engine coolant SUBARU TRIBECA 2009 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1131 of 2453

CO(H6DO)-12

Engine Coolant

COOLING

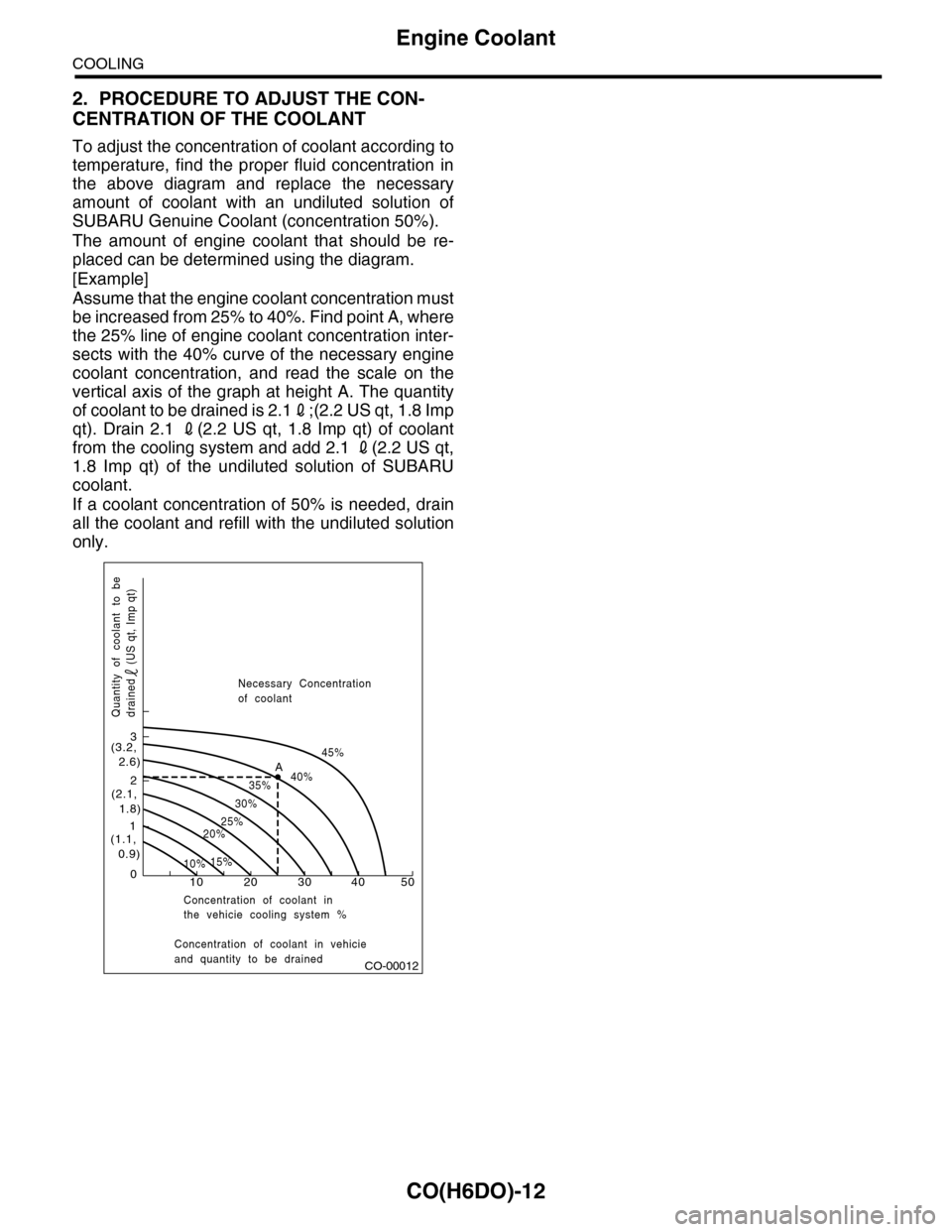

2. PROCEDURE TO ADJUST THE CON-

CENTRATION OF THE COOLANT

To adjust the concentration of coolant according to

temperature, find the proper fluid concentration in

the above diagram and replace the necessary

amount of coolant with an undiluted solution of

SUBARU Genuine Coolant (concentration 50%).

The amount of engine coolant that should be re-

placed can be determined using the diagram.

[Example]

Assume that the engine coolant concentration must

be increased from 25% to 40%. Find point A, where

the 25% line of engine coolant concentration inter-

sects with the 40% curve of the necessary engine

coolant concentration, and read the scale on the

vertical axis of the graph at height A. The quantity

of coolant to be drained is 2.12;(2.2 US qt, 1.8 Imp

qt). Drain 2.1 2(2.2 US qt, 1.8 Imp qt) of coolant

from the cooling system and add 2.1 2(2.2 US qt,

1.8 Imp qt) of the undiluted solution of SUBARU

coolant.

If a coolant concentration of 50% is needed, drain

all the coolant and refill with the undiluted solution

only.

CO-00012

100

1

2

3

(1.1, 0.9)

(2.1, 1.8)

(3.2, 2.6)

10%15%

25%20%

30%

35%40%

45%A

20 30 40 50

Concentration of coolant in vehicieand quantity to be drained

Quantity of coolant to bedrained (US qt, Imp qt)

Necessary Concentrationof coolant

Concentration of coolant inthe vehicie cooling system %

Page 1132 of 2453

CO(H6DO)-13

Water Pump

COOLING

4. Water Pump

A: REMOVAL

1) Remove the radiator.

2) Remove the V-belts.

3) Remove the front chain cover.

4) Remove the timing chain assembly.

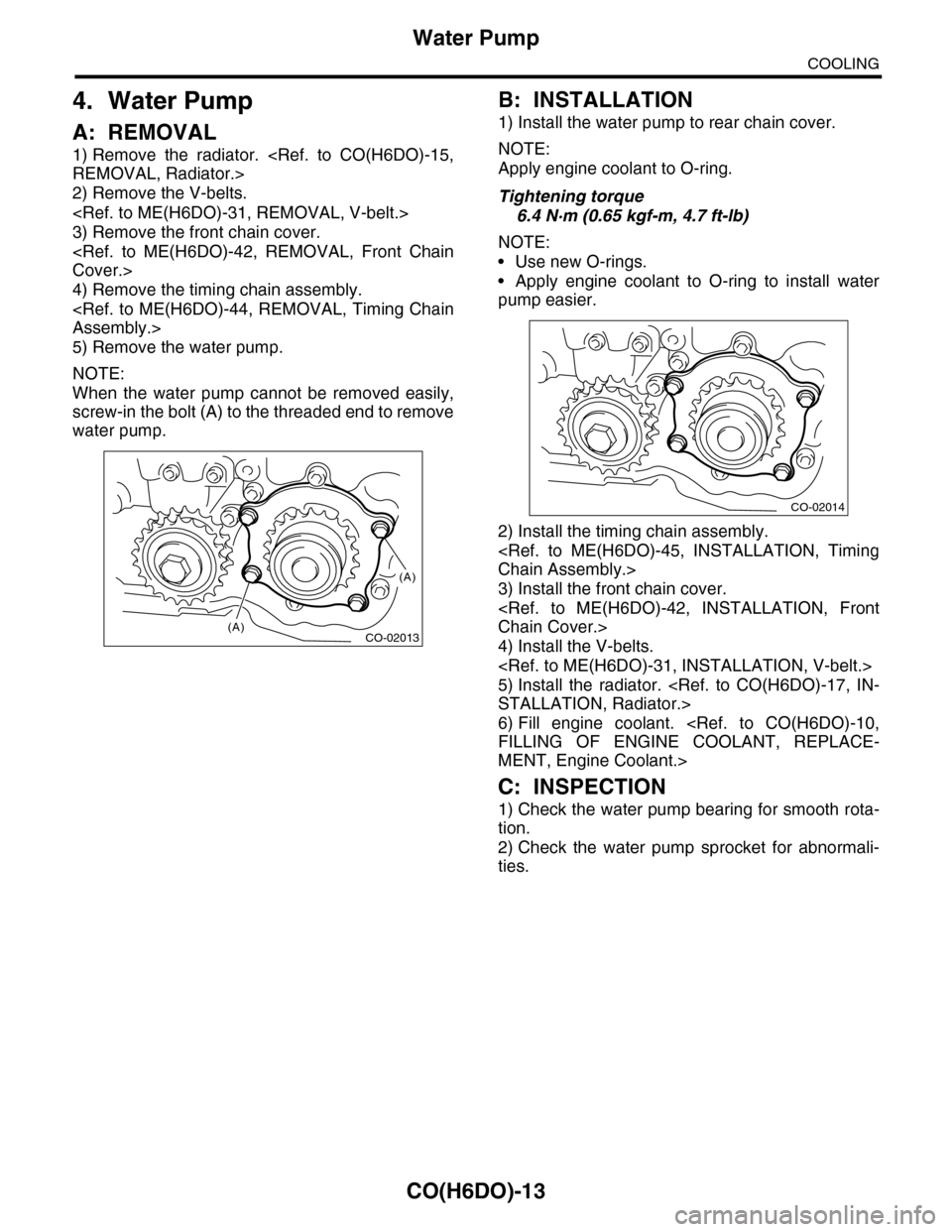

5) Remove the water pump.

NOTE:

When the water pump cannot be removed easily,

screw-in the bolt (A) to the threaded end to remove

water pump.

B: INSTALLATION

1) Install the water pump to rear chain cover.

NOTE:

Apply engine coolant to O-ring.

Tightening torque

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

NOTE:

•Use new O-rings.

•Apply engine coolant to O-ring to install water

pump easier.

2) Install the timing chain assembly.

3) Install the front chain cover.

4) Install the V-belts.

5) Install the radiator.

6) Fill engine coolant.

MENT, Engine Coolant.>

C: INSPECTION

1) Check the water pump bearing for smooth rota-

tion.

2) Check the water pump sprocket for abnormali-

ties.

CO-02013

(A)

(A)

CO-02014

Page 1133 of 2453

CO(H6DO)-14

Thermostat

COOLING

5. Thermostat

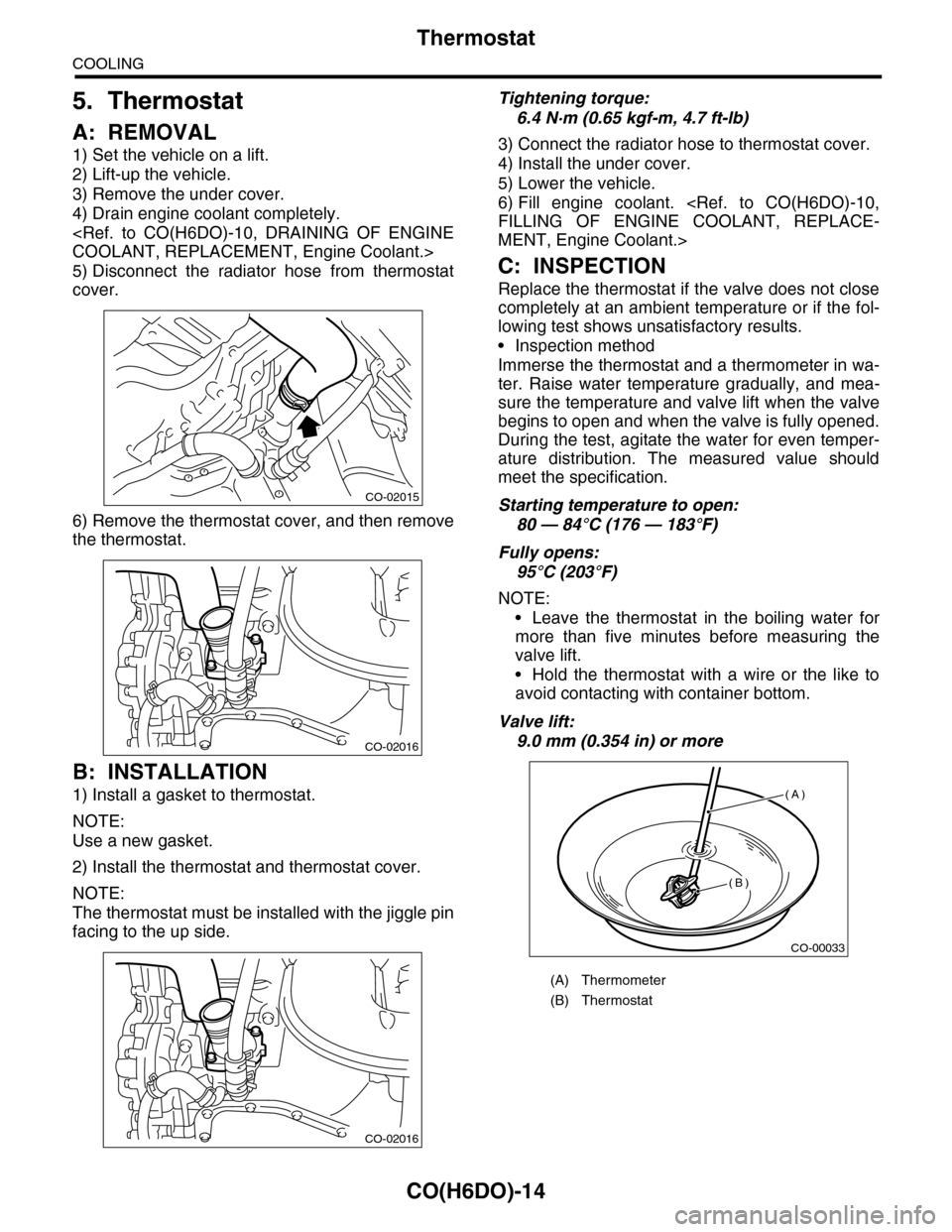

A: REMOVAL

1) Set the vehicle on a lift.

2) Lift-up the vehicle.

3) Remove the under cover.

4) Drain engine coolant completely.

5) Disconnect the radiator hose from thermostat

cover.

6) Remove the thermostat cover, and then remove

the thermostat.

B: INSTALLATION

1) Install a gasket to thermostat.

NOTE:

Use a new gasket.

2) Install the thermostat and thermostat cover.

NOTE:

The thermostat must be installed with the jiggle pin

facing to the up side.

Tightening torque:

6.4 N·m (0.65 kgf-m, 4.7 ft-lb)

3) Connect the radiator hose to thermostat cover.

4) Install the under cover.

5) Lower the vehicle.

6) Fill engine coolant.

MENT, Engine Coolant.>

C: INSPECTION

Replace the thermostat if the valve does not close

completely at an ambient temperature or if the fol-

lowing test shows unsatisfactory results.

•Inspection method

Immerse the thermostat and a thermometer in wa-

ter. Raise water temperature gradually, and mea-

sure the temperature and valve lift when the valve

begins to open and when the valve is fully opened.

During the test, agitate the water for even temper-

ature distribution. The measured value should

meet the specification.

Starting temperature to open:

80 — 84°C (176 — 183°F)

Fully opens:

95°C (203°F)

NOTE:

•Leave the thermostat in the boiling water for

more than five minutes before measuring the

valve lift.

•Hold the thermostat with a wire or the like to

avoid contacting with container bottom.

Valve lift:

9.0 mm (0.354 in) or more

CO-02015

CO-02016

CO-02016

(A) Thermometer

(B) Thermostat

CO-00033

(A)

(B)

Page 1134 of 2453

CO(H6DO)-15

Radiator

COOLING

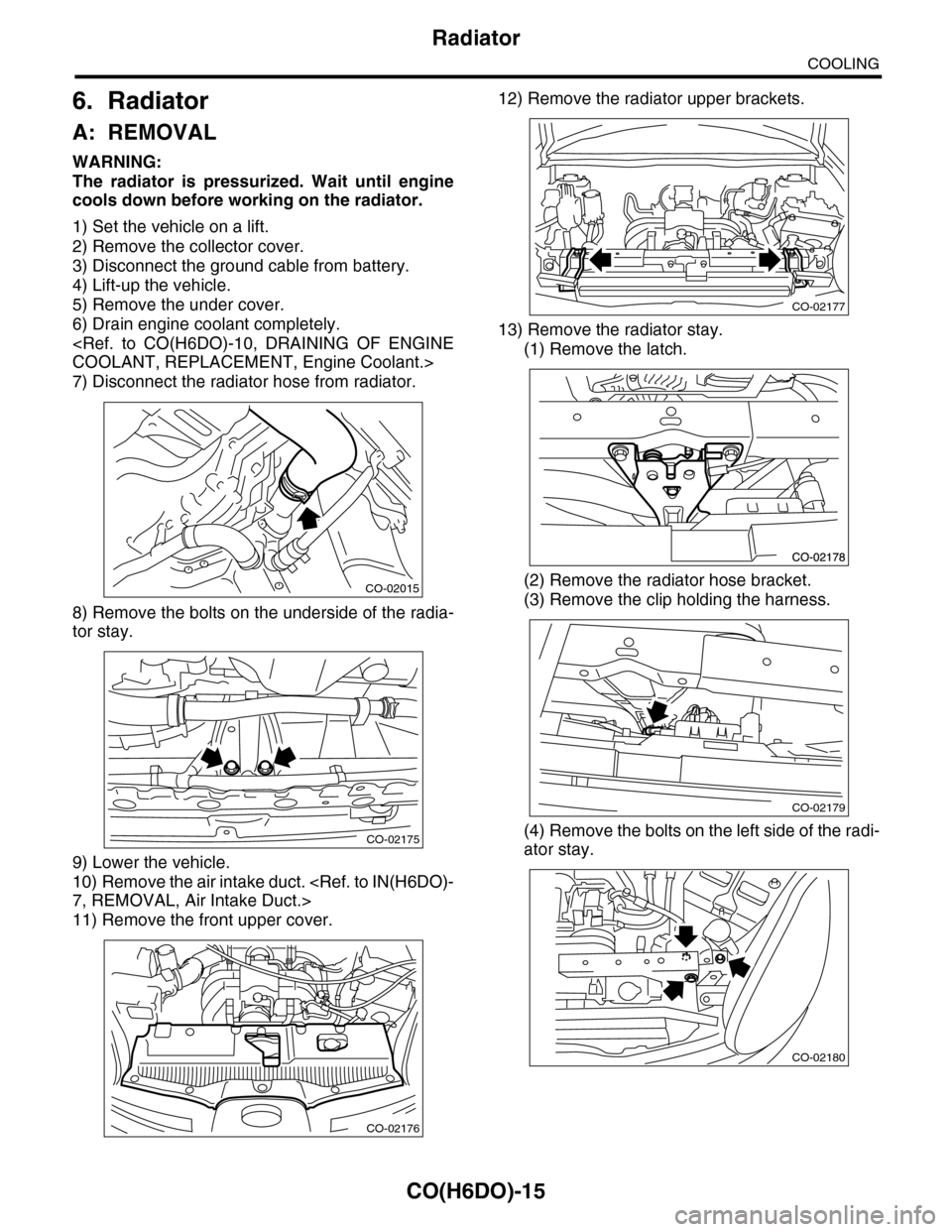

6. Radiator

A: REMOVAL

WARNING:

The radiator is pressurized. Wait until engine

cools down before working on the radiator.

1) Set the vehicle on a lift.

2) Remove the collector cover.

3) Disconnect the ground cable from battery.

4) Lift-up the vehicle.

5) Remove the under cover.

6) Drain engine coolant completely.

7) Disconnect the radiator hose from radiator.

8) Remove the bolts on the underside of the radia-

tor stay.

9) Lower the vehicle.

10) Remove the air intake duct.

11) Remove the front upper cover.

12) Remove the radiator upper brackets.

13) Remove the radiator stay.

(1) Remove the latch.

(2) Remove the radiator hose bracket.

(3) Remove the clip holding the harness.

(4) Remove the bolts on the left side of the radi-

ator stay.

CO-02015

CO-02175

CO-02176

CO-02177

CO-02179

CO-02180

Page 1138 of 2453

CO(H6DO)-19

Radiator

COOLING

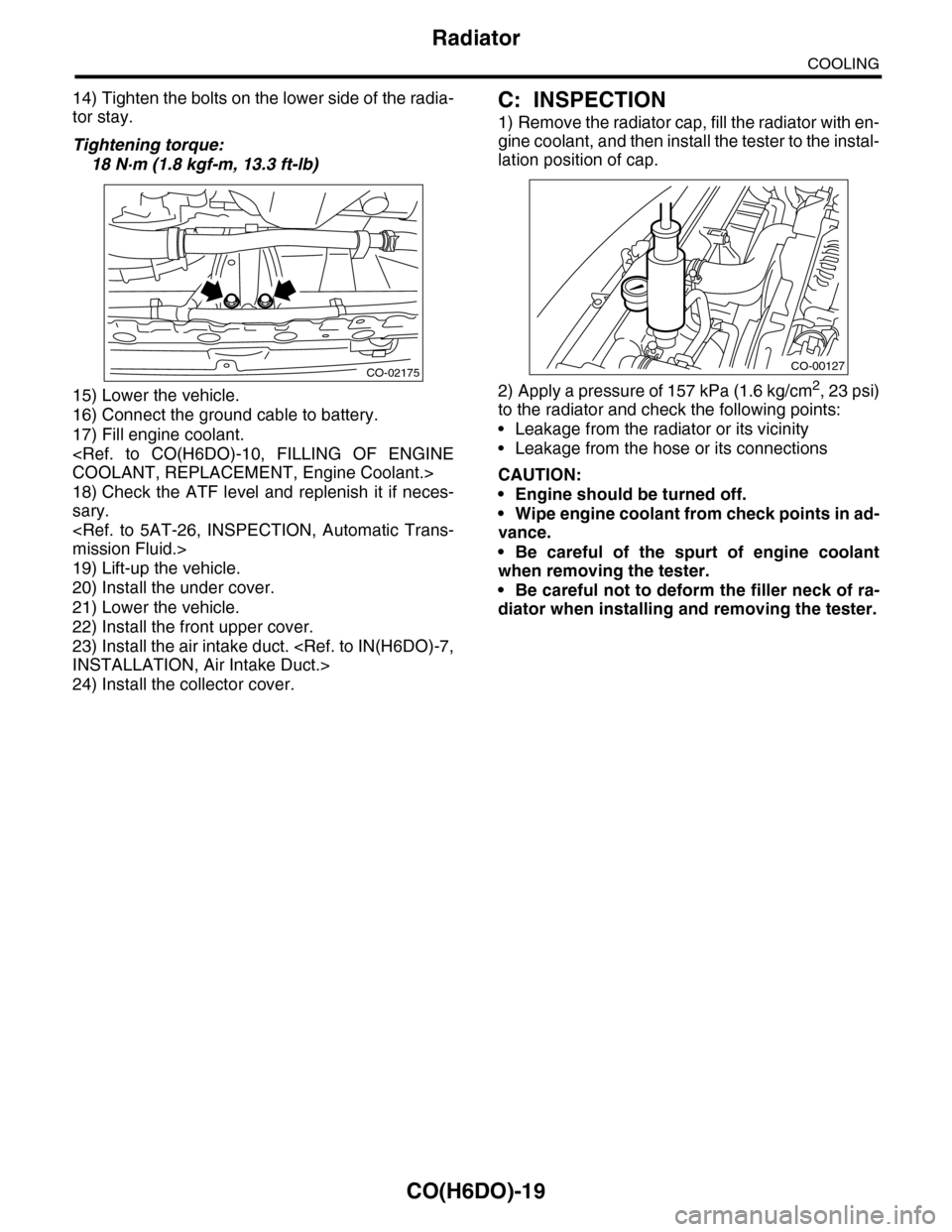

14) Tighten the bolts on the lower side of the radia-

tor stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

15) Lower the vehicle.

16) Connect the ground cable to battery.

17) Fill engine coolant.

18) Check the ATF level and replenish it if neces-

sary.

19) Lift-up the vehicle.

20) Install the under cover.

21) Lower the vehicle.

22) Install the front upper cover.

23) Install the air intake duct.

24) Install the collector cover.

C: INSPECTION

1) Remove the radiator cap, fill the radiator with en-

gine coolant, and then install the tester to the instal-

lation position of cap.

2) Apply a pressure of 157 kPa (1.6 kg/cm2, 23 psi)

to the radiator and check the following points:

•Leakage from the radiator or its vicinity

•Leakage from the hose or its connections

CAUTION:

•Engine should be turned off.

•Wipe engine coolant from check points in ad-

vance.

•Be careful of the spurt of engine coolant

when removing the tester.

•Be careful not to deform the filler neck of ra-

diator when installing and removing the tester.

CO-02175CO-00127

Page 1147 of 2453

CO(H6DO)-28

Reservoir Tank

COOLING

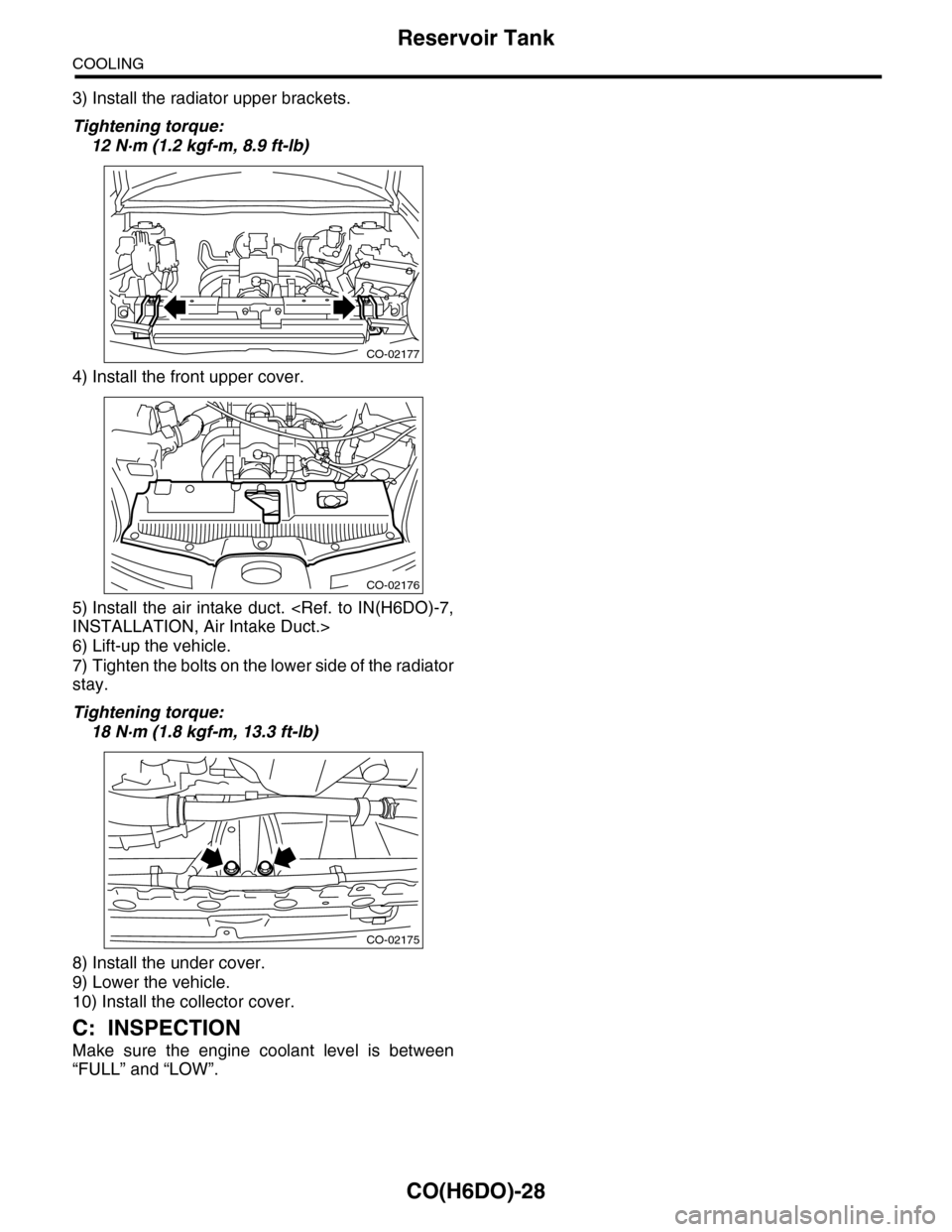

3) Install the radiator upper brackets.

Tightening torque:

12 N·m (1.2 kgf-m, 8.9 ft-lb)

4) Install the front upper cover.

5) Install the air intake duct.

6) Lift-up the vehicle.

7) Tighten the bolts on the lower side of the radiator

stay.

Tightening torque:

18 N·m (1.8 kgf-m, 13.3 ft-lb)

8) Install the under cover.

9) Lower the vehicle.

10) Install the collector cover.

C: INSPECTION

Make sure the engine coolant level is between

“FULL” and “LOW”.

CO-02177

CO-02176

CO-02175

Page 1149 of 2453

CO(H6DO)-30

Engine Cooling System Trouble in General

COOLING

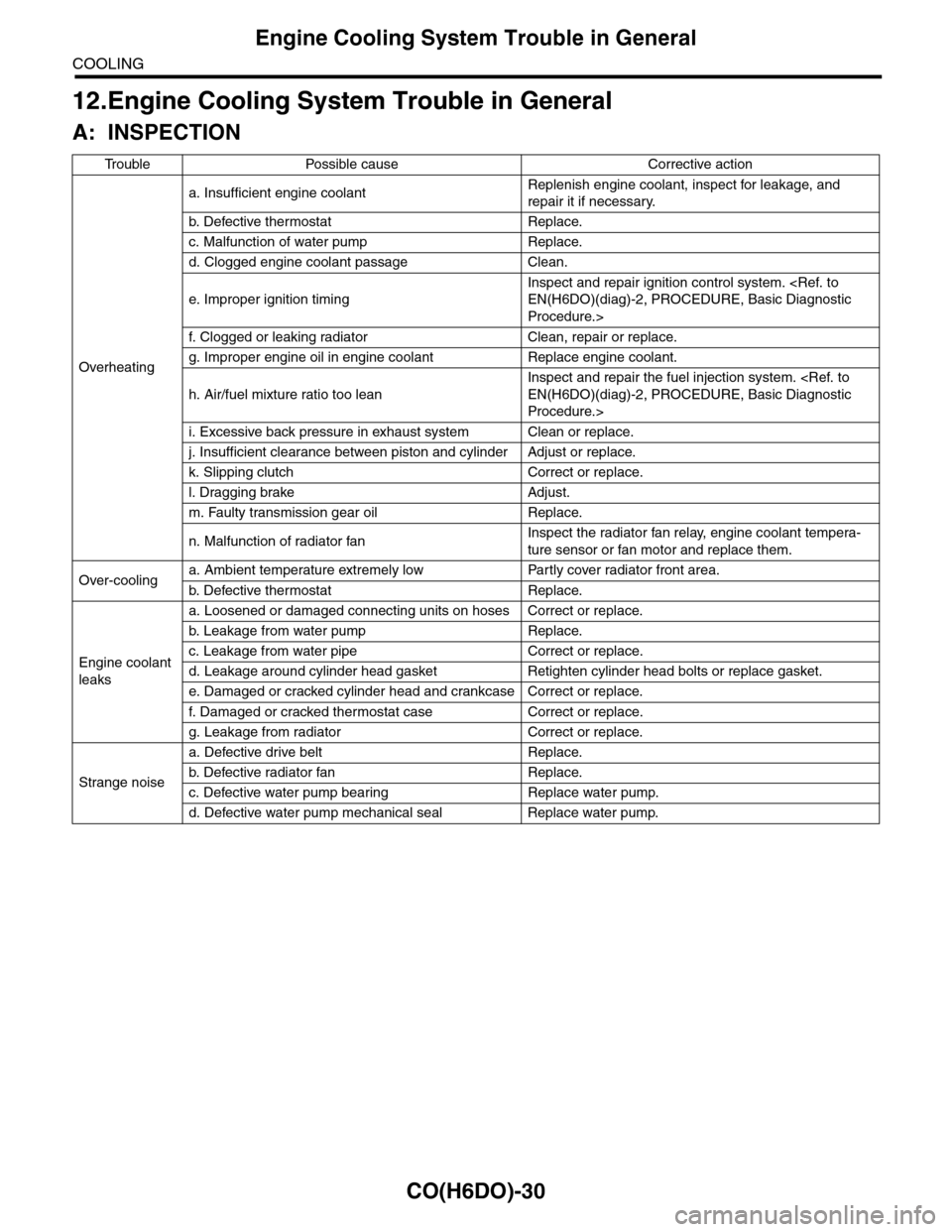

12.Engine Cooling System Trouble in General

A: INSPECTION

Tr o u b l e P o s s i b l e c a u s e C o r r e c t i v e a c t i o n

Overheating

a. Insufficient engine coolantReplenish engine coolant, inspect for leakage, and

repair it if necessary.

b. De fe c ti ve t he r mo st a t Rep la c e.

c. Malfunction of water pump Replace.

d. Clogged engine coolant passage Clean.

e. Improper ignition timing

Inspect and repair ignition control system.

Procedure.>

f. Clogged or leaking radiator Clean, repair or replace.

g. Improper engine oil in engine coolant Replace engine coolant.

h. Air/fuel mixture ratio too lean

Inspect and repair the fuel injection system.

Procedure.>

i. Excessive back pressure in exhaust system Clean or replace.

j. Insufficient clearance between piston and cylinder Adjust or replace.

k. Slipping clutch Correct or replace.

l. Dragging brake Adjust.

m. Faulty transmission gear oil Replace.

n. Malfunction of radiator fanInspect the radiator fan relay, engine coolant tempera-

ture sensor or fan motor and replace them.

Over-coolinga. Ambient temperature extremely low Partly cover radiator front area.

b. De fe c ti ve t he r mo st a t Rep la c e.

Engine coolant

leaks

a. Loosened or damaged connecting units on hoses Correct or replace.

b. L ea k ag e f r o m wat e r pu mp Rep la c e.

c. Leakage from water pipe Correct or replace.

d. Leakage around cylinder head gasket Retighten cylinder head bolts or replace gasket.

e. Damaged or cracked cylinder head and crankcase Correct or replace.

f. Damaged or cracked ther mostat case Correct or replace.

g. Leakage from radiator Correct or replace.

Strange noise

a. Defective drive belt Replace.

b. De fe c ti ve ra di a t or fan Rep la c e.

c. Defective water pump bearing Replace water pump.

d. Defective water pump mechanical seal Replace water pump.

Page 1167 of 2453

EN(H6DO)(diag)-6

General Description

ENGINE (DIAGNOSTICS)

C: NOTE

1. GENERAL DESCRIPTION

•The on-board diagnostics (OBD) system detects

and indicates a fault in various inputs and outputs

of the complex electronic control. Malfunction indi-

cator light in the combination meter indicates oc-

currence of a fault or trouble.

•Further, against such a failure or sensors as may

disable the drive, the fail-safe function is provided

to ensure the minimal drivability.

•The OBD system incorporated with the vehicles

within this engine family complies with OBD-II Reg-

ulations. The OBD system monitors the compo-

nents and the system malfunction listed in Engine

Section which affects on emissions.

•When the system decides that a malfunction oc-

curs, malfunction indicator light illuminates. At the

same time of the malfunction indicator light illumi-

nation or blinking, a DTC and a freeze frame en-

gine conditions are stored into on-board computer.

•The OBD system stores freeze frame engine

condition data (engine load, engine coolant tem-

perature, fuel trim, engine speed and vehicle

speed, etc.) into on-board computer when it detects

a malfunction first.

•If the OBD system detects the various malfunc-

tions including the fault of fuel trim or misfire, the

OBD system first stores freeze frame engine condi-

tions about fuel trim or misfire.

•When the malfunction does not occur again for

three consecutive driving cycles, malfunction indi-

cator light is turned off, but DTC remains at on-

board computer.

•When troubleshooting the vehicle which com-

plies with OBD-II Regulations, connect the Subaru

Select Monitor or general scan tool to the vehicle.

2. ENGINE AND EMISSION CONTROL SYS-

TEM

•The Multipoint Fuel Injection (MFI) system is a

system that supplies the optimum air-fuel mixture

to the engine for all the various operating condi-

tions through the use of the latest electronic tech-

nology.

With this system fuel, which is pressurized at a con-

stant pressure, is injected into the intake air pas-

sage of the cylinder head. The injection quantity of

fuel is controlled by an intermittent injection system

where the electro-magnetic injection valve (fuel in-

jector) opens only for a short period of time, de-

pending on the quantity of air required for one cycle

of operation. In actual operation, the injection quan-

tity is determined by the duration of an electric

pulse applied to the fuel injector and this permits

simple, yet highly precise metering of the fuel.

•Further, all the operating conditions of the engine

are converted into electric signals, and this results

in additional features of the system, such as large

improved adaptability, easier addition of compen-

sating element etc.

The MFI system also has the following features:

•Reduced emission of harmful exhaust gases.

•Reduced in fuel consumption.

•Increased engine output.

•Superior acceleration and deceleration.

•Superior startability and warm-up perfor-

mance in cold weather since compensation is

made for coolant and intake air temperature.

Page 1170 of 2453

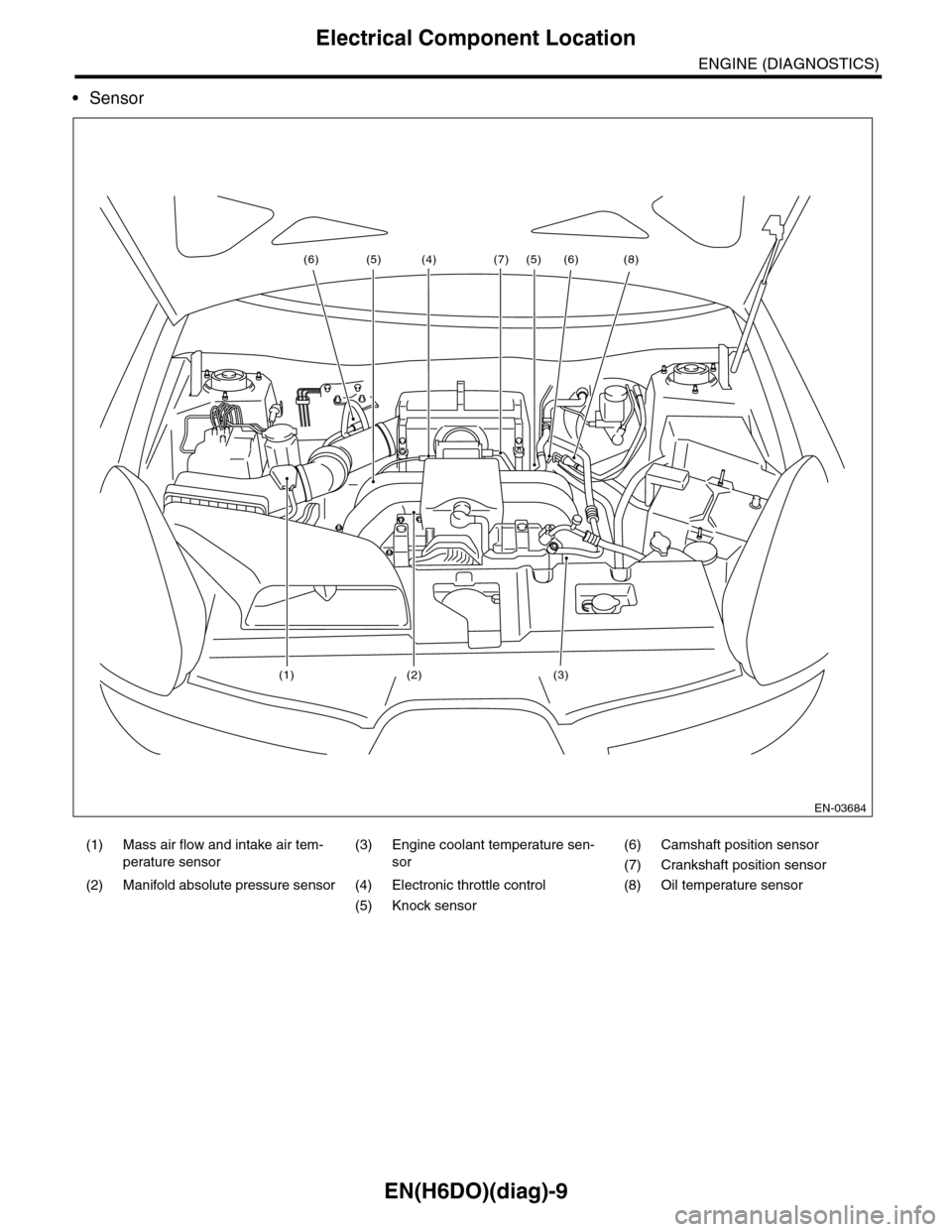

EN(H6DO)(diag)-9

Electrical Component Location

ENGINE (DIAGNOSTICS)

•Sensor

(1) Mass air flow and intake air tem-

perature sensor

(3) Engine coolant temperature sen-

sor

(6) Camshaft position sensor

(7) Crankshaft position sensor

(2) Manifold absolute pressure sensor (4) Electronic throttle control (8) Oil temperature sensor

(5) Knock sensor

EN-03684

(6)(6) (8)

(3)(2)

(7)

(1)

(4) (5)(5)

Page 1177 of 2453

EN(H6DO)(diag)-16

Engine Control Module (ECM) I/O Signal

ENGINE (DIAGNOSTICS)

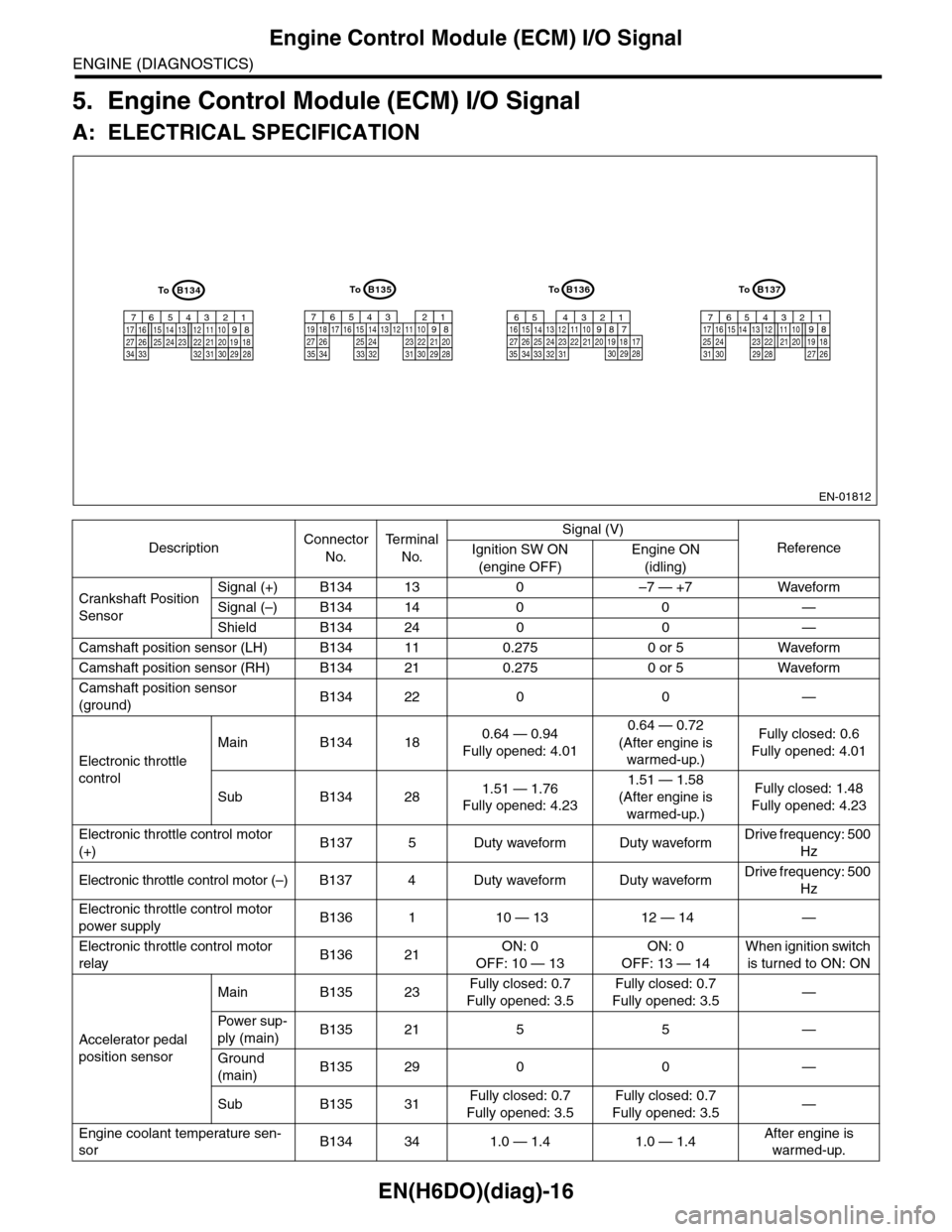

5. Engine Control Module (ECM) I/O Signal

A: ELECTRICAL SPECIFICATION

DescriptionConnector

No.

Te r m i n a l

No.

Signal (V)

ReferenceIgnition SW ON

(engine OFF)

Engine ON

(idling)

Crankshaft Position

Sensor

Signal (+) B134 13 0 –7 — +7 Waveform

Signal (–) B134 14 0 0 —

Shield B134 24 0 0 —

Camshaft position sensor (LH) B134 11 0.275 0 or 5 Waveform

Camshaft position sensor (RH) B134 21 0.275 0 or 5 Waveform

Camshaft position sensor

(ground)B134 22 0 0 —

Electronic throttle

control

Main B134 180.64 — 0.94

Fully opened: 4.01

0.64 — 0.72

(After engine is

warmed-up.)

Fully closed: 0.6

Fully opened: 4.01

Sub B134 281.51 — 1.76

Fully opened: 4.23

1.51 — 1.58

(After engine is

warmed-up.)

Fully closed: 1.48

Fully opened: 4.23

Electronic throttle control motor

(+)B137 5 Duty waveform Duty waveformDrive frequency: 500

Hz

Electronic throttle control motor (–) B137 4 Duty waveform Duty waveformDrive frequency: 500

Hz

Electronic throttle control motor

power supplyB136 1 10 — 13 12 — 14 —

Electronic throttle control motor

relayB136 21ON: 0

OFF: 10 — 13

ON: 0

OFF: 13 — 14

When ignition switch

is turned to ON: ON

Accelerator pedal

position sensor

Main B135 23Fully closed: 0.7

Fully opened: 3.5

Fully closed: 0.7

Fully opened: 3.5—

Powe r s up -

ply (main)B135 21 5 5 —

Ground

(main)B135 29 0 0 —

Sub B135 31Fully closed: 0.7

Fully opened: 3.5

Fully closed: 0.7

Fully opened: 3.5—

Engine coolant temperature sen-

sorB134 34 1.0 — 1.4 1.0 — 1.4After engine is

warmed-up.

EN-01812

B134

5678219431024 2223251112131415262728

1617181920213334 2932 3031

B136

5678219431024 2223251112131415262728

16171819202133342932303135

B135

5678219431024 2223251112131415262728

16171819202129303132333435

B137

5678219431022231112131415242526

1617181920212728293031

ToToToTo