Reverse SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2236 of 2453

5AT(diag)-119

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

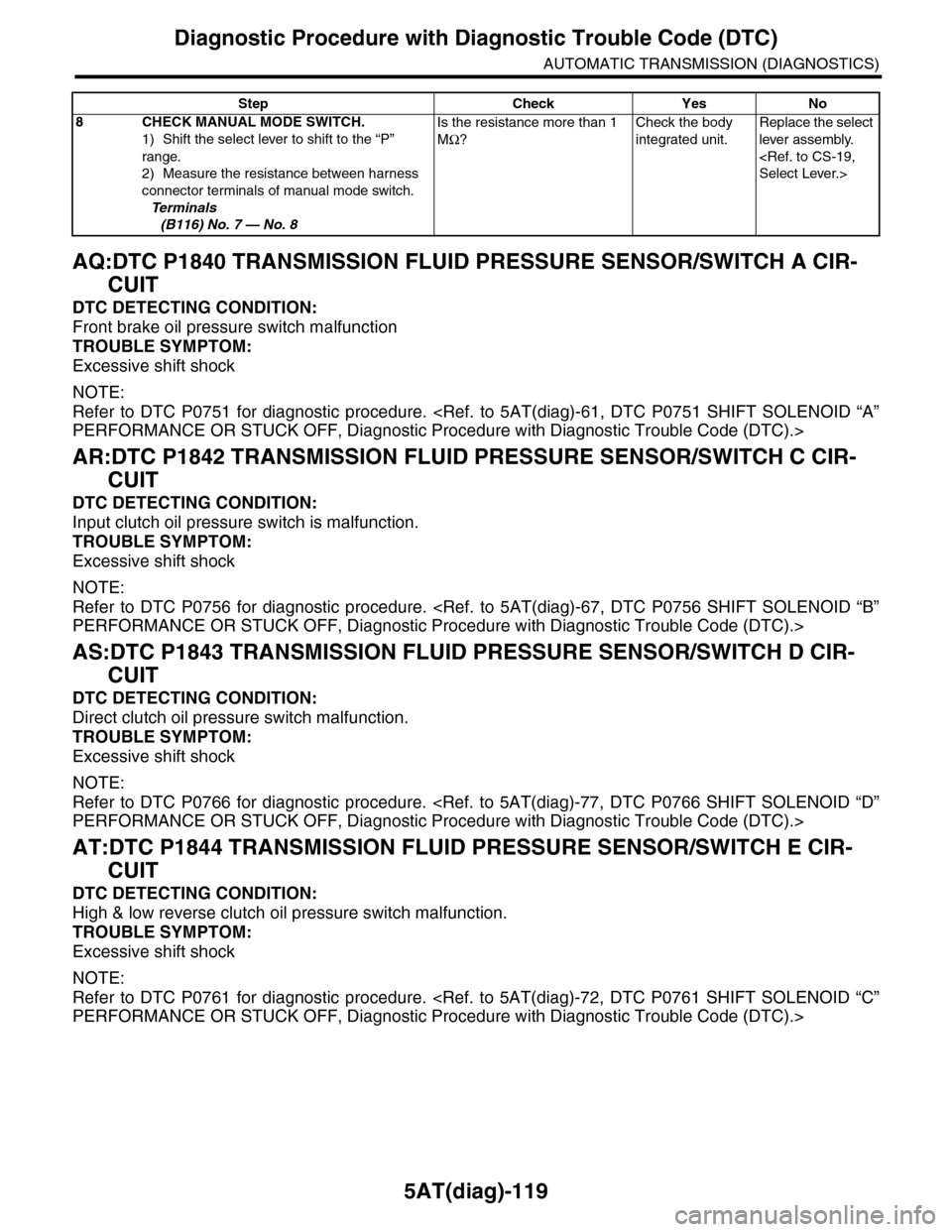

AQ:DTC P1840 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH A CIR-

CUIT

DTC DETECTING CONDITION:

Front brake oil pressure switch malfunction

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0751 for diagnostic procedure.

AR:DTC P1842 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH C CIR-

CUIT

DTC DETECTING CONDITION:

Input clutch oil pressure switch is malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0756 for diagnostic procedure.

AS:DTC P1843 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH D CIR-

CUIT

DTC DETECTING CONDITION:

Direct clutch oil pressure switch malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0766 for diagnostic procedure.

AT:DTC P1844 TRANSMISSION FLUID PRESSURE SENSOR/SWITCH E CIR-

CUIT

DTC DETECTING CONDITION:

High & low reverse clutch oil pressure switch malfunction.

TROUBLE SYMPTOM:

Excessive shift shock

NOTE:

Refer to DTC P0761 for diagnostic procedure.

8CHECK MANUAL MODE SWITCH.

1) Shift the select lever to shift to the “P”

range.

2) Measure the resistance between harness

connector terminals of manual mode switch.

Te r m i n a l s

(B116) No. 7 — No. 8

Is the resistance more than 1

MΩ?

Check the body

integrated unit.

Replace the select

lever assembly.

Step Check Yes No

Page 2245 of 2453

5AT(diag)-128

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

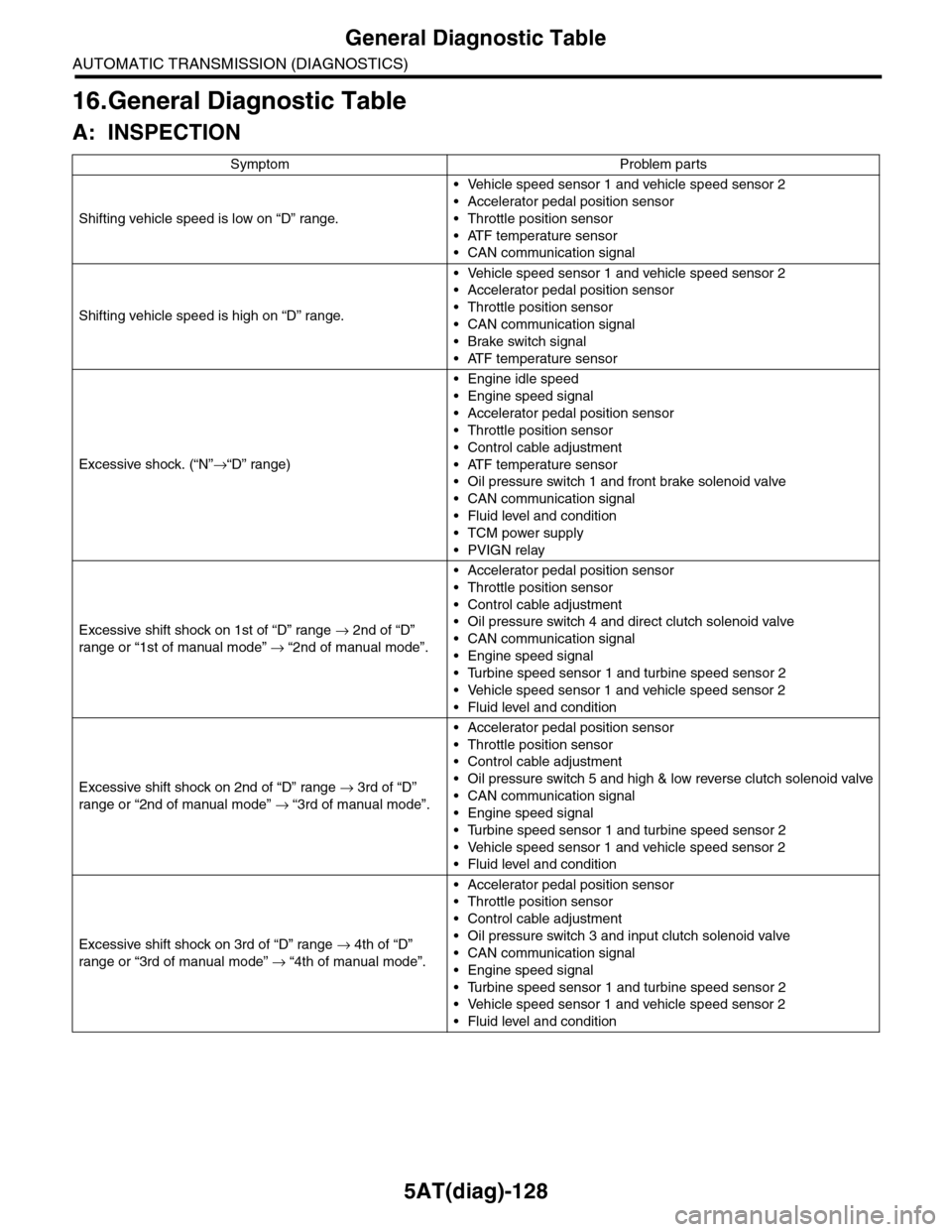

16.General Diagnostic Table

A: INSPECTION

Symptom Problem parts

Shifting vehicle speed is low on “D” range.

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Accelerator pedal position sensor

•Throttle position sensor

•ATF temperature sensor

•CAN communication signal

Shifting vehicle speed is high on “D” range.

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Brake switch signal

•ATF temperature sensor

Excessive shock. (“N”→“D” range)

•Engine idle speed

•Engine speed signal

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•ATF temperature sensor

•Oil pressure switch 1 and front brake solenoid valve

•CAN communication signal

•Fluid level and condition

•TCM power supply

•PVIGN relay

Excessive shift shock on 1st of “D” range → 2nd of “D”

range or “1st of manual mode” → “2nd of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 4 and direct clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shift shock on 2nd of “D” range → 3rd of “D”

range or “2nd of manual mode” → “3rd of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Excessive shift shock on 3rd of “D” range → 4th of “D”

range or “3rd of manual mode” → “4th of manual mode”.

•Accelerator pedal position sensor

•Throttle position sensor

•Control cable adjustment

•Oil pressure switch 3 and input clutch solenoid valve

•CAN communication signal

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Fluid level and condition

Page 2247 of 2453

5AT(diag)-130

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

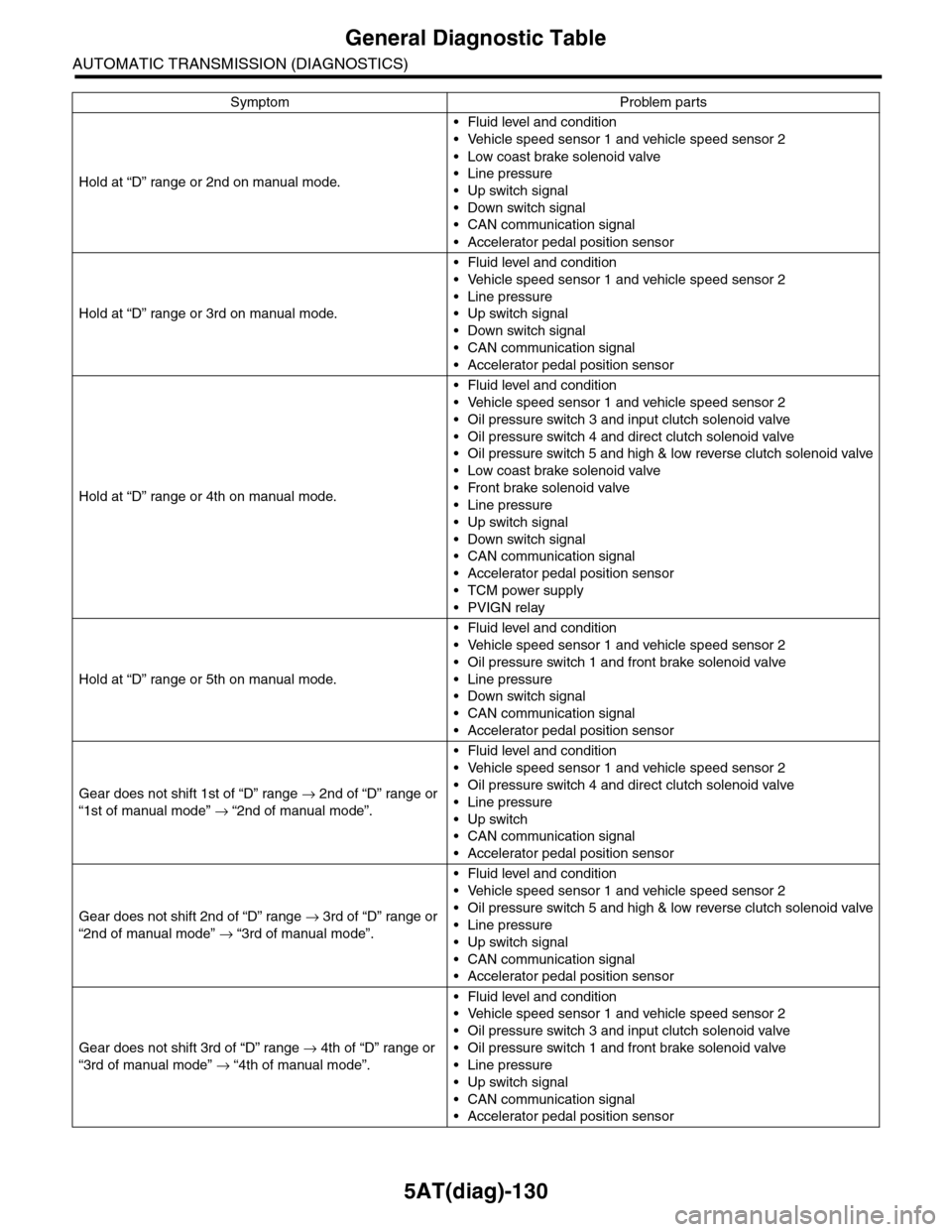

Hold at “D” range or 2nd on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Low coast brake solenoid valve

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Hold at “D” range or 3rd on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Hold at “D” range or 4th on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Low coast brake solenoid valve

•Front brake solenoid valve

•Line pressure

•Up switch signal

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

•TCM power supply

•PVIGN relay

Hold at “D” range or 5th on manual mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 1st of “D” range → 2nd of “D” range or

“1st of manual mode” → “2nd of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Up switch

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 2nd of “D” range → 3rd of “D” range or

“2nd of manual mode” → “3rd of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift 3rd of “D” range → 4th of “D” range or

“3rd of manual mode” → “4th of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Symptom Problem parts

Page 2248 of 2453

5AT(diag)-131

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

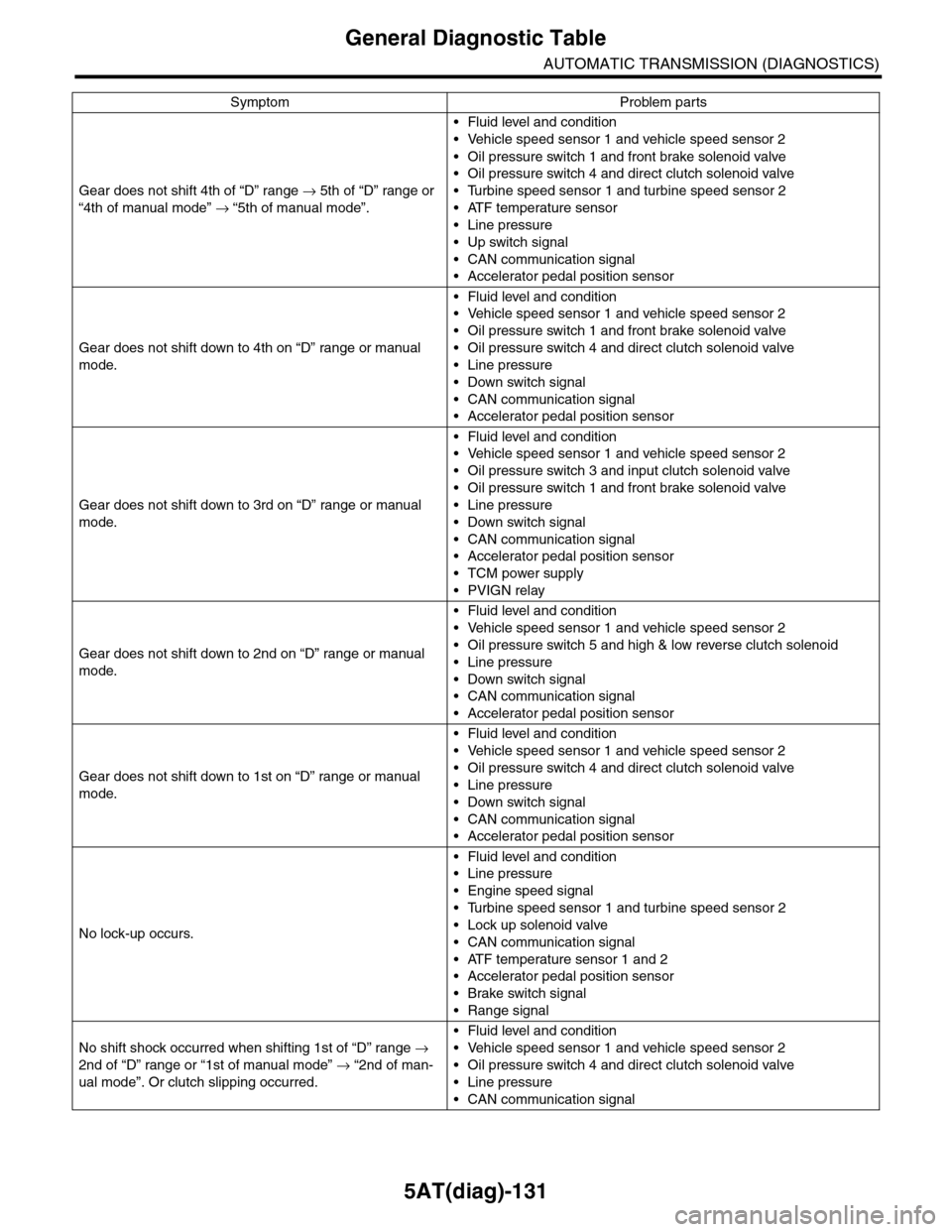

Gear does not shift 4th of “D” range → 5th of “D” range or

“4th of manual mode” → “5th of manual mode”.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Turbine speed sensor 1 and turbine speed sensor 2

•ATF temperature sensor

•Line pressure

•Up switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift down to 4th on “D” range or manual

mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift down to 3rd on “D” range or manual

mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

•TCM power supply

•PVIGN relay

Gear does not shift down to 2nd on “D” range or manual

mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 5 and high & low reverse clutch solenoid

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

Gear does not shift down to 1st on “D” range or manual

mode.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Down switch signal

•CAN communication signal

•Accelerator pedal position sensor

No lock-up occurs.

•Fluid level and condition

•Line pressure

•Engine speed signal

•Turbine speed sensor 1 and turbine speed sensor 2

•Lock up solenoid valve

•CAN communication signal

•ATF temperature sensor 1 and 2

•Accelerator pedal position sensor

•Brake switch signal

•Range signal

No shift shock occurred when shifting 1st of “D” range →

2nd of “D” range or “1st of manual mode” → “2nd of man-

ual mode”. Or clutch slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•CAN communication signal

Symptom Problem parts

Page 2249 of 2453

5AT(diag)-132

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

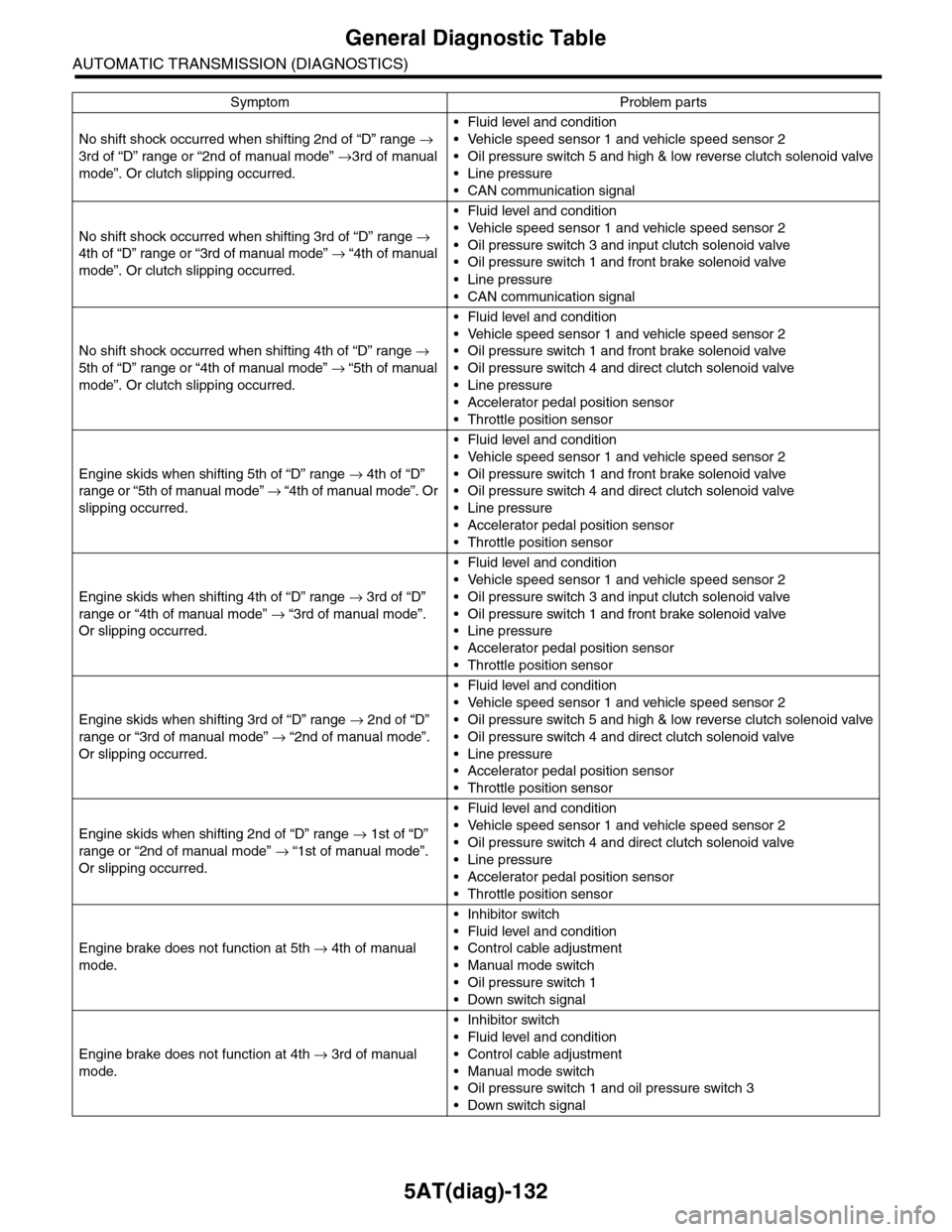

No shift shock occurred when shifting 2nd of “D” range →

3rd of “D” range or “2nd of manual mode” →3rd of manual

mode”. Or clutch slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Line pressure

•CAN communication signal

No shift shock occurred when shifting 3rd of “D” range →

4th of “D” range or “3rd of manual mode” → “4th of manual

mode”. Or clutch slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•CAN communication signal

No shift shock occurred when shifting 4th of “D” range →

5th of “D” range or “4th of manual mode” → “5th of manual

mode”. Or clutch slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

Engine skids when shifting 5th of “D” range → 4th of “D”

range or “5th of manual mode” → “ 4 t h of ma nua l mo d e” . O r

slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 1 and front brake solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

Engine skids when shifting 4th of “D” range → 3rd of “D”

range or “4th of manual mode” → “3rd of manual mode”.

Or slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 3 and input clutch solenoid valve

•Oil pressure switch 1 and front brake solenoid valve

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

Engine skids when shifting 3rd of “D” range → 2nd of “D”

range or “3rd of manual mode” → “2nd of manual mode”.

Or slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

Engine skids when shifting 2nd of “D” range → 1st of “D”

range or “2nd of manual mode” → “1st of manual mode”.

Or slipping occurred.

•Fluid level and condition

•Vehicle speed sensor 1 and vehicle speed sensor 2

•Oil pressure switch 4 and direct clutch solenoid valve

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

Engine brake does not function at 5th → 4th of manual

mode.

•Inhibitor switch

•Fluid level and condition

•Control cable adjustment

•Manual mode switch

•Oil pressure switch 1

•Down switch signal

Engine brake does not function at 4th → 3rd of manual

mode.

•Inhibitor switch

•Fluid level and condition

•Control cable adjustment

•Manual mode switch

•Oil pressure switch 1 and oil pressure switch 3

•Down switch signal

Symptom Problem parts

Page 2250 of 2453

5AT(diag)-133

General Diagnostic Table

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

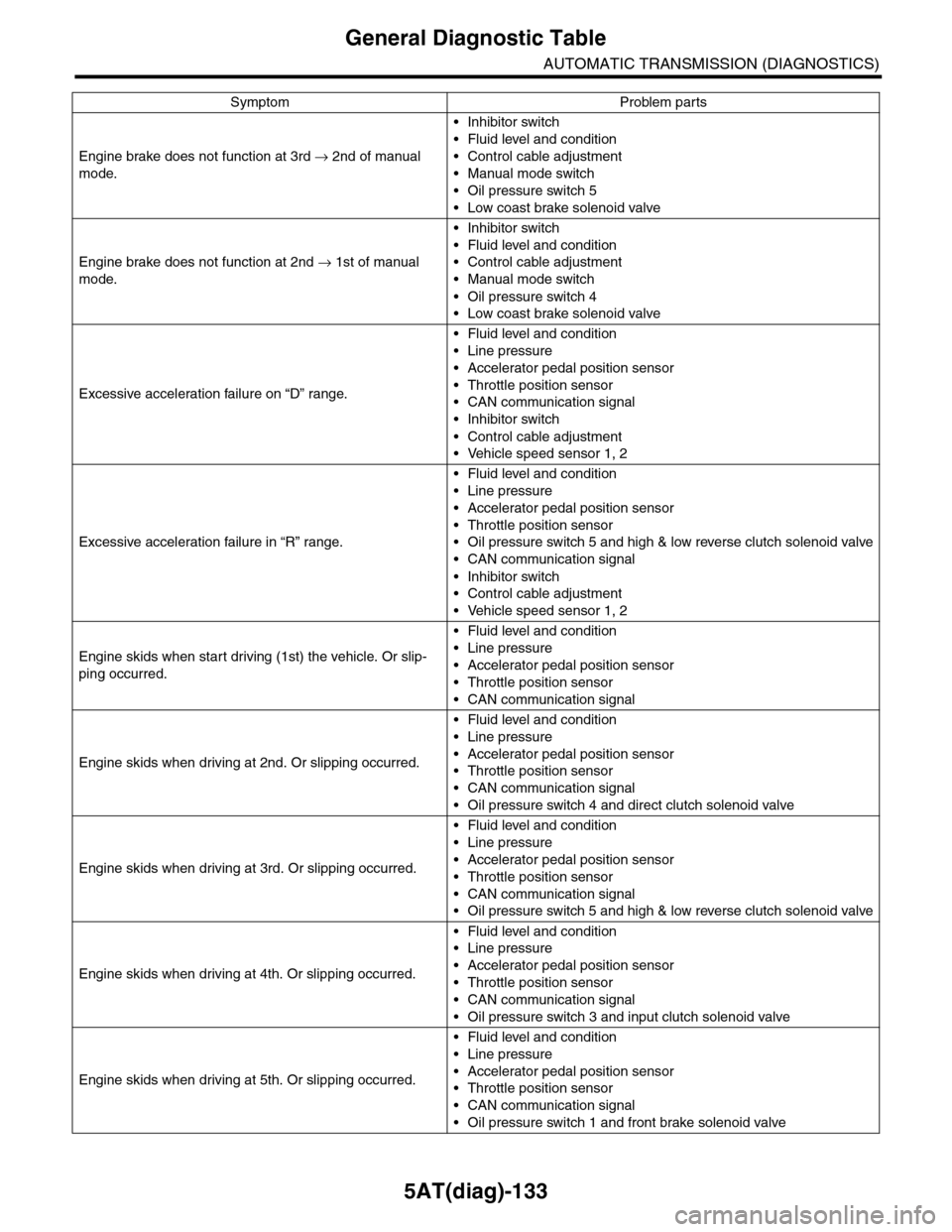

Engine brake does not function at 3rd → 2nd of manual

mode.

•Inhibitor switch

•Fluid level and condition

•Control cable adjustment

•Manual mode switch

•Oil pressure switch 5

•Low coast brake solenoid valve

Engine brake does not function at 2nd → 1st of manual

mode.

•Inhibitor switch

•Fluid level and condition

•Control cable adjustment

•Manual mode switch

•Oil pressure switch 4

•Low coast brake solenoid valve

Excessive acceleration failure on “D” range.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Inhibitor switch

•Control cable adjustment

•Vehicle speed sensor 1, 2

Excessive acceleration failure in “R” range.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

•CAN communication signal

•Inhibitor switch

•Control cable adjustment

•Vehicle speed sensor 1, 2

Engine skids when start driving (1st) the vehicle. Or slip-

ping occurred.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

Engine skids when driving at 2nd. Or slipping occurred.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Oil pressure switch 4 and direct clutch solenoid valve

Engine skids when driving at 3rd. Or slipping occurred.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Oil pressure switch 5 and high & low reverse clutch solenoid valve

Engine skids when driving at 4th. Or slipping occurred.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Oil pressure switch 3 and input clutch solenoid valve

Engine skids when driving at 5th. Or slipping occurred.

•Fluid level and condition

•Line pressure

•Accelerator pedal position sensor

•Throttle position sensor

•CAN communication signal

•Oil pressure switch 1 and front brake solenoid valve

Symptom Problem parts

Page 2277 of 2453

![SUBARU TRIBECA 2009 1.G Service Workshop Manual CS-25

Select Lever

CONTROL SYSTEMS

D: ASSEMBLY

1) Clean all the parts before assembly.

2) Apply grease [Multemp AC-D, and SH-W or

equivalent] to each part. <Ref. to CS-2, AT SE-

LECT LE SUBARU TRIBECA 2009 1.G Service Workshop Manual CS-25

Select Lever

CONTROL SYSTEMS

D: ASSEMBLY

1) Clean all the parts before assembly.

2) Apply grease [Multemp AC-D, and SH-W or

equivalent] to each part. <Ref. to CS-2, AT SE-

LECT LE](/img/17/7322/w960_7322-2276.png)

CS-25

Select Lever

CONTROL SYSTEMS

D: ASSEMBLY

1) Clean all the parts before assembly.

2) Apply grease [Multemp AC-D, and SH-W or

equivalent] to each part.

tion.>

3) Assemble in the reverse order of disassembly.

NOTE:

•Refer to “COMPONENT” for each tightening

torque.

•When pressing in the shift position pin, insert

from the left side of the vehicle.

•Affix the harness of the shift button switch and

the mode change switch at the marked positions.

•Connect the terminals of all switches to the re-

spective connectors.

4) After completing installation, shift the select le-

ver from the “P” range to the “D” range, then check

whether or not the selection indicator in the combi-

nation meter and the select lever position matches.

Also check whether the pointer and position mark

matches, and what the operating force is.

E: INSPECTION

1) Inspect the removed parts by comparing with

new ones for deformation, damage and wear. Re-

pair or replace if defective.

2) Confirm the select lever operating condition be-

fore assembly. Normal if it operates smoothly. CS-00641

(A) Mode change switch (color code: Yellow)

(B) Shift button switch (color code: Brown)

(C) Mode change switch and shift button switch

ground (color code: White)

(D) Shift up switch (color code: Green)

(E) Shift up switch (color code: Gray)

(F) Shift up/down switch ground (color code: Blue)

(G) “P” range switch (wire color: Red)

(H) Shift lock solenoid (color code: Blue)

(I) Shift lock solenoid (color code: Black)

(J) Indicator lamp (color code: Blue)

CS-00642

5432112 11 10 9876

(J)

(J)(F)(E)(D)(A)(B)(C)

(H) (G)(I)

Page 2280 of 2453

CS-28

Select Cable

CONTROL SYSTEMS

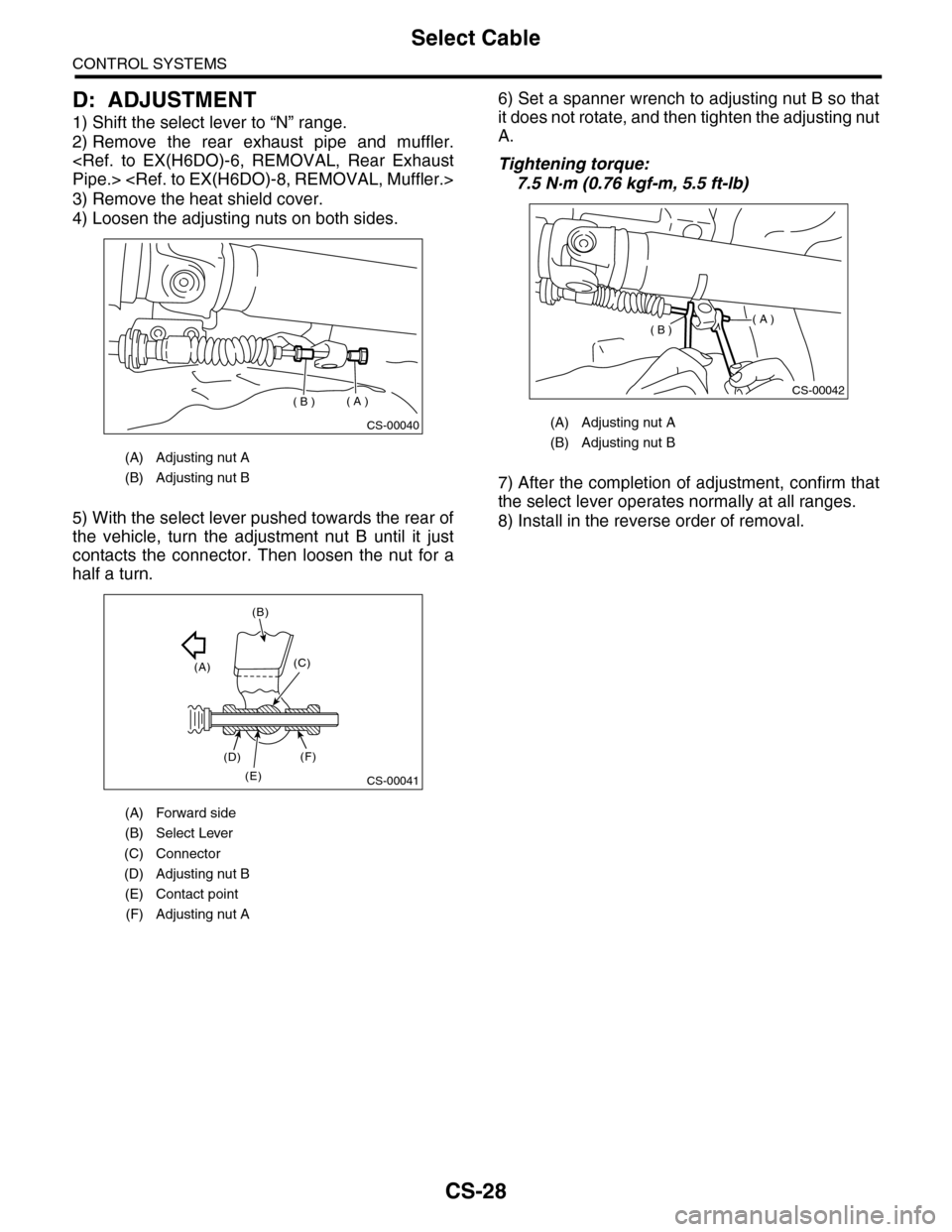

D: ADJUSTMENT

1) Shift the select lever to “N” range.

2) Remove the rear exhaust pipe and muffler.

3) Remove the heat shield cover.

4) Loosen the adjusting nuts on both sides.

5) With the select lever pushed towards the rear of

the vehicle, turn the adjustment nut B until it just

contacts the connector. Then loosen the nut for a

half a turn.

6) Set a spanner wrench to adjusting nut B so that

it does not rotate, and then tighten the adjusting nut

A.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

7) After the completion of adjustment, confirm that

the select lever operates normally at all ranges.

8) Install in the reverse order of removal.

(A) Adjusting nut A

(B) Adjusting nut B

(A) Forward side

(B) Select Lever

(C) Connector

(D) Adjusting nut B

(E) Contact point

(F) Adjusting nut A

CS-00040

( A )( B )

CS-00041

(A)

(B)

(C)

(D)

(E)

(F)

(A) Adjusting nut A

(B) Adjusting nut B

CS-00042

( A )( B )

Page 2282 of 2453

CS-30

AT Shift Lock Solenoid and “P” Range Switch

CONTROL SYSTEMS

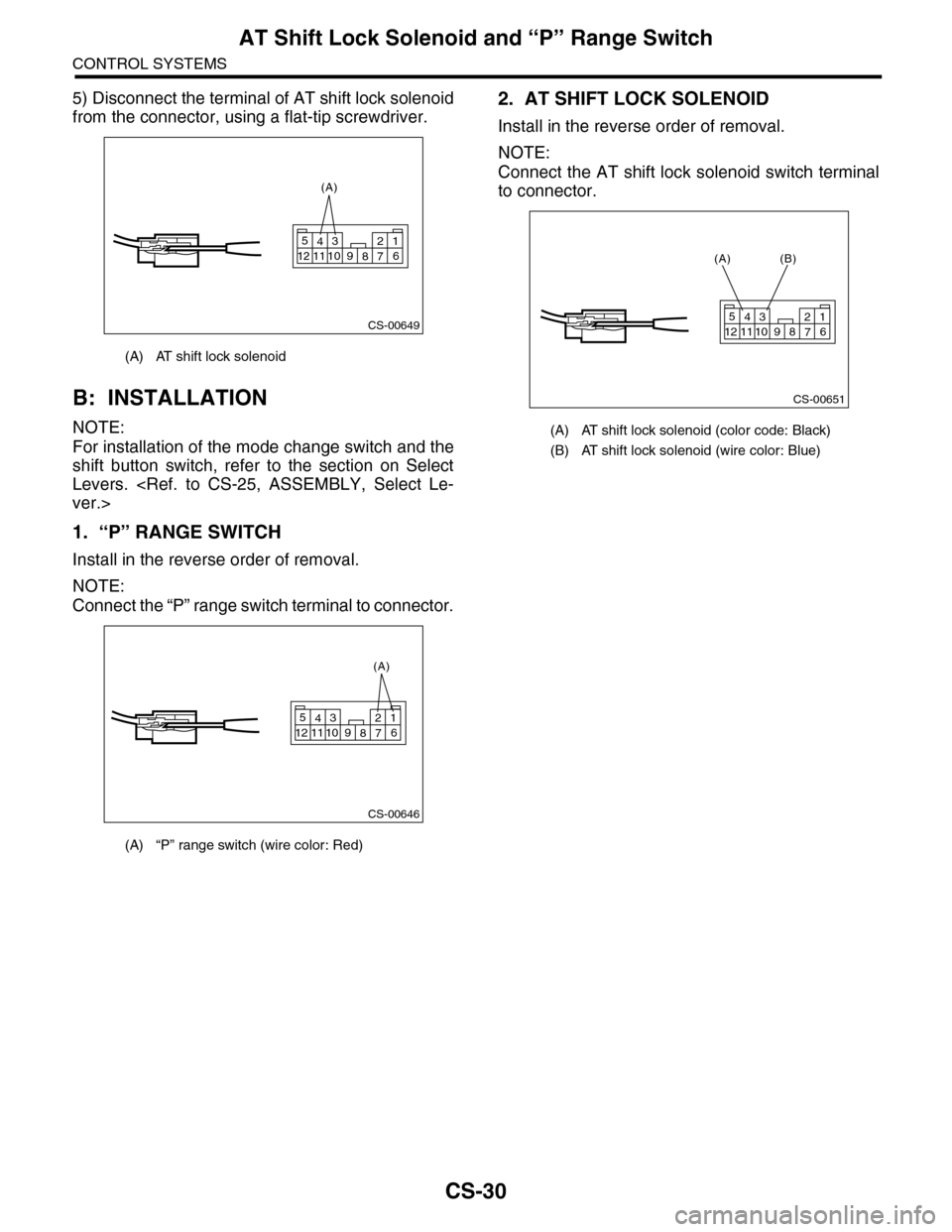

5) Disconnect the terminal of AT shift lock solenoid

from the connector, using a flat-tip screwdriver.

B: INSTALLATION

NOTE:

For installation of the mode change switch and the

shift button switch, refer to the section on Select

Levers.

1. “P” RANGE SWITCH

Install in the reverse order of removal.

NOTE:

Connect the “P” range switch terminal to connector.

2. AT SHIFT LOCK SOLENOID

Install in the reverse order of removal.

NOTE:

Connect the AT shift lock solenoid switch terminal

to connector.

(A) AT shift lock solenoid

(A) “P” range switch (wire color: Red)

CS-00649

5432112 11 10 9876

(A)

CS-00646

5432112 11 10 9876

(A)

(A) AT shift lock solenoid (color code: Black)

(B) AT shift lock solenoid (wire color: Blue)

CS-00651

5432112 11 10 9876

(A) (B)

Page 2287 of 2453

WI-3

Basic Diagnostic Procedure

WIRING SYSTEM

1. Basic Diagnostic Procedure

A: BASIC PROCEDURES

1. GENERAL DESCRIPTION

The most important purpose of diagnostics is to

quickly determine which part is malfunctioning, to

save time and labor.

2. IDENTIFICATION OF TROUBLE SYMP-

TOM

Determine what the problem is based on the symp-

tom.

3. PROBABLE CAUSE OF TROUBLE

Look at the wiring diagram and check the system’s

circuit. Then check the switch, relay, fuse, ground,

etc.

4. LOCATION AND REPAIR OF TROUBLE

1) Using the diagnostics, narrow down the causes.

2) If necessary, use a voltmeter, ohmmeter, etc.

3) Before replacing certain component parts

(switch, relay, etc.), check the power supply,

ground, for open wiring harness, poor connectors,

etc. If no problem is encountered, check the com-

ponent parts.

5. SYSTEM OPERATION CHECK

After repairing, ensure that the system operates

properly.

B: BASIC INSPECTION

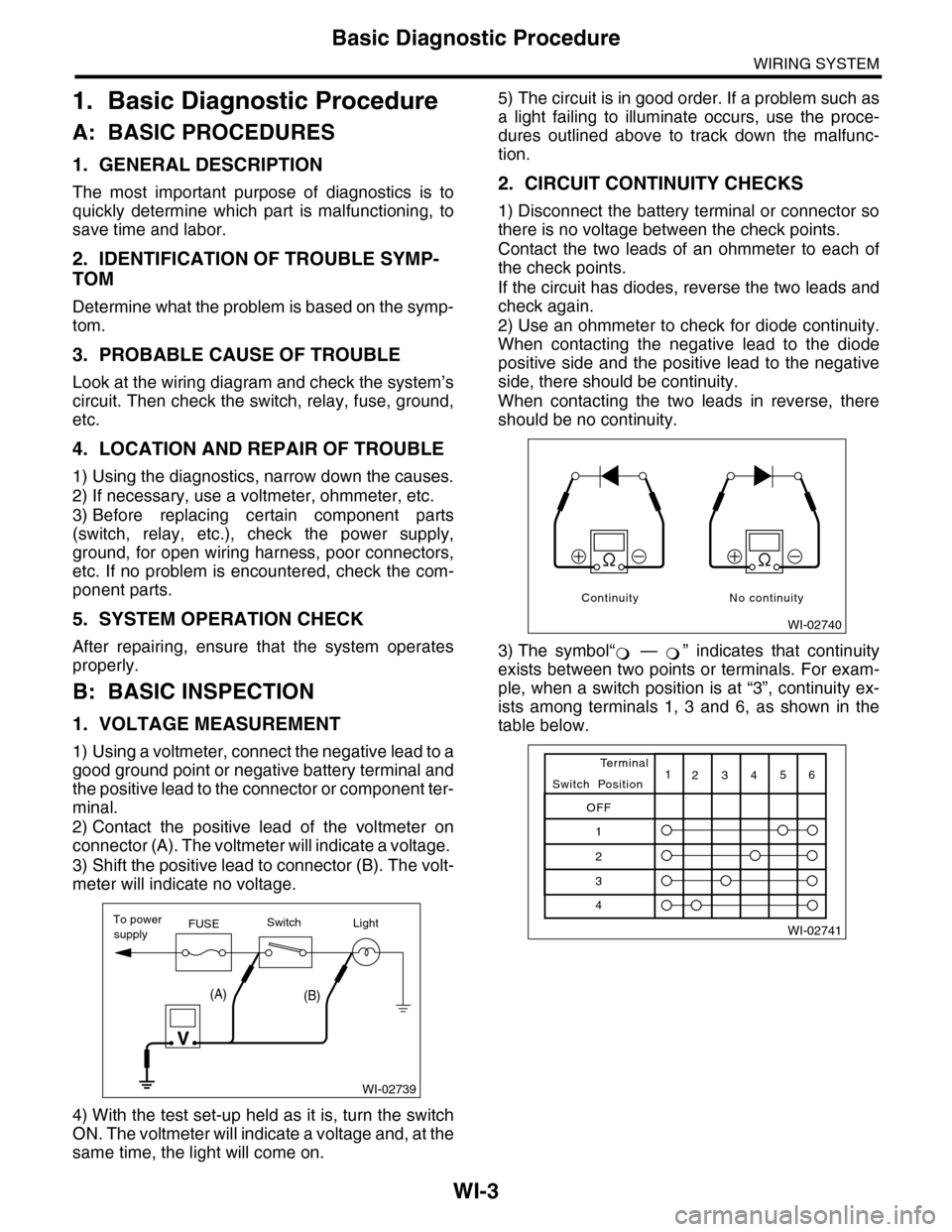

1. VOLTAGE MEASUREMENT

1) Using a voltmeter, connect the negative lead to a

good ground point or negative battery terminal and

the positive lead to the connector or component ter-

minal.

2) Contact the positive lead of the voltmeter on

connector (A). The voltmeter will indicate a voltage.

3) Shift the positive lead to connector (B). The volt-

meter will indicate no voltage.

4) With the test set-up held as it is, turn the switch

ON. The voltmeter will indicate a voltage and, at the

same time, the light will come on.

5) The circuit is in good order. If a problem such as

a light failing to illuminate occurs, use the proce-

dures outlined above to track down the malfunc-

tion.

2. CIRCUIT CONTINUITY CHECKS

1) Disconnect the battery terminal or connector so

there is no voltage between the check points.

Contact the two leads of an ohmmeter to each of

the check points.

If the circuit has diodes, reverse the two leads and

check again.

2) Use an ohmmeter to check for diode continuity.

When contacting the negative lead to the diode

positive side and the positive lead to the negative

side, there should be continuity.

When contacting the two leads in reverse, there

should be no continuity.

3) The symbol“ — ” indicates that continuity

exists between two points or terminals. For exam-

ple, when a switch position is at “3”, continuity ex-

ists among terminals 1, 3 and 6, as shown in the

table below.

WI-02739

To powerFUSEsupplySwitchLight

V

(A)(B)

WI-02740

Continuity No continuity

�