ECU SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 510 of 2453

LAN(diag)-54

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

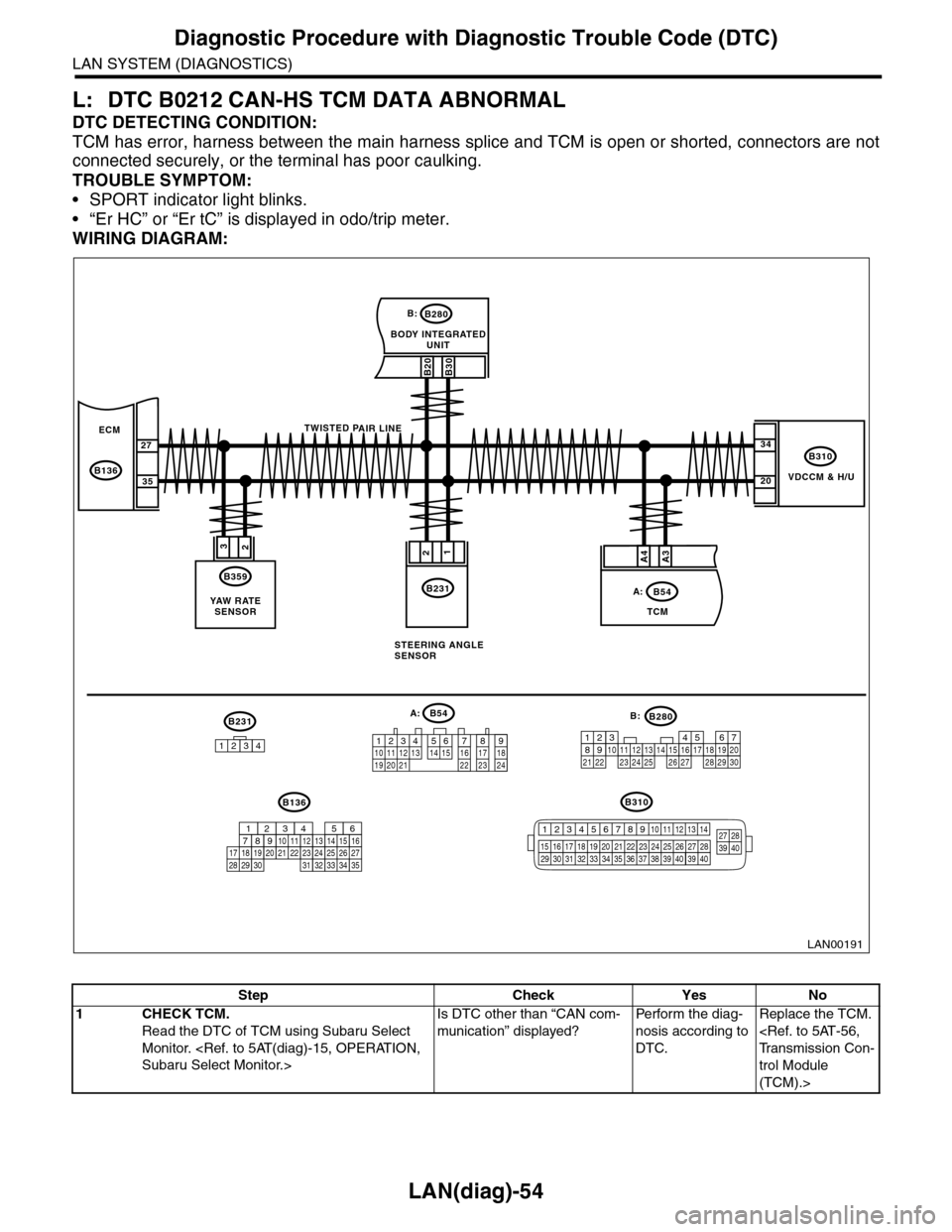

L: DTC B0212 CAN-HS TCM DATA ABNORMAL

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

TROUBLE SYMPTOM:

•SPORT indicator light blinks.

•“Er HC” or “Er tC” is displayed in odo/trip meter.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Step Check Yes No

1CHECK TCM.

Read the DTC of TCM using Subaru Select

Monitor.

Is DTC other than “CAN com-

munication” displayed?

Pe r for m t h e d ia g -

nosis according to

DTC.

Replace the TCM.

trol Module

(TCM).>

Page 515 of 2453

LAN(diag)-59

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

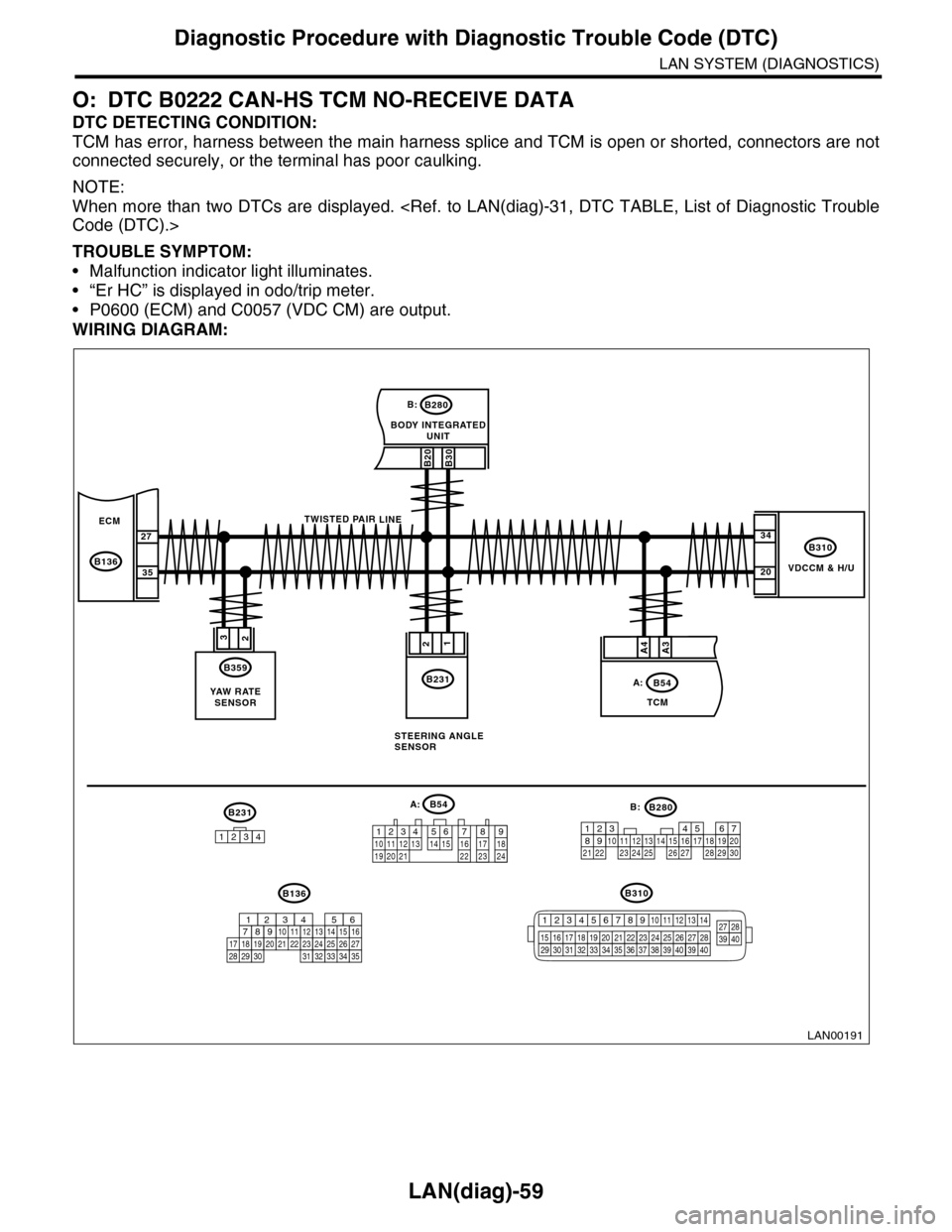

O: DTC B0222 CAN-HS TCM NO-RECEIVE DATA

DTC DETECTING CONDITION:

TCM has error, harness between the main harness splice and TCM is open or shorted, connectors are not

connected securely, or the terminal has poor caulking.

NOTE:

When more than two DTCs are displayed.

TROUBLE SYMPTOM:

•Malfunction indicator light illuminates.

•“Er HC” is displayed in odo/trip meter.

•P0600 (ECM) and C0057 (VDC CM) are output.

WIRING DIAGRAM:

VDCCM & H/U

B310

B20B30

BODY INTEGRATEDUNIT

B280B:

TCM

B54A:

23

B359

YAW R AT ESENSOR

34

20

B231

21

STEERING ANGLESENSOR

B231

1234

B54A:

12 7 8 9563410 11 1219 20 2113 14 15 16 17 1822 23 24

B136B310

B280B:

5467821931022 23111213141524 25 26 2716171828 29192021 30

ECM

B136

27

35

A3A4

TWISTED PAIR LINE

12345678910 11 12 13 14

15 16 17 18 19 2021 22 23 24 25 26 27 2829 30 31 32 33 3435 36 37 38 39403940

27 28394016101112131415252430

9871718192028212223293231

123456

2726333435

LAN00191

Page 526 of 2453

LAN(diag)-70

Diagnostic Procedure with Diagnostic Trouble Code (DTC)

LAN SYSTEM (DIAGNOSTICS)

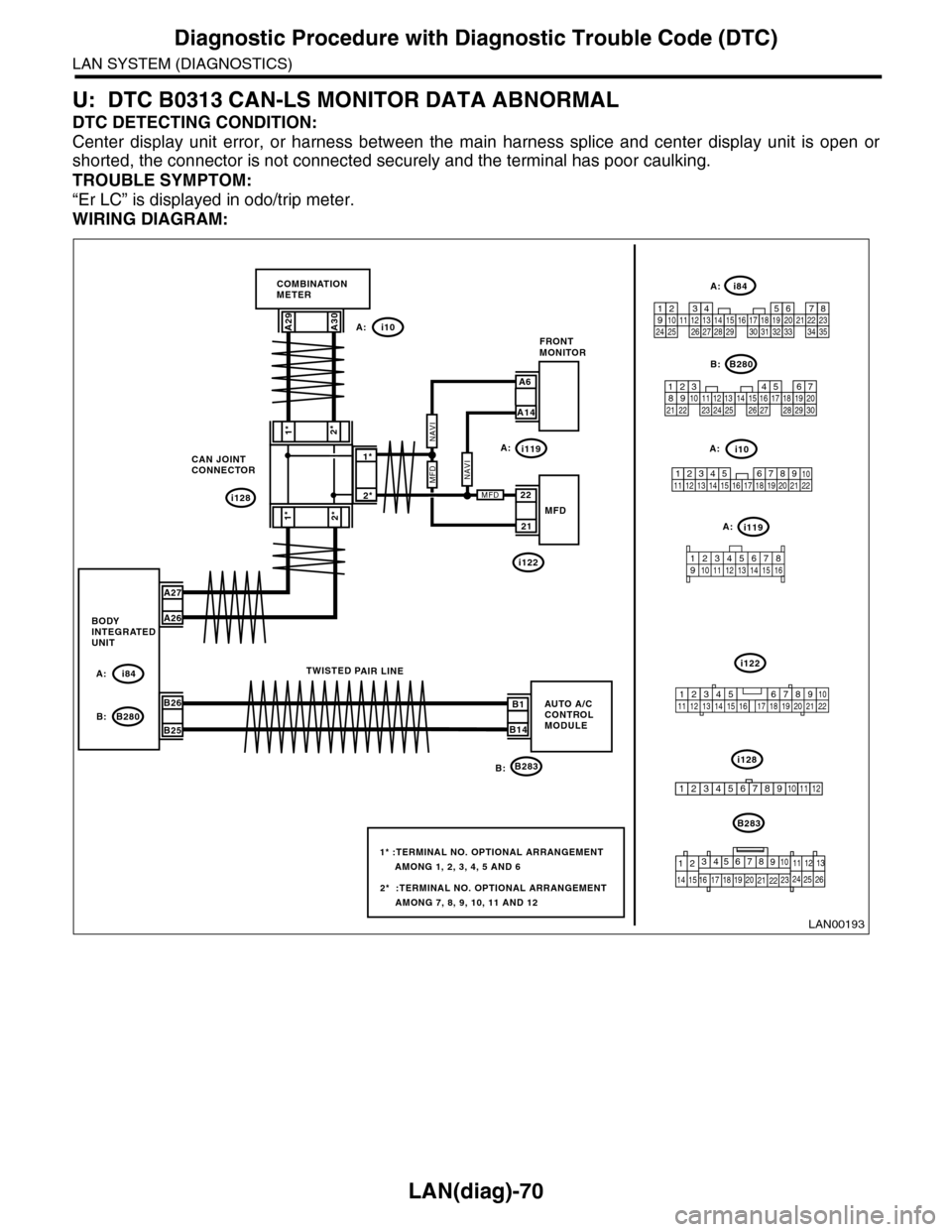

U: DTC B0313 CAN-LS MONITOR DATA ABNORMAL

DTC DETECTING CONDITION:

Center display unit error, or harness between the main harness splice and center display unit is open or

shorted, the connector is not connected securely and the terminal has poor caulking.

TROUBLE SYMPTOM:

“Er LC” is displayed in odo/trip meter.

WIRING DIAGRAM:

i128

1*

2*1*

2*

CAN JOINTCONNECTOR

i10

B283

A29A30

A27

A26

B26

B25

A: i84

B: B280B1

B14

TWISTED PAIR LINE

5467821931022 231112131415242526 2716171828 29192021 30

B280

i84

1234567891011121314151617181920212223242526272829303132333435

2345 678912 13 14 15 16 17 18 19 20 21 2210111

B283

i10

COMBINATIONMETER

BODYINTEGRATEDUNIT

AUTO A/CCONTROLMODULE

123456789101112

LAN00193

A:

B:

2*

1*

A6

A14

FRONTMONITOR

21

22MFD

2* :TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 7, 8, 9, 10, 11 AND 12

1* :TERMINAL NO. OPTIONAL ARRANGEMENT AMONG 1, 2, 3, 4, 5 AND 6

i119

i122

A:

A:

A:

i119A:

i122

i128B:

MFDNAVI

MFD

NAVI

9

19 20

105672143131211

14 15 16 17

8

18222125262423

12345678910 11 12 13 14 15 16

345 678919 20 2114 15 16 17 1812101211 13 22

Page 533 of 2453

LAN(diag)-77

General Diagnostic Table

LAN SYSTEM (DIAGNOSTICS)

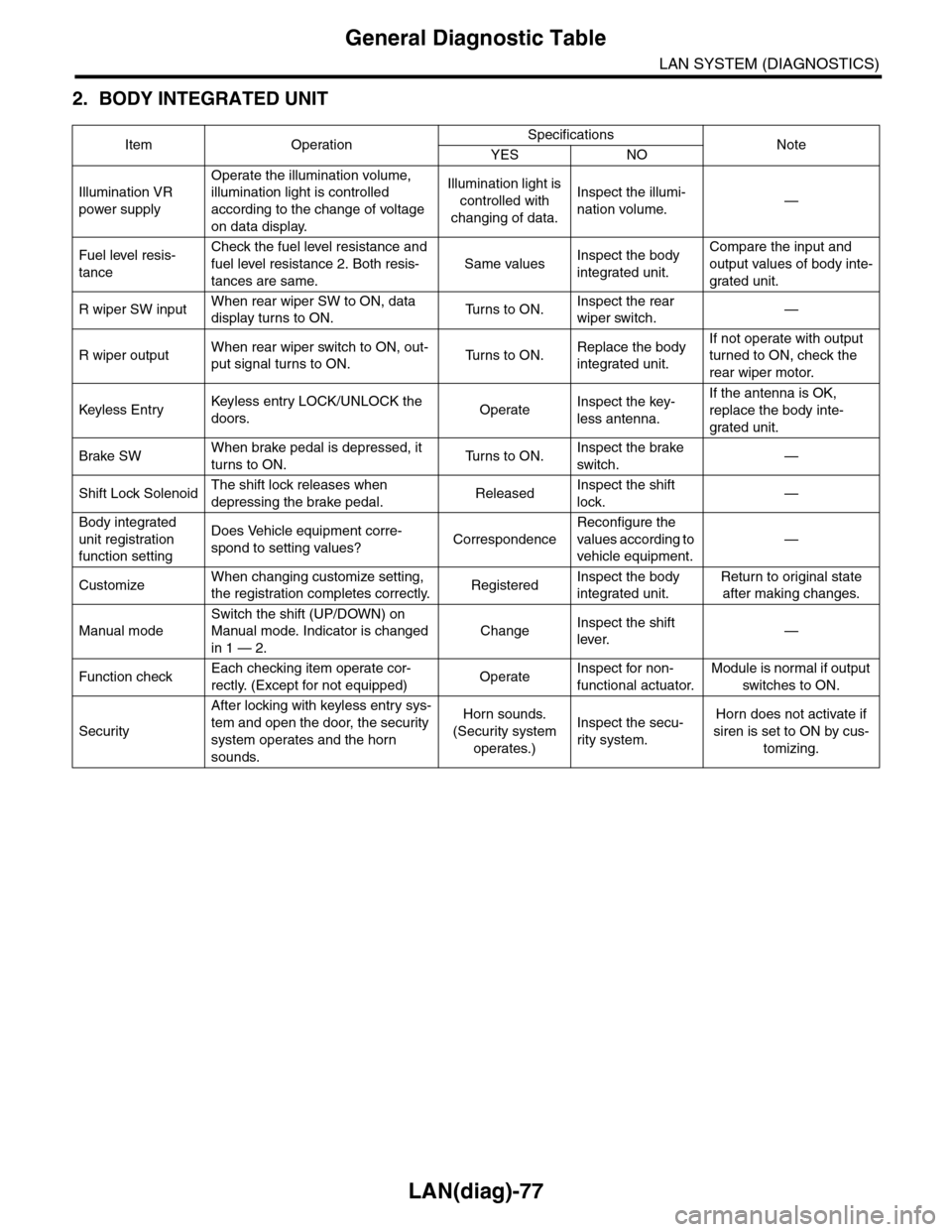

2. BODY INTEGRATED UNIT

Item OperationSpecificationsNoteYES NO

Illumination VR

power supply

Operate the illumination volume,

illumination light is controlled

according to the change of voltage

on data display.

Illumination light is

controlled with

changing of data.

Inspect the illumi-

nation volume.—

Fuel level resis-

tance

Check the fuel level resistance and

fuel level resistance 2. Both resis-

tances are same.

Same valuesInspect the body

integrated unit.

Compare the input and

output values of body inte-

grated unit.

R wiper SW inputWhen rear wiper SW to ON, data

display turns to ON.Tu r n s t o O N .Inspect the rear

wiper switch.—

R wiper outputWhen rear wiper switch to ON, out-

put signal turns to ON.Tu r n s t o O N .Replace the body

integrated unit.

If not operate with output

turned to ON, check the

rear wiper motor.

Keyless Entr yKeyless entr y LOCK/UNLOCK the

doors.OperateInspect the key-

less antenna.

If the antenna is OK,

replace the body inte-

grated unit.

Brake SWWhen brake pedal is depressed, it

turns to ON.Tu r n s t o O N .Inspect the brake

switch.—

Shift Lock SolenoidThe shift lock releases when

depressing the brake pedal.ReleasedInspect the shift

lock.—

Body integrated

unit registration

function setting

Does Vehicle equipment corre-

spond to setting values?Correspondence

Reconfigure the

values according to

vehicle equipment.

—

CustomizeWhen changing customize setting,

the registration completes correctly.RegisteredInspect the body

integrated unit.

Return to original state

after making changes.

Manual mode

Switch the shift (UP/DOWN) on

Manual mode. Indicator is changed

in 1 — 2.

ChangeInspect the shift

lever.—

Function checkEach checking item operate cor-

rectly. (Except for not equipped)OperateInspect for non-

functional actuator.

Module is normal if output

switches to ON.

Security

After locking with keyless entry sys-

tem and open the door, the security

system operates and the horn

sounds.

Horn sounds.

(Security system

operates.)

Inspect the secu-

rity system.

Horn does not activate if

siren is set to ON by cus-

tomizing.

Page 535 of 2453

LI-2

General Description

LIGHTING SYSTEM

1. General Description

A: SPECIFICATION

B: CAUTION

•Before removing or installing parts, always disconnect the battery ground cable from battery. When replac-

ing the audio, control module and other parts provided with memory functions, record the memory contents

before disconnecting the battery ground cable. Otherwise, the memory is cleared.

•Reassemble the parts in the reverse order of disassembly procedure unless otherwise indicated.

•Adjust parts to the given specifications.

•Connect the connectors securely during reassembly.

•After reassembly, make sure functional parts operate smoothly.

WARNING:

•The air bag system wiring harness is routed near electrical parts and switches. Airbag system

wiring harnesses and connectors are yellow. Do not use electrical test equipment on these cir-

cuits.

•Be careful not to damage the air bag system wiring harness when servicing electrical parts and

switches.

C: PREPARATION TOOL

1. GENERAL TOOL

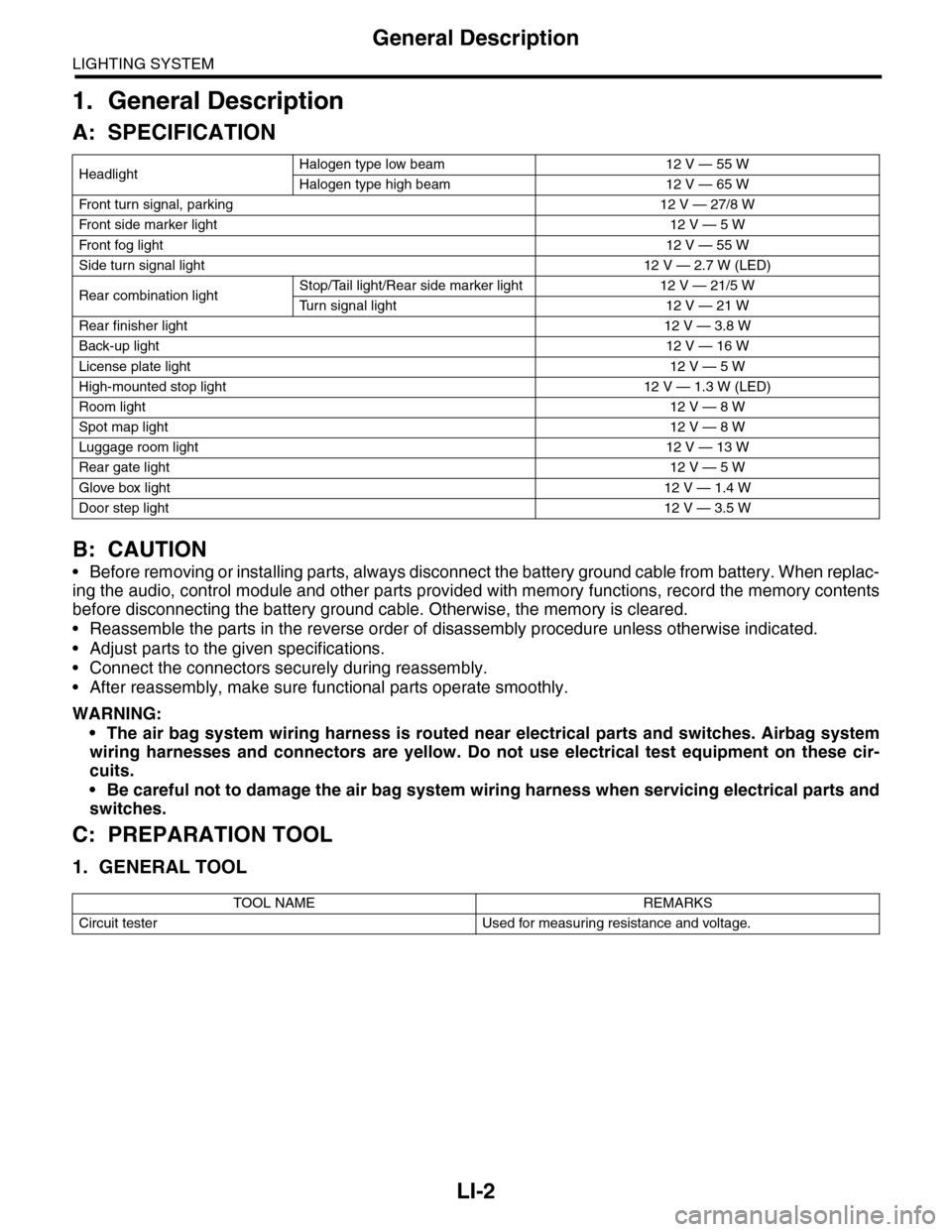

HeadlightHalogen type low beam 12 V — 55 W

Halogen type high beam 12 V — 65 W

Fr o nt t ur n si gn a l, p ar k in g 1 2 V — 27 / 8 W

Fr o nt si d e m ar ke r li gh t12 V — 5 W

Fr o nt fog li g ht12 V — 55 W

Side turn signal light 12 V — 2.7 W (LED)

Rear combination lightStop/Tail light/Rear side marker light 12 V — 21/5 W

Tu r n s i g n a l l i g h t 1 2 V — 2 1 W

Rear finisher light12 V — 3.8 W

Back-up light12 V — 16 W

License plate light12 V — 5 W

High-mounted stop light 12 V — 1.3 W (LED)

Room light12 V — 8 W

Spot map light12 V — 8 W

Luggage room light12 V — 13 W

Rear gate light12 V — 5 W

Glove box light12 V — 1.4 W

Door step light12 V — 3.5 W

TOOL NAME REMARKS

Circuit tester Used for measuring resistance and voltage.

Page 542 of 2453

LI-9

Combination Switch (Light)

LIGHTING SYSTEM

8. Combination Switch (Light)

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the screws and remove the steering

column covers (upper and lower).

3) Disconnect the connector from the combination

switch.

4) Remove the screws which secure the switch,

then remove the combination switch.

B: INSTALLATION

Install in the reverse order of removal.

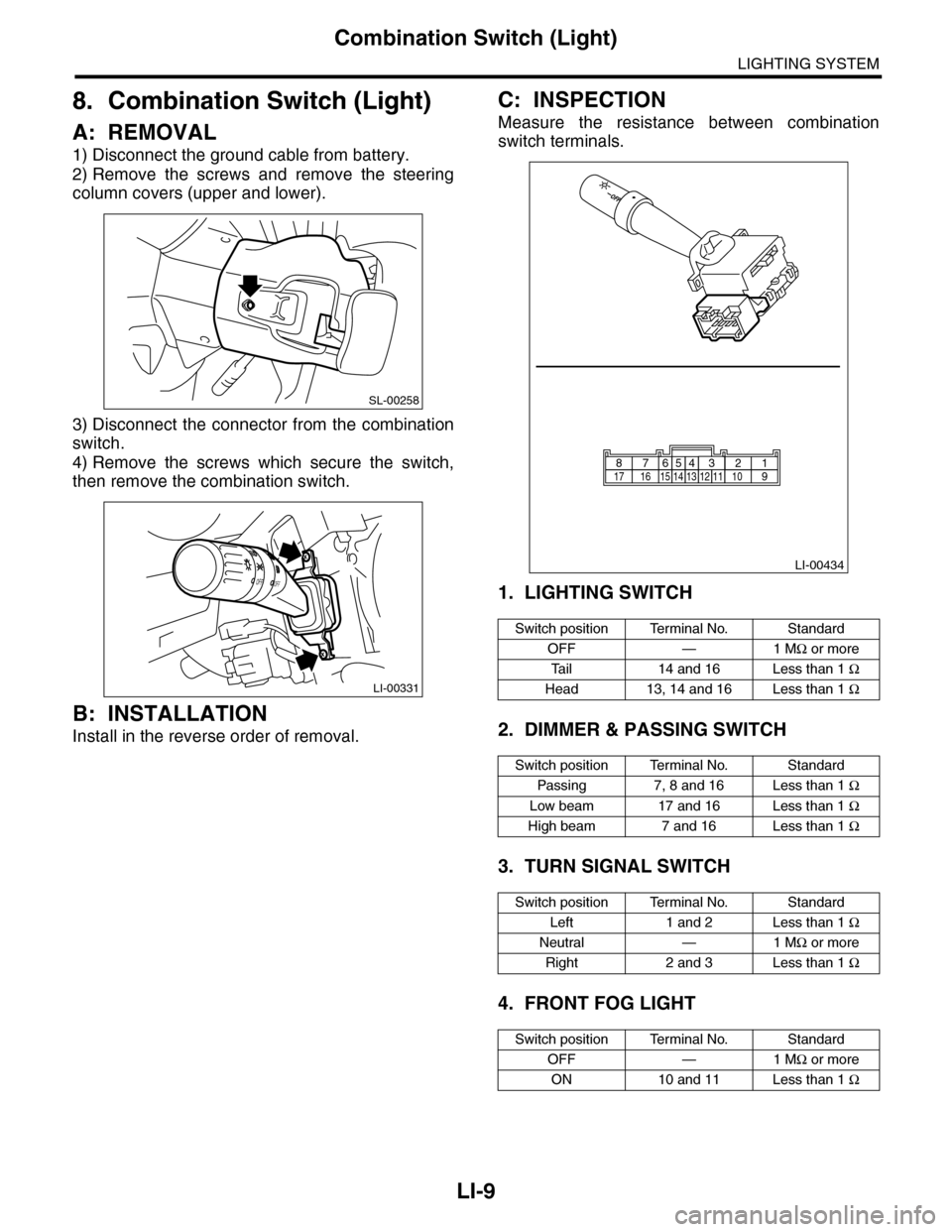

C: INSPECTION

Measure the resistance between combination

switch terminals.

1. LIGHTING SWITCH

2. DIMMER & PASSING SWITCH

3. TURN SIGNAL SWITCH

4. FRONT FOG LIGHT

SL-00258

LI-00331

OFFOFF

Switch position Terminal No. Standard

OFF — 1 MΩ or more

Ta i l 1 4 a n d 1 6 L e s s t h a n 1 Ω

Head 13, 14 and 16 Less than 1 Ω

Switch position Terminal No. Standard

Passing 7, 8 and 16 Less than 1 Ω

Low beam 17 and 16 Less than 1 Ω

High beam 7 and 16 Less than 1 Ω

Switch position Terminal No. Standard

Left 1 and 2 Less than 1 Ω

Neutral — 1 MΩ or more

Right 2 and 3 Less than 1 Ω

Switch position Terminal No. Standard

OFF — 1 MΩ or more

ON 10 and 11 Less than 1 Ω

LI-00434

1514131211109171665432187

Page 544 of 2453

LI-11

Headlight Assembly

LIGHTING SYSTEM

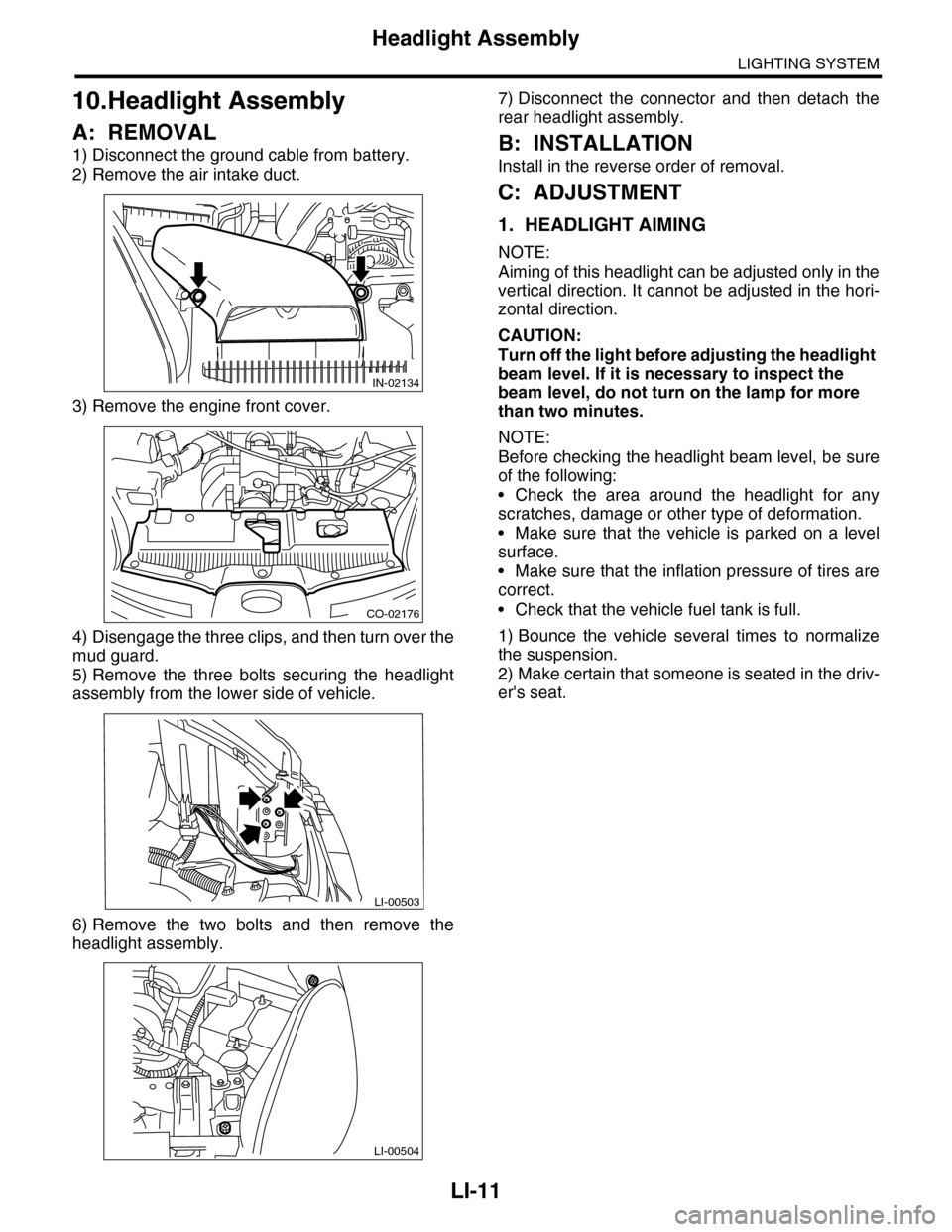

10.Headlight Assembly

A: REMOVAL

1) Disconnect the ground cable from battery.

2) Remove the air intake duct.

3) Remove the engine front cover.

4) Disengage the three clips, and then turn over the

mud guard.

5) Remove the three bolts securing the headlight

assembly from the lower side of vehicle.

6) Remove the two bolts and then remove the

headlight assembly.

7) Disconnect the connector and then detach the

rear headlight assembly.

B: INSTALLATION

Install in the reverse order of removal.

C: ADJUSTMENT

1. HEADLIGHT AIMING

NOTE:

Aiming of this headlight can be adjusted only in the

vertical direction. It cannot be adjusted in the hori-

zontal direction.

CAUTION:

Turn off the light before adjusting the headlight

beam level. If it is necessary to inspect the

beam level, do not turn on the lamp for more

than two minutes.

NOTE:

Before checking the headlight beam level, be sure

of the following:

•Check the area around the headlight for any

scratches, damage or other type of deformation.

•Make sure that the vehicle is parked on a level

surface.

•Make sure that the inflation pressure of tires are

correct.

•Check that the vehicle fuel tank is full.

1) Bounce the vehicle several times to normalize

the suspension.

2) Make certain that someone is seated in the driv-

er's seat.

IN-02134

CO-02176

LI-00503

LI-00504

Page 570 of 2453

OD(diag)-2

Basic Diagnostic Procedure

OCCUPANT DETECTION SYSTEM (DIAGNOSTICS)

1. Basic Diagnostic Procedure

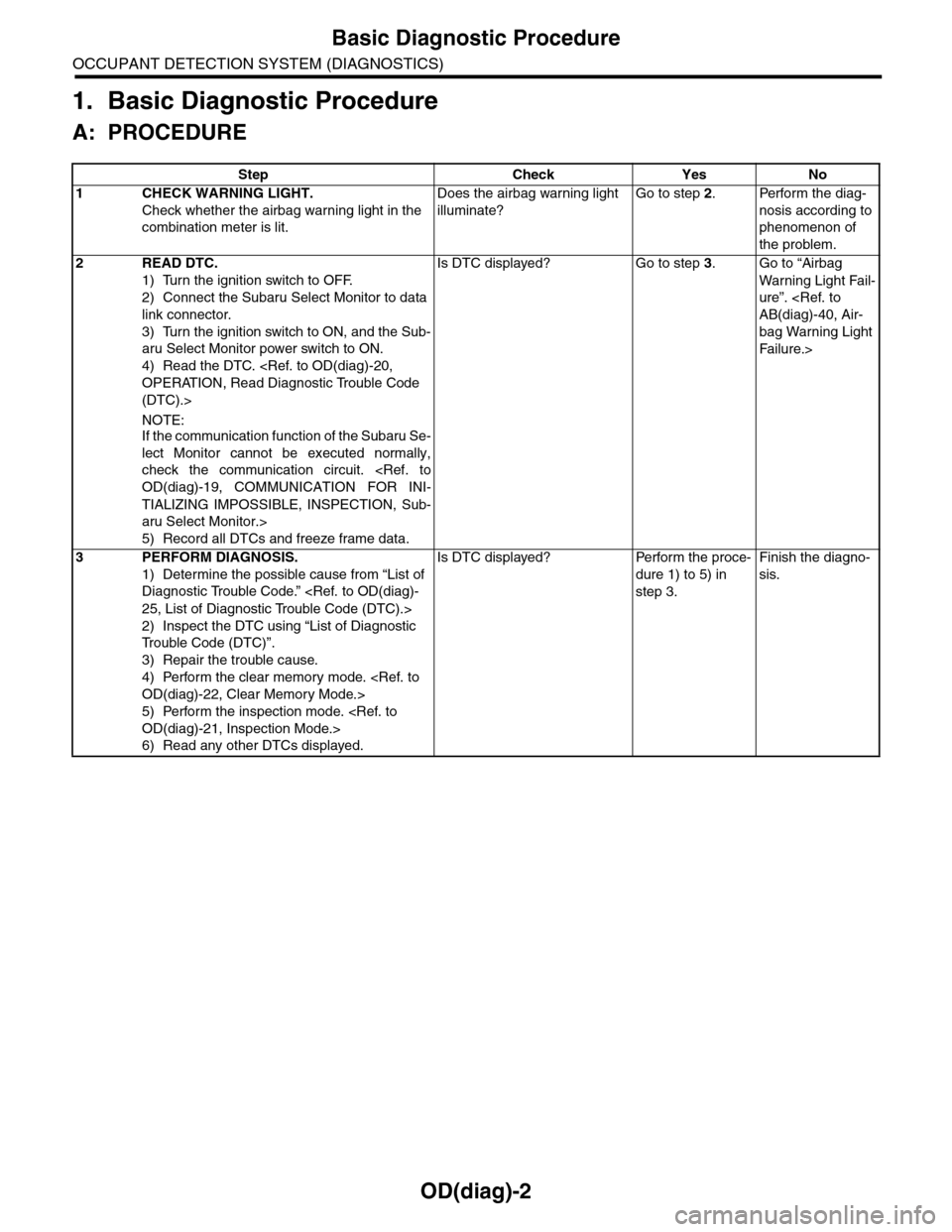

A: PROCEDURE

Step Check Yes No

1CHECK WARNING LIGHT.

Check whether the airbag warning light in the

combination meter is lit.

Does the airbag warning light

illuminate?

Go to step 2.Perform the diag-

nosis according to

phenomenon of

the problem.

2READ DTC.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Read the DTC.

(DTC).>

NOTE:If the communication function of the Subaru Se-

lect Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, INSPECTION, Sub-

aru Select Monitor.>

5) Record all DTCs and freeze frame data.

Is DTC displayed? Go to step 3.Go to “Airbag

Wa r ni n g L ig h t Fa i l-

ure”.

bag Warning Light

Fai lu r e.>

3PERFORM DIAGNOSIS.

1) Determine the possible cause from “List of

Diagnostic Trouble Code.”

2) Inspect the DTC using “List of Diagnostic

Tr o u b l e C o d e ( D T C ) ” .

3) Repair the trouble cause.

4) Perform the clear memory mode.

5) Perform the inspection mode.

6) Read any other DTCs displayed.

Is DTC displayed? Perform the proce-

dure 1) to 5) in

step 3.

Finish the diagno-

sis.

Page 608 of 2453

SB-11

Front Seat Belt

SEAT BELT SYSTEM

B: INSTALLATION

1. OUTER SEAT BELT ASSEMBLY

Install in the reverse order of removal.

CAUTION:

•The parts of driver and passenger sides are

not the same. Before installation, make sure

that the correct part is used.

•Be careful not to twist the seat belts during

installation.

Tightening torque:

2. INNER SEAT BELT ASSEMBLY

Install in the reverse order of removal.

CAUTION:

•After the driver’s and passenger’s inner seat

belt assembly installation, check that the seat

belt buckle switch operates normally using the

Subaru Select Monitor in {Status Data} of “Air-

bag System”.

aru Select Monitor.>Improper buckle switch op-

eration may cause airbag system malfunction.

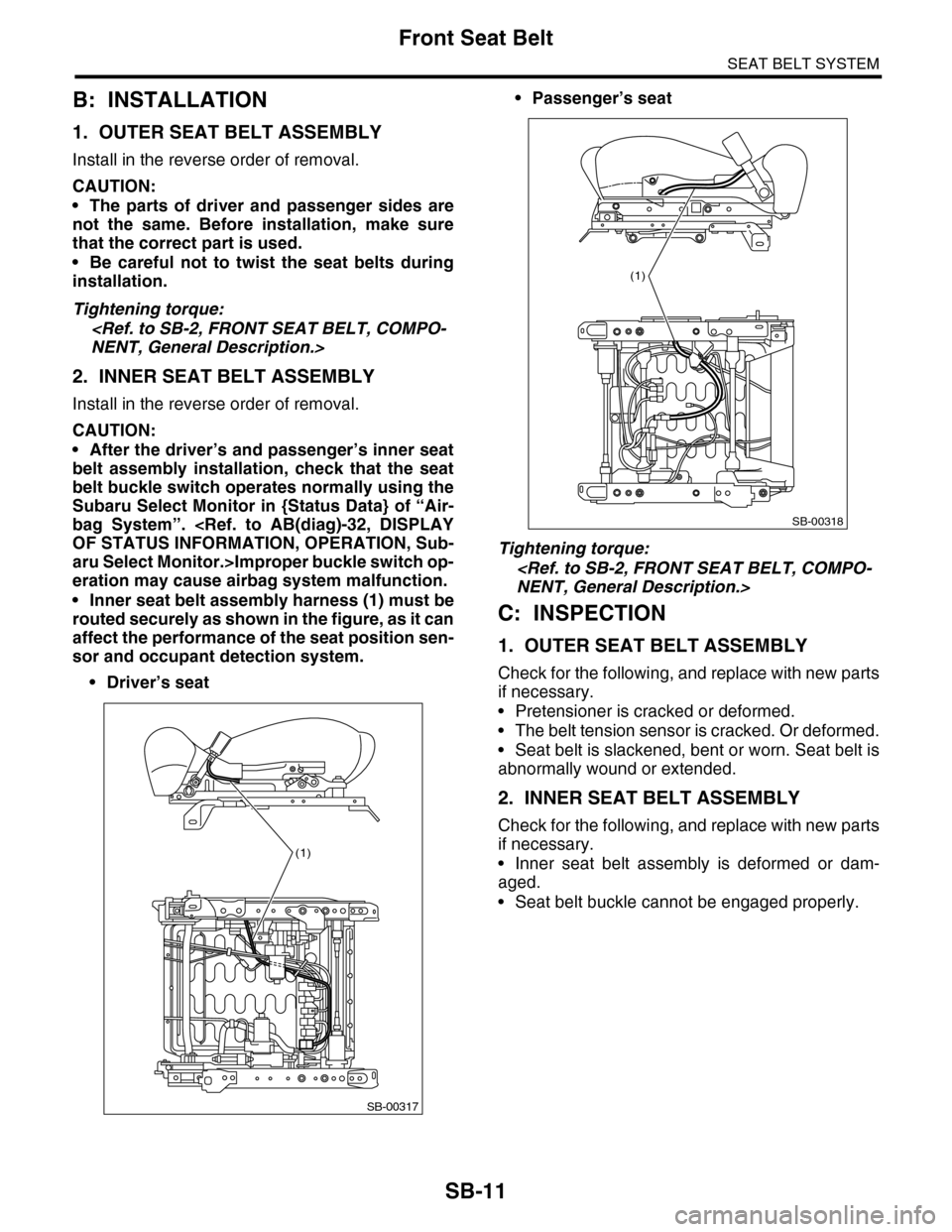

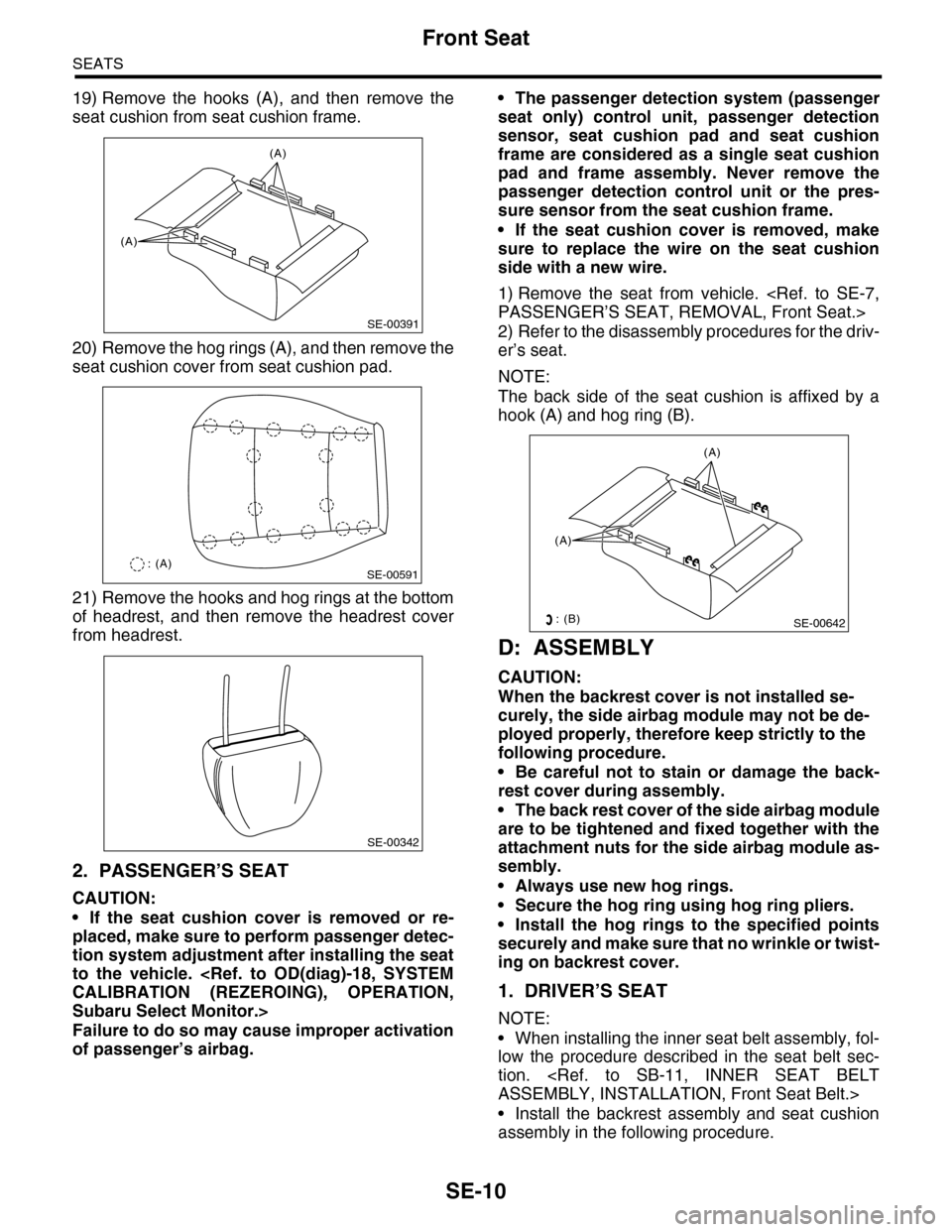

•Inner seat belt assembly harness (1) must be

routed securely as shown in the figure, as it can

affect the performance of the seat position sen-

sor and occupant detection system.

•Driver’s seat

•Passenger’s seat

Tightening torque:

C: INSPECTION

1. OUTER SEAT BELT ASSEMBLY

Check for the following, and replace with new parts

if necessary.

•Pretensioner is cracked or deformed.

•The belt tension sensor is cracked. Or deformed.

•Seat belt is slackened, bent or worn. Seat belt is

abnormally wound or extended.

2. INNER SEAT BELT ASSEMBLY

Check for the following, and replace with new parts

if necessary.

•Inner seat belt assembly is deformed or dam-

aged.

•Seat belt buckle cannot be engaged properly.

SB-00317

(1)

SB-00318

(1)

Page 620 of 2453

SE-10

Front Seat

SEATS

19) Remove the hooks (A), and then remove the

seat cushion from seat cushion frame.

20) Remove the hog rings (A), and then remove the

seat cushion cover from seat cushion pad.

21) Remove the hooks and hog rings at the bottom

of headrest, and then remove the headrest cover

from headrest.

2. PASSENGER’S SEAT

CAUTION:

•If the seat cushion cover is removed or re-

placed, make sure to perform passenger detec-

tion system adjustment after installing the seat

to the vehicle.

Subaru Select Monitor.>

Failure to do so may cause improper activation

of passenger’s airbag.

•The passenger detection system (passenger

seat only) control unit, passenger detection

sensor, seat cushion pad and seat cushion

frame are considered as a single seat cushion

pad and frame assembly. Never remove the

passenger detection control unit or the pres-

sure sensor from the seat cushion frame.

•If the seat cushion cover is removed, make

sure to replace the wire on the seat cushion

side with a new wire.

1) Remove the seat from vehicle.

2) Refer to the disassembly procedures for the driv-

er’s seat.

NOTE:

The back side of the seat cushion is affixed by a

hook (A) and hog ring (B).

D: ASSEMBLY

CAUTION:

When the backrest cover is not installed se-

curely, the side airbag module may not be de-

ployed properly, therefore keep strictly to the

following procedure.

•Be careful not to stain or damage the back-

rest cover during assembly.

•The back rest cover of the side airbag module

are to be tightened and fixed together with the

attachment nuts for the side airbag module as-

sembly.

•Always use new hog rings.

•Secure the hog ring using hog ring pliers.

•Install the hog rings to the specified points

securely and make sure that no wrinkle or twist-

ing on backrest cover.

1. DRIVER’S SEAT

NOTE:

•When installing the inner seat belt assembly, fol-

low the procedure described in the seat belt sec-

tion.

•Install the backrest assembly and seat cushion

assembly in the following procedure.

SE-00391

(A)

(A)

SE-00591: (A)

SE-00342

(A)

(A)

SE-00642: (B)