automatic SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 2055 of 2453

5AT-39

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

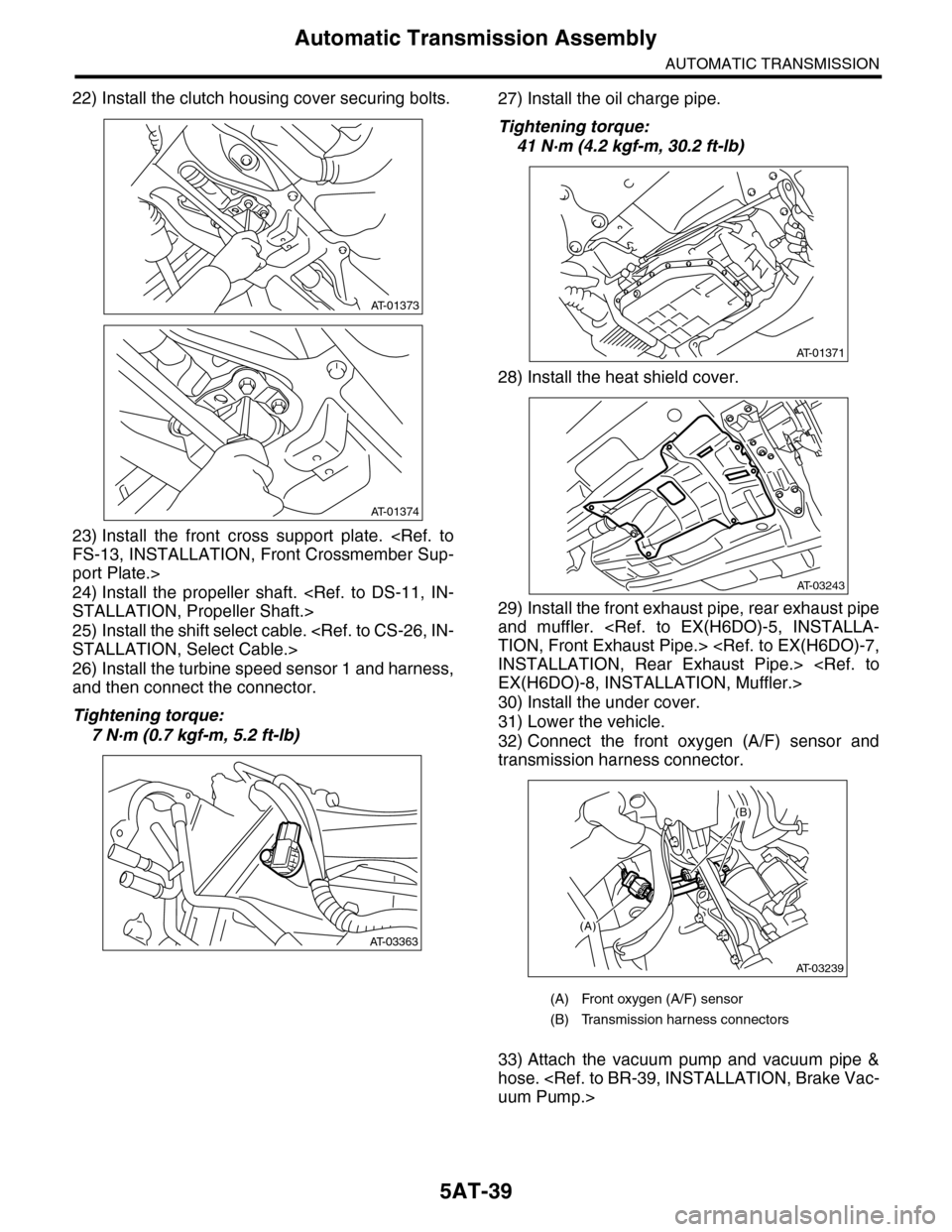

22) Install the clutch housing cover securing bolts.

23) Install the front cross support plate.

port Plate.>

24) Install the propeller shaft.

25) Install the shift select cable.

26) Install the turbine speed sensor 1 and harness,

and then connect the connector.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

27) Install the oil charge pipe.

Tightening torque:

41 N·m (4.2 kgf-m, 30.2 ft-lb)

28) Install the heat shield cover.

29) Install the front exhaust pipe, rear exhaust pipe

and muffler.

30) Install the under cover.

31) Lower the vehicle.

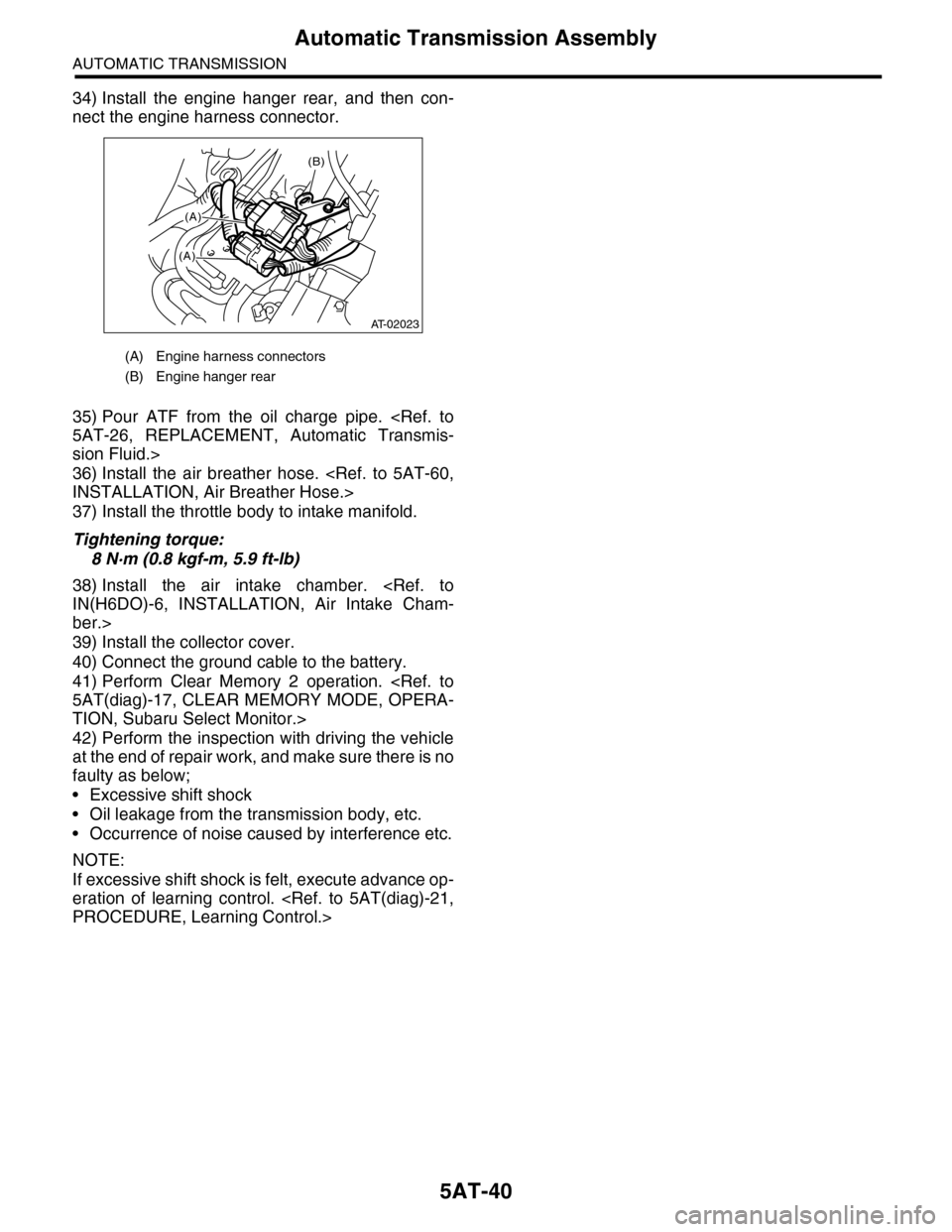

32) Connect the front oxygen (A/F) sensor and

transmission harness connector.

33) Attach the vacuum pump and vacuum pipe &

hose.

AT-01373

AT-01374

AT-03363

(A) Front oxygen (A/F) sensor

(B) Transmission harness connectors

AT-01371

AT-03243

(A)

(B)

AT-03239

Page 2056 of 2453

5AT-40

Automatic Transmission Assembly

AUTOMATIC TRANSMISSION

34) Install the engine hanger rear, and then con-

nect the engine harness connector.

35) Pour ATF from the oil charge pipe.

sion Fluid.>

36) Install the air breather hose.

37) Install the throttle body to intake manifold.

Tightening torque:

8 N·m (0.8 kgf-m, 5.9 ft-lb)

38) Install the air intake chamber.

ber.>

39) Install the collector cover.

40) Connect the ground cable to the battery.

41) Perform Clear Memory 2 operation.

TION, Subaru Select Monitor.>

42) Perform the inspection with driving the vehicle

at the end of repair work, and make sure there is no

faulty as below;

•Excessive shift shock

•Oil leakage from the transmission body, etc.

•Occurrence of noise caused by interference etc.

NOTE:

If excessive shift shock is felt, execute advance op-

eration of learning control.

(A) Engine harness connectors

(B) Engine hanger rear

(B)

(A)

(A)

AT-02023

Page 2057 of 2453

5AT-41

Transmission Mounting System

AUTOMATIC TRANSMISSION

10.Transmission Mounting Sys-

tem

A: REMOVAL

1. PITCHING STOPPER

1) Disconnect the ground cable from battery.

2) Remove the air intake chamber.

3) Remove the pitching stopper.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Disconnect the ground cable from battery.

2) Jack–up the vehicle and support it with rigid

racks.

3) Remove the front exhaust pipe, rear exhaust

pipe and muffler.

4) Remove the heat shield cover.

5) Set the transmission jack under transmission.

Make sure that the support plate of transmission

jack does not touch the oil pan.

6) Remove the transmission rear crossmember.

7) Remove the rear cushion rubber from transmis-

sion.

B: INSTALLATION

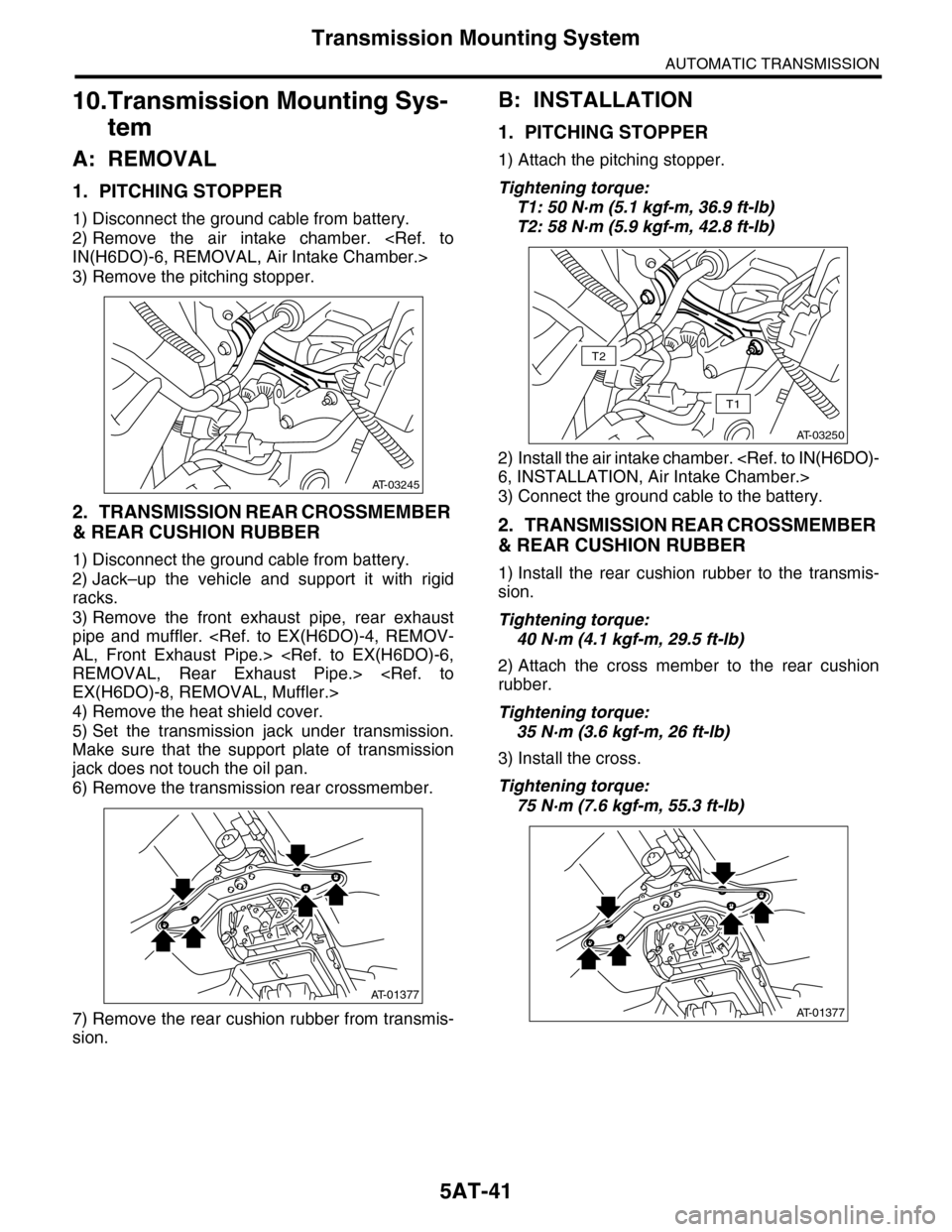

1. PITCHING STOPPER

1) Attach the pitching stopper.

Tightening torque:

T1: 50 N·m (5.1 kgf-m, 36.9 ft-lb)

T2: 58 N·m (5.9 kgf-m, 42.8 ft-lb)

2) Install the air intake chamber.

3) Connect the ground cable to the battery.

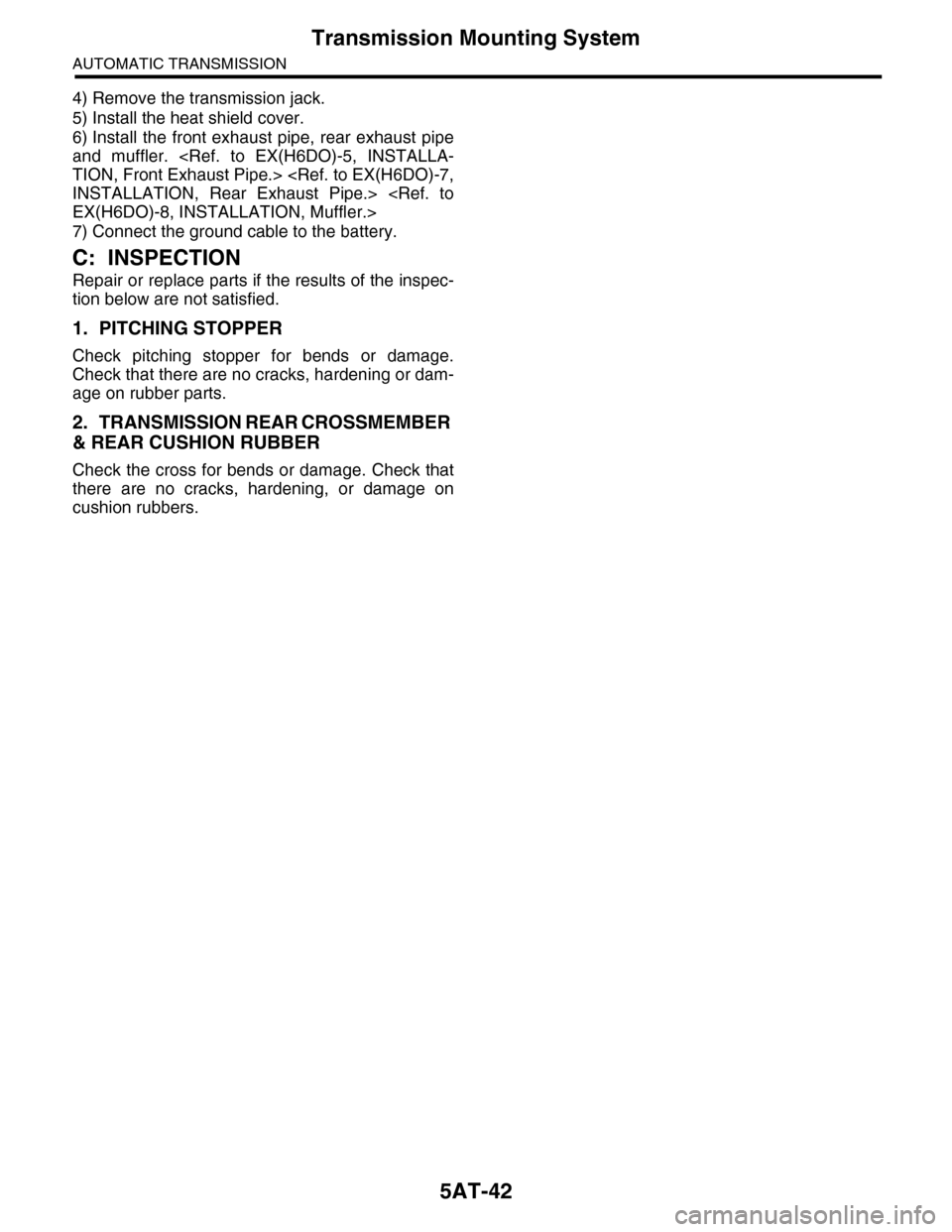

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

1) Install the rear cushion rubber to the transmis-

sion.

Tightening torque:

40 N·m (4.1 kgf-m, 29.5 ft-lb)

2) Attach the cross member to the rear cushion

rubber.

Tightening torque:

35 N·m (3.6 kgf-m, 26 ft-lb)

3) Install the cross.

Tightening torque:

75 N·m (7.6 kgf-m, 55.3 ft-lb)

AT-03245

AT-01377

AT-03250

T2

T1

AT-01377

Page 2058 of 2453

5AT-42

Transmission Mounting System

AUTOMATIC TRANSMISSION

4) Remove the transmission jack.

5) Install the heat shield cover.

6) Install the front exhaust pipe, rear exhaust pipe

and muffler.

7) Connect the ground cable to the battery.

C: INSPECTION

Repair or replace parts if the results of the inspec-

tion below are not satisfied.

1. PITCHING STOPPER

Check pitching stopper for bends or damage.

Check that there are no cracks, hardening or dam-

age on rubber parts.

2. TRANSMISSION REAR CROSSMEMBER

& REAR CUSHION RUBBER

Check the cross for bends or damage. Check that

there are no cracks, hardening, or damage on

cushion rubbers.

Page 2059 of 2453

5AT-43

Extension Case Oil Seal

AUTOMATIC TRANSMISSION

11.Extension Case Oil Seal

A: INSPECTION

Inspect there is no ATF leakage from the joint of

transmission and propeller shaft. If a leak is found,

replace the oil seal.

B: REPLACEMENT

1) Lift-up the vehicle.

2) Clean the transmission exterior.

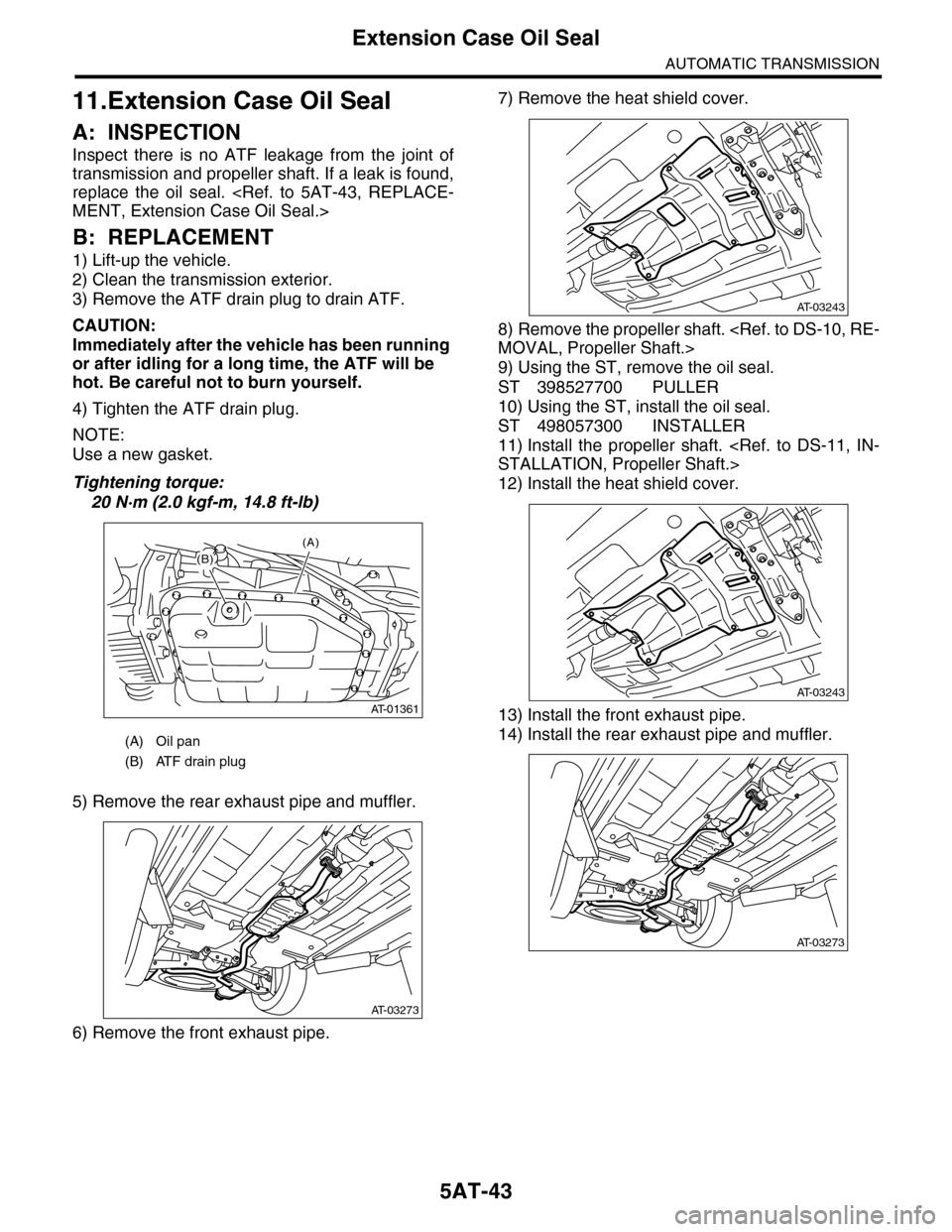

3) Remove the ATF drain plug to drain ATF.

CAUTION:

Immediately after the vehicle has been running

or after idling for a long time, the ATF will be

hot. Be careful not to burn yourself.

4) Tighten the ATF drain plug.

NOTE:

Use a new gasket.

Tightening torque:

20 N·m (2.0 kgf-m, 14.8 ft-lb)

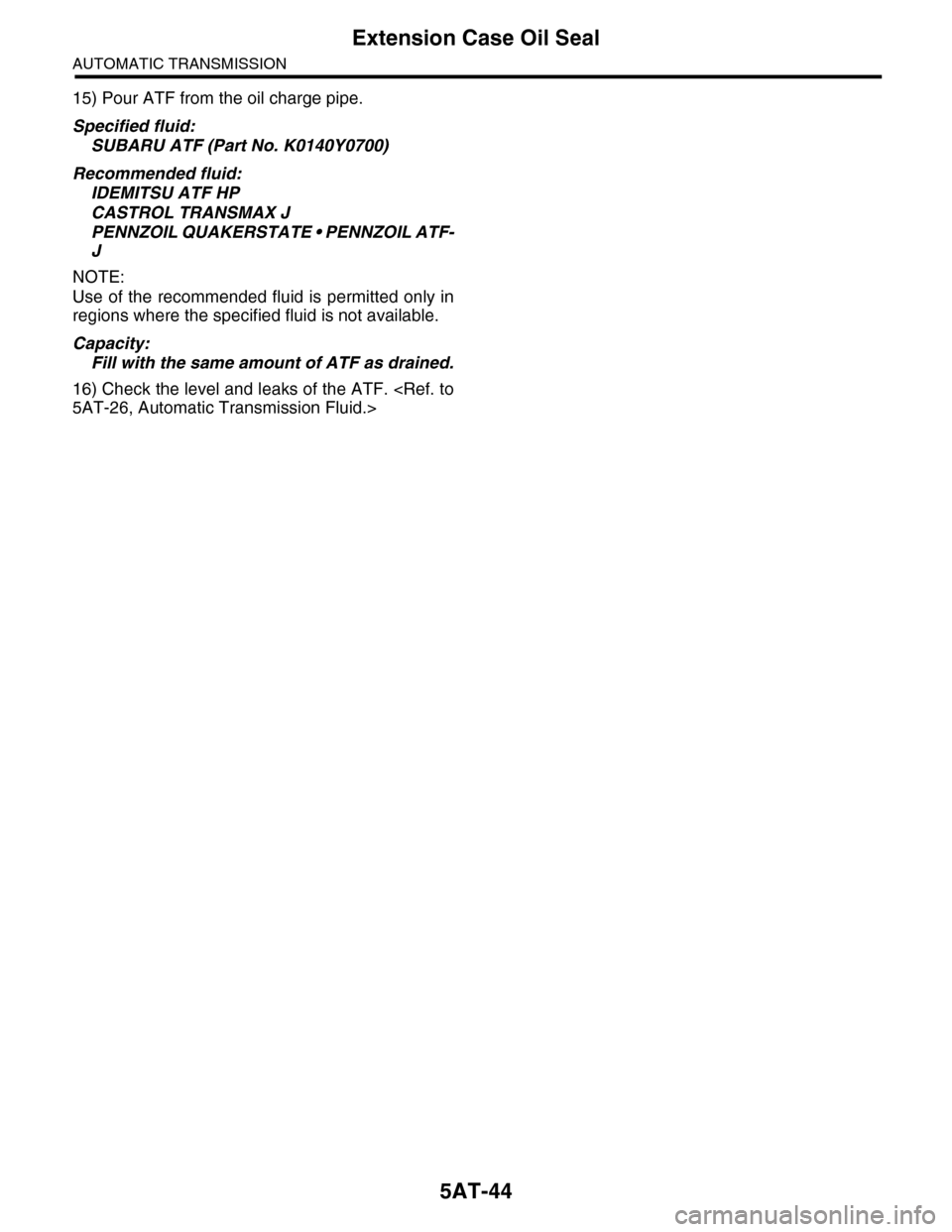

5) Remove the rear exhaust pipe and muffler.

6) Remove the front exhaust pipe.

7) Remove the heat shield cover.

8) Remove the propeller shaft.

9) Using the ST, remove the oil seal.

ST 398527700 PULLER

10) Using the ST, install the oil seal.

ST 498057300 INSTALLER

11) Install the propeller shaft.

12) Install the heat shield cover.

13) Install the front exhaust pipe.

14) Install the rear exhaust pipe and muffler. (A) Oil pan

(B) ATF drain plug

(A)

AT-01361

(B)

AT-03273

AT-03243

AT-03243

AT-03273

Page 2060 of 2453

5AT-44

Extension Case Oil Seal

AUTOMATIC TRANSMISSION

15) Pour ATF from the oil charge pipe.

Specified fluid:

SUBARU ATF (Part No. K0140Y0700)

Recommended fluid:

IDEMITSU ATF HP

CASTROL TRANSMAX J

PENNZOIL QUAKERSTATE • PENNZOIL ATF-

J

NOTE:

Use of the recommended fluid is permitted only in

regions where the specified fluid is not available.

Capacity:

Fill with the same amount of ATF as drained.

16) Check the level and leaks of the ATF.

Page 2061 of 2453

5AT-45

Differential Side Retainer Oil Seal

AUTOMATIC TRANSMISSION

12.Differential Side Retainer Oil

Seal

A: INSPECTION

Check for leakage of gear oil from differential side

retainer oil seal part. If there is an oil leak, replace

the oil seal.

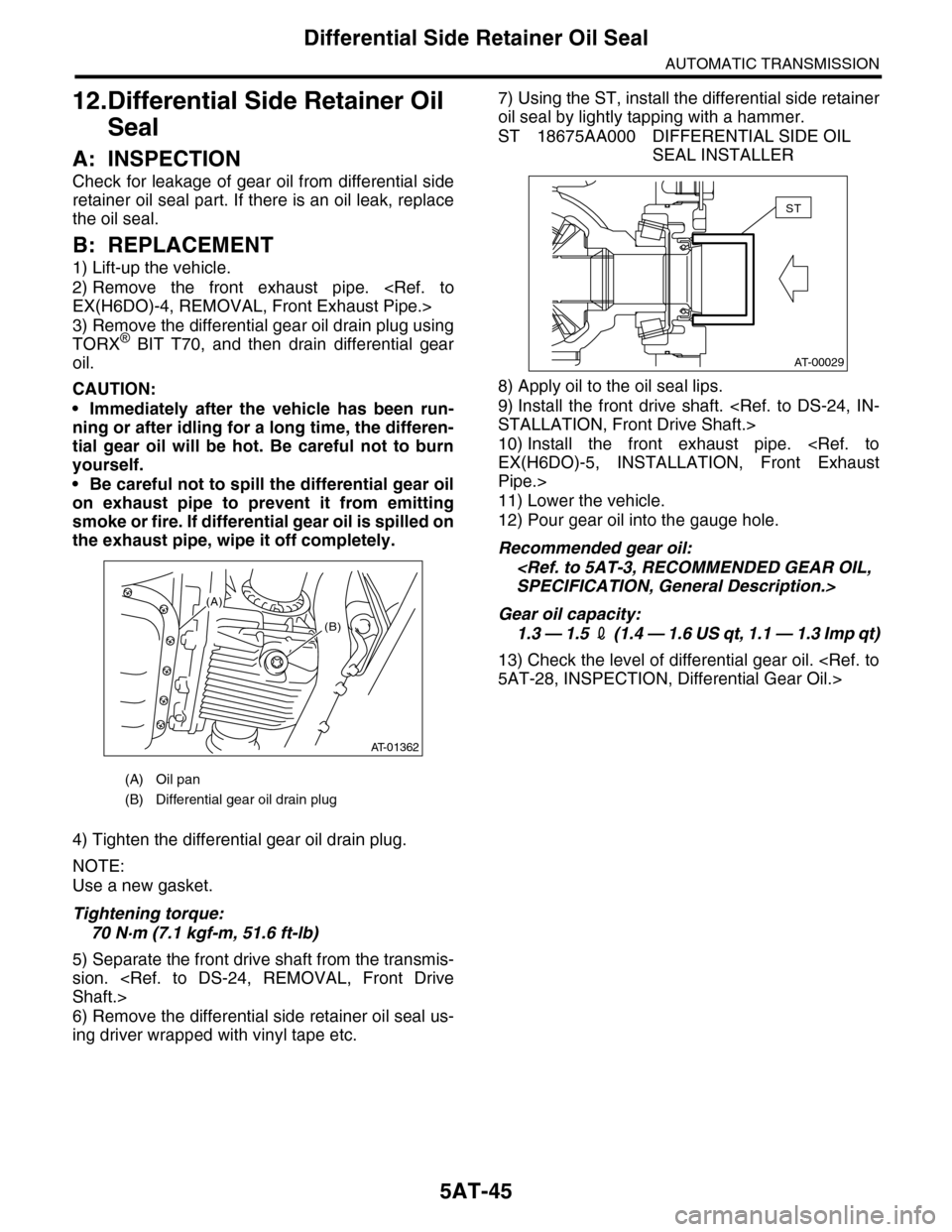

B: REPLACEMENT

1) Lift-up the vehicle.

2) Remove the front exhaust pipe.

3) Remove the differential gear oil drain plug using

TORX® BIT T70, and then drain differential gear

oil.

CAUTION:

•Immediately after the vehicle has been run-

ning or after idling for a long time, the differen-

tial gear oil will be hot. Be careful not to burn

yourself.

•Be careful not to spill the differential gear oil

on exhaust pipe to prevent it from emitting

smoke or fire. If differential gear oil is spilled on

the exhaust pipe, wipe it off completely.

4) Tighten the differential gear oil drain plug.

NOTE:

Use a new gasket.

Tightening torque:

70 N·m (7.1 kgf-m, 51.6 ft-lb)

5) Separate the front drive shaft from the transmis-

sion.

6) Remove the differential side retainer oil seal us-

ing driver wrapped with vinyl tape etc.

7) Using the ST, install the differential side retainer

oil seal by lightly tapping with a hammer.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

8) Apply oil to the oil seal lips.

9) Install the front drive shaft.

10) Install the front exhaust pipe.

Pipe.>

11) Lower the vehicle.

12) Pour gear oil into the gauge hole.

Recommended gear oil:

Gear oil capacity:

1.3 — 1.5 2 ( 1 . 4 — 1 . 6 U S q t , 1 . 1 — 1 . 3 I m p q t )

13) Check the level of differential gear oil.

(A) Oil pan

(B) Differential gear oil drain plug

(B)

AT-01362

(A)

AT-00029

ST

Page 2062 of 2453

5AT-46

Inhibitor Switch

AUTOMATIC TRANSMISSION

13.Inhibitor Switch

A: INSPECTION

Inhibitor switch cannot be checked, because the in-

hibitor switch is installed on control valve assembly.

When a malfunction occurs, refer to 5AT (diag)

section.

(PRNDL INPUT), Diagnostic Procedure with Diag-

nostic Trouble Code (DTC).>

Page 2063 of 2453

5AT-47

Front Vehicle Speed Sensor

AUTOMATIC TRANSMISSION

14.Front Vehicle Speed Sensor

A: REMOVAL

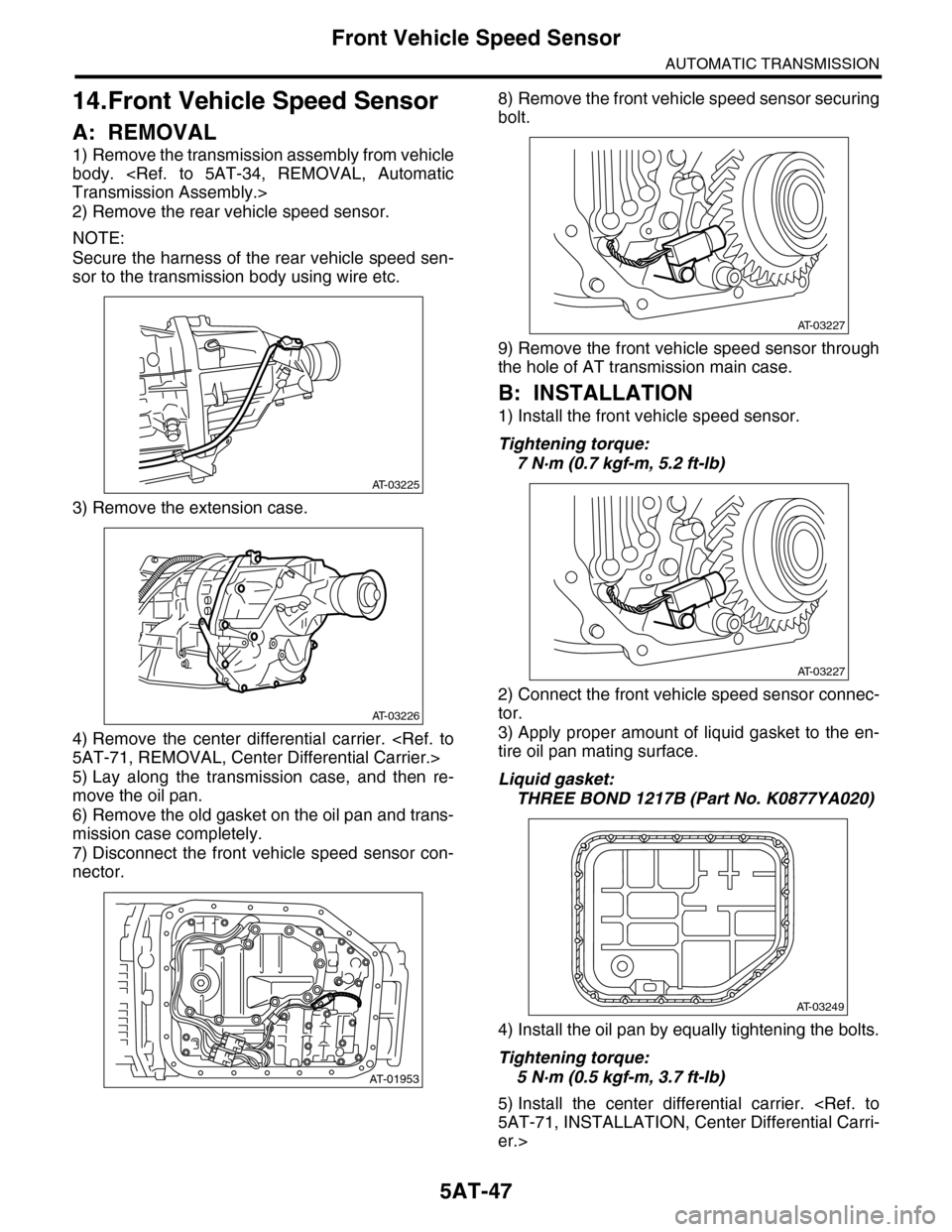

1) Remove the transmission assembly from vehicle

body.

2) Remove the rear vehicle speed sensor.

NOTE:

Secure the harness of the rear vehicle speed sen-

sor to the transmission body using wire etc.

3) Remove the extension case.

4) Remove the center differential carrier.

5) Lay along the transmission case, and then re-

move the oil pan.

6) Remove the old gasket on the oil pan and trans-

mission case completely.

7) Disconnect the front vehicle speed sensor con-

nector.

8) Remove the front vehicle speed sensor securing

bolt.

9) Remove the front vehicle speed sensor through

the hole of AT transmission main case.

B: INSTALLATION

1) Install the front vehicle speed sensor.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

2) Connect the front vehicle speed sensor connec-

tor.

3) Apply proper amount of liquid gasket to the en-

tire oil pan mating surface.

Liquid gasket:

THREE BOND 1217B (Part No. K0877YA020)

4) Install the oil pan by equally tightening the bolts.

Tightening torque:

5 N·m (0.5 kgf-m, 3.7 ft-lb)

5) Install the center differential carrier.

er.>

AT-03225

AT-03226

AT-01953

AT-03227

AT-03227

AT-03249

Page 2064 of 2453

5AT-48

Front Vehicle Speed Sensor

AUTOMATIC TRANSMISSION

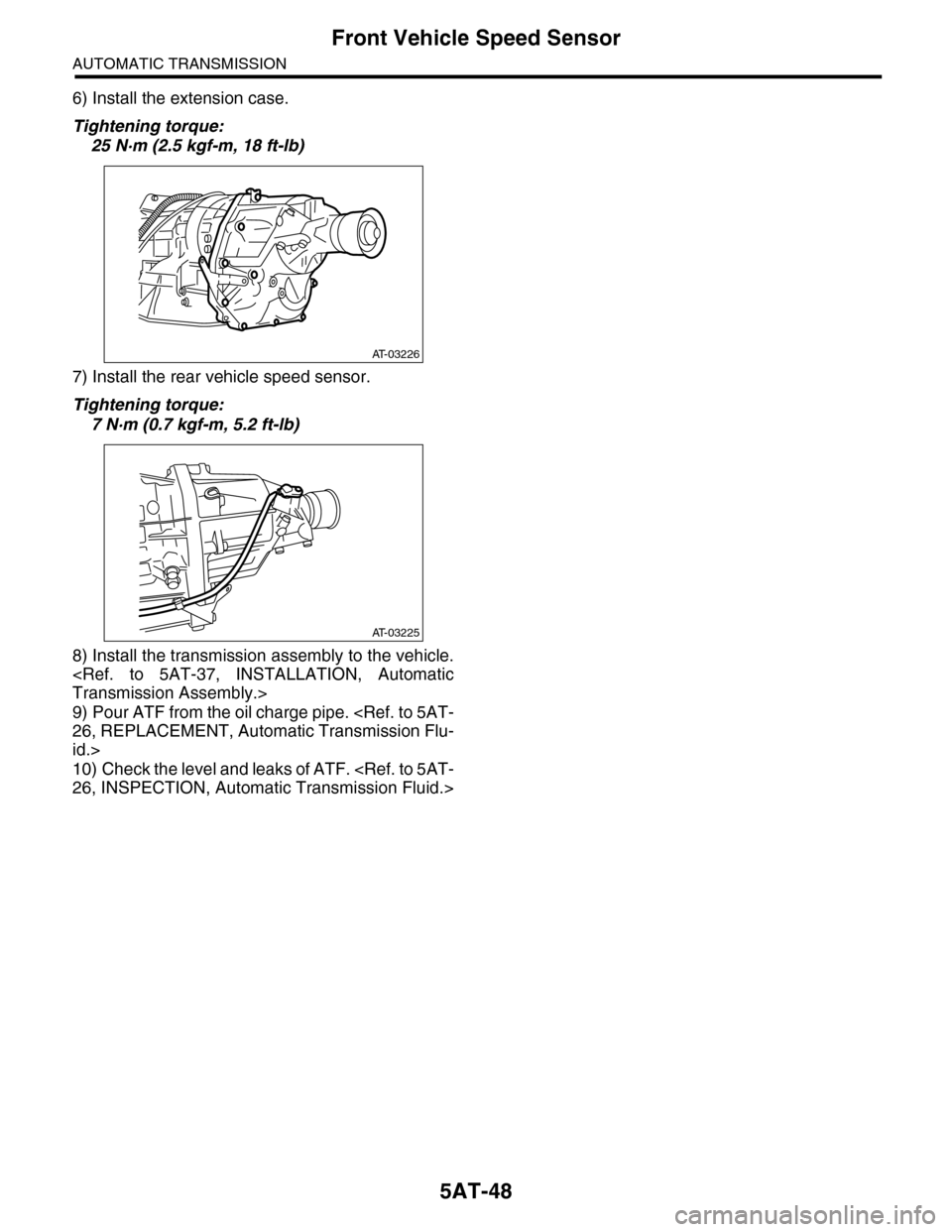

6) Install the extension case.

Tightening torque:

25 N·m (2.5 kgf-m, 18 ft-lb)

7) Install the rear vehicle speed sensor.

Tightening torque:

7 N·m (0.7 kgf-m, 5.2 ft-lb)

8) Install the transmission assembly to the vehicle.

9) Pour ATF from the oil charge pipe.

id.>

10) Check the level and leaks of ATF.

AT-03226

AT-03225