harness SUBARU TRIBECA 2009 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 1599 of 2453

FU(H6DO)-38

Fuel Tank

FUEL INJECTION (FUEL SYSTEMS)

22.Fuel Tank

A: REMOVAL

WARNING:

•Place “NO FIRE” signs near the working area.

•Be careful not to spill fuel on the floor.

1) Set the vehicle on a lift.

2) Release the fuel pressure.

DURE, Fuel.>

3) Disconnect the ground cable from battery.

4) Drain fuel from fuel tank.

5) Remove the second seat.

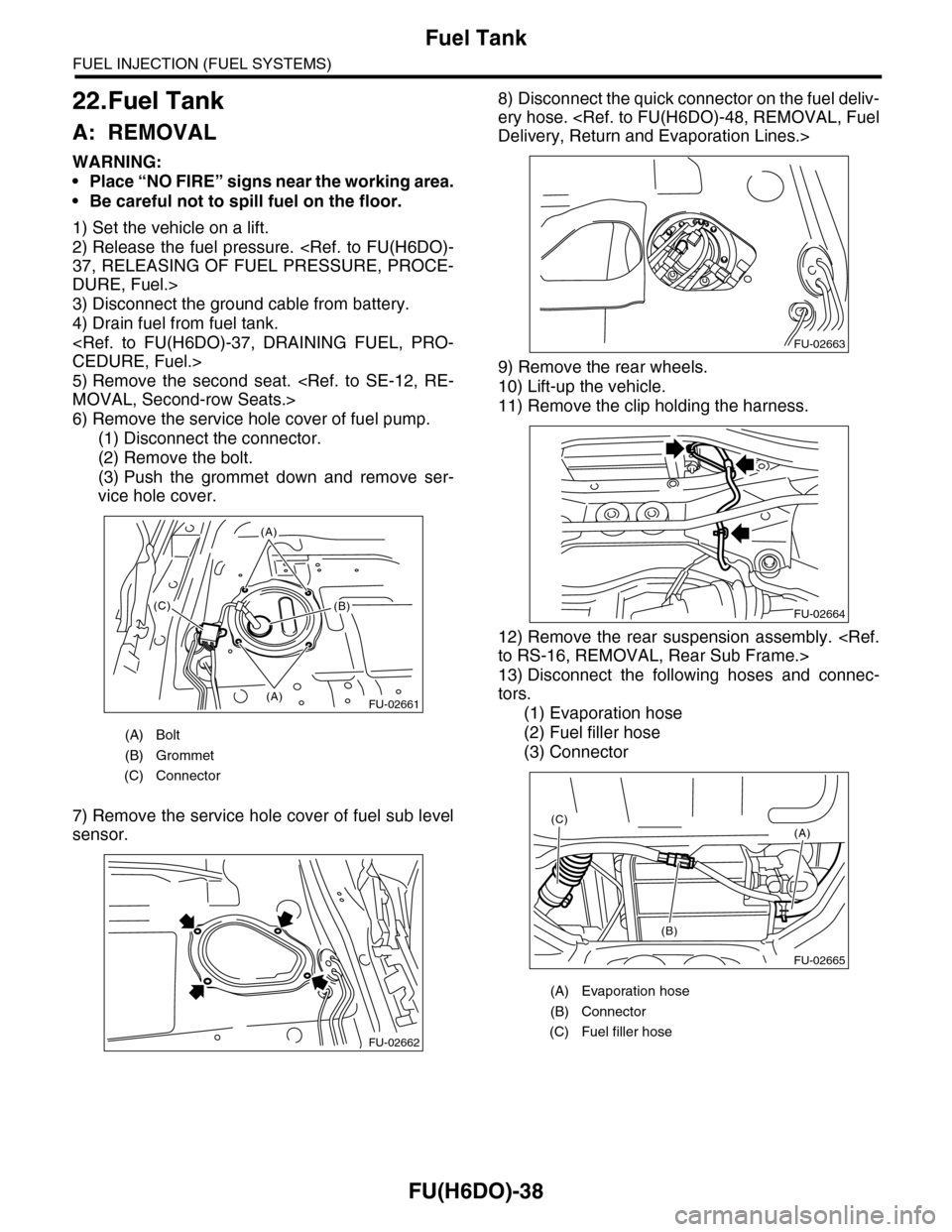

6) Remove the service hole cover of fuel pump.

(1) Disconnect the connector.

(2) Remove the bolt.

(3) Push the grommet down and remove ser-

vice hole cover.

7) Remove the service hole cover of fuel sub level

sensor.

8) Disconnect the quick connector on the fuel deliv-

ery hose.

9) Remove the rear wheels.

10) Lift-up the vehicle.

11) Remove the clip holding the harness.

12) Remove the rear suspension assembly.

13) Disconnect the following hoses and connec-

tors.

(1) Evaporation hose

(2) Fuel filler hose

(3) Connector

(A) Bolt

(B) Grommet

(C) Connector

FU-02661(A)

(A)

(B)(C)

FU-02662

(A) Evaporation hose

(B) Connector

(C) Fuel filler hose

FU-02663

FU-02664

FU-02665

(A)

(B)

(C)

Page 1600 of 2453

FU(H6DO)-39

Fuel Tank

FUEL INJECTION (FUEL SYSTEMS)

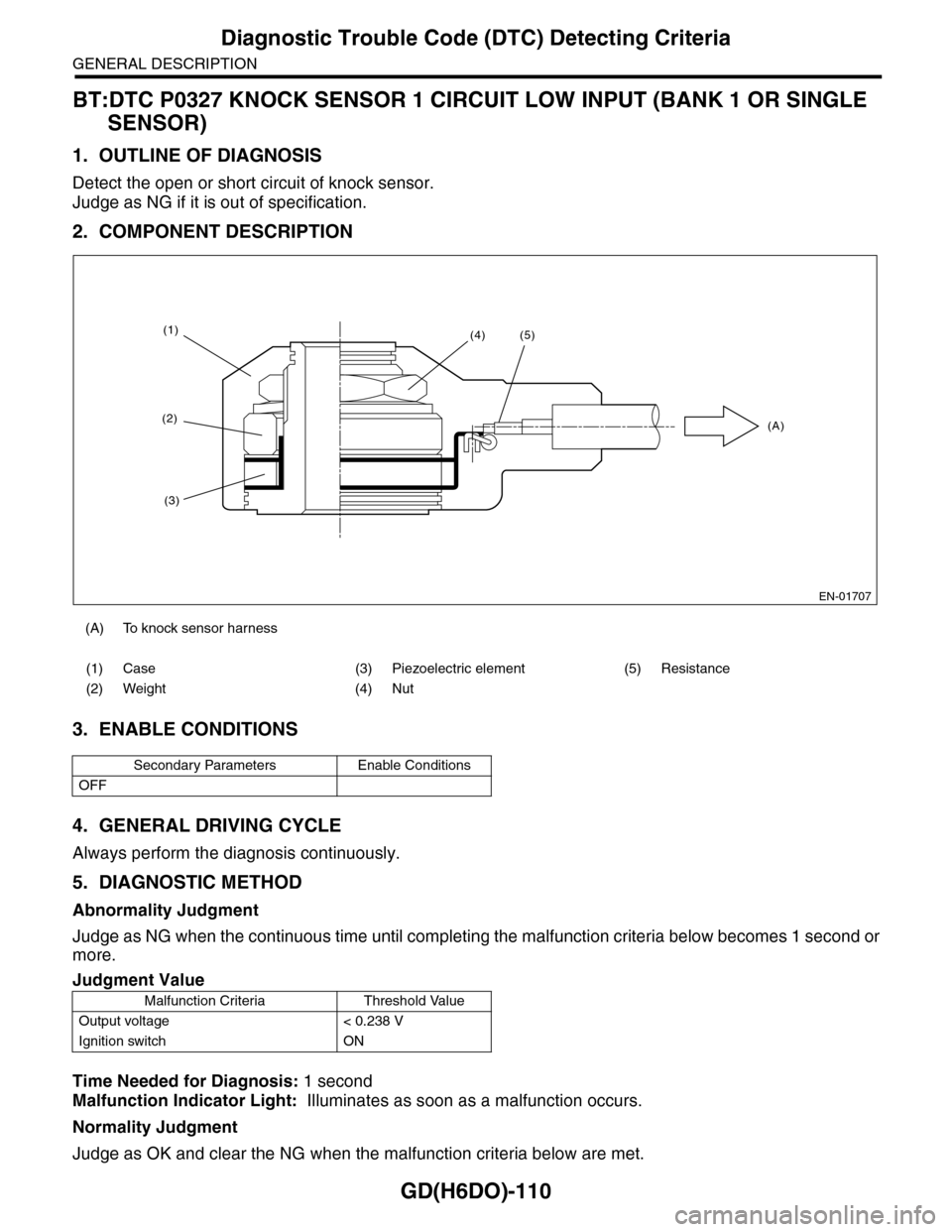

14) Remove the fuel tank from the vehicle.

WARNING:

A helper is required to perform this work.

(1) Support the fuel tank with the transmission

jack.

(2) Remove the fuel tank band that holds the

fuel tank.

(3) Remove the fuel tank from the vehicle.

B: INSTALLATION

1) Install the fuel tank to the vehicle.

WARNING:

A helper is required to perform this work.

(1) Lift the fuel tank with the transmission jack.

(2) Mount the fuel tank to the vehicle with a jack.

(3) Install the fuel tank band that holds the fuel

tank.

Tightening torque:

33 N·m (3.4 kgf-m, 25 ft-lb)

2) Connect the following hoses and connectors.

(1) Evaporation hose

(2) Fuel filler hose

(3) Connector

3) Install the rear suspension assembly.

4) Install the clip that holds the harness.

5) Lower the vehicle.

6) Install the rear wheels.

7) Connect the quick connector on fuel delivery

hose.

8) Install the service hole cover of fuel sub level

sensor.

FU-02666

FU-02666

(A) Evaporation hose

(B) Connector

(C) Fuel filler hose

FU-02665

(A)

(B)

(C)

FU-02664

FU-02662

Page 1605 of 2453

FU(H6DO)-44

Fuel Pump

FUEL INJECTION (FUEL SYSTEMS)

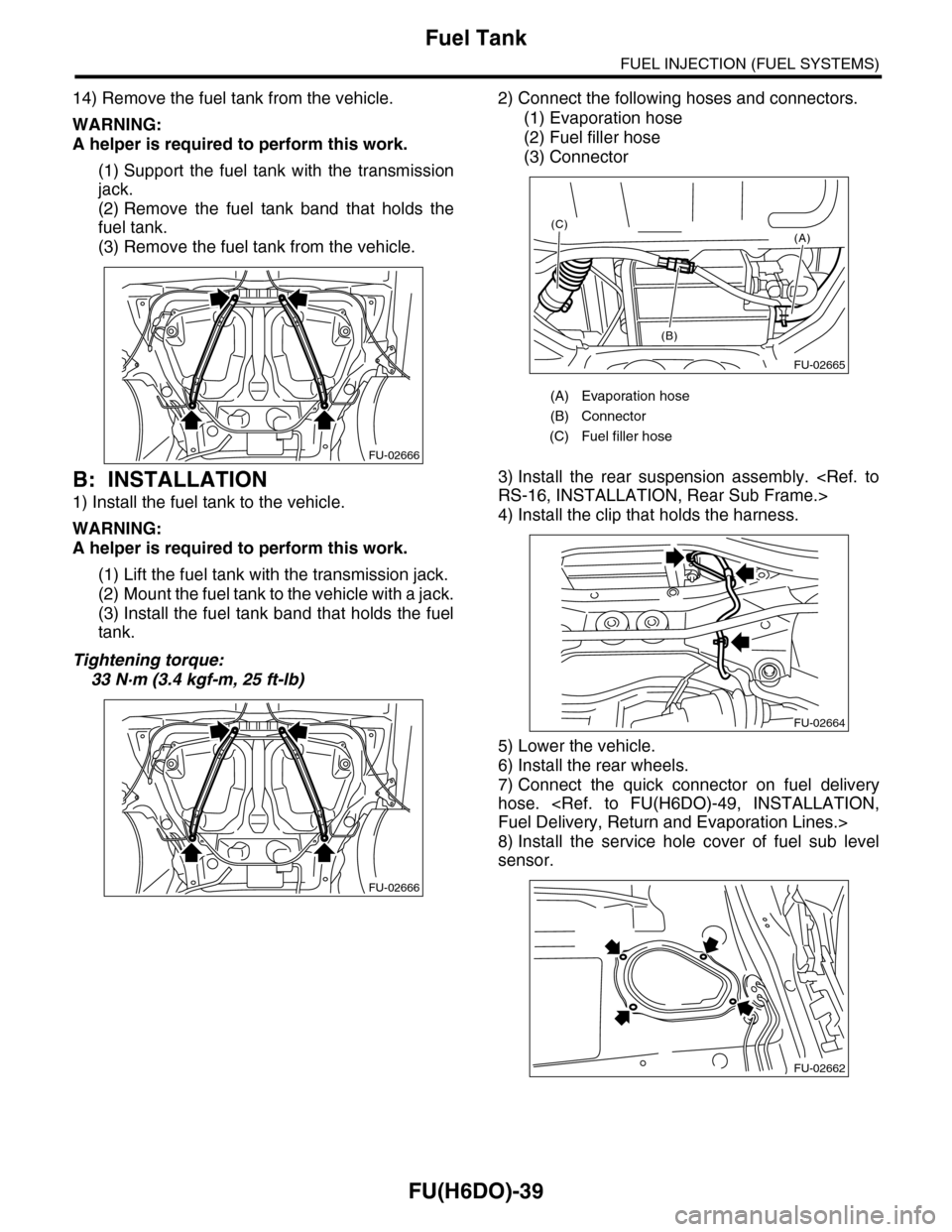

C: INSPECTION

Connect the lead harness to the connector terminal

of fuel pump, and apply the battery power supply to

check whether the pump operates.

WARNING:

•Wipe off fuel completely.

•Keep the battery as far apart from fuel pump

as possible.

•Be sure to turn the battery supply to ON and

OFF on the battery side.

•Do not run the fuel pump for a long time un-

der non-load condition.

FU-01330

246

135

Page 1722 of 2453

GD(H6DO)-110

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

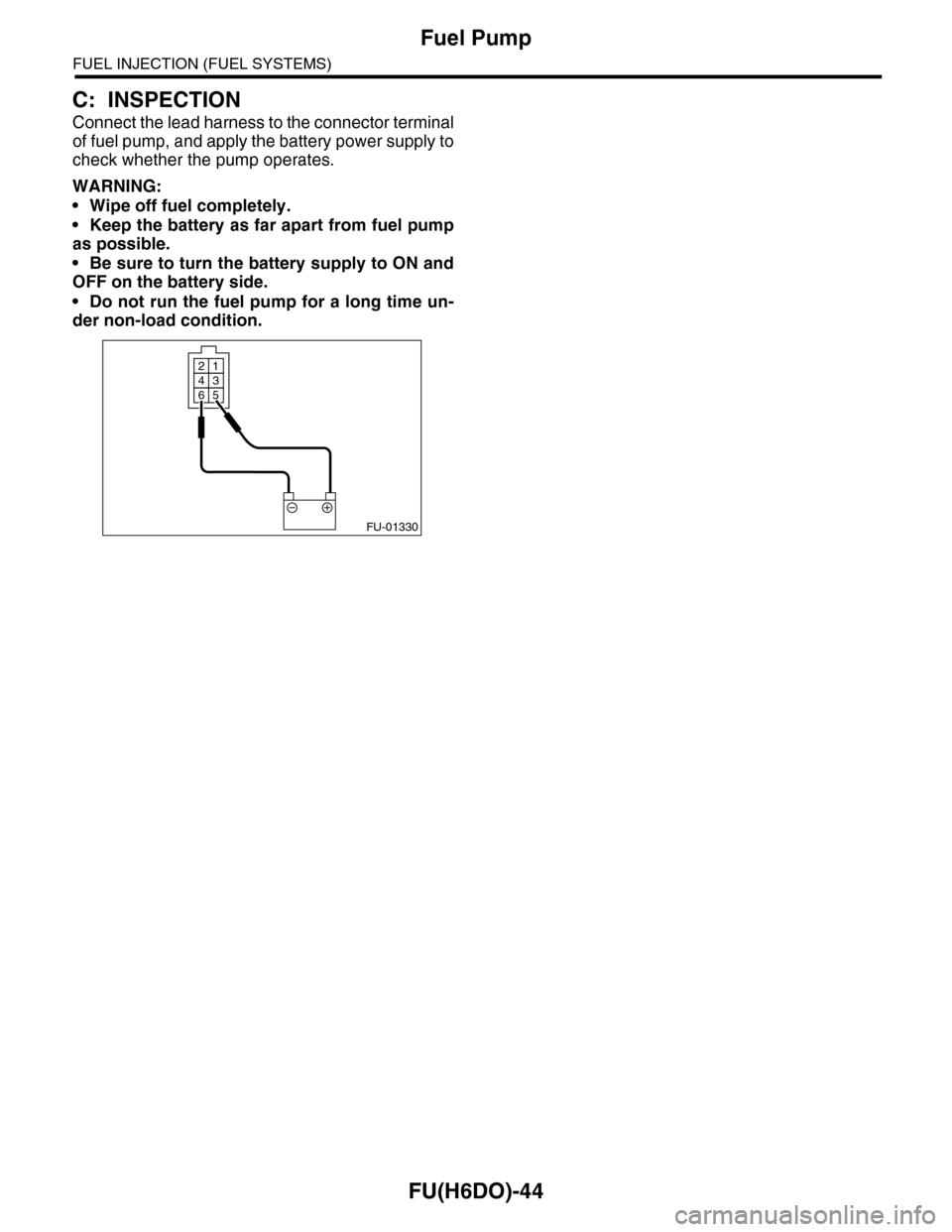

BT:DTC P0327 KNOCK SENSOR 1 CIRCUIT LOW INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

OFF

Judgment Value

Malfunction Criteria Threshold Value

Output voltage < 0.238 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1724 of 2453

GD(H6DO)-112

Diagnostic Trouble Code (DTC) Detecting Criteria

GENERAL DESCRIPTION

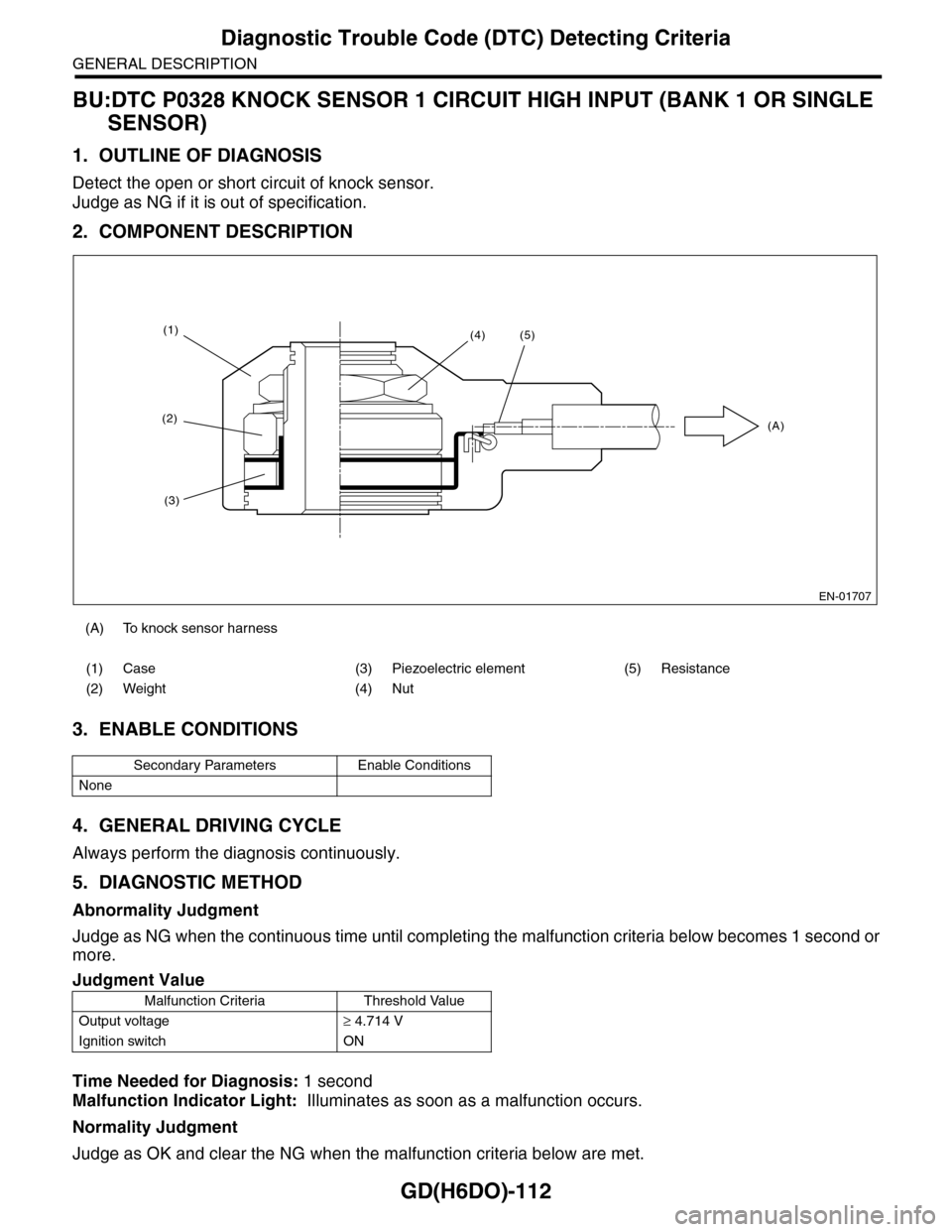

BU:DTC P0328 KNOCK SENSOR 1 CIRCUIT HIGH INPUT (BANK 1 OR SINGLE

SENSOR)

1. OUTLINE OF DIAGNOSIS

Detect the open or short circuit of knock sensor.

Judge as NG if it is out of specification.

2. COMPONENT DESCRIPTION

3. ENABLE CONDITIONS

4. GENERAL DRIVING CYCLE

Always perform the diagnosis continuously.

5. DIAGNOSTIC METHOD

Abnormality Judgment

Judge as NG when the continuous time until completing the malfunction criteria below becomes 1 second or

more.

Time Needed for Diagnosis: 1 second

Malfunction Indicator Light: Illuminates as soon as a malfunction occurs.

Normality Judgment

Judge as OK and clear the NG when the malfunction criteria below are met.

(A) To knock sensor harness

(1) Case (3) Piezoelectric element (5) Resistance

(2) Weight (4) Nut

Secondary Parameters Enable Conditions

None

Judgment Value

Malfunction Criteria Threshold Value

Output voltage≥ 4.714 V

Ignition switch ON

EN-01707

(1)

(2)

(3)

(4)(5)

(A)

Page 1855 of 2453

LU(H6DO)-6

Oil Pressure System

LUBRICATION

B: INSPECTION

Step Check Yes No

1CHECK COMBINATION METER.

1) Turn the ignition switch ON. (Engine OFF)

2) Check the warning light of combination

meter.

Does the warning light illumi-

nate?

Go to step 2.Repair or replace

the combination

meter.

Combination

Meter System.>

2CHECK HARNESS CONNECTOR BETWEEN

COMBINATION METER AND OIL PRES-

SURE SWITCH.

1) Turn the ignition switch to OFF.

2) Disconnect the connector from oil pressure

switch.

3) Turn the ignition switch ON.

4) Measure the voltage of harness between oil

pressure switch connector and chassis ground.

Connector & terminal

(E11) No. 1 (+) — Chassis ground (–):

Is the voltage more than 10 V? Replace the oil

pressure switch.

Go to step 3.

3CHECK COMBINATION METER.

1) Turn the ignition switch to OFF.

2) Remove the combination meter.

3) Measure the resistance of combination

meter.

Te r m i n a l s

(i10) No. 4 — (i77) No. 10:

(i10) No. 3 — (i77) No. 10:

Is the resistance less than 10

Ω?

Replace the har-

ness connector

between combina-

tion meter and oil

pressure switch.

Repair or replace

the combination

meter.

Combination

Meter System.>

Page 1866 of 2453

LU(H6DO)-17

General Diagnostics Table

LUBRICATION

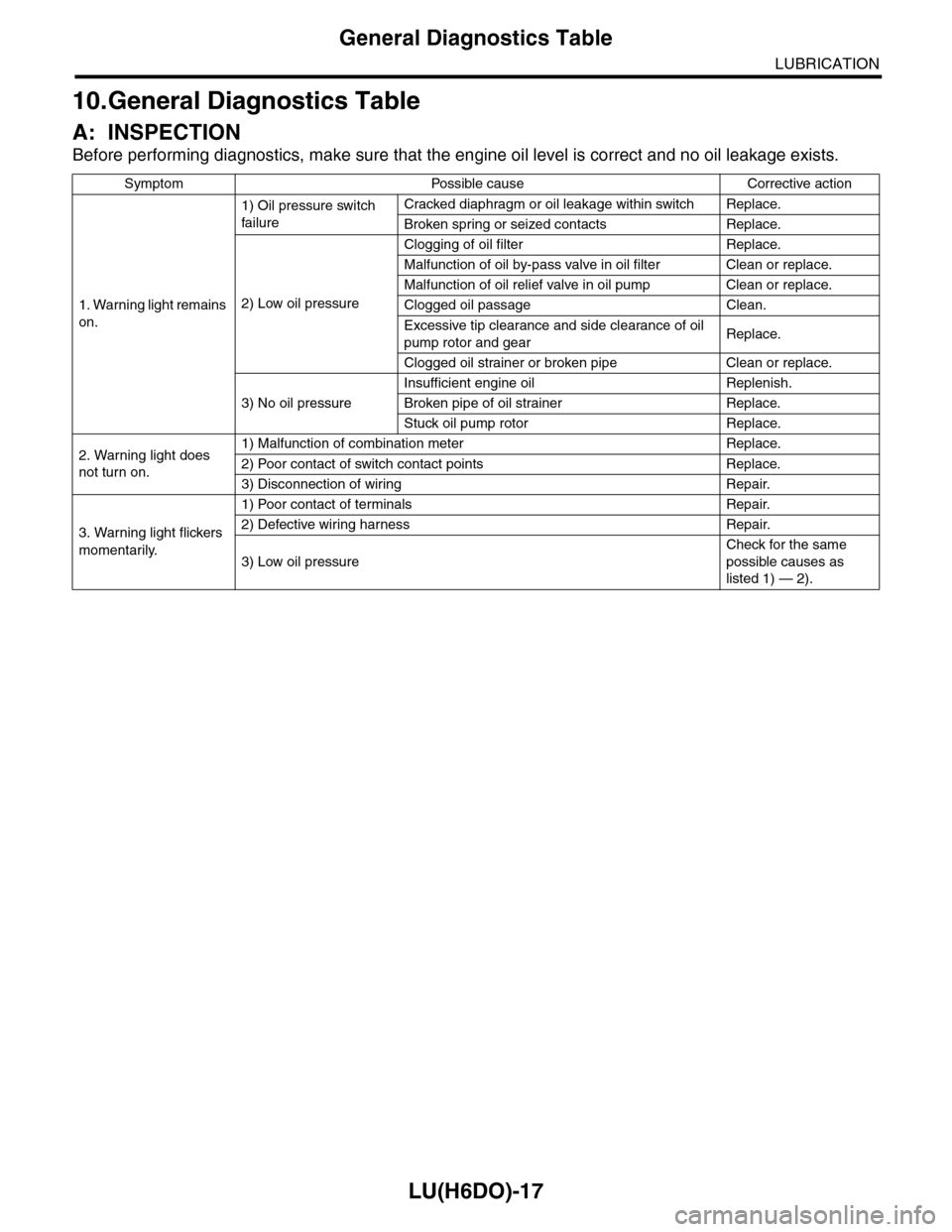

10.General Diagnostics Table

A: INSPECTION

Before performing diagnostics, make sure that the engine oil level is correct and no oil leakage exists.

Symptom Possible cause Corrective action

1. Warning light remains

on.

1) Oil pressure switch

failure

Cracked diaphragm or oil leakage within switch Replace.

Broken spring or seized contacts Replace.

2) Low oil pressure

Clogging of oil filter Replace.

Malfunction of oil by-pass valve in oil filter Clean or replace.

Malfunction of oil relief valve in oil pump Clean or replace.

Clogged oil passage Clean.

Excessive tip clearance and side clearance of oil

pump rotor and gearReplace.

Clogged oil strainer or broken pipe Clean or replace.

3) No oil pressure

Insufficient engine oil Replenish.

Broken pipe of oil strainer Replace.

Stuck oil pump rotor Replace.

2. Warning light does

not turn on.

1) Malfunction of combination meter Replace.

2) Poor contact of switch contact points Replace.

3) Disconnection of wiring Repair.

3. Warning light flickers

momentarily.

1) Poor contact of terminals Repair.

2) Defective wiring harness Repair.

3) Low oil pressure

Check for the same

possible causes as

listed 1) — 2).

Page 1898 of 2453

ME(H6DO)-32

Engine Assembly

MECHANICAL

10.Engine Assembly

A: REMOVAL

1) Set the vehicle on a lift.

2) Change the bolt mounting position from (A) to

(B), then completely open the front hood.

3) Remove the collector cover.

4) Collect the refrigerant from A/C system.

cedure.>

5) Release the fuel pressure.

6) Remove the battery from vehicle.

7) Remove the air intake duct, air cleaner case and

air intake chamber.

8) Remove the engine front cover.

9) Remove the radiator from the vehicle.

NOTE:

Protect the condenser so that it will not be dam-

aged.

10) Remove the fuel hose bracket.

11) Remove the V-belts.

12) Disconnect the A/C pressure hoses from A/C

compressor.

13) Remove the engine ground terminal.

14) Disconnect the following connector.

(1) Engine harness connectors

(2) Generator connector, terminal and A/C

compressor connector

(3) Power steering switch connector

ME-02652

(A)

(B)

CO-02176

ME-02653

ME-00476

ME-02654

Page 1904 of 2453

ME(H6DO)-38

Engine Assembly

MECHANICAL

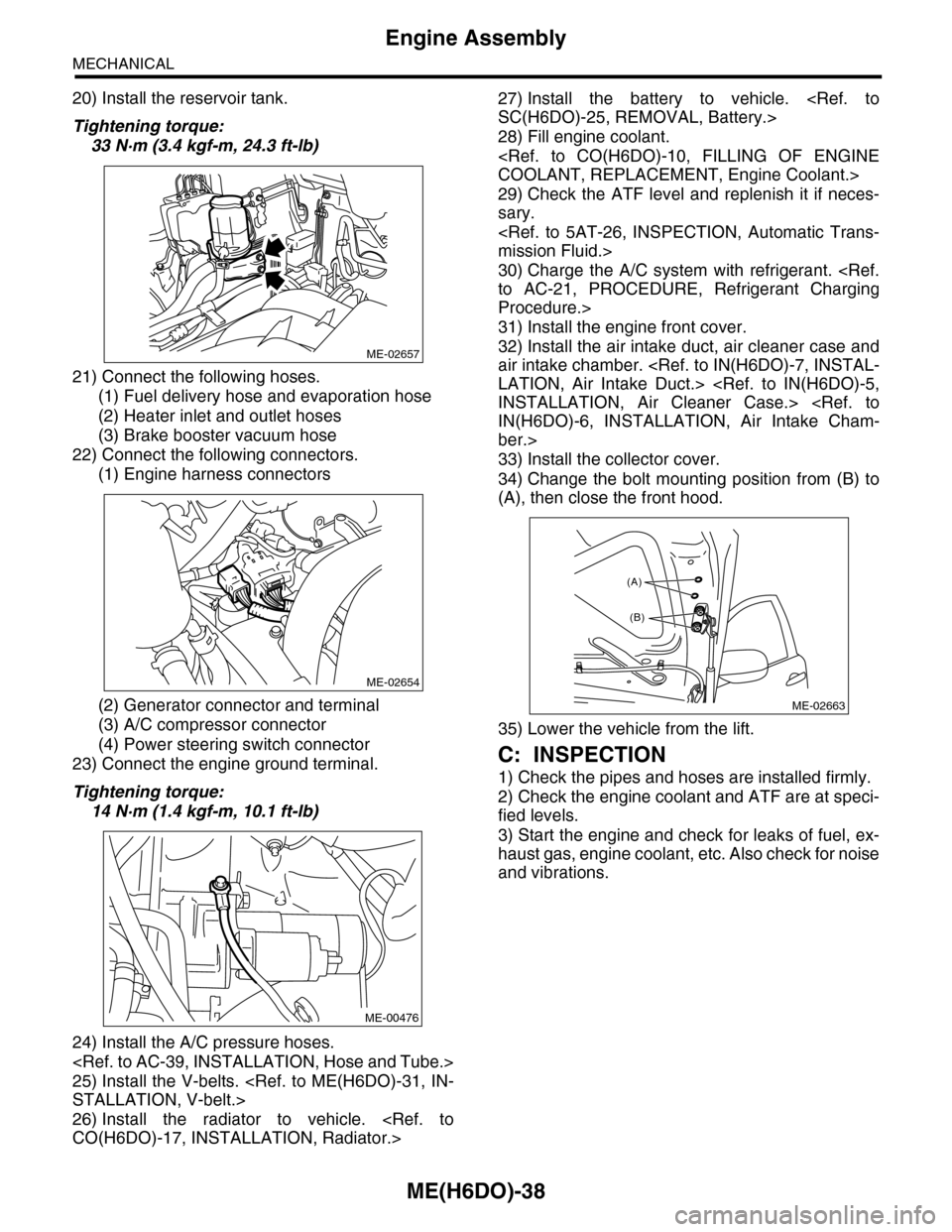

20) Install the reservoir tank.

Tightening torque:

33 N·m (3.4 kgf-m, 24.3 ft-lb)

21) Connect the following hoses.

(1) Fuel delivery hose and evaporation hose

(2) Heater inlet and outlet hoses

(3) Brake booster vacuum hose

22) Connect the following connectors.

(1) Engine harness connectors

(2) Generator connector and terminal

(3) A/C compressor connector

(4) Power steering switch connector

23) Connect the engine ground terminal.

Tightening torque:

14 N·m (1.4 kgf-m, 10.1 ft-lb)

24) Install the A/C pressure hoses.

25) Install the V-belts.

26) Install the radiator to vehicle.

27) Install the battery to vehicle.

28) Fill engine coolant.

29) Check the ATF level and replenish it if neces-

sary.

30) Charge the A/C system with refrigerant.

Procedure.>

31) Install the engine front cover.

32) Install the air intake duct, air cleaner case and

air intake chamber.

ber.>

33) Install the collector cover.

34) Change the bolt mounting position from (B) to

(A), then close the front hood.

35) Lower the vehicle from the lift.

C: INSPECTION

1) Check the pipes and hoses are installed firmly.

2) Check the engine coolant and ATF are at speci-

fied levels.

3) Start the engine and check for leaks of fuel, ex-

haust gas, engine coolant, etc. Also check for noise

and vibrations.

ME-02657

ME-02654

ME-00476

ME-02663

(A)

(B)

Page 1906 of 2453

ME(H6DO)-40

Preparation for Overhaul

MECHANICAL

12.Preparation for Overhaul

A: REMOVAL

1) Remove the engine assembly from the body.

2) Set the engine on ST.

ST 18232AA000 ENGINE STAND

3) Before servicing overhaul, remove the sensor,

pipe and hose that installed to engine.

(1) Remove the intake manifold.

(2) Remove the generator.

(3) Remove the A/C compressor.

(4) Disconnect the water pipe and hose.

(5) Disconnect the engine harness.

(6) Remove the spark plug.

(7) Remove the camshaft position sensor.

(8) Remove the crankshaft position sensor.

(9) Remove the knock sensor.

(10) Remove the engine coolant temperature

sensor.

(11) Remove the oil pressure switch.

Switch.>

(12) Remove the oil filter.

(13) Remove the oil cooler.

STME-02448