconds

(4) VDC warning light (14) RL decompression valve (24) 1 second

(5) VDC operation lamp (CAN output) (15) RL compression valve (25) 1.6 seconds

(6) Stop light switch (16) Pump motor (26) Point A

(7) Valve relay (17) Linear valve 1 (27) Reset

(8) FL decompression valve (18) Linear valve 2 (28) 0.8 seconds

(9) FL compression valve (19) 1.5 seconds (29) 1.2 seconds

(10) FR decompression valve (20) Approx. 3 sec. (30) 0.4 seconds

Page 1129 of 2453

CO(H6DO)-10

Engine Coolant

COOLING

3. Engine Coolant

A: REPLACEMENT

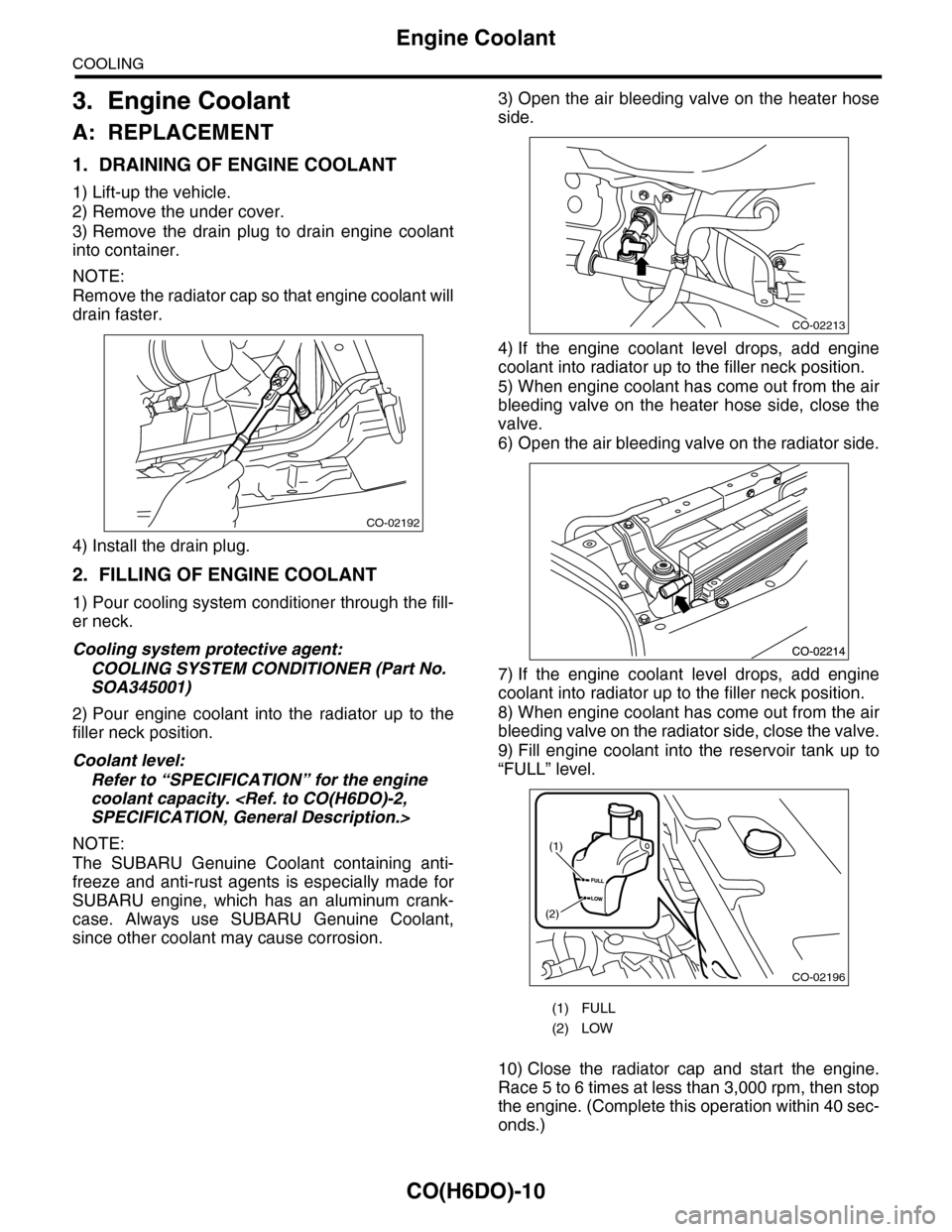

1. DRAINING OF ENGINE COOLANT

1) Lift-up the vehicle.

2) Remove the under cover.

3) Remove the drain plug to drain engine coolant

into container.

NOTE:

Remove the radiator cap so that engine coolant will

drain faster.

4) Install the drain plug.

2. FILLING OF ENGINE COOLANT

1) Pour cooling system conditioner through the fill-

er neck.

Cooling system protective agent:

COOLING SYSTEM CONDITIONER (Part No.

SOA345001)

2) Pour engine coolant into the radiator up to the

filler neck position.

Coolant level:

Refer to “SPECIFICATION” for the engine

coolant capacity.

NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

3) Open the air bleeding valve on the heater hose

side.

4) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

5) When engine coolant has come out from the air

bleeding valve on the heater hose side, close the

valve.

6) Open the air bleeding valve on the radiator side.

7) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

8) When engine coolant has come out from the air

bleeding valve on the radiator side, close the valve.

9) Fill engine coolant into the reservoir tank up to

“FULL” level.

10) Close the radiator cap and start the engine.

Race 5 to 6 times at less than 3,000 rpm, then stop

the engine. (Complete this operation within 40 sec-

onds.)

CO-02192

(1) FULL

(2) LOW

CO-02213

CO-02196

(1)

(2)

Page 1130 of 2453

CO(H6DO)-11

Engine Coolant

COOLING

11) Wait for one minute after the engine stops,

open the radiator cap. If the engine coolant level

drops, add engine coolant into radiator up to the fill-

er neck position.

12) Perform the procedures 10) and 11) again.

13) Attach the radiator cap and reservoir tank cap

properly.

14) Start the engine and operate the heater at max-

imum hot position and the blower speed setting to

“LO.”

15) Run the engine at 2,000 rpm or less until radia-

tor fan starts and stops.

NOTE:

•Be careful with the engine coolant temperature

gauge to prevent overheating.

•If the radiator hose becomes harden with the

pressure of engine coolant, air bleeding operation

seems to be almost completed.

16) Stop the engine and wait until the engine cool-

ant temperature lowers to 30°C (86°F).

17) Open the radiator cap. If the engine coolant lev-

el drops, add engine coolant into radiator up to the

filler neck position and reservoir tank to the “FULL”

level.

18) Attach the radiator cap and reservoir tank cap

properly.

19) Set the heater setting to maximum hot position

and the blower speed setting to “LO” and start the

engine. Perform racing at less than 3,000 rpm. If

the flowing sound is heard at this time, perform the

procedures from 15) again.

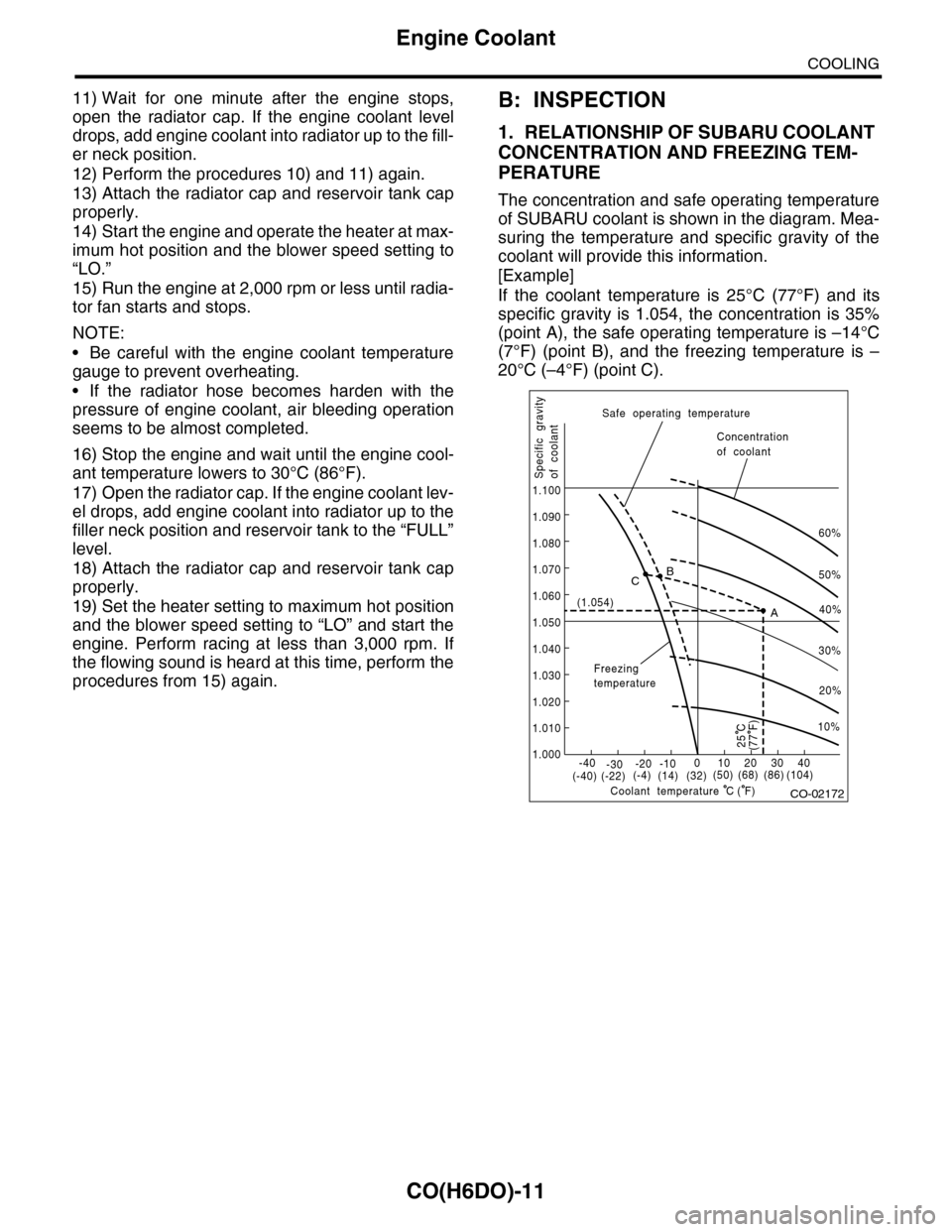

B: INSPECTION

1. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of SUBARU coolant is shown in the diagram. Mea-

suring the temperature and specific gravity of the

coolant will provide this information.

[Example]

If the coolant temperature is 25°C (77°F) and its

specific gravity is 1.054, the concentration is 35%

(point A), the safe operating temperature is –14°C

(7°F) (point B), and the freezing temperature is –

20°C (–4°F) (point C).

CO-02172

60%

(1.054)

1.000

1.010

1.020

1.030

1.040

1.050

1.060

1.070

1.080

1.090

1.100

Safe operating temperature

Freezingtemperature

Concentrationof coolant

Specific gravityof coolant

Coolant temperature

B

A

C

-40(-40) (-22)(-4)(14)(32)(50) (68) (86)

( F)

(104)-30-20 -10010203040

(77 F)

50%

40%

30%

20%

25 C

10%

C

Page 1166 of 2453

EN(H6DO)(diag)-5

General Description

ENGINE (DIAGNOSTICS)

3. General Description

A: CAUTION

1) Airbag system wiring harness is routed near the

ECM, main relay and fuel pump relay.

CAUTION:

•All airbag system wiring harnesses and con-

nectors are colored yellow. Do not use electri-

cal test equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness when servicing the ECM, TCM,

main relay and fuel pump relay.

2) Never connect the battery in reverse polarity.

•The ECM will be destroyed instantly.

•The fuel injector and other parts will be dam-

aged.

3) Do not disconnect the battery terminals while the

engine is running.

A large counter electromotive force will be generat-

ed in the generator, and this voltage may damage

electronic parts such as ECM etc.

4) Before disconnecting the connectors of each

sensor and ECM, be sure to turn the ignition switch

to OFF. Perform the clear memory mode after con-

necting the connectors.

5) Poor contact has been identified as a primary

cause of this problem. Measure the voltage or re-

sistance of individual sensor or all electrical control

modules using a tapered pin with a diameter of less

than 0.64 mm (0.025 in). Do not insert the pin more

than 5 mm (0.20 in) into the part.

6) Remove the ECM from the located position after

disconnecting two cables on battery.

Otherwise, the ECM may be damaged.

CAUTION:

When replacing the ECM, be careful not to use

the wrong spec. ECM to avoid any damage on

the fuel injection system.

7) Connectors of each sensor in the engine com-

partment and the harness connectors on the en-

gine side and body side are all designed to be

waterproof. Even if the connectors are waterproof,

take care not to allow water to get into them when

washing the vehicle, or when servicing the vehicle

in rainy weather.

8) Use ECM mounting stud bolts as the grounding

point to chassis when measuring voltage and resis-

tance in the passenger compartment.

9) Use the engine ground terminal or engine as-

sembly as the grounding point to chassis when

measuring the voltage and resistance in engine

compartment.

10) Every MFI-related part is a precision part. Do

not drop them.

11) Observe the following cautions when installing

a radio in MFI equipped models.

CAUTION:

•The antenna must be kept as far apart as pos-

sible from control unit. (The ECM is located un-

der the steering column, inside of the

instrument panel lower trim panel.)

•The antenna feeder must be placed as far apart

as possible from the ECM and MFI harness.

•Carefully adjust the antenna for correct

matching.

•When mounting a large power type radio, pay

special attention to the three items mentioned

above.

•Incorrect installation of the radio may affect

the operation of ECM.

12) Release the pressure in the fuel system before

disconnecting the fuel hose. If engine starts during

this operation, run it until it stops.

13) For the model with ABS, the ABS warning light

may illuminate when performing driving test with

jacked-up or lifted-up condition, but this is not a

system malfunction. The reason for this is the

speed difference between the front and rear

wheels. After diagnosis of engine control system,

perform the ABS memory clear procedure of self-

diagnosis function.

B: INSPECTION

Before performing diagnostics, check the following

item which might affect engine problems.

1. BATTERY

1) Measure the battery voltage and specific gravity

of electrolyte.

Standard voltage: 12 V

Specific gravity: Above 1.260

2) Check the condition of the main and other fuses,

and harnesses and connectors. Also check for

proper grounding.

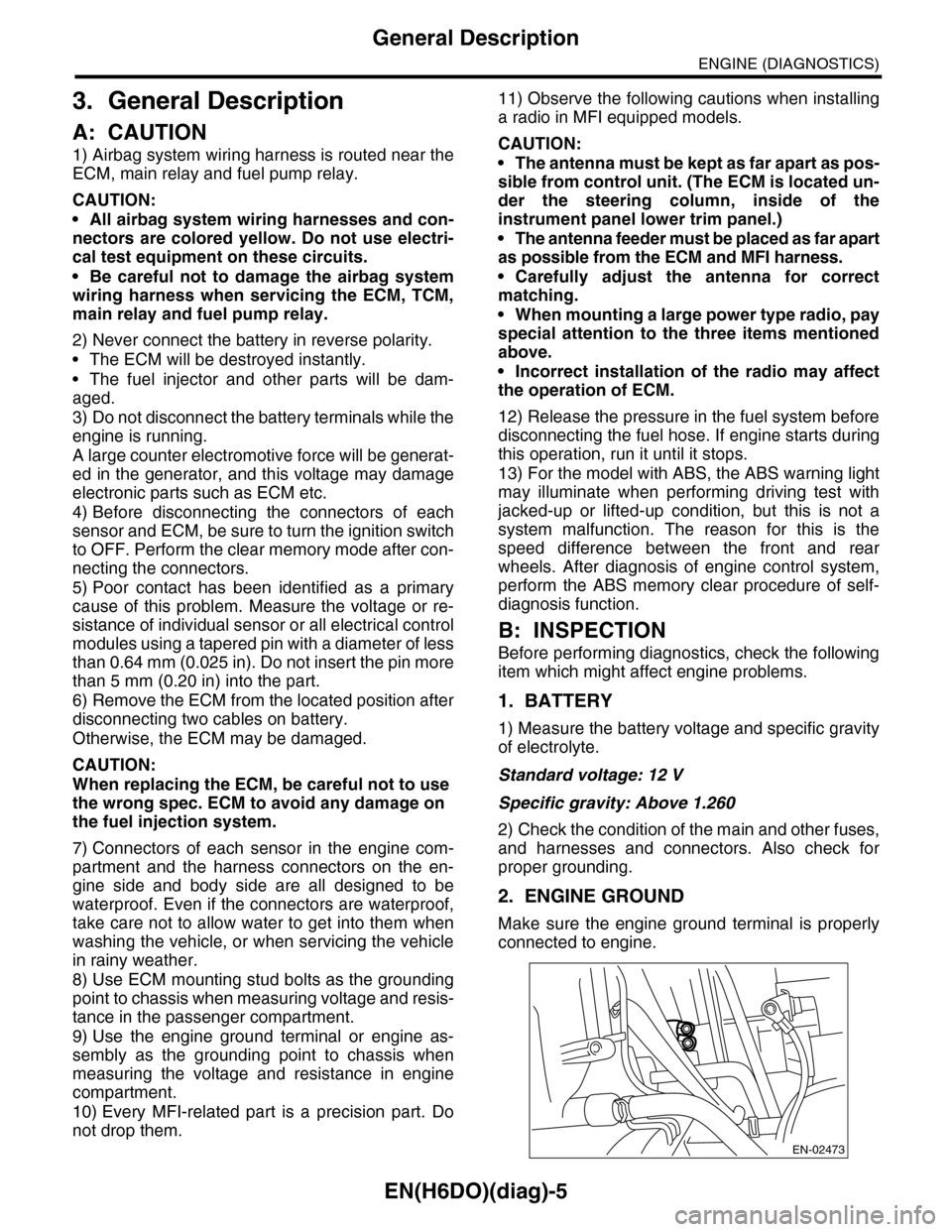

2. ENGINE GROUND

Make sure the engine ground terminal is properly

connected to engine.

EN-02473

Page 1193 of 2453

![SUBARU TRIBECA 2009 1.G Service Owners Manual EN(H6DO)(diag)-32

Subaru Select Monitor

ENGINE (DIAGNOSTICS)

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the SUBARU TRIBECA 2009 1.G Service Owners Manual EN(H6DO)(diag)-32

Subaru Select Monitor

ENGINE (DIAGNOSTICS)

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the](/img/17/7322/w960_7322-1192.png)

EN(H6DO)(diag)-32

Subaru Select Monitor

ENGINE (DIAGNOSTICS)

7. LED OPERATION MODE FOR ENGINE

1) On the «Main Menu» display screen, select the {Each System Check} and press the [YES] key.

2) On the «System Selection Menu» display screen, select the {Engine} and press the [YES] key.

3) Press the [YES] key after the information of engine type has been displayed.

4) On the «Engine Diagnosis» display screen, select the {Current Data Display/Save}, and then press the

[YES] key.

5) On the «Data Display» screen, select the {Data LED Display} and press the [YES] key.

6) Using the scroll key, scroll the display screen up or down until the desired data is shown.

•A list of the support data is shown in the following table.

NOTE:

For detailed operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MANUAL”.

Description Display Message When LED “ON” required

Te s t m o d e s i g n a l Te s t m o d e t e r m i n a l D c h e c k / U c h e c k D c h e c k

Neutral position switch signal Neutral SW Neutral/Other than neutral Neutral

Idle switch signal Soft idle SW Idle/Other than idle In idle

Ignition switch signal Ignition SW ON Input/OFF Input ON input

Pow er s te e r in g sw it c h s ig n al Pow er s te e r in g S W ON I np u t/ O FF I np u t ON i np ut

Air conditioning switch signal A/C SW ON Input/OFF Input ON input

Starter switch signal Starter SW ON Input/OFF Input ON input

Fr o nt ox yg e n mo n it o r 1 Ft O 2 mo n it o r 1 Le a n/ Ri ch Ric h

Fr o nt ox yg e n mo n it o r 2 Ft O 2 mo n it o r 2 Le a n/ Ri ch Ric h

Knocking signal Knock signal Yes/No Yes

Crankshaft position sensor signal Crankshaft angle signal Yes/No Yes

Camshaft position sensor signal Camshaft angle signal Yes/No Yes

Rear defogger switch signal Rear defogger SW ON Input/OFF Input ON input

Blower fan switch signal Blower fan SW ON Input/OFF Input ON input

Light switch signal Light SW ON Input/OFF Input ON input

Wiper switch signal Wiper SW ON Input/OFF Input ON input

A/C middle pressure switch signal A/C middle pressure SW ON Input/OFF Input ON input

Air conditioner compressor relay sig-

nalCompressor relay ON output/OFF output ON output

Drain valve signal Vent. Solenoid Valve ON or OFF When drain valve is ON.

AT r e t a r d a n g l e d e m a n d s i g n a l AT r e t a r d a n g l e d e m a n d Ye s / N o Ye s

AT f u e l c u t s i g n a l AT f u e l c u t Ye s / N o Ye s

VDC torque down prohibition output Torque down output ON/OFF Prohibition

VDC torque down demand Torque down demand Yes/No Yes

AT c o o r d i n a t e p e r m i s s i o n s i g n a lAT c o o r d i n a t e p e r m i s s i o n

signalON/OFF Permission

Electronic throttle control motor relay

signalETC motor relay ON/OFF ON

Stop light switch signal Stop SW ON Input/OFF Input ON input

SET/COAST switch signal SET/CST SW ON Input/OFF Input ON input

RESUME/ACCEL switch signal RES/ACC SW ON Input/OFF Input ON input

Brake switch signal Brake SW ON Input/OFF Input ON input

Main switch signal Main SW ON Input/OFF Input ON input

Body integrated unit data reception Body Int. Unit Data Yes/No Yes

Body integrated unit counter update Body Int. Unit Count Yes/No Yes

Cruise control cancel switch signal CC Cancel SW ON Input/OFF Input ON input

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s -

sure switch signal 1Oil Temperature SW1 ON/OFF ON

Va r i a b l e va l v e l i f t d i a g n o s i s o i l p r e s -

sure switch signal 2Oil Temperature SW2 ON/OFF ON

Page 1197 of 2453

EN(H6DO)(diag)-36

Inspection Mode

ENGINE (DIAGNOSTICS)

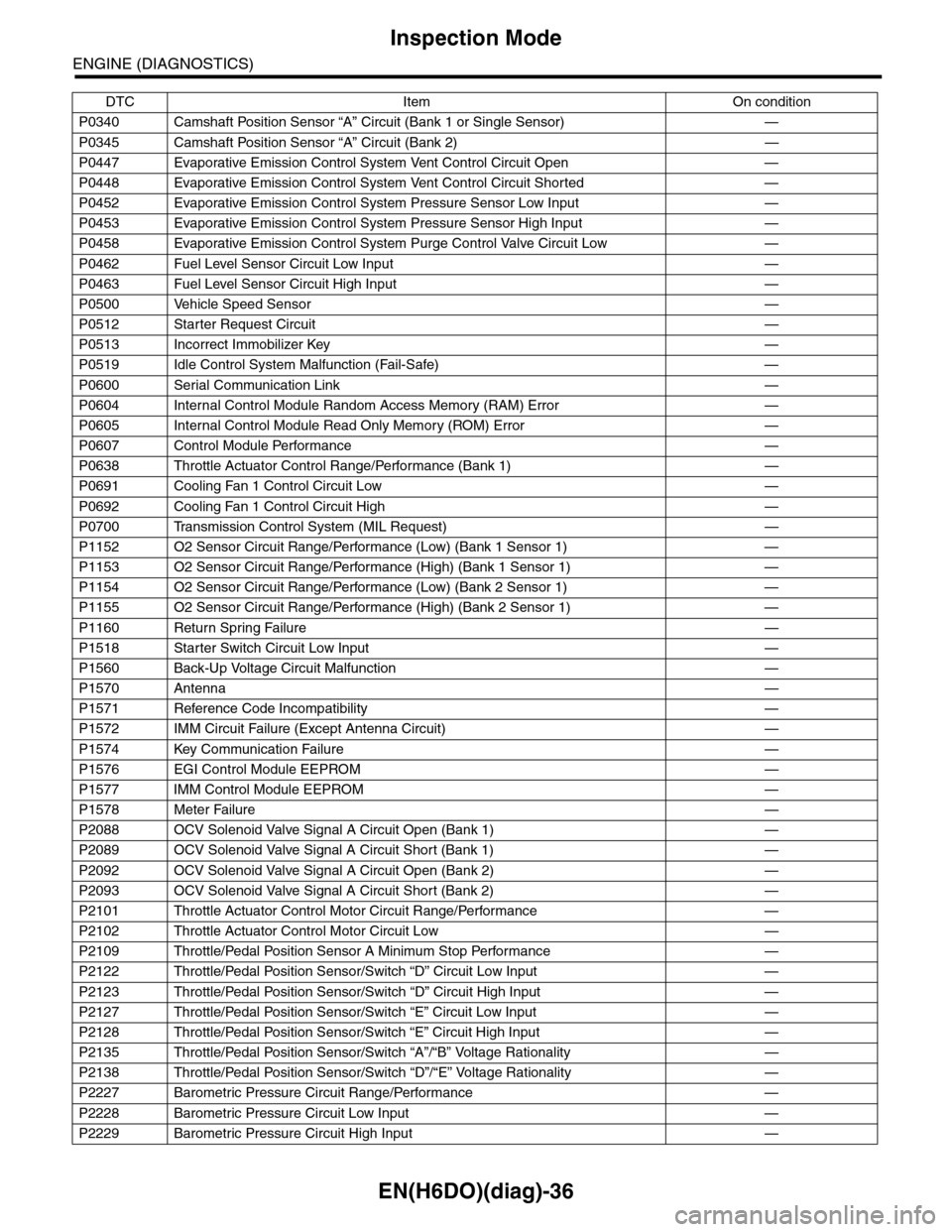

P0340 Camshaft Position Sensor “A” Circuit (Bank 1 or Single Sensor) —

P0345 Camshaft Position Sensor “A” Circuit (Bank 2) —

P0447 Evaporative Emission Control System Vent Control Circuit Open —

P0448 Evaporative Emission Control System Vent Control Circuit Shorted —

P0452 Evaporative Emission Control System Pressure Sensor Low Input —

P0453 Evaporative Emission Control System Pressure Sensor High Input —

P0458 Evaporative Emission Control System Purge Control Valve Circuit Low —

P0462 Fuel Level Sensor Circuit Low Input —

P0463 Fuel Level Sensor Circuit High Input —

P0500 Vehicle Speed Sensor—

P0512 Starter Request Circuit—

P0513 Incorrect Immobilizer Key —

P0519 Idle Control System Malfunction (Fail-Safe) —

P0600 Serial Communication Link —

P0604 Internal Control Module Random Access Memory (RAM) Error —

P0605 Internal Control Module Read Only Memory (ROM) Error —

P0607 Control Module Performance —

P0638 Throttle Actuator Control Range/Performance (Bank 1) —

P0691 Cooling Fan 1 Control Circuit Low —

P0692 Cooling Fan 1 Control Circuit High —

P0700 Transmission Control System (MIL Request) —

P1152 O2 Sensor Circuit Range/Performance (Low) (Bank 1 Sensor 1) —

P1153 O2 Sensor Circuit Range/Performance (High) (Bank 1 Sensor 1) —

P1154 O2 Sensor Circuit Range/Performance (Low) (Bank 2 Sensor 1) —

P1155 O2 Sensor Circuit Range/Performance (High) (Bank 2 Sensor 1) —

P1160 Return Spring Failure—

P1518 Starter Switch Circuit Low Input —

P1560 Back-Up Voltage Circuit Malfunction —

P1570 Antenna—

P1571 Reference Code Incompatibility —

P1572 IMM Circuit Failure (Except Antenna Circuit) —

P1574 Key Communication Failure —

P1576 EGI Control Module EEPROM —

P1577 IMM Control Module EEPROM —

P1578 Meter Failure—

P2088 OCV Solenoid Valve Signal A Circuit Open (Bank 1) —

P2089 OCV Solenoid Valve Signal A Circuit Short (Bank 1) —

P2092 OCV Solenoid Valve Signal A Circuit Open (Bank 2) —

P2093 OCV Solenoid Valve Signal A Circuit Short (Bank 2) —

P2101 Throttle Actuator Control Motor Circuit Range/Performance —

P2102 Throttle Actuator Control Motor Circuit Low —

P2109 Throttle/Pedal Position Sensor A Minimum Stop Performance —

P2122 Throttle/Pedal Position Sensor/Switch “D” Circuit Low Input —

P2123 Throttle/Pedal Position Sensor/Switch “D” Circuit High Input —

P2127 Throttle/Pedal Position Sensor/Switch “E” Circuit Low Input —

P2128 Throttle/Pedal Position Sensor/Switch “E” Circuit High Input —

P2135 Throttle/Pedal Position Sensor/Switch “A”/“B” Voltage Rationality —

P2138 Throttle/Pedal Position Sensor/Switch “D”/“E” Voltage Rationality —

P2227 Barometric Pressure Circuit Range/Performance —

P2228 Barometric Pressure Circuit Low Input —

P2229 Barometric Pressure Circuit High Input —

DTC Item On condition

Page 1201 of 2453

EN(H6DO)(diag)-40

Drive Cycle

ENGINE (DIAGNOSTICS)

12.Drive Cycle

A: PROCEDURE

For the troubleshooting, there are five driving pat-

terns of drive cycles A to E. Driving in the specified

pattern allows to diagnose malfunctioning items

listed below. After the repair of the following trouble

items, be sure to drive the vehicle with the specified

drive patterns to check whether the function is re-

sumed correctly.

1. PREPARATION FOR DRIVE CYCLE

1) Check battery voltage is more than 12 V and fuel

remains half [20 to 40 2 (5.3 to 10.6 US gal, 4.4 to

8.8 Imp gal)].

2) After performing the diagnostics and clearing the

memory, check for any remaining unresolved trou-

ble data.

3) Disconnect the test mode connectors.

NOTE:

•Perform the diagnosis after warming up the en-

gine except when the engine coolant temperature

at starting is specified.

•Perform the diagnosis twice if the DTC marked

with *. After completing the first diagnosis, stop the

engine and perform second diagnosis in same con-

dition.

Page 1669 of 2453

GD(H6DO)-57

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

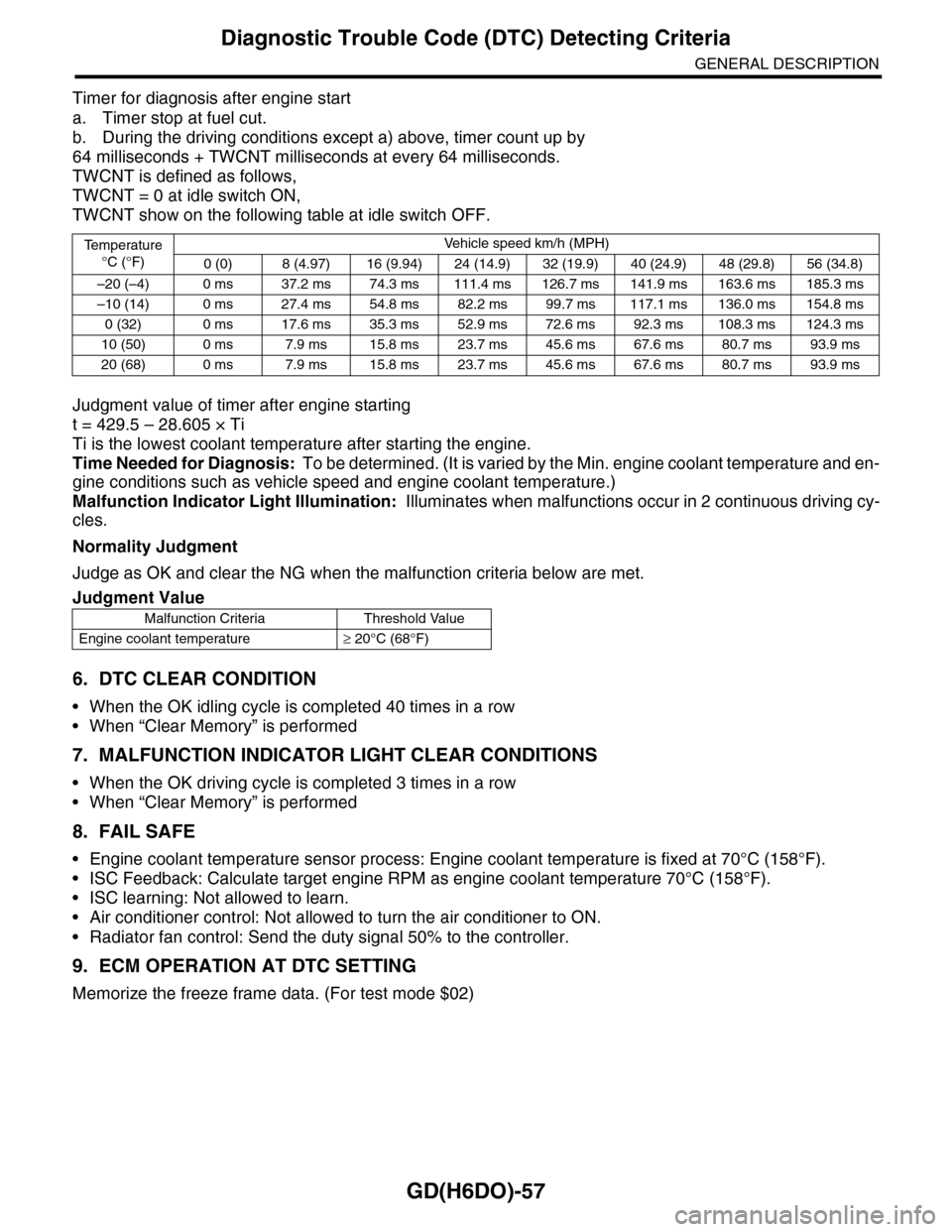

Timer for diagnosis after engine start

a. Timer stop at fuel cut.

b. During the driving conditions except a) above, timer count up by

64 milliseconds + TWCNT milliseconds at every 64 milliseconds.

TWCNT is defined as follows,

TWCNT = 0 at idle switch ON,

TWCNT show on the following table at idle switch OFF.

Judgment value of timer after engine starting

t = 429.5 – 28.605 × Ti

Ti is the lowest coolant temperature after starting the engine.

Time Needed for Diagnosis: To be determined. (It is varied by the Min. engine coolant temperature and en-

gine conditions such as vehicle speed and engine coolant temperature.)

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

•Engine coolant temperature sensor process: Engine coolant temperature is fixed at 70°C (158°F).

•ISC Feedback: Calculate target engine RPM as engine coolant temperature 70°C (158°F).

•ISC learning: Not allowed to learn.

•Air conditioner control: Not allowed to turn the air conditioner to ON.

•Radiator fan control: Send the duty signal 50% to the controller.

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Te m p e r a t u r e

°C (°F)

Ve h i c l e s p e e d k m / h ( M P H )

0 (0) 8 (4.97) 16 (9.94) 24 (14.9) 32 (19.9) 40 (24.9) 48 (29.8) 56 (34.8)

–20 (–4) 0 ms 37.2 ms 74.3 ms 111.4 ms 126.7 ms 141.9 ms 163.6 ms 185.3 ms

–10 (14) 0 ms 27.4 ms 54.8 ms 82.2 ms 99.7 ms 117.1 ms 136.0 ms 154.8 ms

0 (32) 0 ms 17.6 ms 35.3 ms 52.9 ms 72.6 ms 92.3 ms 108.3 ms 124.3 ms

10 (50) 0 ms 7.9 ms 15.8 ms 23.7 ms 45.6 ms 67.6 ms 80.7 ms 93.9 ms

20 (68) 0 ms 7.9 ms 15.8 ms 23.7 ms 45.6 ms 67.6 ms 80.7 ms 93.9 ms

Judgment Value

Malfunction Criteria Threshold Value

Engine coolant temperature≥ 20°C (68°F)

Page 1670 of 2453

GD(H6DO)-58

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

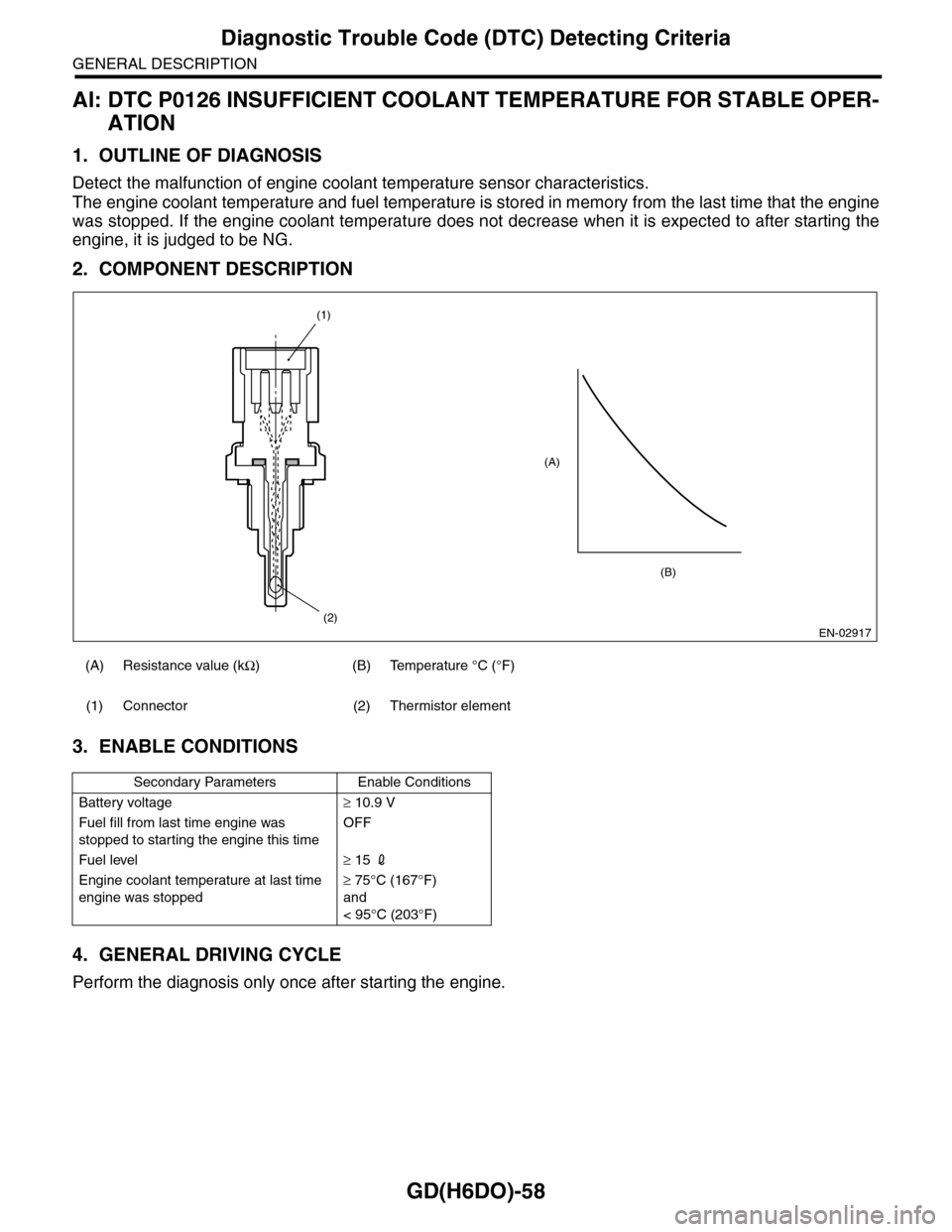

AI: DTC P0126 INSUFFICIENT COOLANT TEMPERATURE FOR STABLE OPER-

ATION

1. OUTLINE OF DIAGNOSIS

Detect the malfunction of engine coolant temperature sensor characteristics.

The engine coolant temperature and fuel temperature is stored in memory from the last time that the engine

was stopped. If the engine coolant temperature does not decrease when it is expected to after starting the

engine, it is judged to be NG.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Perform the diagnosis only once after starting the engine.

(A) Resistance value (kΩ)(B)Temperature °C (°F)

(1) Connector (2) Thermistor element

Secondary Parameters Enable Conditions

Battery voltage≥ 10.9 V

Fuel fill from last time engine was

stopped to starting the engine this time

OFF

Fuel level≥ 15 2

Engine coolant temperature at last time

engine was stopped

≥ 75°C (167°F)

and

< 95°C (203°F)

EN-02917

(A)

(2)

(1)

(B)

Page 1671 of 2453

GD(H6DO)-59

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

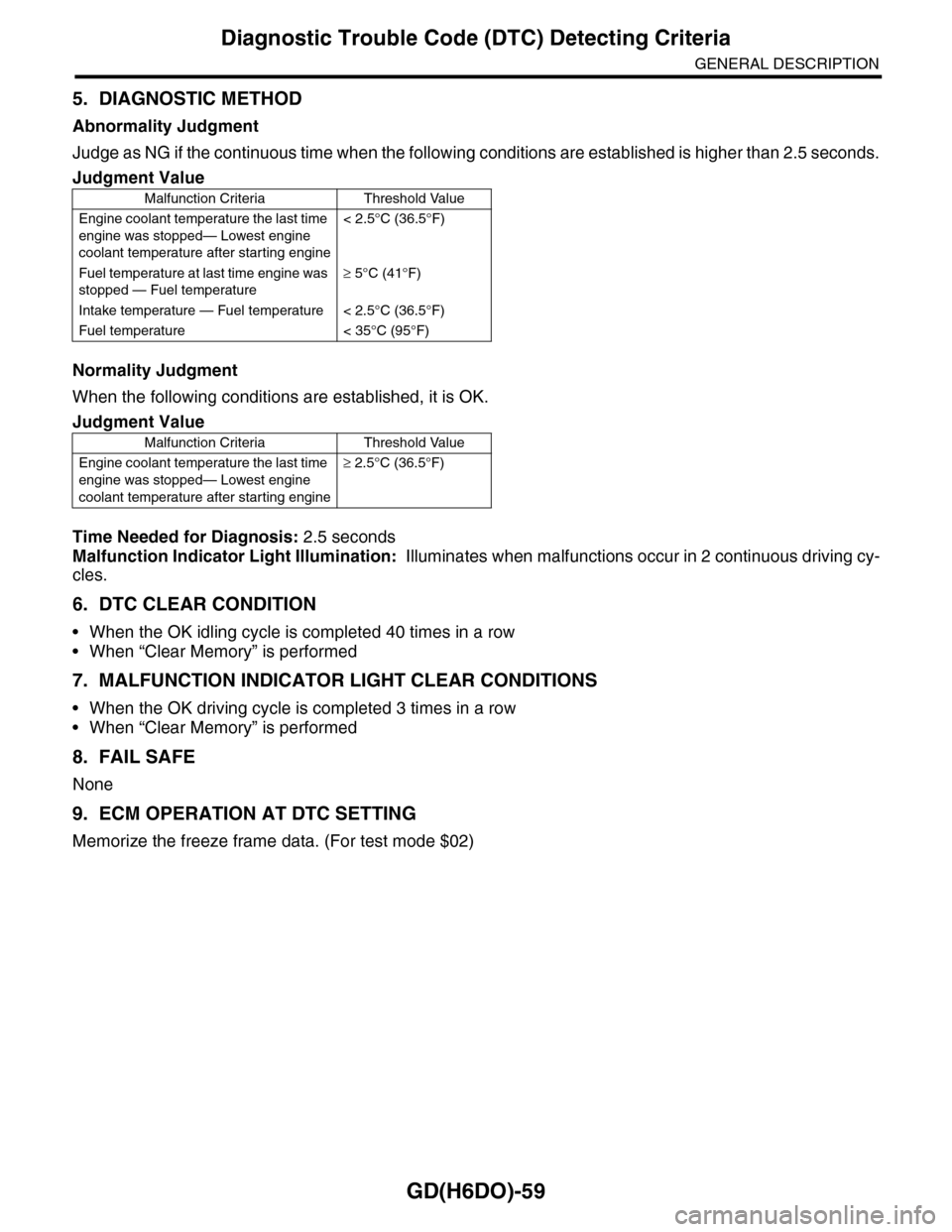

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG if the continuous time when the following conditions are established is higher than 2.5 seconds.

Normality Judgment

When the following conditions are established, it is OK.

Time Needed for Diagnosis: 2.5 seconds

Malfunction Indicator Light Illumination: Illuminates when malfunctions occur in 2 continuous driving cy-

cles.

6. DTC CLEAR CONDITION

•When the OK idling cycle is completed 40 times in a row

•When “Clear Memory” is performed

7. MALFUNCTION INDICATOR LIGHT CLEAR CONDITIONS

•When the OK driving cycle is completed 3 times in a row

•When “Clear Memory” is performed

8. FAIL SAFE

None

9. ECM OPERATION AT DTC SETTING

Memorize the freeze frame data. (For test mode $02)

Judgment Value

Malfunction Criteria Threshold Value

Engine coolant temperature the last time

engine was stopped— Lowest engine

coolant temperature after starting engine

< 2.5°C (36.5°F)

Fuel temperature at last time engine was

stopped — Fuel temperature

≥ 5°C (41°F)

Intake temperature — Fuel temperature < 2.5°C (36.5°F)

Fuel temperature < 35°C (95°F)

Judgment Value

Malfunction Criteria Threshold Value

Engine coolant temperature the last time

engine was stopped— Lowest engine

coolant temperature after starting engine

≥ 2.5°C (36.5°F)