checking oil SUZUKI GRAND VITARA 1987 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 1987, Model line: GRAND VITARA, Model: SUZUKI GRAND VITARA 1987Pages: 962, PDF Size: 27.87 MB

Page 114 of 962

3) Run engine at specified idling speed and,

under this running condition, read vacuum

gauge. Vacuum should not be lower than

45 cm Hg (17.7 in. Hg).

A low vacuum reading means that any combi-

nation of following malconditions is the cause,

which must be corrected before releasing

machine to customer:

Oil Filler Cap

The cap has a packing. Be sure that packing is in

good condition, free of any damage and signs of

deterioration, and is tight In place: it is replacea-

ble.

(a) Leaky cylinder head gasket

(b) Leaky inlet manifold gasket

(c) Leaky valves

(d) Weakened valve springs

(e) Maladjusted valve clearance

(f) Valve timing out of adjustment

(g) Ignition mistimed

(h) Carburetor improperly adjusted

NOTE:

Should indicating hand of the vacuum gauge

oscillate violently, turn adjusting nut @I to

steady it

4

Standard vacuum45- 55cm Hg

(sea level)(17.7 - 21.6 in. Hg)

Idling speedBOO f 50 r/min (rpm)

specification(Take vacuum reading

at this speed.)L

4) After checking, remove vacuum gauge.

5) Before reinstalling vacuum checking plug,

be sure to wrap its screw threads with

sealing tape and tighten plug.

3-57

Page 182 of 962

![SUZUKI GRAND VITARA 1987 Service User Guide [Checking ECM power circuits]

Connected to the ECM are the ignition coil and solenoids or solenoid valves. If a disconnection or a

failure of contact occurs within a circuit (power circuit) including SUZUKI GRAND VITARA 1987 Service User Guide [Checking ECM power circuits]

Connected to the ECM are the ignition coil and solenoids or solenoid valves. If a disconnection or a

failure of contact occurs within a circuit (power circuit) including](/img/20/57437/w960_57437-181.png)

[Checking ECM power circuits]

Connected to the ECM are the ignition coil and solenoids or solenoid valves. If a disconnection or a

failure of contact occurs within a circuit (power circuit) including any of these coil or solenoids or sole-

noid valves, signals will not be sent to the ECM and as a result, the feed back system will not operate

properly. Therefore, check the power circuits according to the following procedure.

1) Disconnect the coupler connected to the ECM.

2) Turn ON the ignition switch but be sure not to run the engine.

3) Connect a voltmeter between the terminal @ of the disconnected coupler (on the wiring harness side)

and the body (ground) as shown in below figure and measure the voltage. And then repeat the same

with each of the terminals 0, 0, 0, 0, 8, @ and 0. If the measured voltage between each

terminal and the body is about 12V, each circuit is in good condition.

4) If about 12V is not obtained in the above check, the particular circuit may be disconnected or out of

contact. Check the circuit for such conditions.

5) After checking, connect the coupler to ECM securely..

1. Coupler (Viewed from wire harness side)10. Three way solenoid valve (EGR system)

2. Battery11. Br (Brown) lead wire

3. Ignition switch (ON)!2. BI/R (Blue/Red) lead wire

4. Ignition coil13. B/W (Black/White) lead wire

5. Vacuum switching valve14. Br/W (Brown/White) lead wire(secondary throttle valve)15. BI/B (Blue/Black) lead wire6. Three way solenoid valve (Idle-up)16. BI/Y (Blue/Yellow) lead wire7. Mixture control solenoid17. BI/W (Blue/White) lead wire8. Switch vent solenoid18. BllG (Blue/Green) lead wire9. Fuel cut solenoid valve

Fig. 5-3-42 Checking ECM power circuits

Page 217 of 962

I

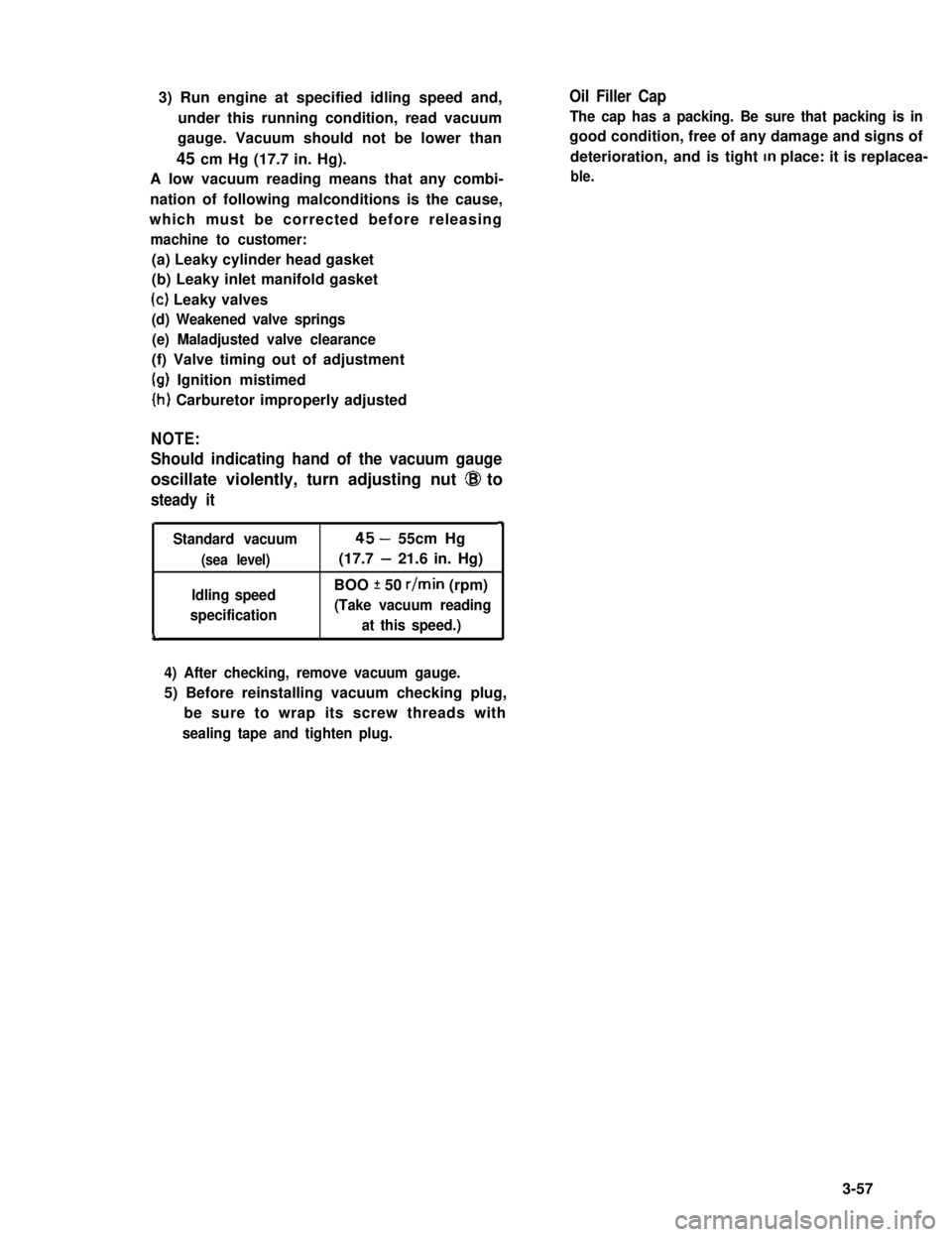

Generator (Pickup

coil) resistance130 - 190 ohmsI

1

1. White wire2. Red wire

Fig. 8-14

5. After checking, connect red and white wires

to ignitor as shown in Figure 8-15, and then

install dust cover.

NOTE:

NEVER connect red and white wires reversely.

Reverse connection may cause damage to

generator and ignitor.

1. White wire2. Red wire

3. lgnitor

4. Generator

Fig. 8-15

6. After generator has been assembled on

distributor, make sure to adjust air gap and

install ignitor.

7. Install distributor referring to page 8-11.

[ Ignitorl

1. Disconnect negative cable at battery. Remove

distributor, and then ignitor and generator.

2. Remove dust cover from ignitor.

3. Disconnect red and white wires from ignitor.

4. Connect an ohmmeter, a bulb and 12 voltage

battery to ignitor as shown in Figure 8-16.

Set ohmmeter at 1 ohm to 10 ohm range.

Then bring ohmmeter negative @ prod to

touch red wire terminal of ignitor, and

positive @ prod to touch white wire terminal.

If bulb is illuminated, it indicates that ignitor

is satisfactory. If not, replace ignitor.

NOTE:

l Never connect battery positive and negative

wires reversely. Reverse connection may cause

damage to ignitior.

l Under no circumstances should ohmmeter be

connected reversely.

l Be sure to perform this ohmmeter check

within a short time (two to three seconds).

1

1. lgnitor5.Negative prod9.Black/Whitewire

2. Bulb6.Red wire terminal10.Brown wire

3. Ohmmeter7.Positive prod11.Earth

4. Battery (12V)8.White wire terminal

Fig. 8-16

c---------~

Bulb

T_-.

ITester (+) PIUSL------------

Fig. 8-17

8-7

Page 220 of 962

![SUZUKI GRAND VITARA 1987 Service User Guide [Checking vacuum advancer]

Remove distributor cap.

Disconnect vacuum hose from vacuum hose 3

way joint, and connect vacuum pump gauge

(0991747910) to its hose. Apply vacuum (ab-

out 400 mmHg). And the SUZUKI GRAND VITARA 1987 Service User Guide [Checking vacuum advancer]

Remove distributor cap.

Disconnect vacuum hose from vacuum hose 3

way joint, and connect vacuum pump gauge

(0991747910) to its hose. Apply vacuum (ab-

out 400 mmHg). And the](/img/20/57437/w960_57437-219.png)

[Checking vacuum advancer]

Remove distributor cap.

Disconnect vacuum hose from vacuum hose 3

way joint, and connect vacuum pump gauge

(0991747910) to its hose. Apply vacuum (ab-

out 400 mmHg). And then with pump stopped,

check to ensure that vacuum pump gauge

indicator remains at the same level, and release

it. Check that generator base plate with gene-

rator moves smoothly. If plate does not move

smoothly, replace defective parts.

Fig. 8-24

1. Distributor drive gear

2. Camshaft3. Cylinder head

Fig. 8-23

@I Vacuum pump gauge (a991 7-47910)

1. Generator base plate

2. Vacuum controller

Distributor Drive Gear

NOTE:

When removing distributor gear case from cylin-

der head, engine oil in cylinder head may come

out. So place waste or receiver under gear case

when removing.

Inspect drive gear for wear.

Worn gear is likely to disturb ignition timing

and therefore must be replaced.

Replacing worn-down drive gear is not enough.

Inspect driven gear (a part of the distributor

assembly), too, and replace it if badly worn

down.

[Important reminders for removal and installa-

tion]

Before removing drive gear from camshaft,

scribe a match mark on this shaft to root

center line of drive gear as shown in Fig.

B-25 and, when mounting replacement drive

gear, refer to this mark.

When pressing replacement drive gear onto

camshaft, be sure to position gear angularly

as shown in Fig. B-25. (align mark on Cam-

shaft scribed in removal with root center of

drive gear)

NOTE:

There is no need to discriminate between two

end faces of drive gear.

Distributor side view

1. Drive gear

2. Camshaft

3. Center line of

45mmhole

4. Center line ofroot5. @5mm hole(Provided on pulleyside of camshaft)

6. Scribed matchmark

7. 5O

Fig. 8-25

l About 30 cc(1.01/l .05 US/Imp 02) of

engine oil must be fed into distributor gear

case after servicing this case, that is, removing

and putting it back. Be sure to add this much

oil before starting engine for the first time

after servicing.

8-11

Page 327 of 962

Rest dummy with dial indicator on surface

plate, and the dial indicator pointer may have

deflected from “0” mark to show a certain

value; read this value, which is “b”.

SURFACE PLATE

Fig. 16-21-4

Add this reading to 94 mm (= “a” + “c”) and,

from the sum, subtract the value marked on

bevel pinion. The remainder is required shim

thickness: (94+“b”) - marked value = required

shim thickness1

Fig. 16-22 I. Marked value

5)Shim stock is available in twelve selective L

thicknesses. Select one or two shim(s) from

the below to obtain the closest thickness to

above required thickness, and insert selected

shim piece(s) into clearance indicated as

Fig. 16-21-3 0.

1.00, 1.03, 1.06, 1.09, 1.12, 1.15, 1.18,

Bevel Pinion Bearing Preload Adjustment

The bevel pinion, as installed in normal manner

in carrier, is required to offer a certain torque

resistance when checked by using prescribed

preload adjuster (special tool @ ) as shown in

Fig. 16-23. This resistance is a “preload,”

which is due to the tighteness of the two tapered

roller bearings by which the pinion is held in the

carrier. And this tighteness is determined prima-

rily by tightening torque of bevel pinion nut.

Adjust preload of bevel pinion bearings as

follows.

1) Install pinion bearings, spacer, bevel pinion,

oil seal and universal joint flange to diffe-

rential carrier.

At this time, be sure to apply gear oil to

bearings lightly and grease to oil seal lip.

2) Tighten bevel pinion nut by hand, and install

special tool to universal joint flange.

3) After turning pinion several times, tighten

pinion nut gradually, while checking pinion

starting torque with spring balance, and stop

tightening when starting torque reaches

specification given below.

4) Caulk bevel pinion nut to prevent it from

loosening.

NOTE:

Bevel pinion bearing preload is adjusted by

tightening bevel pinion nut to crush spacer.

Therefore, be sure to use a new spacer for

adjustment and tighten pinion nut step by step

and check for starting torque (preload) as often

as tightening to prevent over crushing of spacer.

If exceeds specification given below during

adjustment, replace spacer and repeat preload

adjustment procedure. Attempt to decrease

starting torque (preload) by loosening pinion

nut will not do.

The below data are not tightening torque of

pinion nut but pinion bearing preload.

Fig. 16-23 @ Spring balance

@ Special tool (Differential gear preload

adjuster 09922-75221)

16-9

Page 357 of 962

Before giving a test pull to knuckle arm with a

spring balance in the alternative method, in-

stall a large amount of shims on each kingpin to

lighten preload on tapered roller bearing.

Keep on reading the torque, each time decreas-

ing shim thickness a little, and continue this

process until specified torque value is obtained.

(This process protects kingpins because it ensure

that no excessive pull will be applied to bearings

at the onset.) If the process fails to produce

specified torque, that is, if desired torque

resistance does not occur even when shim

thickness has been reduced to zero on each

kingpin, it means that bearings or kingpins are

excessively worn and need replacement.

NOTE:

l Read spring balance indication when knuckle

arm begins to turn. In other words, you are

to read “starting torque.”

l When checking knuckle arm starting torque,

be sure to have axle hub oil seal removed

and tighten king pin bolts to specified torque.

Knuckle arm starting1 .O - 1.8 kg (2.20 - 3.96 lb)

torque (force)without oil seal

Available sizes of0.1,0.5 mm

shim for kingpins(0.004,0.02 in.)

/r--QzL- -\King pin shim

Fig. 17-3-13

Upon completion of this check and/or adjust-

ment, be sure to connect tie rod end to steering

knuckle and install oil seal retainer, oil seal,

felt packing oil seal cover and wheel.

Refer to “INSTALLATION” in this section.

Steering Knuckle Oil Seal

The oil seal used at the spherical sliding joint

between knuckle and inner case accomplishes

additional purposes of keeping out road dust

and of acting as the damper for steering hand-

wheel. As wear of this seal advances, its damping

effect decreases and thus makes front wheel

develop a tendency to “shimmy” not onI9 that

road dust begins to creep into sliding clearance

to promote wear of spherical sliding surfaces.

The oil seal is an expendable item, and must be

replaced at regular intervals.

Fig. 17-3-14

[How to replace oil seal]

1) Remove 8 bolts securing joint seat, and

displace oil seal cover and felt packing inward.

Fig. 17-3-15

17-23

Page 464 of 962

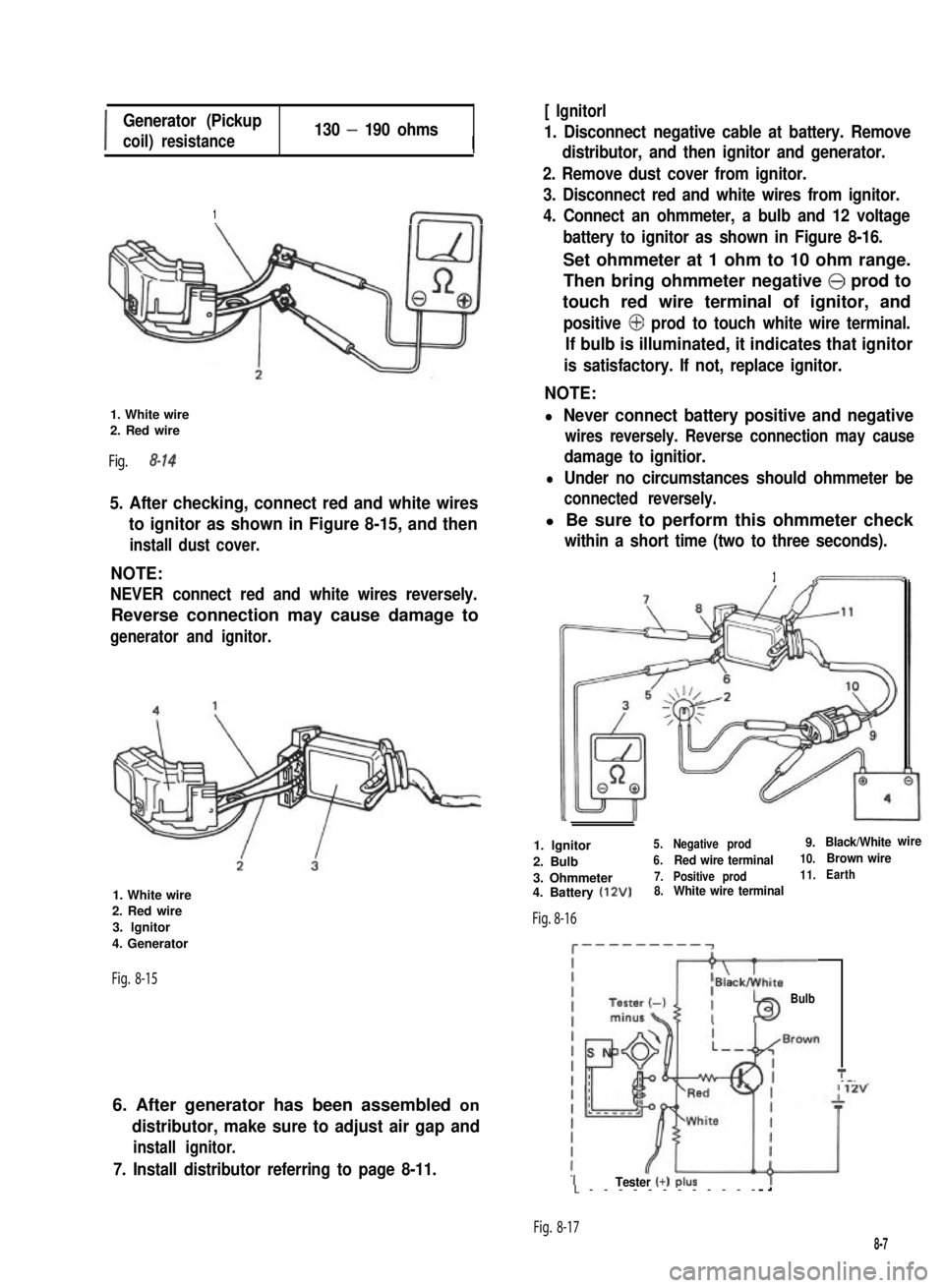

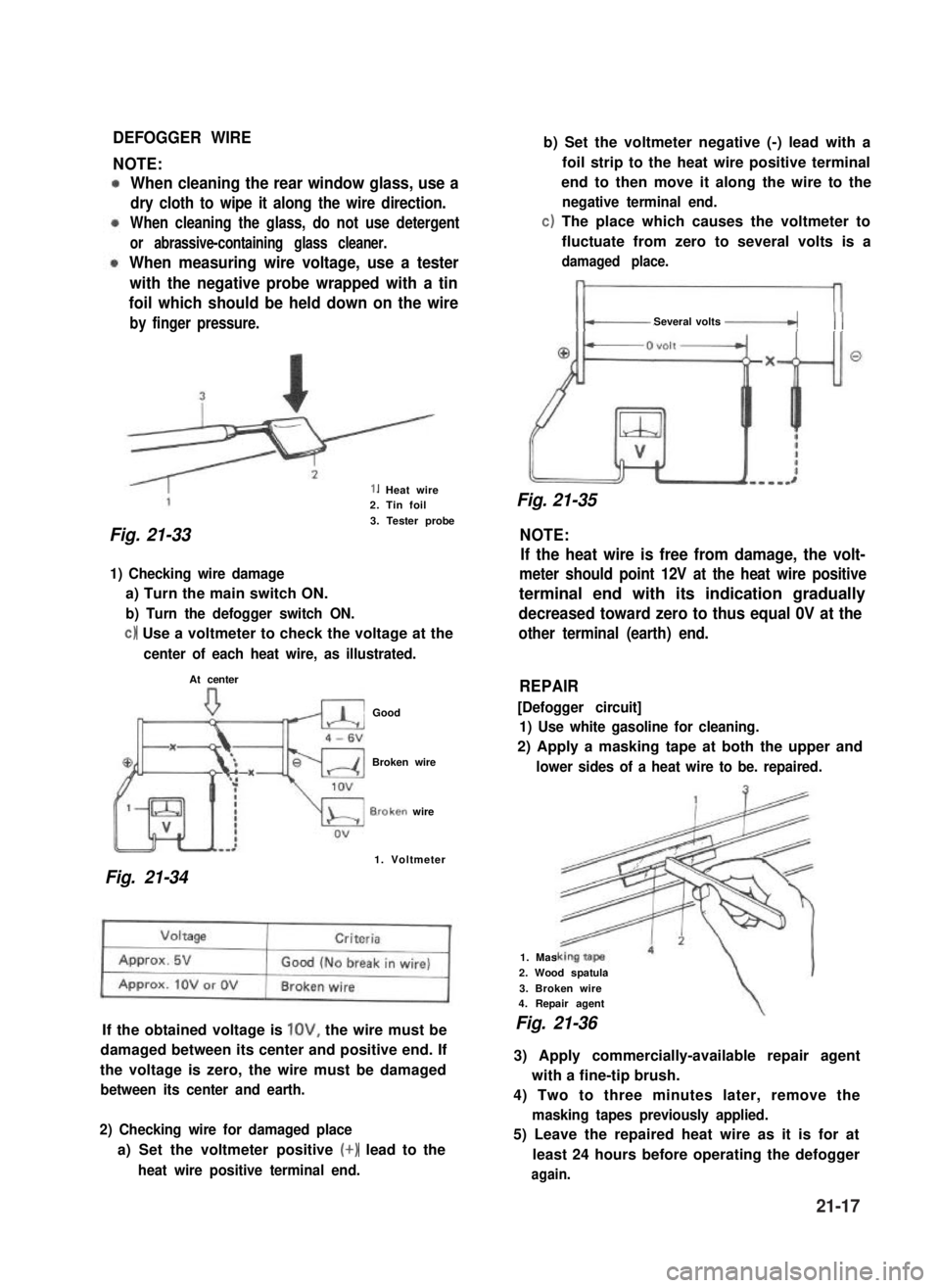

DEFOGGER WIRE

NOTE:

When cleaning the rear window glass, use a

dry cloth to wipe it along the wire direction.

When cleaning the glass, do not use detergent

or abrassive-containing glass cleaner.

When measuring wire voltage, use a tester

with the negative probe wrapped with a tin

foil which should be held down on the wire

by finger pressure.

1. Heat wire2. Tin foil

3. Tester probe

Fig. 21-33 NOTE:

1) Checking wire damage

a) Turn the main switch ON.

b) Turn the defogger switch ON.

c) Use a voltmeter to check the voltage at the

center of each heat wire, as illustrated.

At center

Good

Broken wire

B.roken wire

1. Voltmeter

Fig. 21-34

If the obtained voltage is lOV, the wire must be

damaged between its center and positive end. If

the voltage is zero, the wire must be damaged

between its center and earth.

2) Checking wire for damaged place

a) Set the voltmeter positive (+) lead to the

heat wire positive terminal end.

b) Set the voltmeter negative (-) lead with a

foil strip to the heat wire positive terminal

end to then move it along the wire to the

negative terminal end.

c) The place which causes the voltmeter to

fluctuate from zero to several volts is a

damaged place.

Several volts -_(( (

Fig. 21-35

If the heat wire is free from damage, the volt-

meter should point 12V at the heat wire positive

terminal end with its indication gradually

decreased toward zero to thus equal 0V at the

other terminal (earth) end.

REPAIR

[Defogger circuit]

1) Use white gasoline for cleaning.

2) Apply a masking tape at both the upper and

lower sides of a heat wire to be. repaired.

1. Mas

2. Wood spatula

3. Broken wire4. Repair agent

Fig. 21-36

3) Apply commercially-available repair agent

with a fine-tip brush.

4) Two to three minutes later, remove the

masking tapes previously applied.

5) Leave the repaired heat wire as it is for at

least 24 hours before operating the defogger

again.

21-17