engine coolant SUBARU TRIBECA 2009 1.G Service User Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 532 of 2453

LAN(diag)-76

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

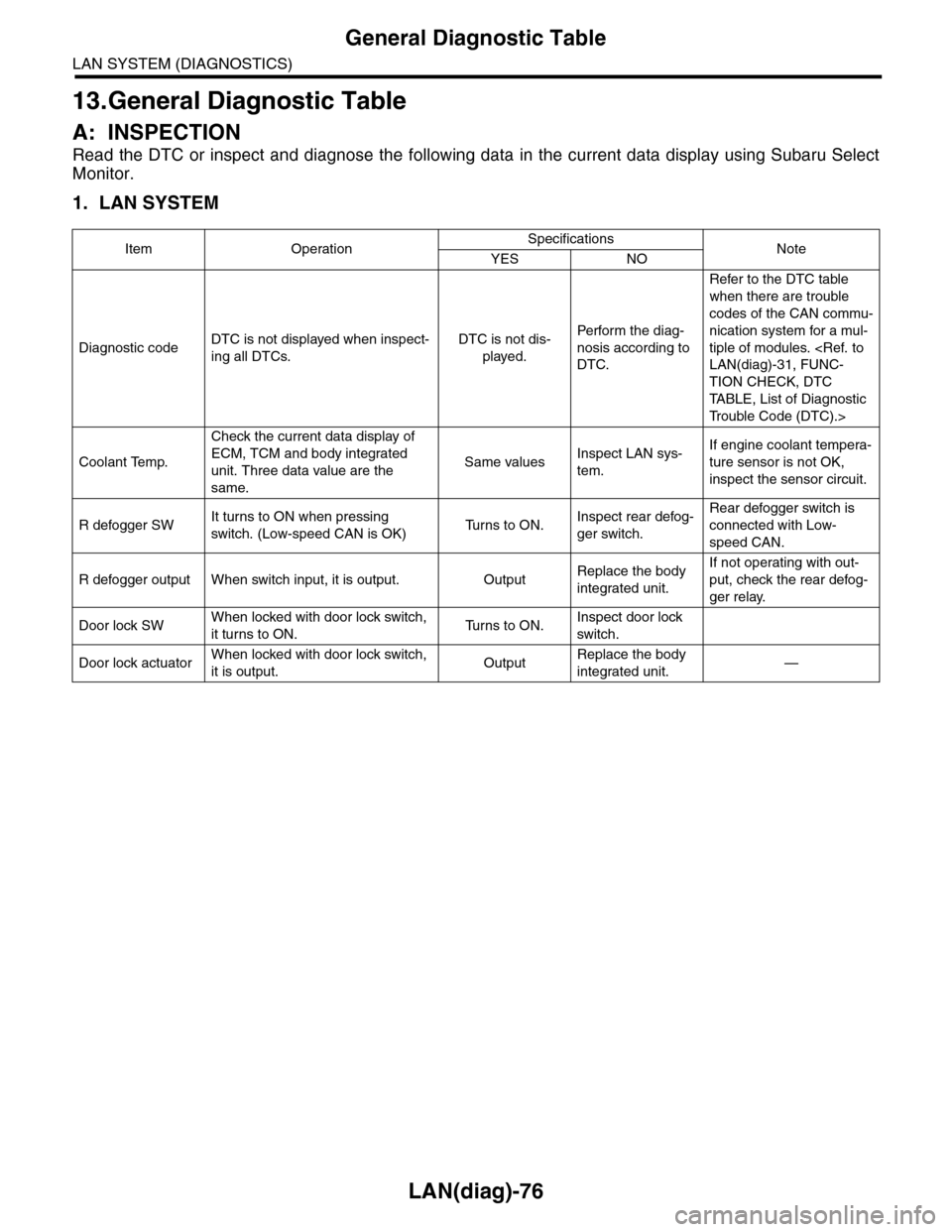

13.General Diagnostic Table

A: INSPECTION

Read the DTC or inspect and diagnose the following data in the current data display using Subaru Select

Monitor.

1. LAN SYSTEM

Item OperationSpecificationsNoteYES NO

Diagnostic codeDTC is not displayed when inspect-

ing all DTCs.

DTC is not dis-

played.

Perfor m the diag-

nosis according to

DTC.

Refer to the DTC table

when there are trouble

codes of the CAN commu-

nication system for a mul-

tiple of modules.

TION CHECK, DTC

TA B L E , L i s t o f D i a g n o s t i c

Tr o u b l e C o d e ( D T C ) . >

Coolant Temp.

Check the current data display of

ECM, TCM and body integrated

unit. Three data value are the

same.

Same valuesInspect LAN sys-

tem.

If engine coolant tempera-

ture sensor is not OK,

inspect the sensor circuit.

R defogger SWIt turns to ON when pressing

switch. (Low-speed CAN is OK)Tu r n s t o O N .Inspect rear defog-

ger switch.

Rear defogger switch is

connected with Low-

speed CAN.

R defogger output When switch input, it is output. OutputReplace the body

integrated unit.

If not operating with out-

put, check the rear defog-

ger relay.

Door lock SWWhen locked with door lock switch,

it turns to ON.Tu r n s t o O N .Inspect door lock

switch.

Door lock actuatorWhen locked with door lock switch,

it is output.OutputReplace the body

integrated unit.—

Page 1017 of 2453

VDC(diag)-25

Warning Light Illumination Pattern

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

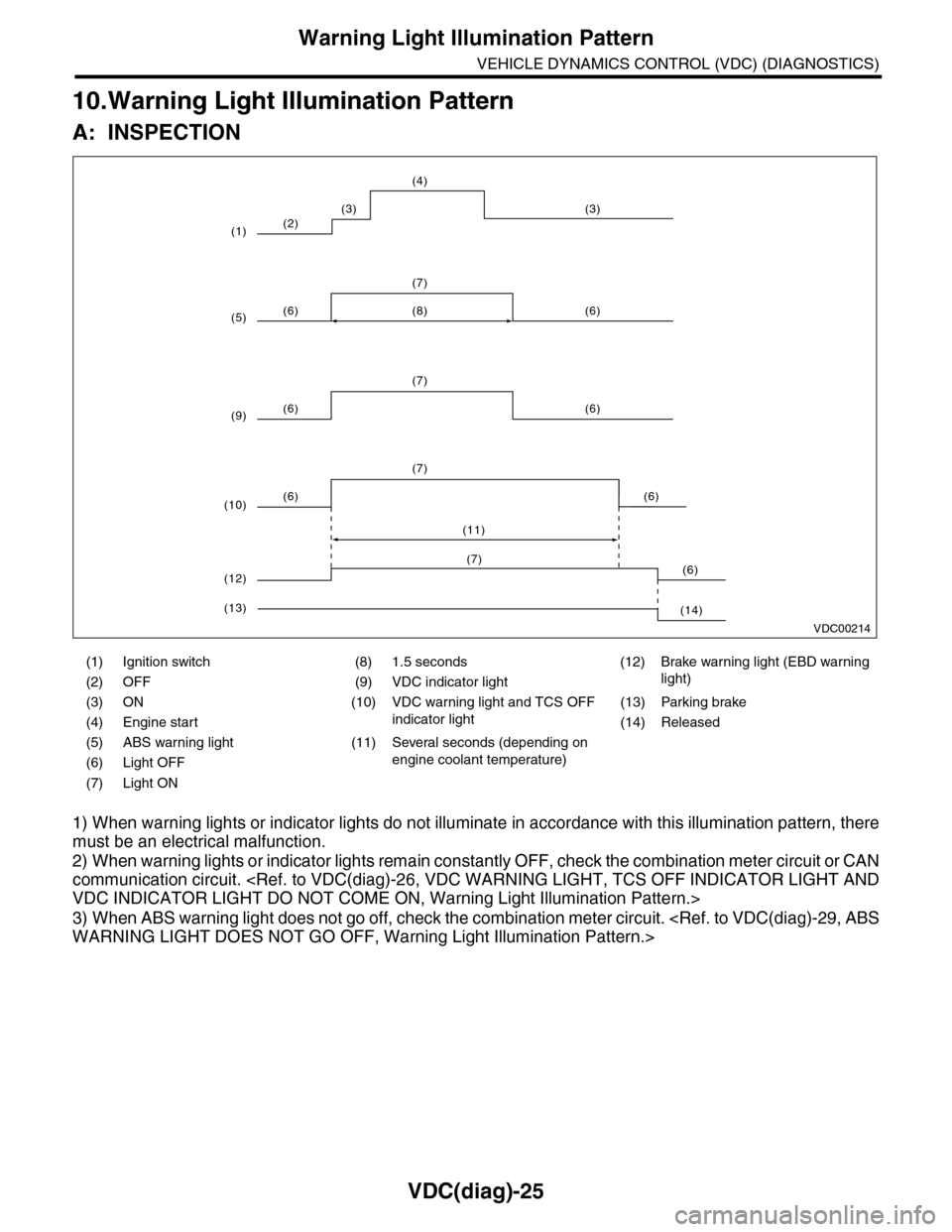

10.Warning Light Illumination Pattern

A: INSPECTION

1) When warning lights or indicator lights do not illuminate in accordance with this illumination pattern, there

must be an electrical malfunction.

2) When warning lights or indicator lights remain constantly OFF, check the combination meter circuit or CAN

communication circuit.

3) When ABS warning light does not go off, check the combination meter circuit.

(1) Ignition switch (8) 1.5 seconds (12) Brake warning light (EBD warning

light)(2) OFF (9) VDC indicator light

(3) ON (10) VDC warning light and TCS OFF

indicator light

(13) Parking brake

(4) Engine start (14) Released

(5) ABS warning light (11) Several seconds (depending on

engine coolant temperature)(6) Light OFF

(7) Light ON

VDC00214

(2)

(6) (6)

(7)

(6) (6)

(7)

(8)

(6) (6)

(7)

(11)

(3) (3)

(4)

(1)

(5)

(9)

(10)

(6)(7)

(12)

(14)(13)

Page 1018 of 2453

VDC(diag)-26

Warning Light Illumination Pattern

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

4) When the VDC indicator light, VDC warning light and TCS OFF indicator light do not go off, check the com-

bination meter circuit or CAN communication circuit.

NOTE:

•Even though the ABS warning light does not go off after 1.5 seconds from ABS warning light illumination,

the ABS system operates normally when the warning light goes off while driving at approximately 12 km/h (7

MPH). However, the ABS system does not work while the ABS warning light is illuminated.

•It may take several minutes before VDC warning light and TCS OFF indicator light goes off if the vehicle

is parked under low temperature for a specified time. This is not defective because it is resulted from low en-

gine coolant temperature.

•With the vehicle jack-up/lift-up or set on free rollers, when the wheels lock or spin after starting the engine,

ABS warning light, VDC warning light and TCS OFF indicator light may illuminate because VDCCM&H/U de-

tects the abnormal conditions from ABS wheel speed sensors. In this case, this is not a malfunction. Perform

the clear memory mode.

B: VDC WARNING LIGHT, TCS OFF INDICATOR LIGHT AND VDC INDICATOR

LIGHT DO NOT COME ON

DETECTING CONDITION:

•Defective combination meter

•Defective CAN communication

TROUBLE SYMPTOM:

When the ignition switch is turned to ON (engine OFF), VDC indicator light, VDC warning light and TCS OFF

indicator light do not come on.

NOTE:

When pressing the TCS OFF switch for more than 10 seconds, the TCS OFF indicator light goes off and can-

not operate any more. When turning the ignition switch from OFF to ON, the OFF operation enabled status

is restored.

Step Check Yes No

1CHECK OTHER INDICATOR LIGHT.

Tu r n t h e i g n i t i o n s w i t c h t o O N .

Does other indicator light illu-

minate soon after “ON”.

Go to step 2.Perform the self-

diagnosis of com-

bination meter.

2CHECK VDCCM.

When the engine does not start, display the

current data of VDCCM using Subaru Select

Monitor.

Is “VDC warning light” output

set to “ON”?

Go to step 3.Replace the

VDCCM&H/U.

3CHECK LAN SYSTEM.

Perfor m the diagnosis for LAN system.

Tr o u b l e C o d e ( D T C ) . >

Is there any fault in LAN sys-

tem?

Pe r for m t h e d ia g -

nosis according to

DTC for LAN sys-

tem.

Go to step 4.

4CHECK COMBINATION METER.

Check the combination meter.

Is combination meter OK? Replace the

VDCCM&H/U.

Repair the combi-

nation meter

assembly.

Page 1023 of 2453

VDC(diag)-31

Warning Light Illumination Pattern

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

F: VDC WARNING LIGHT AND TCS OFF INDICATOR LIGHT DO NOT GO OFF

DETECTING CONDITION:

•Defective combination meter

•Defective CAN communication

•Defective engine

•TCS OFF switch is shorted.

TROUBLE SYMPTOM:

When starting the engine, TCS OFF indicator light is kept ON.

NOTE:

When pressing the TCS OFF switch for more than 10 seconds, the TCS OFF indicator light goes off and can-

not operate any more. When turning the ignition switch from OFF to ON, the OFF operation enabled status

is restored.

Step Check Yes No

1READ DTC.

Read the DTC.

Is DTC displayed? Perform the diag-

nosis according to

DTC.

Go to step 2.

2CHECK ENGINE.Does the malfunction indicator

light illuminate?

Repair the engine. Go to step 3.

3CHECK ENGINE COOLANT TEMPERA-

TURE.

War m up the engine and check if VDC war ning

light and TCS OFF indicator light illumination

condition changes.

When the engine coolant tem-

perature is too low, VDC warn-

ing light and TCS OFF

indicator light illuminate. Do

the lights go off when the

engine is warmed-up?

Normal Go to step 4.

4CHECK TCS OFF SWITCH.

Remove and check TCS OFF switch.

Is TCS OFF switch normal? Go to step 5.Replace the TCS

OFF switch.

5CHECK LAN SYSTEM.

Perfor m the diagnosis for LAN system.

Tr o u b l e C o d e ( D T C ) . >

Is there any fault in LAN sys-

tem?

Pe r for m t h e d ia g -

nosis according to

DTC for LAN sys-

tem.

Go to step 6.

6CHECK COMBINATION METER.

Check the combination meter.

Is combination meter OK? Replace the

VDCCM&H/U.

Repair the combi-

nation meter.

Page 1121 of 2453

CO(H6DO)-2

General Description

COOLING

1. General Description

A: SPECIFICATION

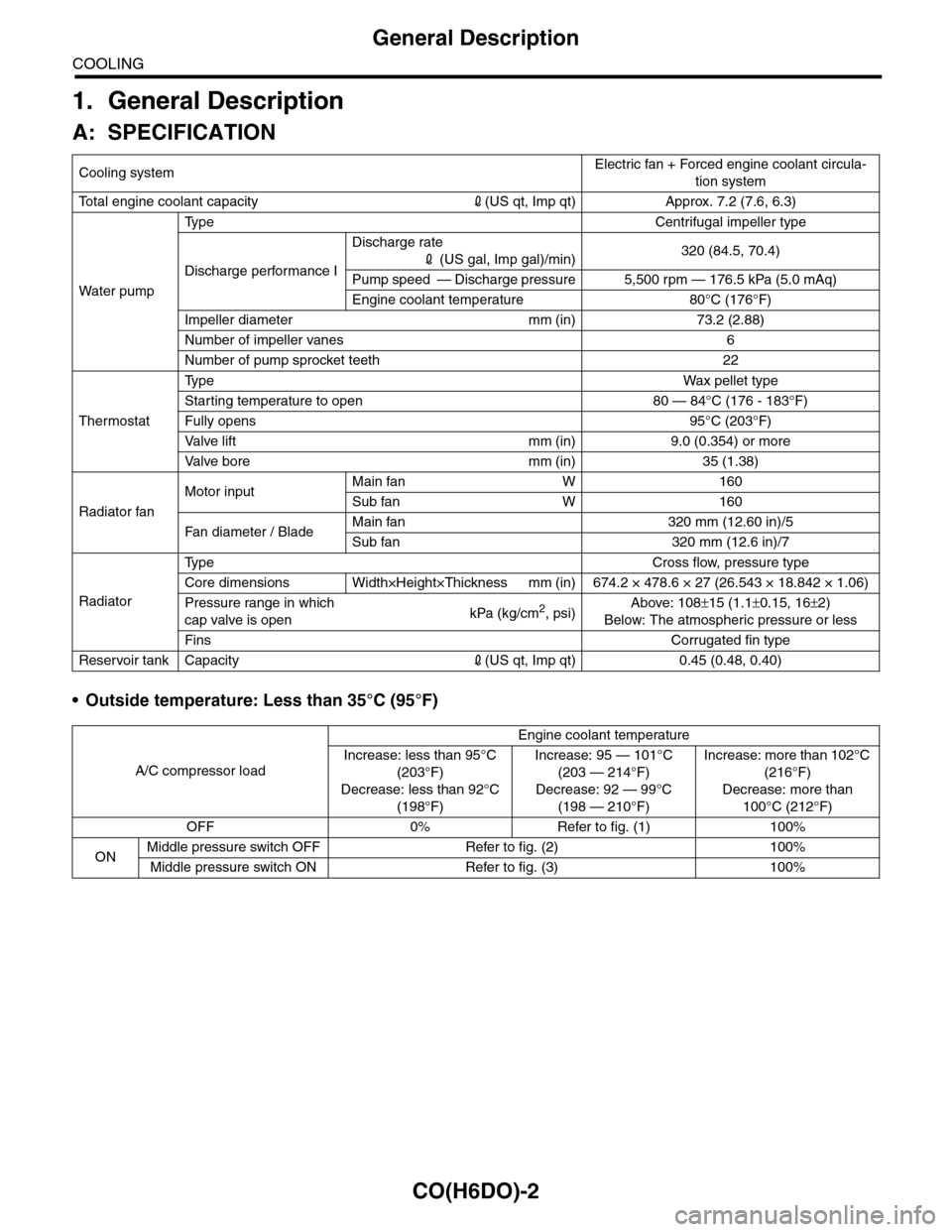

•Outside temperature: Less than 35°C (95°F)

Cooling systemElectric fan + Forced engine coolant circula-

tion system

To t a l e n g i n e c o o l a n t c a p a c i t y2(US qt, Imp qt) Approx. 7.2 (7.6, 6.3)

Wa t er p u mp

Ty p e C e n t r i f u g a l i m p e l l e r t y p e

Discharge performance I

Discharge rate

2 (US gal, Imp gal)/min)320 (84.5, 70.4)

Pump speed — Discharge pressure 5,500 rpm — 176.5 kPa (5.0 mAq)

Engine coolant temperature 80°C (176°F)

Impeller diameter mm (in) 73.2 (2.88)

Number of impeller vanes 6

Number of pump sprocket teeth 22

Thermostat

Ty p eWa x p el l et t yp e

Starting temperature to open 80 — 84°C (176 - 183°F)

Fully opens 95°C (203°F)

Va l ve l i f t m m ( i n ) 9 . 0 ( 0 . 3 5 4 ) o r m o r e

Va l ve b o r e m m ( i n ) 3 5 ( 1 . 3 8 )

Radiator fan

Motor inputMain fan W 160

Sub fan W 160

Fan di a me t er / B la deMain fan 320 mm (12.60 in)/5

Sub fan 320 mm (12.6 in)/7

Radiator

Ty p e C r o s s f l o w , p r e s s u r e t y p e

Core dimensions Width×Height×Thickness mm (in) 674.2 × 478.6 × 27 (26.543 × 18.842 × 1.06)

Pressure range in which

cap valve is openkPa (kg/cm2, psi)Above: 108±15 (1.1±0.15, 16±2)

Below: The atmospheric pressure or less

FinsCorrugated fin type

Reservoir tank Capacity2(US qt, Imp qt) 0.45 (0.48, 0.40)

A/C compressor load

Engine coolant temperature

Increase: less than 95°C

(203°F)

Decrease: less than 92°C

(198°F)

Increase: 95 — 101°C

(203 — 214°F)

Decrease: 92 — 99°C

(198 — 210°F)

Increase: more than 102°C

(216°F)

Decrease: more than

100°C (212°F)

OFF 0% Refer to fig. (1) 100%

ONMiddle pressure switch OFF Refer to fig. (2) 100%

Middle pressure switch ON Refer to fig. (3) 100%

Page 1122 of 2453

CO(H6DO)-3

General Description

COOLING

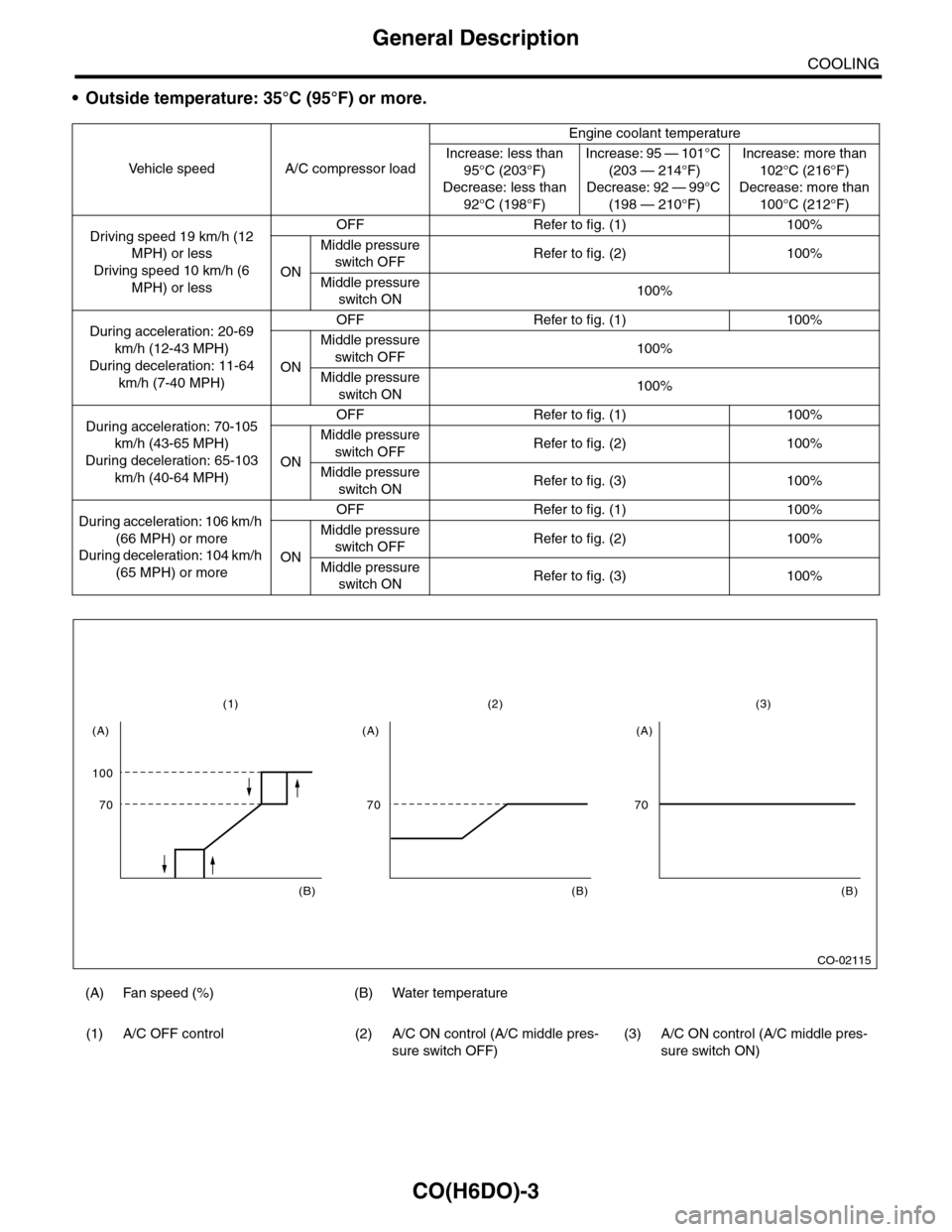

•Outside temperature: 35°C (95°F) or more.

Ve h i c l e s p e e d A / C c o m p r e s s o r l o a d

Engine coolant temperature

Increase: less than

95°C (203°F)

Decrease: less than

92°C (198°F)

Increase: 95 — 101°C

(203 — 214°F)

Decrease: 92 — 99°C

(198 — 210°F)

Increase: more than

102°C (216°F)

Decrease: more than

100°C (212°F)

Driving speed 19 km/h (12

MPH) or less

Driving speed 10 km/h (6

MPH) or less

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ON100%

During acceleration: 20-69

km/h (12-43 MPH)

During deceleration: 11-64

km/h (7-40 MPH)

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFF100%

Middle pressure

switch ON100%

During acceleration: 70-105

km/h (43-65 MPH)

During deceleration: 65-103

km/h (40-64 MPH)

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ONRefer to fig. (3) 100%

During acceleration: 106 km/h

(66 MPH) or more

During deceleration: 104 km/h

(65 MPH) or more

OFF Refer to fig. (1) 100%

ON

Middle pressure

switch OFFRefer to fig. (2) 100%

Middle pressure

switch ONRefer to fig. (3) 100%

(A) Fan speed (%) (B) Water temperature

(1) A/C OFF control (2) A/C ON control (A/C middle pres-

sure switch OFF)

(3) A/C ON control (A/C middle pres-

sure switch ON)

CO-02115

100

(1)

70

(A)

(B)

(2)

70

(A)

(B)

(3)

70

(A)

(B)

Page 1124 of 2453

CO(H6DO)-5

General Description

COOLING

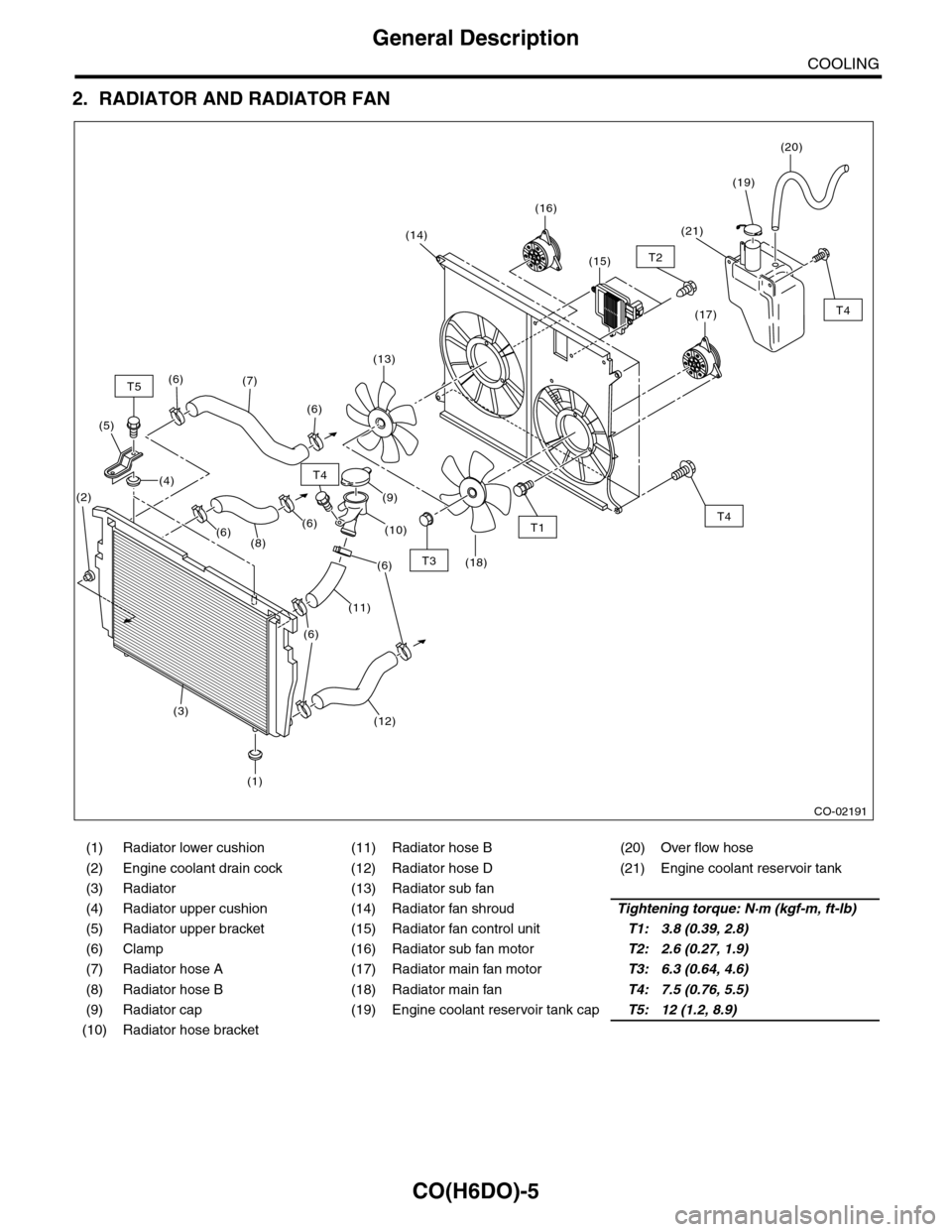

2. RADIATOR AND RADIATOR FAN

(1) Radiator lower cushion (11) Radiator hose B (20) Over flow hose

(2) Engine coolant drain cock (12) Radiator hose D (21) Engine coolant reservoir tank

(3) Radiator (13) Radiator sub fan

(4) Radiator upper cushion (14) Radiator fan shroudTightening torque: N·m (kgf-m, ft-lb)

(5) Radiator upper bracket (15) Radiator fan control unitT1: 3.8 (0.39, 2.8)

(6) Clamp (16) Radiator sub fan motorT2: 2.6 (0.27, 1.9)

(7) Radiator hose A (17) Radiator main fan motorT3: 6.3 (0.64, 4.6)

(8) Radiator hose B (18) Radiator main fanT4: 7.5 (0.76, 5.5)

(9) Radiator cap (19) Engine coolant reservoir tank capT5: 12 (1.2, 8.9)

(10) Radiator hose bracket

CO-02191

T4

T4

T4

T2

T1

T3

T5(7)

(6)

(13)

(18)

(14)

(16)

(17)

(15)

(21)

(19)

(20)

(9)

(10)

(6)

(11)

(6)

(1)

(3)

(2)

(12)

(6)

(8)

(4)

(5)

(6)(6)

Page 1127 of 2453

CO(H6DO)-8

Radiator Fan System

COOLING

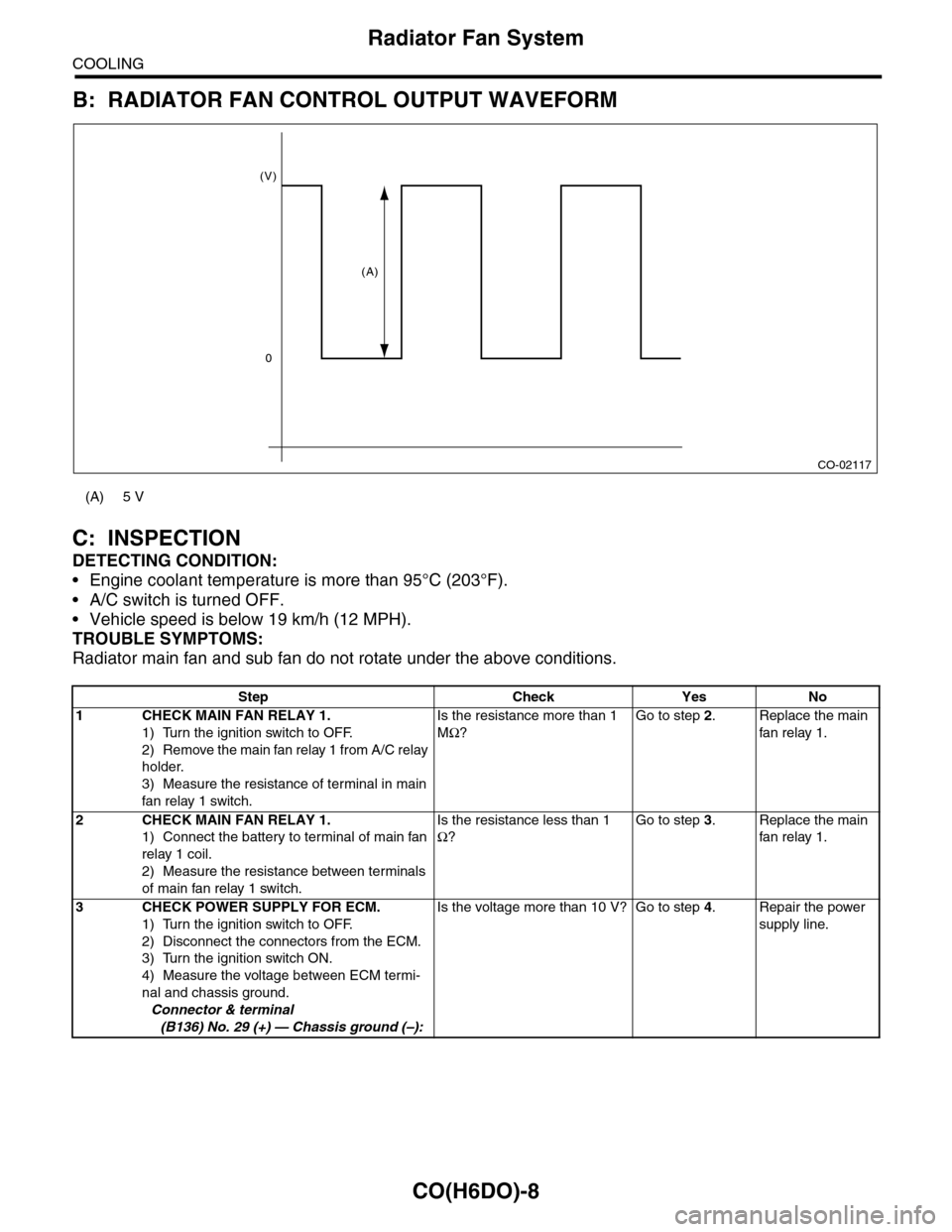

B: RADIATOR FAN CONTROL OUTPUT WAVEFORM

C: INSPECTION

DETECTING CONDITION:

•Engine coolant temperature is more than 95°C (203°F).

•A/C switch is turned OFF.

•Vehicle speed is below 19 km/h (12 MPH).

TROUBLE SYMPTOMS:

Radiator main fan and sub fan do not rotate under the above conditions.

(A) 5 V

Step Check Yes No

1CHECK MAIN FAN RELAY 1.

1) Turn the ignition switch to OFF.

2) Remove the main fan relay 1 from A/C relay

holder.

3) Measure the resistance of terminal in main

fan relay 1 switch.

Is the resistance more than 1

MΩ?

Go to step 2.Replace the main

fan relay 1.

2CHECK MAIN FAN RELAY 1.

1) Connect the battery to terminal of main fan

relay 1 coil.

2) Measure the resistance between terminals

of main fan relay 1 switch.

Is the resistance less than 1

Ω?

Go to step 3.Replace the main

fan relay 1.

3CHECK POWER SUPPLY FOR ECM.

1) Turn the ignition switch to OFF.

2) Disconnect the connectors from the ECM.

3) Turn the ignition switch ON.

4) Measure the voltage between ECM termi-

nal and chassis ground.

Connector & terminal

(B136) No. 29 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Repair the power

supply line.

CO-02117

(V)

0

(A)

Page 1129 of 2453

CO(H6DO)-10

Engine Coolant

COOLING

3. Engine Coolant

A: REPLACEMENT

1. DRAINING OF ENGINE COOLANT

1) Lift-up the vehicle.

2) Remove the under cover.

3) Remove the drain plug to drain engine coolant

into container.

NOTE:

Remove the radiator cap so that engine coolant will

drain faster.

4) Install the drain plug.

2. FILLING OF ENGINE COOLANT

1) Pour cooling system conditioner through the fill-

er neck.

Cooling system protective agent:

COOLING SYSTEM CONDITIONER (Part No.

SOA345001)

2) Pour engine coolant into the radiator up to the

filler neck position.

Coolant level:

Refer to “SPECIFICATION” for the engine

coolant capacity.

NOTE:

The SUBARU Genuine Coolant containing anti-

freeze and anti-rust agents is especially made for

SUBARU engine, which has an aluminum crank-

case. Always use SUBARU Genuine Coolant,

since other coolant may cause corrosion.

3) Open the air bleeding valve on the heater hose

side.

4) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

5) When engine coolant has come out from the air

bleeding valve on the heater hose side, close the

valve.

6) Open the air bleeding valve on the radiator side.

7) If the engine coolant level drops, add engine

coolant into radiator up to the filler neck position.

8) When engine coolant has come out from the air

bleeding valve on the radiator side, close the valve.

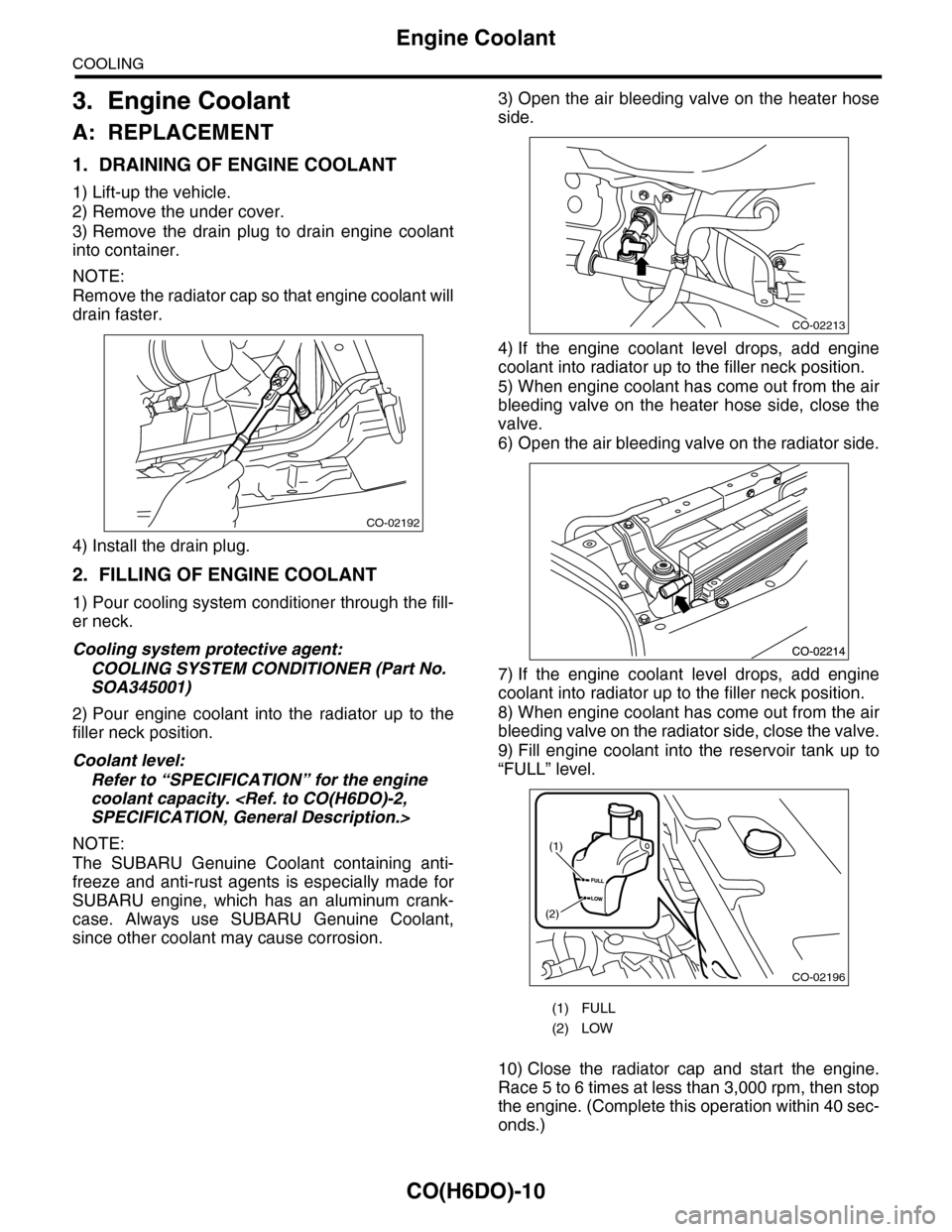

9) Fill engine coolant into the reservoir tank up to

“FULL” level.

10) Close the radiator cap and start the engine.

Race 5 to 6 times at less than 3,000 rpm, then stop

the engine. (Complete this operation within 40 sec-

onds.)

CO-02192

(1) FULL

(2) LOW

CO-02213

CO-02196

(1)

(2)

Page 1130 of 2453

CO(H6DO)-11

Engine Coolant

COOLING

11) Wait for one minute after the engine stops,

open the radiator cap. If the engine coolant level

drops, add engine coolant into radiator up to the fill-

er neck position.

12) Perform the procedures 10) and 11) again.

13) Attach the radiator cap and reservoir tank cap

properly.

14) Start the engine and operate the heater at max-

imum hot position and the blower speed setting to

“LO.”

15) Run the engine at 2,000 rpm or less until radia-

tor fan starts and stops.

NOTE:

•Be careful with the engine coolant temperature

gauge to prevent overheating.

•If the radiator hose becomes harden with the

pressure of engine coolant, air bleeding operation

seems to be almost completed.

16) Stop the engine and wait until the engine cool-

ant temperature lowers to 30°C (86°F).

17) Open the radiator cap. If the engine coolant lev-

el drops, add engine coolant into radiator up to the

filler neck position and reservoir tank to the “FULL”

level.

18) Attach the radiator cap and reservoir tank cap

properly.

19) Set the heater setting to maximum hot position

and the blower speed setting to “LO” and start the

engine. Perform racing at less than 3,000 rpm. If

the flowing sound is heard at this time, perform the

procedures from 15) again.

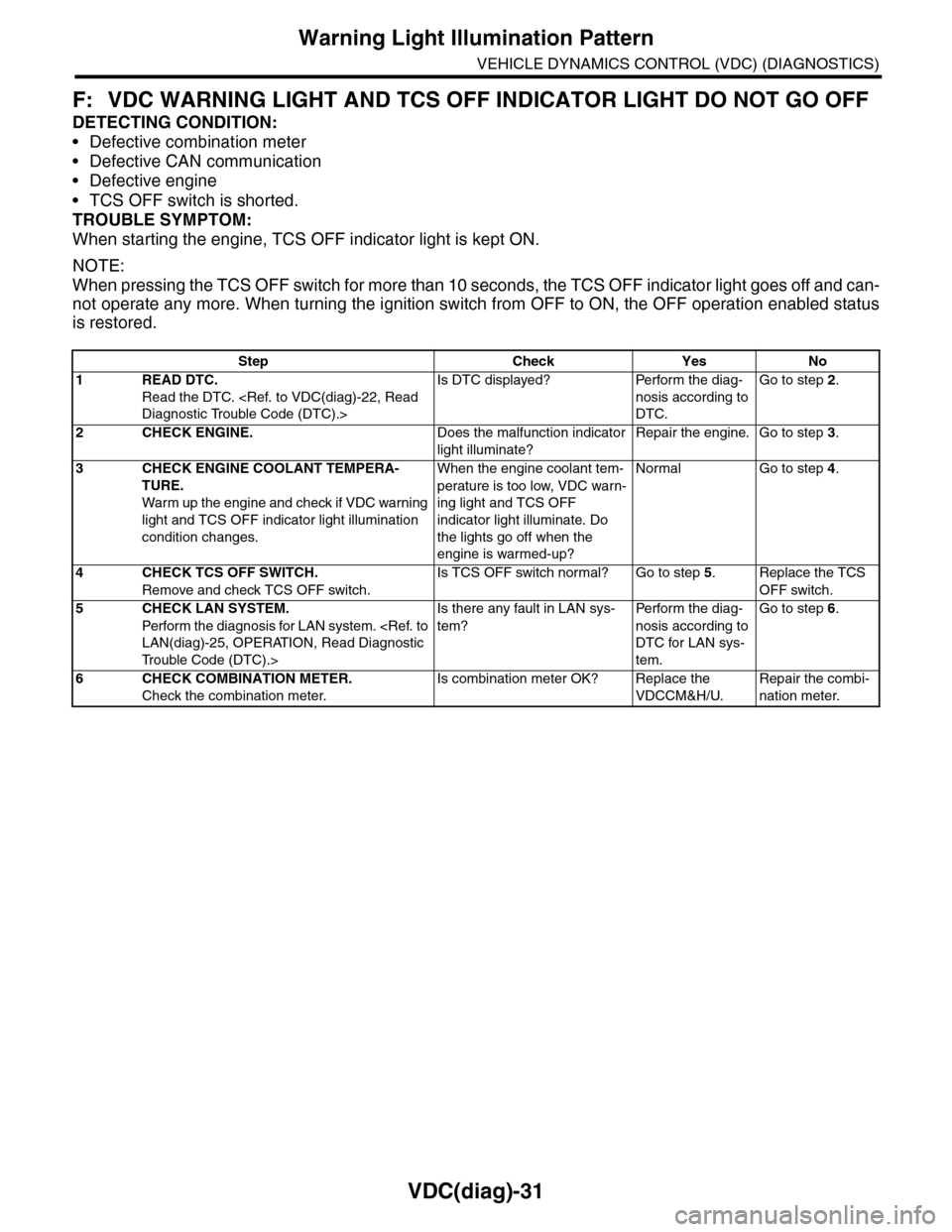

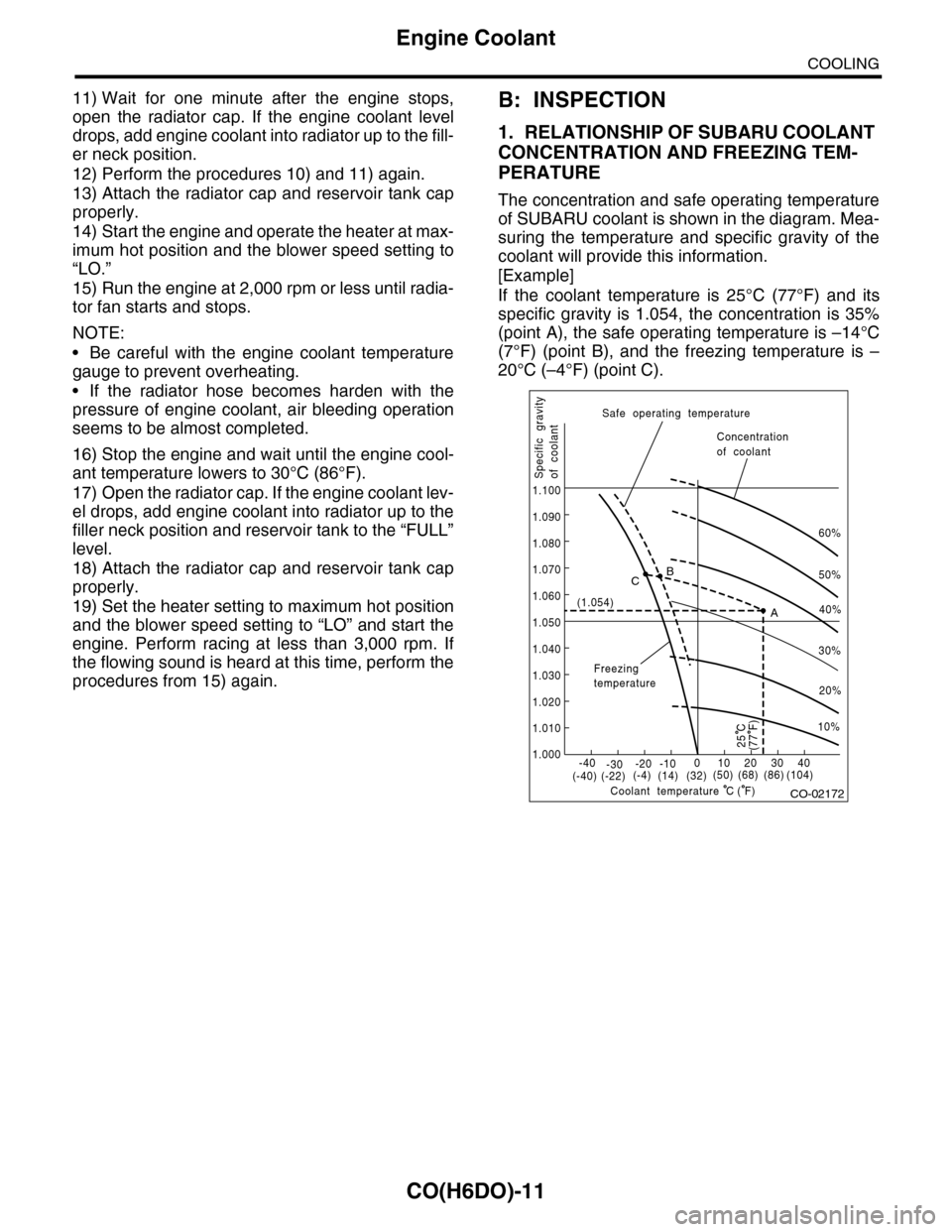

B: INSPECTION

1. RELATIONSHIP OF SUBARU COOLANT

CONCENTRATION AND FREEZING TEM-

PERATURE

The concentration and safe operating temperature

of SUBARU coolant is shown in the diagram. Mea-

suring the temperature and specific gravity of the

coolant will provide this information.

[Example]

If the coolant temperature is 25°C (77°F) and its

specific gravity is 1.054, the concentration is 35%

(point A), the safe operating temperature is –14°C

(7°F) (point B), and the freezing temperature is –

20°C (–4°F) (point C).

CO-02172

60%

(1.054)

1.000

1.010

1.020

1.030

1.040

1.050

1.060

1.070

1.080

1.090

1.100

Safe operating temperature

Freezingtemperature

Concentrationof coolant

Specific gravityof coolant

Coolant temperature

B

A

C

-40(-40) (-22)(-4)(14)(32)(50) (68) (86)

( F)

(104)-30-20 -10010203040

(77 F)

50%

40%

30%

20%

25 C

10%

C