ECU SUBARU TRIBECA 2009 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 313 of 2453

GW-18

Windshield Glass

GLASS/WINDOWS/MIRRORS

13.Windshield Glass

A: REMOVAL

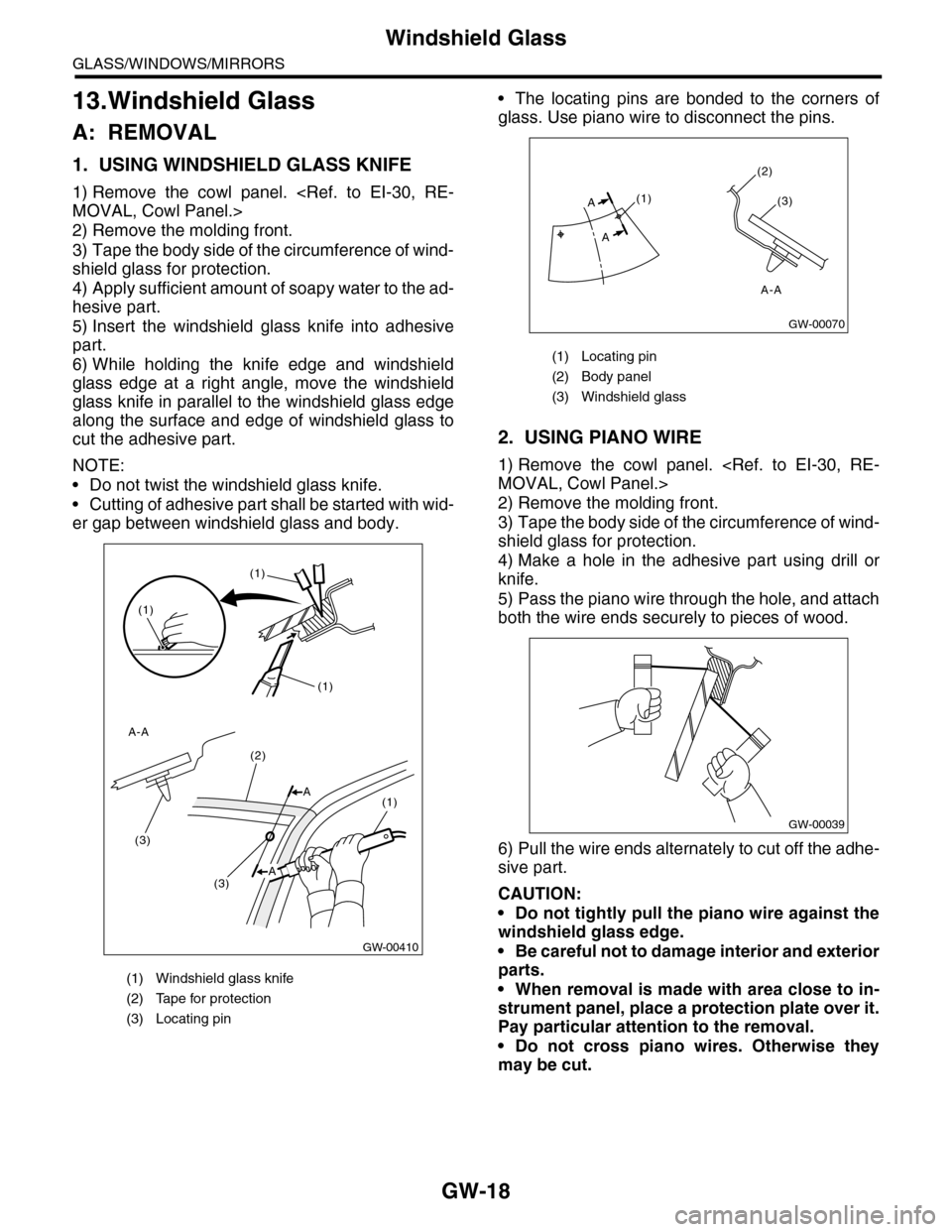

1. USING WINDSHIELD GLASS KNIFE

1) Remove the cowl panel.

2) Remove the molding front.

3) Tape the body side of the circumference of wind-

shield glass for protection.

4) Apply sufficient amount of soapy water to the ad-

hesive part.

5) Insert the windshield glass knife into adhesive

part.

6) While holding the knife edge and windshield

glass edge at a right angle, move the windshield

glass knife in parallel to the windshield glass edge

along the surface and edge of windshield glass to

cut the adhesive part.

NOTE:

•Do not twist the windshield glass knife.

•Cutting of adhesive part shall be started with wid-

er gap between windshield glass and body.

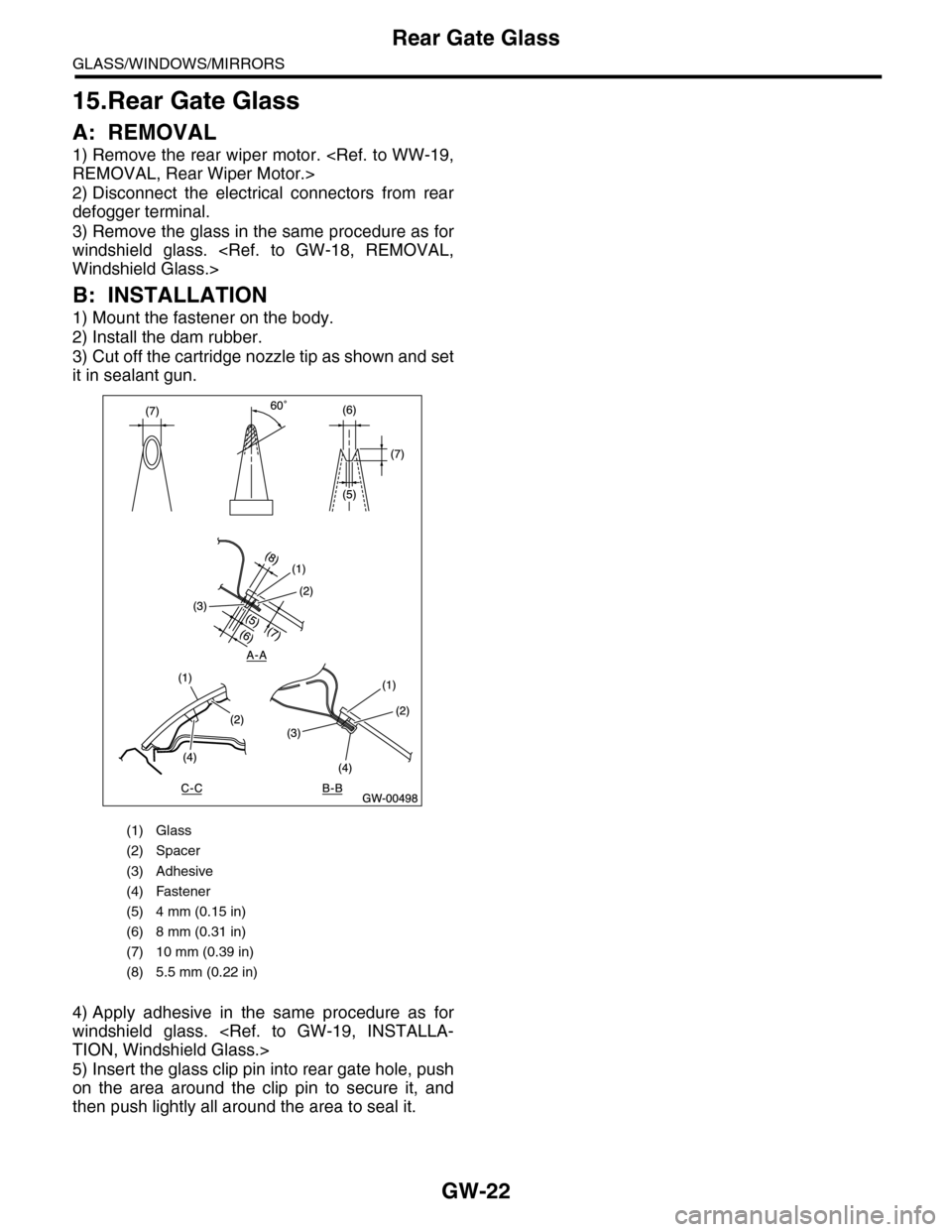

•The locating pins are bonded to the corners of

glass. Use piano wire to disconnect the pins.

2. USING PIANO WIRE

1) Remove the cowl panel.

2) Remove the molding front.

3) Tape the body side of the circumference of wind-

shield glass for protection.

4) Make a hole in the adhesive part using drill or

knife.

5) Pass the piano wire through the hole, and attach

both the wire ends securely to pieces of wood.

6) Pull the wire ends alternately to cut off the adhe-

sive part.

CAUTION:

•Do not tightly pull the piano wire against the

windshield glass edge.

•Be careful not to damage interior and exterior

parts.

•When removal is made with area close to in-

strument panel, place a protection plate over it.

Pay particular attention to the removal.

•Do not cross piano wires. Otherwise they

may be cut.

(1) Windshield glass knife

(2) Tape for protection

(3) Locating pin

GW-00410

(1)

(1)

(1)

(3)

(3)

(2)

(1)A

A-A

A

(1) Locating pin

(2) Body panel

(3) Windshield glass

(1)

(2)

(3)

A

A

GW-00070

A-A

GW-00039

Page 317 of 2453

GW-22

Rear Gate Glass

GLASS/WINDOWS/MIRRORS

15.Rear Gate Glass

A: REMOVAL

1) Remove the rear wiper motor.

2) Disconnect the electrical connectors from rear

defogger terminal.

3) Remove the glass in the same procedure as for

windshield glass.

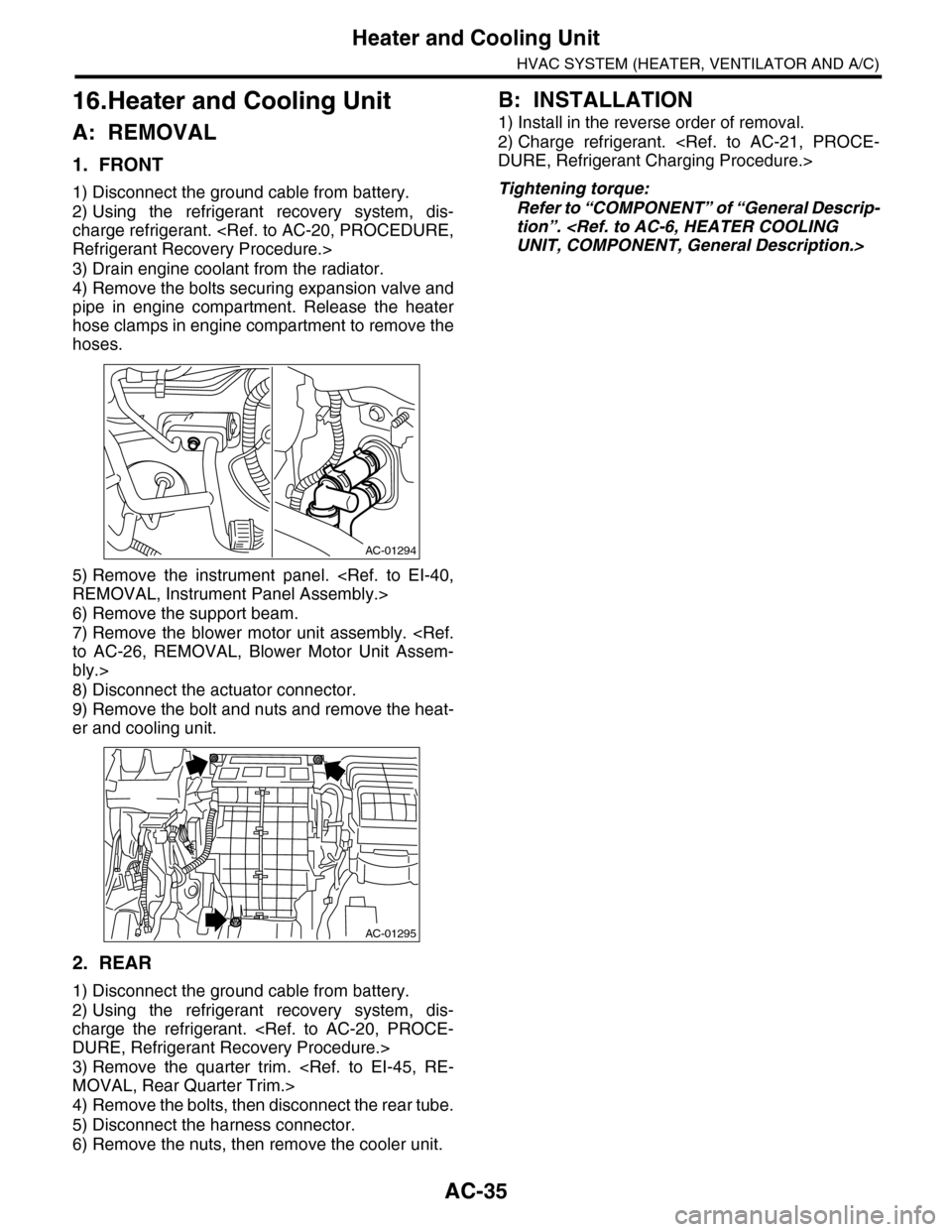

B: INSTALLATION

1) Mount the fastener on the body.

2) Install the dam rubber.

3) Cut off the cartridge nozzle tip as shown and set

it in sealant gun.

4) Apply adhesive in the same procedure as for

windshield glass.

5) Insert the glass clip pin into rear gate hole, push

on the area around the clip pin to secure it, and

then push lightly all around the area to seal it.

(1) Glass

(2) Spacer

(3) Adhesive

(4) Fastener

(5) 4 mm (0.15 in)

(6) 8 mm (0.31 in)

(7) 10 mm (0.39 in)

(8) 5.5 mm (0.22 in)

Page 361 of 2453

AC-35

Heater and Cooling Unit

HVAC SYSTEM (HEATER, VENTILATOR AND A/C)

16.Heater and Cooling Unit

A: REMOVAL

1. FRONT

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge refrigerant.

3) Drain engine coolant from the radiator.

4) Remove the bolts securing expansion valve and

pipe in engine compartment. Release the heater

hose clamps in engine compartment to remove the

hoses.

5) Remove the instrument panel.

6) Remove the support beam.

7) Remove the blower motor unit assembly.

bly.>

8) Disconnect the actuator connector.

9) Remove the bolt and nuts and remove the heat-

er and cooling unit.

2. REAR

1) Disconnect the ground cable from battery.

2) Using the refrigerant recovery system, dis-

charge the refrigerant.

3) Remove the quarter trim.

4) Remove the bolts, then disconnect the rear tube.

5) Disconnect the harness connector.

6) Remove the nuts, then remove the cooler unit.

B: INSTALLATION

1) Install in the reverse order of removal.

2) Charge refrigerant.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion”.

AC-01294

AC-01295

Page 418 of 2453

IM (diag)-2

Basic Diagnostic Procedure

IMMOBILIZER (DIAGNOSTICS)

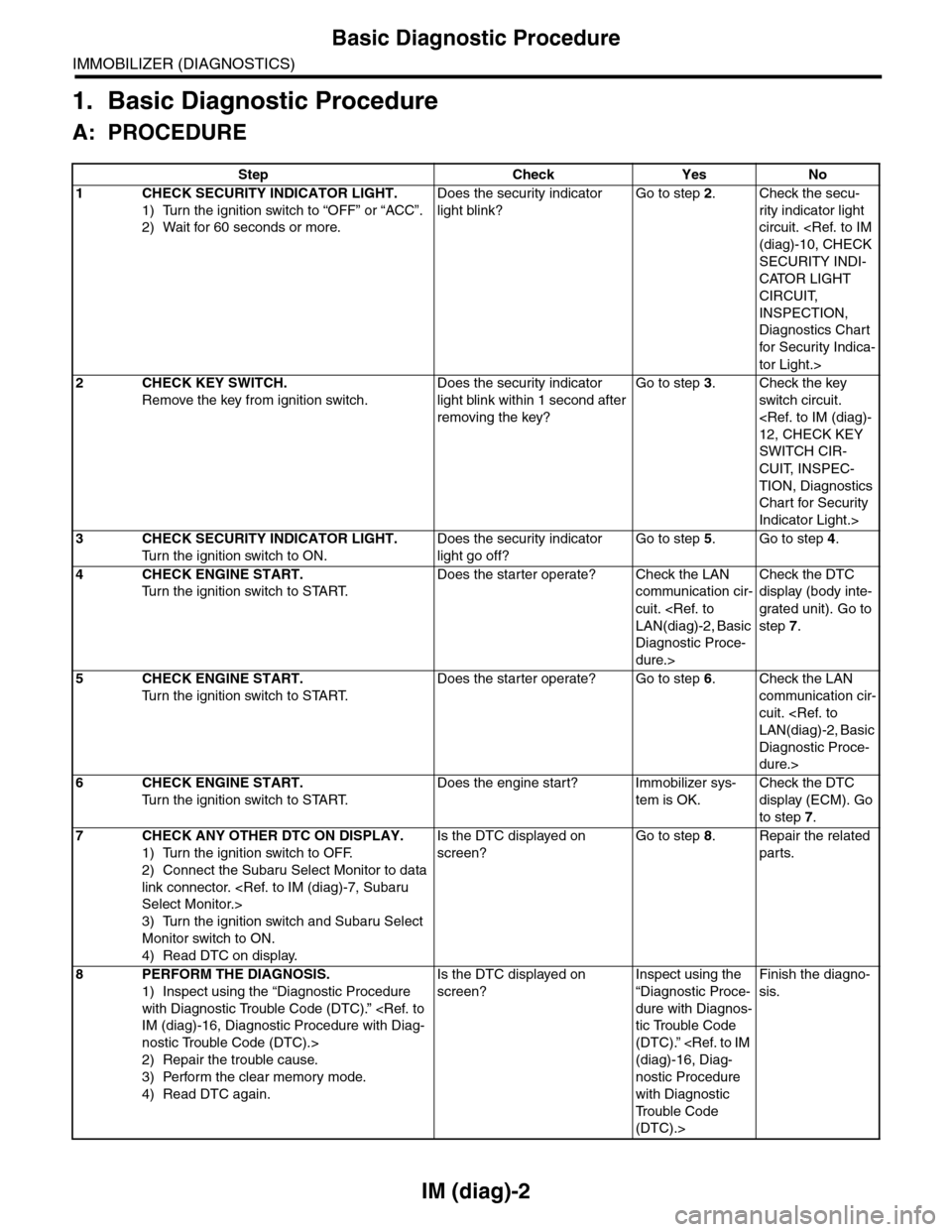

1. Basic Diagnostic Procedure

A: PROCEDURE

Step Check Yes No

1CHECK SECURITY INDICATOR LIGHT.

1) Turn the ignition switch to “OFF” or “ACC”.

2) Wait for 60 seconds or more.

Does the security indicator

light blink?

Go to step 2.Check the secu-

rity indicator light

circuit.

SECURITY INDI-

CATOR LIGHT

CIRCUIT,

INSPECTION,

Diagnostics Chart

for Secur ity Indica-

tor Light.>

2CHECK KEY SWITCH.

Remove the key from ignition switch.

Does the security indicator

light blink within 1 second after

removing the key?

Go to step 3.Check the key

switch circuit.

SWITCH CIR-

CUIT, INSPEC-

TION, Diagnostics

Chart for Security

Indicator Light.>

3CHECK SECURITY INDICATOR LIGHT.

Tu r n t h e i g n i t i o n s w i t c h t o O N .

Does the security indicator

light go off?

Go to step 5.Go to step 4.

4CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the starter operate? Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

Check the DTC

display (body inte-

grated unit). Go to

step 7.

5CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the starter operate? Go to step 6.Check the LAN

communication cir-

cuit.

Diagnostic Proce-

dure.>

6CHECK ENGINE START.

Tu r n t h e i g n i t i o n s w i t c h t o S TA R T.

Does the engine start? Immobilizer sys-

tem is OK.

Check the DTC

display (ECM). Go

to step 7.

7CHECK ANY OTHER DTC ON DISPLAY.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch and Subaru Select

Monitor switch to ON.

4) Read DTC on display.

Is the DTC displayed on

screen?

Go to step 8.Repair the related

parts.

8PERFORM THE DIAGNOSIS.

1) Inspect using the “Diagnostic Procedure

with Diagnostic Trouble Code (DTC).”

nostic Trouble Code (DTC).>

2) Repair the trouble cause.

3) Perform the clear memory mode.

4) Read DTC again.

Is the DTC displayed on

screen?

Inspect using the

“Diagnostic Proce-

dure with Diagnos-

tic Trouble Code

(DTC).”

nostic Procedure

with Diagnostic

Tr o u b l e C o d e

(DTC).>

Finish the diagno-

sis.

Page 419 of 2453

IM (diag)-3

General Description

IMMOBILIZER (DIAGNOSTICS)

2. General Description

A: CAUTION

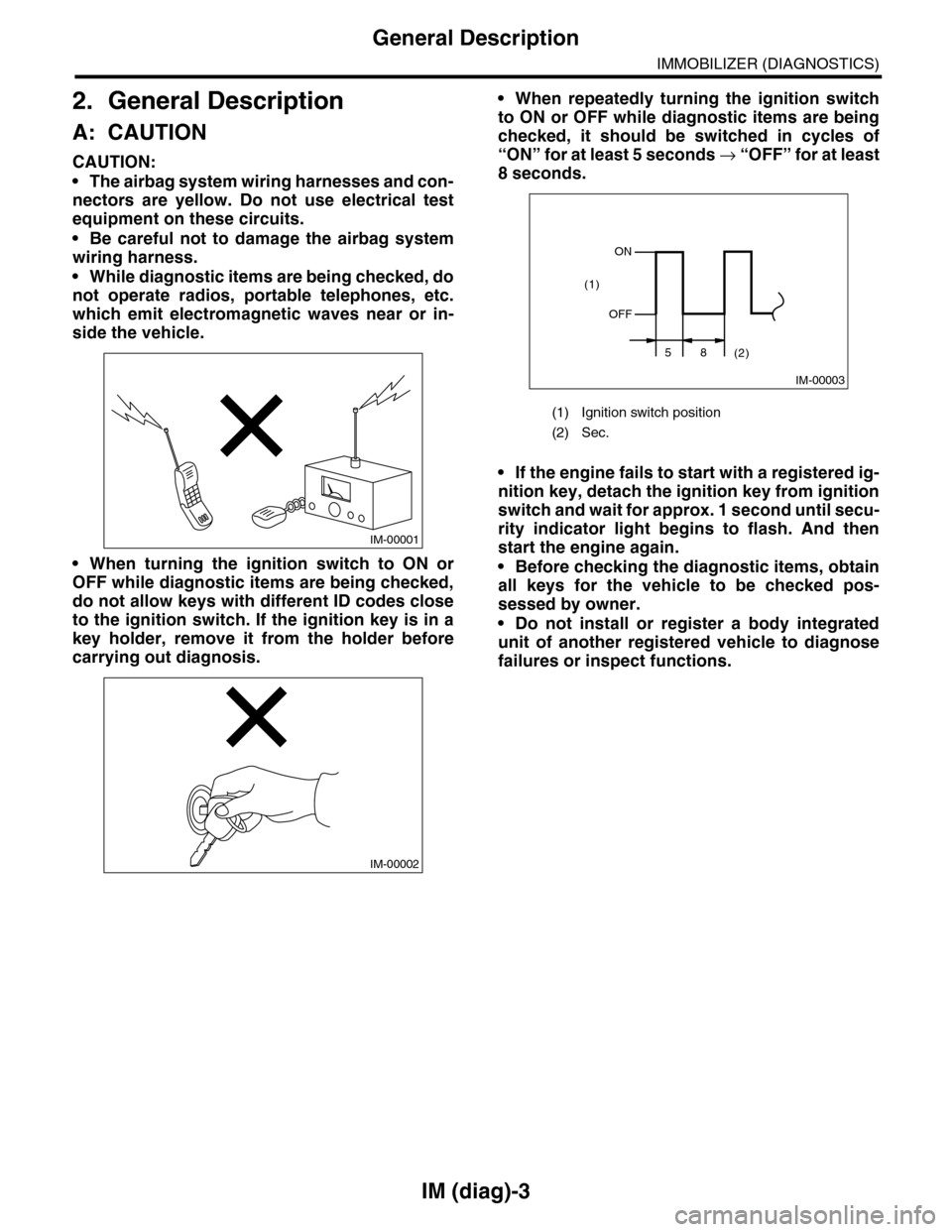

CAUTION:

•The airbag system wiring harnesses and con-

nectors are yellow. Do not use electrical test

equipment on these circuits.

•Be careful not to damage the airbag system

wiring harness.

•While diagnostic items are being checked, do

not operate radios, portable telephones, etc.

which emit electromagnetic waves near or in-

side the vehicle.

•When turning the ignition switch to ON or

OFF while diagnostic items are being checked,

do not allow keys with different ID codes close

to the ignition switch. If the ignition key is in a

key holder, remove it from the holder before

carrying out diagnosis.

•When repeatedly turning the ignition switch

to ON or OFF while diagnostic items are being

checked, it should be switched in cycles of

“ON” for at least 5 seconds → “O F F ” fo r a t le a s t

8 seconds.

•If the engine fails to start with a registered ig-

nition key, detach the ignition key from ignition

switch and wait for approx. 1 second until secu-

rity indicator light begins to flash. And then

start the engine again.

•Before checking the diagnostic items, obtain

all keys for the vehicle to be checked pos-

sessed by owner.

•Do not install or register a body integrated

unit of another registered vehicle to diagnose

failures or inspect functions.

IM-00001

IM-00002

(1) Ignition switch position

(2) Sec.

IM-00003

ON

OFF

58(2)

(1)

Page 421 of 2453

IM (diag)-5

Electrical Component Location

IMMOBILIZER (DIAGNOSTICS)

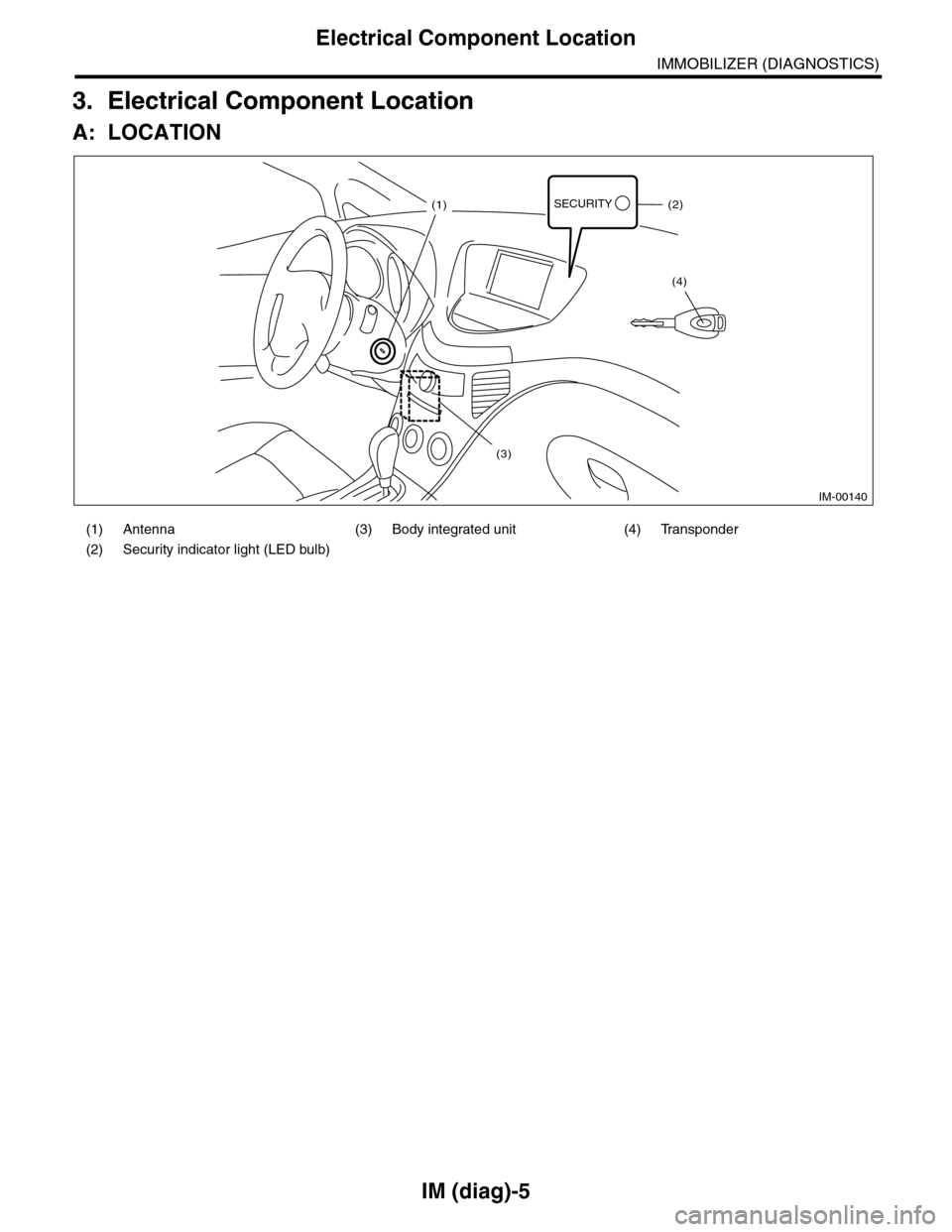

3. Electrical Component Location

A: LOCATION

(1) Antenna (3) Body integrated unit (4) Transponder

(2) Security indicator light (LED bulb)

IM-00140

SECURITY(1)(2)

(4)

(3)

Page 423 of 2453

IM (diag)-7

Subaru Select Monitor

IMMOBILIZER (DIAGNOSTICS)

5. Subaru Select Monitor

A: OPERATION

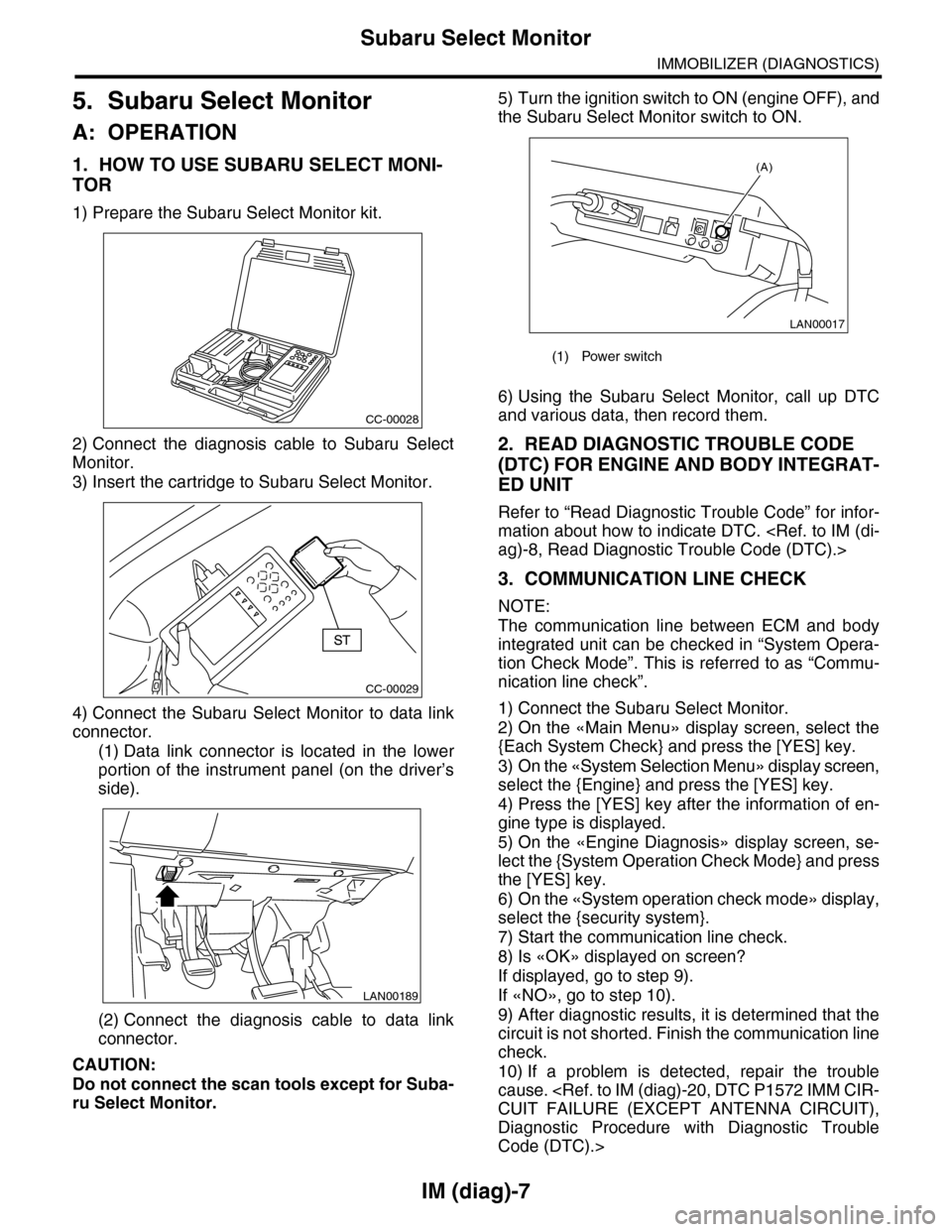

1. HOW TO USE SUBARU SELECT MONI-

TOR

1) Prepare the Subaru Select Monitor kit.

2) Connect the diagnosis cable to Subaru Select

Monitor.

3) Insert the cartridge to Subaru Select Monitor.

4) Connect the Subaru Select Monitor to data link

connector.

(1) Data link connector is located in the lower

portion of the instrument panel (on the driver’s

side).

(2) Connect the diagnosis cable to data link

connector.

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor.

5) Turn the ignition switch to ON (engine OFF), and

the Subaru Select Monitor switch to ON.

6) Using the Subaru Select Monitor, call up DTC

and various data, then record them.

2. READ DIAGNOSTIC TROUBLE CODE

(DTC) FOR ENGINE AND BODY INTEGRAT-

ED UNIT

Refer to “Read Diagnostic Trouble Code” for infor-

mation about how to indicate DTC.

3. COMMUNICATION LINE CHECK

NOTE:

The communication line between ECM and body

integrated unit can be checked in “System Opera-

tion Check Mode”. This is referred to as “Commu-

nication line check”.

1) Connect the Subaru Select Monitor.

2) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

3) On the «System Selection Menu» display screen,

select the {Engine} and press the [YES] key.

4) Press the [YES] key after the information of en-

gine type is displayed.

5) On the «Engine Diagnosis» display screen, se-

lect the {System Operation Check Mode} and press

the [YES] key.

6) On the «System operation check mode» display,

select the {security system}.

7) Start the communication line check.

8) Is «OK» displayed on screen?

If displayed, go to step 9).

If «NO», go to step 10).

9) After diagnostic results, it is determined that the

circuit is not shorted. Finish the communication line

check.

10) If a problem is detected, repair the trouble

cause.

Diagnostic Procedure with Diagnostic Trouble

Code (DTC).>

CC-00028

CC-00029

LAN00189

(1) Power switch

LAN00017

(A)

Page 426 of 2453

IM (diag)-10

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

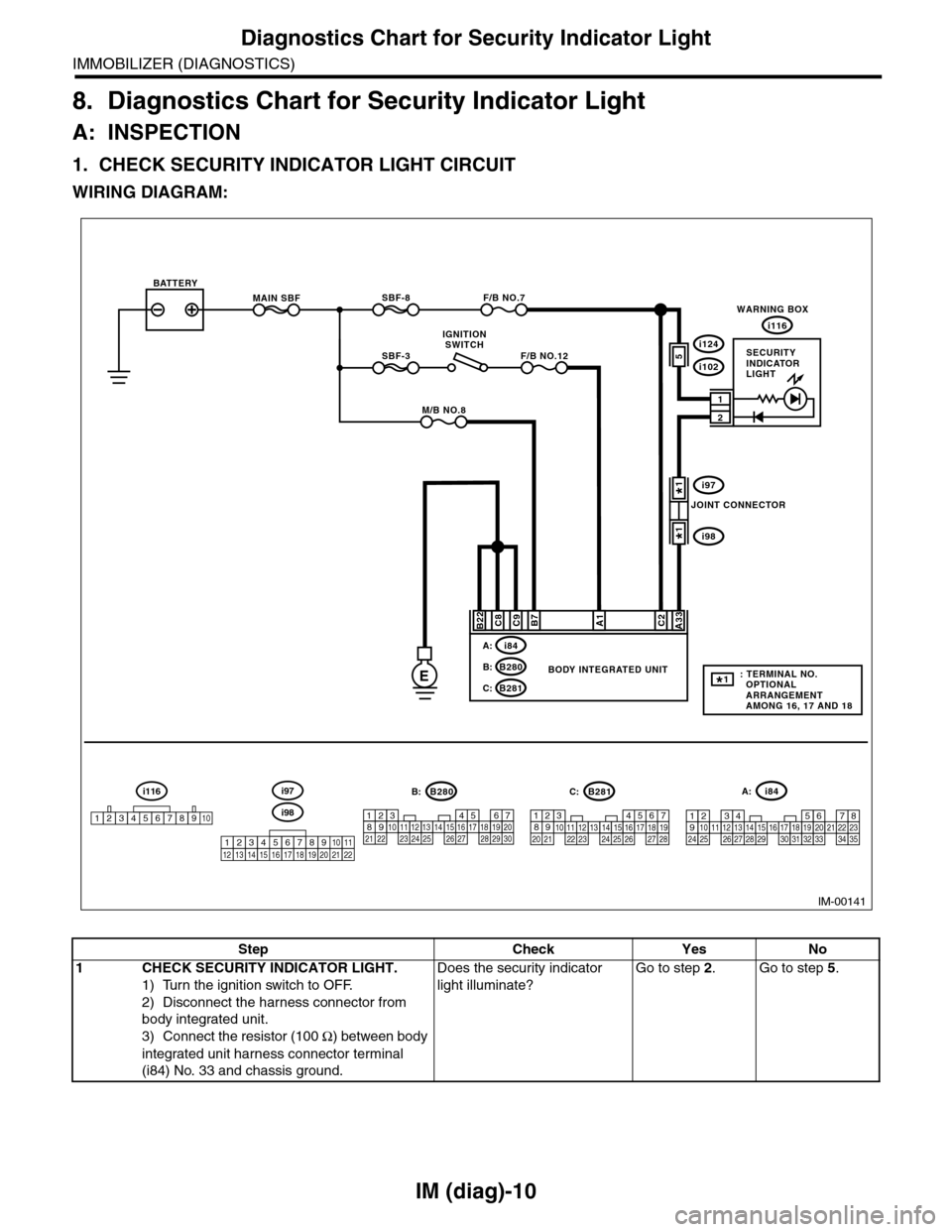

8. Diagnostics Chart for Security Indicator Light

A: INSPECTION

1. CHECK SECURITY INDICATOR LIGHT CIRCUIT

WIRING DIAGRAM:

IM-00141

MAIN SBF

SBF-3

BATTERY

WARNING BOX

BODY INTEGRATED UNIT

i116

F/B NO.7

F/B NO.12

IGNITIONSWITCH

A33C2B7C9C8

2

1

E

A1

M/B NO.8

SBF-8

B22

i84A:

B280B:

B281C:

567821943102422 23 25111213141526 27281617181920 21

B281i84

1234567891011121314151617181920212223242526272829303132333435

5467821931022 231112131415242526 2716171828 29192021 30

B280A:C:B:

5i124

i102

i97

i98

SECURITYINDICATORLIGHT

JOINT CONNECTOR

i116

12345678910i98

i97

12345678910111213141516171819202122

: TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 16, 17 AND 18

1*

1*

1*

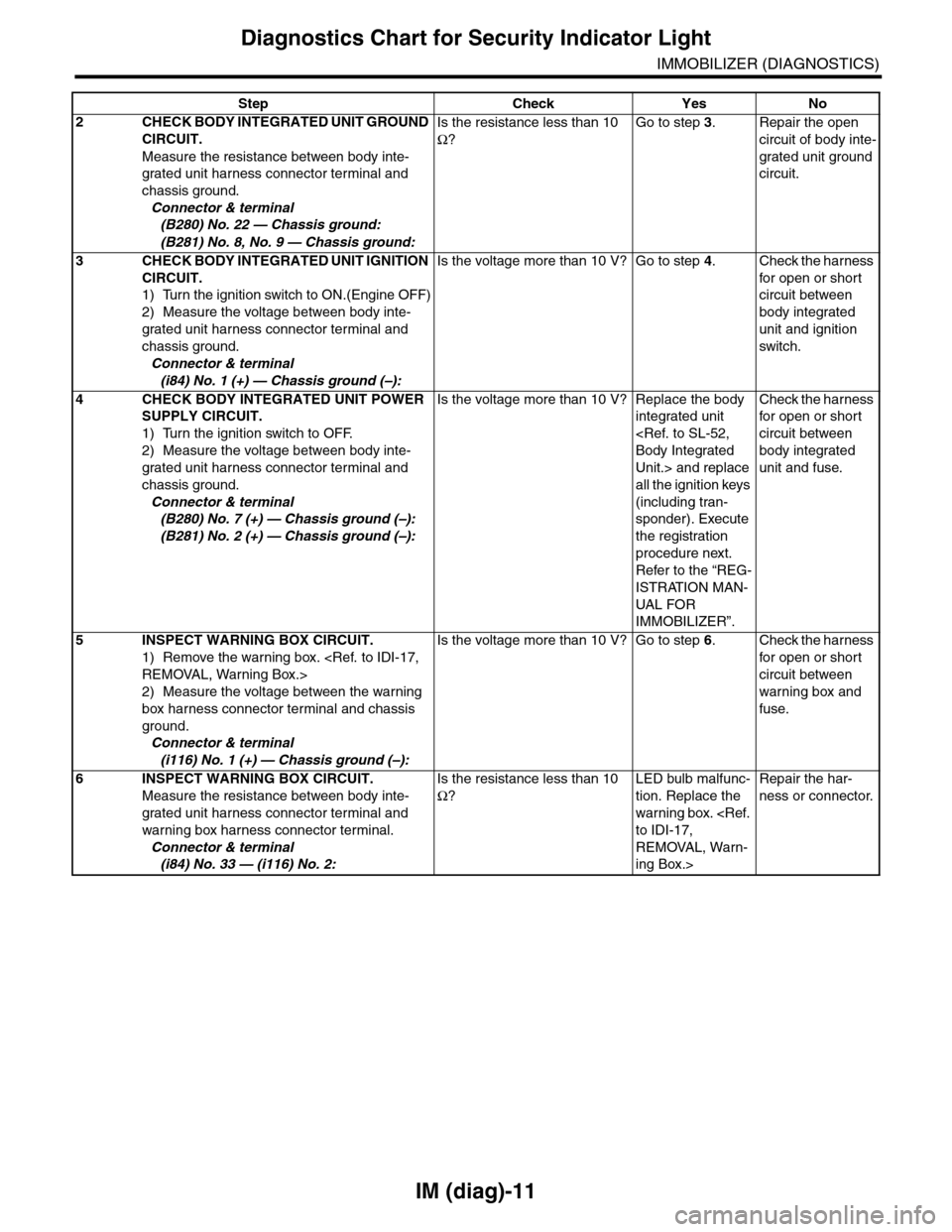

Step Check Yes No

1CHECK SECURITY INDICATOR LIGHT.

1) Turn the ignition switch to OFF.

2) Disconnect the harness connector from

body integrated unit.

3) Connect the resistor (100 Ω) between body

integrated unit harness connector terminal

(i84) No. 33 and chassis ground.

Does the security indicator

light illuminate?

Go to step 2.Go to step 5.

Page 427 of 2453

IM (diag)-11

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

2CHECK BODY INTEGRATED UNIT GROUND

CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 22 — Chassis ground:

(B281) No. 8, No. 9 — Chassis ground:

Is the resistance less than 10

Ω?

Go to step 3.Repair the open

circuit of body inte-

grated unit ground

circuit.

3CHECK BODY INTEGRATED UNIT IGNITION

CIRCUIT.

1) Turn the ignition switch to ON.(Engine OFF)

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(i84) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 4.Check the harness

for open or shor t

circuit between

body integrated

unit and ignition

switch.

4CHECK BODY INTEGRATED UNIT POWER

SUPPLY CIRCUIT.

1) Turn the ignition switch to OFF.

2) Measure the voltage between body inte-

grated unit harness connector terminal and

chassis ground.

Connector & terminal

(B280) No. 7 (+) — Chassis ground (–):

(B281) No. 2 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the body

integrated unit

Unit.> and replace

all the ignition keys

(including tran-

sponder). Execute

the registration

procedure next.

Refer to the “REG-

ISTRATION MAN-

UAL FO R

IMMOBILIZER”.

Check the harness

for open or shor t

circuit between

body integrated

unit and fuse.

5INSPECT WARNING BOX CIRCUIT.

1) Remove the warning box.

2) Measure the voltage between the warning

box harness connector terminal and chassis

ground.

Connector & terminal

(i116) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Go to step 6.Check the harness

for open or shor t

circuit between

warning box and

fuse.

6INSPECT WARNING BOX CIRCUIT.

Measure the resistance between body inte-

grated unit harness connector terminal and

warning box harness connector terminal.

Connector & terminal

(i84) No. 33 — (i116) No. 2:

Is the resistance less than 10

Ω?

LED bulb malfunc-

tion. Replace the

warning box.

REMOVAL, Warn-

ing Box.>

Repair the har-

ness or connector.

Step Check Yes No

Page 428 of 2453

IM (diag)-12

Diagnostics Chart for Security Indicator Light

IMMOBILIZER (DIAGNOSTICS)

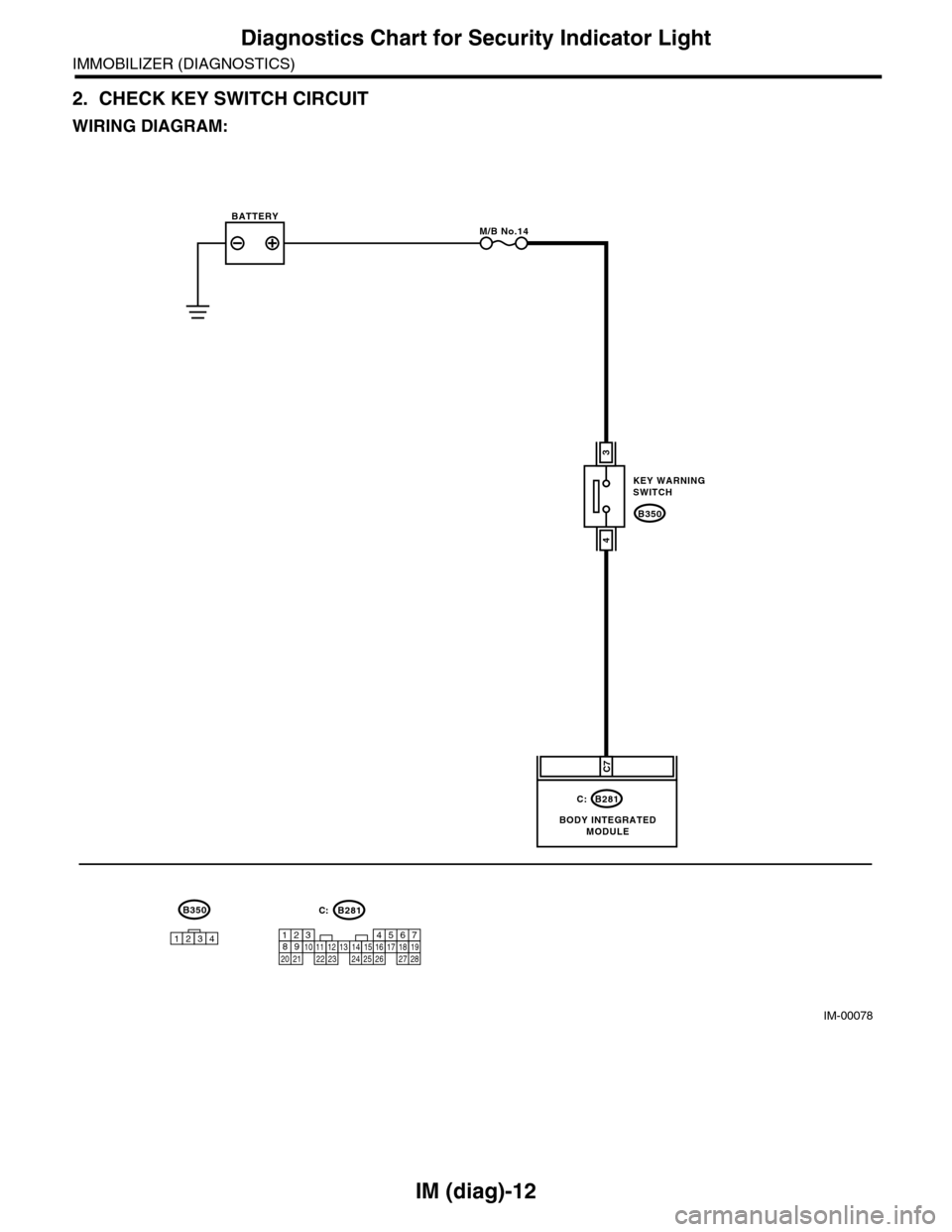

2. CHECK KEY SWITCH CIRCUIT

WIRING DIAGRAM:

IM-00078

B350

KEY WARNINGSWITCH

B281

BODY INTEGRATEDMODULE

BATTERYM/B No.14

C7

3

4

C:

567821943102422 23 25111213141526 27281617181920 21

B281C:B350

1234