abs SUBARU TRIBECA 2009 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 939 of 2453

RS-6

General Description

REAR SUSPENSION

2. GENERAL TOOL

28099PA090 OIL SEAL PROTEC-

TOR

•Used for installing the rear drive shaft to the

rear differential.

•For oil seal protection

TOOL NAME REMARKS

Alignment tester Used for measuring wheel alignment.

To e – i n g a u g e U s e d f o r t o e – i n m e a s u r e m e n t .

Jack Used for removing and installing suspension.

Bearing puller Used for removing bushings.

Coil spring compressor Used for disassembling and assembling shock absorber.

ILLUSTRATION TOOL NUMBER DESCRIPTION REMARKS

ST28099PA090

Page 942 of 2453

RS-9

Rear Trailing Link

REAR SUSPENSION

4. Rear Trailing Link

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Remove the bracket, and remove the parking

brake cable from the guide.

3) Remove the ABS wheel speed sensor harness

from the trailing link.

4) Remove the trailing link.

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

Install in the reverse order of removal.

Tightening torque:

Trailing link

120 N·m (12.2 kgf-m, 89 ft-lb)

Parking Brake Cable bracket

33 N·m (3.4 kgf-m, 24 ft-lb)

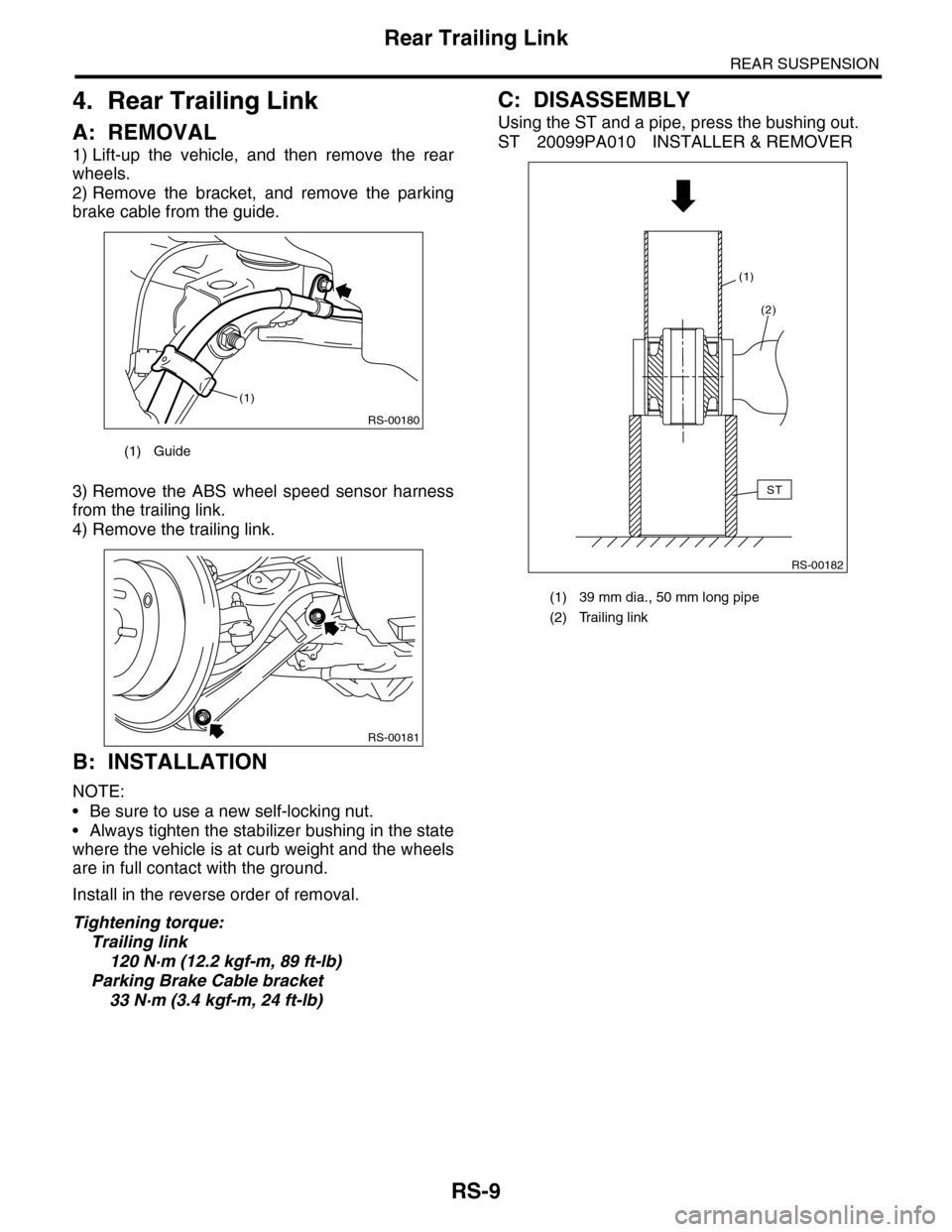

C: DISASSEMBLY

Using the ST and a pipe, press the bushing out.

ST 20099PA010 INSTALLER & REMOVER

(1) Guide

RS-00180

(1)

RS-00181

(1) 39 mm dia., 50 mm long pipe

(2) Trailing link

RS-00182

ST

(2)

(1)

Page 945 of 2453

RS-12

Rear Shock Absorber

REAR SUSPENSION

6. Rear Shock Absorber

A: REMOVAL

1) Remove the strut cap of quarter trim.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Remove the nut and detach the rear stabilizer link.

4) Remove the bolts on the bottom side of the

shock absorber.

5) Detach the rear lateral link.

6) Remove the nuts of the shock absorber mount.

7) Remove the shock absorber.

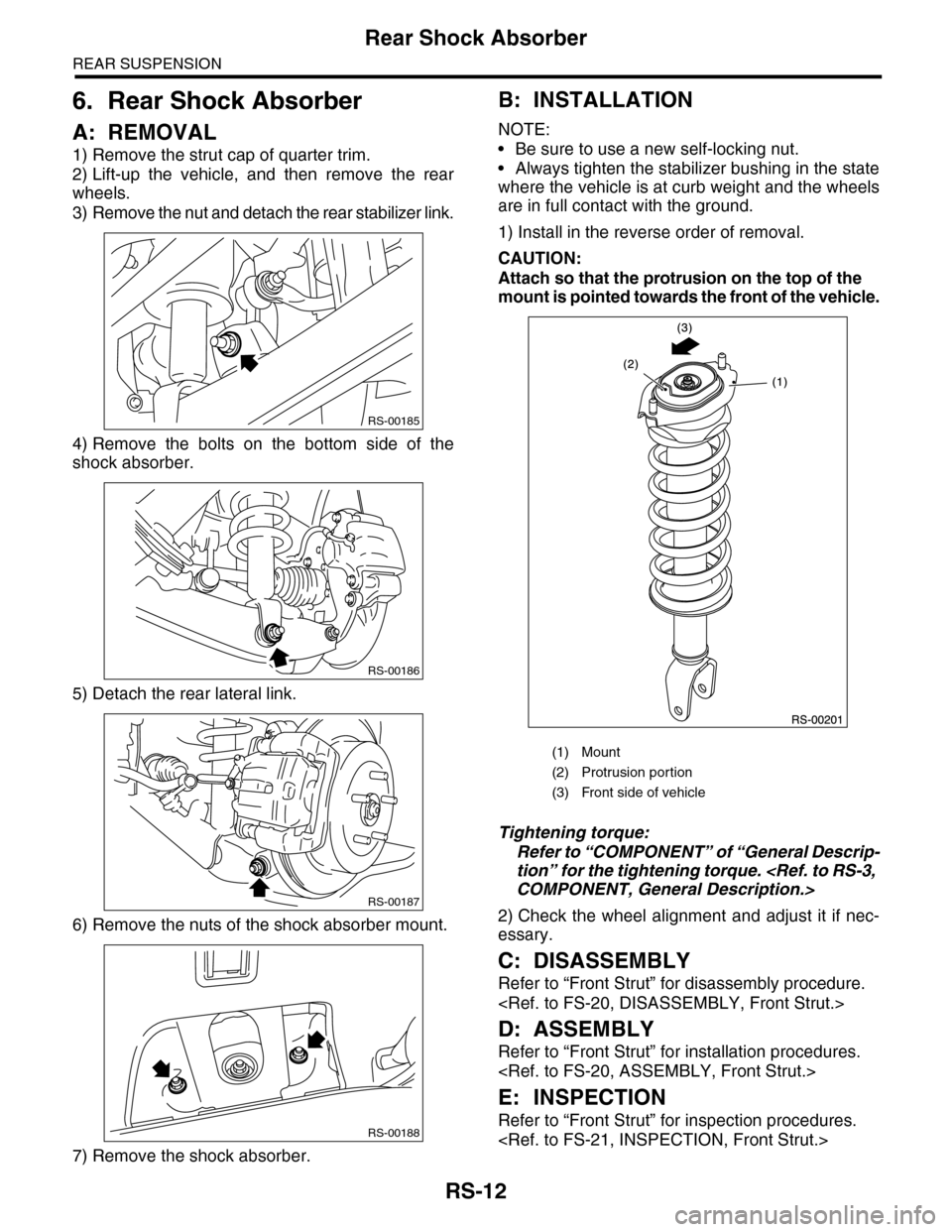

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

1) Install in the reverse order of removal.

CAUTION:

Attach so that the protrusion on the top of the

mount is pointed towards the front of the vehicle.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion” for the tightening torque.

2) Check the wheel alignment and adjust it if nec-

essary.

C: DISASSEMBLY

Refer to “Front Strut” for disassembly procedure.

D: ASSEMBLY

Refer to “Front Strut” for installation procedures.

E: INSPECTION

Refer to “Front Strut” for inspection procedures.

RS-00185

RS-00186

RS-00187

RS-00188

(1) Mount

(2) Protrusion por tion

(3) Front side of vehicle

Page 946 of 2453

RS-13

Rear Shock Absorber

REAR SUSPENSION

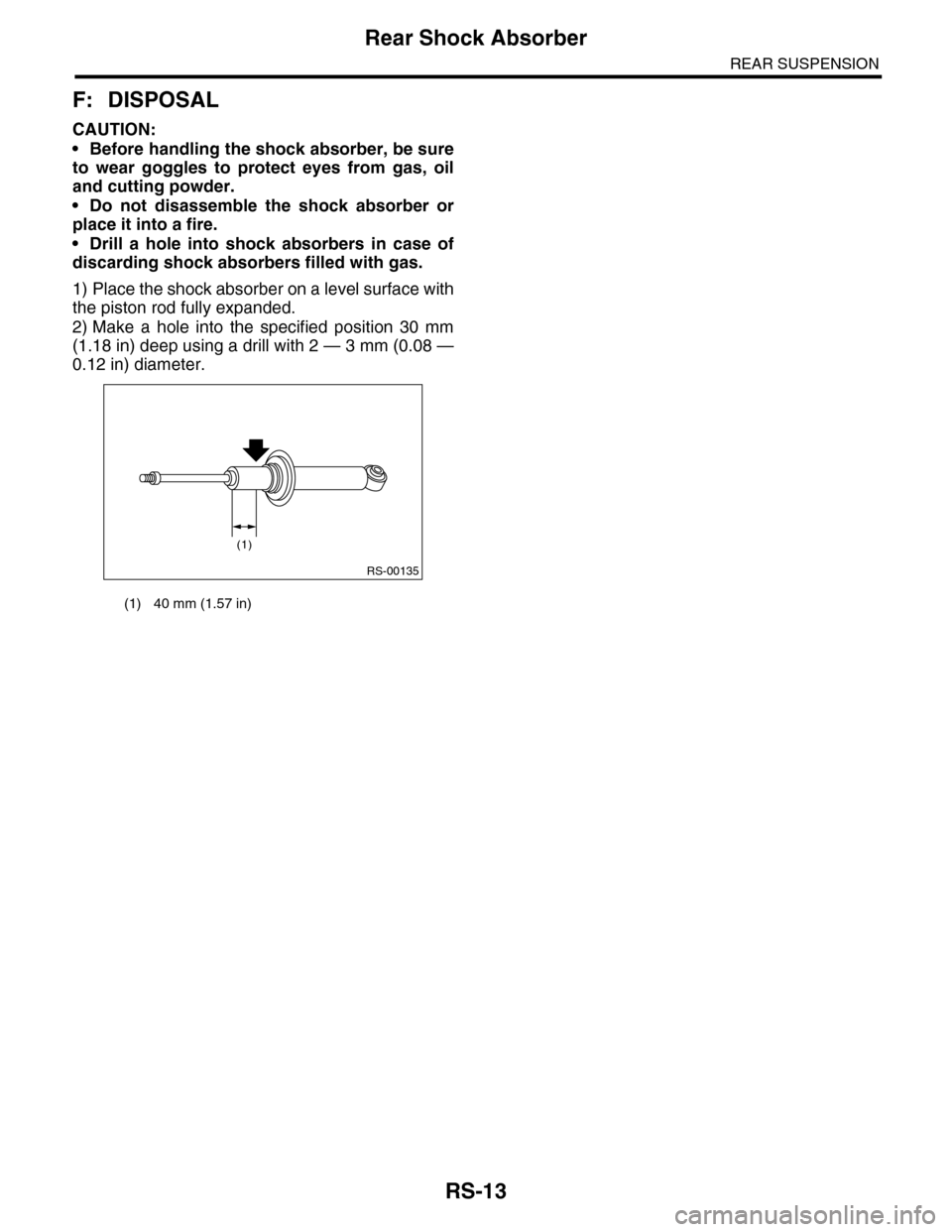

F: DISPOSAL

CAUTION:

•Before handling the shock absorber, be sure

to wear goggles to protect eyes from gas, oil

and cutting powder.

•Do not disassemble the shock absorber or

place it into a fire.

•Drill a hole into shock absorbers in case of

discarding shock absorbers filled with gas.

1) Place the shock absorber on a level surface with

the piston rod fully expanded.

2) Make a hole into the specified position 30 mm

(1.18 in) deep using a drill with 2 — 3 mm (0.08 —

0.12 in) diameter.

(1) 40 mm (1.57 in)

RS-00135

(1)

Page 948 of 2453

RS-15

Rear Lateral Link

REAR SUSPENSION

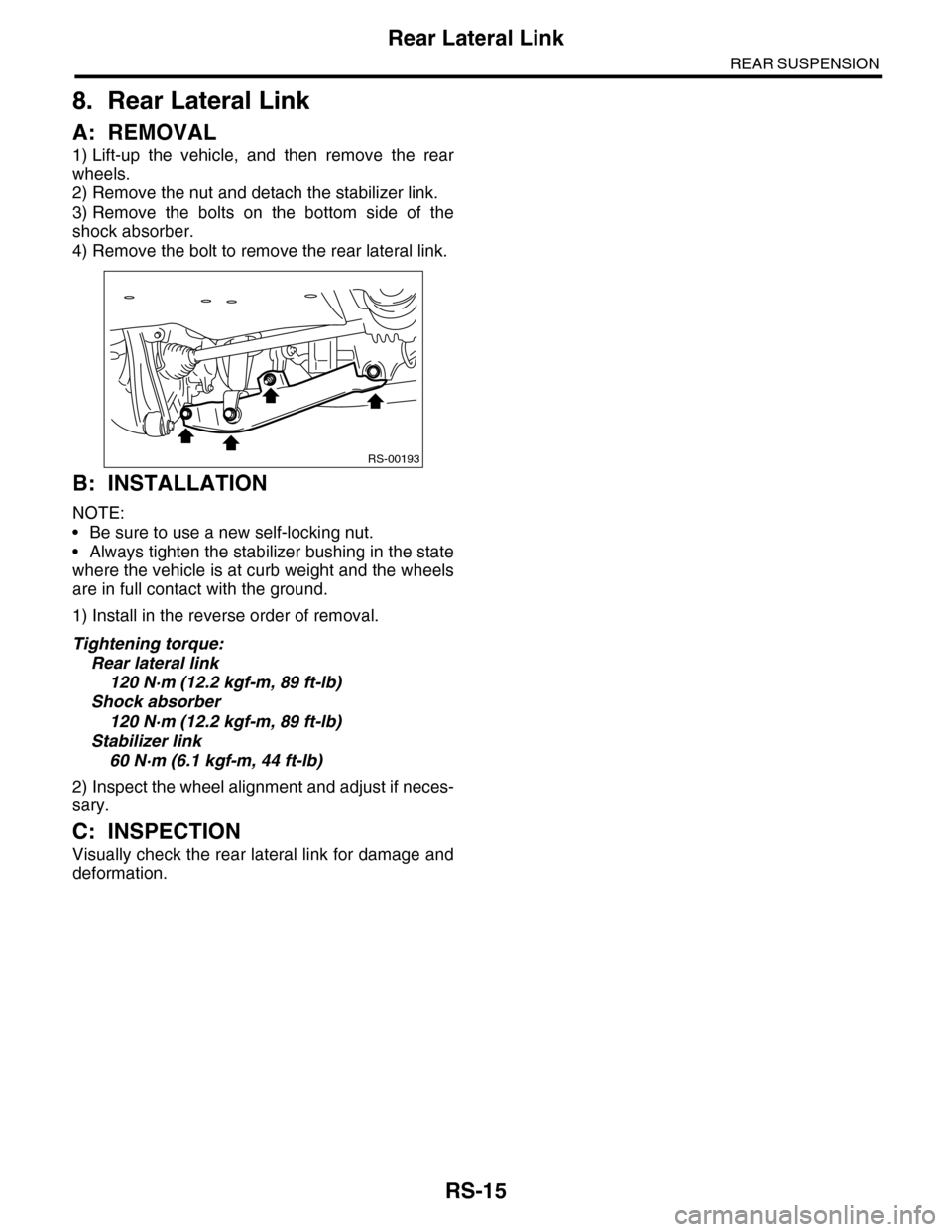

8. Rear Lateral Link

A: REMOVAL

1) Lift-up the vehicle, and then remove the rear

wheels.

2) Remove the nut and detach the stabilizer link.

3) Remove the bolts on the bottom side of the

shock absorber.

4) Remove the bolt to remove the rear lateral link.

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

1) Install in the reverse order of removal.

Tightening torque:

Rear lateral link

120 N·m (12.2 kgf-m, 89 ft-lb)

Shock absorber

120 N·m (12.2 kgf-m, 89 ft-lb)

Stabilizer link

60 N·m (6.1 kgf-m, 44 ft-lb)

2) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Visually check the rear lateral link for damage and

deformation.

RS-00193

Page 949 of 2453

RS-16

Rear Sub Frame

REAR SUSPENSION

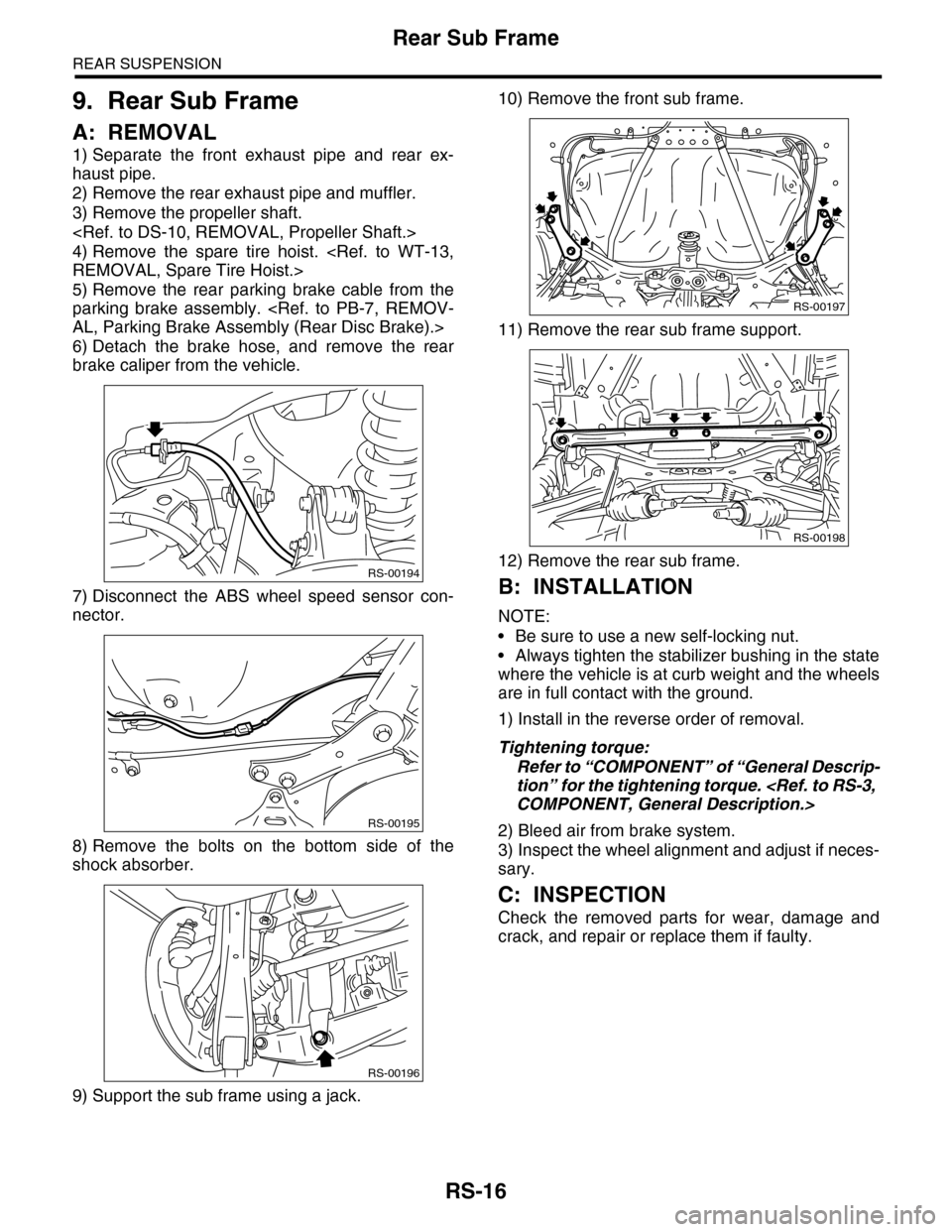

9. Rear Sub Frame

A: REMOVAL

1) Separate the front exhaust pipe and rear ex-

haust pipe.

2) Remove the rear exhaust pipe and muffler.

3) Remove the propeller shaft.

4) Remove the spare tire hoist.

5) Remove the rear parking brake cable from the

parking brake assembly.

6) Detach the brake hose, and remove the rear

brake caliper from the vehicle.

7) Disconnect the ABS wheel speed sensor con-

nector.

8) Remove the bolts on the bottom side of the

shock absorber.

9) Support the sub frame using a jack.

10) Remove the front sub frame.

11) Remove the rear sub frame support.

12) Remove the rear sub frame.

B: INSTALLATION

NOTE:

•Be sure to use a new self-locking nut.

•Always tighten the stabilizer bushing in the state

where the vehicle is at curb weight and the wheels

are in full contact with the ground.

1) Install in the reverse order of removal.

Tightening torque:

Refer to “COMPONENT” of “General Descrip-

tion” for the tightening torque.

2) Bleed air from brake system.

3) Inspect the wheel alignment and adjust if neces-

sary.

C: INSPECTION

Check the removed parts for wear, damage and

crack, and repair or replace them if faulty.

RS-00194

RS-00195

RS-00196

RS-00197

RS-00198

Page 950 of 2453

RS-17

General Diagnostic Table

REAR SUSPENSION

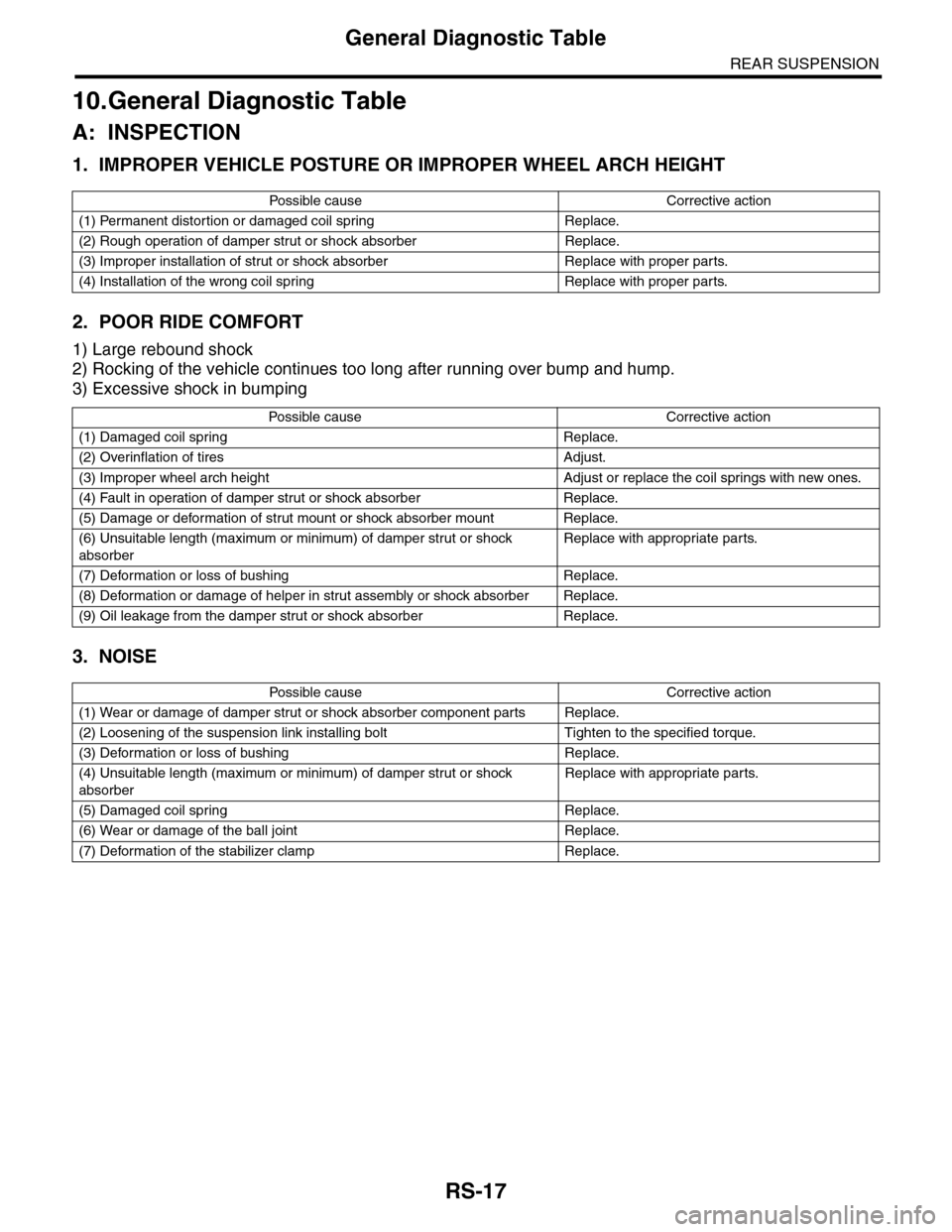

10.General Diagnostic Table

A: INSPECTION

1. IMPROPER VEHICLE POSTURE OR IMPROPER WHEEL ARCH HEIGHT

2. POOR RIDE COMFORT

1) Large rebound shock

2) Rocking of the vehicle continues too long after running over bump and hump.

3) Excessive shock in bumping

3. NOISE

Po ss ibl e c a us e C o r r e ct ive ac ti o n

(1) Permanent distortion or damaged coil spring Replace.

(2) Rough operation of damper strut or shock absorber Replace.

(3) Improper installation of strut or shock absorber Replace with proper parts.

(4) Installation of the wrong coil spring Replace with proper parts.

Po ss ibl e ca us e C or r e ct i ve a ct io n

(1) Damaged coil spring Replace.

(2) Overinflation of tires Adjust.

(3) Improper wheel arch height Adjust or replace the coil springs with new ones.

(4) Fault in operation of damper strut or shock absorber Replace.

(5) Damage or deformation of strut mount or shock absorber mount Replace.

(6) Unsuitable length (maximum or minimum) of damper strut or shock

absorber

Replace with appropriate parts.

(7) Deformation or loss of bushing Replace.

(8) Deformation or damage of helper in strut assembly or shock absorber Replace.

(9) Oil leakage from the damper strut or shock absorber Replace.

Po ss ibl e c a us e C o r r e ct ive ac ti o n

(1) Wear or damage of damper strut or shock absorber component parts Replace.

(2) Loosening of the suspension link installing bolt Tighten to the specified torque.

(3) Deformation or loss of bushing Replace.

(4) Unsuitable length (maximum or minimum) of damper strut or shock

absorber

Replace with appropriate parts.

(5) Damaged coil spring Replace.

(6) Wear or damage of the ball joint Replace.

(7) Deformation of the stabilizer clamp Replace.

Page 958 of 2453

TPM(diag)-8

Subaru Select Monitor

TIRE PRESSURE MONITORING SYSTEM (DIAGNOSTICS)

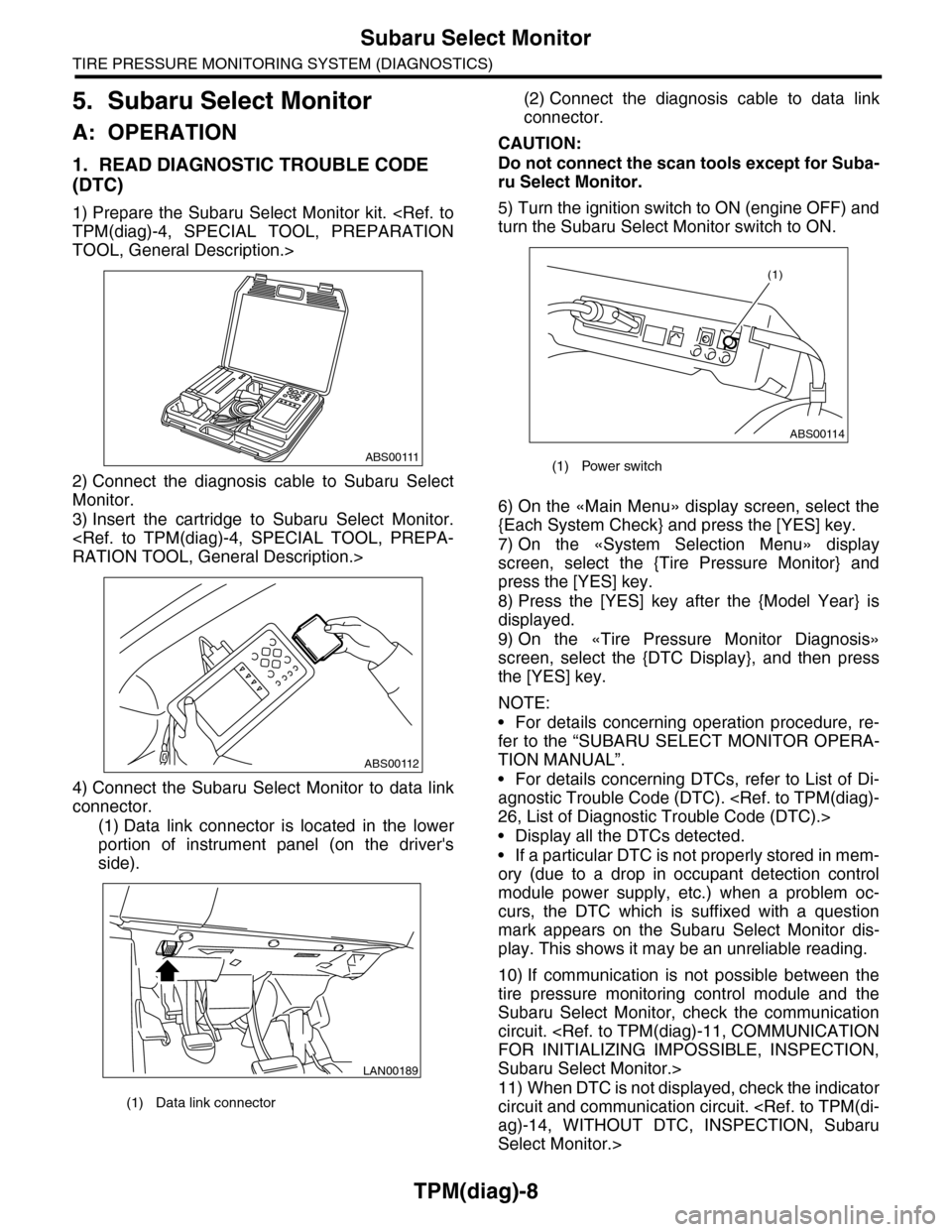

5. Subaru Select Monitor

A: OPERATION

1. READ DIAGNOSTIC TROUBLE CODE

(DTC)

1) Prepare the Subaru Select Monitor kit.

TOOL, General Description.>

2) Connect the diagnosis cable to Subaru Select

Monitor.

3) Insert the cartridge to Subaru Select Monitor.

4) Connect the Subaru Select Monitor to data link

connector.

(1) Data link connector is located in the lower

portion of instrument panel (on the driver's

side).

(2) Connect the diagnosis cable to data link

connector.

CAUTION:

Do not connect the scan tools except for Suba-

ru Select Monitor.

5) Turn the ignition switch to ON (engine OFF) and

turn the Subaru Select Monitor switch to ON.

6) On the «Main Menu» display screen, select the

{Each System Check} and press the [YES] key.

7) On the «System Selection Menu» display

screen, select the {Tire Pressure Monitor} and

press the [YES] key.

8) Press the [YES] key after the {Model Year} is

displayed.

9) On the «Tire Pressure Monitor Diagnosis»

screen, select the {DTC Display}, and then press

the [YES] key.

NOTE:

•For details concerning operation procedure, re-

fer to the “SUBARU SELECT MONITOR OPERA-

TION MANUAL”.

•For details concerning DTCs, refer to List of Di-

agnostic Trouble Code (DTC).

•Display all the DTCs detected.

•If a particular DTC is not properly stored in mem-

ory (due to a drop in occupant detection control

module power supply, etc.) when a problem oc-

curs, the DTC which is suffixed with a question

mark appears on the Subaru Select Monitor dis-

play. This shows it may be an unreliable reading.

10) If communication is not possible between the

tire pressure monitoring control module and the

Subaru Select Monitor, check the communication

circuit.

Subaru Select Monitor.>

11) When DTC is not displayed, check the indicator

circuit and communication circuit.

Select Monitor.>

(1) Data link connector

ABS00111

ABS00112

LAN00189

(1) Power switch

ABS00114

(1)

Page 994 of 2453

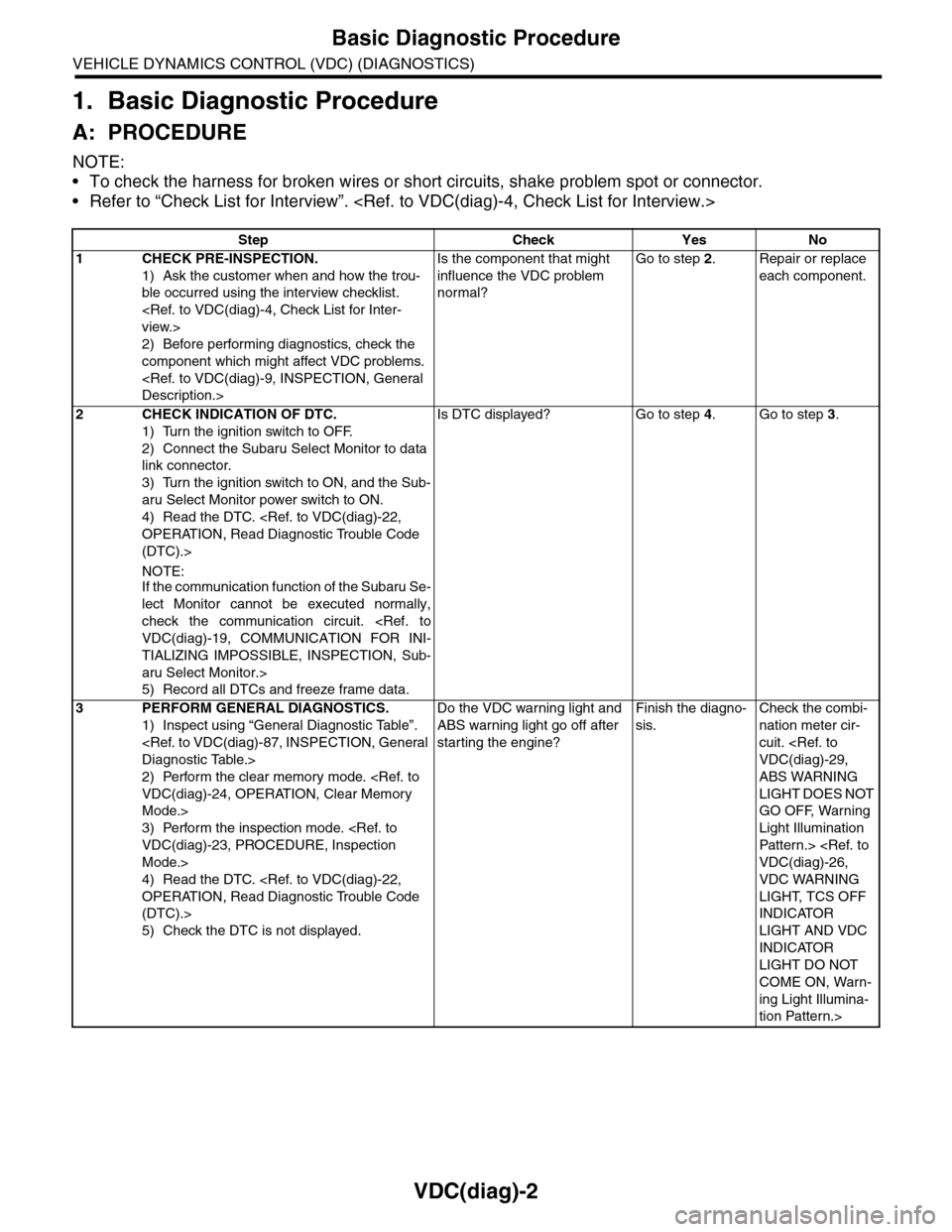

VDC(diag)-2

Basic Diagnostic Procedure

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

1. Basic Diagnostic Procedure

A: PROCEDURE

NOTE:

•To check the harness for broken wires or short circuits, shake problem spot or connector.

•Refer to “Check List for Interview”.

Step Check Yes No

1CHECK PRE-INSPECTION.

1) Ask the customer when and how the trou-

ble occurred using the interview checklist.

2) Before performing diagnostics, check the

component which might affect VDC problems.

Is the component that might

influence the VDC problem

normal?

Go to step 2.Repair or replace

each component.

2CHECK INDICATION OF DTC.

1) Turn the ignition switch to OFF.

2) Connect the Subaru Select Monitor to data

link connector.

3) Turn the ignition switch to ON, and the Sub-

aru Select Monitor power switch to ON.

4) Read the DTC.

(DTC).>

NOTE:If the communication function of the Subaru Se-

lect Monitor cannot be executed normally,

check the communication circuit.

TIALIZING IMPOSSIBLE, INSPECTION, Sub-

aru Select Monitor.>

5) Record all DTCs and freeze frame data.

Is DTC displayed? Go to step 4.Go to step 3.

3PERFORM GENERAL DIAGNOSTICS.

1) Inspect using “General Diagnostic Table”.

2) Perform the clear memory mode.

Mode.>

3) Perform the inspection mode.

Mode.>

4) Read the DTC.

(DTC).>

5) Check the DTC is not displayed.

Do the VDC warning light and

ABS warning light go off after

starting the engine?

Finish the diagno-

sis.

Check the combi-

nation meter cir-

cuit.

ABS WARNING

LIGHT DOES NOT

GO OFF, Warning

Light Illumination

Patter n.>

VDC WARNING

LIGHT, TCS OFF

INDICATOR

LIGHT AND VDC

INDICATOR

LIGHT DO NOT

COME ON, Warn-

ing Light Illumina-

tion Pattern.>

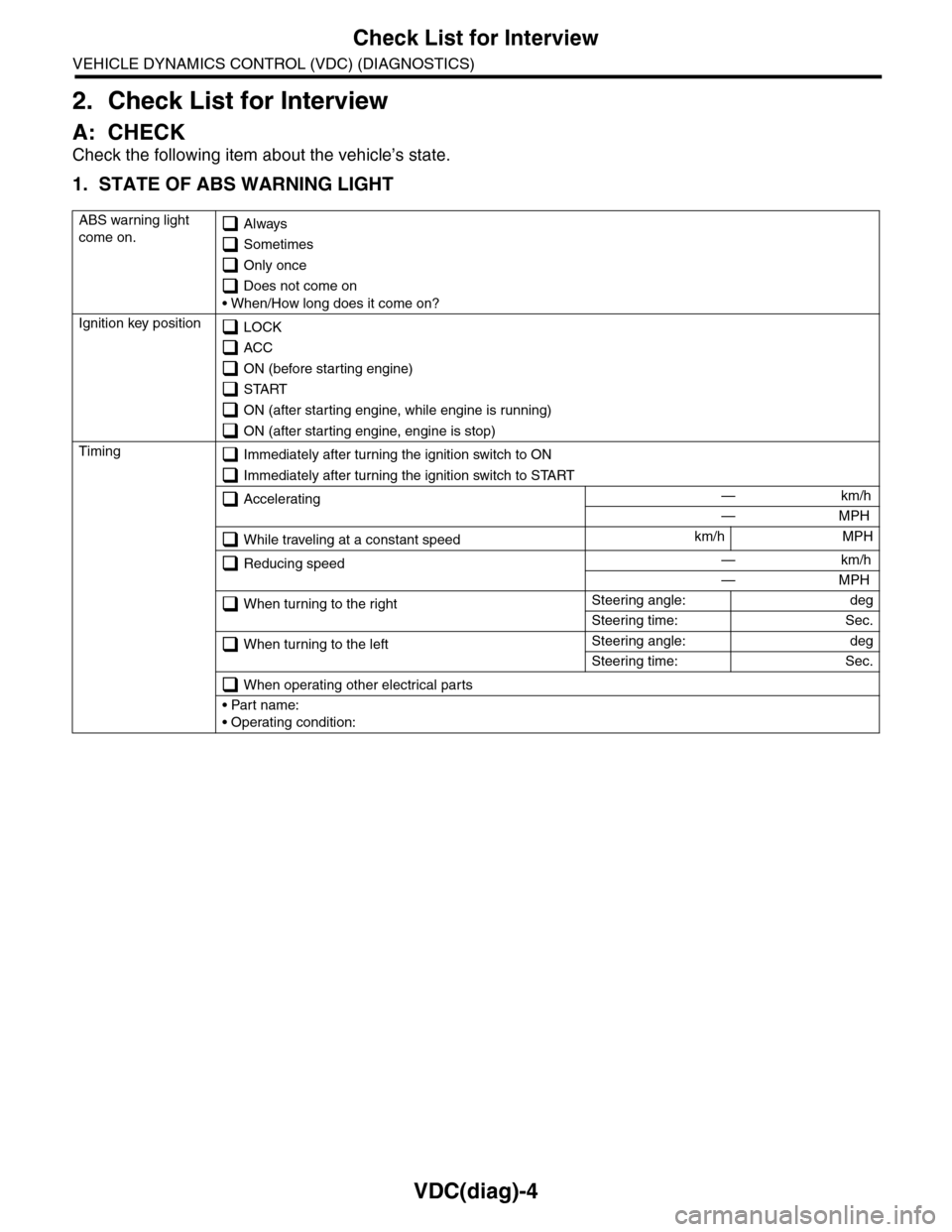

Page 996 of 2453

VDC(diag)-4

Check List for Interview

VEHICLE DYNAMICS CONTROL (VDC) (DIAGNOSTICS)

2. Check List for Interview

A: CHECK

Check the following item about the vehicle’s state.

1. STATE OF ABS WARNING LIGHT

ABS warning light

come on. Always

Sometimes

Only once

Does not come on

• When/How long does it come on?

Ignition key position LOCK

ACC

ON (before starting engine)

START

ON (after starting engine, while engine is running)

ON (after starting engine, engine is stop)

Timing Immediately after turning the ignition switch to ON

Immediately after turning the ignition switch to START

Accelerating — km/h

— MPH

While traveling at a constant speedkm/h MPH

Reducing speed — km/h

— MPH

When turning to the rightSteering angle: deg

Steering time: Sec.

When turning to the leftSteering angle: deg

Steering time: Sec.

When operating other electrical parts

• Part name:

• Operating condition: