Transmission speed sensor SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2089 of 2453

5AT-73

Parking Pawl

AUTOMATIC TRANSMISSION

29.Parking Pawl

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the extension case.

3) Remove the center differential carrier.

4) Remove the front vehicle speed sensor.

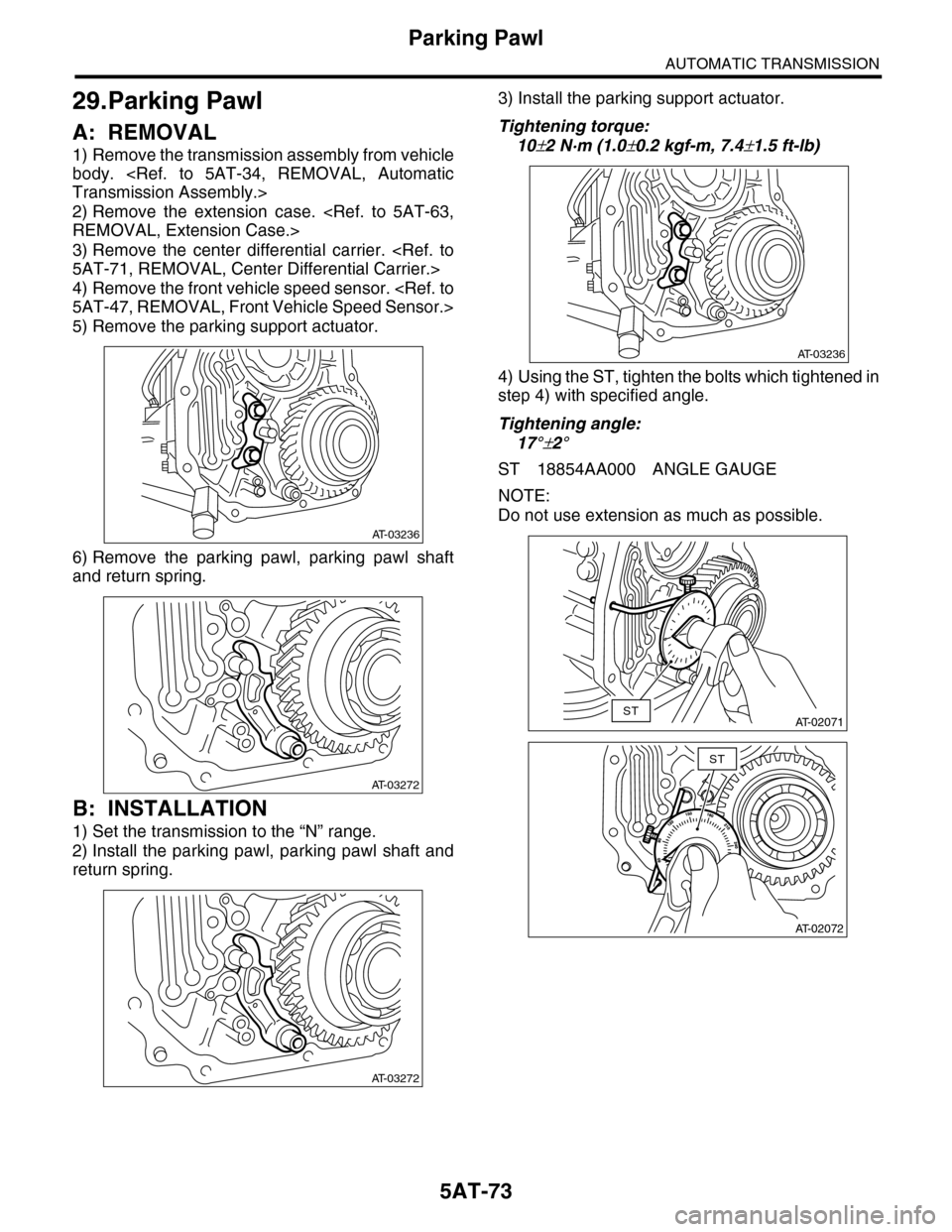

5) Remove the parking support actuator.

6) Remove the parking pawl, parking pawl shaft

and return spring.

B: INSTALLATION

1) Set the transmission to the “N” range.

2) Install the parking pawl, parking pawl shaft and

return spring.

3) Install the parking support actuator.

Tightening torque:

10±2 N·m (1.0±0.2 kgf-m, 7.4±1.5 ft-lb)

4) Using the ST, tighten the bolts which tightened in

step 4) with specified angle.

Tightening angle:

17°±2°

ST 18854AA000 ANGLE GAUGE

NOTE:

Do not use extension as much as possible.

AT-03236

AT-03272

AT-03272

AT-03236

AT-02071ST

AT-02072

ST

Page 2090 of 2453

5AT-74

Parking Pawl

AUTOMATIC TRANSMISSION

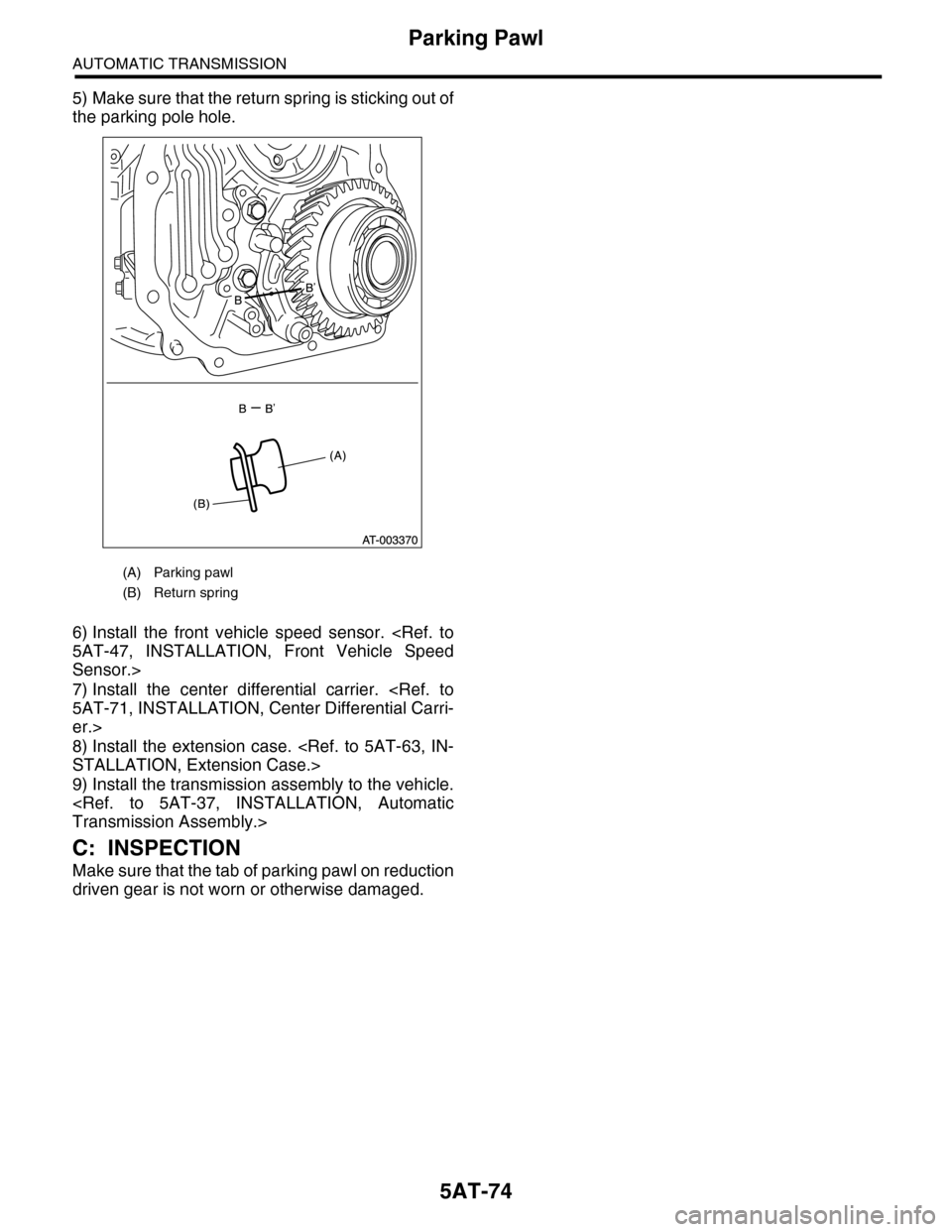

5) Make sure that the return spring is sticking out of

the parking pole hole.

6) Install the front vehicle speed sensor.

Sensor.>

7) Install the center differential carrier.

er.>

8) Install the extension case.

9) Install the transmission assembly to the vehicle.

C: INSPECTION

Make sure that the tab of parking pawl on reduction

driven gear is not worn or otherwise damaged.

(A) Parking pawl

(B) Return spring

Page 2091 of 2453

5AT-75

Converter Case

AUTOMATIC TRANSMISSION

30.Converter Case

A: REMOVAL

1) Remove the transmission assembly from vehicle

body.

2) Remove the torque converter assembly.

3) Remove the transmission harness connector

from stay.

4) Remove the turbine speed sensor 1.

5) Remove the oil charge pipe.

6) Remove the ATF filter inlet and outlet pipes.

7) Remove the converter case attachment bolts.

8) Lay along the transmission body, and then re-

move the oil pan.

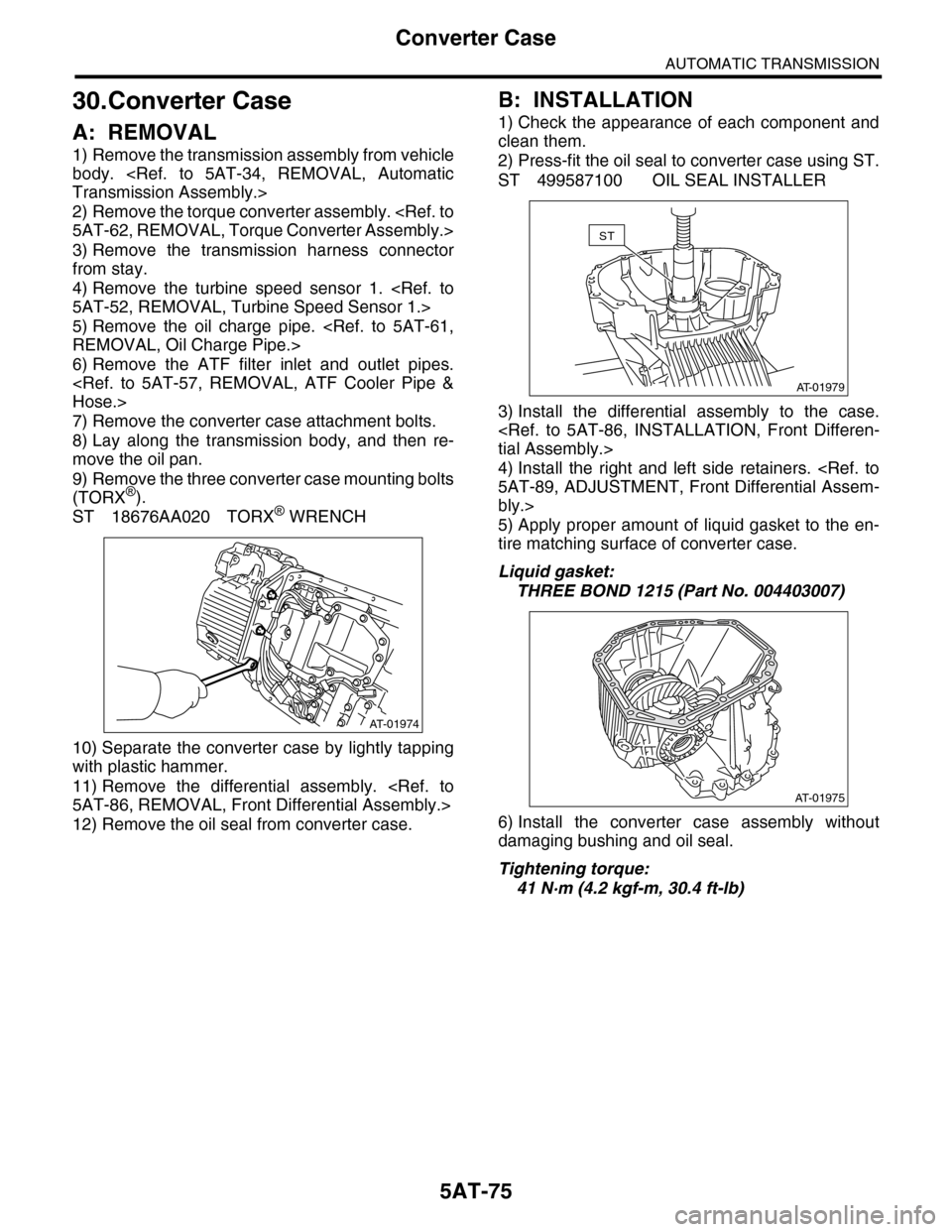

9) Remove the three converter case mounting bolts

(TORX®).

ST 18676AA020 TORX® WRENCH

10) Separate the converter case by lightly tapping

with plastic hammer.

11) Remove the differential assembly.

12) Remove the oil seal from converter case.

B: INSTALLATION

1) Check the appearance of each component and

clean them.

2) Press-fit the oil seal to converter case using ST.

ST 499587100 OIL SEAL INSTALLER

3) Install the differential assembly to the case.

4) Install the right and left side retainers.

bly.>

5) Apply proper amount of liquid gasket to the en-

tire matching surface of converter case.

Liquid gasket:

THREE BOND 1215 (Part No. 004403007)

6) Install the converter case assembly without

damaging bushing and oil seal.

Tightening torque:

41 N·m (4.2 kgf-m, 30.4 ft-lb)

AT-01974

AT-01979

ST

AT-01975

Page 2125 of 2453

5AT(diag)-8

Electrical Component Location

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

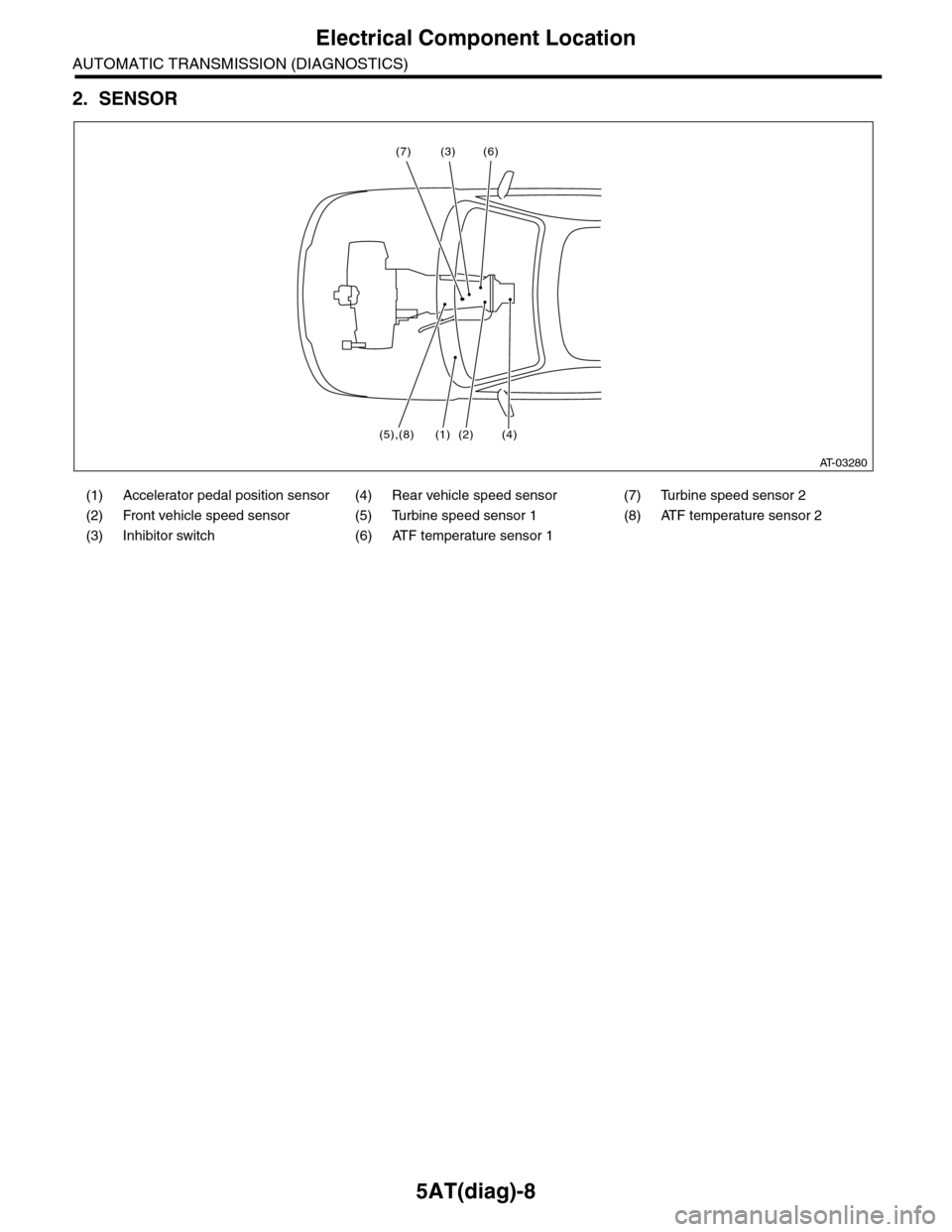

2. SENSOR

(1) Accelerator pedal position sensor (4) Rear vehicle speed sensor (7) Turbine speed sensor 2

(2) Front vehicle speed sensor (5) Turbine speed sensor 1 (8) ATF temperature sensor 2

(3) Inhibitor switch (6) ATF temperature sensor 1

AT-03280

(3) (6)

(5),(8) (2) (4)

(7)

(1)

Page 2130 of 2453

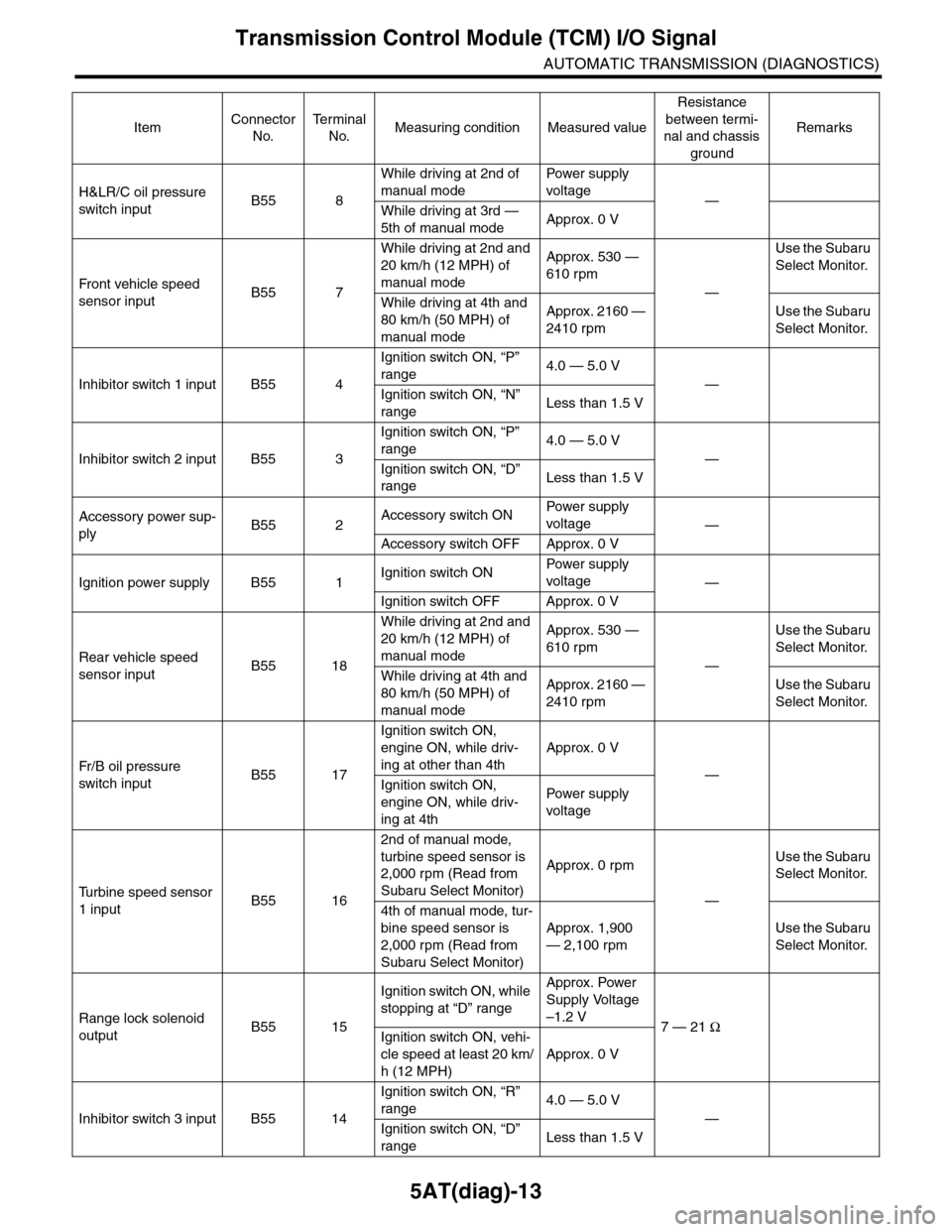

5AT(diag)-13

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

H&LR/C oil pressure

switch inputB55 8

While driving at 2nd of

manual mode

Pow er s up p ly

voltage—

While driving at 3rd —

5th of manual modeApprox. 0 V

Fr o nt veh ic l e sp e ed

sensor inputB55 7

While driving at 2nd and

20 km/h (12 MPH) of

manual mode

Approx. 530 —

610 rpm

—

Use the Subaru

Select Monitor.

While driving at 4th and

80 km/h (50 MPH) of

manual mode

Approx. 2160 —

2410 rpm

Use the Subaru

Select Monitor.

Inhibitor switch 1 input B55 4

Ignition switch ON, “P”

range4.0 — 5.0 V

—

Ignition switch ON, “N”

rangeLess than 1.5 V

Inhibitor switch 2 input B55 3

Ignition switch ON, “P”

range4.0 — 5.0 V

—

Ignition switch ON, “D”

rangeLess than 1.5 V

Accessory power sup-

plyB55 2Accessory switch ONPow er s up p ly

voltage—

Accessory switch OFF Approx. 0 V

Ignition power supply B55 1Ignition switch ONPow er s up p ly

voltage—

Ignition switch OFF Approx. 0 V

Rear vehicle speed

sensor inputB55 18

While driving at 2nd and

20 km/h (12 MPH) of

manual mode

Approx. 530 —

610 rpm

—

Use the Subaru

Select Monitor.

While driving at 4th and

80 km/h (50 MPH) of

manual mode

Approx. 2160 —

2410 rpm

Use the Subaru

Select Monitor.

Fr / B oi l p r e ssu r e

switch inputB55 17

Ignition switch ON,

engine ON, while driv-

ing at other than 4th

Approx. 0 V

—

Ignition switch ON,

engine ON, while driv-

ing at 4th

Pow er s up p ly

voltage

Tu r b i n e s p e e d s e n s o r

1 inputB55 16

2nd of manual mode,

turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

Approx. 0 rpm

—

Use the Subaru

Select Monitor.

4th of manual mode, tur-

bine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

Approx. 1,900

— 2,100 rpm

Use the Subaru

Select Monitor.

Range lock solenoid

outputB55 15

Ignition switch ON, while

stopping at “D” range

Approx. Power

Supply Voltage

–1.2 V7 — 21 Ω

Ignition switch ON, vehi-

cle speed at least 20 km/

h (12 MPH)

Approx. 0 V

Inhibitor switch 3 input B55 14

Ignition switch ON, “R”

range4.0 — 5.0 V

—

Ignition switch ON, “D”

rangeLess than 1.5 V

ItemConnector

No.

Te r m i n a l

No.Measuring condition Measured value

Resistance

between termi-

nal and chassis

ground

Remarks

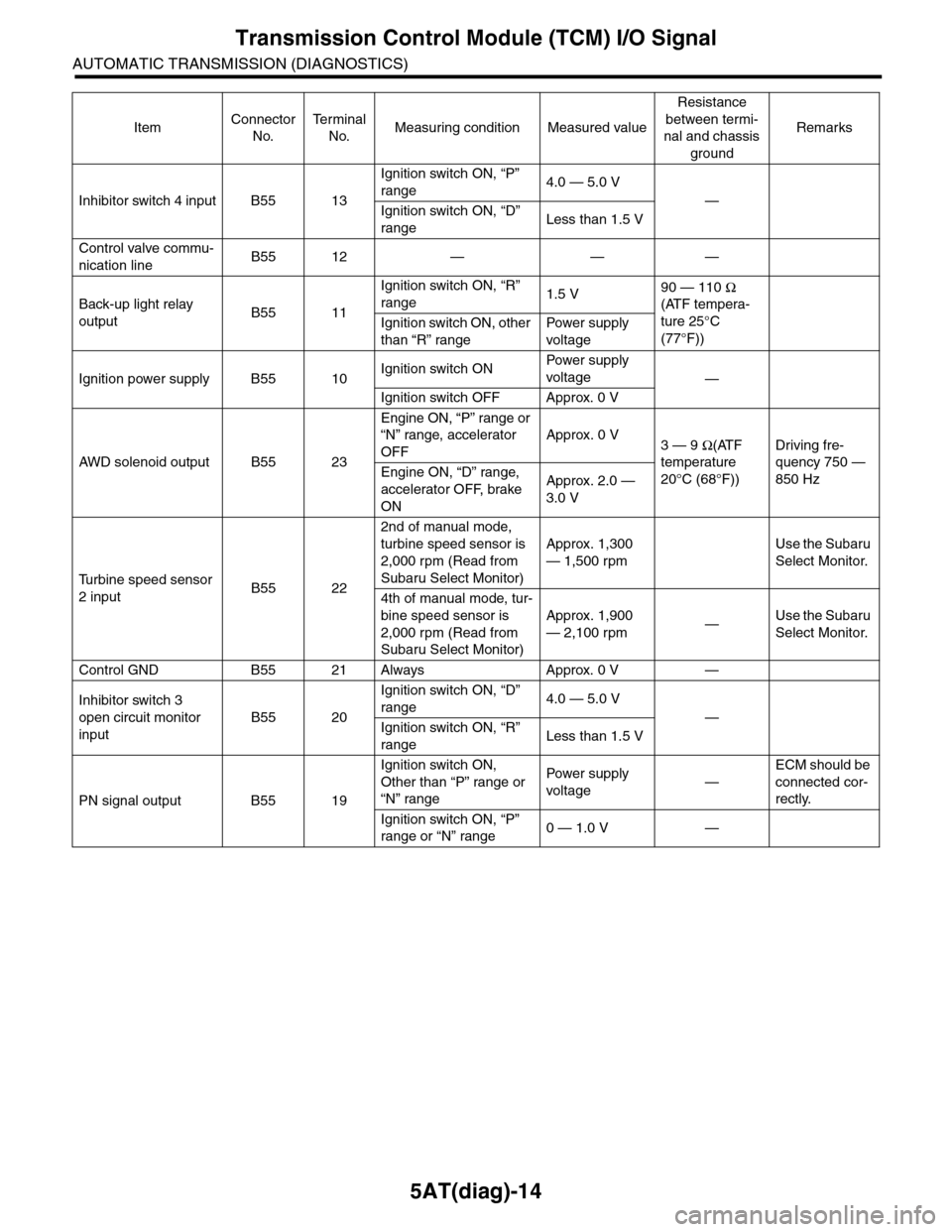

Page 2131 of 2453

5AT(diag)-14

Transmission Control Module (TCM) I/O Signal

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

Inhibitor switch 4 input B55 13

Ignition switch ON, “P”

range4.0 — 5.0 V

—

Ignition switch ON, “D”

rangeLess than 1.5 V

Control valve commu-

nication lineB55 12 — — —

Back-up light relay

outputB55 11

Ignition switch ON, “R”

range1.5 V90 — 110 Ω

(ATF tempera-

ture 25°C

(77°F))

Ignition switch ON, other

than “R” range

Pow er s up p ly

voltage

Ignition power supply B55 10Ignition switch ONPow er s up p ly

voltage—

Ignition switch OFF Approx. 0 V

AW D s o le n oi d o u tp u t B 5 5 2 3

Engine ON, “P” range or

“N” range, accelerator

OFF

Approx. 0 V3 — 9 Ω(ATF

temperature

20°C (68°F))

Driving fre-

quency 750 —

850 HzEngine ON, “D” range,

accelerator OFF, brake

ON

Approx. 2.0 —

3.0 V

Tu r b i n e s p e e d s e n s o r

2 inputB55 22

2nd of manual mode,

turbine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

Approx. 1,300

— 1,500 rpm

Use the Subaru

Select Monitor.

4th of manual mode, tur-

bine speed sensor is

2,000 rpm (Read from

Subaru Select Monitor)

Approx. 1,900

— 2,100 rpm—Use the Subaru

Select Monitor.

Control GND B55 21 Always Approx. 0 V —

Inhibitor switch 3

open circuit monitor

input

B55 20

Ignition switch ON, “D”

range4.0 — 5.0 V

—

Ignition switch ON, “R”

rangeLess than 1.5 V

PN signal output B55 19

Ignition switch ON,

Other than “P” range or

“N” range

Pow er s up p ly

voltage—

ECM should be

connected cor-

rectly.

Ignition switch ON, “P”

range or “N” range0 — 1.0 V —

ItemConnector

No.

Te r m i n a l

No.Measuring condition Measured value

Resistance

between termi-

nal and chassis

ground

Remarks

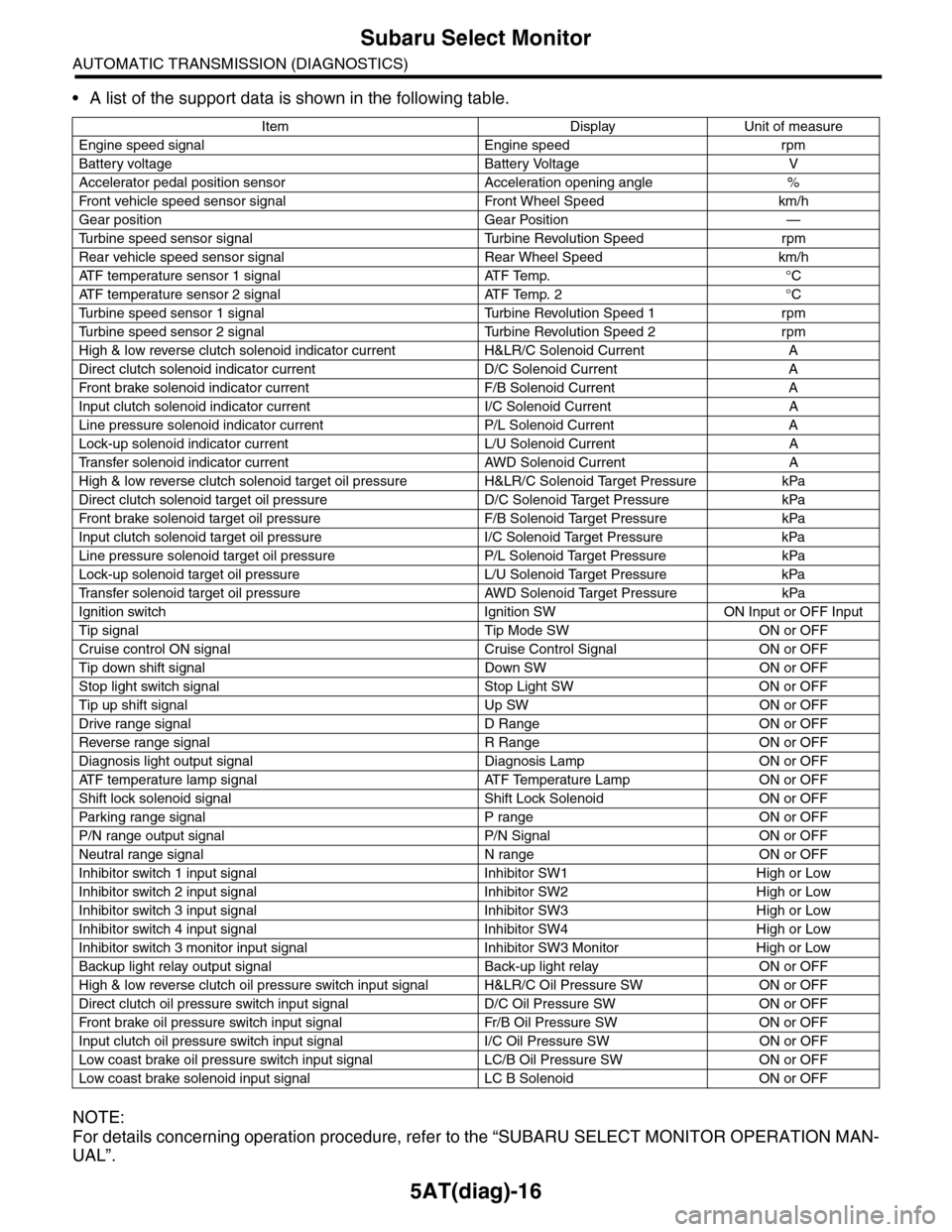

Page 2133 of 2453

5AT(diag)-16

Subaru Select Monitor

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

•A list of the support data is shown in the following table.

NOTE:

For details concerning operation procedure, refer to the “SUBARU SELECT MONITOR OPERATION MAN-

UAL”.

Item Display Unit of measure

Engine speed signal Engine speed rpm

Battery voltage Battery Voltage V

Accelerator pedal position sensor Acceleration opening angle %

Fr o nt veh ic l e sp e ed se n so r s ig n al Fr o n t W h ee l S p e ed km/ h

Gear position Gear Position —

Tu r b i n e s p e e d s e n s o r s i g n a l Tu r b i n e R e v o l u t i o n S p e e d r p m

Rear vehicle speed sensor signal Rear Wheel Speed km/h

ATF temperature sensor 1 signal ATF Temp. °C

ATF temperature sensor 2 signal ATF Temp. 2 °C

Tu r b i n e s p e e d s e n s o r 1 s i g n a l Tu r b i n e R e v o l u t i o n S p e e d 1 r p m

Tu r b i n e s p e e d s e n s o r 2 s i g n a l Tu r b i n e R e v o l u t i o n S p e e d 2 r p m

High & low reverse clutch solenoid indicator current H&LR/C Solenoid Current A

Direct clutch solenoid indicator current D/C Solenoid Current A

Fr o nt b rake so l en oi d in di c at o r c u rr e n t F / B S o l en o id Cur r e nt A

Input clutch solenoid indicator current I/C Solenoid Current A

Line pressure solenoid indicator current P/L Solenoid Current A

Lock-up solenoid indicator current L/U Solenoid Current A

Tr a n s f e r s o l e n o i d i n d i c a t o r c u r r e n t A W D S o l e n o i d C u r r e n t A

High & low reverse clutch solenoid target oil pressure H&LR/C Solenoid Target Pressure kPa

Direct clutch solenoid target oil pressure D/C Solenoid Target Pressure kPa

Fr o nt b rake so l en oi d ta r g et o il pr e ss ur e F / B S o l en o id Ta r g et P r es su r e kPa

Input clutch solenoid target oil pressure I/C Solenoid Target Pressure kPa

Line pressure solenoid target oil pressure P/L Solenoid Target Pressure kPa

Lock-up solenoid target oil pressure L/U Solenoid Target Pressure kPa

Tr a n s f e r s o l e n o i d t a r g e t o i l p r e s s u r e A W D S o l e n o i d Ta r g e t P r e s s u r e k P a

Ignition switch Ignition SW ON Input or OFF Input

Tip signal Tip Mode SW ON or OFF

Cruise control ON signal Cruise Control Signal ON or OFF

Tip down shift signal Down SW ON or OFF

Stop light switch signal Stop Light SW ON or OFF

Tip up shift signal Up SW ON or OFF

Drive range signal D Range ON or OFF

Reverse range signal R Range ON or OFF

Diagnosis light output signal Diagnosis Lamp ON or OFF

AT F t e m p e r a t u r e l a m p s i g n a l AT F Te m p e r a t u r e L a m p O N o r O F F

Shift lock solenoid signal Shift Lock Solenoid ON or OFF

Par king range signal P range ON or OFF

P/N range output signal P/N Signal ON or OFF

Neutral range signal N range ON or OFF

Inhibitor switch 1 input signal Inhibitor SW1 High or Low

Inhibitor switch 2 input signal Inhibitor SW2 High or Low

Inhibitor switch 3 input signal Inhibitor SW3 High or Low

Inhibitor switch 4 input signal Inhibitor SW4 High or Low

Inhibitor switch 3 monitor input signal Inhibitor SW3 Monitor High or Low

Backup light relay output signal Back-up light relay ON or OFF

High & low reverse clutch oil pressure switch input signal H&LR/C Oil Pressure SW ON or OFF

Direct clutch oil pressure switch input signal D/C Oil Pressure SW ON or OFF

Fr o nt b rake oi l pr e ss ur e swi tc h i n pu t si gn a l Fr / B Oi l P r e ss ur e S W ON or OF F

Input clutch oil pressure switch input signal I/C Oil Pressure SW ON or OFF

Low coast brake oil pressure switch input signal LC/B Oil Pressure SW ON or OFF

Low coast brake solenoid input signal LC B Solenoid ON or OFF

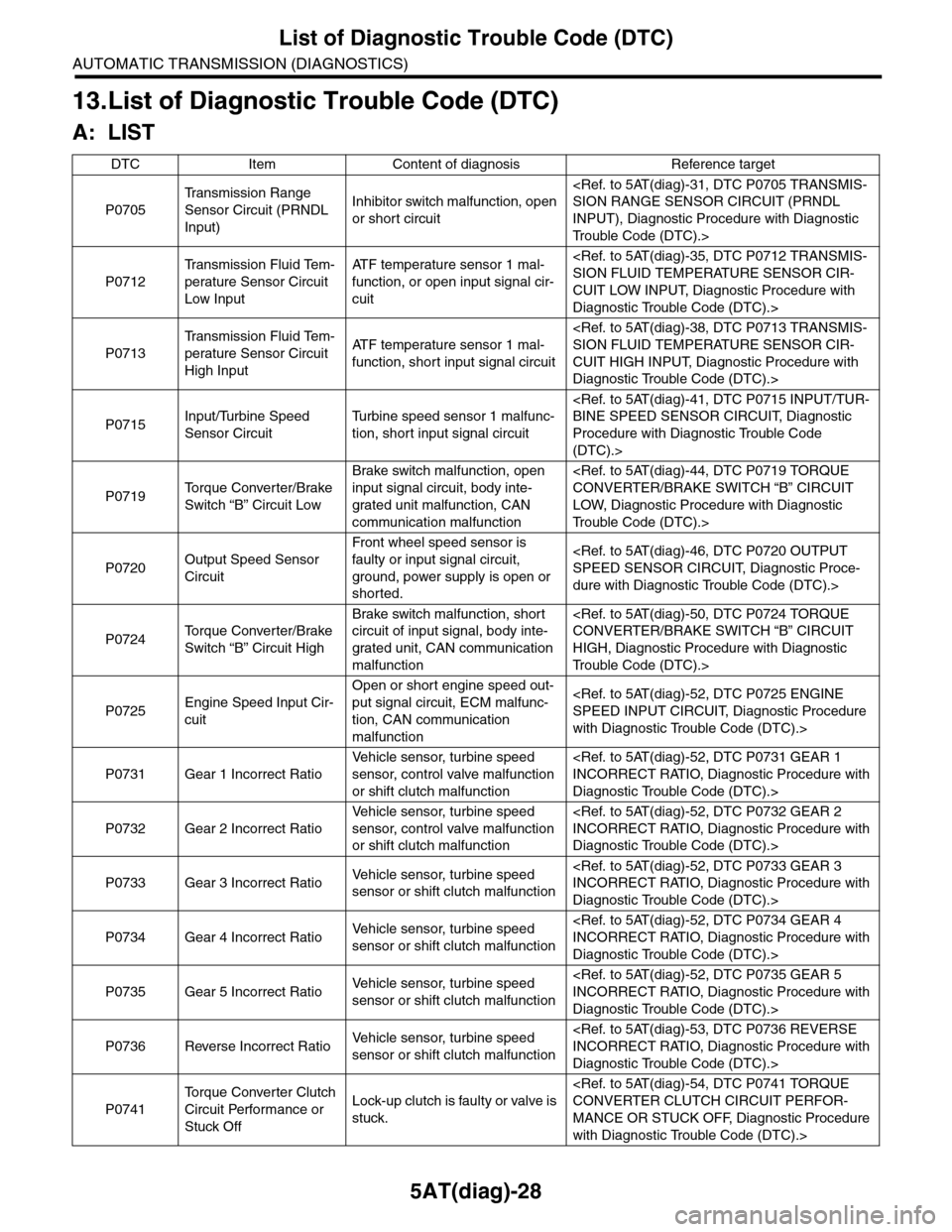

Page 2145 of 2453

5AT(diag)-28

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

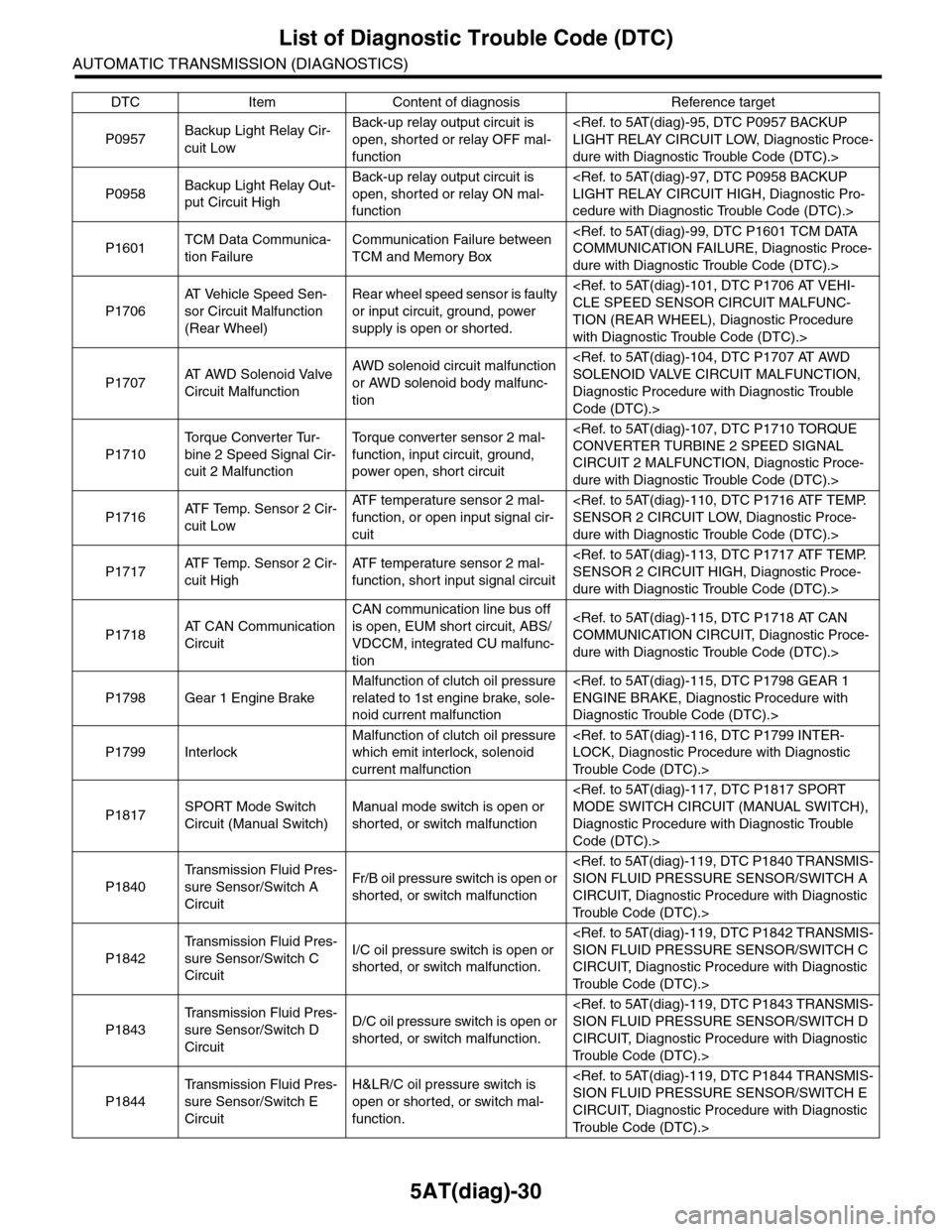

13.List of Diagnostic Trouble Code (DTC)

A: LIST

DTC Item Content of diagnosis Reference target

P0705

Tr a n s m i s s i o n R a n g e

Sensor Circuit (PRNDL

Input)

Inhibitor switch malfunction, open

or short circuit

INPUT), Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0712

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

Low Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, or open input signal cir-

cuit

CUIT LOW INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0713

Tr a n s m i s s i o n F l u i d Te m -

perature Sensor Circuit

High Input

AT F t e m p e r a t u r e s e n s o r 1 m a l -

function, short input signal circuit

CUIT HIGH INPUT, Diagnostic Procedure with

Diagnostic Trouble Code (DTC).>

P0715Input/Turbine Speed

Sensor Circuit

Tu r b i n e s p e e d s e n s o r 1 m a l f u n c -

tion, short input signal circuit

Procedure with Diagnostic Trouble Code

(DTC).>

P0719To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit Low

Brake switch malfunction, open

input signal circuit, body inte-

grated unit malfunction, CAN

communication malfunction

LOW, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0720Output Speed Sensor

Circuit

Front wheel speed sensor is

faulty or input signal circuit,

ground, power supply is open or

shorted.

dure with Diagnostic Trouble Code (DTC).>

P0724To r q u e C o n v e r t e r / B r a k e

Switch “B” Circuit High

Brake switch malfunction, short

circuit of input signal, body inte-

grated unit, CAN communication

malfunction

HIGH, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P0725Engine Speed Input Cir-

cuit

Open or short engine speed out-

put signal circuit, ECM malfunc-

tion, CAN communication

malfunction

with Diagnostic Trouble Code (DTC).>

P0731 Gear 1 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0732 Gear 2 Incorrect Ratio

Ve h i c l e s e n s o r, t u r b i n e s p e e d

sensor, control valve malfunction

or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0733 Gear 3 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0734 Gear 4 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0735 Gear 5 Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0736 Reverse Incorrect RatioVe h i c l e s e n s o r, t u r b i n e s p e e d

sensor or shift clutch malfunction

Diagnostic Trouble Code (DTC).>

P0741

To r q u e C o n v e r t e r C l u t c h

Circuit Performance or

Stuck Off

Lock-up clutch is faulty or valve is

stuck.

MANCE OR STUCK OFF, Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

Page 2147 of 2453

5AT(diag)-30

List of Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

P0957Backup Light Relay Cir-

cuit Low

Back-up relay output circuit is

open, shorted or relay OFF mal-

function

dure with Diagnostic Trouble Code (DTC).>

P0958Backup Light Relay Out-

put Circuit High

Back-up relay output circuit is

open, shorted or relay ON mal-

function

cedure with Diagnostic Trouble Code (DTC).>

P1601TCM Data Communica-

tion Failure

Communication Failure between

TCM and Memory Box

dure with Diagnostic Trouble Code (DTC).>

P1706

AT Ve h i c l e S p e e d S e n -

sor Circuit Malfunction

(Rear Wheel)

Rear wheel speed sensor is faulty

or input circuit, ground, power

supply is open or shorted.

TION (REAR WHEEL), Diagnostic Procedure

with Diagnostic Trouble Code (DTC).>

P1707AT A W D S o l e n o i d V a l v e

Circuit Malfunction

AWD solenoid circuit malfunction

or AWD solenoid body malfunc-

tion

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1710

To r q u e C o n v e r t e r Tu r -

bine 2 Speed Signal Cir-

cuit 2 Malfunction

To r q u e c o n v e r t e r s e n s o r 2 m a l -

function, input circuit, ground,

power open, short circuit

CIRCUIT 2 MALFUNCTION, Diagnostic Proce-

dure with Diagnostic Trouble Code (DTC).>

P1716AT F Te m p . S e n s o r 2 C i r -

cuit Low

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, or open input signal cir-

cuit

dure with Diagnostic Trouble Code (DTC).>

P1717AT F Te m p . S e n s o r 2 C i r -

cuit High

AT F t e m p e r a t u r e s e n s o r 2 m a l -

function, short input signal circuit

dure with Diagnostic Trouble Code (DTC).>

P1718AT C A N C o m m u n i c a t i o n

Circuit

CAN communication line bus off

is open, EUM short circuit, ABS/

VDCCM, integrated CU malfunc-

tion

dure with Diagnostic Trouble Code (DTC).>

P1798 Gear 1 Engine Brake

Malfunction of clutch oil pressure

related to 1st engine brake, sole-

noid current malfunction

Diagnostic Trouble Code (DTC).>

P1799 Interlock

Malfunction of clutch oil pressure

which emit interlock, solenoid

current malfunction

Tr o u b l e C o d e ( D T C ) . >

P1817SPORT Mode Switch

Circuit (Manual Switch)

Manual mode switch is open or

shorted, or switch malfunction

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

P1840

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch A

Circuit

Fr/B oil pressure switch is open or

shorted, or switch malfunction

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1842

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch C

Circuit

I/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1843

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch D

Circuit

D/C oil pressure switch is open or

shorted, or switch malfunction.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

P1844

Tr a n s m i s s i o n F l u i d P r e s -

sure Sensor/Switch E

Circuit

H&LR/C oil pressure switch is

open or shorted, or switch mal-

function.

CIRCUIT, Diagnostic Procedure with Diagnostic

Tr o u b l e C o d e ( D T C ) . >

DTC Item Content of diagnosis Reference target

Page 2158 of 2453

5AT(diag)-41

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

AUTOMATIC TRANSMISSION (DIAGNOSTICS)

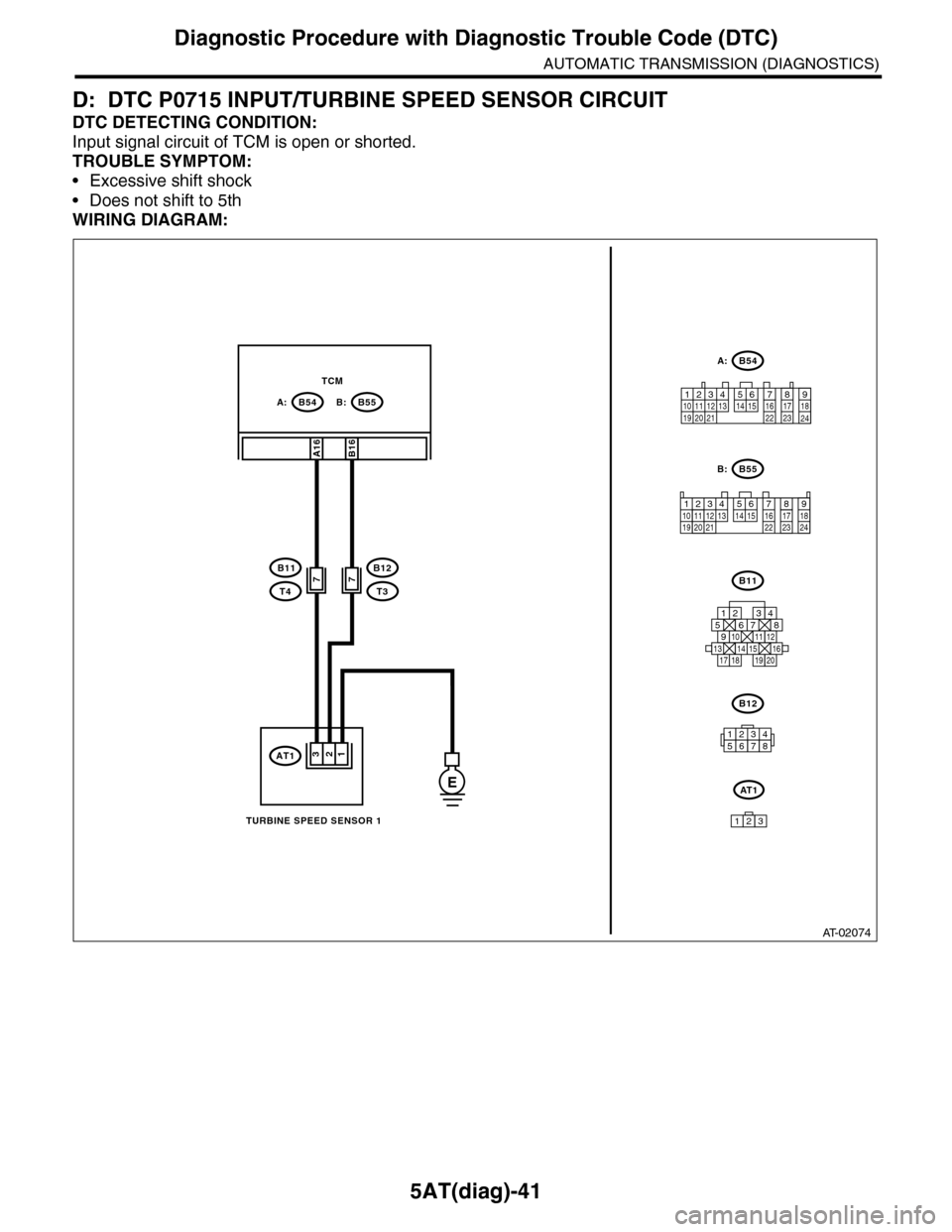

D: DTC P0715 INPUT/TURBINE SPEED SENSOR CIRCUIT

DTC DETECTING CONDITION:

Input signal circuit of TCM is open or shorted.

TROUBLE SYMPTOM:

•Excessive shift shock

•Does not shift to 5th

WIRING DIAGRAM:

AT-02074

12341011 121920 21135614 1578916 17 1822 23 24

AT 1

123

12345678

B54

B55

12789563410 11 1219 20 2113 14 15 16 17 18222324

B11

B12

125678

131415169101112

34

17181920

B54A:B55B:

A16

7B11

T4

B12

T3

TCM

TURBINE SPEED SENSOR 1

B16

7

E

B:

A:

321AT1