stop start SUBARU TRIBECA 2009 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1968 of 2453

SC(H6DO)-10

Starter

STARTING/CHARGING SYSTEMS

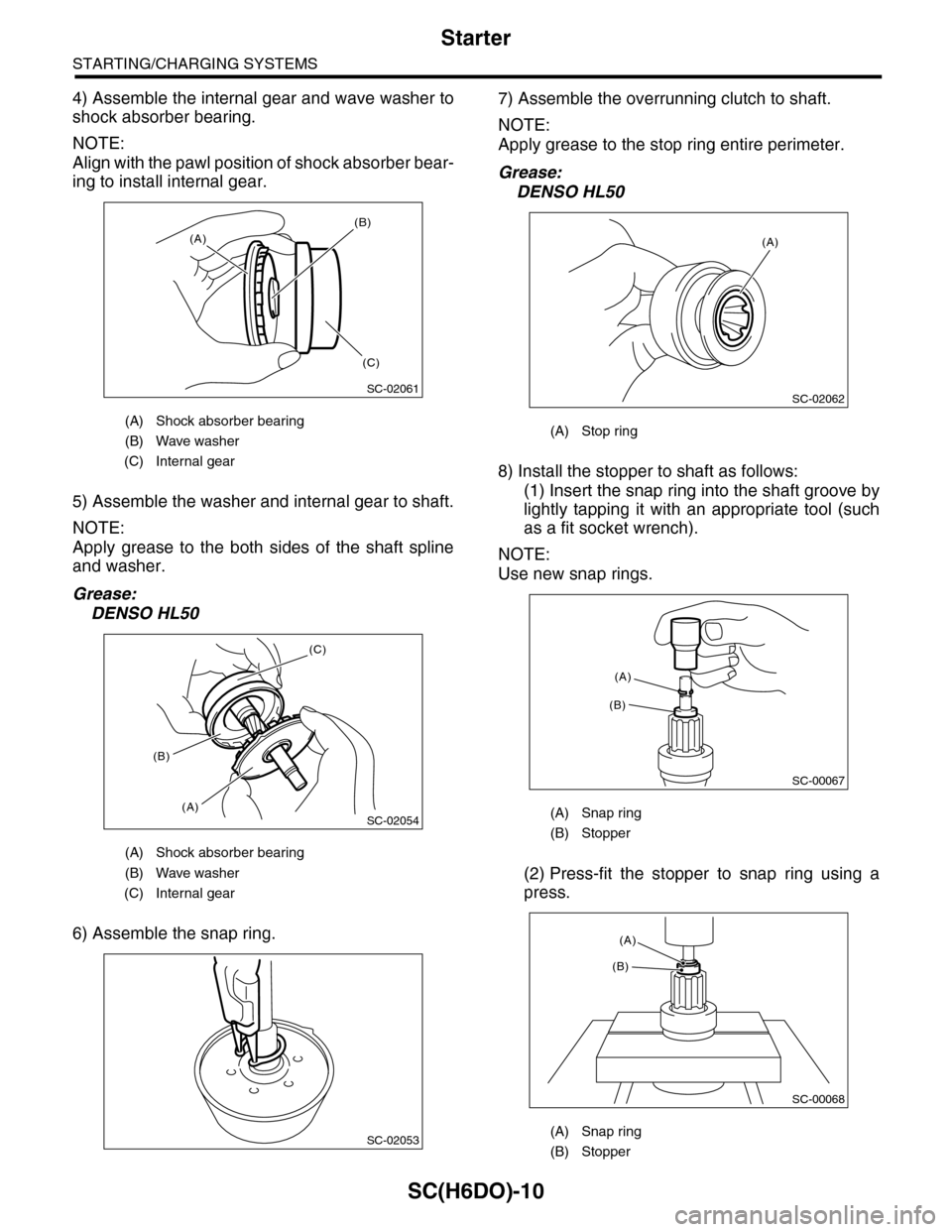

4) Assemble the internal gear and wave washer to

shock absorber bearing.

NOTE:

Align with the pawl position of shock absorber bear-

ing to install internal gear.

5) Assemble the washer and internal gear to shaft.

NOTE:

Apply grease to the both sides of the shaft spline

and washer.

Grease:

DENSO HL50

6) Assemble the snap ring.

7) Assemble the overrunning clutch to shaft.

NOTE:

Apply grease to the stop ring entire perimeter.

Grease:

DENSO HL50

8) Install the stopper to shaft as follows:

(1) Insert the snap ring into the shaft groove by

lightly tapping it with an appropriate tool (such

as a fit socket wrench).

NOTE:

Use new snap rings.

(2) Press-fit the stopper to snap ring using a

press.

(A) Shock absorber bearing

(B) Wave washer

(C) Internal gear

(A) Shock absorber bearing

(B) Wave washer

(C) Internal gear

SC-02061

(A)

(B)

(C)

SC-02054

(C)

(A)

(B)

SC-02053

(A) Stop ring

(A) Snap ring

(B) Stopper

(A) Snap ring

(B) Stopper

SC-02062

(A)

SC-00067

(B)

(A)

SC-00068

(A)

(B)

Page 1971 of 2453

SC(H6DO)-13

Starter

STARTING/CHARGING SYSTEMS

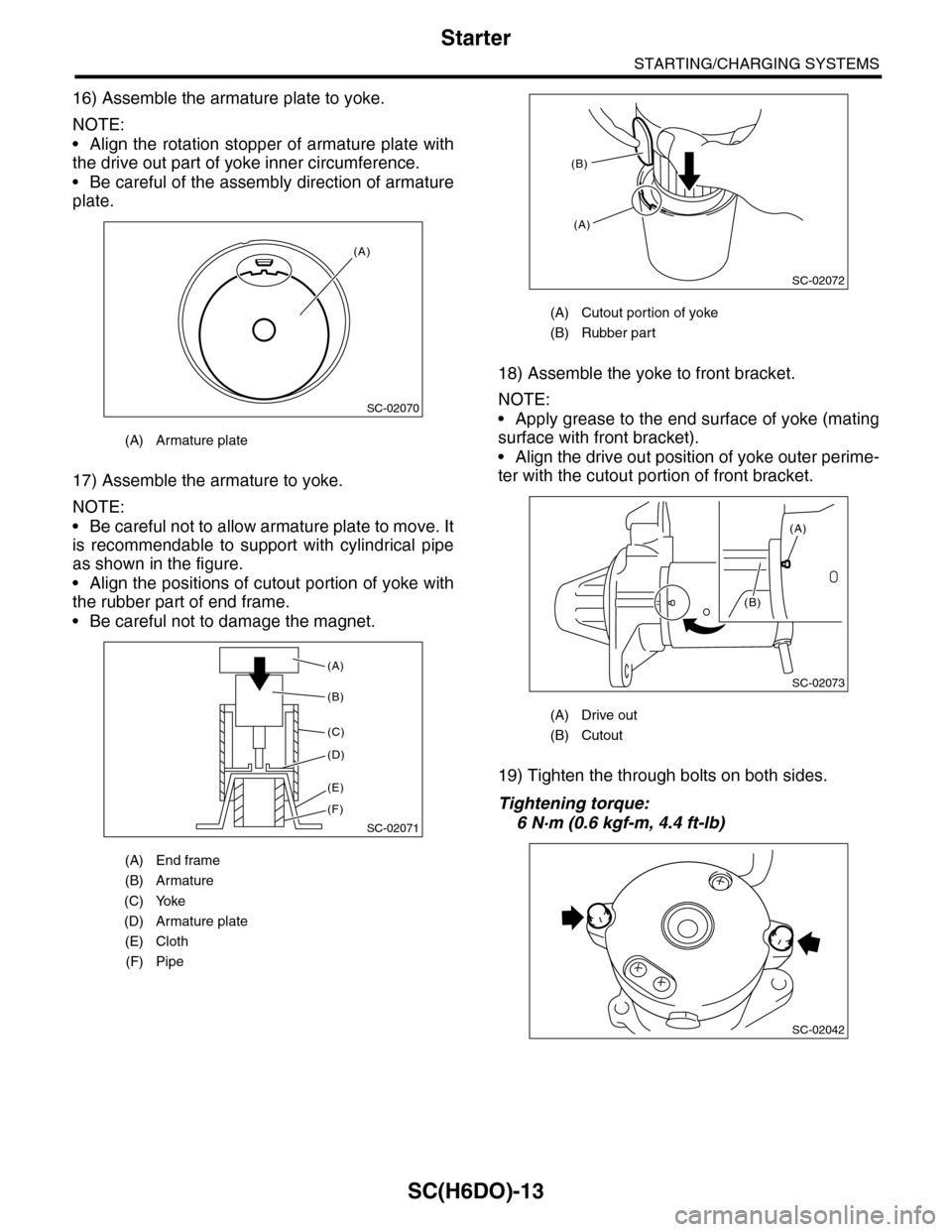

16) Assemble the armature plate to yoke.

NOTE:

•Align the rotation stopper of armature plate with

the drive out part of yoke inner circumference.

•Be careful of the assembly direction of armature

plate.

17) Assemble the armature to yoke.

NOTE:

•Be careful not to allow armature plate to move. It

is recommendable to support with cylindrical pipe

as shown in the figure.

•Align the positions of cutout portion of yoke with

the rubber part of end frame.

•Be careful not to damage the magnet.

18) Assemble the yoke to front bracket.

NOTE:

•Apply grease to the end surface of yoke (mating

surface with front bracket).

•Align the drive out position of yoke outer perime-

ter with the cutout portion of front bracket.

19) Tighten the through bolts on both sides.

Tightening torque:

6 N·m (0.6 kgf-m, 4.4 ft-lb)

(A) Armature plate

(A) End frame

(B) Armature

(C) Yoke

(D) Armature plate

(E) Cloth

(F) Pipe

SC-02070

(A)

SC-02071

(A)

(B)

(C)

(D)

(E)

(F)

(A) Cutout portion of yoke

(B) Rubber part

(A) Drive out

(B) Cutout

SC-02072

(B)

(A)

SC-02073

(A)

(B)

SC-02042

Page 1989 of 2453

PM-6

Engine Oil

PERIODIC MAINTENANCE SERVICES

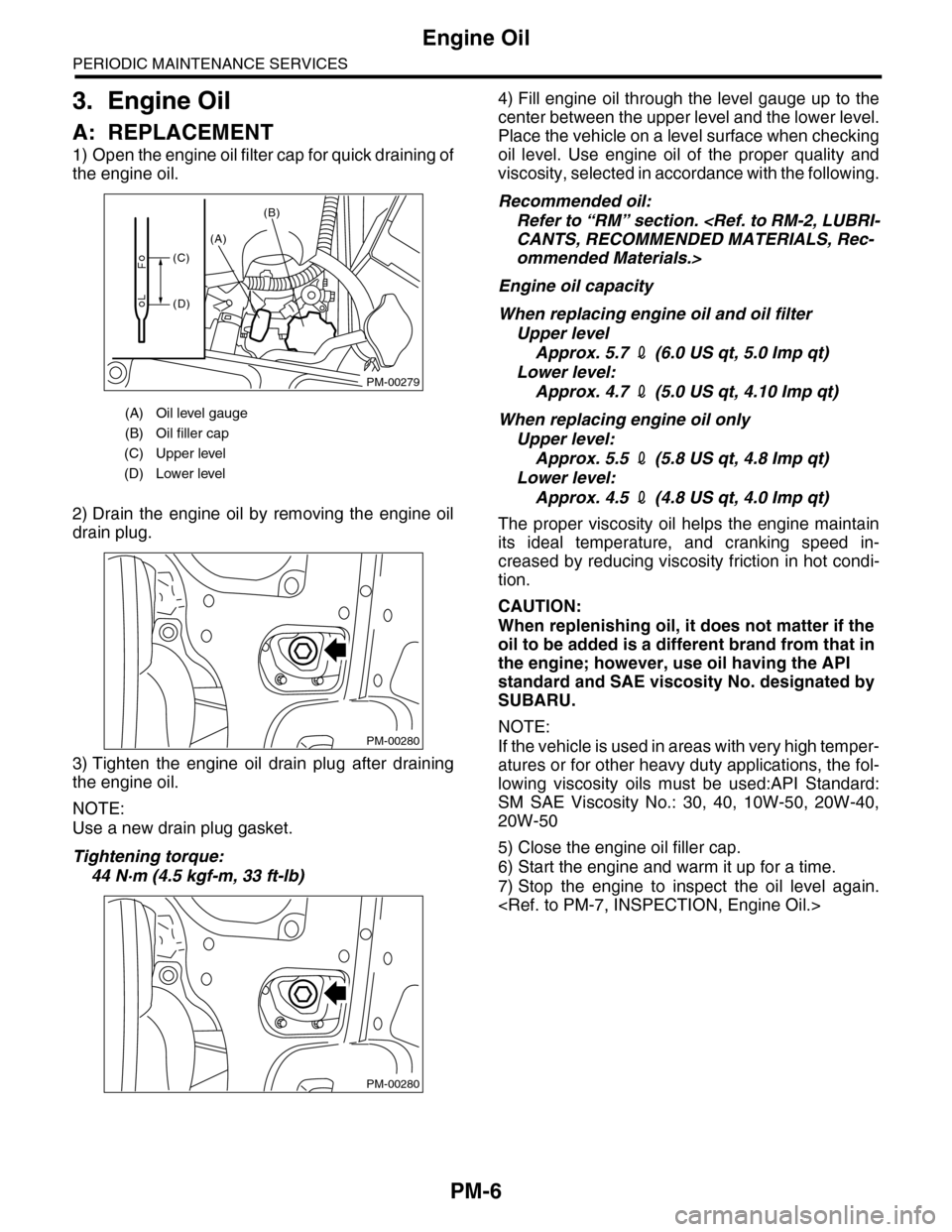

3. Engine Oil

A: REPLACEMENT

1) Open the engine oil filter cap for quick draining of

the engine oil.

2) Drain the engine oil by removing the engine oil

drain plug.

3) Tighten the engine oil drain plug after draining

the engine oil.

NOTE:

Use a new drain plug gasket.

Tightening torque:

44 N·m (4.5 kgf-m, 33 ft-lb)

4) Fill engine oil through the level gauge up to the

center between the upper level and the lower level.

Place the vehicle on a level surface when checking

oil level. Use engine oil of the proper quality and

viscosity, selected in accordance with the following.

Recommended oil:

Refer to “RM” section.

ommended Materials.>

Engine oil capacity

When replacing engine oil and oil filter

Upper level

Approx. 5.7 2 (6.0 US qt, 5.0 Imp qt)

Lower level:

Approx. 4.7 2 (5.0 US qt, 4.10 Imp qt)

When replacing engine oil only

Upper level:

Approx. 5.5 2 (5.8 US qt, 4.8 Imp qt)

Lower level:

Approx. 4.5 2 (4.8 US qt, 4.0 Imp qt)

The proper viscosity oil helps the engine maintain

its ideal temperature, and cranking speed in-

creased by reducing viscosity friction in hot condi-

tion.

CAUTION:

When replenishing oil, it does not matter if the

oil to be added is a different brand from that in

the engine; however, use oil having the API

standard and SAE viscosity No. designated by

SUBARU.

NOTE:

If the vehicle is used in areas with very high temper-

atures or for other heavy duty applications, the fol-

lowing viscosity oils must be used:API Standard:

SM SAE Viscosity No.: 30, 40, 10W-50, 20W-40,

20W-50

5) Close the engine oil filler cap.

6) Start the engine and warm it up for a time.

7) Stop the engine to inspect the oil level again.

(A) Oil level gauge

(B) Oil filler cap

(C) Upper level

(D) Lower level

PM-00279

(A)

(B)

(C)

(D)

PM-00280

PM-00280

Page 1996 of 2453

PM-13

Cooling System

PERIODIC MAINTENANCE SERVICES

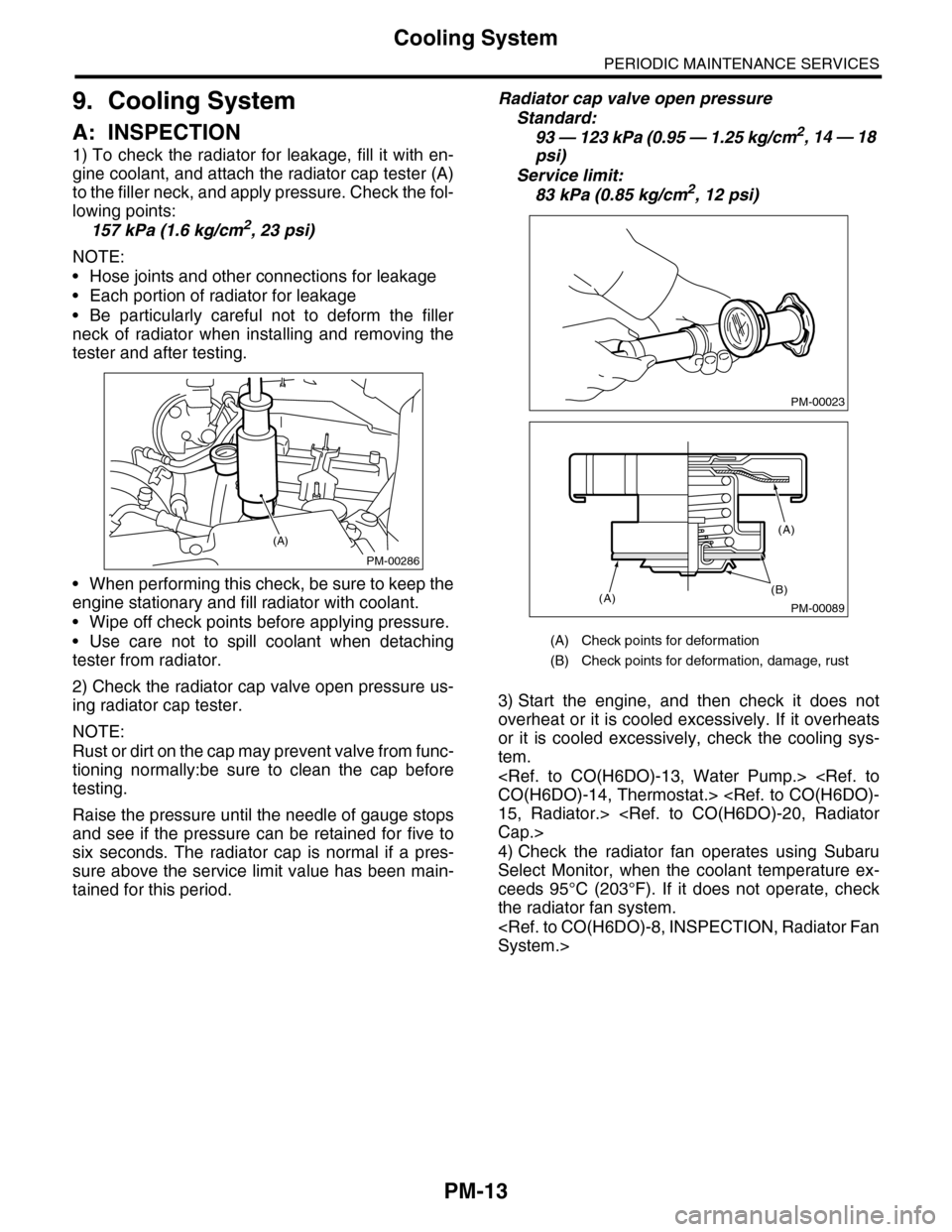

9. Cooling System

A: INSPECTION

1) To check the radiator for leakage, fill it with en-

gine coolant, and attach the radiator cap tester (A)

to the filler neck, and apply pressure. Check the fol-

lowing points:

157 kPa (1.6 kg/cm2, 23 psi)

NOTE:

•Hose joints and other connections for leakage

•Each portion of radiator for leakage

•Be particularly careful not to deform the filler

neck of radiator when installing and removing the

tester and after testing.

•When performing this check, be sure to keep the

engine stationary and fill radiator with coolant.

•Wipe off check points before applying pressure.

•Use care not to spill coolant when detaching

tester from radiator.

2) Check the radiator cap valve open pressure us-

ing radiator cap tester.

NOTE:

Rust or dirt on the cap may prevent valve from func-

tioning normally:be sure to clean the cap before

testing.

Raise the pressure until the needle of gauge stops

and see if the pressure can be retained for five to

six seconds. The radiator cap is normal if a pres-

sure above the service limit value has been main-

tained for this period.

Radiator cap valve open pressure

Standard:

93 — 123 kPa (0.95 — 1.25 kg/cm2, 14 — 18

psi)

Service limit:

83 kPa (0.85 kg/cm2, 12 psi)

3) Start the engine, and then check it does not

overheat or it is cooled excessively. If it overheats

or it is cooled excessively, check the cooling sys-

tem.

4) Check the radiator fan operates using Subaru

Select Monitor, when the coolant temperature ex-

ceeds 95°C (203°F). If it does not operate, check

the radiator fan system.

PM-00286

(A)

(A) Check points for deformation

(B) Check points for deformation, damage, rust

PM-00023

PM-00089

(B)(A)

(A)

Page 1997 of 2453

PM-14

Engine Coolant

PERIODIC MAINTENANCE SERVICES

10.Engine Coolant

A: REPLACEMENT

1. REPLACEMENT OF ENGINE COOLANT

WARNING:

The radiator is of the pressurized type. Do not

attempt to open the radiator cap immediately

after the engine has been stopped.

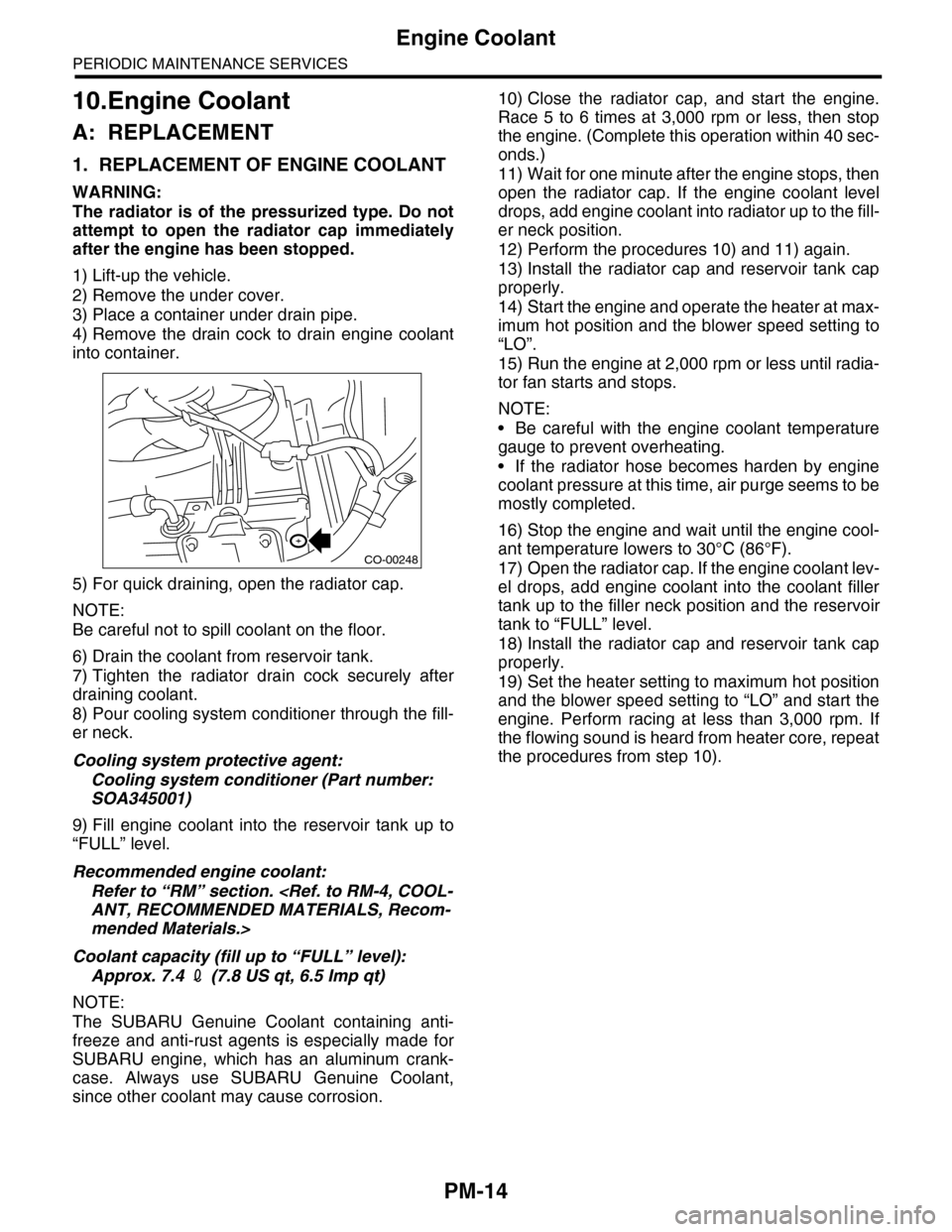

1) Lift-up the vehicle.

2) Remove the under cover.

3) Place a container under drain pipe.

4) Remove the drain cock to drain engine coolant

into container.

5) For quick draining, open the radiator cap.

NOTE:

Be careful not to spill coolant on the floor.

6) Drain the coolant from reservoir tank.

7) Tighten the radiator drain cock securely after

draining coolant.

8) Pour cooling system conditioner through the fill-

er neck.

Cooling system protective agent:

Cooling system conditioner (Part number:

SOA345001)

9) Fill engine coolant into the reservoir tank up to

“FULL” level.

Recommended engine coolant:

Refer to “RM” section.

mended Materials.>

Coolant capacity (fill up to “FULL” level):

Approx. 7.4 2 (7.8 US qt, 6.5 Imp qt)

NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

10) Close the radiator cap, and start the engine.

Race 5 to 6 times at 3,000 rpm or less, then stop

the engine. (Complete this operation within 40 sec-

onds.)

11) Wait for one minute after the engine stops, then

open the radiator cap. If the engine coolant level

drops, add engine coolant into radiator up to the fill-

er neck position.

12) Perform the procedures 10) and 11) again.

13) Install the radiator cap and reservoir tank cap

properly.

14) Start the engine and operate the heater at max-

imum hot position and the blower speed setting to

“LO”.

15) Run the engine at 2,000 rpm or less until radia-

tor fan starts and stops.

NOTE:

•Be careful with the engine coolant temperature

gauge to prevent overheating.

•If the radiator hose becomes harden by engine

coolant pressure at this time, air purge seems to be

mostly completed.

16) Stop the engine and wait until the engine cool-

ant temperature lowers to 30°C (86°F).

17) Open the radiator cap. If the engine coolant lev-

el drops, add engine coolant into the coolant filler

tank up to the filler neck position and the reservoir

tank to “FULL” level.

18) Install the radiator cap and reservoir tank cap

properly.

19) Set the heater setting to maximum hot position

and the blower speed setting to “LO” and start the

engine. Perform racing at less than 3,000 rpm. If

the flowing sound is heard from heater core, repeat

the procedures from step 10).

CO-00248

Page 2003 of 2453

PM-20

Brake Line

PERIODIC MAINTENANCE SERVICES

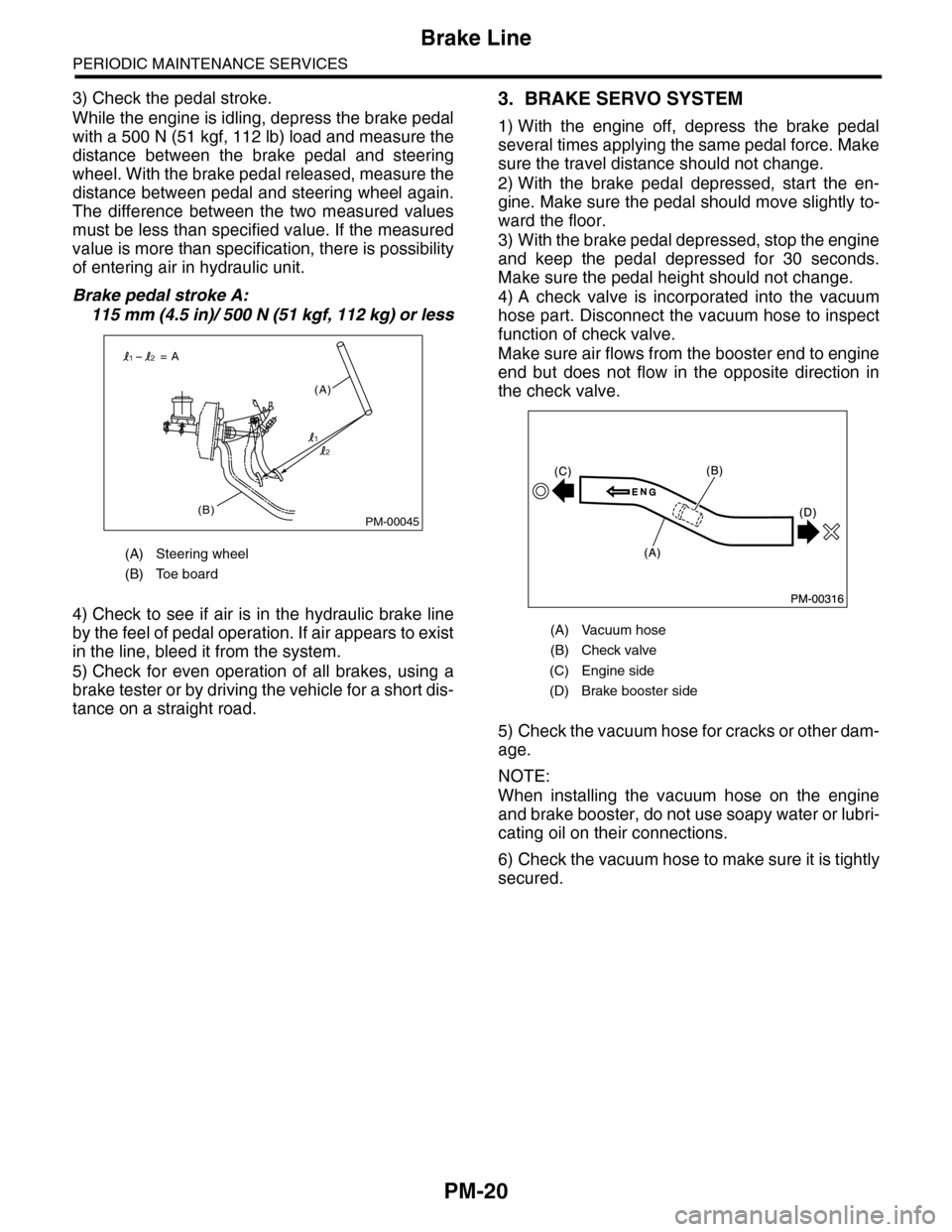

3) Check the pedal stroke.

While the engine is idling, depress the brake pedal

with a 500 N (51 kgf, 112 lb) load and measure the

distance between the brake pedal and steering

wheel. With the brake pedal released, measure the

distance between pedal and steering wheel again.

The difference between the two measured values

must be less than specified value. If the measured

value is more than specification, there is possibility

of entering air in hydraulic unit.

Brake pedal stroke A:

115 mm (4.5 in)/ 500 N (51 kgf, 112 kg) or less

4) Check to see if air is in the hydraulic brake line

by the feel of pedal operation. If air appears to exist

in the line, bleed it from the system.

5) Check for even operation of all brakes, using a

brake tester or by driving the vehicle for a short dis-

tance on a straight road.

3. BRAKE SERVO SYSTEM

1) With the engine off, depress the brake pedal

several times applying the same pedal force. Make

sure the travel distance should not change.

2) With the brake pedal depressed, start the en-

gine. Make sure the pedal should move slightly to-

ward the floor.

3) With the brake pedal depressed, stop the engine

and keep the pedal depressed for 30 seconds.

Make sure the pedal height should not change.

4) A check valve is incorporated into the vacuum

hose part. Disconnect the vacuum hose to inspect

function of check valve.

Make sure air flows from the booster end to engine

end but does not flow in the opposite direction in

the check valve.

5) Check the vacuum hose for cracks or other dam-

age.

NOTE:

When installing the vacuum hose on the engine

and brake booster, do not use soapy water or lubri-

cating oil on their connections.

6) Check the vacuum hose to make sure it is tightly

secured.

(A) Steering wheel

(B) Toe board

PM-00045(B)

(A)

= A

1

12

2

(A) Vacuum hose

(B) Check valve

(C) Engine side

(D) Brake booster side

Page 2047 of 2453

5AT-31

Time Lag Test

AUTOMATIC TRANSMISSION

6. Time Lag Test

A: INSPECTION

NOTE:

When the select lever is shifted while the engine is

idling, there will be a certain time elapse or lag be-

fore shock is felt. Using this, check the condition of

forward brake, reverse brake, 1st one-way clutch,

forward one-way clutch and 3rd one-way clutch.

•Perform the test at normal operation fluid tem-

perature of 70 — 80°C (158 — 176°F).

•Be sure to allow a one minute interval between

tests.

•Make three measurements and take the average

value.

1) Fully apply the parking brake.

2) Start the engine.

Check the idle speed (A/C OFF).

3) Shift the select lever from “N” to “D” range. Using

a stop watch, measure the time-lag from shifting

the lever until the shock is felt.

Time-lag

Specification: 1.2 sec. or less

If “N” → “D” time-lag is longer than specification:

•Line pressure too low

•Forward brake worn

•One–way clutch not operating properly

4) In the same manner, measure the time lag of “N”

→ “R”.

Time-lag

Specification: 1.5 sec. or less

If “N” → “R” time lag is longer than specification:

•Line pressure too low

•Reverse brake worn

Page 2050 of 2453

5AT-34

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

9. Automatic Transmission As-

sembly

A: REMOVAL

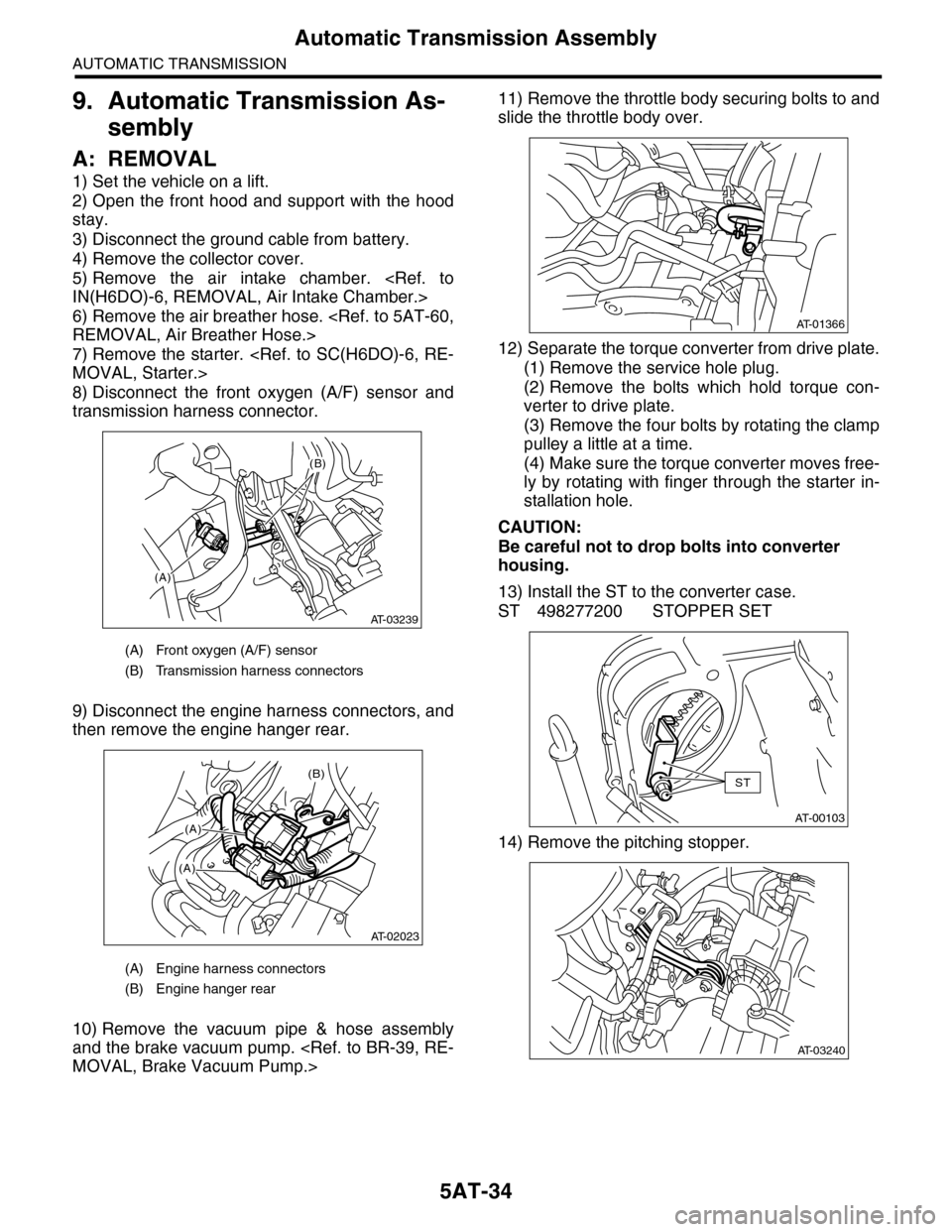

1) Set the vehicle on a lift.

2) Open the front hood and support with the hood

stay.

3) Disconnect the ground cable from battery.

4) Remove the collector cover.

5) Remove the air intake chamber.

6) Remove the air breather hose.

7) Remove the starter.

8) Disconnect the front oxygen (A/F) sensor and

transmission harness connector.

9) Disconnect the engine harness connectors, and

then remove the engine hanger rear.

10) Remove the vacuum pipe & hose assembly

and the brake vacuum pump.

11) Remove the throttle body securing bolts to and

slide the throttle body over.

12) Separate the torque converter from drive plate.

(1) Remove the service hole plug.

(2) Remove the bolts which hold torque con-

verter to drive plate.

(3) Remove the four bolts by rotating the clamp

pulley a little at a time.

(4) Make sure the torque converter moves free-

ly by rotating with finger through the starter in-

stallation hole.

CAUTION:

Be careful not to drop bolts into converter

housing.

13) Install the ST to the converter case.

ST 498277200 STOPPER SET

14) Remove the pitching stopper.

(A) Front oxygen (A/F) sensor

(B) Transmission harness connectors

(A) Engine harness connectors

(B) Engine hanger rear

(A)

(B)

AT-03239

(B)

(A)

(A)

AT-02023

AT-01366

AT-00103

ST

AT-03240

Page 2053 of 2453

5AT-37

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

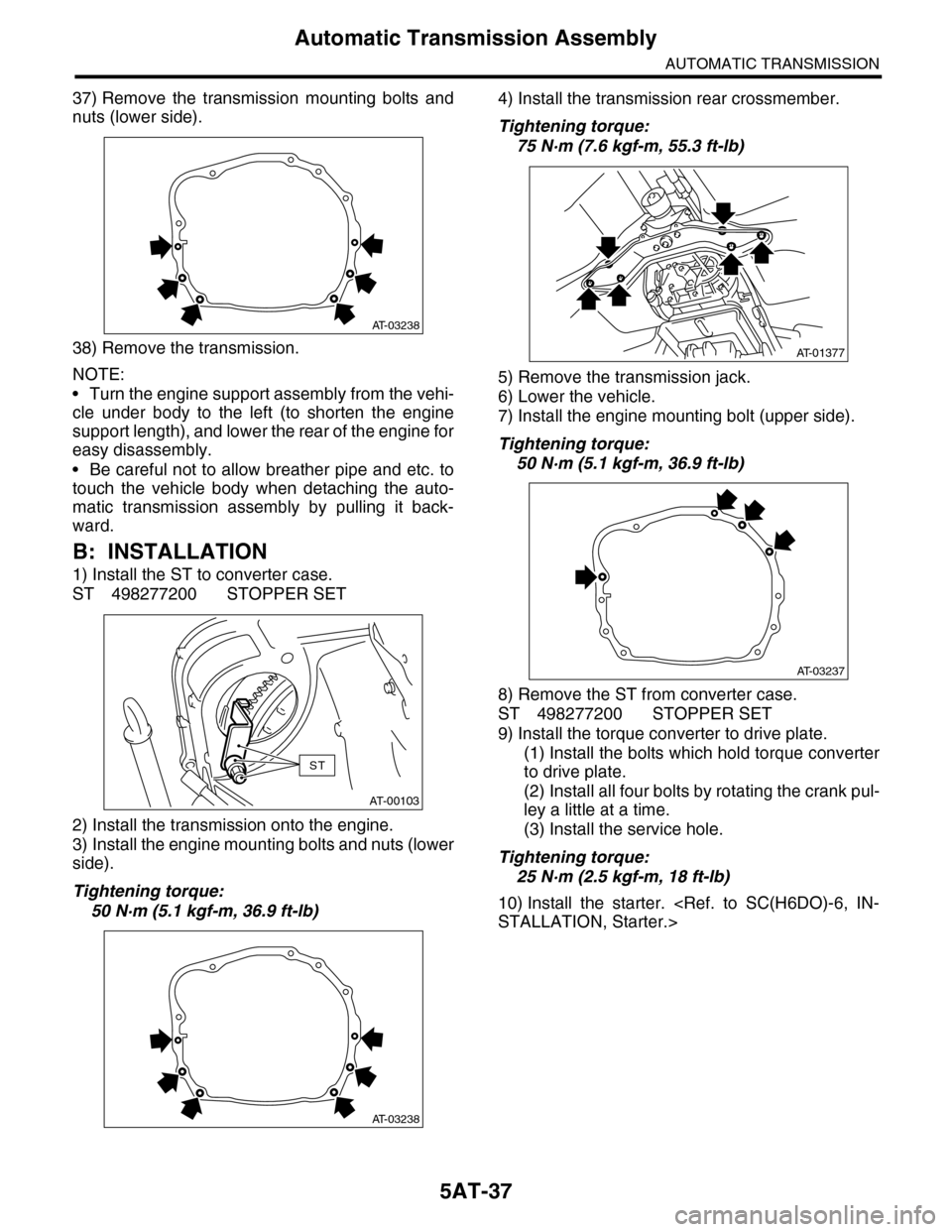

37) Remove the transmission mounting bolts and

nuts (lower side).

38) Remove the transmission.

NOTE:

•Turn the engine support assembly from the vehi-

cle under body to the left (to shorten the engine

support length), and lower the rear of the engine for

easy disassembly.

•Be careful not to allow breather pipe and etc. to

touch the vehicle body when detaching the auto-

matic transmission assembly by pulling it back-

ward.

B: INSTALLATION

1) Install the ST to converter case.

ST 498277200 STOPPER SET

2) Install the transmission onto the engine.

3) Install the engine mounting bolts and nuts (lower

side).

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

4) Install the transmission rear crossmember.

Tightening torque:

75 N·m (7.6 kgf-m, 55.3 ft-lb)

5) Remove the transmission jack.

6) Lower the vehicle.

7) Install the engine mounting bolt (upper side).

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

8) Remove the ST from converter case.

ST 498277200 STOPPER SET

9) Install the torque converter to drive plate.

(1) Install the bolts which hold torque converter

to drive plate.

(2) Install all four bolts by rotating the crank pul-

ley a little at a time.

(3) Install the service hole.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

10) Install the starter.

AT-03238

AT-00103

ST

AT-03238

AT-01377

AT-03237

Page 2259 of 2453

CS-7

AT Shift Lock Control System

CONTROL SYSTEMS

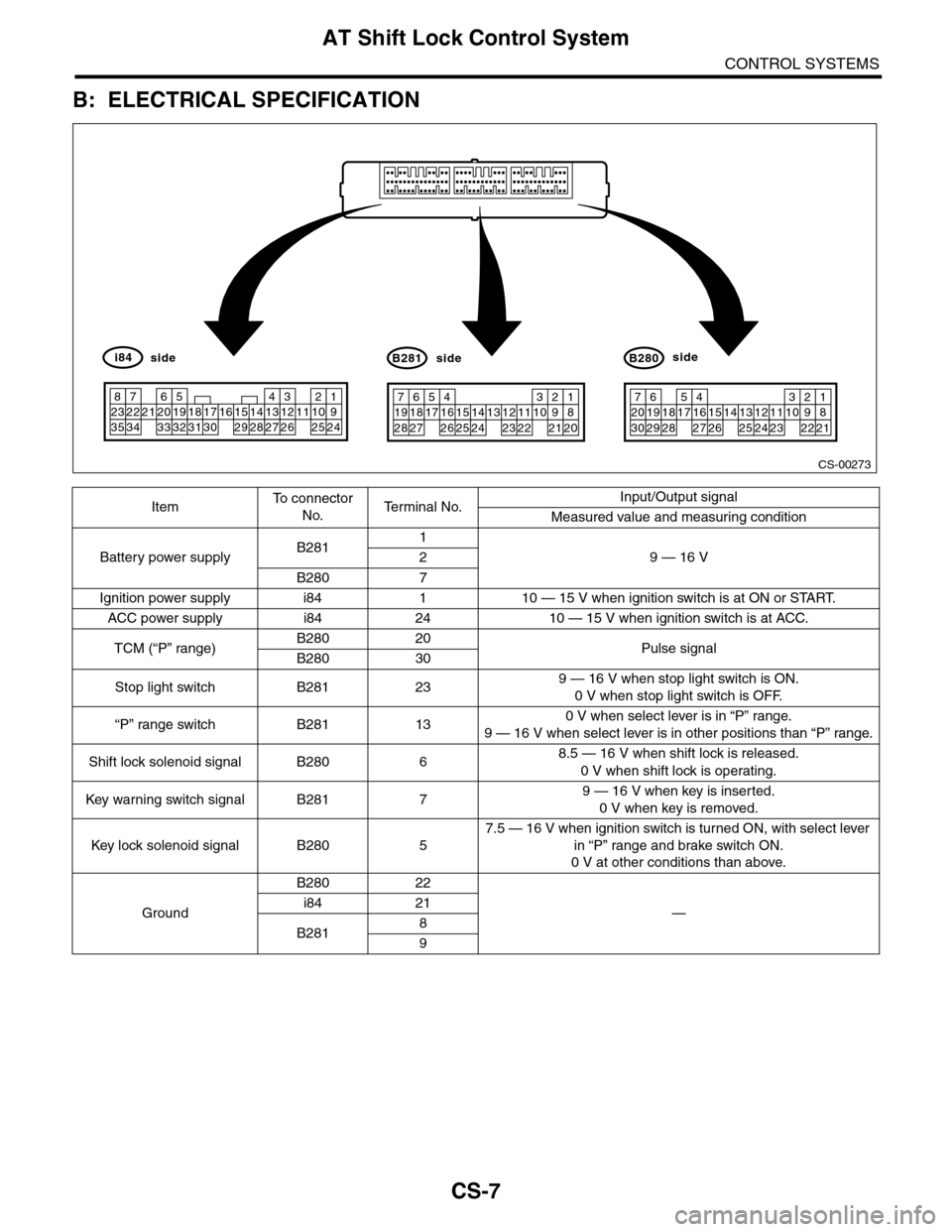

B: ELECTRICAL SPECIFICATION

ItemTo c o n n e c t o r

No.Te r m i n a l N o .Input/Output signal

Measured value and measuring condition

Battery power supplyB2811

9 — 16 V2

B280 7

Ignition power supply i84 1 10 — 15 V when ignition switch is at ON or START.

ACC power supply i84 24 10 — 15 V when ignition switch is at ACC.

TCM (“P” range)B280 20Pulse signalB280 30

Stop light switch B281 239 — 16 V when stop light switch is ON.

0 V when stop light switch is OFF.

“P” range switch B281 130 V when select lever is in “P” range.

9 — 16 V when select lever is in other positions than “P” range.

Shift lock solenoid signal B280 68.5 — 16 V when shift lock is released.

0 V when shift lock is operating.

Key war ning switch signal B281 79 — 16 V when key is inserted.

0 V when key is removed.

Key lock solenoid signal B280 5

7.5 — 16 V when ignition switch is turned ON, with select lever

in “P” range and brake switch ON.

0 V at other conditions than above.

Ground

B280 22

—i84 21

B2818

9

CS-00273

71928

61827

51741626152514241312231122

3102921

1820

B281side

72030

619291828

51741627152614132512241123

3102922

1821

B280side

82335

722342162033

51932183117301615291428

41327

312261121025

1924

i84side