Reverse SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1980 of 2453

SC(H6DO)-22

Generator

STARTING/CHARGING SYSTEMS

D: ASSEMBLY

Assemble in the reverse order of disassembly.

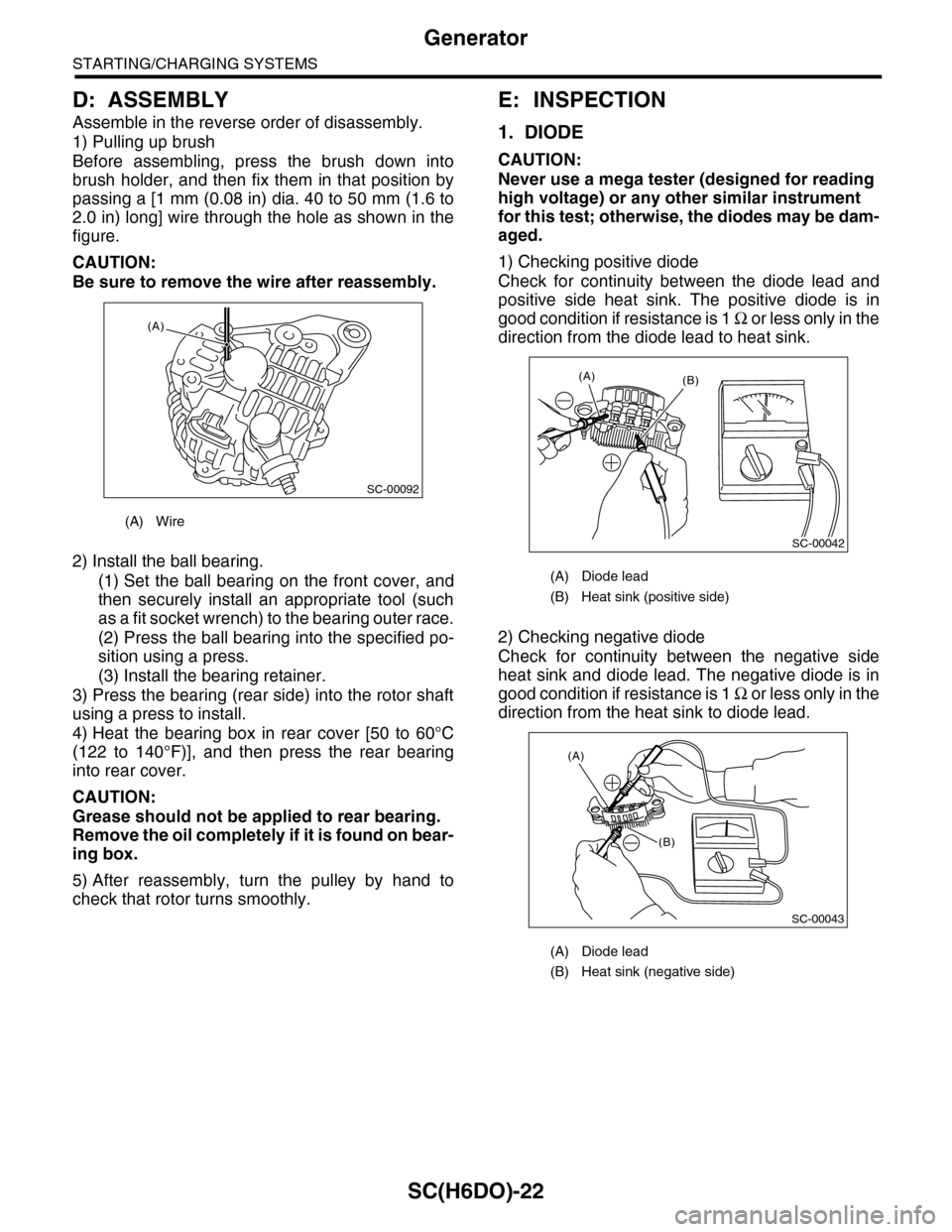

1) Pulling up brush

Before assembling, press the brush down into

brush holder, and then fix them in that position by

passing a [1 mm (0.08 in) dia. 40 to 50 mm (1.6 to

2.0 in) long] wire through the hole as shown in the

figure.

CAUTION:

Be sure to remove the wire after reassembly.

2) Install the ball bearing.

(1) Set the ball bearing on the front cover, and

then securely install an appropriate tool (such

as a fit socket wrench) to the bearing outer race.

(2) Press the ball bearing into the specified po-

sition using a press.

(3) Install the bearing retainer.

3) Press the bearing (rear side) into the rotor shaft

using a press to install.

4) Heat the bearing box in rear cover [50 to 60°C

(122 to 140°F)], and then press the rear bearing

into rear cover.

CAUTION:

Grease should not be applied to rear bearing.

Remove the oil completely if it is found on bear-

ing box.

5) After reassembly, turn the pulley by hand to

check that rotor turns smoothly.

E: INSPECTION

1. DIODE

CAUTION:

Never use a mega tester (designed for reading

high voltage) or any other similar instrument

for this test; otherwise, the diodes may be dam-

aged.

1) Checking positive diode

Check for continuity between the diode lead and

positive side heat sink. The positive diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the diode lead to heat sink.

2) Checking negative diode

Check for continuity between the negative side

heat sink and diode lead. The negative diode is in

good condition if resistance is 1 Ω o r l e s s o n l y i n t h e

direction from the heat sink to diode lead.

(A) Wire

SC-00092

(A)

(A) Diode lead

(B) Heat sink (positive side)

(A) Diode lead

(B) Heat sink (negative side)

SC-00042

(B)(A)

(A)

(B)

SC-00043

Page 1983 of 2453

SC(H6DO)-25

Battery

STARTING/CHARGING SYSTEMS

4. Battery

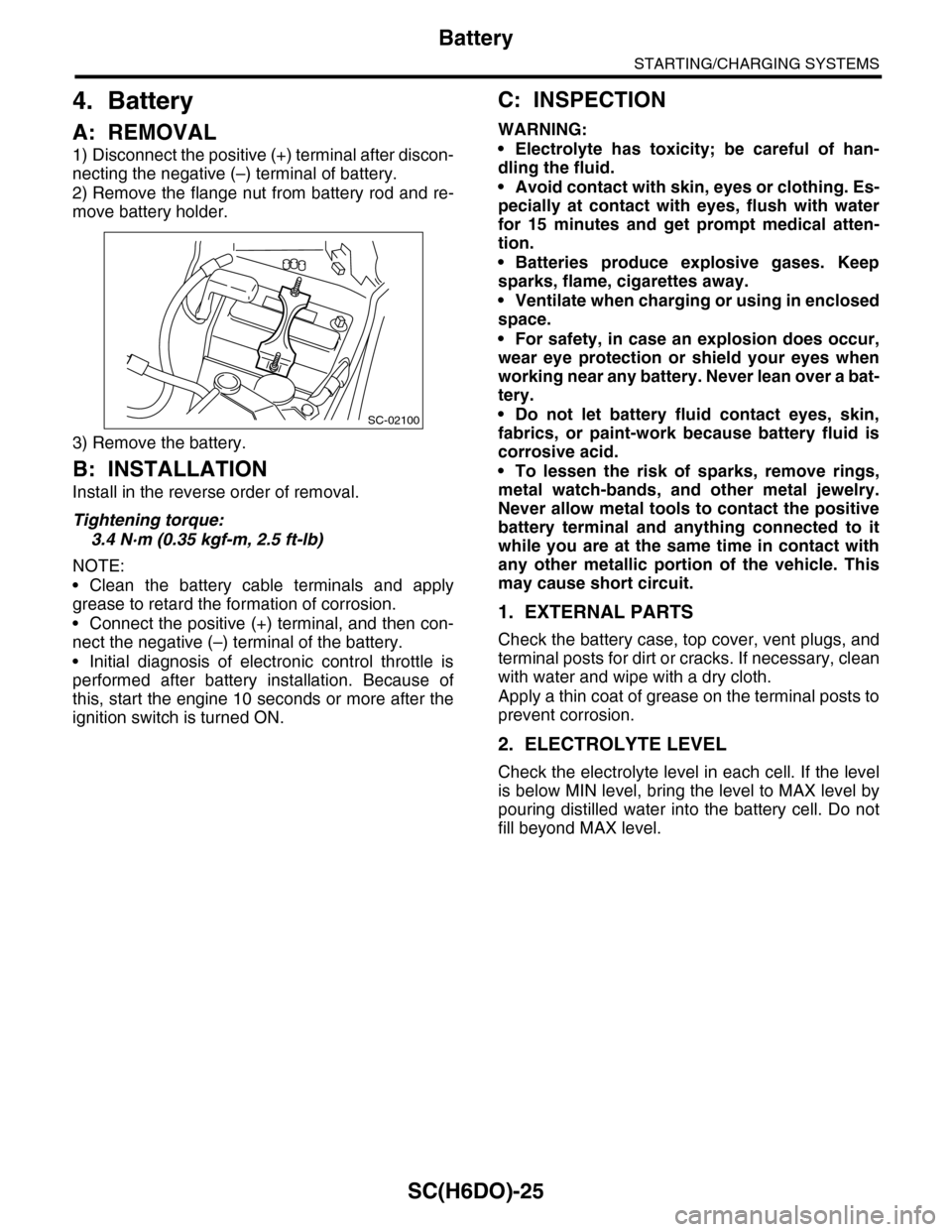

A: REMOVAL

1) Disconnect the positive (+) terminal after discon-

necting the negative (–) terminal of battery.

2) Remove the flange nut from battery rod and re-

move battery holder.

3) Remove the battery.

B: INSTALLATION

Install in the reverse order of removal.

Tightening torque:

3.4 N·m (0.35 kgf-m, 2.5 ft-lb)

NOTE:

•Clean the battery cable terminals and apply

grease to retard the formation of corrosion.

•Connect the positive (+) terminal, and then con-

nect the negative (–) terminal of the battery.

•Initial diagnosis of electronic control throttle is

performed after battery installation. Because of

this, start the engine 10 seconds or more after the

ignition switch is turned ON.

C: INSPECTION

WARNING:

•Electrolyte has toxicity; be careful of han-

dling the fluid.

•Avoid contact with skin, eyes or clothing. Es-

pecially at contact with eyes, flush with water

for 15 minutes and get prompt medical atten-

tion.

•Batteries produce explosive gases. Keep

sparks, flame, cigarettes away.

•Ventilate when charging or using in enclosed

space.

•For safety, in case an explosion does occur,

wear eye protection or shield your eyes when

working near any battery. Never lean over a bat-

tery.

•Do not let battery fluid contact eyes, skin,

fabrics, or paint-work because battery fluid is

corrosive acid.

•To lessen the risk of sparks, remove rings,

metal watch-bands, and other metal jewelry.

Never allow metal tools to contact the positive

battery terminal and anything connected to it

while you are at the same time in contact with

any other metallic portion of the vehicle. This

may cause short circuit.

1. EXTERNAL PARTS

Check the battery case, top cover, vent plugs, and

terminal posts for dirt or cracks. If necessary, clean

with water and wipe with a dry cloth.

Apply a thin coat of grease on the terminal posts to

prevent corrosion.

2. ELECTROLYTE LEVEL

Check the electrolyte level in each cell. If the level

is below MIN level, bring the level to MAX level by

pouring distilled water into the battery cell. Do not

fill beyond MAX level.

SC-02100

Page 1993 of 2453

PM-10

V-belt

PERIODIC MAINTENANCE SERVICES

6. V-belt

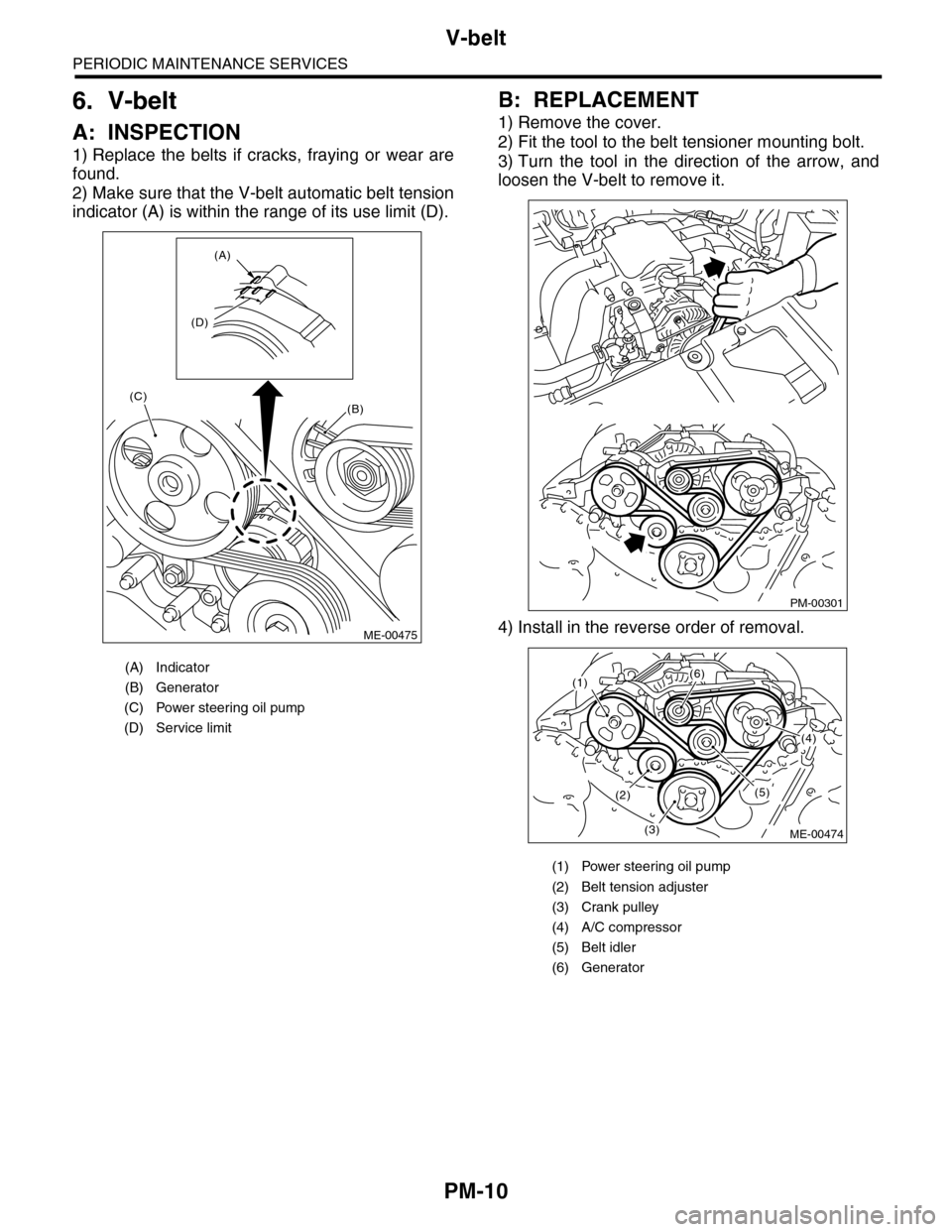

A: INSPECTION

1) Replace the belts if cracks, fraying or wear are

found.

2) Make sure that the V-belt automatic belt tension

indicator (A) is within the range of its use limit (D).

B: REPLACEMENT

1) Remove the cover.

2) Fit the tool to the belt tensioner mounting bolt.

3) Turn the tool in the direction of the arrow, and

loosen the V-belt to remove it.

4) Install in the reverse order of removal.

(A) Indicator

(B) Generator

(C) Power steering oil pump

(D) Service limit

(B)

(A)

(D)

(C)

ME-00475

(1) Power steering oil pump

(2) Belt tension adjuster

(3) Crank pulley

(4) A/C compressor

(5) Belt idler

(6) Generator

PM-00301

(1)(6)

(4)

(5)(2)

(3)ME-00474

Page 1995 of 2453

PM-12

Air Cleaner Element

PERIODIC MAINTENANCE SERVICES

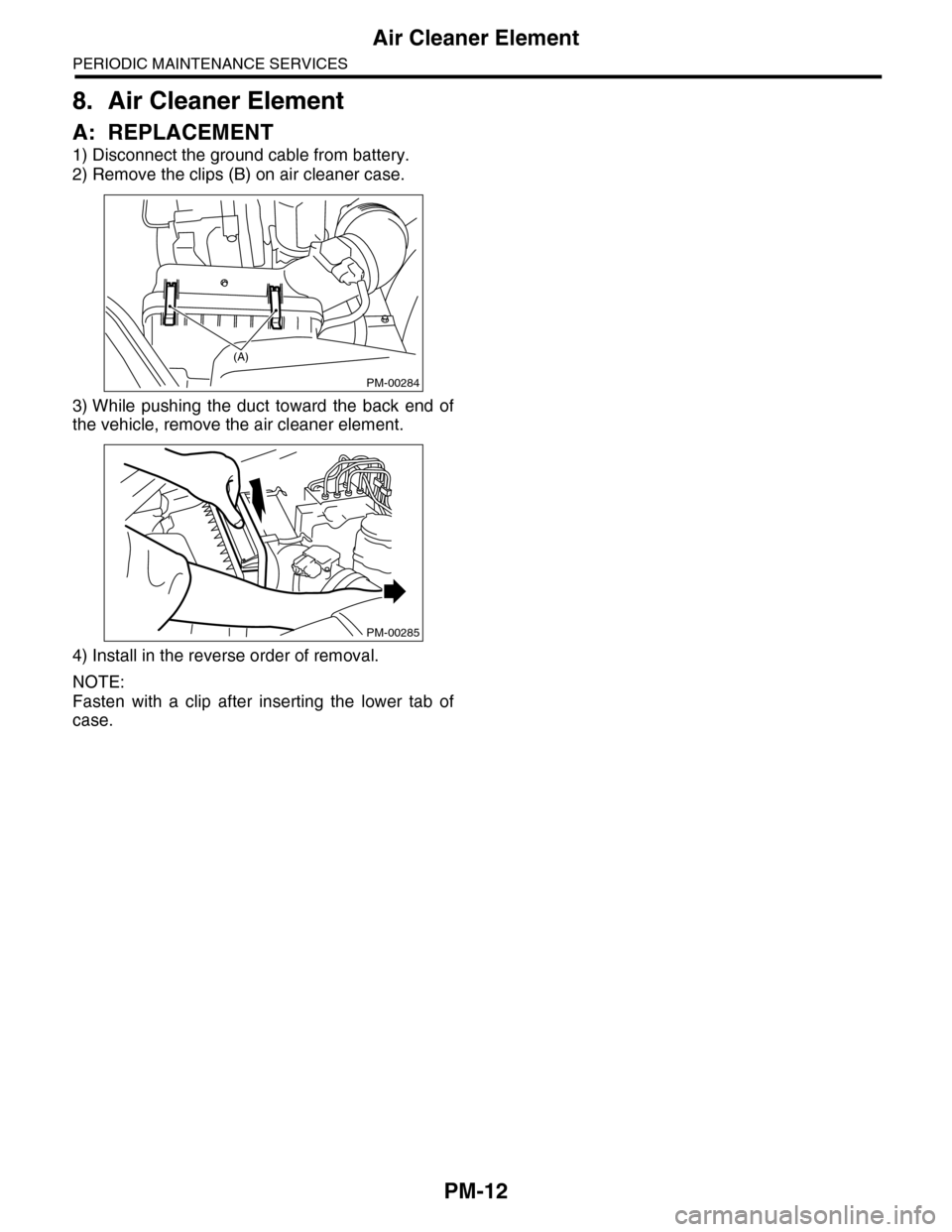

8. Air Cleaner Element

A: REPLACEMENT

1) Disconnect the ground cable from battery.

2) Remove the clips (B) on air cleaner case.

3) While pushing the duct toward the back end of

the vehicle, remove the air cleaner element.

4) Install in the reverse order of removal.

NOTE:

Fasten with a clip after inserting the lower tab of

case.

PM-00284

(A)

PM-00285

Page 2018 of 2453

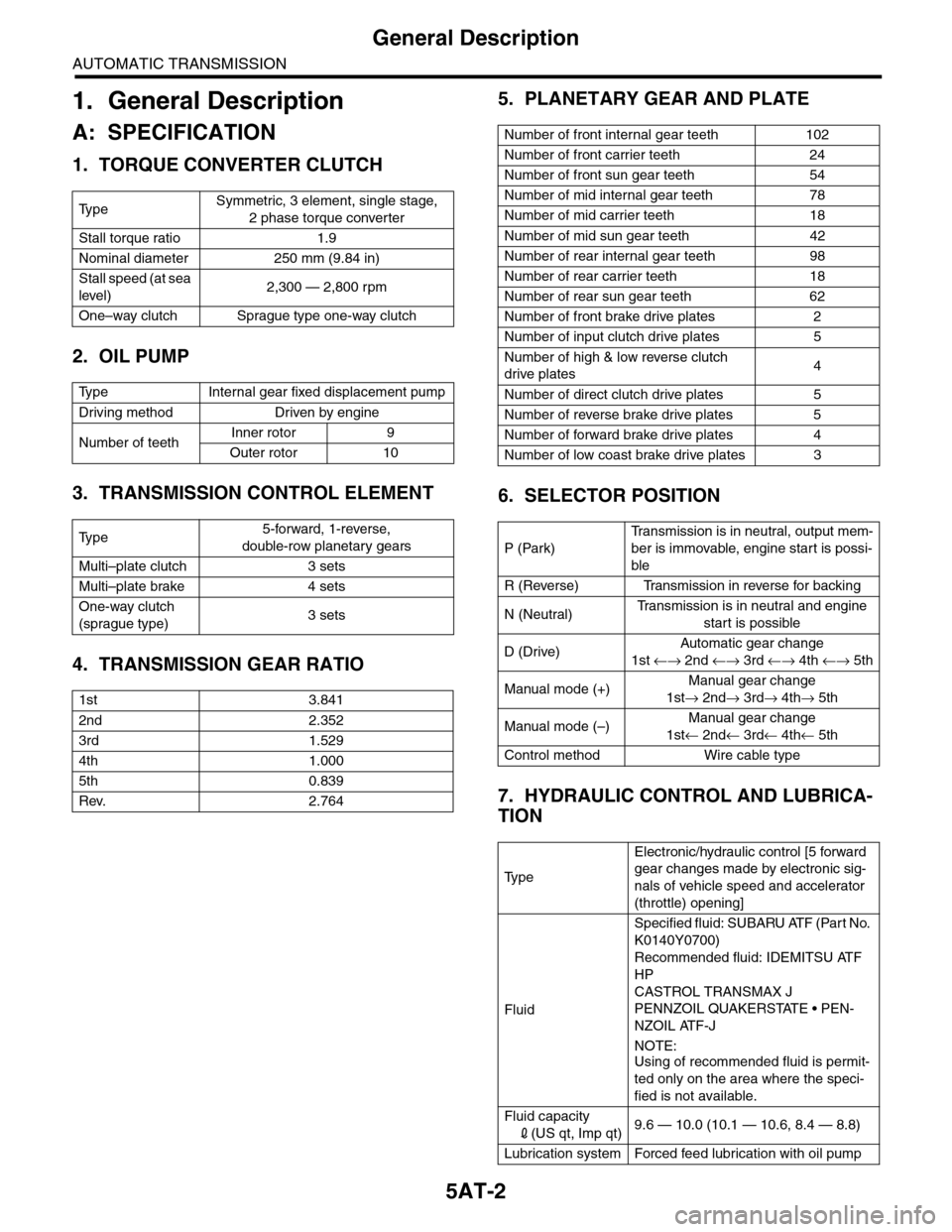

5AT-2

General Description

AUTOMATIC TRANSMISSION

1. General Description

A: SPECIFICATION

1. TORQUE CONVERTER CLUTCH

2. OIL PUMP

3. TRANSMISSION CONTROL ELEMENT

4. TRANSMISSION GEAR RATIO

5. PLANETARY GEAR AND PLATE

6. SELECTOR POSITION

7. HYDRAULIC CONTROL AND LUBRICA-

TION

Ty p eSymmetric, 3 element, single stage,

2 phase torque converter

Stall torque ratio 1.9

Nominal diameter 250 mm (9.84 in)

Stall speed (at sea

level)2,300 — 2,800 rpm

One–way clutch Sprague type one-way clutch

Ty p e I n t e r n a l g e a r f i x e d d i s p l a c e m e n t p u m p

Driving method Driven by engine

Number of teethInner rotor 9

Outer rotor 10

Ty p e5-forward, 1-reverse,

double-row planetary gears

Multi–plate clutch 3 sets

Multi–plate brake 4 sets

One-way clutch

(sprague type)3 sets

1st 3.841

2nd 2.352

3rd 1.529

4th 1.000

5th 0.839

Rev. 2.764

Number of front internal gear teeth 102

Number of front carrier teeth 24

Number of front sun gear teeth 54

Number of mid internal gear teeth 78

Number of mid carrier teeth 18

Number of mid sun gear teeth 42

Number of rear internal gear teeth 98

Number of rear carrier teeth 18

Number of rear sun gear teeth 62

Number of front brake drive plates 2

Number of input clutch drive plates 5

Number of high & low reverse clutch

drive plates4

Number of direct clutch drive plates 5

Number of reverse brake drive plates 5

Number of forward brake drive plates 4

Number of low coast brake drive plates 3

P (Park)

Tr a n s m i s s i o n i s i n n e u t r a l , o u t p u t m e m -

ber is immovable, engine start is possi-

ble

R (Reverse) Transmission in reverse for backing

N (Neutral)Tr a n s m i s s i o n i s i n n e u t r a l a n d e n g i n e

start is possible

D (Drive)Automatic gear change

1st ←→ 2nd ←→ 3rd ←→ 4th ←→ 5th

Manual mode (+)Manual gear change

1st→ 2nd→ 3rd→ 4th→ 5th

Manual mode (–)Manual gear change

1st← 2nd← 3rd← 4th← 5th

Control method Wire cable type

Ty p e

Electronic/hydraulic control [5 forward

gear changes made by electronic sig-

nals of vehicle speed and accelerator

(throttle) opening]

Fluid

Specified fluid: SUBARU ATF (Part No.

K0140Y0700)

Recommended fluid: IDEMITSU ATF

HP

CASTROL TRANSMAX J

PENNZOIL QUAKERSTATE • PEN-

NZOIL ATF-J

NOTE:

Using of recommended fluid is permit-

ted only on the area where the speci-

fied is not available.

Fluid capacity

2(US qt, Imp qt)9.6 — 10.0 (10.1 — 10.6, 8.4 — 8.8)

Lubrication system Forced feed lubrication with oil pump

Page 2023 of 2453

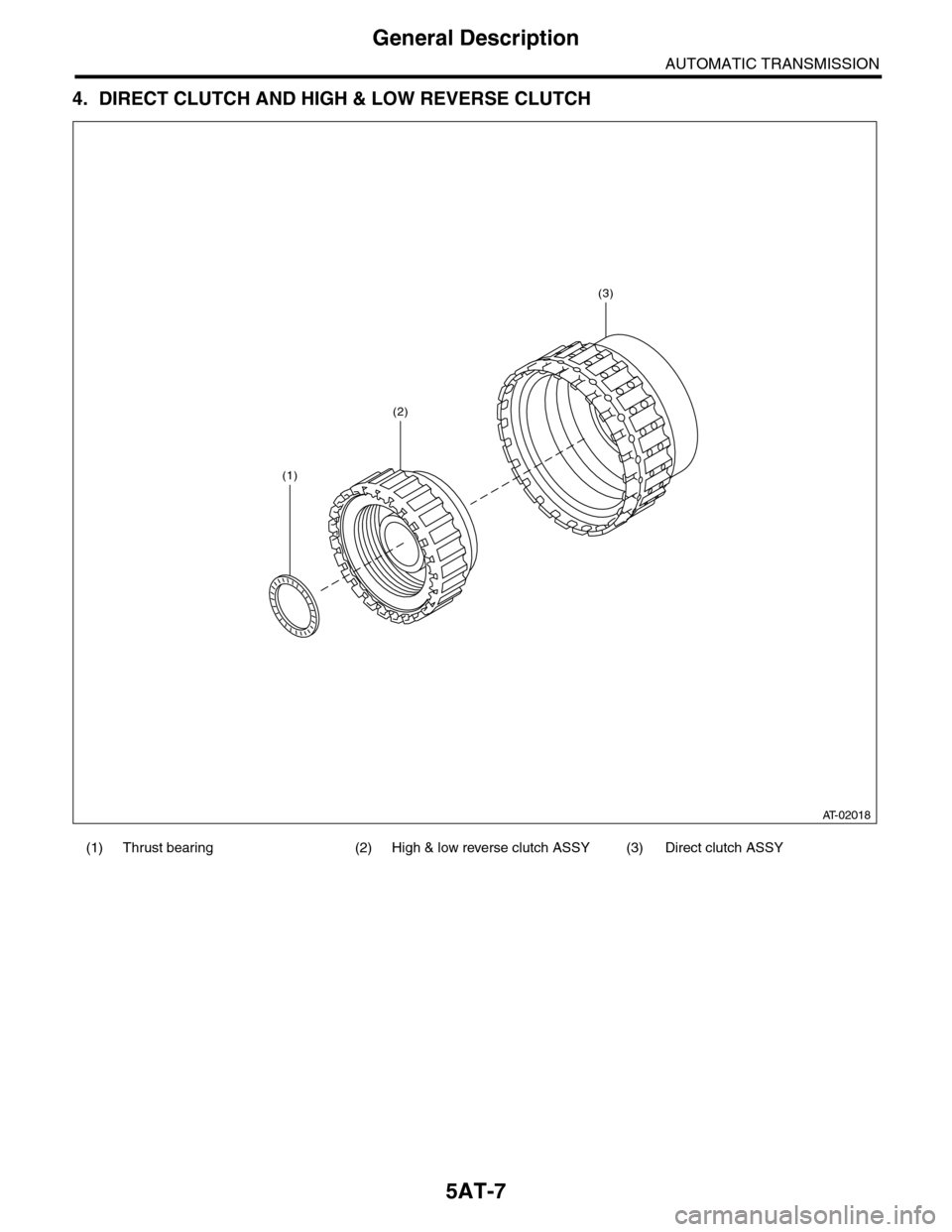

5AT-7

General Description

AUTOMATIC TRANSMISSION

4. DIRECT CLUTCH AND HIGH & LOW REVERSE CLUTCH

(1) Thrust bearing (2) High & low reverse clutch ASSY (3) Direct clutch ASSY

AT-02018

(3)

(2)

(1)

Page 2024 of 2453

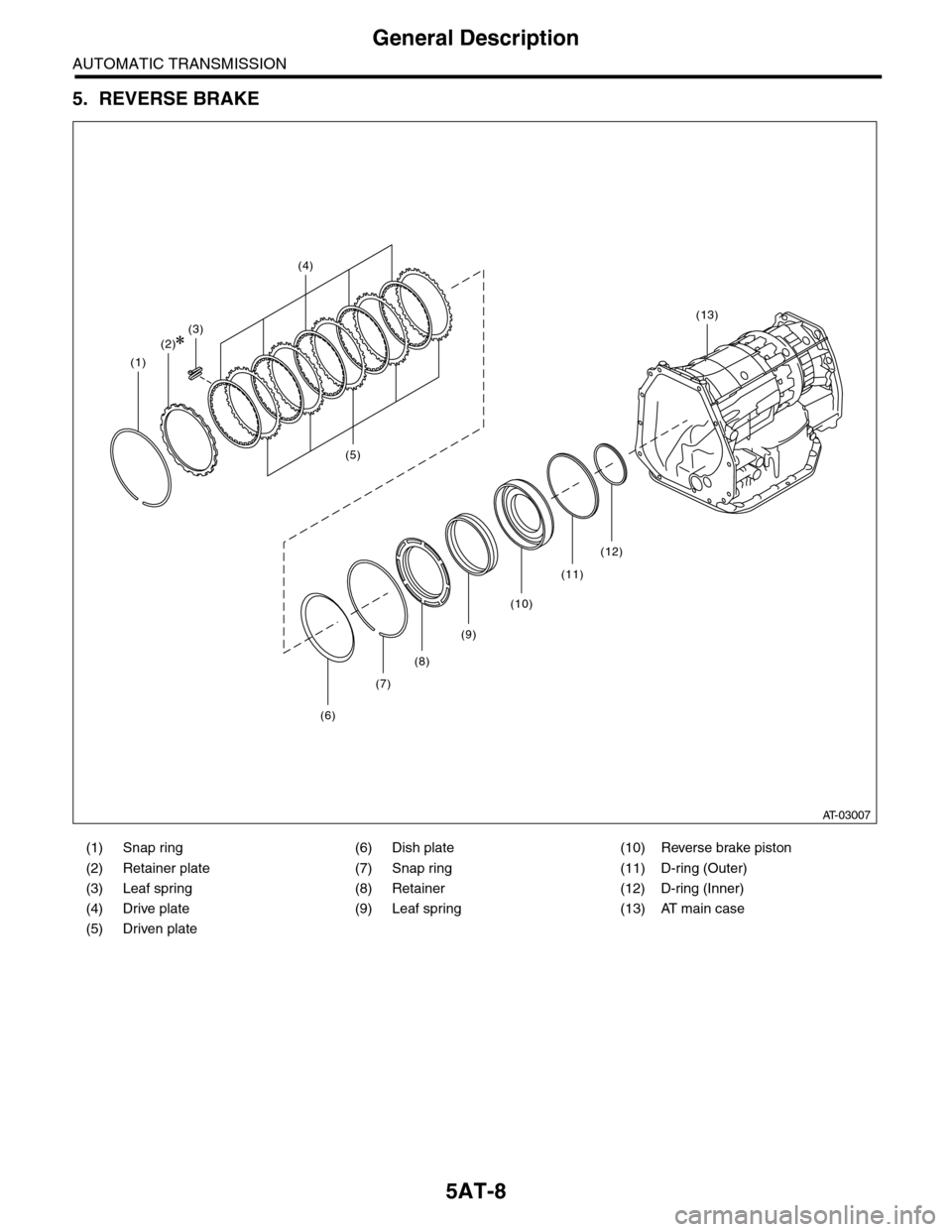

5AT-8

General Description

AUTOMATIC TRANSMISSION

5. REVERSE BRAKE

(1) Snap ring (6) Dish plate (10) Reverse brake piston

(2) Retainer plate (7) Snap ring (11) D-ring (Outer)

(3) Leaf spring (8) Retainer (12) D-ring (Inner)

(4) Drive plate (9) Leaf spring (13) AT main case

(5) Driven plate

AT-03007

(1)

(6)

(5)

(7)

(8)

(9)

(10)

(11)

(12)

(4)

(2)(3)(13)

Page 2046 of 2453

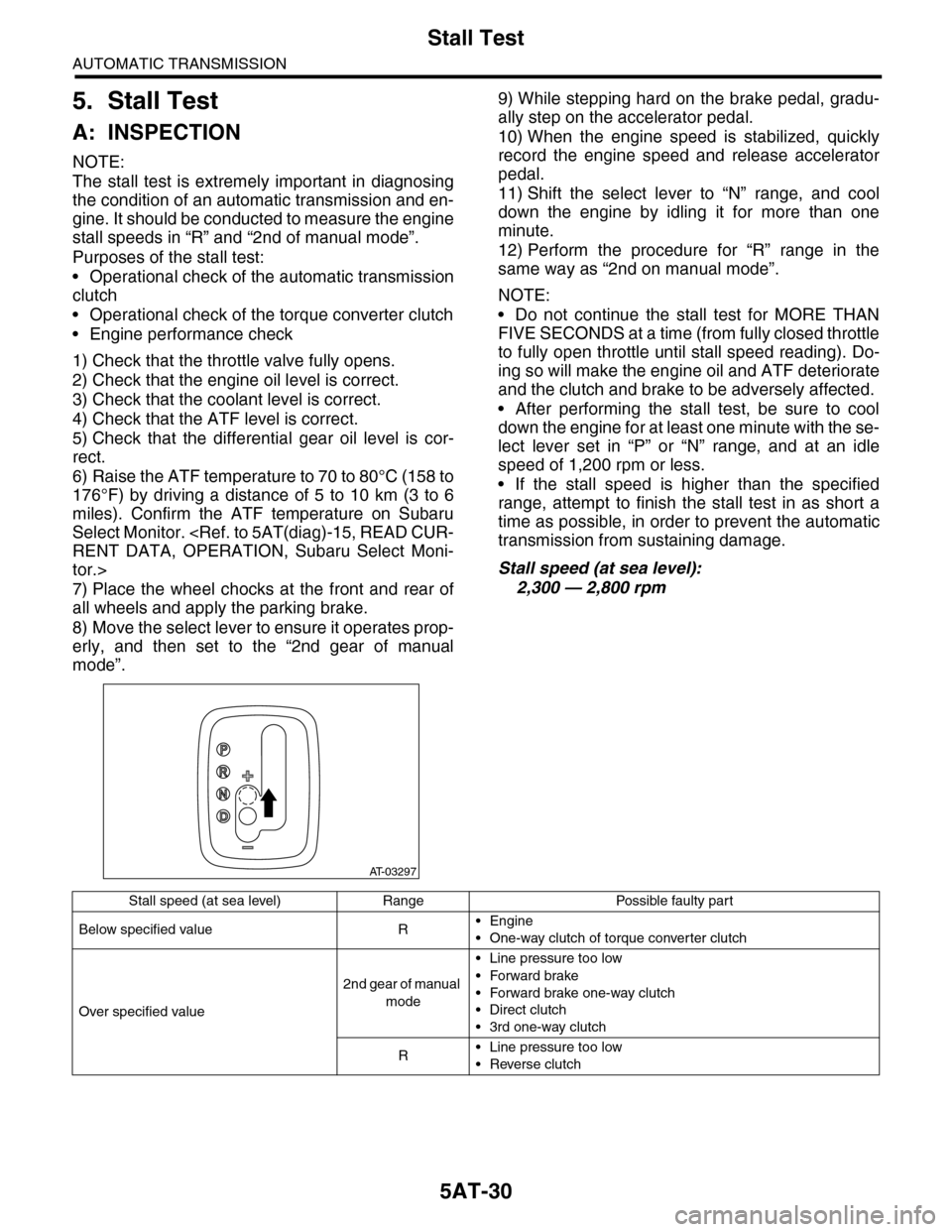

5AT-30

Stall Test

AUTOMATIC TRANSMISSION

5. Stall Test

A: INSPECTION

NOTE:

The stall test is extremely important in diagnosing

the condition of an automatic transmission and en-

gine. It should be conducted to measure the engine

stall speeds in “R” and “2nd of manual mode”.

Purposes of the stall test:

•Operational check of the automatic transmission

clutch

•Operational check of the torque converter clutch

•Engine performance check

1) Check that the throttle valve fully opens.

2) Check that the engine oil level is correct.

3) Check that the coolant level is correct.

4) Check that the ATF level is correct.

5) Check that the differential gear oil level is cor-

rect.

6) Raise the ATF temperature to 70 to 80°C (158 to

176°F) by driving a distance of 5 to 10 km (3 to 6

miles). Confirm the ATF temperature on Subaru

Select Monitor.

tor.>

7) Place the wheel chocks at the front and rear of

all wheels and apply the parking brake.

8) Move the select lever to ensure it operates prop-

erly, and then set to the “2nd gear of manual

mode”.

9) While stepping hard on the brake pedal, gradu-

ally step on the accelerator pedal.

10) When the engine speed is stabilized, quickly

record the engine speed and release accelerator

pedal.

11) Shift the select lever to “N” range, and cool

down the engine by idling it for more than one

minute.

12) Perform the procedure for “R” range in the

same way as “2nd on manual mode”.

NOTE:

•Do not continue the stall test for MORE THAN

FIVE SECONDS at a time (from fully closed throttle

to fully open throttle until stall speed reading). Do-

ing so will make the engine oil and ATF deteriorate

and the clutch and brake to be adversely affected.

•After performing the stall test, be sure to cool

down the engine for at least one minute with the se-

lect lever set in “P” or “N” range, and at an idle

speed of 1,200 rpm or less.

•If the stall speed is higher than the specified

range, attempt to finish the stall test in as short a

time as possible, in order to prevent the automatic

transmission from sustaining damage.

Stall speed (at sea level):

2,300 — 2,800 rpm

AT-03297

Stall speed (at sea level) Range Possible faulty part

Below specified value R•Engine

•One-way clutch of torque converter clutch

Over specified value

2nd gear of manual

mode

•Line pressure too low

•Forward brake

•Forward brake one-way clutch

•Direct clutch

•3rd one-way clutch

R•Line pressure too low

•Reverse clutch

Page 2047 of 2453

5AT-31

Time Lag Test

AUTOMATIC TRANSMISSION

6. Time Lag Test

A: INSPECTION

NOTE:

When the select lever is shifted while the engine is

idling, there will be a certain time elapse or lag be-

fore shock is felt. Using this, check the condition of

forward brake, reverse brake, 1st one-way clutch,

forward one-way clutch and 3rd one-way clutch.

•Perform the test at normal operation fluid tem-

perature of 70 — 80°C (158 — 176°F).

•Be sure to allow a one minute interval between

tests.

•Make three measurements and take the average

value.

1) Fully apply the parking brake.

2) Start the engine.

Check the idle speed (A/C OFF).

3) Shift the select lever from “N” to “D” range. Using

a stop watch, measure the time-lag from shifting

the lever until the shock is felt.

Time-lag

Specification: 1.2 sec. or less

If “N” → “D” time-lag is longer than specification:

•Line pressure too low

•Forward brake worn

•One–way clutch not operating properly

4) In the same manner, measure the time lag of “N”

→ “R”.

Time-lag

Specification: 1.5 sec. or less

If “N” → “R” time lag is longer than specification:

•Line pressure too low

•Reverse brake worn

Page 2072 of 2453

5AT-56

Transmission Control Module (TCM)

AUTOMATIC TRANSMISSION

19.Transmission Control Mod-

ule (TCM)

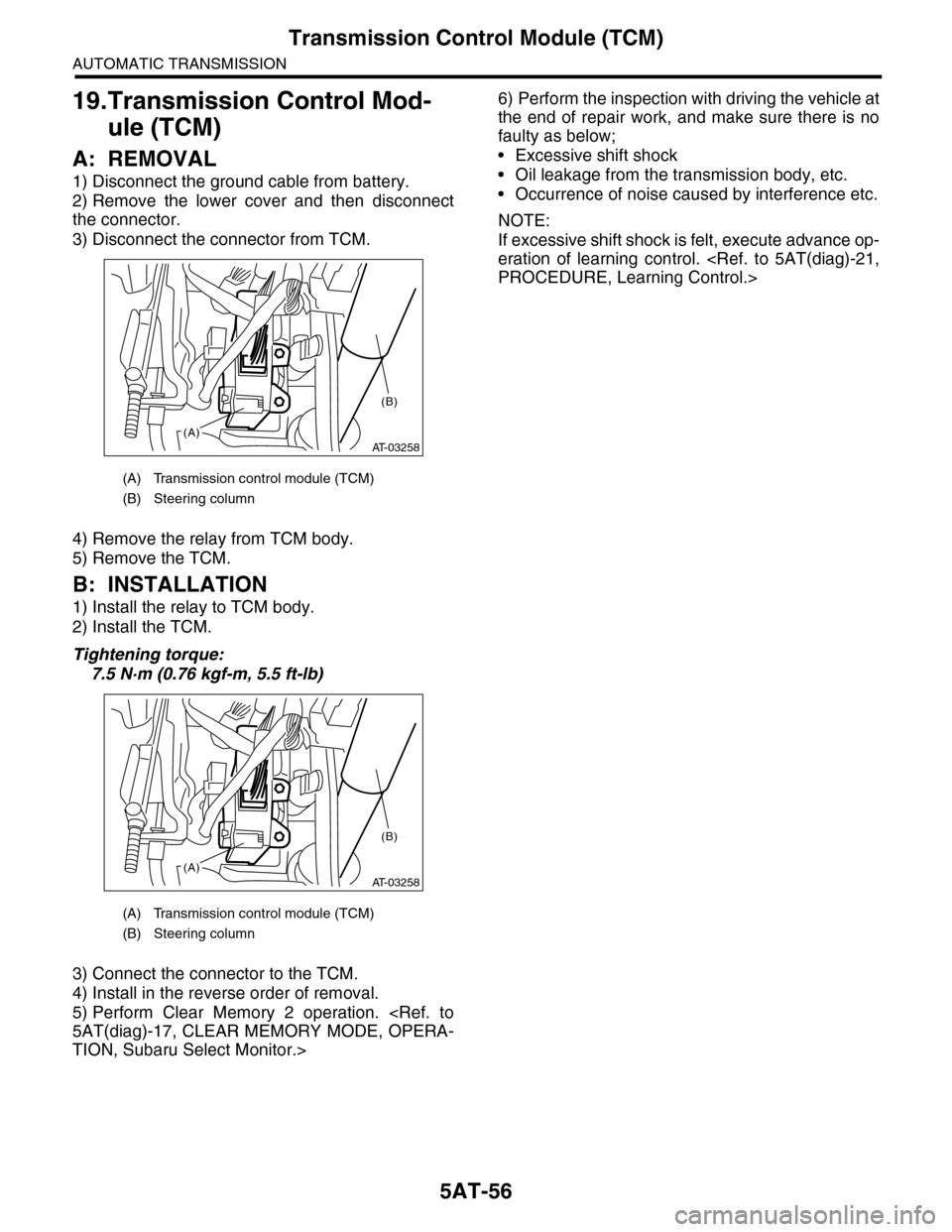

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the lower cover and then disconnect

the connector.

3) Disconnect the connector from TCM.

4) Remove the relay from TCM body.

5) Remove the TCM.

B: INSTALLATION

1) Install the relay to TCM body.

2) Install the TCM.

Tightening torque:

7.5 N·m (0.76 kgf-m, 5.5 ft-lb)

3) Connect the connector to the TCM.

4) Install in the reverse order of removal.

5) Perform Clear Memory 2 operation.

TION, Subaru Select Monitor.>

6) Perform the inspection with driving the vehicle at

the end of repair work, and make sure there is no

faulty as below;

•Excessive shift shock

•Oil leakage from the transmission body, etc.

•Occurrence of noise caused by interference etc.

NOTE:

If excessive shift shock is felt, execute advance op-

eration of learning control.

(A) Transmission control module (TCM)

(B) Steering column

(A) Transmission control module (TCM)

(B) Steering column

AT-03258(A)

(B)

AT-03258(A)

(B)