diff SUBARU TRIBECA 2009 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUBARU, Model Year: 2009, Model line: TRIBECA, Model: SUBARU TRIBECA 2009 1.GPages: 2453, PDF Size: 46.32 MB

Page 830 of 2453

DS-13

Front Axle

DRIVE SHAFT SYSTEM

3. Front Axle

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and remove the front wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the stabilizer link.

6) Remove the disc brake caliper from the front

housing, and suspend it from strut using a piece of

wire.

7) Remove the disc rotor from the hub.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive the 8 mm of bolt into the threaded end of rotor,

then remove the rotor.

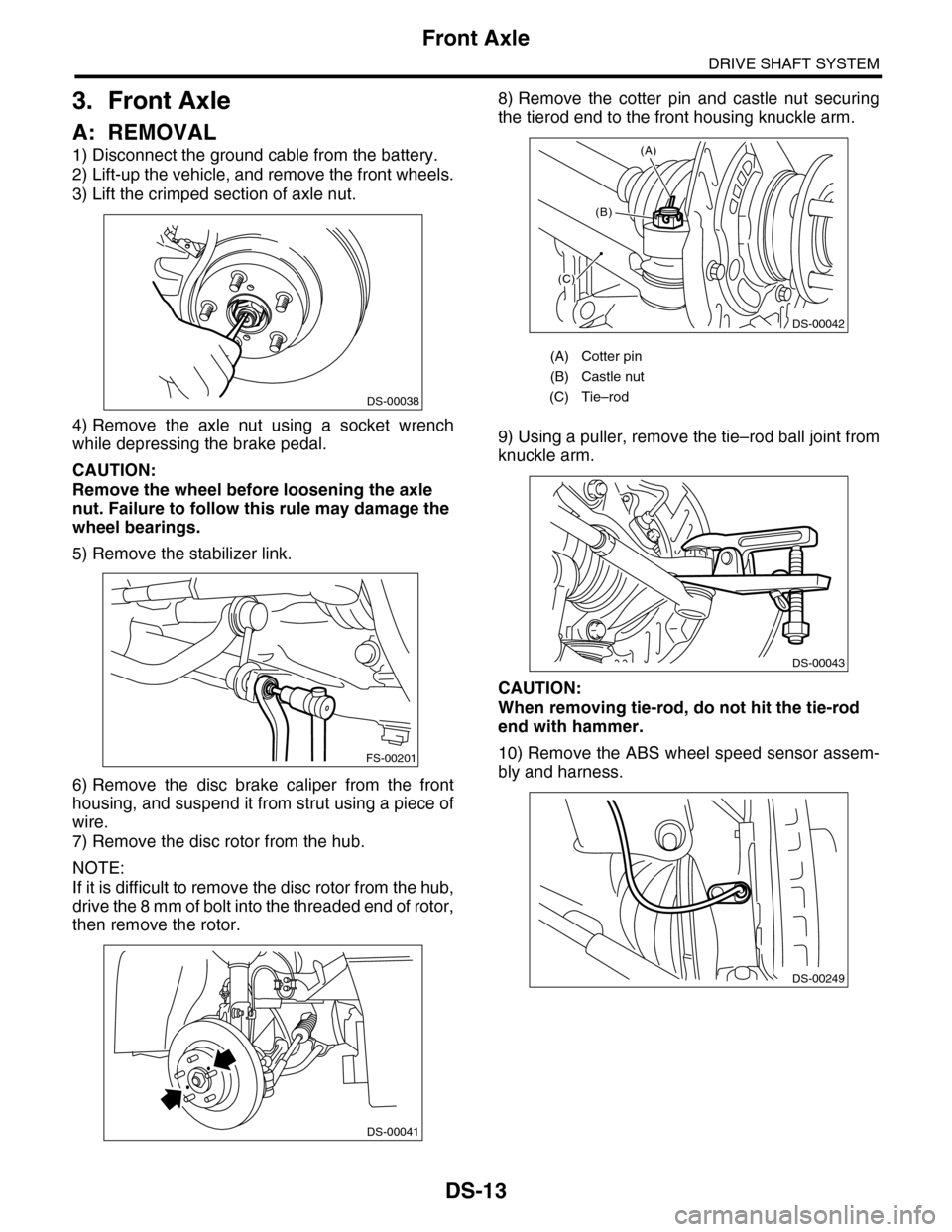

8) Remove the cotter pin and castle nut securing

the tierod end to the front housing knuckle arm.

9) Using a puller, remove the tie–rod ball joint from

knuckle arm.

CAUTION:

When removing tie-rod, do not hit the tie-rod

end with hammer.

10) Remove the ABS wheel speed sensor assem-

bly and harness.

DS-00038

FS-00201

DS-00041

(A) Cotter pin

(B) Castle nut

(C) Tie–rod

DS-00042

(C)

(B)

(A)

DS-00043

DS-00249

Page 836 of 2453

DS-19

Front Hub Unit Bearing

DRIVE SHAFT SYSTEM

5. Front Hub Unit Bearing

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and remove the front wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the disc brake caliper from the front

housing, and suspend it from strut using a piece of

wire.

6) Remove the disc rotor from the hub.

NOTE:

If it is difficult to remove the disc rotor from the hub,

drive the 8 mm of bolt into the threaded end of rotor,

then remove the rotor.

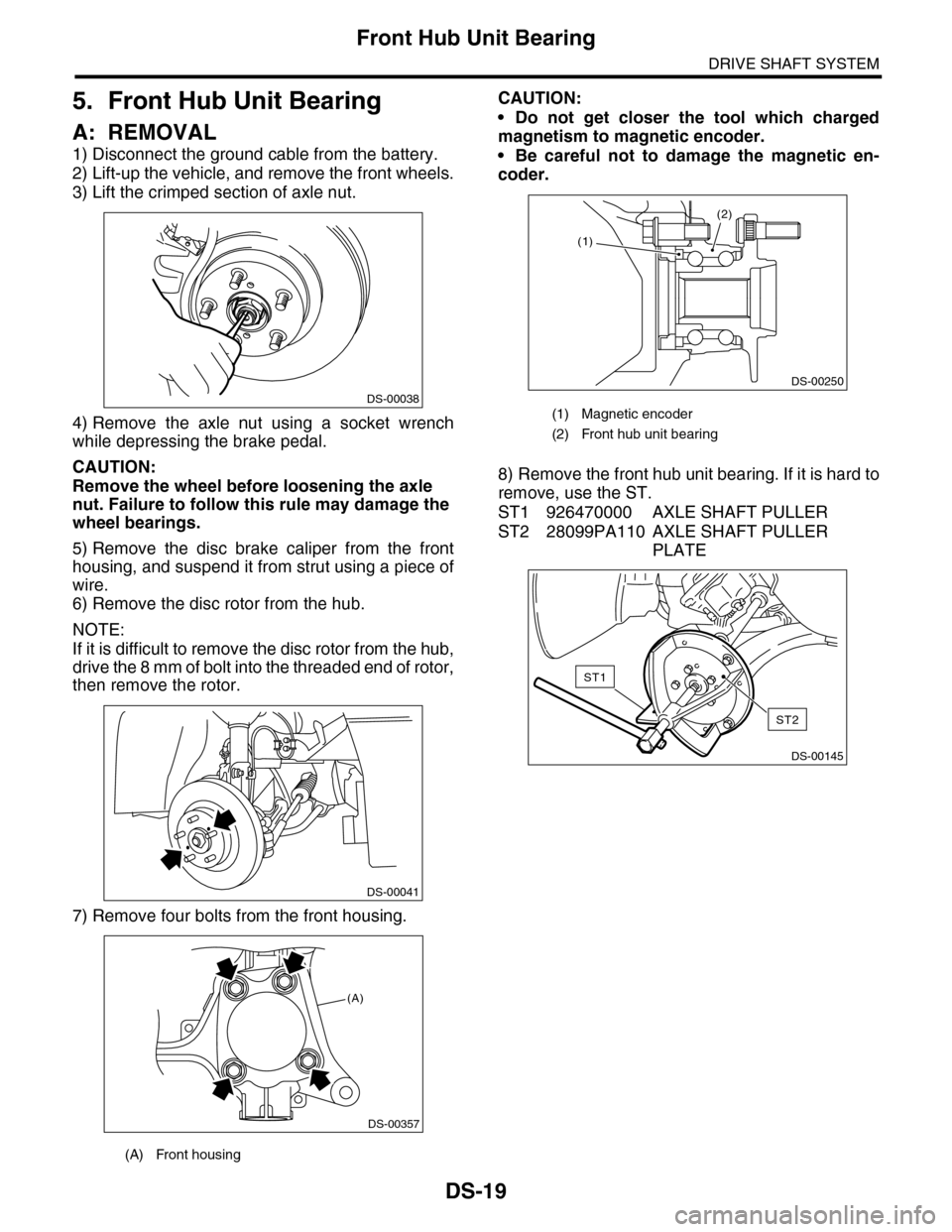

7) Remove four bolts from the front housing.

CAUTION:

•Do not get closer the tool which charged

magnetism to magnetic encoder.

•Be careful not to damage the magnetic en-

coder.

8) Remove the front hub unit bearing. If it is hard to

remove, use the ST.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

(A) Front housing

DS-00038

DS-00041

(A)

DS-00357

(1) Magnetic encoder

(2) Front hub unit bearing

(2)

DS-00250

(1)

DS-00145

ST2

ST1

Page 838 of 2453

DS-21

Rear Hub Unit Bearing

DRIVE SHAFT SYSTEM

6. Rear Hub Unit Bearing

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Release the parking brake.

6) Remove the disc brake caliper from the rear

housing, and suspend it from the vehicle using a

piece of rope.

7) Remove the disc rotor from the hub.

NOTE:

•Mark the mating surface of hub and disc rotor be-

fore removing the disc rotor to avoid confusing

when installing.

•If it is difficult to remove the disc rotor from the

hub, drive the 8 mm of bolt into the threaded end of

rotor, then remove the rotor.

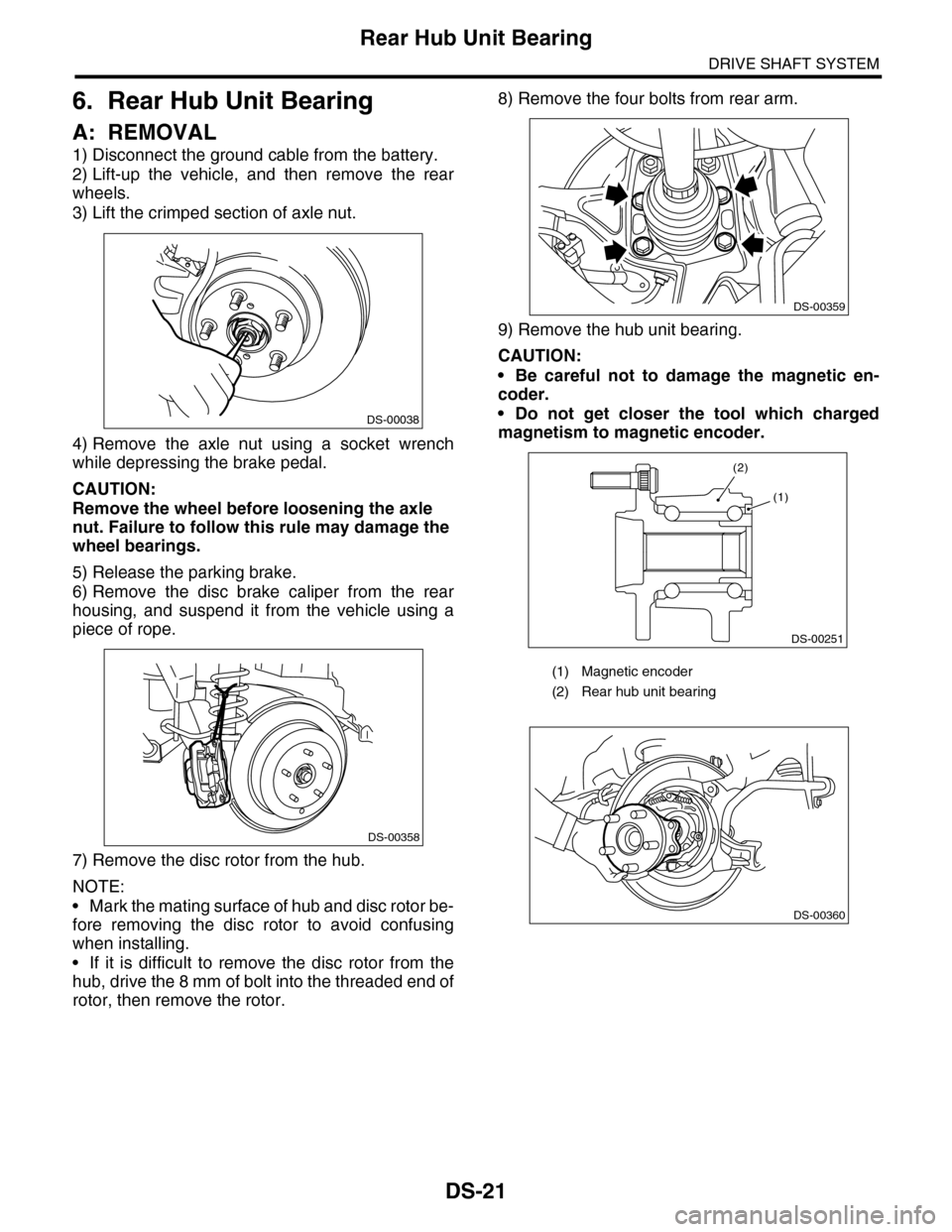

8) Remove the four bolts from rear arm.

9) Remove the hub unit bearing.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.DS-00038

DS-00358

(1) Magnetic encoder

(2) Rear hub unit bearing

DS-00359

DS-00251

(2)

(1)

DS-00360

Page 841 of 2453

DS-24

Front Drive Shaft

DRIVE SHAFT SYSTEM

7. Front Drive Shaft

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and remove the front wheels.

3) Lift the crimped section of axle nut.

4) Remove the axle nut using a socket wrench

while depressing the brake pedal.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the stabilizer link from front arm.

6) Disconnect the front arm ball joint from the front

housing.

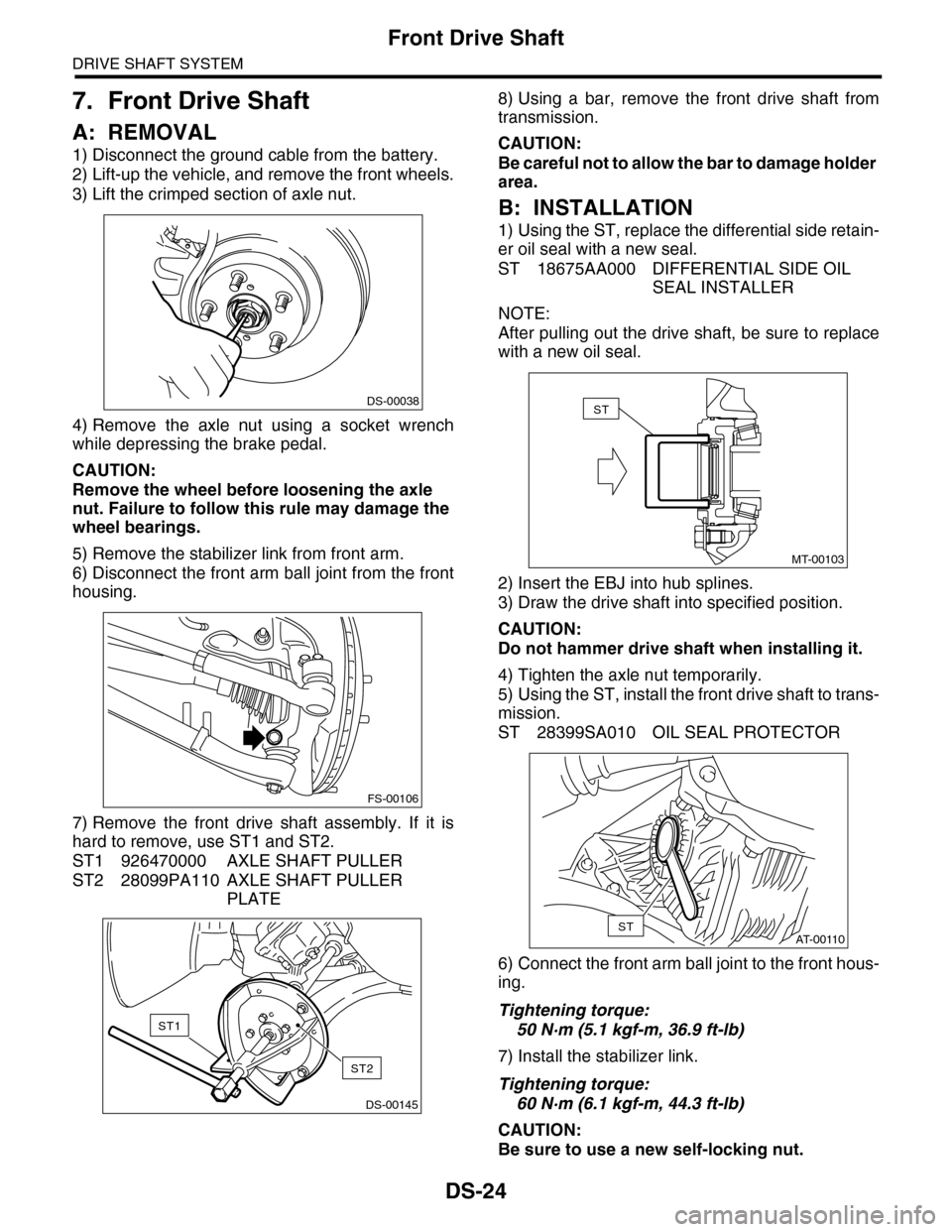

7) Remove the front drive shaft assembly. If it is

hard to remove, use ST1 and ST2.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

8) Using a bar, remove the front drive shaft from

transmission.

CAUTION:

Be careful not to allow the bar to damage holder

area.

B: INSTALLATION

1) Using the ST, replace the differential side retain-

er oil seal with a new seal.

ST 18675AA000 DIFFERENTIAL SIDE OIL

SEAL INSTALLER

NOTE:

After pulling out the drive shaft, be sure to replace

with a new oil seal.

2) Insert the EBJ into hub splines.

3) Draw the drive shaft into specified position.

CAUTION:

Do not hammer drive shaft when installing it.

4) Tighten the axle nut temporarily.

5) Using the ST, install the front drive shaft to trans-

mission.

ST 28399SA010 OIL SEAL PROTECTOR

6) Connect the front arm ball joint to the front hous-

ing.

Tightening torque:

50 N·m (5.1 kgf-m, 36.9 ft-lb)

7) Install the stabilizer link.

Tightening torque:

60 N·m (6.1 kgf-m, 44.3 ft-lb)

CAUTION:

Be sure to use a new self-locking nut.

DS-00038

FS-00106

DS-00145

ST2

ST1

MT-00103

ST

AT-00110ST

Page 845 of 2453

DS-28

Rear Drive Shaft

DRIVE SHAFT SYSTEM

8. Rear Drive Shaft

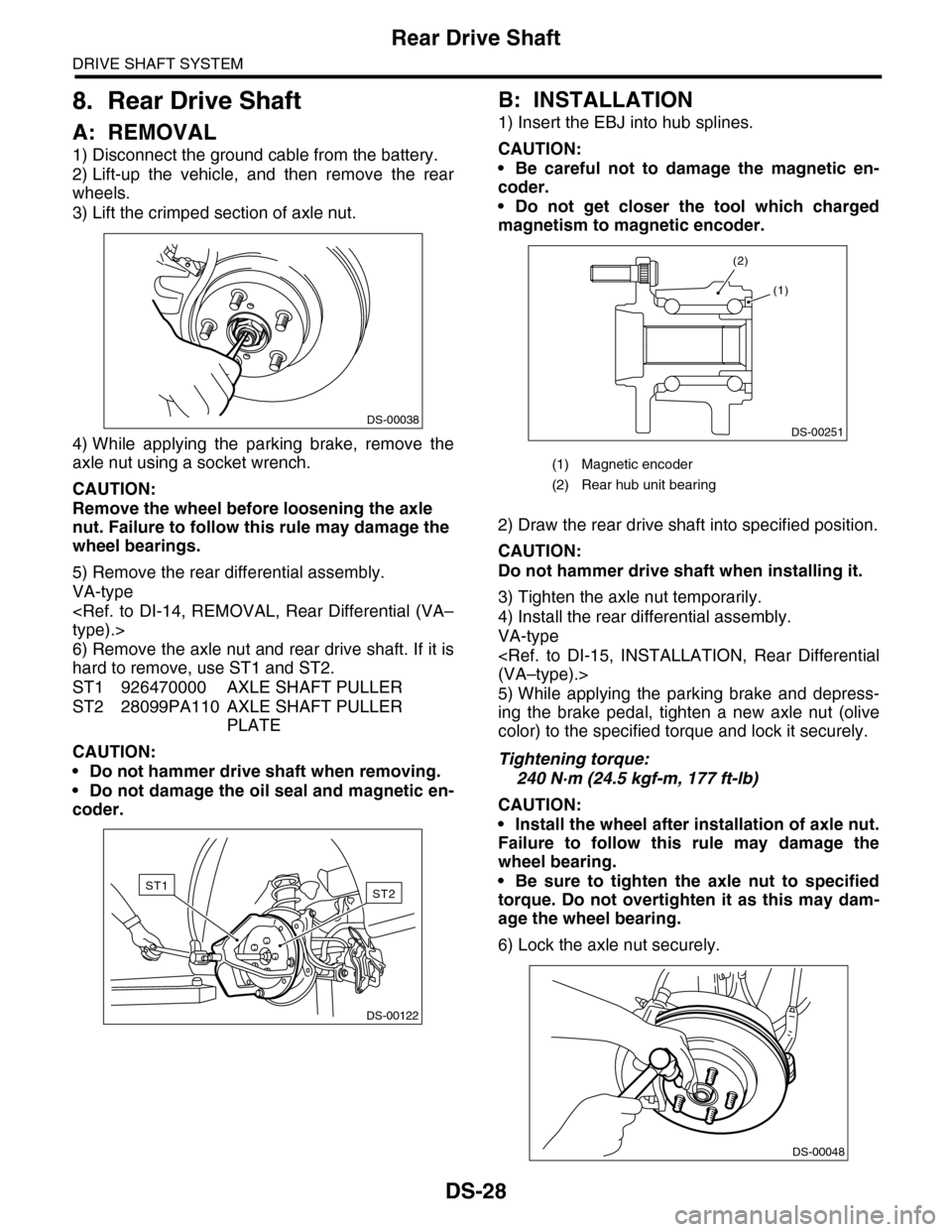

A: REMOVAL

1) Disconnect the ground cable from the battery.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Lift the crimped section of axle nut.

4) While applying the parking brake, remove the

axle nut using a socket wrench.

CAUTION:

Remove the wheel before loosening the axle

nut. Failure to follow this rule may damage the

wheel bearings.

5) Remove the rear differential assembly.

VA-type

6) Remove the axle nut and rear drive shaft. If it is

hard to remove, use ST1 and ST2.

ST1 926470000 AXLE SHAFT PULLER

ST2 28099PA110 AXLE SHAFT PULLER

PLATE

CAUTION:

•Do not hammer drive shaft when removing.

•Do not damage the oil seal and magnetic en-

coder.

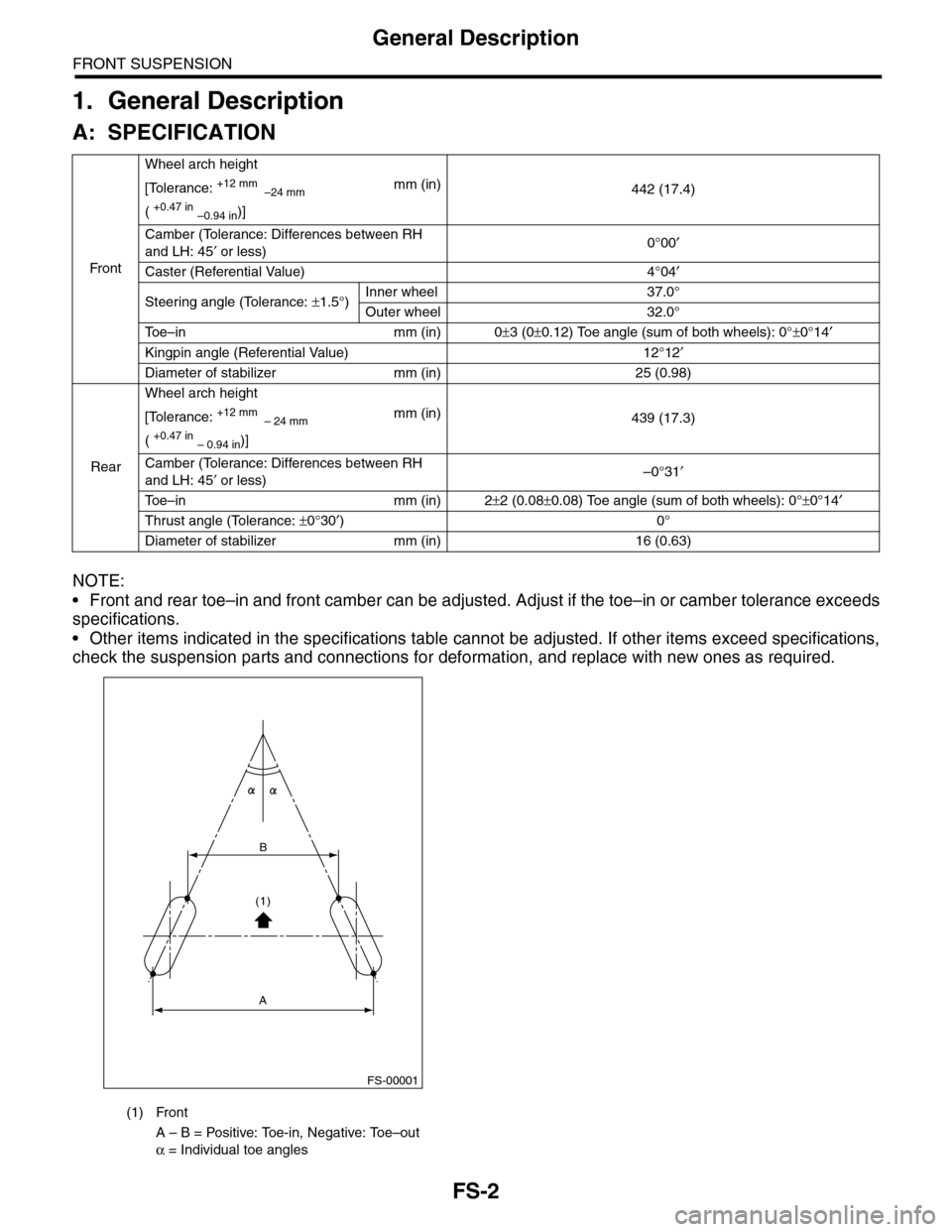

B: INSTALLATION

1) Insert the EBJ into hub splines.

CAUTION:

•Be careful not to damage the magnetic en-

coder.

•Do not get closer the tool which charged

magnetism to magnetic encoder.

2) Draw the rear drive shaft into specified position.

CAUTION:

Do not hammer drive shaft when installing it.

3) Tighten the axle nut temporarily.

4) Install the rear differential assembly.

VA-type

5) While applying the parking brake and depress-

ing the brake pedal, tighten a new axle nut (olive

color) to the specified torque and lock it securely.

Tightening torque:

240 N·m (24.5 kgf-m, 177 ft-lb)

CAUTION:

•Install the wheel after installation of axle nut.

Failure to follow this rule may damage the

wheel bearing.

•Be sure to tighten the axle nut to specified

torque. Do not overtighten it as this may dam-

age the wheel bearing.

6) Lock the axle nut securely.

DS-00038

DS-00122

ST2ST1

(1) Magnetic encoder

(2) Rear hub unit bearing

DS-00251

(2)

(1)

DS-00048

Page 850 of 2453

FS-2

General Description

FRONT SUSPENSION

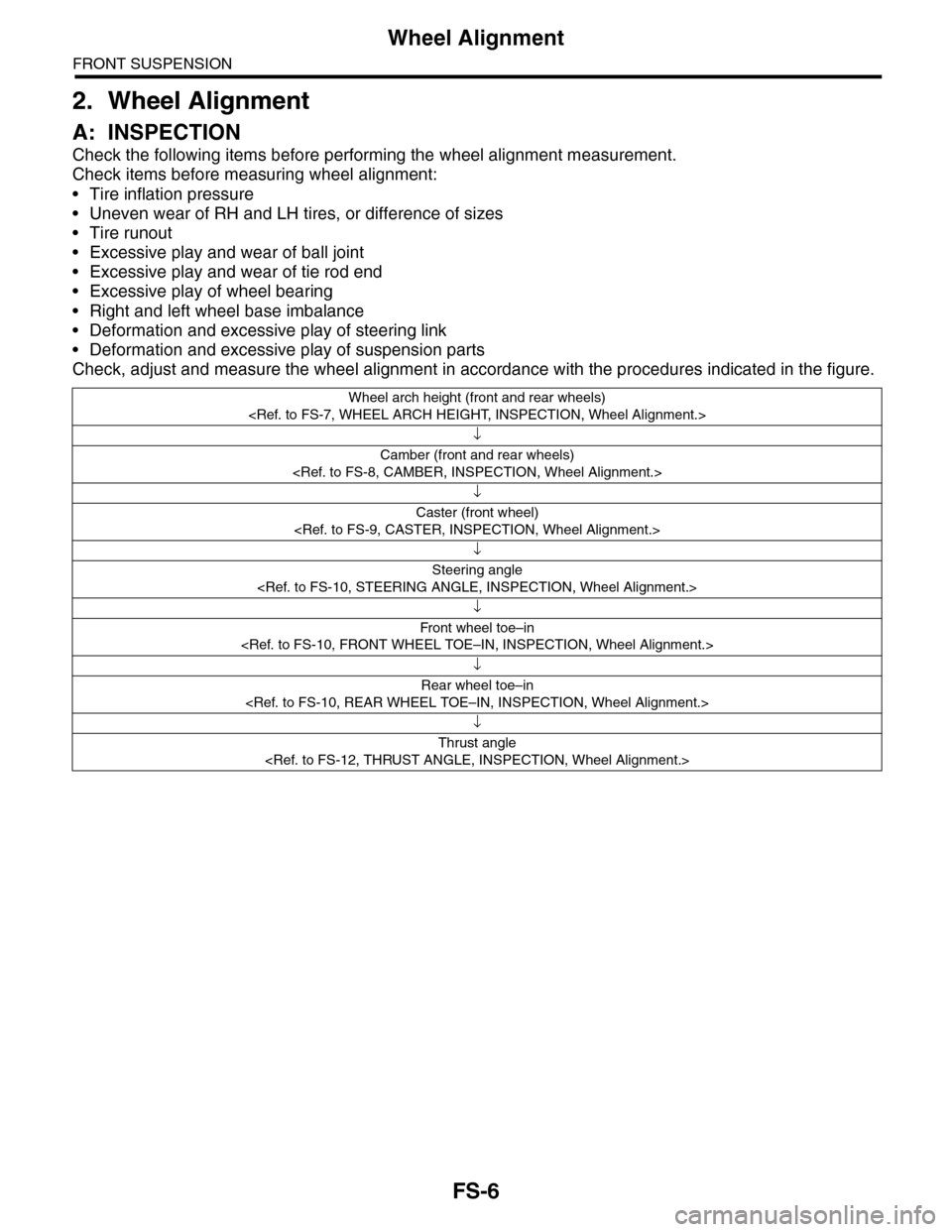

1. General Description

A: SPECIFICATION

NOTE:

•Front and rear toe–in and front camber can be adjusted. Adjust if the toe–in or camber tolerance exceeds

specifications.

•Other items indicated in the specifications table cannot be adjusted. If other items exceed specifications,

check the suspension parts and connections for deformation, and replace with new ones as required.

Fr o nt

Wheel arch height

442 (17.4)[Tolerance: +12 mm –24 mm

( +0.47 in –0.94 in)]

mm (in)

Camber (Tolerance: Differences between RH

and LH: 45′ or less)0°00′

Caster (Referential Value) 4°04′

Steering angle (Tolerance: ±1.5°)Inner wheel 37.0°

Outer wheel 32.0°

To e – i n m m ( i n ) 0±3 (0±0.12) Toe angle (sum of both wheels): 0°±0°14′

Kingpin angle (Referential Value) 12°12′

Diameter of stabilizer mm (in) 25 (0.98)

Rear

Wheel arch height

439 (17.3)[Tolerance: +12 mm – 24 mm

( +0.47 in – 0.94 in)]

mm (in)

Camber (Tolerance: Differences between RH

and LH: 45′ or less)–0°31′

To e – i n m m ( i n ) 2±2 (0.08±0.08) Toe angle (sum of both wheels): 0°±0°14′

Thrust angle (Tolerance: ±0°30′)0°

Diameter of stabilizer mm (in) 16 (0.63)

(1) Front

A – B = Positive: Toe-in, Negative: Toe–out

α = Individual toe angles

FS-00001

B

A

(1)

Page 854 of 2453

FS-6

Wheel Alignment

FRONT SUSPENSION

2. Wheel Alignment

A: INSPECTION

Check the following items before performing the wheel alignment measurement.

Check items before measuring wheel alignment:

•Tire inflation pressure

•Uneven wear of RH and LH tires, or difference of sizes

•Tire runout

•Excessive play and wear of ball joint

•Excessive play and wear of tie rod end

•Excessive play of wheel bearing

•Right and left wheel base imbalance

•Deformation and excessive play of steering link

•Deformation and excessive play of suspension parts

Check, adjust and measure the wheel alignment in accordance with the procedures indicated in the figure.

Wheel arch height (front and rear wheels)

↓

Camber (front and rear wheels)

↓

Caster (front wheel)

↓

Steering angle

↓

Fr o nt wh ee l to e –i n

↓

Rear wheel toe–in

↓

Thrust angle

Page 856 of 2453

FS-8

Wheel Alignment

FRONT SUSPENSION

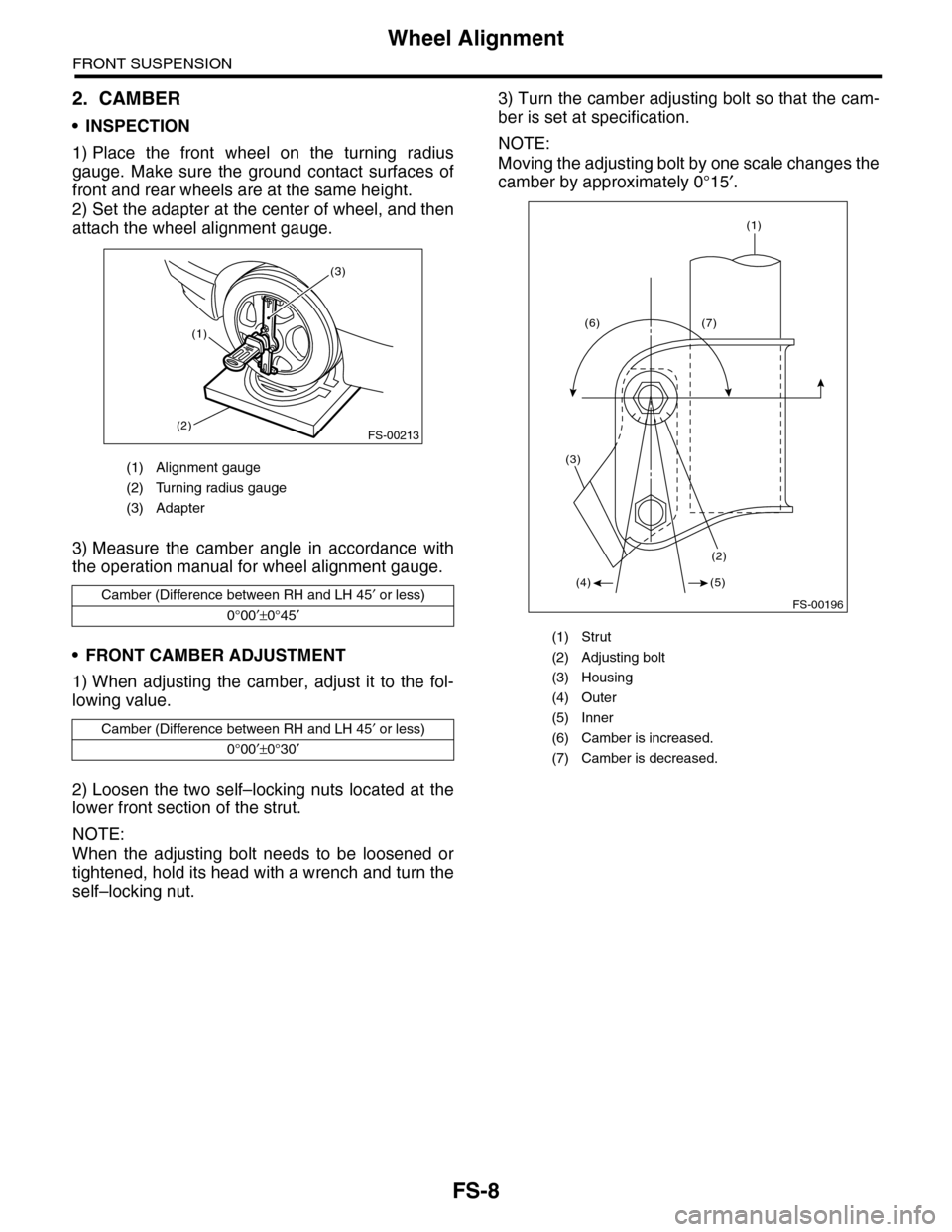

2. CAMBER

•INSPECTION

1) Place the front wheel on the turning radius

gauge. Make sure the ground contact surfaces of

front and rear wheels are at the same height.

2) Set the adapter at the center of wheel, and then

attach the wheel alignment gauge.

3) Measure the camber angle in accordance with

the operation manual for wheel alignment gauge.

•FRONT CAMBER ADJUSTMENT

1) When adjusting the camber, adjust it to the fol-

lowing value.

2) Loosen the two self–locking nuts located at the

lower front section of the strut.

NOTE:

When the adjusting bolt needs to be loosened or

tightened, hold its head with a wrench and turn the

self–locking nut.

3) Turn the camber adjusting bolt so that the cam-

ber is set at specification.

NOTE:

Moving the adjusting bolt by one scale changes the

camber by approximately 0°15′.

(1) Alignment gauge

(2) Turning radius gauge

(3) Adapter

Camber (Difference between RH and LH 45′ or less)

0°00′±0°45′

Camber (Difference between RH and LH 45′ or less)

0°00′±0°30′

FS-00213

(1)

(2)

(3)

(1) Strut

(2) Adjusting bolt

(3) Housing

(4) Outer

(5) Inner

(6) Camber is increased.

(7) Camber is decreased.

(1)

(4)

(6) (7)

(2)

(3)

(5)

FS-00196

Page 878 of 2453

PB-7

Parking Brake Assembly (Rear Disc Brake)

PARKING BRAKE

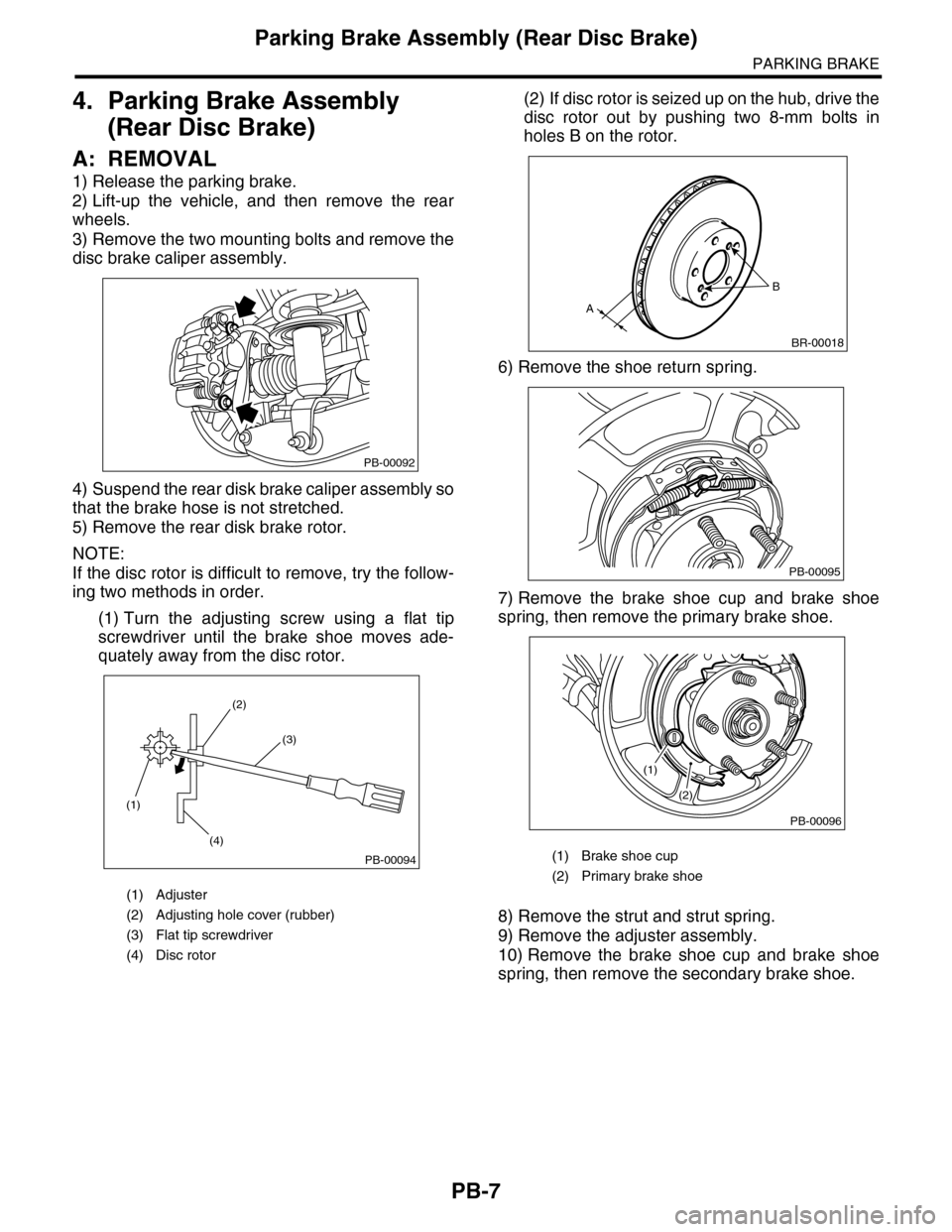

4. Parking Brake Assembly

(Rear Disc Brake)

A: REMOVAL

1) Release the parking brake.

2) Lift-up the vehicle, and then remove the rear

wheels.

3) Remove the two mounting bolts and remove the

disc brake caliper assembly.

4) Suspend the rear disk brake caliper assembly so

that the brake hose is not stretched.

5) Remove the rear disk brake rotor.

NOTE:

If the disc rotor is difficult to remove, try the follow-

ing two methods in order.

(1) Turn the adjusting screw using a flat tip

screwdriver until the brake shoe moves ade-

quately away from the disc rotor.

(2) If disc rotor is seized up on the hub, drive the

disc rotor out by pushing two 8-mm bolts in

holes B on the rotor.

6) Remove the shoe return spring.

7) Remove the brake shoe cup and brake shoe

spring, then remove the primary brake shoe.

8) Remove the strut and strut spring.

9) Remove the adjuster assembly.

10) Remove the brake shoe cup and brake shoe

spring, then remove the secondary brake shoe.

(1) Adjuster

(2) Adjusting hole cover (rubber)

(3) Flat tip screwdriver

(4) Disc rotor

PB-00092

(1)

(4)

(2)

(3)

PB-00094(1) Brake shoe cup

(2) Primary brake shoe

B

A

BR-00018

PB-00095

(1)

(2)

PB-00096

Page 882 of 2453

PS-2

General Description

POWER ASSISTED SYSTEM (POWER STEERING)

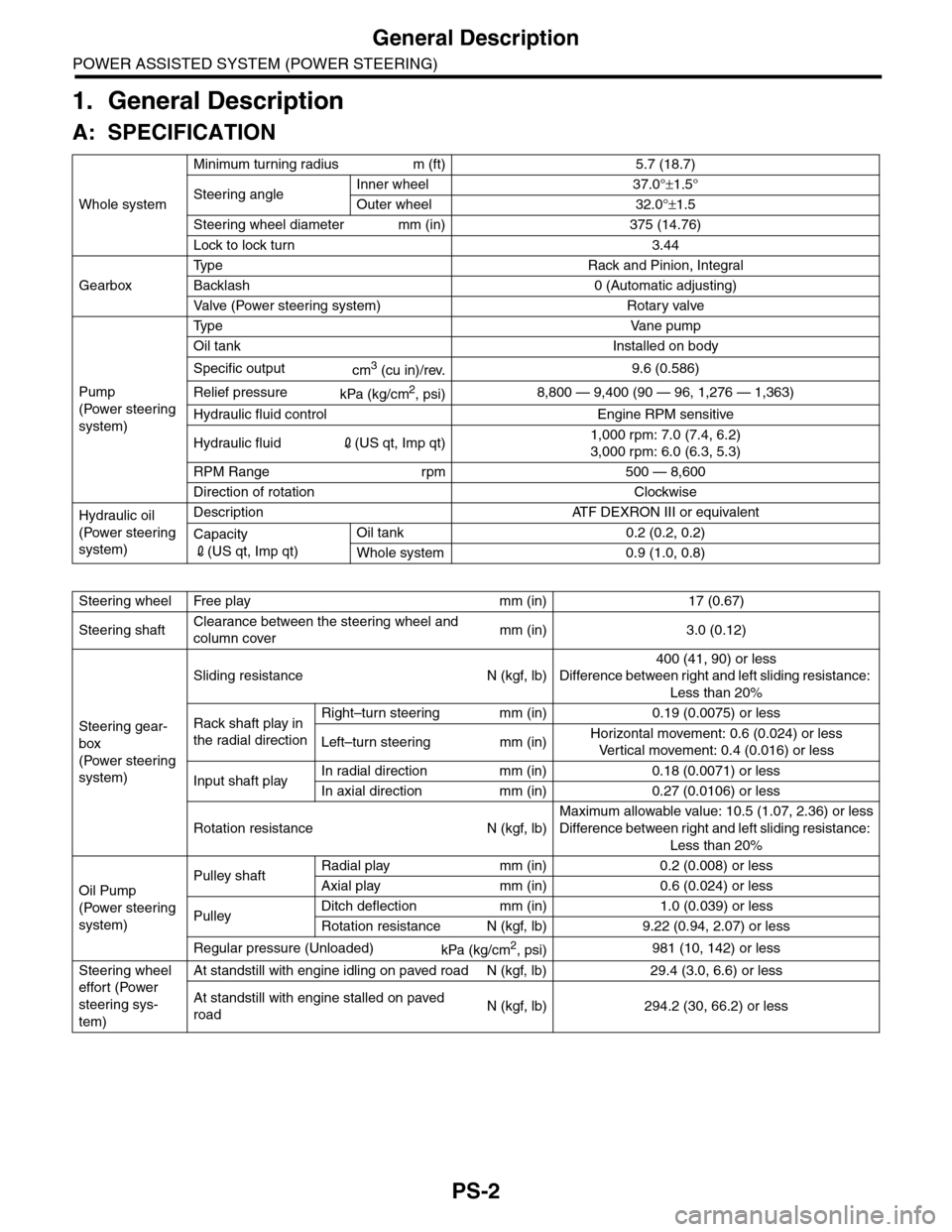

1. General Description

A: SPECIFICATION

Whole system

Minimum turning radius m (ft) 5.7 (18.7)

Steering angleInner wheel 37.0°±1.5°

Outer wheel 32.0°±1.5

Steering wheel diameter mm (in) 375 (14.76)

Lock to lock turn 3.44

Gearbox

Ty p e R a c k a n d P i n i o n , I n t e g r a l

Backlash 0 (Automatic adjusting)

Va l ve ( Po w e r s t e e r i n g s y s t e m ) R o t a r y va l ve

Pump

(Power steering

system)

Ty p e Va n e p u m p

Oil tank Installed on body

Specific outputcm3 (cu in)/rev.9.6 (0.586)

Relief pressurekPa (kg/cm2, psi)8,800 — 9,400 (90 — 96, 1,276 — 1,363)

Hydraulic fluid control Engine RPM sensitive

Hydraulic fluid2(US qt, Imp qt)1,000 rpm: 7.0 (7.4, 6.2)

3,000 rpm: 6.0 (6.3, 5.3)

RPM Range rpm 500 — 8,600

Direction of rotation Clockwise

Hydraulic oil

(Power steering

system)

Description ATF DEXRON III or equivalent

Capacity

2(US qt, Imp qt)

Oil tank 0.2 (0.2, 0.2)

Whole system 0.9 (1.0, 0.8)

Steering wheel Free play mm (in) 17 (0.67)

Steering shaftClearance between the steering wheel and

column covermm (in) 3.0 (0.12)

Steering gear-

box

(Power steering

system)

Sliding resistance N (kgf, lb)

400 (41, 90) or less

Difference between right and left sliding resistance:

Less than 20%

Rack shaft play in

the radial direction

Right–turn steering mm (in) 0.19 (0.0075) or less

Left–turn steering mm (in)Horizontal movement: 0.6 (0.024) or less

Ve r t i c a l m o v e m e n t : 0 . 4 ( 0 . 0 1 6 ) o r l e s s

Input shaft playIn radial direction mm (in) 0.18 (0.0071) or less

In axial direction mm (in) 0.27 (0.0106) or less

Rotation resistance N (kgf, lb)

Maximum allowable value: 10.5 (1.07, 2.36) or less

Difference between right and left sliding resistance:

Less than 20%

Oil Pump

(Power steering

system)

Pulley shaftRadial play mm (in) 0.2 (0.008) or less

Axial play mm (in) 0.6 (0.024) or less

PulleyDitch deflection mm (in) 1.0 (0.039) or less

Rotation resistance N (kgf, lb) 9.22 (0.94, 2.07) or less

Regular pressure (Unloaded)kPa (kg/cm2, psi)981 (10, 142) or less

Steering wheel

effort (Power

steering sys-

tem)

At standstill with engine idling on paved road N (kgf, lb) 29.4 (3.0, 6.6) or less

At standstill with engine stalled on paved

roadN (kgf, lb) 294.2 (30, 66.2) or less